1. Introduction

The construction industry faces mounting pressure to deliver affordable, sustainable, and disaster-resilient housing while improving productivity and environmental performance. Traditional construction methods often generate significant waste, safety risks, and cost overruns. Modular construction—an integral component of Modern Methods of Construction (MMC)—offers a promising alternative through enhanced efficiency, quality, and speed, aligning with global sustainability goals such as the United Nations’ Sustainable Development Goals (SDGs) [

1,

2,

3,

4,

5].

Globally, modular construction adoption remains uneven. Developed economies such as the United Kingdom, Japan, and the United States have successfully implemented volumetric and hybrid modular systems supported by strong industrial capabilities, standardized regulations, and mature supply chains [

6,

7,

8,

9,

10]. In contrast, developing countries face multiple constraints, including limited manufacturing capacity, policy uncertainty, and skill shortages, which hinder large-scale adoption [

11,

12,

13,

14].

Indonesia exemplifies this disparity. The nation’s construction sector is challenged by rapid urbanization, housing shortages, and recurring natural disasters, particularly in regions such as Aceh, where rapid, resilient, and cost-effective housing is urgently needed. Although modular construction could address these challenges, its adoption remains limited due to fragmented supply chains, a lack of policy alignment, and cultural resistance among practitioners.

Recent Indonesian research provides promising momentum toward localized MMC development [

15,

16]. Paper [

13] introduced a risk-based ISO framework to assess modular prefabrication readiness across Indonesian contractors, emphasizing the need for standardized quality and safety assurance. Papers [

17,

18,

19] examined the feasibility of flat-pack modular housing for the Ibu Kota Nusantara (IKN) workforce, demonstrating the logistical and environmental benefits of modularization in large-scale national projects. Paper [

20] explored Design For Manufacture And Assembly (DFMA) integrated with Building Information Modeling (BIM) to streamline prefabricated housing workflows, while paper [

21] linked modular deployment to disaster-resilient reconstruction strategies in Banda Aceh. Complementary studies by [

22,

23] emphasized modular business models, cost efficiency, and policy alignment, underscoring Indonesia’s gradual movement toward modular industrialization. Collectively, these findings highlight the growing relevance of modular construction for addressing both post-disaster housing and national productivity challenges [

24].

Significant research gaps persist in understanding modular construction adoption, particularly in developing contexts. Previous studies have primarily focused on technical feasibility and economic performance while overlooking the diverse perspectives of stakeholders who influence real-world implementation. Modular construction decisions involve multiple actors, engineers, architects, contractors, policymakers, and academics, each holding distinct priorities and perceptions of risk. Capturing these perspectives is essential for identifying leverage points for adoption. Moreover, most existing decision-support tools, such as the Analytic Hierarchy Process (AHP), rely on deterministic assumptions that neglect the uncertainty inherent in expert evaluations [

25].

Guided by these gaps and the need for probabilistic decision support, this study introduces a novel hybrid decision-support framework that integrates the Analytic Hierarchy Process (AHP) with Monte Carlo simulation to quantify both stakeholder diversity and uncertainty in modular adoption decisions. The approach captures the probabilistic nature of expert judgments and generates confidence intervals for modular preferences, enhancing robustness and transparency in decision-making. Empirical data were collected from five professional groups, academics, planners, architects, consultants, and contractors, in Aceh, Indonesia, where modular strategies are increasingly critical for disaster recovery and housing resilience.

Accordingly, this study addresses three research questions: (1) What are the relative priorities of key criteria and sub-criteria influencing modular adoption in Aceh? (2) Which modular alternative is most preferred by different stakeholder groups? and (3) How robust are these preferences and rankings under uncertainty as assessed through Monte Carlo simulation? Together, these inquiries structure the analytical and empirical foundation of this research.

2. Literature Review

2.1. Barriers to the Adoption of Modern Methods of Construction (MMC)

Previous studies have highlighted numerous challenges affecting the adoption of Modern Methods of Construction (MMC) in both developed and developing countries. These challenges can be broadly categorized into operational, financial, technological, regulatory, and cultural factors, summarized in

Table 1.

As summarized in

Table 1, the adoption of Modern Methods of Construction (MMC) is shaped by a complex interplay of operational, financial, technological, regulatory, and cultural factors. In developed countries, adoption is often driven by economic efficiency and sustainability goals supported by digital innovation and advanced manufacturing technologies [

22,

27]. In contrast, developing countries—including Indonesia—continue to face fundamental barriers such as limited technological capacity, inadequate financing mechanisms, and workforce skill shortages [

29]. Recognizing and systematically addressing these contextual constraints is essential for the successful implementation of MMC, particularly in disaster-prone and resource-limited regions such as Aceh.

Recent empirical studies across Southeast Asia further demonstrate the accelerating yet uneven trajectory of modular construction adoption in developing economies. Paper [

34] reported that in Vietnam, regulatory inconsistencies and weak technology transfer remain significant challenges to industrialized building system deployment. Similarly, paper [

35] observed that Malaysia’s modular housing initiatives suffer from fragmented supply chain integration between digital design and prefabrication processes. In Thailand and the Philippines, government-led programs have begun to integrate modular methods into public housing and disaster recovery efforts [

36,

37], though institutional readiness remains uneven. These regional insights highlight the urgent need for localized adaptive strategies—reinforcing the empirical focus of this study on modular construction adoption in Indonesia and its broader implications for other developing regions.

2.2. Gaps in the Literature

Despite substantial advancements in multi-criteria decision-making (MCDM) methodologies, several critical gaps persist in the literature concerning flood vulnerability assessment and modular adoption, particularly in developing countries. These gaps hinder the development of robust, context-sensitive frameworks essential for effective decision-making in these regions.

Lack of Multi-Stakeholder Evaluation in Developing Countries. Existing studies predominantly focus on expert-driven assessments or single-stakeholder perspectives, which may not adequately capture the diversity of local knowledge, community priorities, and institutional constraints in developing regions.

Limited Probabilistic Analysis to Account for Uncertainty in Expert Judgments. Many traditional MCDM approaches rely on deterministic weights and do not fully capture the uncertainty in expert judgments. Integrating probabilistic techniques enhances robustness [

25].

Scarce Comparative Studies Between Developed and Developing Economies Regarding Modular Adoption. The concentration of studies in developed contexts leaves a limited understanding of adoption patterns in developing economies [

38].

Addressing the Gaps: Integrating AHP with Monte Carlo Simulation. This study establishes a probabilistic MCDM framework that combines structured expert evaluations with stochastic simulations, enabling more inclusive and robust results [

25,

38]. Specifically, the integration of Monte Carlo simulation within the AHP directly addresses the Limited Probabilistic Analysis gap by transforming static pairwise comparisons into probabilistic distributions of priorities. Through repeated random perturbations of expert weights, the hybrid AHP–Monte Carlo framework quantifies uncertainty, generates confidence intervals for criteria importance, and tests the stability of modular housing rankings under variable assumptions. This approach provides a more rigorous, data-driven foundation for decision-making in uncertain, developing-country contexts such as Indonesia.

3. Materials and Methods

This study adopts a quantitative, multi-criteria decision-making (MCDM) approach, with the Analytic Hierarchy Process (AHP) serving as the primary analytical technique. AHP was selected due to its ability to decompose complex, multi-dimensional problems into a hierarchical framework, enabling systematic evaluation of multiple criteria and alternatives while incorporating expert judgments. This aligns with the gaps identified in the literature, particularly the need for structured, probabilistic evaluation methods in modular housing adoption in developing countries [

29,

32].

