Abstract

In the industrial internet environment, the operation and control of production equipment have become increasingly complex, and their performance directly affects the efficiency, benefits and sustainable development of manufacturing enterprises. From the three-dimensional perspective of “asset-application-maintenance”, this paper constructs a performance analysis framework for the operation and control of production equipment, systematically identifies the combination of core factors affecting performance, and fills the research gap in the current lack of empirical analysis from the configuration perspective in this field. On the basis of data from 82 manufacturing enterprises, the fsQCA method was used to identify three performance improvement paths: the high-load output mode, the lean management and control mode, and the low-failure operation mode. These paths clarify the equivalent approaches to achieve high performance in the operation and control of production equipment under the interaction of multiple factors. On this basis, the study demonstrates the operability and effectiveness of the proposed strategies in actual industrial scenarios through empirical verification in a manufacturing workshop of aero-engine transmission units. In contrast to existing studies, this study introduces the fsQCA method in the field of industrial equipment management and control for the first time to reveal the influencing paths; its originality and methodology have significant innovative significance. The research results provide new ideas and methodological guidance for enterprise managers to improve the performance of production equipment operations and controls in the industrial internet environment, which helps to enhance the sustainable development capability of manufacturing enterprises.

1. Introduction

Amid the current wave of in-depth digital transformation in the manufacturing industry, production equipment has become the core unit of enterprises’ intelligent operation. The stable operation of production equipment is the cornerstone supporting the sustainable development of enterprises, and the sustainable development goals provide strategic direction for equipment operation control. With the continuous advancement of large-scale equipment networking, real-time data interaction, and the integration of intelligent algorithms, enterprises’ dependence on equipment operations has significantly increased. Equipment is not only a single executive tool but also a key hub that collaborates with production lines, connects with systems, and links resources. However, this evolution has also brought unprecedented management challenges: the diversity of equipment types, complexity of system interfaces, and rapid changes in status have made the equipment operation process highly dynamic and uncertain. Against the backdrop of the national initiative to promote large-scale equipment renewal and intelligent transformation, achieving high-quality operation and control of production equipment with “visibility, controllability, and optimizability” has become an urgent task for manufacturing enterprises to ensure stable production lines and improve operational performance. Therefore, constructing an analytical framework oriented toward the industrial internet environment and capable of identifying multiple influencing factors of production equipment operation and control performance is highly important for guiding enterprises to improve equipment management and control performance.

Currently, research on the operation and control performance of production equipment in the industrial internet environment has made certain progress. Many scholars, from the perspective of engineering practice, have explored ways to improve overall equipment efficiency through intelligent technologies and operation and maintenance optimization methods. For example, Singh et al. (2023) used machine learning algorithms to predict the remaining useful life of equipment, reducing the average repair time for production equipment failures and thereby improving the overall equipment efficiency [1]. Yu et al. (2025) enhanced the operation, management, and control performance of production equipment by integrating parallel equipment scheduling with intra- and interprocess constraints [2]. Other studies have analyzed equipment performance management and control paths via the structural equation model (SEM) method. Li (2019) used SEM to analyze the positive influence relationship between equipment management capabilities and equipment performance [3]. However, most existing studies treat influencing factors as isolated variables and rely on linear models, such as regression analysis and causal inference. They ignore the complexity of multi-factor linkage, complementarity, and non-linear interaction in real-world management, making it difficult to identify multiple equivalent paths where “different combinations of conditions can achieve the same result” and fail to meet the practical needs of enterprises for diversified performance improvement solutions in practice.

On the basis of the aforementioned research gaps, this study draws on existing achievements and considers the intelligent manufacturing production equipment of manufacturing enterprises in the industrial internet environment as the research object. It collects equipment operation data from 82 manufacturing enterprises, focuses on the three core dimensions of asset management, application management, and maintenance management, and constructs an equipment operation and control evaluation system that covers eight key indicators. These indicators include the utilization rate of production equipment assets, the production equipment load rate, the comprehensive energy consumption per unit output value, and the average repair time for production equipment failure. Furthermore, by adopting the fuzzy-set qualitative comparative analysis (fsQCA) method, this study identifies three main configurations for high equipment performance: the “high-pressure output type” driven by high-load collaboration, the “lean management and control type” emphasizing precise matching and response efficiency, and the “stable operation type” focusing on preventive maintenance and energy efficiency optimization.

