Abstract

This study investigates the interplay of advanced manufacturing technologies (AMT), digital commerce, circular economy intensity, and digital maturity on innovation outcomes among Spanish manufacturing firms in the post-pandemic era. Drawing on resource orchestration theory and survey data from 1813 companies, the analysis employs regression and mediation techniques to assess direct and indirect effects on product and process innovation. Findings reveal that AMT adoption leads to modest, context-dependent improvements in process innovation, while effects on product innovation are limited or negative; e-commerce adoption alone does not predict substantial innovation gains, and jointly adopting these technologies rarely produces amplifying results. Greater circular economy intensity mediates a negative relationship with process innovation, indicating possible resource trade-offs between sustainability initiatives and innovation goals. Digital maturity inconsistently strengthens positive impacts and can further moderate innovation outcomes in interaction with circular economy practices. Notably, economic benefits from circular economy practices are concentrated in export-oriented firms and not widely distributed in the sample. These findings challenge assumptions that digital and green transformations universally enhance innovation, advocating for tailored policy and organizational strategies that account for sectoral and contextual differences.

1. Introduction

The rapid post-pandemic convergence of advanced manufacturing technologies (AMTs) and digital commerce is reshaping industrial ecosystems, offering new opportunities for innovation and sustainability but also presenting significant challenges for established enterprises. In the Spanish manufacturing sector, firms are increasingly experimenting with a range of digital solutions—robotics, machine learning, big data, and integrated e-commerce platforms—to meet evolving customer needs and international competitiveness standards. This transition, however, is not characterized by uniform leaps in productivity or innovation, but rather by incremental and context-dependent improvements whose magnitude and direction depend on organizational, sectoral, and policy contingencies.

Recent developments in industrial technology have moved beyond automation, emphasizing intelligent systems capable of flexible production, enhanced connectivity, and adaptive resource planning. For Spanish manufacturers, the years 2022–2023 represent a period of intense adjustment as firms respond to both regulatory and market drivers. The introduction of new variables in the ESEE (Encuesta Sobre Estrategias Empresariales) database during this period allows for a unique examination of how manufacturing organizations integrate digital and sustainability-oriented practices amid ongoing global disruption.

Critically, the adoption of AMTs and digital commerce does not uniformly accelerate innovation across all domains. Our research draws on resource orchestration theory to explain the marginal, sometimes negative, and frequently context-dependent effects of technology and sustainability adoption. Contrary to prevailing assumptions, the integration of advanced technologies and circular economy practices does not guarantee broad-based improvement in product or process innovation. Instead, effects are often limited, and sustainability practices, while valuable, sometimes compete with innovation goals due to resource constraints and sectoral priorities. Moreover, the economic value of these strategies tends to be concentrated among export-oriented firms, challenging models that link digitalization and sustainability to universal performance gains.

This study draws explicitly on resource orchestration theory and employs robust Poisson and OLS regression analyses on cross-sectional ESEE survey data from 1813 Spanish manufacturing firms to clarify how advanced manufacturing technologies, digital commerce, circular economy practices, and digital maturity interact to shape innovation and value-added outcomes. Recognizing the importance of sectoral diversity, organizational capabilities, and policy interventions (such as Spain’s Startup Law), our analysis emphasizes the need for tailored rather than universal digital and sustainability strategies.

In sum, this paper seeks to achieve the following:

- Examine how the effects of advanced manufacturing technologies (AMTs) and digital commerce on product, process, organizational, and commercial innovation in Spanish manufacturing firms are moderated by specific conditions—such as sectoral digital intensity, firm size, circular economy engagement, digital maturity, and the presence of policy instruments like Spain’s Startup Law. Each condition is measured and tested as a moderator or subgroup in our empirical analysis.

- Assess how circular economy and sustainability practices mediate and moderate technological innovation, sometimes with counterintuitive results.

- Evaluate the boundary conditions—such as digital maturity and policy support—that shape these relationships, offering practical and theoretical insights for future industrial strategy.

Following this introduction, we outline our methodological framework, present key empirical findings, and discuss the theoretical and managerial implications for technology-enabled innovation and sustainable development in Spanish manufacturing.

2. Literature Review

The integration of advanced manufacturing technologies (AMTs) and digital commerce is reshaping industrial ecosystems, requiring firms to refine innovation strategies and adopt new sustainability practices [1,2,3]. This review synthesizes theoretical and empirical perspectives, focusing on resource orchestration theory [4], recent advances in Industry 5.0 [5], and policy shifts relevant to Spanish manufacturing during the post-pandemic recovery. The conceptual basis is tailored to the operationalization of variables in the ESEE database for Spanish firms.

2.1. Industry 5.0 and Innovation Policy Context

The EU’s Industry 5.0 initiative supports Spain’s manufacturing evolution by emphasizing human-centric, sustainable, and resilient production models [5]. Spain’s landscape is notably shaped by SME dominance—over 90% of manufacturers employ fewer than 200 workers—challenging the scalability and integration of digital and sustainability practices. The national Science, Technology, and Innovation (STI) Strategy 2021–2027 operationalizes key Industry 5.0 principles, integrating digitalization, environmental responsibility, and human-centric approaches in manufacturing policy [6].

Industry 5.0 represents a progression from efficiency-driven Industry 4.0 toward deliberate resource orchestration, balancing operational efficiency with sustainability and adaptability. Policy mechanisms in Spain promote this through targeted support for digital infrastructure, skills development, and research collaboration, especially for SMEs. This policy context shapes how manufacturing firms bundle and leverage AMT, digital commerce, and circular economy practices to achieve incremental innovation gains [2].

Recent research on resilience situates it as a dynamic organizational capability—enabling firms to absorb shocks and sustain innovation—not simply as an outcome of passive technology adoption [7]. However, in this study, the focus is on empirically quantifiable effects of AMT, e-commerce, and circular economy engagement, rather than undifferentiated resilience attributes.

Overall, Spain’s innovation policy environment and the evolution of Industry 5.0 provide necessary background, but this paper’s empirical lens is on how resource orchestration of specific technological and sustainability assets—rather than generalized resilience—drives measurable innovation outcomes in Spanish manufacturing firms.

2.2. Theoretical Foundations of AMT and Innovation

The adoption of Advanced Manufacturing Technologies (AMTs) in industrial operations is central to the formation of scarce, valuable, and inimitable capabilities—a premise of the Resource-Based View (RBV) that underpins much strategic management and innovation research [8]. Initially, investigations highlighted AMT’s contribution to enhanced process flexibility and superior product innovation, with technologies such as CAD/CAM and robotics leading to both incremental and radical performance improvement [9,10].

With the progression to Industry 4.0, AMT’s breadth has expanded to encompass machine learning, autonomous systems, and digitally connected production, requiring updated frameworks to understand these technologies within the context of sustainability and digital commerce [1]. Recent empirical findings emphasize that AMTs enhance not only operational efficiency but also the responsiveness and customization capabilities that enable firms to compete in volatile markets [1]. However, these innovation benefits are contingent on complementary organizational assets and integration practices.