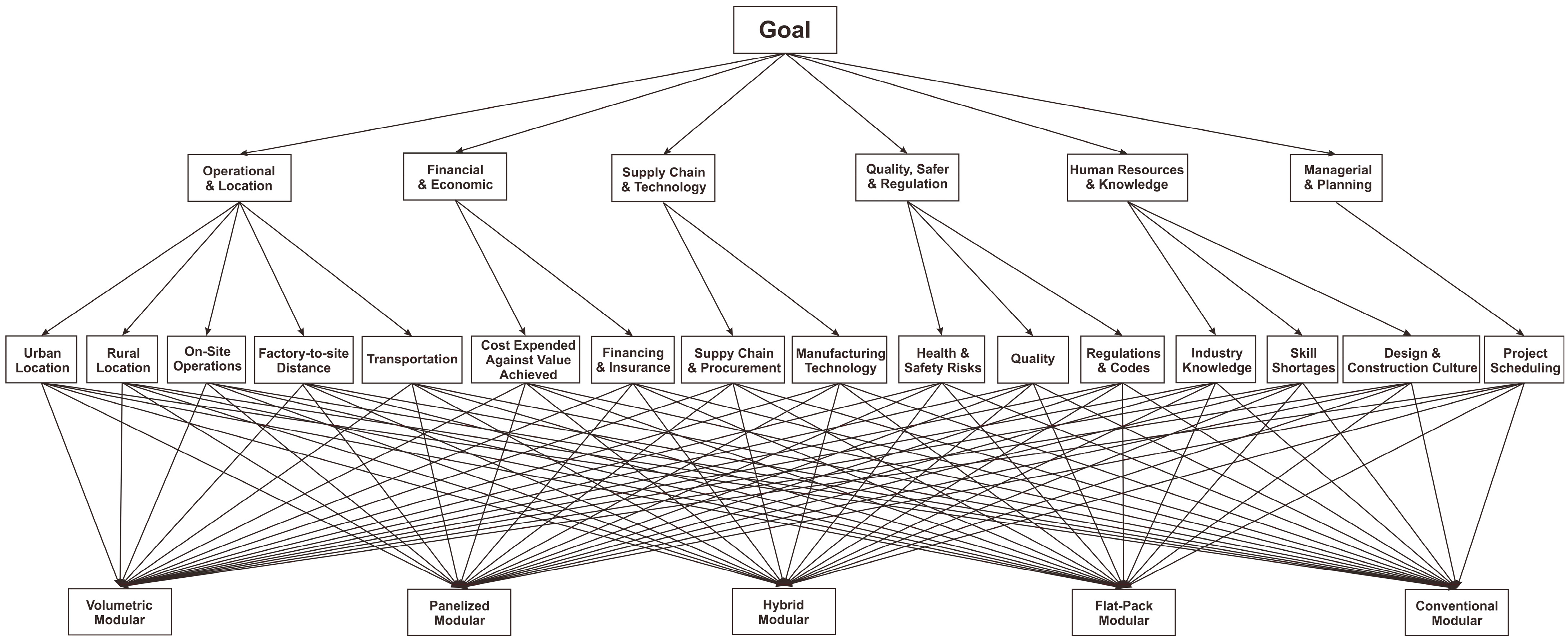

A hierarchical framework was developed comprising six main criteria: (1) Operational and Location; (2) Financial and Economic; (3) Supply Chain and Technology; (4) Quality, Safety and Regulation; (5) Human Resources and Knowledge; and (6) Managerial and Planning.

These criteria were further subdivided into sixteen sub-criteria to capture the nuanced factors influencing modular housing adoption in form of a hierarchical structure of analysis (see

Figure 1). The study evaluated five modular housing alternatives: Volumetric, Panelized, Hybrid, Flat-Pack, and Conventional (non-modular prefabrication). These reflect commonly used modular construction typologies.

3.1. Study Design and Participants

We employed a multi-criteria decision-making (MCDM) design grounded in the Analytic Hierarchy Process (AHP) to structure the problem into a three-level hierarchy: six main criteria, sixteen sub-criteria, and five modular alternatives (Volumetric, Panelized, Hybrid, Flat-Pack, Conventional). The expert panel consisted of 25 professionals representing five major stakeholder groups involved in modular construction projects in Aceh and Indonesia more broadly. Selection was based on recognized expertise, professional credentials, and a minimum of ten years of experience in relevant fields. This multidisciplinary approach ensured that perspectives from academics, design, planning, construction management, and consultancy were comprehensively captured. This composition ensured diversity across professional domains, balancing academic insight with practical field experience. Such heterogeneity is consistent with best practices for expert elicitation in AHP-based decision studies. The retrieved responses were analyzed utilizing Microsoft Excel 2019 and Python 3.10 to synthesize multiple experts. We used the geometric mean of individual judgments, consistent with axiomatic justifications for group AHP aggregation and common practice in engineering decision studies [

39,

40].

Prior to full elicitation, we piloted the hierarchy and the questionnaire to ensure clarity of constructs and scale use (Saaty 1–9). Responses were screened for logical coherence and missing entries; where necessary, respondents were asked to revisit judgments with high inconsistency. All pairwise comparison matrices satisfied Consistency Ratio (CR) ≤ 0.10, following standard AHP guidance; matrices exceeding the threshold were returned for revision with targeted feedback on the most influential triads [

39,

41,

42].

3.2. Application of AHP and Monte Carlo Simulation

The Analytic Hierarchy Process (AHP) was used to structure the decision problem hierarchically, beginning with the main goal (adoption of modular construction under uncertainty), followed by six criteria and sixteen sub-criteria, and ending with five modular alternatives. The six main criteria and sixteen sub-criteria used for the assessment were derived from a synthesis of global and regional MMC literature (

Table 1) and validated through expert consultation to ensure contextual relevance to Indonesia’s construction sector. Expert judgments were collected through pairwise comparisons using a nine-point Saaty scale, as shown in

Table 2, capturing the relative importance of criteria and sub-criteria from five stakeholder groups: academics, planners, architects, consultants, and contractors. Individual judgments were aggregated using the geometric mean method, and consistency was verified through the Consistency Ratio (CR ≤ 0.10) to ensure logical coherence of responses.

Following the deterministic AHP computation, the resulting priority weights were treated as input distributions for the Monte Carlo simulation, which performed 10,000 iterations to model uncertainty in expert judgments. Each simulation randomly perturbed the AHP weights within their confidence bounds to produce a probabilistic distribution of criteria importance and alternative rankings. This hybrid approach enabled the study to quantify not only the average stakeholder priorities but also the stability and confidence intervals of the modular adoption outcomes, thereby addressing the “limited probabilistic analysis” gap identified in the literature.

