Hybrid Technology of Beet Pulp Dewatering with Process Intensification in a Convection Dryer as an Element of Sustainable Processing of Agro-Industrial Waste into Bioenergy

Abstract

1. Introduction

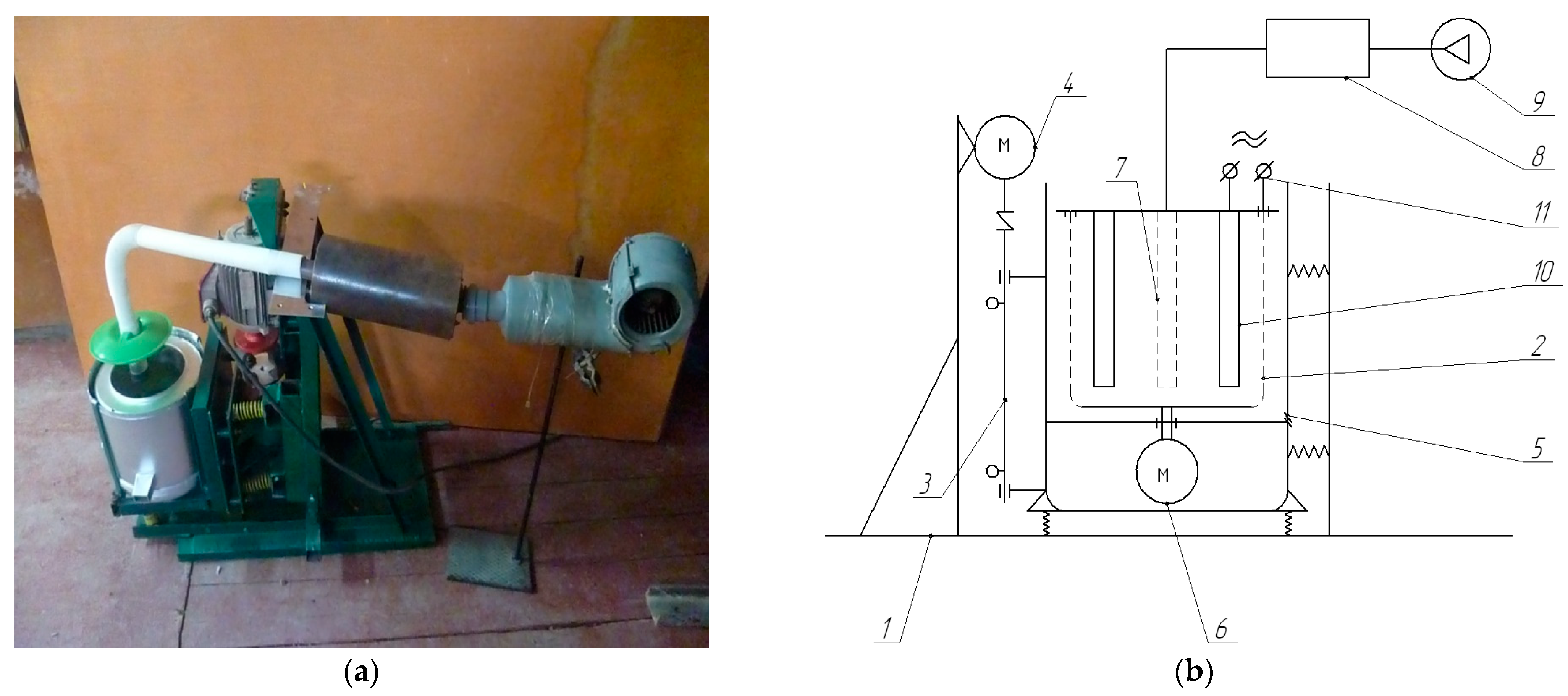

2. Materials and Methods

