Integration into the International Economic Cycle, Shift in Growth Drivers, and Green Innovation in Manufacturing

Abstract

1. Introduction

2. Literature Review

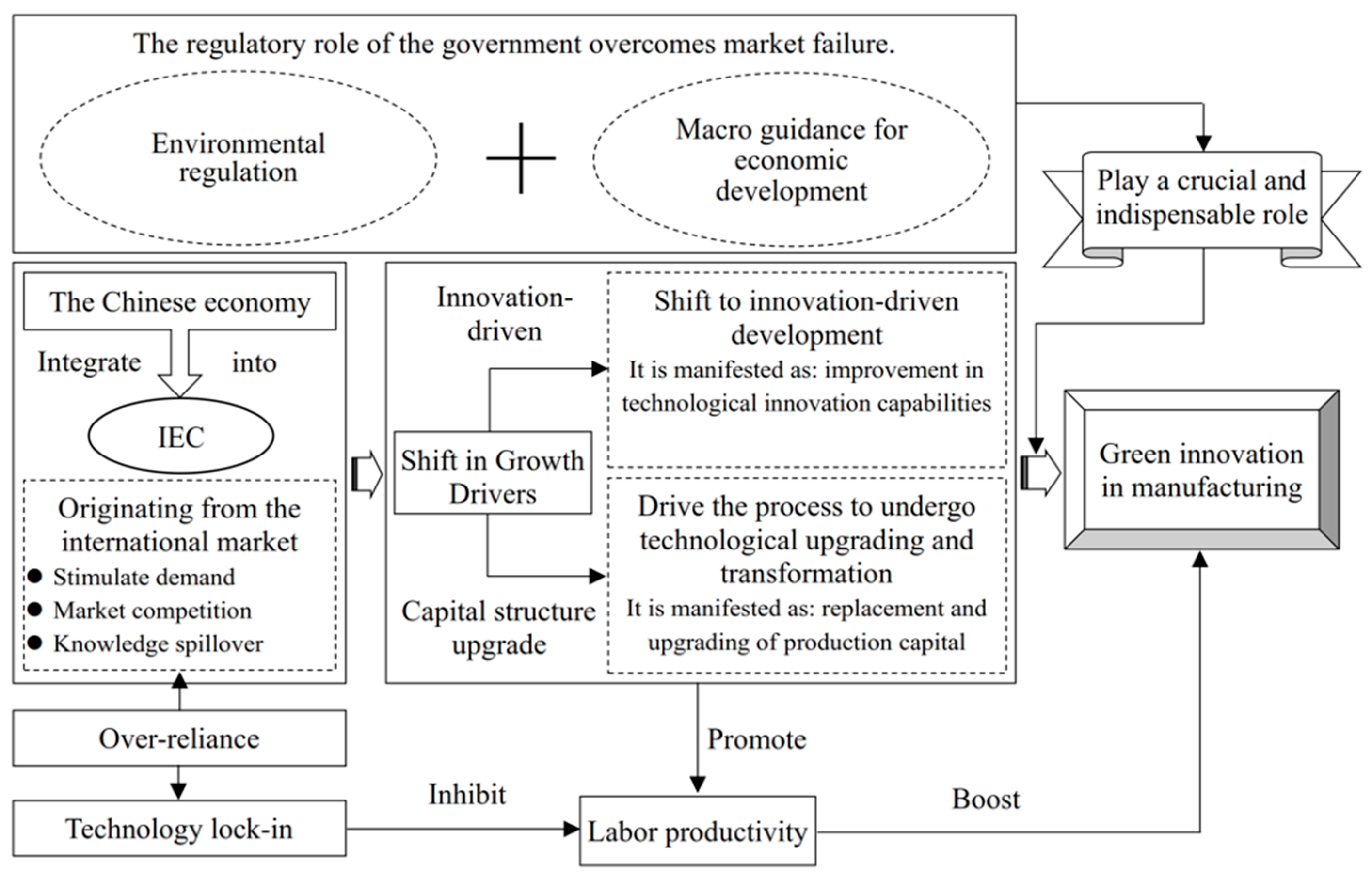

3. Mechanism Analysis and Research Hypotheses

4. Research Design

4.1. Model Setting

4.2. Indicator Construction and Data Presentation

4.2.1. Explained Variable: Green Innovation

4.2.2. Explanatory Variable: IEC

4.2.3. Mediating Mechanism Variables

4.2.4. Relevant Variables in the Government Sector

4.2.5. Control Variables

5. Empirical Analysis

5.1. Baseline Regression

5.2. Robustness Test

5.3. Mechanism Testing

5.3.1. Shift to Innovation-Driven Development: Enhancement of Innovation Capacity

5.3.2. Upgrading of Production Capital Structure: Upgrading of Production Capital

5.4. Heterogeneity Analysis

5.4.1. Heterogeneity of External Demand Sources

5.4.2. Heterogeneity of Property Rights

5.4.3. Heterogeneity of Industry Technical Attributes

6. Further Analysis

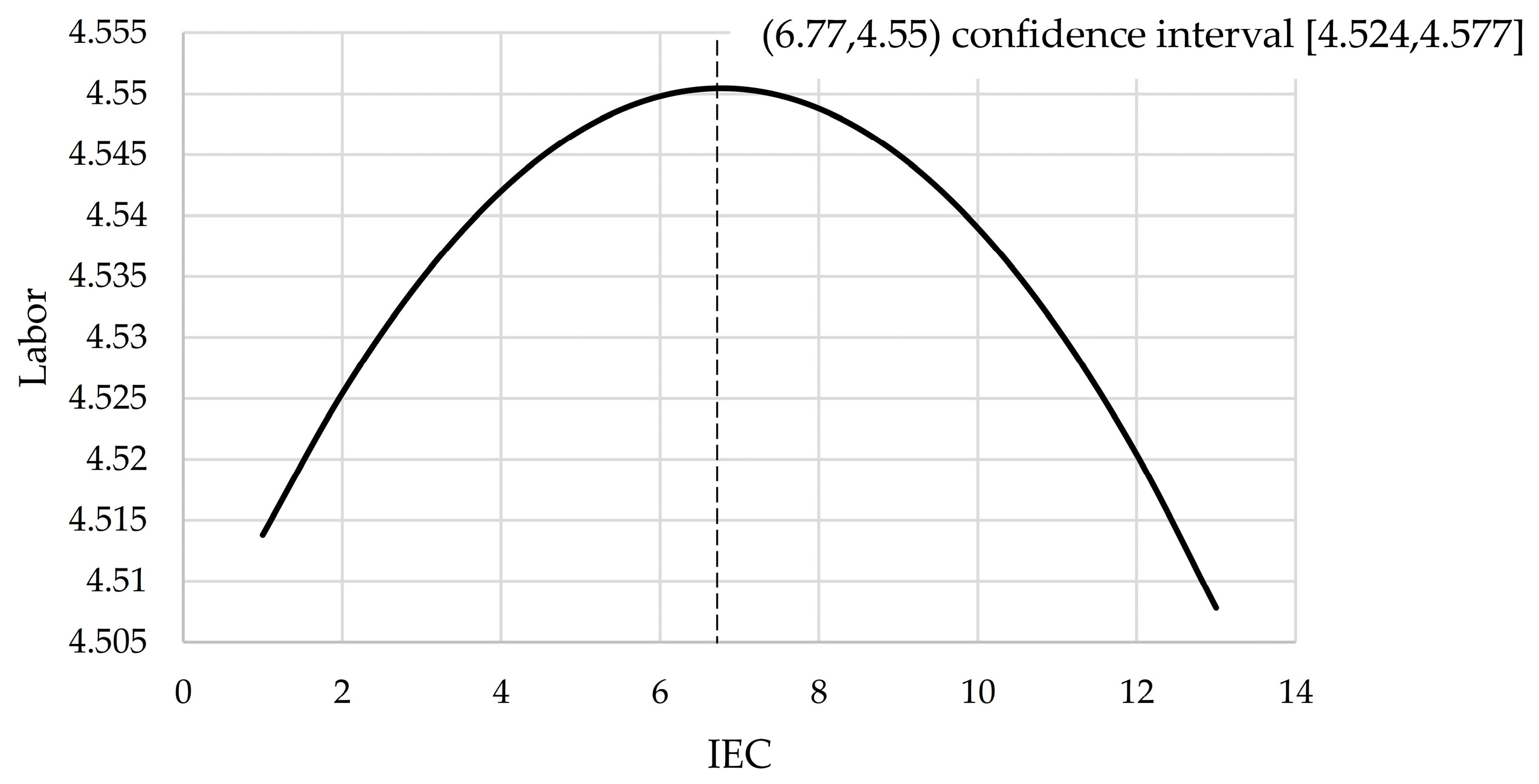

6.1. The Potential Adverse Effects of Over-Reliance on the IEC

6.2. The Key Role of Effective Regulation by Government Departments

7. Conclusions and Policy Recommendations

7.1. Research Conclusions

7.2. Policy Implications

- (1)

- It has been confirmed that integrating into the IEC promotes green innovation in Chinese manufacturing enterprises by advancing the transformation of economic growth drivers. Efforts should be made to further enhance the level of opening-up, motivate enterprises to proactively participate in global market competition, and cultivate independent green innovation capacity.

- (2)

- China should steer clear of over-reliance on the IEC by establishing a new development pattern centered on domestic circulation with mutual reinforcement between domestic and international circulations. Speeding up the development of domestic large-scale circulation and the establishment of a unified national market can stimulate domestic demand, facilitate the continuous optimization and upgrading of the industrial structure, and attain the steady improvement of labor productivity. This is conducive to increasing residents’ income, promoting employment, and fully leveraging the driving force of consumption on economic growth. Ultimately, a higher-quality IEC based on the domestic economic cycle should be established and, through the IEC, continuous innovative impetus should be injected into the domestic economic cycle, thereby achieving beneficial interaction.