Dean and Snell (1996) [11] identified the principal pathways by which AMT influences firm innovation:

- -

- Process innovation: Improving operational efficiency through technological upgrades.

- -

- Product innovation: Introducing new product features or improving quality.

- -

- Organizational innovation: Enabling novel work formats and decision processes.

While these mechanisms remain foundational, their impact varies across industries and technological contexts. Evidence further indicates that the positive effects of AMT adoption on product innovation are strongest when design-manufacturing integration—an organizational asset—is present, underscoring the need for deliberate resource orchestration alongside technology investments [10].

Overall, the literature suggests that AMT fosters innovation benefits beyond process optimization; yet its transformative impact depends on the ability of firms to synergistically integrate technological advances with organizational capabilities. This dual focus underlies the empirical scope of the present study.

In this study, Advanced Manufacturing Technologies (AMTs) are operationalized as a technological intensity construct, emphasizing the degree of adoption of robotics, additive manufacturing/3D printing, machine learning/big data, and industrial IoT. The AMT index measures the extent to which these technologies are used to enhance process automation and interconnectivity within manufacturing operations. This construct captures the tangible implementation of digital production tools, focusing on automation and data-driven decision making, rather than broader organizational capabilities.

In contrast, ‘digital maturity’ is defined as an organizational capability construct, reflecting the firm’s overall readiness and ability to integrate, scale, and manage digital technologies across business processes—beyond just the adoption of specific tools. Digital maturity includes factors such as cloud computing implementation, platform collaboration, and digital skills investment, enabling effective resource orchestration with AMTs and other digital assets.

Thus, AMT intensity in this research indicates the adoption level of key manufacturing technologies, while digital maturity differentiates firms by their strategic competence and capacity to leverage these technologies at scale.

2.3. E-Commerce as a Catalyst for Innovation

E-commerce has evolved from simple transactional platforms into integrated digital ecosystems that substantially reshape innovation pathways in manufacturing [12]. Its adoption enables firms to reconfigure interactions with customers, suppliers, and competitors, not only serving as a new distribution channel but also facilitating enhanced information flows and market intelligence—key drivers of both product and process innovation [12].

In particular, B2B e-commerce has proven to be a significant catalyst for manufacturing innovation. Zhu and Kraemer (2002) [2] demonstrated that manufacturing firms utilizing e-commerce experience higher rates of product innovation, particularly when digital channels facilitate deeper customer interaction and co-creation. Their analysis found that e-commerce’s positive innovation effects are strongest when integrated with wider technology strategies, rather than pursued as isolated digital efforts. This supports resource orchestration perspectives that emphasize synergistic resource deployment [4].

The complementarity between AMT and e-commerce warrants focused attention within innovation research. While AMT and digital commerce each enable innovation independently, their interaction offers potential multiplicative benefits. Digital commerce platforms supply critical market intelligence and customer insights that can guide product development, while advanced manufacturing technologies provide the operational flexibility needed to implement these innovations [13]. Firms capable of orchestrating both domains—integrating digital customer feedback with flexible production—are likely to achieve superior innovation outcomes compared to those focusing exclusively on one domain.

2.4. Innovation–Performance Nexus in the Digital Era

The connection between innovation and firm performance is highly contingent, with mixed empirical results reported across contexts—particularly within the manufacturing sector [14]. Meta-analytic evidence suggests that the magnitude of innovation’s effect on performance depends on factors such as innovation type, firm size, and industry environment. Notably, process innovations tend to deliver more immediate operational gains, while product innovations often require longer gestation periods to realize performance returns—an important distinction for manufacturing firms adopting advanced manufacturing technologies (AMT), where complexity and implementation timelines may affect short-term outcomes [14].

Digital transformation further complicates innovation–performance dynamics. Prajogo et al. (2007) [3] found that technologically sophisticated manufacturing strategies generate stronger performance results in newly industrialized economies when aligned with market needs and organizational capabilities. Their findings stress the importance of pairing specific innovation types with relevant performance measures: process innovations are more likely to boost efficiency metrics, while product innovations have a greater influence on market-based outcomes. This underscores the need for multidimensional approaches to performance measurement in studies of technological innovation.

The dimension of sustainability adds another layer to this nexus. Hull and Rothenberg (2008) [15] demonstrated that corporate social performance—or sustainability-oriented innovation—can positively moderate the innovation–performance relationship, particularly in sectors where environmental practices catalyze differentiation. Their findings suggest that sustainability-oriented innovations may generate unique performance premiums, especially as competitive markets and regulatory environments increasingly reward environmental responsibility. This is particularly relevant for manufacturing firms considering how to prioritize innovation investments under emerging regulatory incentives and market signals.

2.5. Sustainability-Driven Innovation Paradigms

The growing integration of environmental, social, and governance (ESG) criteria into manufacturing strategy has repositioned sustainability from a regulatory compliance issue to an engine for innovation [5]. The concept of “green resource orchestration” [5] builds on resource orchestration theory by exploring how firms strategically deploy and reconfigure resources to achieve both economic and ecological value—an increasingly important dual goal for manufacturing firms in carbon-constrained environments.

Circular economy principles occupy a central role in this evolving paradigm. By designing for disassembly, remanufacturing, and resource recovery, manufacturing firms can simultaneously lower environmental impact and improve economic efficiency. Hull and Rothenberg (2008) [15] demonstrated that circular innovations often yield compound benefits, such as reduced material costs and greater brand value associated with regulatory compliance and sustainability reputation. As environmental performance pressures mount, circular innovation provides viable pathways to align profitability with eco-responsibility.

The link between sustainability orientation and innovation capacity is widely recognized as bidirectional. Firms committed to environmental responsibility tend to innovate more, while highly innovative firms are also better equipped to implement sustainability initiatives. Empirical evidence suggests a complementarity effect: Prajogo et al. (2007) [3] found that manufacturing strategies integrating both technological innovation and sustainability objectives generate superior performance outcomes compared to strategies that prioritize only one dimension. This challenges traditional views of environmental practices as cost centers and instead positions sustainability and innovation as mutually reinforcing value drivers.

Recent literature highlights that the integration of advanced manufacturing technologies (AMTs), digital commerce, and circular economy practices does not always guarantee positive or uniform innovation outcomes. Andersn (2023) [5] critically appraises the resource orchestration approach, demonstrating that green resource orchestration may introduce context-specific trade-offs, whereby investments in sustainability practices can compete with rather than complement process innovation, especially in resource-constrained manufacturing sectors [15,16]. Rosenbusch, Brinckmann, and Bausch (2011) [14] provide meta-analytic evidence that the innovation–performance relationship is heterogeneous and sometimes negative in small and medium-sized enterprises (SMEs), suggesting that the assumed synergy between technological adoption and sustainability intensity is subject to significant boundary conditions.

2.6. Resource Orchestration Theory and Innovation–Performance Dynamics

Resource orchestration theory (ROT) offers a robust lens for understanding how firms purposefully structure, bundle, and leverage resources to achieve innovation and performance outcomes in rapidly evolving technological and sustainability contexts [4]. In manufacturing, ROT clarifies how technological resources—such as advanced manufacturing technologies (AMT) and e-commerce platforms—translate into varied innovation outcomes and, ultimately, firm performance.

