1. Introduction

As global industrialization and urbanization proceed at an accelerated pace, challenges such as excessive greenhouse gas emissions and worsening environmental pollution have emerged as severe threats to human health, the sustainable socioeconomic development of societies, and the stability of global ecosystems. Against this backdrop, pursuing green and low-carbon development has evolved into a broadly acknowledged consensus within the international community [

1]. To drive low-carbon transitions across entire industrial chains, developed countries primarily leverage legislative measures. For instance, the European Union (EU), through the European Climate Law, mandates a five-year assessment of emission reduction progress starting from 2023: it also advances energy transition and research and development (R&D) on low-carbon technologies such as hydrogen energy. The United States, via the Inflation Reduction Act, has allocated hundreds of billions of dollars to guide the reshoring of clean energy supply chains. Meanwhile, Japan revised its Basic Energy Plan, increasing funding for the Green Innovation Fund to support R&D in hydrogen technologies and carbon capture, utilization, and storage. By contrast, developing countries focus on low-carbon initiatives that integrate technology introduction with local innovation. Brazil, for example, has established social and environmental sustainability standards across multiple industries, providing certification for products and services that meet these criteria. It has also launched “green equities” to incentivize enterprises to enhance environmental investments and channel capital into green industries. India introduced the National Geothermal Energy Policy, which aims to advance R&D in hybrid geothermal–solar power plants and the retrofitting of abandoned oil wells for geothermal applications. Uzbekistan, through collaboration with China, has constructed waste-to-energy facilities—an effort that has effectively reduced carbon emissions associated with landfills. These diverse practices underscore that green and low-carbon development, as the core strategy for global sustainable development in the 21st century, holds dual critical values. On the one hand, it helps mitigate resource constraints, alleviate environmental pressures, and advance ecological conservation. On the other hand, it has gradually emerged as a key pathway to drive economic restructuring and achieve high-quality development [

2].

In the development of a low-carbon economy, the industrial sector, as the core carrier of energy consumption and carbon emissions, faces an urgent need for low-carbon transformation [

3]. Green technological innovation serves as the key support to address this challenge: through technological advancement, it helps enterprises reduce pollution, enhance resource efficiency, and develop eco-friendly products [

4]. Covering the R&D of renewable energy technologies, energy-saving technologies, clean production processes, and eco-friendly materials, green technological innovation acts as the core driver of low-carbon economic development [

5]. Against this backdrop, the rise in new-quality productive forces provides new impetus and direction for green technological development. New-quality productive forces are an important component of Xi Jinping’s economic thought and a significant innovation in China’s independent knowledge system of economics. Compared with traditional productive forces, new-quality productive forces embody a profound transformative shift. They move beyond the outdated production model defined by high energy consumption, high emissions, and low efficiency, and instead evolve into a new form of productive capacity centered on scientific and technological innovation, integrating cutting-edge technologies such as data, networks, and intelligence [

6]. This transformation fundamentally changes the path of productive forces, making production activities cleaner, more efficient, and more sustainable [

2]. There is an inherent unity between new-quality productive forces and green productive forces [

7]. New-quality productive forces themselves are green productive forces, and green should be a necessary condition for new-quality productive forces, while new-quality productive forces should promote green development. The innovation and green development orientation of new-quality productive forces are the key support for building a modern economic system with new-quality productive forces. Specifically, green technology innovation is needed to promote the transformation of industrial chains to high-end, green and intelligent directions.

The industrial and supply chains are pivotal to the smooth operation of a nation’s economy, and the optimization and upgrading of industrial chains constitute a core component of building a modern industrial system [

8]. Globally, the modernization of industrial chains has become a core area of competition among countries [

9]. The European Union, through the “European Green Deal,” has designated green technological innovation as the core driver of industrial chain upgrading, aiming to raise the share of renewable energy to 42.5% by 2030 and thereby forcing industrial chains to undergo low-carbon restructuring. The United States released the “Advanced Manufacturing Leadership Strategy” report, focusing on key sectors such as semiconductors and new energy, and strengthening the autonomy and controllability of industrial chains through government subsidies and technological blockades. Emerging economies like India and Vietnam are accelerating the transfer of mid-to-low-end industrial chains, seeking to break free from the division-of-labor lock-in by leveraging factor cost advantages. Meanwhile, the restructuring of international rules, such as carbon tariffs and technology export controls, has further intensified the security and green competition in global industrial chains [

10]. Against this backdrop, the modernization of China’s industrial chains not only requires addressing domestic bottlenecks in factors and technologies but also demands cultivating “green + digital” dual advantages through new-quality productive forces, thereby shifting from scale advantages to quality advantages in the global industrial chain division of labor. This is both a necessary choice to respond to international competition and an inherent requirement for achieving the “dual carbon” goals and high-quality development.