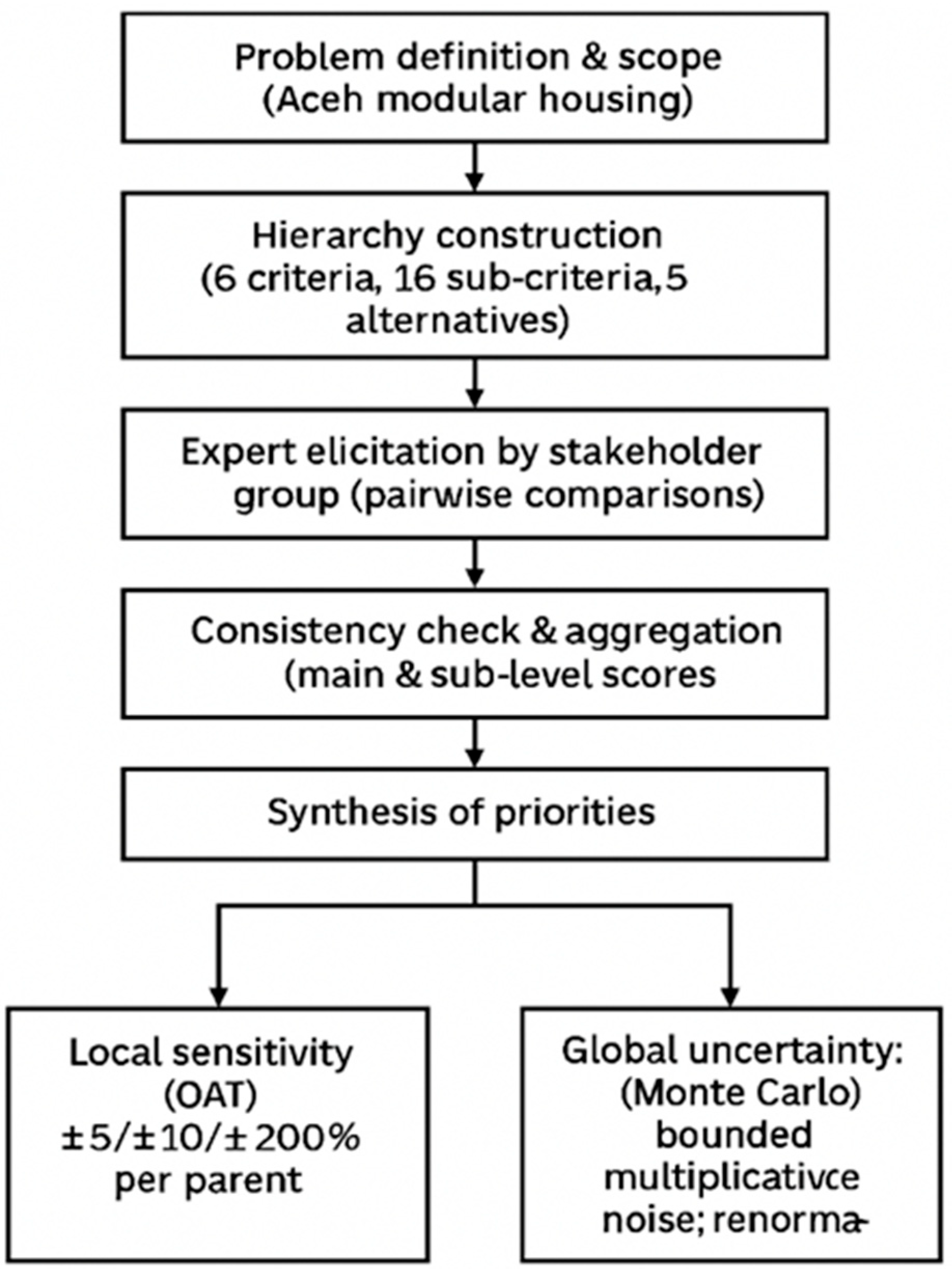

Figure 2 consolidates the workflow of the study design and analytical procedures. The process begins with defining the problem scope and constructing the hierarchical framework comprising criteria, sub-criteria, and alternatives. Expert judgments are obtained through pairwise comparisons and aggregated using the geometric mean method, followed by a consistency assessment based on the consistency index and ratio (CI/CR). The synthesized local and global priority weights are then used to establish the overall ranking of alternatives. Finally, a dual-mode sensitivity analysis is conducted: local sensitivity using One-at-a-Time (OAT) perturbations of ±5%, ±10%, and ±20% per criterion, and global uncertainty analysis using Monte Carlo simulations with bounded multiplicative noise to assess the robustness and stability of the decision model.

3.2.1. Analytic Hierarchy Process (AHP) in Modular Housing Evaluation

The Analytic Hierarchy Process (AHP), introduced by Saaty, decomposes complex problems into hierarchical structures. It relies on pairwise comparisons to determine relative weights among criteria and alternatives. AHP involves defining the objective, identifying criteria and sub-criteria, listing alternatives, constructing the hierarchy, and performing pairwise comparisons.

At each node, priority vectors were derived from the principal right eigenvector of the pairwise comparison matrix and normalized to unity. For each parent criterion, sub-criteria priorities were normalized to one, and the corresponding global sub-weights were obtained by multiplying the parent weight by the local sub-criterion weight. These global weights were then used directly as the base for alternative prioritization, ensuring that the influence of both main and sub-criteria was proportionally reflected in the final decision hierarchy.

Unlike the earlier version, no separate comparison or synthesis was performed between main- and sub-criteria pathways. Instead, the integration of main- and sub-criterion weights was treated as a single hierarchical aggregation process to derive global priorities for the modular alternatives. This approach follows standard AHP hierarchical synthesis logic, in which local priorities are successively propagated through the hierarchy to yield final global weights.

The aggregation across stakeholder groups was conducted using the geometric mean of corresponding entries before eigenvector extraction to preserve ratio-scale properties [

39,

40,

43,

44].

Let A denote a pairwise matrix with entries a

ij (importance of i over j), w the priority vector, and λ

max the maximal eigenvalue. The Consistency Index CI = (λ

max −

n)/(

n − 1) and Consistency Ratio CR = CI/RI were computed with RI as the random index for order

n, as shown in

Table 3. We adopted CR ≤ 0.10 as the accept/revise threshold; when CR > 0.10, targeted coaching was provided and re-elicitation performed [

38,

39,

40,

41,

42,

43,

45].

3.2.2. Sensitivity and Uncertainty Analysis

We combined local (OAT) and global (Monte Carlo) sensitivity analyses to assess rank stability. For OAT, each main-criterion weight wk was perturbed by ±δ ∈ {0.05, 0.10, 0.20} with renormalization:

to

. Alternative priorities were held fixed to isolate the effect of changing stakeholder emphasis across parents. OAT results identify the largest levers at the parent level and are interpreted as local derivatives around the baseline [

29,

46].

For Monte Carlo, we modeled judgment and emphasis uncertainty by applying bounded multiplicative noise to (i) main-criterion weights and (ii) alternative priorities within each main criterion. Each perturbed vector was renormalized to preserve the simplex constraint. We used a fixed seed for reproducibility and ran large ensembles (N on the order of 10^4) to obtain stable estimates of Top-1 frequency, mean weight, and dispersion for each alternative. As a robustness check, we verified that Latin Hypercube Sampling over the perturbation ranges produced indistinguishable rank statistics, consistent with guidance in global sensitivity literature [

46,

47]. While variance-based indices (e.g., Sobol’) are informative, our objective here was rank robustness under bounded perturbations; thus, OAT + Monte Carlo is sufficient and computationally efficient for decision support [

46,

48,

49,

50,

51,

52,

53].

3.3. Implementation and Reproducibility

All computations were scripted to ensure replicability. Random seeds were set before simulations; all weight vectors and local priority matrices were validated to sum to one after perturbation (numerical tolerance <

). We report parameter values (δ levels, ensemble size) and publish the analysis artifacts on request. The chosen OAT + Monte Carlo design follows standard practice for MCDM robustness assessment under bounded uncertainty and aligns with methodological recommendations for policy-facing analyses [

4,

42,

48,

49,

54].

Additional methodological details (questionnaire templates, consistency diagnostics, and sampling settings) are available upon request and can be included as

Supplementary Material.

4. Results and Discussion

4.1. Criteria Prioritization

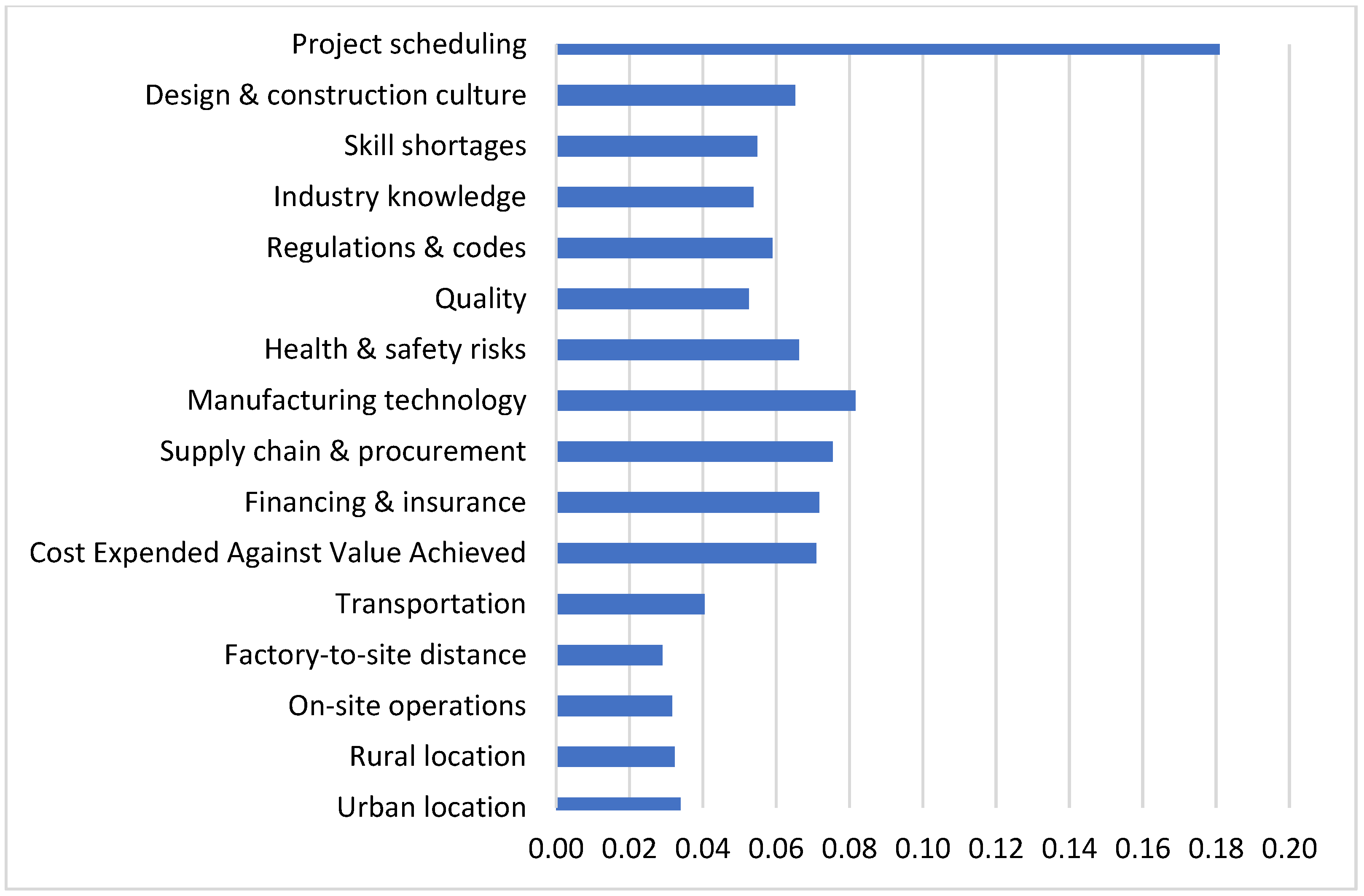

The evaluation of six main criteria and sixteen sub-criteria produced clear differentiation among stakeholders (see