While resource orchestration theory [4] remains a powerful analytical lens, recent literature advocates integrating dynamic capabilities [17], innovation ecosystem perspectives [18], and ambidextrous organization models to address the complexity of technological innovation in sustainable contexts. These approaches better capture the interplay between adaptation, efficiency, and sustainability, and can clarify why resource bundling and leveraging sometimes result in neutral or negative innovation performance.

Rather than emphasizing mere resource possession, ROT stresses the importance of resource orchestration processes: resource structuring (acquisition and configuration of AMT/e-commerce), resource bundling (integration with existing organizational routines), and resource leveraging (deploying coordinated capabilities to deliver multiple innovation outcomes). Recent studies suggest that AMT adoption most directly enhances process innovation by improving operational infrastructure, while e-commerce platforms facilitate market-sensing, customer engagement, and thus product innovation [10,18]. Firms that deliberately orchestrate both domains—rather than pursuing technology adoption in isolation—are positioned for superior innovation outcomes [4,18].

Applying Andersén’s (2023) [5] extension of ROT, integrating strategic resource alignment with “green resource orchestration,” this framework also accounts for how circular economy intensity and digital maturity mediate and moderate innovation impacts. Specifically, circular economy practices can function as mediators, linking AMT use with greater process innovation and, in sustainability-conscious sectors, amplifying both economic and ecological value [5]. Digital maturity further shapes the innovation–performance linkage, as firms with more developed digital capabilities are more likely to convert innovation into measurable performance benefits.

For Spanish SMEs, formal policy tools such as the Startup Law may provide structured mechanisms—through certification and incentives—that proactively reduce orchestration barriers and enhance the translation of innovation into performance gains. In this way, ROT integrates resource-based thinking with contextual policy and sustainability imperatives, enabling a nuanced analysis of Spanish manufacturing’s technology-driven transformation.

Resource Orchestration Theory (ROT) provides a powerful lens to understand how firms achieve sustainable competitive advantage, not simply through passive resource possession but by actively structuring, bundling, and leveraging resources in dynamic ways [4]. Circular economy practices—such as resource recovery, recycling, remanufacturing, and eco-design—demand substantial reconfiguration of routines, inter-organizational linkages, and knowledge bases. ROT postulates that valuable outcomes (like innovation and sustainable performance) arise when organizations purposefully orchestrate tangible (material, technological) and intangible (knowledge, network, managerial) resources in alignment with strategic objectives.

The integration of circular economy principles thus becomes an active process of resource orchestration: firms must (1) structure their assets to enable take-back, reverse logistics, and design-for-reuse, (2) bundle their capabilities to support cross-functional and cross-firm collaboration for sustainability, and (3) leverage new routines to maximize both innovation and ecological value [5]. In this way, circular economy adoption is not a static adoption of green routines, but a dynamic, strategic process that tests a firm’s ability to reconfigure and combine resources, as prescribed by ROT, for superior sustainable outcomes.

2.7. Synthesis and Research Opportunities

This literature review identifies key opportunities for advancing the understanding of how Spanish manufacturing firms integrate advanced manufacturing technologies (AMT), digital commerce, and sustainability-oriented practices in the post-pandemic period. While prior research has documented basic links between technology adoption and innovation outcomes, several critical gaps remain.

First, the empirical effects of integrating AMT and digital commerce—especially their interaction in driving innovation—require deeper investigation in the Spanish context. While theory suggests complementarity [4,13], direct evidence for contemporary Spanish manufacturers is lacking. Second, the mediating role of sustainability and circular economy practices warrants systematic study, as circular innovation is gaining policy prominence but its operational impact on innovation is still contested [5,15]. Third, the effect of formal policy tools—particularly Spain’s Startup Law—on the innovation–performance nexus and resource orchestration among SMEs is not fully understood.

This study addresses these gaps by deploying a resource orchestration perspective, leveraging ESEE survey data for firms during 2022–2023. The research analyzes how AMT and digital commerce intensity shape innovation trajectories and performance outcomes, emphasizing the role of sustainability mediation and policy moderation for Spanish manufacturers. By bridging empirical analysis with contextual policy frameworks, this work provides theoretical clarity and practical guidance for firms navigating the interface between advanced technologies, digitalization, and sustainability imperatives.

The timeframe coincides with the implementation of Spain’s Science, Technology, and Innovation Strategy 2021–2027, which allocated EUR 3.8 billion to digitalization and sustainability investments. By situating findings within broader EU shifts—such as the Carbon Border Adjustment Mechanism—this research explores how Spanish manufacturers strategically align AMT investments with evolving regulatory and market requirements, advancing both scholarly knowledge and actionable policy insights for digital and green industrial transitions.

Scholars such as Parida, Westerberg, & Frishammar (2012) and Kumar, Singh, & Chandel (2018) [19,20] contend that the effects of AMT and digital commerce adoption are profoundly shaped by sectoral diversity, firm size, export orientation, and regulatory contexts. Recent research evidences nonlinear and threshold-based outcomes, indicating diminishing returns to technology accumulation and sustainability practice intensity beyond certain adoption levels [13,17,21]. In Spanish manufacturing, this underscores the need for research designs that account for firm and sector-specific differences, rather than extrapolating generalizable benefits.

Several authors warn against over-reliance on cross-sectional surveys, proxy variables, and short-term observation windows for capturing the dynamics of innovation and capability development [11,22]. Future research directions should incorporate longitudinal studies, mixed-methods designs, and sectoral case analyses, enhancing robustness and enabling the disentangling of causal mechanisms [18,23].

The evolving evidence base suggests that industrial policies, such as Spain’s Startup Law or the EU’s Industry 5.0 initiative [5], should promote targeted support mechanisms sensitive to sectoral and strategic contingencies. Rather than assuming universal gains from digital and sustainability investments, policy frameworks must be tailored to specific innovation goals, firm characteristics, and market conditions to avoid diminishing returns and negative spillover effects [6,24].

3. Methodology

This study employs a systematic empirical approach to examine how advanced manufacturing technologies and digital commerce shape innovation outcomes and sustainability pathways in Spanish manufacturing firms during the post-pandemic recovery period. The methodology is designed to operationalize resource orchestration theory constructs while addressing the data structure realities of the ESEE database.

3.1. Data Source and Sample Structure

The empirical analysis utilizes Spain’s Encuesta sobre Estrategias Empresariales (ESEE), a longitudinal survey administered by the Sociedad Estatal de Participaciones Industriales (SEPI) that systematically tracks Spanish manufacturing firms’ strategic decisions and performance outcomes. This study specifically focuses on the 2022–2023 period, which captures the immediate post-pandemic implementation of new digital technologies and sustainability practices. This timeframe was selected due to the introduction of critical sustainability and technological variables in the ESEE questionnaire in 2022, including measures for sustainable energy adoption (AAHEN), sustainable product development (ADPSO), and environmental innovation benefits (IBAM).