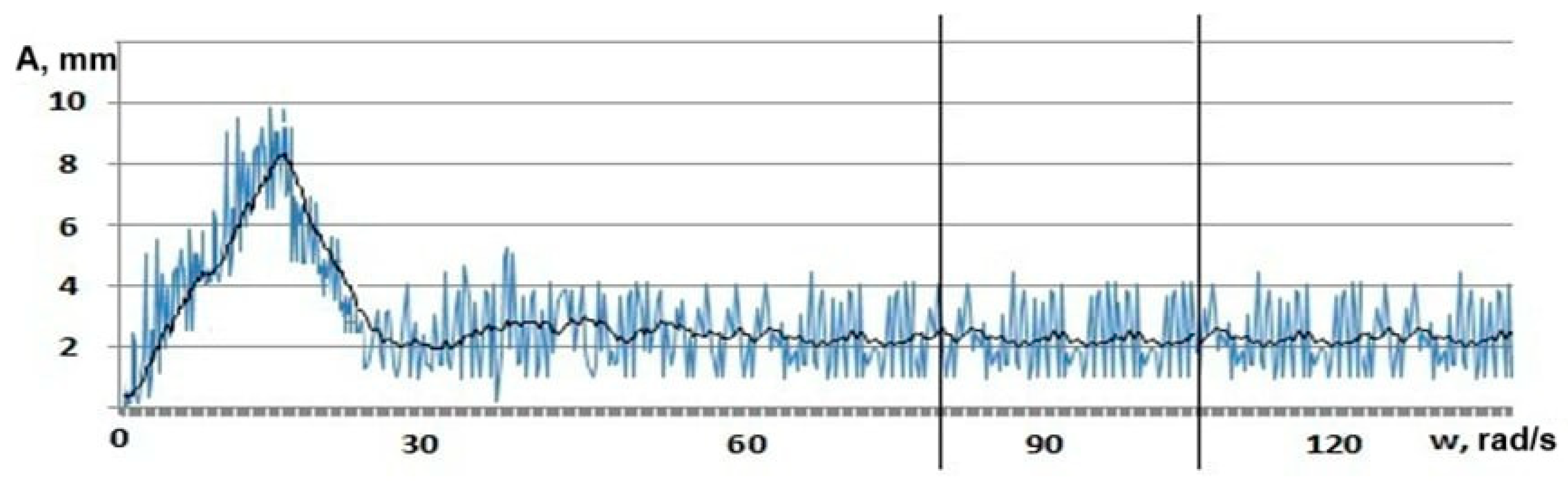

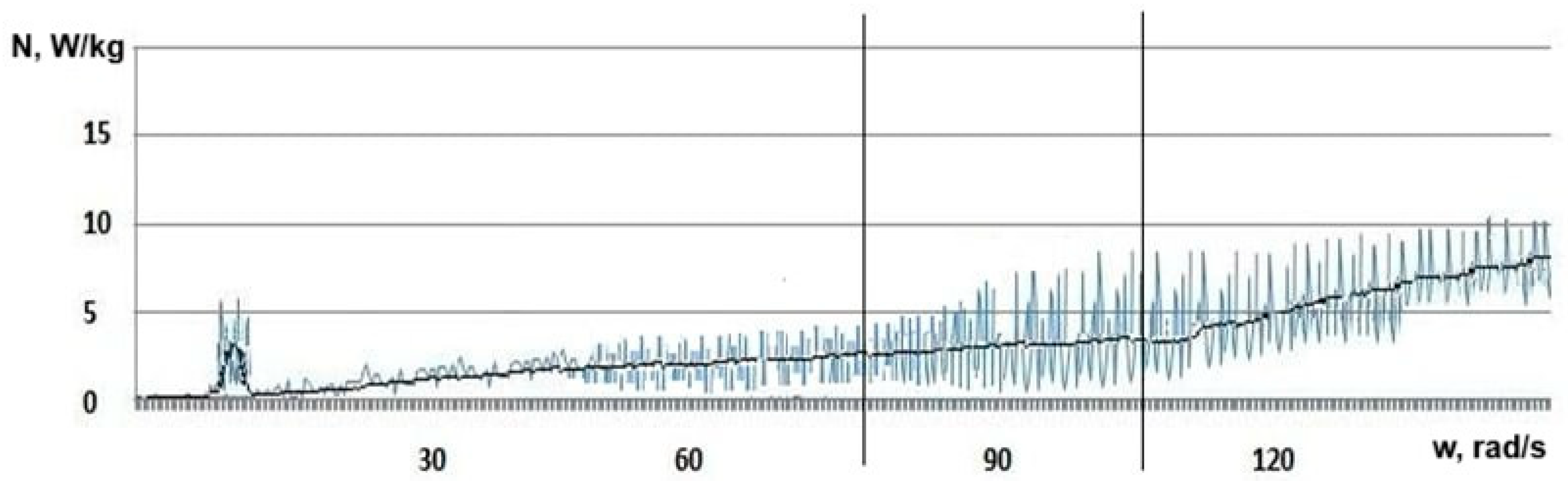

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Huang, X.; Li, D.; Wang, L. Effect of particle size of sugar beet pulp on the extraction and property of pectin. J. Food Eng. 2018, 218, 44–49. [Google Scholar] [CrossRef]