- (3)

- Investment in the construction of digital information infrastructure should be expanded to support and foster the growth of the digital industry. Enterprises should be encouraged and guided to undertake digital transformation, which is crucial for them to better participate in the IEC, absorb external innovation resources, and drive the transformation of economic growth drivers in the rapidly developing digital economy.

- (4)

- Amid the reconstruction of global value chains, we should proactively engage in economic and trade cooperation with developing countries, leverage complementary advantages, and pursue win-win cooperation to provide broad market space for the green transformation of China’s manufacturing industry.

- (5)

- Efforts should be made to consolidate the foundational function of SOEs in the strategic green transformation of China’s manufacturing sector. With appropriate policy inclinations, the strategic leading role of high-tech industries in green transformation should be fully exerted, and these enterprises should be encouraged to extend their overseas business layout while improving their own development quality via international cooperation.

- (6)

- It is imperative to fully acknowledge the significant role of government authorities in overcoming market failures and their guiding role in promoting economic green transformation, which is crucial for effectively utilizing the IEC to facilitate green innovation in China’s manufacturing industry. Environmental regulations should be appropriately designed in light of specific circumstances, and blind pursuit of environmental assessment indicators while neglecting reality must be avoided. The government-market relationship should be correctly understood, with increased application of market-based environmental regulation measures. Environmental costs should be internalized through market mechanisms to drive enterprises to strengthen their independent green innovation capacity. Ultimately, the performance evaluation mechanism for local governments needs to be further improved, and supervision and inspection efforts enhanced to boost the efficiency of environmental investment and crackdown on corruption.