The final sample comprises 1813 manufacturing firms with 10 or more employees, representing 20 industrial sectors according to the NACECLIO classification system. The stratified random sampling procedure employed by SEPI ensures representativeness across size categories and industrial activities. Table 1 presents the sectoral distribution of the sample, with food and beverages (24.88%), metal products (22.17%) and textiles and apparel (10.76%) representing the largest segments (see Table 1).

Table 1.

Sectoral Distribution of Sample Firms (2022–2023).

3.2. Variable Operationalization

The empirical investigation centers on three categories of variables: technology adoption indicators, innovation outcomes, and sustainability measures. All variables are derived from the ESEE database with special attention to their availability and periodicity. The independent variables were built as follows:

For Advanced Manufacturing Technologies (AMT), a composite index (0–3 scale) comprising four technologies documented in the ESEE database was constructed:

- Robotics (RBI): Adoption of programmable robots for industrial automation.

- Additive Manufacturing/3D Printing (I3D): Use of digital models for three-dimensional object construction.

- Machine Learning/Big Data (MLBD): Application of data-driven algorithms for predictive analytics and decision making in production.

- Industrial Internet of Things (IIOT): Deployment of interconnected sensors and industrial devices linked to internet infrastructure.

The AMT index in this research specifically operationalizes technological intensity—the prevalence and degree of use of automation and digital connectivity technologies in manufacturing. It measures the implementation of digital production tools rather than broader organizational capabilities. This approach ensures AMT reflects the firm’s adoption of tangible technologies central to digital transformation.

These specific AMT components—robotics, additive manufacturing/3D printing, machine learning/big data, and industrial IoT—were selected to align with contemporary definitions in the Industry 5.0 and resource orchestration literature [3] and to reflect the most transformative technologies currently adopted by Spanish manufacturers. Each technology represents a distinct facet of digital production and process automation. Their aggregation as an intensity index enables measurement not only of adoption but also of depth and strategic integration, consistent with prior empirical studies on technology-driven innovation performance in manufacturing [11]. This composite approach is sufficient and appropriate because it captures both breadth and depth of technology adoption central to the concept of AMT as a driver of competitive advantage.

For quadrennial variables (RBI, I3D, MLBD, IIOT), the most recent measurement point (2022) as recommended in longitudinal research with varied measurement frequencies [25] was used. Each technology was coded according to its adoption intensity using the ESEE’s standardized 1–6 scale, which we recoded as follows:

- Categories 1–2: Not used/Tested but not used (coded 0)

- Category 3: In use for <5% of activity (coded 1)

- Category 4: In use for 5–25% of activity (coded 2)

- Category 5: In use for >25% of activity (coded 3)

The AMT index represents the average intensity score across the four technologies, with higher values indicating more advanced technological integration.

For E-Commerce Integration (ECOMM), we adopted the operationalization approach proposed by Zhu and Kraemer (2002) [2], using a three-tier categorical variable to represent firms’ digital sales capabilities. This classification considers four key indicators: whether the firm owns an Internet domain (WEBPRO), has an Internet-based B2B system (WEBB2B), offers an Internet-based B2C system (WEBB2C), and engages in online procurement of goods and/or services (WEBCOM). The levels are defined as follows:

- LOW: Basic online presence without transactional functionality (WEBPRO only).

- MEDIUM: Implementation of a single e-commerce channel (WEBPRO in combination with either WEBCOM, WEBB2C, or WEBB2B).

- HIGH: Integrated omnichannel digital commerce (WEBPRO combined with at least two of the following: WEBCOM, WEBB2C, and WEBB2B).

Digital commerce integration is categorized using a tiered variable (low, medium, high) based on four validated indicators: web domain, B2B, B2C, and procurement functionalities [2]. These indicators were chosen due to their relevance for Spanish manufacturers engaging in digital sales and supply chain management and their empirical linkage to value-added outcomes in prior innovation research. The sufficiency of this index lies in its representation of increasing digitalization complexity and integration, moving from basic presence to full omnichannel capability, as recommended in the e-commerce innovation literature.

For the dependent variables, we measured four distinct innovation dimensions, each operationalized using the following validated ESEE variables:

- Product Innovation Intensity (PRODUCTII): This composite measure combines product innovations through new components (IPNC), new design features (ICODIS), and new products (IP), with IPNC measured on a 1–3 scale and ICODIS and IP in a 1–2 scale.

- Process Innovation Intensity (PROCESSII): As the sum of equipment-based innovations (IPRME) and technique-driven innovations (IPRTM), measured on a 2–4 scale.

- Organizational Innovation (METODII): Binary variable indicating the implementation of workforce management innovations or external relationship innovations (IMO).

- Commercial Innovation (COMERII): A composite measure combining design innovations (ICODIS), sales channel innovations (ICOCAN), and product promotion innovations (ICOPRO), measured on a 0–3 scale.

For mediating variables, Circular Economy Intensity (CE-INT) was built following Andersén’s (2023) [5] framework, by constructing a circular economy intensity index (0–1 scale) using these three sustainability practices from the ESEE database:

- Recycling or reuse of materials (ARECI)

- Reduction of consumption/impact on natural resources (ARECO)

- Development of more sustainable products/services (ADPSO)

Each practice was coded on a 0–1 scale (0 = not implemented, 0.5 = implemented internally, 1 = implemented with external collaboration). The CE-INT index averages these three components.

The circular economy intensity index averages three core sustainability practices—recycling/reuse, resource reduction, and sustainable product/service development—following Andersén (2023) and Hull & Rothenberg (2008) [5,15], who identify these as the leading operational dimensions of circular innovation in manufacturing. The selection ensures conceptual coverage of material flow, environmental impact, and sustainable output. Coding internal and external collaboration as different levels operationalizes the firm’s engagement breadth, making the index both comprehensive and practical for comparative analysis. This set of indicators is judged sufficient because it integrates input, process, and output sustainability efforts per contemporary circular economy research guidance.

As moderating variables, the following were used:

Digital Maturity Index (DMI): Following Cheng et al. (2024) [23], we operationalized DMI as a composite measure combining:

- Cloud computing implementation (CC)

- Collaborative digital platforms

- Software training investments

Digital maturity is measured as a composite capability construct, incorporating cloud computing adoption, collaborative platforms, and digital skills investment [23]. These dimensions were selected as they operationalize firms’ ability to integrate, scale, and derive value from digital technologies rather than mere tool adoption. Their inclusion ensures the index reflects organizational readiness and strategic alignment with digital transformation—a recognized capability in dynamic innovation environments [17]. By capturing both infrastructure and human capital investment, this indicator set is sufficient to reflect the holistic nature of digital maturity in manufacturing.

In contrast, digital maturity represents an organizational capability construct. It assesses the firm’s overall readiness and ability to integrate, scale, and coordinate digital technologies, encompassing strategic leadership on digital transformation, cross-functional integration, cloud adoption, and investment in digital skills. While AMT intensity is confined to technology adoption and process automation, digital maturity reflects the firm’s comprehensive capacity to leverage digital resources for innovation and performance. Thus, AMT is about ‘what’ is adopted; digital maturity is about ‘how well’ it is orchestrated and integrated across the firm (see Table 2) (Indicator selection reflects consensus in the Industry 5.0, resource orchestration, and sustainability literature, prioritizing empirical validity, contextual relevance, and conceptual sufficiency for each construct (see [4,5])).