This study overcomes the explanatory limitations of traditional linear methods, clarifies the equivalent paths to achieve high performance in production equipment operation and control under the interaction of multiple factors, and reveals the mechanism by which different combinations of indicators affect the performance of equipment operation and control. In addition, taking the manufacturing workshop of aero-engine transmission units as an example, this study demonstrates the operability and effectiveness of the proposed strategies in actual industrial scenarios. The research results provide new ideas and methodological guidance for enterprise managers to improve the performance of production equipment operations and controls in the industrial internet environment, which helps to enhance the sustainable development capability of manufacturing enterprises.

2. Literature Review

2.1. Operation and Control Performance of Production Equipment

Against the backdrop of intense global competition, manufacturing enterprises are striving to enhance and optimize their production efficiency to maintain their competitiveness. By defining performance measurement indicators, enterprise managers can grasp their management level, thereby optimizing management capabilities and bringing products to the market at the lowest cost. As core assets in the manufacturing industry, the operation and control performance of production equipment are directly related to an enterprise’s production efficiency, product quality, and cost control. In this context, manufacturing enterprises generally carry out new models and applications based on industrial internet platforms, such as digital management [4], intelligent manufacturing [5], personalized customization [6], and service-oriented extension [7], to achieve ubiquitous connections, dynamic control, and capability sharing of production equipment. Currently, extensive research has been conducted at home and abroad on evaluation indicators for the operation and control performance of production equipment.

Nakajima (1988) proposed the concept of total productive maintenance (TPM) in the 1980s, which provides a comprehensive quantitative indicator for measuring the operation and control performance of equipment in factories, namely, overall equipment efficiency (OEE) [8]. In addition, relevant standards define quantitative indicators for different types of equipment operations and control activities. The IEC 62264 series standards [9,10] specify the main activities and activity models of production operation management, maintenance operation management, quality operation management, and inventory operation management and list the corresponding performance analysis indicators. However, the IEC 62264 series standards do not provide a clear performance evaluation indicator system. On the basis of its extensive engineering practice experience in the discrete manufacturing industry, the German Mechanical Engineering Industry Association (VDMA) systematically constructed a manufacturing execution management evaluation indicator system containing 22 key performance indicators. Subsequently, led by the VDMA, the International Organization for Standardization (ISO) developed the ISO 22400 series standard [11]. On the basis of the 22 key indicators, an indicator set consisting of 34 indicators (employee work efficiency, productivity, overall equipment efficiency, rework rate, and mean time between failures) was established from four aspects: production operation management, maintenance operation management, quality operation management, and inventory operation management. The national standard GB/T 23023-2022 Integration of Informatization and Industrialization Management Systems—Indicator Set for Production Equipment Operation Performance Evaluation [12] constructs an evaluation indicator system for production equipment operation performance from dimensions such as basic support, operation management, maintenance, and benefit output. This system includes 14 indicators in four categories: production operation, maintenance, energy and material, and safety and environmental protection. It explains the calculation methods and optimization improvement measures for each category of indicators.

Although existing indicator systems (such as the TPM and ISO 22400) have certain guiding values, there are significant differences in their applicable scenarios and goal orientations. For example, the TPM places greater emphasis on full-staff participation in maintenance and the construction of a production system with “zero failures, zero defects, and zero accidents.” However, the ISO 22400 system has a complex structure and does not clarify the logical relationships between indicators. Most studies fail to explain the resource conditions under which the indicator systems they adopt are more effective, which weakens their guiding value for enterprise practice. It is difficult for enterprise managers to identify the key factors influencing equipment operation and control performance by using many evaluation indicators. Therefore, this study introduced the fsQCA method and constructed a multidimensional analysis framework for equipment operation and control performance. This framework breaks the single-cause, single-effect thinking of traditional research, systematically and scientifically analyzes the key factors affecting the operation and control performance of production equipment in manufacturing enterprises, and expands the research perspective under complex causal relationships.