7.3. Limitations of This Study

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Magat, W.A. Pollution control and technological advance: A dynamic model of the firm. J. Environ. Econ. Manag. 1978, 5, 1–25. [Google Scholar] [CrossRef]

- Clarke, R.A.; Stavins, R.N.; Greeno, J.L.; Bavaria, J.L.; Cairncross, F.; Esty, D.C.; Smart, B.; Piet, J.; Wells, R.P.; Gray, R.; et al. The challenge of going green. Harv. Bus Rev. 1994, 72, 37–48. [Google Scholar]

- Wang, L.H.; Wang, H.; Dong, Z.Q. Economic growth and environmental quality compatibility policy conditions: A test of policy bias effects from the perspective of the direction of environmental technology progress. Manag. World 2020, 3, 39–60. [Google Scholar] [CrossRef]

- Grossman, G.M.; Helpman, E. Trade, Innovation, and Growth. Am. Econ. Rev. 1990, 80, 86–91. [Google Scholar]

- Copeland, B.R.; Taylor, M.S. North-south trade and the environment. Q. J. Econ. 1994, 109, 755–787. [Google Scholar] [CrossRef]

- Antweiler, W.; Copeland, B.R.; Taylor, M.S. Is free trade good for the environment. Am. Econ. Rev. 2001, 91, 877–908. [Google Scholar] [CrossRef]

- Su, L.J.; Liang, J.S. Understanding China’s new dual circulation development strategy: A Marxian input-output analysis. Rev. Radical. Pol. Econ. 2021, 53, 590–599. [Google Scholar] [CrossRef]

- Jiang, X.J.; Meng, L.J. Domestic circulation as the mainstay, external circulation as the empowerment, and a higher level of dual circulation: International experience and Chinese practice. Manag. World 2021, 5, 1–19. [Google Scholar] [CrossRef]

- Wang, Y.; Pan, W.J.; Dong, W.H. Can a new infrastructure plan really promote the dual circulation strategy in China? Singap. Econ. Rev. 2024, 69, 61–79. [Google Scholar] [CrossRef]

- Zhu, J.S.; Qu, D.D. Research on the impact of “Dual Circulation” on high-quality full employment in China. World Surv. Res. 2025, 9, 41–54. [Google Scholar] [CrossRef]

- Dai, X.; Liu, C.P. Unimpeded dual circulation in manufacturing and enhanced innovation efficiency from the perspective of factor input. China Bus. Mark. 2024, 12, 58–70. [Google Scholar] [CrossRef]

- Zhang, X.Y.; Dong, F. Temporal and spatial evolution of embodied carbon transfer network in the context of the domestic economic cycle. Carbon Manag. 2023, 14, 1–21. [Google Scholar] [CrossRef]

- Dangelico, R.M. Green product innovation: Where we are and where we are going? Bus. Strategy Environ. 2016, 25, 560–576. [Google Scholar] [CrossRef]

- Yang, B.; Li, B. The Belt and Road initiative and the green transformation and upgrading of enterprises. Int. Econ. Trade Explor. 2021, 6, 20–36. [Google Scholar] [CrossRef]

- She, W.; Mabrouk, F. Impact of natural resources and globalization on green economic recovery: Role of FDI and green innovations in BRICS economies. Resour. Policy 2023, 82, 103479. [Google Scholar] [CrossRef]

- Torrecillas, C.; Fernandez, S. Exports and outward FDI as drivers of eco-innovations: An analysis based on Spanish manufacturing firms. J. Clean Prod. 2022, 349, 131243. [Google Scholar] [CrossRef]

- Qin, B.; Gao, Y.; Ge, L. The influence mechanism of outward fdi reverse technology spillovers on China’s green innovation. Technol. Econ. Dev. Econ. 2023, 29, 468–499. [Google Scholar] [CrossRef]

- Yang, L.; Zeng, H.; Xu, P. A comparative study of service trade competitiveness for green innovation development using the WWYZ model—Based on China and the 26 countries along ‘the Belt and Road’. Int. J. Technol. Manag. 2021, 85, 165–189. [Google Scholar] [CrossRef]

- Pan, H.; Yang, J.; Zhou, H. Global value chain embeddedness, digital economy and green innovation-Evidence from provincial-level regions in China. Front. Environ. Sci. 2022, 10, 1027130. [Google Scholar] [CrossRef]

- Chiarvesio, M.; Marchi, V.D.; Maria, E. Environmental innovations and internationalization: Theory and practices. Bus. Strategy Environ. 2015, 24, 790–801. [Google Scholar] [CrossRef]

- Szalavetz, A. Impact of greening on the upgrading of manufacturing subsidiaries’ technological capabilities—A Hungarian perspective. J. East Eur. Manag. Stud. 2018, 23, 426–446. [Google Scholar] [CrossRef]

- Zhang, D. Environmental regulation, green innovation, and export product quality: What is the role of greenwashing. Int. Rev. Financ. Anal. 2022, 83, 102311. [Google Scholar] [CrossRef]

- Greenstone, M.; List, J.A.; Syverson, C. The effects of environmental regulation on the competitiveness of US manufacturing. NBER Work. Pap. 2012, w18392. [Google Scholar] [CrossRef]

- Popp, D. International innovation and diffusion of air pollution control technologies: The effects of NOx and SO2 regulation in the US, Japan, and Germany. J. Environ. Econ. Manag. 2006, 51, 46–71. [Google Scholar] [CrossRef]

- Li, Y.; Gao, D.; Wei, P. Can central environmental inspections induce green innovation in enterprises? Stud. Sci. Sci. 2021, 8, 1504–1516. [Google Scholar] [CrossRef]