Table 4 and

Figure 3). The results of the Analytical Hierarchy Process (AHP) reveal that stakeholders assign the highest priority to Managerial and Planning, particularly emphasizing the importance of Project Scheduling (0.181). This indicates that stakeholders perceive the timely delivery of modular housing projects as the most critical success factor in adoption. Closely following are Quality, Safety and Regulation (0.178) and Human Resources and Knowledge (0.174), underscoring concerns about regulatory compliance, workforce competency, and the prevailing construction culture in Indonesia and Aceh.

Operational and Location (0.167) and Supply Chain and Technology (0.157) rank moderately, reflecting the logistical challenges of transporting and installing modules in both urban and rural contexts. Interestingly, Financial and Economic considerations (0.143) were weighted the lowest, suggesting that while cost and insurance remain relevant, they are secondary to technical and managerial feasibility.

On the sub-criteria level, the most critical drivers were identified as Manufacturing Technology (0.080), Financing and Insurance (0.072), and Supply Chain and Procurement (0.077). These findings align with prior literature emphasizing the dependence of modular construction on advanced production systems, robust financing models, and efficient supply chains [

22,

27].

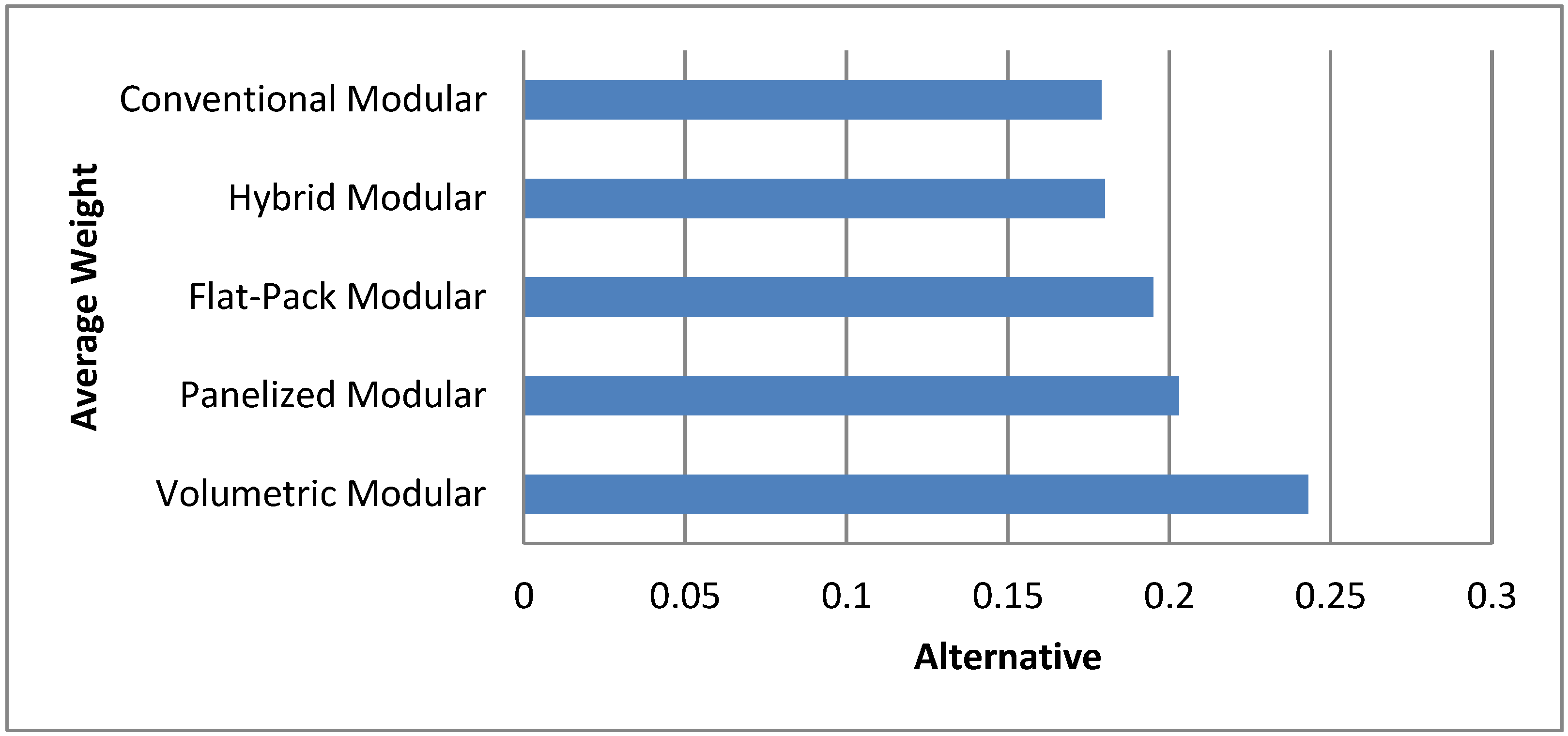

4.2. Stakeholder Perspectives on Modular Alternatives

The evaluation of five modular housing alternatives produced clear differentiation among stakeholders (see

Table 5 and

Figure 4). Volumetric Modular emerged as the most preferred option across the majority of stakeholder groups, with an average weight of 0.243, and was strongly supported by academics (0.249), consultants (0.284), and contractors (0.283). This preference reflects recognition of volumetric systems’ ability to deliver complete, factory-assembled units that minimize on-site risks and accelerate deployment, which is especially critical in disaster-prone Aceh.

Panelized Modular ranked second (0.203), benefiting from its balance of standardization and design flexibility, which aligns with urban housing needs. Flat-Pack Modular (0.195) placed third, suggesting interest in lightweight, transport-efficient solutions, particularly for rural and remote contexts.

A clear divergence emerged among stakeholders: while most favored Volumetric Modular, the Indonesian Architects Association (IAI) preferred Conventional (non-modular prefabrication) (0.242). This reflects architects’ emphasis on design freedom, aesthetic expression, and contextual adaptability, qualities often constrained in fully standardized modular systems [

55,

56]. Conventional (non-modular prefabrication) methods, involving partial prefabrication, preserve flexibility and creative authorship within industrialized construction frameworks [

57]. Culturally, volumetric systems are perceived as foreign and repetitive, conflicting with local identity and craftsmanship [

58,

59]. Regulatory ambiguity regarding modular permits and building codes further discourages experimentation [

60]. Limited BIM and DfMA integration isolates architects from manufacturers, reinforcing perceptions that conventional systems are safer and more manageable. Similar trends in Malaysia and Thailand reveal a preference for hybrid systems enabling local adaptation. Overcoming such resistance in Indonesia requires regulatory clarity, targeted training, and demonstration projects that highlight modular design’s cultural and aesthetic versatility.

Hybrid Modular (0.180) ranked closely to conventional, reflecting its position as a transitional solution but with lower perceived scalability.

4.3. Synthesis and Implications

The convergence of most stakeholders on Volumetric Modular highlights a shared recognition of its potential for rapid, large-scale deployment under uncertainty, particularly in post-disaster housing programs in Aceh [

61]. However, the divergence observed among architects signals the need for greater regulatory clarity and design flexibility within modular systems.