2.2. Capability–Performance Relationship

The operation and control performance of production equipment is determined mainly by the production equipment operation and control capability of manufacturing enterprises. Thus, this relationship is abstracted into research on the “capability–performance” nexus. Guangyu et al. analyzed the positive impact of enterprises’ marketing capabilities and production operation capabilities on corporate performance [13]. Li Ting et al. (2025) categorized green innovation into green management innovation and green technology innovation [14]. On the basis of data from Chinese listed companies from 2008 to 2022, they analyzed the mechanism through which different types of green innovation affect enterprises’ short-term and long-term performance. Zhao et al. (2025) introduced institutional entrepreneurship theory into the field of digital transformation and used enterprise survey data to analyze the impact of digital leadership on enterprises’ digital transformation performance [15]. Yu et al. (2024) incorporated big data capabilities (as a mediating variable) and organizational structure flexibility (as a moderating variable) to construct a research framework for the process mechanism through which digital innovation network embedding influences the new product development performance of manufacturing enterprises [16]. On the basis of data from 559 manufacturing enterprises in South China, they verified that moderate structural embedding and relational embedding of digital innovation networks can promote improvements in the new product development performance of manufacturing enterprises. However, there remains a lack of systematic theoretical construction regarding the relationship between equipment operation and control capabilities and their corresponding performance. Most existing studies rely on methods such as structural equation modeling (SEM), which assumes linear causal paths and overlooks the complexity of nonlinear interactions among multiple conditional factors in real-world scenarios. Li (2019) classified equipment management capabilities into equipment management strategic capabilities, organizational process capabilities, personnel capabilities, and IT infrastructure capabilities and empirically verified the positive impact of equipment management capabilities on equipment performance [3]. Nevertheless, this study failed to identify more specific influencing factors of production equipment operation and control, making it difficult to directly guide enterprises to effectively improve equipment operation and control performance. In contrast, the fsQCA method is more suitable for revealing multi-factor concurrency and equivalent paths, and the application of this research paradigm in equipment operation and control remains unexplored, warranting an in-depth investigation.

In summary, the operation and control performance of production equipment are influenced by multiple dimensions, including asset management, application management, and maintenance management. These dimensions are not mutually independent, and their interactive combinations play a more decisive role in determining management and control effectiveness. Under such a complex causal mechanism, traditional linear models struggle to identify complementary and alternative paths among the conditions. On the basis of capability–performance theory, this study proposes treating eight key indicators as conditional variables and adopting the fsQCA method to identify multiple equivalent configuration paths for achieving high performance. This approach expands the understanding of the asymmetric causal mechanism between the “capability structure and performance outcomes.” Although fsQCA has begun to be applied in fields such as digital transformation [17], supply chain management [18], and innovation performance [19], research on its application in the field of production equipment management and control in the industrial internet environment remains scarce. In particular, in terms of identifying performance improvement paths, mainstream studies still tend to use methods such as SEM, which presupposes linear independence among variables while ignoring the highly coupled and multi-occurring characteristics of real-world manufacturing scenarios. Therefore, as a method for identifying “multicause combination–outcome” paths to address causal complexity, fsQCA has significant research potential and theoretical breakthrough value in this field, and this study attempts to fill this research gap.