- Bai, Y.; Song, S.; Jiao, J. The impacts of government r&d subsidies on green innovation: Evidence from Chinese energy-intensive firms. J. Clean Prod. 2019, 233, 819–829. [Google Scholar] [CrossRef]

- Xiang, X.; Liu, C.; Yang, M. Who is financing corporate green innovation? Int. Rev. Econ. Financ. 2022, 78, 321–337. [Google Scholar] [CrossRef]

- Wang, X.; Wang, Y. Research on green credit policy promoting green innovation. Manag. World. 2021, 6, 173–188+11. [Google Scholar] [CrossRef]

- Xia, L.; Gao, S.; Wei, J. Government subsidy and corporate green innovation—Does board governance play a role. Energ. Policy 2022, 161, 112720. [Google Scholar] [CrossRef]

- Goetz, M. Financing conditions and toxic emissions. Safe Work Pap. 2019, 254. [Google Scholar] [CrossRef]

- He, L.; Zhang, L.; Zhong, Z. Green credit, renewable energy investment and green economy development. J. Clean Prod. 2019, 208, 363–372. [Google Scholar] [CrossRef]

- Liu, J.K.; Xiao, Y.Y. China’s environmental protection tax and green innovation. leverage or crowding-out? Econ. Res. J. 2022, 1, 72–88. [Google Scholar]

- Luo, S.; Yimamu, N.; Li, Y. Digitalization and sustainable development: How could digital economy development improve green innovation in China. Bus. Strategy Environ. 2022, 32, 1847–1871. [Google Scholar] [CrossRef]

- Zhang, Z.N.; Qian, X.Y.; Cao, X.W. Research on the green innovation effects of enterprise digital transformation: Substantive innovation or strategic innovation? Ind. Econ. Res. 2023, 1, 86–100. [Google Scholar] [CrossRef]

- Cao, Y.; Li, X.; Hu, H.L. How does digitalization drive the green transformation of manufacturing enterprises? An exploratory case study from the perspective of resource orchestration theory. Manag. World 2023, 3, 96–112+126+113. [Google Scholar] [CrossRef]

- Xiao, J.; Zeng, P. Can digitalization achieve “quality improvement and quantity increase” of green innovation in enterprises? From the perspective of resources. Stud. Sci. Sci. 2023, 5, 925–935+960. [Google Scholar] [CrossRef]

- Wang, F.Z.; Liu, X.L.; Zhang, L. Does digitalization promote green technology innovation in resource-based enterprises? Stud. Sci. Sci. 2022, 2, 332–344. [Google Scholar] [CrossRef]

- Kong, F.X.; Liu, X.Z. Research on the impact of digital economy development on industrial green transformation: Empirical evidence based on Chinese cities. Soft Sci. 2023, 4, 27–35. [Google Scholar] [CrossRef]

- Zhu, Q.Q.; Sun, J.W. The Belt and Road initiative and green innovation of Chinese enterprises. Nanjing Soc. Sci. 2020, 11, 33–40. [Google Scholar] [CrossRef]

- Hu, D.; Jiao, J.; Tang, Y. How global value chain participation affects green technology innovation processes: A moderated mediation model. Technol. Soc. 2022, 68, 101916. [Google Scholar] [CrossRef]

- Wu, L.C.; Cong, S.; Lin, L. A theoretical and empirical study on the impact of exports on green technological innovation in enterprises. South China J. Econ. 2022, 8, 52–72. [Google Scholar] [CrossRef]

- Robert, H.A.; Ram, D.S. The role of standards in innovation. Technol. Forecast. Soc. 2000, 64, 171–181. [Google Scholar] [CrossRef]

- Bowen, F.E.; Rostami, M.; Steel, P. Timing is everything: A meta-analysis of the relationships between organizational performance and innovation. J. Bus. Res. 2010, 11, 1179–1185. [Google Scholar] [CrossRef]

- Pan, C.C.; Wang, F. How does digital empowerment affect the green transformation of enterprises? Analysis of the dual impact of green innovation capacity and organizational inertia. J. Nanjing Tech Univ. 2022, 4, 89–100+116. [Google Scholar]

- Awan, U.; Nauman, S.; Sroufe, R. Exploring the effect of buyer engagement on green product innovation: Empirical evidence from manufacturers. Bus. Strategy Environ. 2021, 30, 463–477. [Google Scholar] [CrossRef]

- Wang, J.; Xue, Y.; Yang, J. Boundary-spanning search and firms’ green innovation: The moderating role of resource orchestration capability. Bus. Strategy Environ. 2020, 29, 361–374. [Google Scholar] [CrossRef]

- Tao, F.; Zhao, J.Y.; Zhou, H. Does environmental regulation achieve “incremental and quality improvement” in green technology innovation? Evidence from environmental target responsibility. Chin. Ind. Econ. 2021, 2, 136–154. [Google Scholar] [CrossRef]

- Baron, R.M.; Kenny, D. The moderator-mediator variable distinction in social psychological research: Conceptual, strategic, and statistical considerations. J. Pers. Soc. Psychol. 1986, 51, 1173–1182. [Google Scholar] [CrossRef]

- Li, W.J.; Zheng, M.N. Substantive innovation or strategic innovation? The impact of macro industrial policies on micro enterprise innovation. Econ. Res. J. 2016, 4, 60–73. [Google Scholar]

- Ley, M.; Stucki, T.; Woerter, M. The impact of energy prices on green innovation. Energ. J. 2016, 37, 41–76. [Google Scholar] [CrossRef]

- Mi, Z.; Zheng, J.; Meng, J.; Ou, J.M.; Hubacek, K.; Liu, Z.; Coffman, D.; Stern, N.; Liang, S.; We, Y.-M. Economic development and converging household carbon footprints in China. Nat. Sustain. 2020, 3, 529–537. [Google Scholar] [CrossRef]