The divergence in architects’ preferences underscores an important challenge in modular construction adoption: achieving architectural buy-in. While architects value the efficiency and resilience of volumetric systems, their hesitancy often stems from perceived constraints on creativity, spatial flexibility, and aesthetic control. To enhance acceptance, volumetric modular systems should be designed with modular adaptability in mind, allowing for façade customization, varied module combinations, and adaptable interior layouts. Furthermore, co-design platforms and BIM-integrated visualization tools can empower architects to engage in early-stage module configuration, bridging the gap between design intent and prefabrication constraints. From a market perspective, developers and policymakers should emphasize architectural freedom within modular parameters, showcasing successful design-driven modular projects through pilot programs, competitions, and professional training. By reframing modular design as a medium for creative innovation rather than standardization, stakeholders can foster stronger architectural endorsement and accelerate MMC integration in Indonesia.

The findings indicate that modular adoption in Indonesia is not hindered primarily by cost but by systemic barriers such as limited technology availability, workforce skills, and entrenched construction culture. Addressing these gaps requires investment in local manufacturing capacity, standardized regulatory frameworks, and capacity-building programs to align stakeholder expectations [

62].

In the context of Aceh, the strong emphasis on volumetric solutions mirrors the region’s pressing housing needs amid disaster recovery and rapid urbanization. This preference underscores modular construction’s advantages in speed, quality control, and resilience, key factors in post-disaster and high-demand settings [

61,

63]. Policymakers should therefore strengthen supply-chain resilience, promote public–private financing, and develop adaptive building codes to accelerate modular adoption [

64].

Although volumetric modular construction emerged as the most preferred and robust alternative, several trade-offs merit attention. The initial investment required for factory establishment, specialized machinery, and quality-control systems can be substantially higher than that of panelized or hybrid systems, posing financial barriers for widespread adoption in resource-constrained regions. Moreover, the design flexibility of volumetric systems is inherently limited, as fully integrated modules allow less freedom for customization, façade variation, or incremental expansion—attributes often valued by architects and clients in Indonesia. In contrast, panelized systems offer greater adaptability for diverse layouts and architectural expression, albeit at the expense of slower on-site assembly. Recognizing and managing these trade-offs through phased infrastructure investment, modular-friendly regulations, and hybrid design strategies will be essential to ensure both scalability and contextual suitability of volumetric modular housing in Aceh and similar developing regions.

These insights align with global experiences in modular construction. In advanced economies such as the UK, the US, and Japan, large-scale adoption is enabled by integrated supply chains, robust regulation, and technological maturity. The UK leads in volumetric housing programs; Japan applies modular techniques for earthquake-resilient design [

57]; and the US expands modular use in healthcare and education under cost and sustainability pressures [

3,

24]. Furthermore, by situating these results within Aceh’s post-disaster reconstruction context, the discussion emphasizes how stakeholder preferences reflect both global modular trends and local institutional realities, bridging international evidence with Indonesia’s emerging MMC landscape. Conversely, developing countries face barriers to scalability. Malaysia and Thailand employ hybrid systems combining factory prefabrication with on-site assembly to address logistical and regulatory challenges [

4,

60], while Latin American initiatives show modular’s promise for affordable housing yet remain constrained by financing and policy gaps [

1]. Indonesia reflects similar conditions: although conventional construction still dominates, rapid urbanization and infrastructure growth create opportunities for industrialized and hybrid modular strategies that enhance efficiency, quality, and sustainability [

3].

Overall, Indonesia’s trajectory parallels early stages of MMC adoption in other emerging economies, where institutional readiness and stakeholder alignment are crucial. Strengthening these foundations can bridge the gap with advanced economies and position modular construction as a transformative approach for resilient, sustainable, and rapidly deployable housing in disaster-prone and urbanizing regions.