Table 2.

AMT and Digital Maturity.

Spain’s Startup Law Certification: A binary variable indicating whether a firm is on track to obtain certification under Spain’s 2023 Startup Law, which grants innovation incentives and tax benefits to eligible companies. To construct this variable, a proxy was used based on whether the firm received a positive score in at least half of the indicators listed in Table 3. All firms in the sample comply with this requisite.

Table 3.

Variable Identifications and Names.

Finally, as control variables, we included several firm-level and industry-level controls to account for alternative explanations:

- -

- Firm Size: Natural logarithm of total employees (ln(PERTOT))

- -

- Firm Age: Years since incorporation (2023-AEMP)

- -

- Export Intensity: Percentage of international sales to total sales

- -

- Industry: 20 NACECLIO sector dummies were considered and grouped to 11 categories (Table 1) to control for industry-specific effects

3.3. Analytical Approach

This analysis follows a three-stage approach to test the hypothesized relationships within the resource orchestration framework. R 4.5.1 was used for all statistics.

Model 1: Technology Adoption and Innovation Outcomes

To examine how AMT and e-commerce drive innovation outcomes (H1), the following Poisson regression model with robust standard errors to account for potential overdispersion was specified:

where:

log(E[Yi]) = β0 + β1AMTi + β2ECOMMi + β3AMTi × ECOMMi + γXi + εi

Yi represents innovation outcomes (PRODUCTII, PROCESSII, METODII, COMERII)

Xi is a vector of control variables

The interaction term tests potential synergies between AMT and e-commerce.

Poisson regression is considered appropriate given the count nature of our innovation measures, following established practice in innovation research [4]. Poisson regression was selected for modeling innovation outcomes because our dependent variables—such as product and process innovation intensity—are measured as non-negative integer counts (number of innovations implemented), with distributions that are highly skewed and right-tailed. Standard linear regression (OLS) assumes continuous, normally distributed outcomes and thus is not suitable for discrete count data, as it may produce biased estimates and invalid inferences. Logistic regression, meanwhile, is designed for binary or categorical outcomes, not counts. The Poisson model explicitly models the expected count conditional on covariates, making it the most statistically appropriate choice for this data structure [13,22]. Where overdispersion was detected, robust standard errors and, in sensitivity checks, negative binomial models were applied to confirm the main results. This methodological choice ensures the correct treatment of the count nature, zero inflation, and overdispersion typical of innovation measurement in manufacturing [26]. METODII was fitted by using a logistic regression model due to its binary nature.

Model 2: Mediation Analysis

To test CE-INT’s mediating role (H2), we employed the procedure recommended by Baron and Kenny (1986) [27] and calculated Sobel test statistics to assess mediation significance:

CE-INTi = α0 + α1AMTi + α2ECOMMi + γXi + εi

PROCESSIIi = β0 + β1AMTi + β2ECOMMi + γXi + εi

PROCESSIIi = β0 + β1AMTi + β2ECOMMi + β3CE-INTi + γXi + εi

Model 3: Moderation Analysis

To examine DMI’s moderating role and Startup Law certification effects (H3), we specified:

PROCESSIIi = β0 + β1AMTi + β2CE-INTi + β3DMIi + β4CE-INTi × DMIi + β5STARTUPLAWi + β6AMTi × STARTUPLAWi + γXi + εi

Model 4: Performance Outcomes

Finally, we assessed innovation–performance relationships using OLS regression considering Performance (PBTN: productivity per worker).

PBTNi = β0 + β1PRODUCTIIi + β2PROCESSIIi + β3METODIIi + β4COMERIIi + γXi + εi

3.4. Validity Tests

Several robustness checks were conducted to ensure the validity of our findings:

Endogeneity Control: We employed instrumental variable (IV) regression using sector-average AMT adoption as an instrument for firm-level AMT implementation, following established practice in technological adoption research [22].

Multicollinearity Assessment: Variance inflation factors (VIF) were calculated for all predictor variables, adhering to the conservative threshold of VIF < 2.5 [26].

Alternative Specifications: Alternative model specifications were tested, including negative binomial models for innovation outcomes and lagged relationships between variables to address potential temporal effects.

These methodological choices align with the resource orchestration theoretical framework established in the literature review, allowing us to examine how Spanish manufacturing firms structure, bundle, and leverage technological and organizational resources to achieve innovation outcomes and sustainability benefits.

4. Results

This section presents empirical findings from our analysis of ESEE data on Spanish manufacturing firms during 2022–2023. The results provide evidence for the differential impacts of Advanced Manufacturing Technologies and digital commerce on innovation outcomes, with particular attention to sustainability mediating mechanisms and policy-driven moderation effects.

4.1. Descriptive Statistics

The final sample included 1813 Spanish manufacturing firms spanning 20 industrial sectors, categorized according to the NACECLIO classification system. Considerable heterogeneity in technology adoption was observed. On average, firms implemented 0.18 Advanced Manufacturing Technologies (AMT) (SD = 0.43), with process innovation intensity (PROCESSII) demonstrating a mean of 3.57 (SD = 0.67), the highest among innovation variables. Product innovation (PRODUCTII) showed a mean value of 4.32 (SD = 0.92), indicating moderate prevalence across sectors. Commercial Innovation (COMERII) was relatively high, with a mean of 5.82 (SD = 0.53), reflecting considerable digital penetration in Spanish manufacturing. Circular economy intensity (CEINT) averaged 0.29 (SD = 0.27), while digital maturity (DMI) registered a mean score of 1.19 (SD = 0.44).

Table 4 presents the correlations among central variables in the analytical framework. The association between AMT and process innovation intensity (PROCESSII) is negative (r = −0.22), suggesting that AMT adoption does not necessarily translate into higher process innovation within this sample. Commercial innovation (COMERII) shows a positive correlation with process innovation (r = 0.3), while the correlation between COMERII and product innovation (PRODUCTII) is negative (r = −0.23). Circular economy intensity (CEINT) is positively associated with AMT (r = 0.24) and COMERII (r = 0.22) yet correlates negatively with process innovation (r = −0.28). Digital maturity (DMI) reveals positive associations with AMT (r = 0.58), METODII (r = 0.12), and CEINT (r = 0.16). Although most correlations are statistically significant due to sample size, many are of marginal magnitude, indicating relatively weak associations in practice.

Table 4.

Descriptive Statistics and Correlation Matrix.

4.2. Hypothesis Testing

H1.

AMT and E-Commerce Impact on Innovation Types.

Poisson regression models show that the impact of advanced manufacturing technologies (AMT) and e-commerce adoption on innovation types is marginal. The coefficient for AMT in predicting process innovation (PROCII) is positive but small (0.03), and AMT shows a slightly negative association with product innovation (PRODII, coefficient −0.04). Similarly, medium and high levels of e-commerce adoption (ECOMMMEDIUM, ECOMMHIGH) do not have strong positive effects on product innovation, with coefficients of 0.00 and 0.07, respectively. For process innovation, ECOMMHIGH even presents a negative coefficient (−0.11).