- Wang, Y.Q.; Dong, W. How does the rise of robots affect China’s labor market? Evidence from manufacturing listed companies. Econ. Res. J. 2020, 10, 159–175. [Google Scholar]

- Acemoglu, D.; Restrepo, P. Robots and jobs: Evidence from Us labor markets. J. Polit. Econ. 2020, 128, 2188–2244. [Google Scholar] [CrossRef]

| Names of Variables | Variables | Observations | Mean | Std | Minimum | Maximum | |

|---|---|---|---|---|---|---|---|

| GI | Green Innovation | 3948 | 2.569 | 16.456 | 0.000 | 626 | |

| GI-S | Strategic Green Innovation | 3948 | 1.606 | 11.420 | 0.000 | 450 | |

| GI-T | Tactical Green Innovation | 3948 | 0.963 | 6.037 | 0.000 | 176 | |

| IEC | IEC | 6138 | 4.857 | 2.230 | 0.001 | 13.245 | |

| Innovation capacity: “Quantity” aspect | Scale | Scale of innovation investment | 3948 | 9.166 | 1.812 | 0.016 | 16.578 |

| Intensity | Intensity of innovation input | 3948 | 3.567 | 1.156 | 0.001 | 11.521 | |

| Innovation capacity: “Quality” aspect | CE | Innovation capital efficiency | 3948 | 0.210 | 0.397 | 0.000 | 5.655 |

| CE-S | Strategic innovation capital efficiency | 3948 | 0.098 | 0.240 | 0.000 | 5.550 | |

| CE-T | Tactical innovation capital efficiency | 3948 | 0.138 | 0.327 | 0.000 | 4.252 | |

| LE | Innovation labor efficiency | 3948 | 1.301 | 1.384 | 0.000 | 10.021 | |

| LE-S | Strategic innovation labor efficiency | 3948 | 0.793 | 1.017 | 0.000 | 9.987 | |

| LE-T | Tactical innovation labor efficiency | 3948 | 0.850 | 1.175 | 0.000 | 10.023 | |

| Digital | Unchanging capital upgrades | 7896 | 3948 | 1.843 | 0.000 | 11.033 | |

| Labor | Labor productivity | 7896 | 3948 | 1.051 | 0.002 | 11.123 | |

| ER-Index | Environmental regulation index | 7896 | 3948 | 0.670 | 0.000 | 2.585 | |

| ER-Intensity | Intensity of environmental regulation | 7896 | 3948 | 0.002 | 0.000 | 0.021 | |

| EG-Target | Government macroeconomic guidance on economic development | 7896 | 3948 | 1.488 | 5.000 | 14.000 | |

| Enterprise-level control variables | Tobin | Tobin’s Q value | 3948 | 1.993 | 1.272 | 0.444 | 19.824 |

| Cost | Operating costs | 3948 | 0.746 | 2.683 | 0.001 | 88.160 | |

| Sell | Sales expenses | 3948 | 0.457 | 1.916 | 0.000 | 63.420 | |

| Admin | Administrative expenses | 3948 | 0.478 | 1.383 | 0.011 | 36.720 | |

| NFA | Net fixed assets | 3948 | 0.269 | 0.771 | 0.000 | 15.070 | |

| Provincial-level control variables | Economy | Per capita GDP | 93 | 7.168 | 2.793 | 2.315 | 14.021 |

| Internet | Internet broadband number of households | 93 | 1.612 | 0.993 | 0.019 | 3.598 | |

| Traffic | Railway mileage | 93 | 3.618 | 1.807 | 0.465 | 12.766 | |

| House | House price | 93 | 1.021 | 0.640 | 0.389 | 3.382 | |

| Urban | Urban population share | 93 | 6.457 | 1.218 | 2.393 | 8.960 | |

| Variables | (1) GI | (2) GI | (3) GI-S | (4) GI-S | (5) GI-T | (6) GI-T |

|---|---|---|---|---|---|---|

| IEC | 0.0115 *** | 0.0105 ** | 0.0115 ** | 0.0096 *** | 0.0149 *** | 0.0144 *** |

| (0.0020) | (0.0021) | (0.0023) | (0.0023) | (0.0025) | (0.0025) | |

| Tobin | −0.1097 *** | −0.1097 *** | −0.1393 *** | −0.1390 *** | −0.1247 *** | −0.1289 *** |

| (0.00268) | (0.0039) | (0.0046) | (0.0046) | (0.0051) | (0.0052) | |

| Cost | 0.0018 | 0.0045 | 0.0121 ** | 0.0099 * | −0.0335 *** | −0.0388 *** |

| (0.0043) | (0.0043) | (0.0053) | (0.0053) | (0.0033) | (0.0031) | |

| Sell | 0.0048 *** | 0.0074 ** | −0.0017 *** | −0.0014 *** | 0.0054 *** | 0.0056 *** |

| (0.0015) | (0.0037) | (0.0004) | (0.0004) | (0.0004) | (0.0004) | |

| Admin | 0.0118 *** | 0.0115 *** | 0.0164 *** | 0.0158 *** | 0.0060 *** | 0.0064 *** |