During his inspection tour in Guangdong Province, China in 2023, President Xi Jinping emphasized “promoting the advanced development of industrial foundations and the modernization of industrial chains.” Advancing the modernization of industrial chains serves as the core focus of accelerating the construction of a modern industrial system rooted in the real economy. The modernization of industrial chains can enhance China’s advantages in international industrial competition, enabling it to respond more safely and swiftly to sudden shocks and challenges in the global environment, and prevent issues such as chain breaks and missing links [

11]. Nevertheless, China’s industrial chains still face pressing challenges such as limited technological development, high input with low output, poor circulation of industrial chain elements, and low resource integration capabilities [

12]. The 2024 Government Work Report of China proposed accelerating the development of new-quality productive forces and vigorously promoting the construction of a modern industrial system. It emphasizes the need to fully leverage the leading role of scientific and technological innovation, speed up the optimization and upgrading of industrial and supply chains, enhance the resilience and competitiveness of industrial chains, and promote their transformation toward higher-end, smarter, and greener development. As the primary driver of industrial transformation and upgrading, new-quality productive forces provide strong support for advancing industrial foundation modernization and upgrading industrial structures through scientific and technological innovation, and the adoption of emerging, efficient, and green production methods [

13]. Specifically, their role manifests in three key aspects: Firstly, new-quality productive forces take scientific and technological innovation as their core driving force. This enables them to break through technical “bottlenecks” and address “chain failures,” while optimizing industrial production processes and elevating the level of independent innovation across entire industrial chains. Secondly, new-quality productive forces foster innovative workforce models. These models not only significantly improve corporate operational efficiency but also drive organizational transformation, accelerating the industrial chains from “low-end specialization” to “high-end expansion”. Thirdly, by redefining the combination of production factor, these advanced productive forces disrupt traditional manufacturing paradigms and catalyze emerging business models. Meanwhile, they leverage the multiplier effect of data to enhance industrial chains’ capabilities in data acquisition, transmission, and processing, strengthening supply chain resilience and propelling the transition from “fragmented short chains” to “coordinated long chains”.

A review of existing literature reveals that few scholars have explored the mechanism of green technology innovation between new-quality productive forces and the modernization of China’s industrial chain. In the research field of new-quality productive forces and industrial chain modernization, some studies point out that new-quality productive forces possess empowering value for the modernization of industrial and supply chains. Specifically, new-quality productive forces drive the upgrading of industrial chains from low-end to high-end by restructuring production factors and optimizing organizational models, with technological innovation and digital transformation functioning as mediating and moderating variables in this process [

14,

15,

16,

17,

18]. In the context of green technology innovation, new-quality productive forces are built on the integration and collaboration of modern green technologies as well as the innovative linkage of productivity structure elements. They facilitate the innovative development of green technologies in cultivating green production relations, transforming technological innovation achievements, and expanding international exchanges and cooperation [

19]. Meanwhile, green technology innovations such as artificial intelligence, industrial internet, and new energy have accelerated the modernization of industrial chains [

20,

21,

22].

It is evident that research on new-quality productive forces, green technological innovation, and the modernization of China’s industrial chain is relatively scarce, leaving significant room for theoretical expansion. Under the background of the “dual control” policy on energy and the “dual carbon” goals, new-quality productive forces offer unprecedented development opportunities for the construction of a modern industrial system. However, how can new-quality productive forces effectively promote the transformation and upgrading of industrial chains? What role does green technological innovation play in this process? Do new-quality productive forces have a spatial spillover effect? A systematic exploration of these questions not only enriches theoretical research on the interaction between new-quality productive forces and industrial chains but also provides practical guidance for China to achieve the modernization of its industrial chain and boost high-quality economic development, carrying both academic value and practical significance.

The innovation points and potential impacts of this study are as follows:

Key Innovations: (1) Research Framework: Existing literature primarily focuses on either the direct impact of new-quality productive forces on industrial chain modernization or the role of green technological innovation in industrial upgrading. However, few studies systematically reveal the mediating mechanisms between these two factors. This study fills the gap in the “new-quality productive forces–industrial chain modernization” intermediate mechanism by establishing a multi-path analytical framework. (2) Research Methodology: The study establishes a progressive empirical system across three dimensions—holistic effects and moderating effects. By adopting a multidimensional model design and conducting “structural disparity” analysis of spatial effects, it further enhances the rigor and reliability of the research conclusions.