- Chryat, Y.; Romdhana, H.; Esteban-Decloux, M. Reducing energy requirement for drying of beet-pulp: Simulation of energy integration between superheated steam and air drying systems. Dry. Technol. 2017, 35, 838–848. [Google Scholar] [CrossRef]

- Priss, O.; Pugachov, M.; Pugachov, V.; Yaremko, I.; Shchabelska, V. The Development of the World Economy and the Impact of the Global Food Crisis 2022–2023. Econ. Aff. 2023, 68, 35–42. [Google Scholar] [CrossRef]

- Nakov, G.; Ivanova, N. The effect of different methods for production of crackers on their physical and sensory characteristics. Technol. Acta-Sci. Prof. J. Chem. Technol. 2020, 13, 41–45. [Google Scholar]

- Martseniuk, O.S.; Mysiura, T.H.; Popova, N.V. Peculiarities of modeling complex technological systems in food technologies. Sci. Work NUHT 2018, 24, 122–133. [Google Scholar] [CrossRef]

- Calín-Sánchez, Á.; Lipan, L.; Cano-Lamadrid, M.; Kharaghani, A.; Masztalerz, K.; Carbonell-Barrachina, Á.A.; Figiel, A. Comparison of Traditional and Novel Drying Techniques and Its Effect on Quality of Fruits, Vegetables and Aromatic Herbs. Foods 2020, 9, 1261. [Google Scholar] [CrossRef]

- Burdo, O.G.; Bandura, V.N.; Levtrinskaya, Y.O. Electrotechnologies of Targeted Energy Delivery in the Processing of Food Raw Materials. Surf. Eng. Appl. Electrochem. 2018, 54, 210–218. [Google Scholar] [CrossRef]

- Mohamed, A.S.A.; Ahmed, M.S.; Maghrabie, H.M.; Shahdy, A.G. Desalination process using humidification–dehumidification technique: A detailed review. Int. J. Energy Res. 2020, 45, 3698–3749. [Google Scholar] [CrossRef]

- Şevik, S.; Aktaş, M.; Dolgun, E.C.; Arslan, E.; Tuncer, A.D. Performance analysis of solar and solar-infrared dryer of mint and apple slices using energy-exergy methodology. Sol. Energy 2019, 180, 537–549. [Google Scholar] [CrossRef]

- Tuncer, A.D.; Sözen, A.; Afshari, F.; Khanlari, A.; Şirin, C.; Gungor, A. Testing of a novel convex-type solar absorber drying chamber in dehumidification process of municipal sewage sludge. J. Clean. Prod. 2020, 272, 122862. [Google Scholar] [CrossRef]

- Wathelet, M.; Chatelain, J.L.; Cornou, C.; Di Giulio, G.; Guillier, B.; Ohrnberger, M.; Savvaidis, A. Geopsy: A user-friendly open-source tool set for ambient vibration processing. Seismol. Res. Lett. 2020, 91, 1878–1889. [Google Scholar] [CrossRef]

- Sun, W.; Jo, S.; Seok, J. Development of the optimal bluff body for wind energy harvesting using the synergetic effect of coupled vortex-induced vibration and galloping phenomena. Int. J. Mech. Sci. 2019, 156, 435–445. [Google Scholar] [CrossRef]

- Wang, J.; Geng, L.; Ding, L.; Zhu, H.; Yurchenko, D. The state-of-the-art review on energy harvesting from flow-induced vibrations. Appl. Energy 2020, 267, 114902. [Google Scholar] [CrossRef]

- Gomez, R.S.; Gomes, K.C.; Gurgel, J.M.A.M.; Alves, L.B.; Magalhães, H.L.F.; Queiroga, R.A.; Sousa, G.C.P.; Oliveira, A.S.; Vilela, A.F.; Silva, B.T.A.; et al. Investigating the Drying Process of Ceramic Sanitary Ware at Low Temperature. Energies 2023, 16, 4242. [Google Scholar] [CrossRef]