| (0.0006) | (0.0006) | (0.0007) | (0.0008) | (0.0006) | (0.0006) | |

| NFA | 0.0027 *** | 0.0027 *** | 0.0023 *** | 0.0023 *** | 0.0034 *** | 0.0035 *** |

| (0.0001) | (0.0001) | (0.0001) | (0.0001) | (0.0001) | (0.0001) | |

| Economy | −0.0720 *** | −0.1428 *** | −0.0552 *** | |||

| (0.0130) | (0.0153) | (0.0159) | ||||

| Internet | 0.0095 *** | 0.0049 * | 0.0144 *** | |||

| (0.0022) | (0.0026) | (0.0027) | ||||

| Traffic | 0.0055 *** | 0.0029 *** | 0.0037 *** | |||

| (0.0004) | (0.0006) | (0.0020) | ||||

| House | 0.5418 *** | 0.7539 *** | 0.6678 *** | |||

| (0.0453) | (0.0537) | (0.0548) | ||||

| Urban | −0.0039 *** | −0.0203 *** | −0.0091 ** | |||

| (0.0012) | (0.0042) | (0.0043) | ||||

| Time fixed effects | Yes | Yes | Yes | Yes | Yes | Yes |

| Industry fixed effects | Yes | Yes | Yes | Yes | Yes | Yes |

| Province–time fixed effects | Yes | Yes | Yes | Yes | Yes | Yes |

| R-squared | 260,568 | 260,568 | 260,568 | 260,568 | 260,568 | 260,568 |

| Observations | 0.0918 | 0.0930 | 0.1062 | 0.1080 | 0.1177 | 0.1191 |

| Variables | Substitution of Variables (Lag Two Periods) | Sample Tail Trimming (Lag One Period) | Sample Tail Trimming (Lag Two Periods) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| (1) GI | (2) GI-S | (3) GI-T | (4) GI | (5) GI-S | (6) GI-T | (7) GI | (8) GI-S | (9) GI-T | |

| IEC | 0.0261 *** | 0.0017 *** | 0.0389 *** | 0.0136 *** | 0.0135 *** | 0.0188 *** | 0.0284 *** | 0.0203 *** | 0.0394 *** |

| (0.0023) | (0.0026) | (0.0030) | (0.0023) | (0.0028) | (0.0029) | (0.0027) | (0.0032) | (0.0035) | |

| Control variables | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes |

| Time fixed effects | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes |

| Industry fixed effects | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes |

| Province–time fixed effects | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes |

| R-squared | 260,568 | 260,568 | 260,568 | 205,326 | 205,326 | 205,326 | 207,900 | 207,900 | 207,900 |

| Observations | 0.1114 | 0.1182 | 0.1557 | 0.0896 | 0.1012 | 0.1183 | 0.1098 | 0.1117 | 0.1577 |

| Variables | Logit (Lag One Period) | Poisson (Lag One Period) | OLS (Lag One Period) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| (1) GI | (2) GI-S | (3) GI-T | (4) GI | (5) GI-S | (6) GI-T | (7) GI | (8) GI-S | (9) GI-T | |

| IEC | 0.0097 *** | 0.0137 *** | 0.0138 *** | 0.0096 *** | 0.0089 *** | 0.0133 *** | 0.0033 *** | 0.0020 *** | 0.0027 *** |

| (0.0026) | (0.0028) | (0.0030) | (0.0020) | (0.0024) | (0.0025) | (0.0008) | (0.0007) | (0.0006) | |

| Control variables | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes |

| Time fixed effects | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes |

| Industry fixed effects | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes |

| Province–time fixed effects | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes |

| R-squared | 0.1071 | 0.1180 | 0.1215 | 0.1394 | 0.1510 | 0.1540 | 0.2082 | 0.2057 | 0.1875 |

| Observations | 260,568 | 260,568 | 260,568 | 260,568 | 260,568 | 260,568 | 260,568 | 260,568 | 260,568 |

| Variables | Logit (Lag Two Periods) | Poisson (Lag Two Periods) | OLS (Lag Two Periods) | ||||||

| (10) GI | (11) GI-S | (12) GI-T | (13) GI | (14) GI-S | (15) GI-T | (16) GI | (17) GI-S | (18) GI-T | |

| IEC | 0.0330 *** | 0.0241 *** | 0.0452 *** | 0.0213 *** | 0.0134 *** | 0.0328 *** | 0.0063 *** | 0.0029 *** | 0.0051 *** |

| (0.0028) | (0.0031) | (0.0034) | (0.0023) | (0.0026) | (0.0029) | (0.0008) | (0.0006) | (0.0006) | |

| Control variables | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes |

| Time fixed effects | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes |

| Industry fixed effects | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes |

| Province–time fixed effects | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes |

| R-squared | 0.1413 | 0.1466 | 0.1736 | 0.1691 | 0.1691 | 0.2060 | 0.1944 | 0.1965 | 0.1431 |

| Observations | 260,568 | 260,568 | 260,568 | 260,568 | 260,568 | 260,568 | 260,568 | 260,568 | 260,568 |

| Variables | First Stage | Second Stage | ||

|---|---|---|---|---|

| (1) IEC | (2) GI | (3) GI-S | (4) GI-T | |

| IV | 0.6335 *** | |||

| (0.0018) | ||||

| IEC | 0.1334 *** | 0.0509 *** | 0.0825 *** | |

| (0.0334) | (0.0236) | (0.0122) | ||

| Cragg–Donald Wald F | 9.0 × 104 | |||

| Kleibergen–Paap rk Wald F | 1.1 × 105 | |||

| Stock–Yogo critical value (10%) | 16.38 | |||

| Control variables | Yes | Yes | Yes | Yes |

| R-squared | 260,568 | 260,568 | 260,568 | 205,326 |

| Observations | 0.4069 | 0.1944 | 0.1694 | 0.1868 |

| Variables | (1) Scale | (2) GI | (3) GI-S | (4) GI-T | (5) Intensity | (6) GI | (7) GI-S | (8) GI-T |

|---|---|---|---|---|---|---|---|---|

| IEC | 0.0153 *** | 0.0160 *** | 0.0158 *** | 0.0192 *** | 0.0178 *** | 0.0122 *** | 0.0115 *** | 0.0158 *** |

| (0.0016) | (0.0020) | (0.0023) | (0.0024) | (0.0011) | (0.0020) | (0.0023) | (0.0025) | |