Potential Impact: Against the backdrop of global supply chain turbulence and the “dual carbon” goals becoming an international consensus, the findings of this study hold international reference value. For developing countries, it provides actionable pathways to leverage green technological innovation for the coordinated advancement of industrial chain upgrades, helping them avoid the traditional pitfall of polluting first and then cleaning up. Meanwhile, it validates that green technology innovation can enhance the role of new-quality productive forces in empowering industrial chains, offering China solutions for the global industrial chains and green upgrading.

2. Mechanism Analysis and Research Hypothesis

2.1. New-Quality Productive Forces Contribute to the Modernization of the Industrial Chain

The Marxist theory of productive forces and production relations holds that their dynamic interaction constitutes the contradictory movement inherent in the mode of production. Specifically, the advancement of productive forces necessitates corresponding adjustments in production relations, while optimized production relations; conversely, fuel the development of productive forces. New-quality productive forces, with technological innovation as their core driver, represent a new stage in the evolution of productive forces. Their defining characteristic lies in the reconfiguration of production factor combinations through digital technologies, green innovations, and artificial intelligence. In contrast, industrial chain modernization focuses on optimizing production relations, particularly in production factor allocation and industrial collaboration models. The interplay between these two aspects embodies the law of productive forces and production relations. New-quality productive forces provide material foundations and technical support for industrial chain modernization, while the production relations adjustments achieved through industrial chain modernization further propel the development of new-quality productive forces.

New-quality productive forces are logically aligned with the requirements of industrial chain modernization, manifesting three key facilitative effects. First, they drive organizational transformation in industrial chains by restructuring factor collaboration. Horizontally, digital technologies dismantle physical barriers between traditional industries, enabling the free flow and recombination of production factors across sectors—exemplified by technological integration between manufacturing and services, or cross-sectoral convergence between agriculture and the digital economy. This factor reorganization compels industrial chains to shift from linear divisions of labor to networked collaborative production models. Such changes not only reduce transaction costs among stakeholders but also foster new value distribution patterns through industrial convergence, ultimately shaping industrial chains with networked and ecological organizational characteristics. Vertically, new-quality productive forces embed data elements throughout the entire chain, restructuring information transmission mechanisms between upstream and downstream sectors. This addresses factor misallocation caused by information asymmetry in traditional production relations, shifting resource allocation authority from hierarchical control to data-driven mechanisms while enhancing upstream–downstream coordination. Fundamentally, this represents a profound adjustment in the governance of production factors. Second, they drive transformations in industrial forms and value distribution by upgrading the attributes of traditional factors. Unlike conventional productive forces where factors operate in fixed proportions, new-quality productive forces empower production factors through technological innovation, endowing the means of production, objects of labor, and the workforce with new attributes. This factor upgrade not only enhances production efficiency but also drives transformative changes in the logic of resource allocation within production relations. On the one hand, the integration of data as a production factor shifts value distribution in industrial chains from the traditional model based on capital and labor contributions to one centered on data’s value-creation capacity. This transition propels industries from resource-intensive to technology-intensive models, representing the inevitable adaptation of production relations to the evolution of productivity. On the other hand, new-quality productive forces gradually replace traditional production factors, transforming industrial chains from extensive production models to green, low-carbon production patterns that achieve dual improvements in factor utilization efficiency and sustainable development capabilities. Third, new-quality productive forces strengthen industrial chain control by reconfiguring production factor allocation. Internally, they enable remote management of production factor flows via digital information systems, reducing information errors and scheduling losses while safeguarding supply chain security. By digitally transforming traditional production factors, they accelerate the integration of mid-to-low-end industrial chains, shorten supply chain length, minimize the risk of disruptions, and enhance overall stability. Externally, they drive digital and intelligent industrial innovation: while transforming traditional production models, they create new demands and products on both the demand and supply sides of industrial chains. This process fosters strategic emerging industries and future-oriented sectors, effectively mitigating external environmental impacts on industrial chains and enhancing their risk resilience. Fundamentally, this represents productivity advancements that propel production relations to adapt to higher-level competition.