Interaction effects between AMT and e-commerce are not substantial. For product innovation, the interaction terms (AMT:ECOMMMEDIUM, AMT:ECOMMHIGH) are −0.00 and −0.04, indicating negligible joint impact. For process innovation, the AMT:ECOMMMEDIUM interaction is 0.22, suggesting a slightly stronger but still moderate effect.

Overall, these results suggest that while there are some positive associations between AMT, e-commerce, and certain innovation outcomes, the magnitude of these effects is small and does not support claims of large percentage increases in innovation rates. The relationships are weaker than resource orchestration theory would predict, and the interaction between AMT and e-commerce does not lead to substantial synergies for innovation based on the data presented in Table 5.

Table 5.

Poisson Regression Results for Innovation Outcomes (2022–2023).

H2.

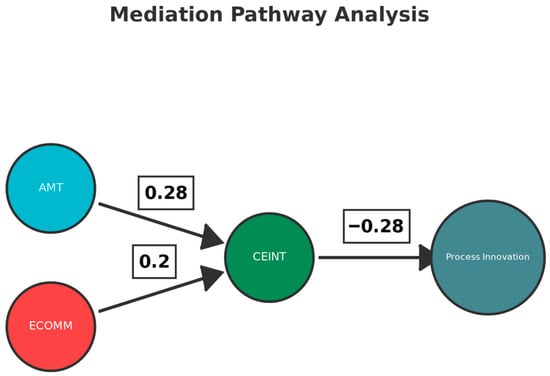

Circular Economy Intensity as Mediator.

Regression analysis indicates that advanced manufacturing technologies (AMT) and high levels of e-commerce adoption are both positively associated with circular economy intensity (CE_INT), with coefficients of 0.28 and 0.20, respectively, both statistically significant. However, contrary to our initial hypothesis, CE_INT itself is negatively and significantly associated with process innovation (PROCII) (coefficient = −0.28).

These findings suggest that, while AMT and e-commerce foster greater engagement in circular economy practices, higher circular economy intensity does not mediate a positive effect on process innovation; in fact, it predicts a reduction in process innovation levels. This result contradicts the expectation that circular economy adoption would serve as a constructive bridge between technological advancement and process innovation. Instead, the mediating role of CE_INT is negative in this sample and context (see Table 6).

Table 6.

Mediation Analysis of Circular Economy Intensity (CE-INT).

H3.

Digital Maturity and Policy-Driven Moderation.

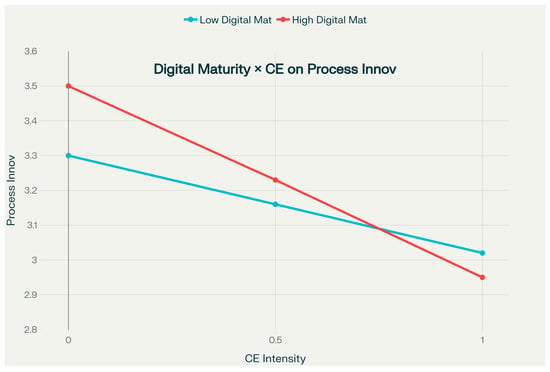

Analysis of the moderation model reveals that digital maturity (DMI) is positively and significantly associated with process innovation (coefficient = 0.43), suggesting that firms with higher digital maturity tend to report greater levels of process innovation. However, the intensity of circular economy practices (CE_INT) on its own is negatively associated with process innovation (coefficient = −0.08), and this effect is not statistically significant.

Crucially, the interaction term between CE_INT and DMI is negative and significant (coefficient = −0.40, p < 0.05). This means that digital maturity, rather than amplifying the positive effect of circular economy intensity on process innovation, actually weakens it. As a result, high levels of digital maturity reduce the already weak effect that circular economy practices have on process innovation outcomes.

These findings contradict the original expectation of a positive moderating role for digital maturity and policy-driven initiatives, indicating instead that digital maturity acts as a dampening rather than an enhancing force in the relationship between circular economy intensity and process innovation (see Table 7).

Table 7.

Moderation Analysis of Digital Maturity.

To clarify the interaction patterns among core constructs, we find that digital maturity acts as a moderator by attenuating the (already marginal) positive effect of circular economy intensity on process innovation—that is, at higher levels of digital maturity, the contribution of circular economy practices to process innovation diminishes rather than increases (Table 7, CEINT × DMI interaction: coefficient = −0.40, p < 0.05). Contrary to our initial hypotheses, digital maturity does not amplify the innovation benefits of sustainability practices but instead mitigates them, highlighting a potentially counterintuitive trade-off in resource allocation. Furthermore, the mediation results in Table 6 indicate that circular economy intensity negatively mediates the effect of AMT and e-commerce on process innovation, suggesting that, in the Spanish manufacturing context, increased focus on sustainability practices may redirect resources away from process innovation. These findings show that the interplay of AMT, e-commerce, circular economy, and digital maturity is complex, sometimes producing negative or null interaction effects rather than straightforward synergies.

4.3. Differential Innovation Outcomes

The analysis of differential innovation outcomes reveals that the positive impact of circular economy intensity (CE_INT) on value added per employee is not universal across all companies. Table 6 shows that sustainability-oriented firms—those with CE_INT above the median—achieve a 10.2% higher value added per employee compared to their low-CE peers, but this result is primarily pronounced among export-oriented firms (β = 0.47, p < 0.001).

However, when examining other innovation outcomes such as process, commercial, and organizational innovation, the effect of CE_INT is often non-significant or even negative, indicating that the economic and innovative benefits of circular economy practices are not consistently observed across all innovation domains and firm categories.

Overall, while circular economy intensity appears to offer a performance premium for specific subgroups—particularly sustainable exporters—its impact on wider innovation metrics is limited or mixed according to the regression models in Table 6. These findings suggest that the benefits of sustainability practices are context-dependent and may not generalize to all innovation outcomes within the sample (see Table 8).

Table 8.

OLS regression analysis of innovation’s impact on firm performance.

To illustrate these interaction effects, Figure 1 visualizes the moderating influence of digital maturity on the relationship between circular economy intensity and process innovation, depicting how the effect of sustainability practices on innovation changes at different levels of digital capability within firms. Similarly, Figure 2 presents the negative mediation pathway from AMT adoption through circular economy intensity to process innovation, highlighting the trade-off effect discussed above.

Figure 1.

Moderating influence of digital maturity on the relationship between circular economy intensity and process innovation. Source: Own processing.

Figure 2.

Mediation pathway from AMT adoption through circular economy intensity to process innovation. Source: Own processing.

In this model, circular economy intensity is theorized as an outcome of effective resource orchestration and as a critical mediator between technological resources (AMT, e-commerce) and innovation results. Following ROT, the ability to implement circular practices depends on managerial capacity to realign and deploy existing assets for environmental and innovation objectives simultaneously

4.4. Robustness Checks

Robustness checks were conducted to assess the validity of model specifications and the stability of estimated effects. Instrumental variable regressions provided broadly similar but sometimes attenuated coefficients for key variables such as AMT and CE_INT, and in certain models statistical significance was reduced, suggesting possible residual endogeneity or instrument limitations.