4.4. Sensitivity Analysis

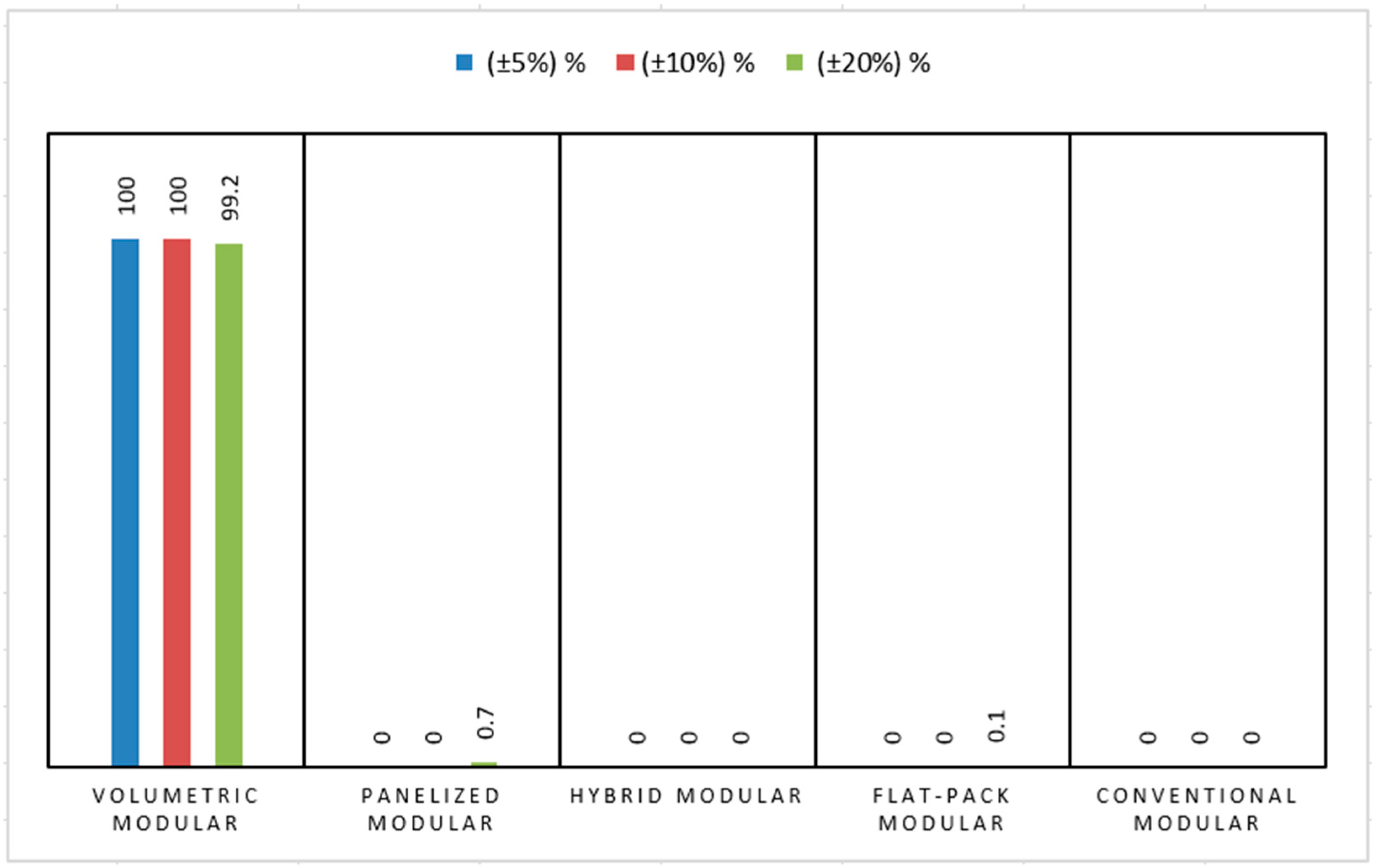

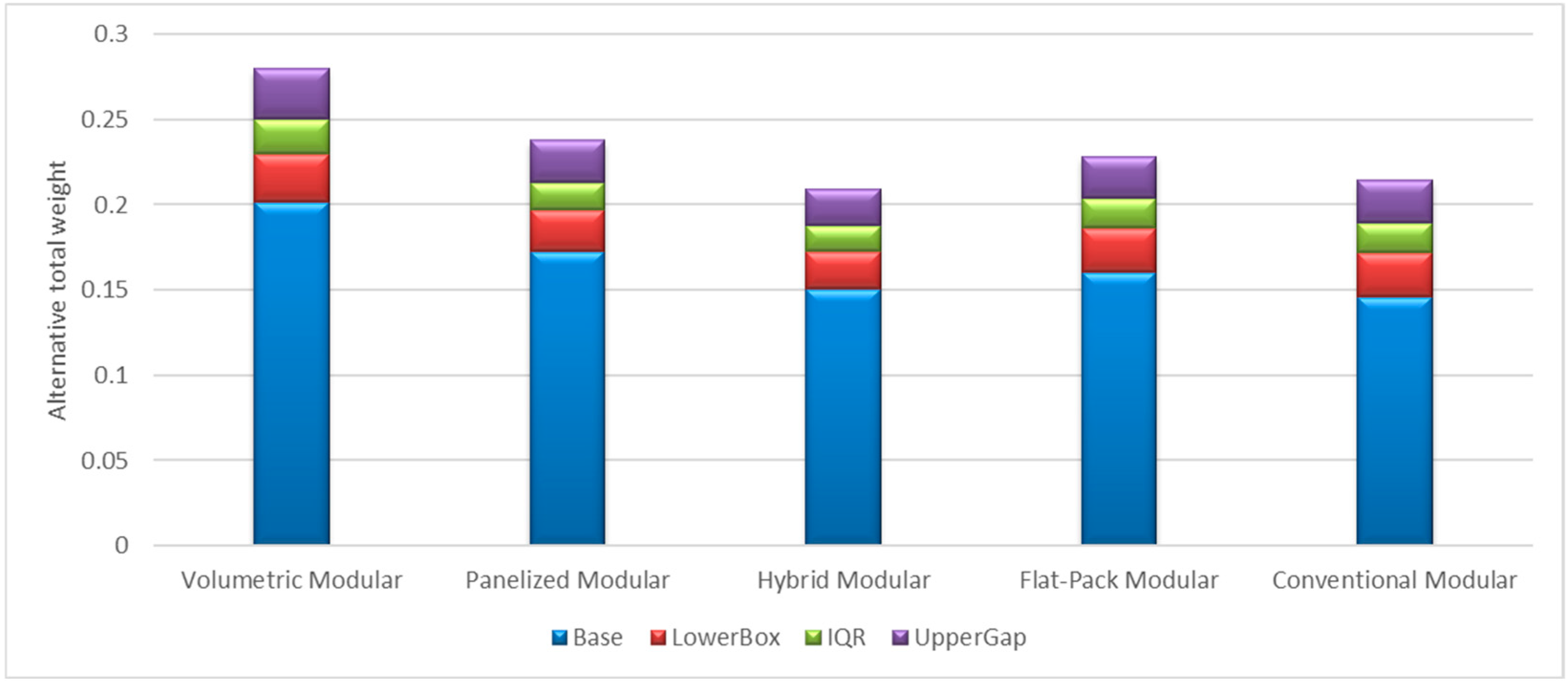

At low–to–moderate perturbations (±5% and ±10% on criteria weights), Volumetric Modular consistently stays at the top (

Table 6;

Figure 5). The average global weight of Volumetric Modular only exhibits minor fluctuations (≤0.005 from baseline), and its Top-1 frequency remains > 80% across simulation runs, confirming the robustness of the baseline decision. Panelized Modular sometimes increases its weight share but does not overtake Volumetric Modular in overall ranking.

Under the highest stress scenario (±20%), the dispersion of weights across alternatives increases (

Figure 6). Volumetric Modular still attains the highest mean weight, but its dominance decreases slightly (Top-1 frequency ~65–70%). In some runs, Panelized Modular or Flat-Pack Modular temporarily overtakes Volumetric Modular—reflecting the influence of extreme shifts, particularly in supply-chain and financial considerations. Even so, Volumetric Modular remains the leading option in most simulations. Panelized Modular occasionally increased in weight but never surpassed Volumetric Modular in overall ranking. This demonstrates strong robustness of the baseline decision outcome.

These results confirm that the adoption of Volumetric Modular housing in Aceh is not only supported by baseline AHP analysis but also by robustness checks under uncertainty. The option’s resilience is largely due to its favorable performance across the most influential criteria: managerial and planning (0.181), supply chain and technology (0.157), and operational and location (0.167). As these criteria capture the structural challenges in Indonesia’s modular construction industry [

8], the fact that Volumetric Modular maintains stability under varying assumptions strengthens confidence in its selection as the preferred alternative. The sensitivity analysis results confirm the robustness of the AHP findings. Unlike developed countries, where modular rankings may shift significantly under cost-sensitive scenarios, the Indonesian and Aceh context shows strong consensus toward Volumetric Modular regardless of weight variations. This stability underscores its suitability as a disaster-resilient, rapidly deployable housing option, making it the most reliable choice for Aceh reconstruction and urban housing expansion.

5. Limitations and Future Research

This study provides valuable insights into modular construction adoption under uncertainty in Indonesia, particularly in Aceh; however, several limitations should be acknowledged.

First, the analysis is based on expert judgments from a limited group of stakeholders, including academics, planners, architects, consultants, and contractors. Although these perspectives are diverse, the inclusion of additional stakeholder groups, such as policymakers, financial institutions, insurers, and end-users, would enhance representativeness and provide a more comprehensive understanding of the adoption ecosystem.

Second, the Analytical Hierarchy Process (AHP) effectively structured the prioritization of adoption criteria but remains sensitive to subjective judgment. Although this limitation was mitigated through expert averaging and the application of Monte Carlo simulation, uncertainty persists. Future research should employ hybrid multi-criteria decision-making approaches, such as Fuzzy AHP–TOPSIS, DEMATEL, or Bayesian networks, to better capture ambiguity and improve decision robustness.

Third, the geographic focus on Indonesia, with Aceh as the case study, limits generalizability. While Aceh’s disaster-prone and urgent housing context offers relevant insights, regional variations in regulation, culture, and market maturity may influence modular construction priorities. Comparative analyses across Indonesian provinces or developing countries could uncover contextual variations and enhance the transferability of findings.

Finally, the study evaluated only five modular alternatives: Volumetric, Panelized, Hybrid, Flat-Pack, and Conventional (non-modular prefabrication) systems. Emerging technologies, such as 3D-printed modular components and digital prefabrication, were excluded but hold potential to reshape future modular construction practices.

These limitations, however, open new opportunities for interdisciplinary research bridging data-driven modeling with stakeholder-based decision frameworks. Future research should therefore (a) broaden stakeholder representation to include government, financial, and community actors; (b) integrate advanced decision-making frameworks capable of modeling uncertainty and interdependence; (c) conduct cross-regional and international comparative analyses; (d) explore the integration of digital technologies (e.g., Building Information Modeling [BIM], digital twins, 3D printing) within modular frameworks; and (e) assess long-term socio-economic impacts related to affordability, sustainability, and community acceptance.

Addressing these areas will enhance methodological rigor, deepen contextual understanding, and advance strategies for modular construction in uncertain environments.

6. Conclusions

This study applied the Analytic Hierarchy Process (AHP) integrated with Monte Carlo simulation to evaluate stakeholder priorities and modular housing alternatives under uncertainty in Aceh, Indonesia.

Main Findings:

The six principal criteria influencing modular construction adoption were identified as follows: Manufacturing technology, Operational and location (0.250), Supply Chain and Technology (0.205), Quality, Safety and Regulation (0.159), Financial and Economic (0.170), Human Resources and Knowledge (0.114), and Managerial and Planning (0.102).

Among the sixteen sub-criteria, Manufacturing technology (0.104), Project Scheduling (0.102) and Supply chain & procurement (0.100) received the highest global weights, reflecting the importance of efficient planning and workforce capacity in post-disaster contexts.

Volumetric Modular Construction emerged as the preferred alternative (0.243) across stakeholders, followed by Panelized Modular (0.203), due to its rapid deployment and advantage of consistent quality.

The Monte Carlo simulation (10,000 iterations) confirmed the robustness of the AHP results, with over 80% of runs preserving the ranking order of modular alternatives.

Policy Recommendations:

Strengthen Regulatory Frameworks: Align with the Quality, Safety and Regulation criterion (0.178) through modular codes and certification systems.

Enhance Manufacturing and Supply Chains: Invest in local factories and logistics networks, reflecting the Supply Chain and Technology criterion (0.157).

Develop Human Capital: Address the Skill Shortages sub-criterion (0.055) by introducing modular training, certification, and university–industry partnerships.

Improve Managerial and Planning Practices: Adopt BIM-based scheduling and coordination systems aligned with Project Scheduling (0.181).

Establish Financial Incentives: Provide modular-friendly financing and risk mitigation schemes, supporting the Financial and Economic criterion (0.143).