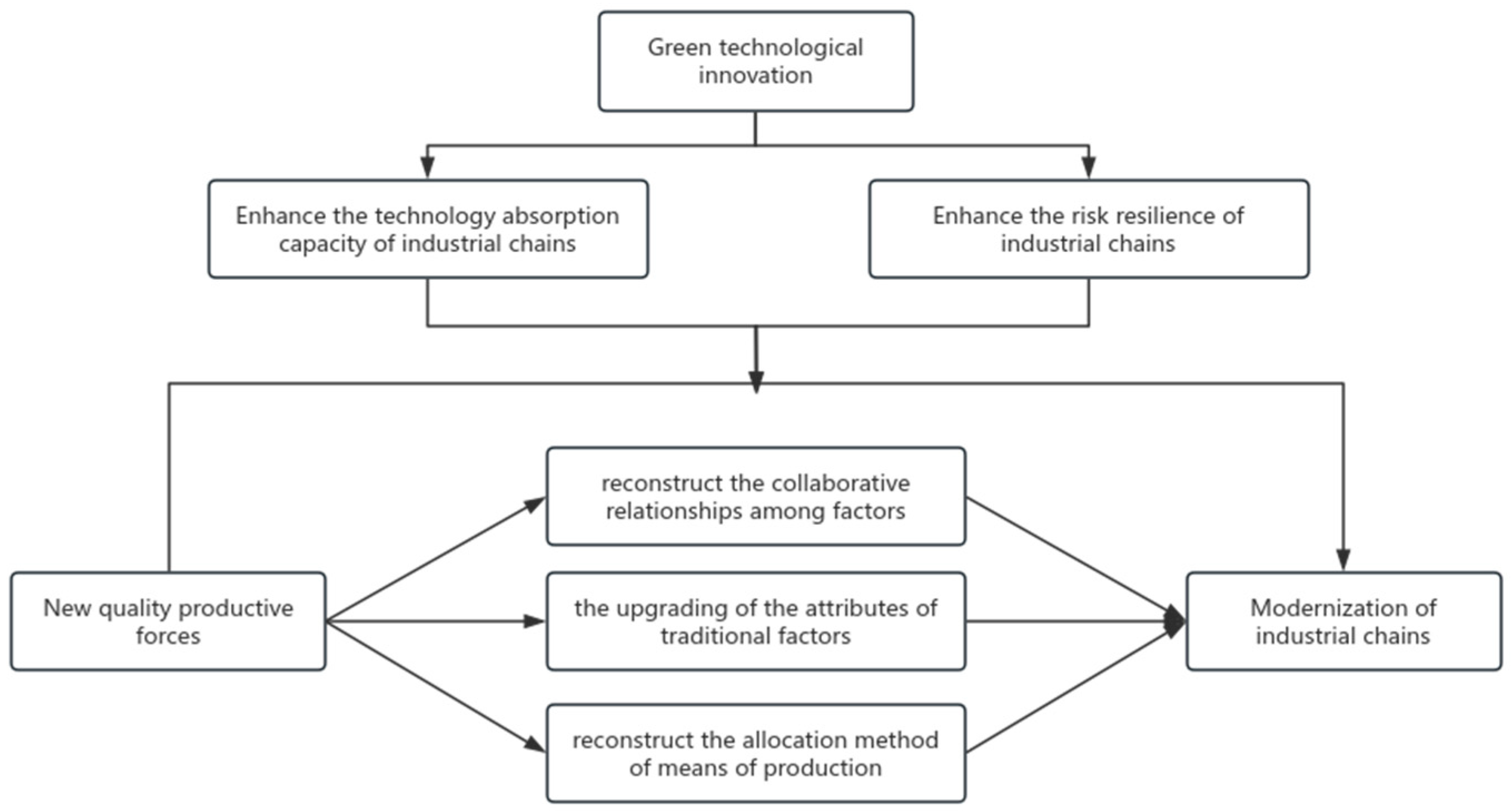

Based on the above analysis, new-quality productive forces promote the modernization and upgrading of industrial chain by reconstructing the cooperative relationship of factors, upgrading the attributes of traditional factors, and reconstructing the allocation mode of means of production. Therefore, the paper puts forward the following hypotheses:

Hypothesis H1: New-quality productive forces significantly promote industrial chain modernization.