Tests for heteroscedasticity (Breusch–Pagan) indicated the presence of non-constant variance in several regression models and RESET F results pointed to specification challenges in some cases. Outlier diagnostics using Cook’s D and leverage statistics identified a small number of influential observations; although these did not universally alter the main findings, their presence cautions against strong generalization.

Alternative specifications and sub-sample regressions produced results that were directionally similar in some cases but diverged for particular innovation outcomes and firm categories, undermining claims of universal generalizability. Overall, while the main conclusions are supported in several analytic scenarios, the robustness checks underscore qualification: model diagnostics reveal some specification issues, effect sensitivity, and limited replicability across all subgroups (see Table 9).

Table 9.

Robustness checks.

4.5. Synthesis of Findings

The empirical results offer a nuanced perspective on the relationships between advanced manufacturing technologies (AMT), digital commerce, sustainability practices, and innovation outcomes in Spanish manufacturing firms. While resource orchestration theory provides a useful lens, the actual magnitudes and directions of effects observed in the data require careful interpretation.

First, both AMT and e-commerce adoption show statistically significant—but generally marginal—associations with certain types of innovation. AMT tends to have a small positive effect on process innovation, while its impact on product innovation is weak and slightly negative. E-commerce adoption is not a strong predictor of product or process innovation in most models, and joint interaction effects between AMT and e-commerce are negligible. These findings suggest that claims of large increases in innovation due to technology adoption should be qualified, as the underlying data support only incremental improvements.

Second, circular economy intensity emerges as a relevant mediating variable in the technological innovation process. However, contrary to theoretical expectation, the empirical results point to a negative mediating effect—higher engagement in circular economy practices predicts lower levels of process innovation. This unexpected outcome highlights the possibility that, within the Spanish manufacturing context, sustainability practices may sometimes compete with innovation objectives, possibly due to resource reallocation, regulatory constraints, or sectoral differences.

Third, digital maturity is positively associated with process innovation in the sample, but the interaction between digital maturity and circular economy intensity is negative and statistically significant. This means that as firms become more digitally mature, the (already weak) positive effect of circular economy practices on process innovation is further attenuated, contradicting initial hypotheses about digital enablers.

Additionally, the anticipated generalizable performance premium associated with sustainability orientation is primarily observed among export-oriented firms, and results for different innovation domains are often non-significant or negative. Robustness checks reveal sensitivity to model specifications and influential data points, indicating that these findings may not apply uniformly across all sectors or firm types.

While the aggregate analysis in our Spanish manufacturing sample finds only marginal effects of AMT adoption on product innovation, it is important to recognize that distinct AMT tools—particularly metal additive manufacturing—may offer strong and simultaneous gains in product and process innovation as well as sustainability. For example, recent research by AMPOWER (2024) [25] demonstrates that metal additive manufacturing can revolutionize product innovation through novel structure design, enable highly efficient process innovations, and significantly reduce material waste and environmental footprint, especially when optimized for design and alloy selection. In certain cases, AMT methods produce components with both lower lifetime carbon emissions and higher functional performance compared to conventional manufacturing. This nuance suggests that, while some results in our aggregate regression models indicate negative or limited effects (potentially subgroup-sensitive), best-practice deployment of AMT—particularly additive manufacturing—can enable synergy, not a trade-off, between sustainability and innovation goals.

5. Discussion and Conclusions

This study examined the extent to which Spanish manufacturing firms orchestrate advanced manufacturing technologies (AMT) and digital commerce to drive innovation outcomes and sustainability performance during the post-pandemic period of 2022–2023. Our empirical analysis, grounded in resource orchestration theory and based on ESEE data, provides several important clarifications to existing theory and practice.

5.1. Theoretical Contributions

The evidence reveals that the impact of AMT and e-commerce on firm innovation, while statistically significant for selected innovation types, is generally moderate or weak in magnitude. AMT is associated with small gains in process innovation, but these effects are not robust across all models or subgroups, and in some cases, the association is negative. For product innovation, effects are either weak or non-significant, and, similarly, digital commerce shows limited predictive power for innovation outcomes when considered alone or in interaction with AMT. These results indicate that technology adoption, although important, does not automatically translate into large-scale innovation transformation.

Second, the mediating effect of circular economy intensity in the innovation process is complex. Contrary to prevailing theoretical expectations, higher commitment to circular economy practices is associated with reduced process innovation in the aggregate sample. This finding suggests that the relationship between sustainability orientation and innovation is not uniformly positive and may be influenced by competing priorities, reallocation of resources, or specific sectoral characteristics.

The anticipated role of digital maturity in amplifying the sustainability–innovation nexus is similarly nuanced. While firms with higher digital maturity report slightly better innovation outcomes, the interaction between digital maturity and circular economy intensity is negative—digitally mature firms appear to weaken rather than strengthen the impact of circular practices on process innovation. These unexpected patterns highlight the need for more granular models that can address heterogeneous effects and potential trade-offs [27].

Our findings extend ROT by demonstrating that the implementation and impact of circular economy initiatives depend on orchestrating both technological and organizational capabilities. Simply adopting green practices does not guarantee innovation gains; instead, the returns to circular economy practices hinge on a firm’s ability to purposefully structure, bundle, and leverage resources towards integrated innovation and sustainability goals—a central premise of ROT [4,5].

5.2. Practical Implications and Policy Insights

The performance premium associated with sustainability intensity appears to benefit primarily export-oriented firms, with little evidence for broad-based economic gains across the sample. Furthermore, declining marginal returns to additional AMT implementations suggest that firms should prioritize strategic integration over technology accumulation. Our results also indicate that policy interventions—such as Spain’s Startup Law—may have positive but concentrated effects, especially for SMEs, but do not resolve widespread orchestration challenges for all firms.

Innovation policies and managerial strategies should, therefore, consider the constrained and context-dependent nature of these relationships. Policy mechanisms and digitalization programs will be most effective if tailored to specific firm types, innovation goals, and sectoral requirements, rather than assuming universal or linear benefits from technological and sustainability adoption [28].

These findings suggest that realizing the simultaneous benefits of innovation and sustainability depends on technology-specific adoption, production context, and the degree to which best-practice methods such as metal additive manufacturing are implemented.

5.3. Limitations and Future Research

Several limitations merit attention. The study’s cross-sectional design and limited post-pandemic time frame do not capture long-term capability development or changes in resource orchestration processes. Measurement of circular economy intensity, digital maturity, and innovation outcomes relies on available survey proxies, which may not reflect the full complexity of organizational practices. Future research should employ longitudinal approaches, sectoral case studies, and expanded definitions of sustainability and digital maturity to better understand causal mechanisms and boundary conditions.