- Wang, D.; Cao, X.; Li, X.; Li, Y.; Wang, X. Experimental investigation of a part air dehumidification cascade-like heat pump drying system. Int. J. Refrig. 2021, 131, 235–243. [Google Scholar] [CrossRef]

- Kruczek, H.; Wnukowski, M.; Niedzwiecki, Ł.; Guziałowska-Tic, J. Torrefaction as a Valorization Method Used Prior to the Gasification of Sewage Sludge. Energies 2019, 12, 175. [Google Scholar] [CrossRef]

- Zhu, Z.; Li, Y.; Sun, D.W.; Wang, H.W. Developments of mathematical models for simulating vacuum cooling processes for food products—A review. Crit. Rev. Food Sci. Nutr. 2019, 59, 715–727. [Google Scholar] [CrossRef] [PubMed]

- Ashtiani, S.H.; Salarikia, A.; Golzarian, M.R. Analyzing drying characteristics and modeling of thin layers of peppermint leaves under hot-air and infrared treatments. Inf. Process. Agric. 2017, 4, 128–139. [Google Scholar] [CrossRef]

- Delfiya, D.S.A.; Prashob, K.; Murali, S.; Alfiya, P.V.; Samuel, M.P.; Pandiselvam, R. Drying kinetics of food materials in infrared radiation drying: A review. J. Food Process Eng. 2021, 45, e13810. [Google Scholar] [CrossRef]

- Shishkin, A.; Sadygova, M.; Belova, M.; Kirillova, T. Mathematical model of resource-saving production technology of baked goods with amaranth flour. J. Eng. Stud. Res. 2020, 26, 195–203. [Google Scholar] [CrossRef]

- Shishatsky, Y.I.; Golubyatnikov, E.I. Drying Technology of Pectin Containing Vegetable Raw Material—Beet Pulp. Issues Mod. Sci. Pract. Vernadsky Univ. 2011, 1, 391–402. [Google Scholar]

- Bulgakov, V.; Bandura, V.; Arak, M.; Olt, J. Intensification of rapeseed drying process through the use of infrared emitters. Agron. Res. 2018, 16, 349–356. [Google Scholar]

- Paziuk, V.; Husarova, O.; Bandura, V.; Fialkovska, L. Intensification of apple drying using convective and combined methods of dehydration. INMATEH-Agric. Eng. 2024, 72, 173–182. [Google Scholar] [CrossRef]

- Bezbah, I.; Zykov, A.; Bandura, V.; Osadchuk, P.; Paladiichuk, Y.; Mazurenko, I. New constructions of dryers for production of environmentally safe cereal products at reduced specific energy consumption. Prz. Elektrotech. 2023, 2023, 110–113. [Google Scholar] [CrossRef]

- Bandura, V.; Yaroshenko, L.; Fialkovska, L.; Palamarchuk, V.; Paladiichuk, Y. Dynamics of sunflower seed movement in the vibrating tray of the infrared dryer and its influence on the drying process. Agraarteadus 2021, 32, 204–213. [Google Scholar]

- Husarova, O.V.; Semko, T.V.; Paziuk, V.M.; Osadchuk, P.I.; Enakiev, Y.I. Increase in Convective Intensity Drying of Sweet Root Fruits. In Proceedings of the 2024 9th International Conference on Energy Efficiency and Agricultural Engineering (EEAE), Ruse, Bulgaria, 27–29 June 2024. [Google Scholar] [CrossRef]

- Bandura, V.; Kalinichenko, R.; Kotov, B.; Spirin, A. Theoretical rationale and identification of heat and mass transfer processes in vibration dryers with ir-energy supply. East.-Eur. J. Enterp. Technol. 2018, 4, 50–58. [Google Scholar] [CrossRef]

- Bezbah, I.; Zykov, A.; Mordynskyi, V.; Yarovyi, I.; Marenchenko, E. Designing the structure and determining the mode characteristics of the grain dryer based on thermosiphons. East.-Eur. J. Enterp. Technol. 2022, 2, 54–61. [Google Scholar] [CrossRef]

- Dzikuć, M.; Tomaszewski, M. The effects of ecological investments in the power industry and their financial structure: A case study for Poland. J. Clean. Prod. 2016, 118, 48–53. [Google Scholar] [CrossRef]