2.2. The Moderating Role of Green Technology Innovation in New-Quality Productive Forces and Industrial Chain Modernization

In the process of new-quality productive forces driving industrial chain modernization, green technology innovation plays a pivotal role in supporting industrial chain optimization and upgrading. Through its inherent technical characteristics and functional attributes, green technology innovation modifies the intensity and scope of new-quality productive forces’ impact on industrial chain modernization. This indicates that green technology innovation may serve as a crucial moderating variable in the modernization process. The specific mechanisms can be elaborated from the following two aspects:

First, green technological innovation can enhance the technological absorption capacity of industrial chains. While new-quality productive forces can foster innovative production models and industrial forms through digital integration and technological breakthroughs, their effectiveness in driving industrial chain modernization heavily depends on the chain’s inherent technological absorption capabilities. Can enterprises, organizations, or regions within industrial chains effectively absorb advanced technological achievements from new-quality productive forces through their resource reserves and technical foundations, and transform them into tangible productive capabilities? In this process, green technological innovation plays a pivotal role. On one hand, green technological innovation is inherently technology-intensive, enabling it to address core challenges within the industrial chain such as high energy consumption, severe pollution, and excessive technological dependence. It helps break external technological monopolies, achieve self-reliance in core technologies, and clear obstacles for the digital integration of productive forces. When green technological innovation reaches advanced levels, the digital elements of new-quality productive forces can integrate more efficiently into upstream and downstream links of the industrial chain. Through network-based restructuring, this enables precise resource allocation and optimized production processes, thereby significantly advancing technological autonomy and intelligent upgrades in industrial chains. Conversely, if green technological innovation remains underdeveloped, key links in the industrial chains will be constrained by technological bottlenecks, making it difficult for the digital elements of new-quality productive forces to penetrate deeply. Also, the driving force for industrial chain modernization will be significantly weakened. On the other hand, the low-carbon substitution effect brought by green technological innovation optimizes the industrial structure foundation of the industrial chain. After eliminating outdated production capacities that are energy-intensive and low-yielding, the industrial chain becomes more receptive to emerging industries like new energy driven by new-quality productive forces, making the promotion effect of new-quality productive forces on industrial chain upgrading more prominent. In contrast, insufficient green technological innovation leads to outdated production capacities dominating the industrial chain, leaving emerging industries spawned by new-quality productive forces struggling to take root, greatly limiting their driving effect on industrial chain modernization.

Second, green technological innovation can enhance the resilience of industrial chains. The modernization of industrial chains not only requires technological upgrading and structural optimization but also demands robust capacity to withstand external risks, primarily through two pathways. Firstly, green innovation reduces dependence on high-risk resources, thereby mitigating supply chain disruption risks. The stability of industrial chains relies on continuous supplies of core resources like energy and raw materials. Traditional high-carbon industrial chains often face significant supply risks, driven by factors like fossil fuel price volatility, scarcity of critical mineral resources, and tightening environmental policy constraints. On the one hand, green innovation shifts industrial chains from fossil fuels to renewable energy through clean energy substitution, thereby reducing risks from international energy price volatility and geopolitical conflicts. On the other hand, it transforms industrial waste into raw materials through circular resource utilization, which lowers dependence on primary mineral resources and avoids supply chain disruptions caused by mining restrictions or changes in import quotas. Secondly, green innovation optimizes industrial chain structures to minimize operational risks. Low-carbon technological upgrades enable industrial chains to better comply with environmental regulations, preventing new-quality productive forces from being constrained by environmental compliance issues, and thus ensuring the sustained dynamism of new-quality productive forces in driving industrial chain modernization. Specifically, when green technological innovation reaches an advanced level, industrial chains can leverage circular economy technologies to shift from linear “extraction–production–waste” models to circular production models. This transformation not only reduces dependence on virgin resources but also mitigates resource cost risks during industrial expansion driven by new-quality productive forces. Conversely, if green technological innovation remains underdeveloped, industrial chains will continue to rely on traditional high-energy-consuming energy sources and linear production models. In such cases, industrial expansion propelled by new-quality productive forces becomes more vulnerable to energy price fluctuations and environmental regulations, leading to unstable effectiveness in industrial chain modernization and even potential temporary stagnation due to risk impacts.

Based on the above analysis, green technological innovation enhances the industrial chain’s capacity for technological adoption and risk resilience, thereby altering the intensity of new-quality productive forces’ impact on industrial chain modernization. Specifically, the higher the level of green technological innovation, the stronger the driving force of new-quality productive forces in advancing industrial chain modernization.

Hypothesis H2: Green technology innovation plays a positive moderating role in the relationship between new-quality productive forces and industrial chain modernization. The higher the level of green technology innovation, the more significant the promoting effect of new-quality productive forces on industrial chain modernization.

Based on the above theoretical analysis, the mechanism of new-quality productive forces promoting the modernization of industrial chain through green technology innovation is shown in

Figure 1.