2.3. Operation and Control of Production Equipment in the Industrial Internet Environment

In recent years, emerging technologies such as artificial intelligence (AI), edge computing, and big data analytics have been widely applied in equipment operation and control. In the industrial internet environment, interactions between underlying production equipment and upper-level management and control systems have become increasingly frequent and intensive, leading to production equipment operation and control characterized by high interconnectivity, abundant data, and complex logic. In recent years, researchers have begun exploring methods to improve equipment operation and control performance from various perspectives, such as deep learning algorithms, data visibility, and predictive maintenance. For example, Song et al. (2025) used deep learning algorithms to predict equipment failures, thereby enhancing equipment reliability, production equipment reliability, and the utilization rate of production equipment assets [20]. The Hu HX team (2023) employed deep generative models for the fault diagnosis of rolling bearings, enabling the rapid identification of fault types and thus reducing the average repair time for production equipment failures [21]. Liu et al. (2024) constructed an assembly workshop model based on digital twin technology, identified production anomalies through simulation and quickly adjusted equipment production plans to improve the production equipment load rate and the process capability index of production equipment [22]. Huang et al. (2024) proposed an energy-saving control strategy for machine tools considering component priority under multiple dormant states, significantly reducing the comprehensive energy consumption per unit output value of the equipment [23]. These studies demonstrate a new paradigm that integrates data-driven, model-driven, and expert knowledge approaches, marking a transition in equipment operation and control from passive response to intelligent perception and proactive prediction.

With the widespread application of next-generation information technologies such as AI, the Internet of Things (IoT), and big data, the number of factors directly or indirectly influencing the operation and control performance of production equipment has increased, including but not limited to, the cloud-integrated application of equipment, the comprehensive energy consumption level of equipment, the duration of equipment fault repair, and the utilization efficiency of equipment assets. However, among these numerous and complex influencing factors, accurately identifying the key elements that play decisive roles in equipment operation and control performance outcomes is difficult. Furthermore, their internal mechanisms and interaction paths remain unclear, which restricts the optimization and improvement of the efficiency and effectiveness of the operation and control of production equipment. Currently, both academia and industry focus primarily on constructing performance indicator systems for production equipment [24,25] and extensively analyze the impact of individual variables on equipment operation and control performance outcomes. Although these analytical approaches can identify key influencing factors, they overlook the intertwined impacts of complex factors, such as different production models, management strategies, and operating environments. As a result, they failed to clarify the interaction effects among various factors and the mechanism through which these factors influence the efficiency and effectiveness of equipment operation and control. By integrating the fsQCA method, this study is the first to incorporate key performance indicators from three aspects—asset management, application management, and maintenance management—into fsQCA. It systematically explores multiple equivalent paths to achieve high performance, providing path exploration to solve the problem of improving production equipment operation and control performance in industrial internet scenarios.

3. Framework for Evaluating the Operation and Control Performance of Production Equipment

This study focuses on key production equipment with high automation, perception capabilities, and integration into industrial internet platforms. Such equipment is widely used in industries such as aerospace, automotive, and electronics manufacturing—industries characterized by complex process routes, high-precision control requirements, and multisensor information flow during operation. In the industrial internet environment, this equipment faces management challenges, including high real-time requirements, significant fluctuations in the operational load, and complex equipment status monitoring. It is particularly necessary to ensure operational performance by coordinating systematic asset allocation, process scheduling, and predictive maintenance.

Starting with relevant authoritative standards and reference architectures in the field of equipment operation and control, this study first develops an analytical framework for equipment operation and control business activities and then identifies business functions that directly affect equipment operation and control performance. On this basis, an analytical framework for evaluating the operation and control performance of production equipment is constructed on the basis of the logic of “influencing factors-results-action paths.” Specifically, by summarizing relevant authoritative standards at home and abroad, the business activities that affect equipment operation and control performance are analyzed, and the relevant influencing factors are summarized for various types of business activities. The key factor sets that affect the operation and control performance results of production equipment are identified through configuration analysis. From the perspective of the interaction between various factors, the action paths of the influencing factor sets on equipment operation and control performance are deeply analyzed, and the key strategies for enterprises to improve the operation and control performance of production equipment under different paths are refined and formed.