- Piwowar, A.; Dzikuć, M. LCA w produkcji agrochemikaliów. Procedura, kategorie wpływu, możliwości wykorzystania. Przemysł Chem. 2017, 96, 271–274. (In Polish) [Google Scholar] [CrossRef]

- Pawlak-Kruczek, H.; Urbanowska, A.; Niedzwiecki, L.; Czerep, M.; Baranowski, M.; Aragon-Briceño, C.; Kabsch-Korbutowicz, M.; Arora, A.; Seruga, P.; Wnukowski, M.; et al. Hydrothermal Carbonisation as Treatment for Effective Moisture Removal from Digestate—Mechanical Dewatering, Flashing-Off, and Condensates’ Processing. Energies 2023, 16, 5102. [Google Scholar] [CrossRef]

- Ünyay, H.; Yılmaz, F.; Başar, İ.A.; Altınay Perendeci, N.; Çoban, I.; Şahinkaya, E. Effects of Organic Loading Rate on Methane Production from Switchgrass in Batch and Semi-Continuous Stirred Tank Reactor System. Biomass Bioenergy 2022, 156, 106306. [Google Scholar] [CrossRef]

- Ryšavý, J.; Čespiva, J.; Kuboňová, L.; Dej, M.; Szramowiat-Sala, K.; Molchanov, O.; Niedzwiecki, L.; Yan, W.-M.; Thangavel, S. Co-Gasification of Pistachio Shells with Wood Pellets in a Semi-Industrial Hybrid Cross/Updraft Reactor for Producer Gas and Biochar Production. Fire 2024, 7, 87. [Google Scholar] [CrossRef]

- Rostocki, A.; Unyay, H.; Ławińska, K.; Obraniak, A. Granulates Based on Bio and Industrial Waste and Biochar in a Sustainable Economy. Energies 2023, 16, 56. [Google Scholar] [CrossRef]

- Szufa, S.; Piersa, P.; Junga, R.; Błaszczuk, A.; Modliński, N.; Sobek, S.; Marczak-Grzesik, M.; Adrian, Ł.; Dzikuć, M. Numerical Modeling of the Co-Firing Process of an in Situ Steam-Torrefied Biomass with Coal in a 230 MW Industrial-Scale Boiler. Energy 2023, 263, 125918. [Google Scholar] [CrossRef]

- Seruga, P.; Wilk, M.; Cibis, E.; Urbanowska, A.; Niedźwiecki, Ł. The Assessment of Anaerobic Digestion Performance and Efficiency in Terms of Waste Collection. Energies 2025, 18, 4876. [Google Scholar] [CrossRef]

- Başar, I.A.; Perendeci, N.A.; Yenilmez, F.; Ünyay, H.; Yaldız, O.; Soylu, S. Characterisation and biofuel production potential assessment of eight switchgrass cultivars grown in Türkiye: Insights from principal component analysis. Biomass Bioenergy 2025, 201, 108103. [Google Scholar] [CrossRef]

- Aragon-Briceño, B.; Pożarlik, A.; Bramer, E.; Brem, G.; Wang, S.; Wen, Y.; Yang, W.; Pawlak-Kruczek, H.; Niedźwiecki, Ł.; Urbanowska, A.; et al. Integration of hydrothermal carbonization treatment for water and energy recovery from organic fraction of municipal solid waste digestate. Renew. Energy 2022, 184, 577–591. [Google Scholar] [CrossRef]

- Siuda, R.; Kwiatek, J.; Szufa, S.; Obraniak, A.; Piersa, P.; Adrian, Ł.; Modrzewski, R.; Ławinska, K.; Siczek, K.; Olejnik, T.P. Industrial Verification and Research Development of Lime–Gypsum Fertilizer Granulation Method. Minerals 2021, 11, 119. [Google Scholar] [CrossRef]

- Ławińska, K.; Szufa, S.; Modrzewski, R.; Obraniak, A.; Wężyk, T.; Rostocki, A.; Olejnik, T.P. Obtaining granules from waste tannery shavings and mineral additives by wet pulp granulation. Molecules 2020, 25, 5419. [Google Scholar] [CrossRef]

- Lawinska, K.; Wodzinski, P.; Modrzewski, R. Verification of the mathematical model of the screen blocking process. Powder Technol. 2014, 256, 506–511. [Google Scholar] [CrossRef]