6. Discussion

This study elucidates the moderating role of green technology innovation in driving industrial chain modernization through new-quality productive forces. The research findings will be discussed in the following section.

Firstly, the new-quality productive forces exert a significant positive driving effect on industrial chain modernization. Empirical results show that the positive driving effect of new-quality productive forces on industrial chain modernization remains statistically significant at the 1% level in both the benchmark regression and three robustness tests, confirming its reliability as a core driving factor for industrial chain upgrading. However, the results of control variables present contradictions worthy of further discussion. On one hand, the coefficient failed the significance test and was negative, contradicting the traditional understanding that human capital supports industrial upgrading. This does not mean human capital is insignificant; instead, it reflects dual issues of quality mismatch and conversion lag in China’s human capital. The expansion of human capital scale brought by the enrollment expansion in higher education institutions has not yet fully matched the precise demand for digital skills and green technology capabilities in industrial chain modernization. The digital transformation of manufacturing requires versatile data talents, while traditional human capital cultivation focuses more on single technologies or basic skills. Meanwhile, transforming human capital into industrial efficiency requires school-enterprise collaborative training, but the current mechanism leads to a long transformation cycle, resulting in the absence of a significant positive effect in empirical results. On the other hand, the coefficient of openness to the outside world was significantly negative, which had a distinct realistic background when combined with the current international environment. Currently, the turbulence in global supply chains, escalating trade frictions, and tightened technology export controls are exposing over-reliant industrial chains to risks of supply chain disruptions and technological blockades. Meanwhile, the inertia of transferring low-end production capacities during opening-up may slow industrial chains’ transformation toward high-end development, ultimately making short-term risks from openness outweigh long-term spillover effects. In the modernization of industrial chains, cultivating new-quality productive forces should be the core focus, prioritizing three dimensions: digital productivity, technological productivity, and green productivity. This approach avoids the pitfalls of blindly pursuing scale expansion and emphasizes the efficiency of technology transfer and factor reorganization.

Secondly, the moderating effect analysis reveals that the interaction term coefficient between green technology innovation and new-quality productive forces is significantly positive at the 1% level. Additionally, green technology innovation alone exerts a significant positive effect on industrial chain modernization. This indicates that green technology innovation can enhance the catalytic role of new-quality productive forces in industrial chain modernization. By improving the industrial chain’s technological adoption capacity and risk resilience, green technology innovation amplifies the marginal effects of new-quality productive forces. When green technology innovation reaches advanced levels, industrial chains can rapidly adapt to digital elements in new-quality productive forces through clean energy substitution and circular resource utilization technologies, avoiding the dilemma of unimplemented technological introductions. Meanwhile, green technology innovation reduces industrial chains’ dependence on fossil fuels and scarce minerals, mitigating resource supply risks during new-quality productive forces-driven industrial expansion and ensuring more sustainable positive effects. To avoid the misconception of prioritizing new-quality productive forces scale over green technology adaptation, green technology innovation should be integrated throughout the cultivation process of new-quality productive forces. This approach focuses on addressing the disconnect between technological R&D and industrial application, preventing resource misallocation during the transformation of new-quality productive forces.

Thirdly, the spatial Durbin model and the analysis of heterogeneity in eastern, central, and western regions jointly reveal that the role of new-quality productive forces exhibits regional imbalance characteristics. When only the time effect is controlled, new-quality productive forces show significant positive spatial spillover effects. However, after introducing provincial fixed effects, the spillover effect disappears and the coefficient turns negative. In the heterogeneity regression, the coefficient of new-quality productive forces in the eastern region is significantly higher than that in the central region, while the western region’s coefficient is statistically insignificant. The core reason for this result lies in the constraints imposed by regional structural differences on the role of new-quality productive forces. From the root cause of regional heterogeneity, due to the better economic development in China’s eastern region, it can form a coordinated industrial chain from R&D to application, enabling the rapid transformation of new-quality productive forces from technological upgrading to value creation. However, enterprises in the central and western regions face shortcomings such as insufficient low-carbon transformation capabilities in traditional manufacturing and weak digital foundations in small and medium-sized enterprises. These hinder the implementation of green technologies in specific production scenarios, making it difficult for new-quality productive forces to translate into actual industrial chain efficiency, ultimately manifested as small or insignificant coefficients. In the process of industrial chain development, it is necessary to abandon the “one-size-fits-all” development policies and design differentiated new-quality productive forces coordination mechanisms for the different development stages of the eastern, central, and western regions, addressing the dilemma of insufficient spillover effects in the east and weak reception capacity in the central and western regions.