| Scale | 0.2645 *** | 0.3111 *** | 0.2370 *** | |||||

| (0.0030) | (0.0037) | (0.0034) | ||||||

| Intensity | 0.1225 *** | 0.1452 *** | 0.1009 *** | |||||

| (0.0035) | (0.0041) | (0.0039) | ||||||

| Control variables | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes |

| Time fixed effects | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes |

| Industry fixed effects | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes |

| Province–time fixed effects | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes |

| R-squared | 0.3027 | 0.1142 | 0.1347 | 0.1364 | 0.1207 | 0.0954 | 0.1111 | 0.1208 |

| Observations | 260,568 | 260,568 | 260,568 | 260,568 | 260,568 | 260,568 | 260,568 | 260,568 |

| Variables | (1) CE | (2) GI | (3) CE-S | (4) GI | (5) CE-T | (6) GI |

|---|---|---|---|---|---|---|

| IEC | 0.0018 *** | 0.0097 *** | 0.0012 *** | 0.0107 *** | 0.0020 *** | 0.0096 *** |

| (0.0004) | (0.0020) | (0.0003) | (0.0020) | (0.0003) | (0.0020) | |

| CE | 0.5703 *** | |||||

| (0.0102) | ||||||

| CE-S | 0.9940 *** | |||||

| (0.0255) | ||||||

| CE-T | 0.4529 *** | |||||

| (0.0102) | ||||||

| Control variables | Yes | Yes | Yes | Yes | Yes | Yes |

| Time fixed effects | Yes | Yes | Yes | Yes | Yes | Yes |

| Industry fixed effects | Yes | Yes | Yes | Yes | Yes | Yes |

| Province–time fixed effects | Yes | Yes | Yes | Yes | Yes | Yes |

| R-squared | 0.0517 | 0.1012 | 0.0244 | 0.1014 | 0.0626 | 0.0965 |

| Observations | 260,568 | 260,568 | 260,568 | 260,568 | 260,568 | 260,568 |

| Variables | (1) LE | (2) GI | (3) LE-S | (4) GI | (5) LE-T | (6) GI |

|---|---|---|---|---|---|---|

| IEC | 0.0073 *** | 0.0085 *** | 0.0047 *** | 0.0095 *** | 0.0092 *** | 0.0073 *** |

| (0.0014) | (0.0020) | (0.0011) | (0.0020) | (0.0012) | (0.0020) | |

| CE | 0.3061 *** | |||||

| (0.0025) | ||||||

| CE-S | 0.4137 *** | |||||

| (0.0035) | ||||||

| CE-T | 0.2783 *** | |||||

| (0.0028) | ||||||

| Control variables | Yes | Yes | Yes | Yes | Yes | Yes |

| Time fixed effects | Yes | Yes | Yes | Yes | Yes | Yes |

| Industry fixed effects | Yes | Yes | Yes | Yes | Yes | Yes |

| Province–time fixed effects | Yes | Yes | Yes | Yes | Yes | Yes |

| R-squared | 0.0710 | 0.1299 | 0.0504 | 0.1257 | 0.1018 | 0.1109 |

| Observations | 260,568 | 260,568 | 260,568 | 260,568 | 260,568 | 260,568 |

| Variables | (1) Digital | (2) GI | (3) GI-S | (4) GI-T |

|---|---|---|---|---|

| IEC | 0.0606 *** | 0.0095 *** | 0.0087 *** | 0.0133 *** |

| (0.0182) | (0.0020) | (0.0023) | (0.0025) | |

| Digital | 0.0940 *** | 0.0943 *** | 0.1245 *** | |

| (0.0026) | (0.0026) | (0.0027) | ||

| Control variables | Yes | Yes | Yes | Yes |

| Time fixed effects | Yes | Yes | Yes | Yes |

| Industry fixed effects | Yes | Yes | Yes | Yes |

| Province–time fixed effects | Yes | Yes | Yes | Yes |

| R-squared | 0.1749 | 0.0964 | 0.1112 | 0.1251 |

| Observations | 260,568 | 260,568 | 260,568 | 260,568 |

| Variables | (1) North America GI | (2) North America GI-S | (3) North America GI-T | (4) East Asia GI | (5) East Asia GI-S | (6) East Asia GI-T |

|---|---|---|---|---|---|---|

| IEC | 0.0045 | 0.0055 | 0.0064 | 0.0038 | 0.0052 | 0.0052 |

| (0.0093) | (0.0109) | (0.0112) | (0.0097) | (0.0114) | (0.0121) | |

| R-squared | 0.0929 | 0.1079 | 0.1190 | 0.0918 | 0.1068 | 0.1190 |

| Observations | 15,484 | 15,484 | 15,484 | 15,484 | 15,484 | 15,484 |

| Variables | (1) Europe GI | (2) Europe GI-S | (3) Europe GI-T | (4) Oceania GI | (5) Oceania GI-S | (6) Oceania GI-T |

| IEC | 0.0145 *** | 0.0128 *** | 0.0199 *** | 0.0341 * | 0.0345 | 0.0458 * |

| (0.0027) | (0.0032) | (0.0034) | (0.0183) | (0.0264) | (0.0277) | |

| R-squared | 0.0930 | 0.1080 | 0.1192 | 0.0912 | 0.1081 | 0.1192 |

| Observations | 7742 | 7742 | 7742 | 127,743 | 127,743 | 127,743 |

| Variables | (1) Southeast Asia GI | (2) Southeast Asia GI-S | (3) Southeast Asia GI-T | (4) South America GI | (5) South America GI-S | (6) South America GI-T |