This research contributes a novel probabilistic, multi-stakeholder framework that integrates AHP and Monte Carlo simulation to enhance the reliability of modular construction decision-making under uncertainty. The findings provide a data-driven foundation for policy, education, and practice to accelerate modular adoption in disaster-prone and developing regions such as Aceh.

Author Contributions

Conceptualization, N.N. and A.A.; methodology, N.N.; software, N.N.; validation, N.N.; formal analysis, Y.A. and I.M.; investigation, Y.A. and I.M.; resources, N.N.; data curation, N.N.; writing—original draft preparation, N.N.; writing—review and editing, N.N.; visualization, N.N.; supervision, N.N.; project administration, N.N.; funding acquisition, N.N. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data and codes are available from the corresponding author upon reasonable request.

Acknowledgments

The authors thank the Faculty of Engineering, USK, and the expert panel for their time and insights.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Amede, E.A.; Woldesenbet, A.K.; Bahiru, A.K.; Tibebu, F.T.; Hailemariam, L.M. Transforming Construction in Emerging Economies: Overcoming Barriers to the Adoption of Industrialized Building Systems. Discov. Appl. Sci. 2025, 7, 765. [Google Scholar] [CrossRef]

- Ali, A.H.; Kineber, A.F.; Elyamany, A.; Ibrahim, A.H.; Daoud, A.O. Identifying and Assessing Modular Construction Implementation Barriers in Developing Nations for Sustainable Building Development. Sustain. Dev. 2023, 31, 3346–3364. [Google Scholar] [CrossRef]

- Bertram, N.; Fuchs, S.; Mischke, J.; Palter, R.; Strube, G.; Woetzel, J. Modular Construction: From Projects to Products; McKinsey and Company: New York City, NY, USA, 2019. [Google Scholar]

- Jaillon, L.; Poon, C. Design Issues of Using Prefabrication in Hong Kong Building Construction. Constr. Manag. Econ. 2010, 28, 1025–1042. [Google Scholar] [CrossRef]

- House of Lords. Off-Site Manufacture for Construction: Building for Change; House of Lords: London, UK, 2018. [Google Scholar]

- Windapo, A.; Lefoka, M.; Hall, J.; Narker, T. Use of Modular and Offsite Technologies in Construction: Barriers and Pathways to Adoption. In Proceedings of the CIB Conferences, West Lafayette, IN, USA, 19–23 May 2025; Volume 1. [Google Scholar] [CrossRef]

- Ministry of Housing, Communities and Local Government (MHCLG). Modern Methods of Construction: Introducing the MMC Definition Framework; Ministry of Housing, Communities and Local Government (MHCLG): London, UK, 2019; ISBN 9780080471716.

- Saad, S.; Rasheed, K.; Ammad, S.; Hasnain, M.; Ullah, H.; Hannan Qureshi, A.; Mohsen Alawag, A.; Altaf, M.; Sadiq, T. Offsite Modular Construction Adoption in Developing Countries: Partial Least Square Approach for Sustainable Future. Ain Shams Eng. J. 2025, 16, 103228. [Google Scholar] [CrossRef]

- Bello, A.O.; Khan, A.A.; Idris, A.; Awwal, H.M. Barriers to Modular Construction Systems Implementation in Developing Countries’ Architecture, Engineering and Construction Industry. Eng. Constr. Archit. Manag. 2024, 31, 3148–3164. [Google Scholar] [CrossRef]

- Adeyemi, A.B.; Ohakawa, T.C.; Okwandu, A.C.; Iwuanyanwu, O.; Ifechukwu, G.-O. Integrating Modular and Prefabricated Construction Techniques in Affordable Housing: Architectural Design Considerations and Benefits. Compr. Res. Rev. Sci. Technol. 2024, 2, 10–19. [Google Scholar] [CrossRef]

- Rahman, M.M. Barriers of Implementing Modern Methods of Construction. J. Manag. Eng. 2014, 30, 69–77. [Google Scholar] [CrossRef]

- Akinradewo, O.; Aigbavboa, C.; Aghimien, D.; Oke, A.; Ogunbayo, B. Modular Method of Construction in Developing Countries: The Underlying Challenges. Int. J. Constr. Manag. 2023, 23, 1344–1354. [Google Scholar] [CrossRef]

- Rahman, D.A.; Latief, Y. Planning Innovation for Implementing Modular Prefabricated Construction in Housing Development in Indonesia Using a Riskbased ISO 56002:2019 Approach to Improve Project Performance. Smart Cities 2024, 4, 4. [Google Scholar] [CrossRef]

- Moon, J.W.; Jung, S.K. Algorithm for Optimal Application of the Setback Moment in the Heating Season Using an Artificial Neural Network Model. Energy Build. 2016, 127, 859–869. [Google Scholar] [CrossRef]

- Viriezky, V.; Susanto, D.; Alkadri, M.F. Flexible and Sustainable Incremental Houses: Advancing Semi-Volumetric Systems of Prefabricated Construction for Rapid Urbanization in Indonesia. Infrastructures 2025, 10, 5. [Google Scholar] [CrossRef]

- Carissa; Larasati, D.; Triyadi, S.; Wimala, M.; Alyssa. Performance Evaluation of Indonesian Prefabricated Modular School Building. Civ. Eng. Archit. 2025, 13, 1760–1776. [Google Scholar] [CrossRef]

- Pramesti, N.P.; Basuki, I. Challenges and Opportunities in Managing Large-Scale Infrastructure Projects: The Case of Indonesia’s New Capital Nusantara. J. Tek. Sipil 2025, 25, 1930–1943. [Google Scholar] [CrossRef]

- Ardhiati, Y.; Hasan, A. Energy-Saving of the Garuda Palace Building: Shaping the New Capital City of Nusantara. Futur. Cities Environ. 2025, 11. [Google Scholar] [CrossRef]

- Nurcahya, Y.; Hambaliana, D. Effective Strategies in Developing Sustainable Cities: Cases Diverting the New National Capital. J. Ilmu Sos. Dan Hum. 2025, 1, 1–8. [Google Scholar]

- Aziiz, A.; Mulyono, B.M.; Prakoso, I. Development of a Prefabricated House Prototype with DFMA and BIM Integration. J. Ilm. Din. Rekayasa 2025, 21, 186–194. [Google Scholar] [CrossRef]

- Irwansyah, M.; Nursaniah, C.; Qadri, L.; Mariana, M. City of Prone Natural Disasters: Mitigating Post-Tsunami on the Coastal of Banda Aceh, Indonesia. Environ. Challenges 2024, 15, 100925. [Google Scholar] [CrossRef]

- Shukor, A.A.A.; Newaz, M.S.; Rahman, M.K.; Taha, A.Z. Supply Chain Integration and Its Impact on Supply Chain Agility and Organizational Flexibility in Manufacturing Firms. Int. J. Emerg. Mark. 2021, 16, 1721–1744. [Google Scholar] [CrossRef]

- Fahlevi, R.; Manurung, E.H.; Purba, A. The Influence of Implementing Modular Construction Methods on Time and Cost Efficiency in Building Construction Projects. Int. J. Multidiscip. Res. Lit. 2025, 4, 104–113. [Google Scholar] [CrossRef]

- Pan, W.; Goodier, C. House-Building Business Models and Off-Site Construction Take-Up. J. Archit. Eng. 2012, 18, 84–93. [Google Scholar] [CrossRef]

- Alwan, Z.; Jones, P.; Holgate, P. Strategic Sustainable Development in the UK Construction Industry, Through the Framework for Strategic Sustainable Development, Using Building Information Modelling. J. Clean. Prod. 2017, 140, 349–358. [Google Scholar] [CrossRef]

- Berardi, U. Sustainable Construction: Green Building Design and Delivery. Intell. Build. Int. 2013, 5, 65–66. [Google Scholar] [CrossRef]

- Pan, W.; Gibb, A.G.F.; Dainty, A.R.J. Strategies for Integrating the Use of Off-Site Production Technologies in House Building. J. Constr. Eng. Manag. 2012, 138, 1331–1340. [Google Scholar] [CrossRef]

- NHBC Foundation. Modern Methods of Construction: Views from the Industry; NHBC Foundation: Milton Keynes, UK, 2016; ISBN 9781848064447. [Google Scholar]

- Triantaphyllou, E.; Sanchez, A. A Sensitivity Analysis Approach for Some Deterministic Multi-Criteria Decision-Making Methods. Decis. Sci. 1997, 28, 151–194. [Google Scholar] [CrossRef]