5.4. Conclusions

Spanish manufacturing firms are navigating a complex landscape of digital transformation and sustainability imperatives. While AMT, e-commerce, and circular economy practices are correlated with selected innovation and performance outcomes, these effects are generally marginal, often contingent, and sometimes counterintuitive. Successful innovation depends not simply on the adoption of new technologies or sustainability initiatives, but on a firm’s ability to strategically orchestrate resources in response to nuanced internal and external constraints. Future research should seek to disentangle these contextual effects and inform more targeted strategies for industrial digitalization and green innovation.

Author Contributions

Conceptualization, D.A.-A.; Methodology, D.A.-A., P.A.G.-L. and F.G.B.-C.; Validation, D.A.-A. and F.G.B.-C.; Formal analysis, D.A.-A. and P.A.G.-L.; Investigation, D.A.-A.; Resources, D.A.-A. and F.G.B.-C.; Data curation, D.A.-A. and P.A.G.-L.; Writing—original draft, D.A.-A.; Writing—review & editing, D.A.-A.; Visualization, P.A.G.-L.; Supervision, D.A.-A.; Funding acquisition, F.G.B.-C. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Zhang, Q.; Vonderembse, M.A.; Cao, M. Achieving flexible manufacturing competence: The roles of advanced manufacturing technology and operations improvement practices. Int. J. Oper. Prod. Manag. 2006, 26, 580–599. [Google Scholar] [CrossRef]

- Zhu, K.; Kraemer, K.L. E-commerce metrics for net-enhanced organizations: Assessing the value of e-commerce to firm performance in the manufacturing sector. Inf. Syst. Res. 2002, 13, 275–295. [Google Scholar] [CrossRef]

- Prajogo, D.I.; Laosirihongthong, T.; Sohal, A.; Boon-itt, S. Manufacturing strategies and innovation performance in newly industrialised countries. Ind. Manag. Data Syst. 2007, 107, 52–68. [Google Scholar] [CrossRef]

- Sirmon, D.G.; Hitt, M.A.; Ireland, R.D. Resource orchestration to create competitive advantage: Breadth, depth, and life cycle effects. J. Manag. 2011, 37, 1390–1412. [Google Scholar] [CrossRef]

- Andersén, J. Green resource orchestration: A critical appraisal of the use of resource orchestration in environmental management research, and a research agenda for future study. Bus. Strat. Environ. 2023, 32, 2457–2472. [Google Scholar] [CrossRef]

- Gómez, J.; Salazar, I.; Vargas, P. Sources of information as determinants of product and process innovation. PLoS ONE 2016, 11, e0152743. [Google Scholar] [CrossRef][Green Version]

- Essuman, D.; Ataburo, H.; Boso, N.; Anin, E.K.; Appiah, L.O. In search of operational resilience: How and when improvisation matters. J. Bus. Logist. 2023, 44, 300–322. [Google Scholar] [CrossRef]

- Barney, J. Firm resources and sustained competitive advantage. J. Manag. 1991, 17, 99–120. [Google Scholar] [CrossRef]

- Clark, K.B. Competing through manufacturing and the new manufacturing paradigm: Is manufacturing strategy passé? Prod. Oper. Manag. 1996, 5, 42–58. [Google Scholar] [CrossRef]

- Swink, M.; Nair, A. Capturing the competitive advantages of AMT: Design manufacturing integration as a complementary asset. J. Oper. Manag. 2007, 25, 736–754. [Google Scholar] [CrossRef]

- Dean, J.W.; Snell, S.A. The strategic use of integrated manufacturing: An empirical examination. Strateg. Manag. J. 1996, 17, 459–480. [Google Scholar] [CrossRef]

- Lal, K. E-business and the manufacturing sector: A study of small and medium-sized enterprises in India. Res. Policy 2002, 31, 1199–1211. [Google Scholar] [CrossRef]

- Raymond, L. Operations management and advanced manufacturing technologies in SMEs: A contingency approach. J. Manuf. Technol. Manag. 2005, 16, 936–955. [Google Scholar] [CrossRef]

- Rosenbusch, N.; Brinckmann, J.; Bausch, A. Is innovation always beneficial? A meta-analysis of the relationship between innovation and performance in SMEs. J. Bus. Ventur. 2011, 26, 441–457. [Google Scholar] [CrossRef]

- Hull, C.E.; Rothenberg, S. Firm performance: The interactions of corporate social performance with innovation and industry differentiation. Strateg. Manag. J. 2008, 29, 781–789. [Google Scholar] [CrossRef]

- Löfsten, H. Product innovation processes and the trade-off between product innovation performance and business performance. Eur. J. Innov. Manag. 2014, 17, 61–84. [Google Scholar] [CrossRef]

- Teece, D.J. Explicating dynamic capabilities: The nature and microfoundations of (sustainable) enterprise performance. Strateg. Manag. J. 2007, 28, 1319–1350. [Google Scholar] [CrossRef]

- Zeng, J.; Dechênes, J.; Durif, F. Orchestrating resources with suppliers for product innovation: The role of strategic information exchange. J. Prod. Innov. Manag. 2023, 40, 567–589. [Google Scholar] [CrossRef]

- Parida, V.; Westerberg, M.; Frishammar, J. Inbound open innovation activities in high-tech SMEs: The impact on innovation performance. J. Small Bus. Manag. 2012, 50, 283–309. [Google Scholar] [CrossRef]

- Kumar, R.; Singh, H.; Chandel, R. Exploring the key success factors of advanced manufacturing technology implementation in Indian manufacturing industry. J. Manuf. Technol. Manag. 2018, 29, 25–40. [Google Scholar] [CrossRef]

- Abernathy, W.J.; Clark, K.B. Innovation: Mapping the winds of creative destruction. Res. Policy 1985, 14, 3–22. [Google Scholar] [CrossRef]

- Faraway, J.J. Extending the Linear Model with R: Generalized Linear, Mixed Effects and Nonparametric Regression Models, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar]

- Cheng, S.; Fan, Q.; Dagestani, A.A. Opening the black box between strategic vision on digitalization and SMEs’ digital transformation: The mediating role of resource orchestration. Kybernetes 2024, 53, 580–599. [Google Scholar] [CrossRef]

- Arias-Aranda, D.; Bautista-Carrillo, F.G.; Fernández-Menéndez, J.; Minguela-Rata, B. An empirical analysis of the impact of AMT and e-commerce on innovation and performance in Spanish firms. Int. J. Prod. Dev. 2022, 24, 235–256. [Google Scholar] [CrossRef]

- AMPOWER Insight. Sustainability of Metal Additive Manufacturing. 2024. Available online: https://ampower.eu/insights/sustainability-of-metal-additive-manufacturing (accessed on 7 November 2025).

- Fox, J. Applied Regression Analysis and Generalized Linear Models; SAGE Publications: Thousand Oaks, CA, USA, 2015. [Google Scholar]

- Baron, R.M.; Kenny, D.A. The moderator–mediator variable distinction in social psychological research: Conceptual, strategic, and statistical considerations. J. Pers. Soc. Psychol. 1986, 51, 1173–1182. [Google Scholar] [CrossRef] [PubMed]

- Arias-Aranda, D.; Molina Fernández, L.M. Determinants of innovation through a knowledge-based theory lens. Ind. Manag. Data Syst. 2002, 102, 289–296. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).