| IEC | 0.0111 * | 0.0106 | 0.0154 ** | 0.0343 ** | 0.0317 ** | 0.0477 *** |

| (0.0061) | (0.0072) | (0.0075) | (0.0135) | (0.0158) | (0.0168) | |

| R-squared | 0.0929 | 0.1028 | 0.1190 | 0.0948 | 0.1079 | 0.1193 |

| Observations | 38,710 | 38,710 | 38,710 | 19,355 | 19,355 | 19,355 |

| R-squared | 0.0828 | 0.0957 | 0.1070 | 0.0830 | 0.0958 | 0.1073 |

| Variables | (1) Central and South Asia GI | (2) Central and South Asia GI-S | (3) Central and South Asia GI-T | (4) Africa GI | (5) Africa GI-S | (6) Africa GI-T |

| IEC | 0.0111 * | 0.0106 | 0.0154 ** | −0.0263 | −0.0232 ** | −0.0345 |

| (0.0061) | (0.0072) | (0.0075) | (0.0211) | (0.0098) | (0.0256) | |

| R-squared | 0.0958 | 0.1025 | 0.1190 | 0.0922 | 0.1096 | 0.1195 |

| Observations | 38,710 | 38,710 | 38,710 | 11,613 | 11,613 | 11,613 |

| Control variables | Yes | Yes | Yes | Yes | Yes | Yes |

| Time fixed effects | Yes | Yes | Yes | Yes | Yes | Yes |

| Industry fixed effects | Yes | Yes | Yes | Yes | Yes | Yes |

| Province–time fixed effects | Yes | Yes | Yes | Yes | Yes | Yes |

| Variables | Property Rights | Technical Attributes | ||||

|---|---|---|---|---|---|---|

| (1) GI | (2) GI-S | (3) GI-T | (4) GI | (5) GI-S | (6) GI-T | |

| IEC·State-owned | 0.3947 *** | 0.5274 *** | 0.2662 *** | |||

| (0.0085) | (0.0099) | (0.0104) | ||||

| IEC·High-tech | 0.0174 *** | 0.0137 *** | 0.0177 *** | |||

| (0.0027) | (0.0032) | (0.0034) | ||||

| Control variables | Yes | Yes | Yes | Yes | Yes | Yes |

| Time fixed effects | Yes | Yes | Yes | Yes | Yes | Yes |

| Industry fixed effects | Yes | Yes | Yes | Yes | Yes | Yes |

| Province–time fixed effects | Yes | Yes | Yes | Yes | Yes | Yes |

| R-squared | 0.0972 | 0.1150 | 0.1213 | 0.0930 | 0.1080 | 0.1190 |

| Observations | 260,568 | 260,568 | 260,568 | 260,568 | 260,568 | 260,568 |

| Variables | (1) Labor (Lag One Period) | (2) Labor (Lag One Period) | (3) Labor (Lag Two Periods) | (4) GI | (5) GI-S | (6) GI-T |

|---|---|---|---|---|---|---|

| IEC | 0.0025 *** | 0.0149 *** | 0.0560 *** | |||

| (0.0008) | (0.0052) | (0.0057) | ||||

| IEC2 | −0.0011 ** | 0.0006 *** | ||||

| (0.0005) | (0.0002) | |||||

| Labor | 0.1345 *** | 0.1450 *** | 0.1658 *** | |||

| (0.0041) | (0.0048) | (0.0045) | ||||

| Control variables | Yes | Yes | Yes | Yes | Yes | Yes |

| Time fixed effects | Yes | Yes | Yes | Yes | Yes | Yes |

| Industry fixed effects | Yes | Yes | Yes | Yes | Yes | Yes |

| Province–time fixed effects | Yes | Yes | Yes | Yes | Yes | Yes |

| R-squared | 0.1876 | 0.1877 | 0.2372 | 0.0978 | 0.1119 | 0.1281 |

| Observations | 260,568 | 260,568 | 260,568 | 3948 | 3948 | 3948 |

| Sample Points | P5 | P10 | P25 | P50 | P75 | P90 | P95 |

|---|---|---|---|---|---|---|---|

| IEC | 1.2360 | 1.9179 | 3.2699 | 4.8282 | 6.3721 | 7.7160 | 8.5088 |

| Variables | (1) GI | (2) GI | (3) GI |

|---|---|---|---|

| IEC | 0.0005 | 0.0076 | −0.0661 *** |

| (0.0026) | (0.0068) | (0.0094) | |

| IEC·ER-Intensity | 1.5149 *** | ||

| (0.5320) | |||

| IEC·ER-Index | −0.0059 *** | ||

| (0.0020) | |||

| IEC·EG-Target | 0.0088 *** | ||

| (0.0012) | |||

| Control variables | Yes | Yes | Yes |

| Time fixed effects | Yes | Yes | Yes |

| Industry fixed effects | Yes | Yes | Yes |

| Province–time fixed effects | Yes | Yes | Yes |

| R-squared | 0.0956 | 0.0949 | 0.0957 |

| Observations | 260,568 | 260,568 | 260,568 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Z.; Zhu, Q. Integration into the International Economic Cycle, Shift in Growth Drivers, and Green Innovation in Manufacturing. Sustainability 2025, 17, 10398. https://doi.org/10.3390/su172210398

Li Z, Zhu Q. Integration into the International Economic Cycle, Shift in Growth Drivers, and Green Innovation in Manufacturing. Sustainability. 2025; 17(22):10398. https://doi.org/10.3390/su172210398

Chicago/Turabian StyleLi, Zhengbo, and Qiaoqiao Zhu. 2025. "Integration into the International Economic Cycle, Shift in Growth Drivers, and Green Innovation in Manufacturing" Sustainability 17, no. 22: 10398. https://doi.org/10.3390/su172210398

APA StyleLi, Z., & Zhu, Q. (2025). Integration into the International Economic Cycle, Shift in Growth Drivers, and Green Innovation in Manufacturing. Sustainability, 17(22), 10398. https://doi.org/10.3390/su172210398