- Karthik, S.; Sharareh, K.; Behzad, R. Modular Construction vs. Traditional Construction: Advantages and Limitations: A Comparative Study. In Proceedings of the Creative Construction e-Conference, Online, 28 June–1 July 2020; pp. 11–19. [Google Scholar]

- Lu, N.; Liska, R.W. Designers’ and General Contractors’ Perceptions of Offsite Construction Techniques in the United State Construction Industry. Int. J. Constr. Educ. Res. 2008, 4, 177–188. [Google Scholar] [CrossRef]

- Masood, R.; Lim, J.B.P.; González, V.A. Performance of the Supply Chains for New Zealand Prefabricated House-Building. Sustain. Cities Soc. 2021, 64, 102537. [Google Scholar] [CrossRef]

- Blismas, N.; Pasquire, C.; Gibb, A. Benefit Evaluation for Off-Site Production in Construction. Constr. Manag. Econ. 2006, 24, 121–130. [Google Scholar] [CrossRef]

- Van Tam, N.; Toan, N.Q.; Van Phong, V. Investigating Potential Barriers to Construction Digitalization in Emerging Economies: A Study in Vietnam. Int. J. Inf. Manag. Data Insights 2024, 4, 100226. [Google Scholar] [CrossRef]

- Aziz, S.; Abdullah, M.R. Modular Construction System in Malaysia: Issues for Research in Sustaining an Affordable Home Project. In Proceedings of the Postgraduate Conference on Global Green Issues (Go Green), Perak, Malaysia, 7–8 October 2015. [Google Scholar]

- Ghannad, P.; Lee, Y.-C.; Choi, J.O. Feasibility and Implications of the Modular Construction Approach for Rapid Post-Disaster Recovery. Int. J. Ind. Constr. 2020, 1, 64–75. [Google Scholar] [CrossRef]

- Gunawardena, T.; Ngo, T.; Mendis, P.; Aye, L.; Crawford, R. Time-Efficient Post-Disaster Housing Reconstruction with Prefabricated Modular Structures. Open House Int. 2014, 39, 59–69. [Google Scholar] [CrossRef]

- Aliu, J.O.; Dunmoye, I.D.; Fakiyesi, V.O.; Feyijimi, T.R. Trends in Modular Construction Research: A Bibliometric Examination of Developed and Developing Regions John. In Proceedings of the American Society for Engineering Education, Montreal, QC, Canada, 22–25 June 2025. [Google Scholar]

- Saaty, T.L. Decision Making with the Analytic Hierarchy Process. Sci. Iran. 2022, 9, 215–229. [Google Scholar] [CrossRef]

- Hsueh, K.; Chen, P.S.; Chu, P.; Liu, J.K. The Procedure for Synthesizing Ratio Judgements. J. Discret. Math. Sci. Cryptogr. 2001, 4, 115–120. [Google Scholar] [CrossRef]

- de Brito, M.M.; Evers, M. Multi-Criteria Decision-Making for Flood Risk Management: A Survey of the Current State of the Art. Nat. Hazards Earth Syst. Sci. 2016, 16, 1019–1033. [Google Scholar] [CrossRef]

- Harker, P.T.; Vargas, L.G. The Theory of Ratio Scale Estimation: Saaty’s Analytic Hierarchy Process. Manag. Sci. 1987, 33, 1383–1403. [Google Scholar] [CrossRef]

- Forman, E.; Peniwati, K. Aggregating Individual Judgments and Priorities with the Analytic Hierarchy Process. Eur. J. Oper. Res. 1998, 108, 165–169. [Google Scholar] [CrossRef]

- Kang, S.K.; Lee, C.K.; Lee, D.E. Examining Cultural Worldview and Experience by International Tourists: A Case of Traditional House Stay. Asia Pac. J. Tour. Res. 2016, 21, 477–499. [Google Scholar] [CrossRef]

- Cheng, E.W.l.; Li, H. Analytic Hierarchy Process. Meas. Bus. Excell. 2001, 5, 30–37. [Google Scholar] [CrossRef]

- Saltelli, A.; Ratto, M.; Andres, T.; Campolongo, F.; Cariboni, J.; Gatelli, D.; Saisana, M.; Tarantola, S. Global Sensitivity Analysis. The Primer; John Wiley & Sons: Hoboken, NJ, USA, 2007; ISBN 9780470059975. [Google Scholar]

- Zhang, J. Modern Monte Carlo Methods for Efficient Uncertainty Quantification and Propagation: A Survey. WIREs Comput. Stat. 2021, 13, 1–23. [Google Scholar] [CrossRef]

- Morgan, M.G.; Henrion, M. Uncertainty: A Guide to Dealing with Uncertainty in Quantitative Risk and Policy Analysis. J. Econ. Lit. 1990, 29, 332. [Google Scholar]

- Díaz, H.; Teixeira, A.P.; Guedes Soares, C. Application of Monte Carlo and Fuzzy Analytic Hierarchy Processes for Ranking Floating Wind Farm Locations. Ocean Eng. 2022, 245, 110453. [Google Scholar] [CrossRef]

- Aitchison, J. The Statistical Analysis of Compositional Data. J. R. Stat. Soc. Ser. B Stat. Methodol. 1982, 44, 139–160. [Google Scholar] [CrossRef]

- Aitchison, J.; Shen, S.M. Logistic-Normal Distributions: Some Properties and Uses. Biometrika 1980, 67, 261–272. [Google Scholar] [CrossRef]

- Kruschke, J.K. Bayesian Data Analysis. WIREs Cogn. Sci. 2010, 1, 658–676. [Google Scholar] [CrossRef]

- Kroese, D.P.; Rubinstein, R.Y. Monte Carlo Methods. WIREs Comput. Stat. 2012, 4, 48–58. [Google Scholar] [CrossRef]

- Mckay, M.D.; Beckman, R.J.; Conover, W.J. A Comparison of Three Methods for Selecting Values of Input Variables in the Analysis of Output from a Computer Code. Technometrics 2000, 42, 55–61. [Google Scholar] [CrossRef]

- Smith, R.E. Prefab Architecture: A Guide to Modular Design and Construction; John Wiley & Sons: Hoboken, NJ, USA, 2011; ISBN 0470880465. [Google Scholar]

- Lawson, M.; Ogden, R.; Goodier, C. Design in Modular Construction; CRC Press: Boca Raton, FL, USA, 2014; ISBN 9780203870785. [Google Scholar]

- Gibb, A.; Isack, F. Re-Engineering Through Pre-Assembly: Client Expectations and Drivers. Build. Res. Inf. 2003, 31, 146–160. [Google Scholar] [CrossRef]

- Abd Rahman, A.B.; Omar, W. Issues and Challenges in the Implementation of Industrialised Building Systems in Malaysia. In Proceedings of the 6th Asia-Pacific Structural Engineering and Construction Conference, Kuala Lumpur, Malaysia, 5–6 September 2006. [Google Scholar]

- Jaillon, L.; Poon, C.S. The Evolution of Prefabricated Residential Building Systems in Hong Kong: A Review of the Public and the Private Sector. Autom. Constr. 2009, 18, 239–248. [Google Scholar] [CrossRef]

- Mohamad Kamar, K.A.; Alshawi, M.; Abd Hamid, Z. Barriers to Industrialized Building Systen (IBS): The Case of Malaysia. In Proceedings of the BuHu 9th International Postgraduate Research Conference, Salford, UK, 29–30 January 2009; pp. 1–16. [Google Scholar]

- Nazara, S.; Resosudarmo, B.P. Aceh-Nias Reconstruction and Rehabilitation: Progress and Challenges at the End of 2006; Asian Development Bank Institute (ADBI): Tokyo, Japan, 2007; ISBN 8133593557. [Google Scholar]

- Rojas, E.M.; Aramvareekul, P. Is Construction Labor Productivity Really Declining? J. Constr. Eng. Manag. 2003, 129, 41–46. [Google Scholar] [CrossRef]

- Tam, V.W.Y.; Tam, C.M.; Zeng, S.X.; Ng, W.C.Y. Towards Adoption of Prefabrication in Construction. Build. Environ. 2007, 42, 3642–3654. [Google Scholar] [CrossRef]

- World Bank Group. World Bank Group Building Regulation for Resilience Managing Risks for Safer Cities; World Bank Group: Washington, DC, USA, 2015. [Google Scholar]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).