- Olejnik, T.P.; Mysakowski, T.; Tomtas, P.; Mostowski, R. Optimization of the Beef Drying Process in a Heat Pump Chamber Dryer. Energies 2021, 14, 4927. [Google Scholar] [CrossRef]

- Junga, R.; Pospolita, J.; Niemiec, P. Combustion and grindability characteristics of palm kernel shells torrefied in a pilot-scale installation. Renew. Energy 2020, 147, 1239–1250. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhao, Y.; Dong, L.; Duan, C.; Zhou, E.; Lu, J.; Zhang, B.; Yang, X. Flow pattern transition characteristics in vibrated gas-solid fluidized bed of Geldart B magnetite powder using pressure drop signals analysis. Powder Technol. 2018, 327, 358–367. [Google Scholar] [CrossRef]

- Zhang, Y.; Yang, X.; Zhu, F.; Li, Y.; Duan, C.; Yang, J.; Dong, L.; Zhao, Y. Characteristics of non-linear dynamics and energy transfer in a vibration gas-solid fluidized bed by using Hilbert-Huang transform. Powder Technol. 2019, 344, 970–980. [Google Scholar] [CrossRef]

- Wei, L.; Zhang, B.; Lu, C.; Lu, Y.; Wang, C.H. Experimental investigation of pressure fluctuation propagation in two orthogonal directions using a clapboard-type internally circulating fluidized bed. Adv. Powder Technol. 2020, 31, 3395–3407. [Google Scholar] [CrossRef]

- Cherntongchai, P.; Chaiwattana, S.; Leruk, R.; Panyaruean, J.; Sriboonnak, S. Influence of standing wave characteristics on hydrodynamic behaviours in sound-assisted fluidization of Geldart group A powder. Powder Technol. 2019, 350, 123–133. [Google Scholar] [CrossRef]

- Stelmach, J.; Kuncewicz, C.; Szufa, S.; Jirout, T.; Rieger, F. The Influence of Hydrodynamic Changes in a System with a Pitched Blade Turbine on Mixing Power. Processes 2021, 9, 68. [Google Scholar] [CrossRef]

- Kryszak, D.; Bartoszewicz, A.; Szufa, S.; Piersa, P.; Obraniak, A.; Olejnik, T.P. Modeling of Transport of Loose Products with the Use of the Non-Grid Method of Discrete Elements (DEM). Processes 2020, 8, 1489. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Palamarchuk, I.; Priss, O.; Zozulyak, O.; Kiurcheva, L.; Vasylenko, O.; Dyadyura, K.; Romanowska-Duda, Z.; Obraniak, A.; Szufa, S.; Hutsol, T. Hybrid Technology of Beet Pulp Dewatering with Process Intensification in a Convection Dryer as an Element of Sustainable Processing of Agro-Industrial Waste into Bioenergy. Sustainability 2025, 17, 10327. https://doi.org/10.3390/su172210327

Palamarchuk I, Priss O, Zozulyak O, Kiurcheva L, Vasylenko O, Dyadyura K, Romanowska-Duda Z, Obraniak A, Szufa S, Hutsol T. Hybrid Technology of Beet Pulp Dewatering with Process Intensification in a Convection Dryer as an Element of Sustainable Processing of Agro-Industrial Waste into Bioenergy. Sustainability. 2025; 17(22):10327. https://doi.org/10.3390/su172210327

Chicago/Turabian StylePalamarchuk, Igor, Olesia Priss, Oksana Zozulyak, Liudmyla Kiurcheva, Oksana Vasylenko, Konstiantyn Dyadyura, Zdzislawa Romanowska-Duda, Andrzej Obraniak, Szymon Szufa, and Taras Hutsol. 2025. "Hybrid Technology of Beet Pulp Dewatering with Process Intensification in a Convection Dryer as an Element of Sustainable Processing of Agro-Industrial Waste into Bioenergy" Sustainability 17, no. 22: 10327. https://doi.org/10.3390/su172210327

APA StylePalamarchuk, I., Priss, O., Zozulyak, O., Kiurcheva, L., Vasylenko, O., Dyadyura, K., Romanowska-Duda, Z., Obraniak, A., Szufa, S., & Hutsol, T. (2025). Hybrid Technology of Beet Pulp Dewatering with Process Intensification in a Convection Dryer as an Element of Sustainable Processing of Agro-Industrial Waste into Bioenergy. Sustainability, 17(22), 10327. https://doi.org/10.3390/su172210327