3.1. Classification of Business Activities for Production Equipment Operation and Control

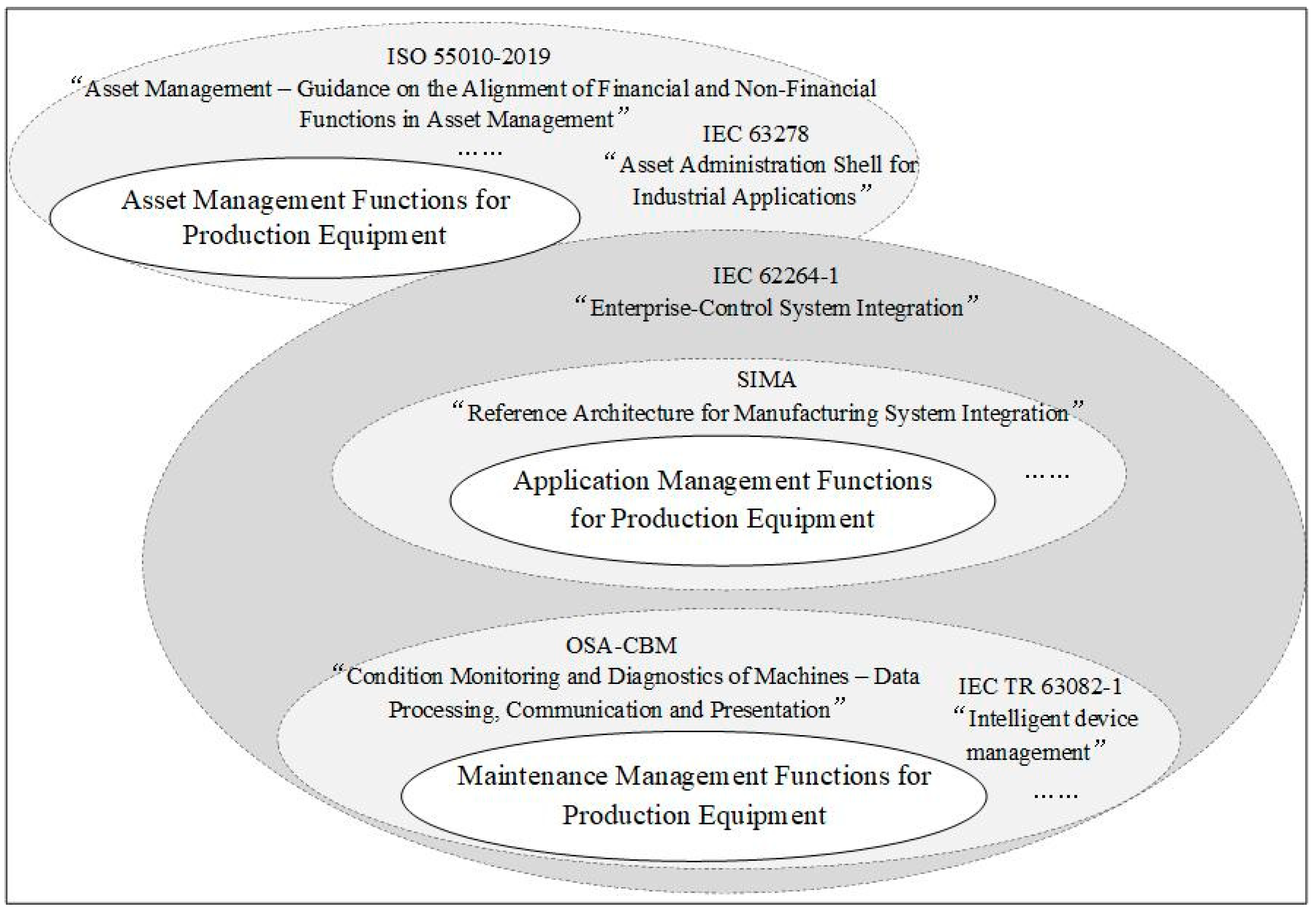

Currently, existing models, such as Total Productive Maintenance (TPM) [12] and Reliability, Availability, Maintainability, Safety (RAMS) [26], mainly focus on equipment maintenance management activities, making it difficult to support the analysis of equipment operation and control business functions and performance research in the industrial internet environment. Therefore, this study summarizes international standards and reference architectures related to production equipment operation and control worldwide and constructs a classification framework for business activities related to equipment operation and control. The relevant international standards or reference architectures can be divided into three main categories, as detailed below (see Figure 1).

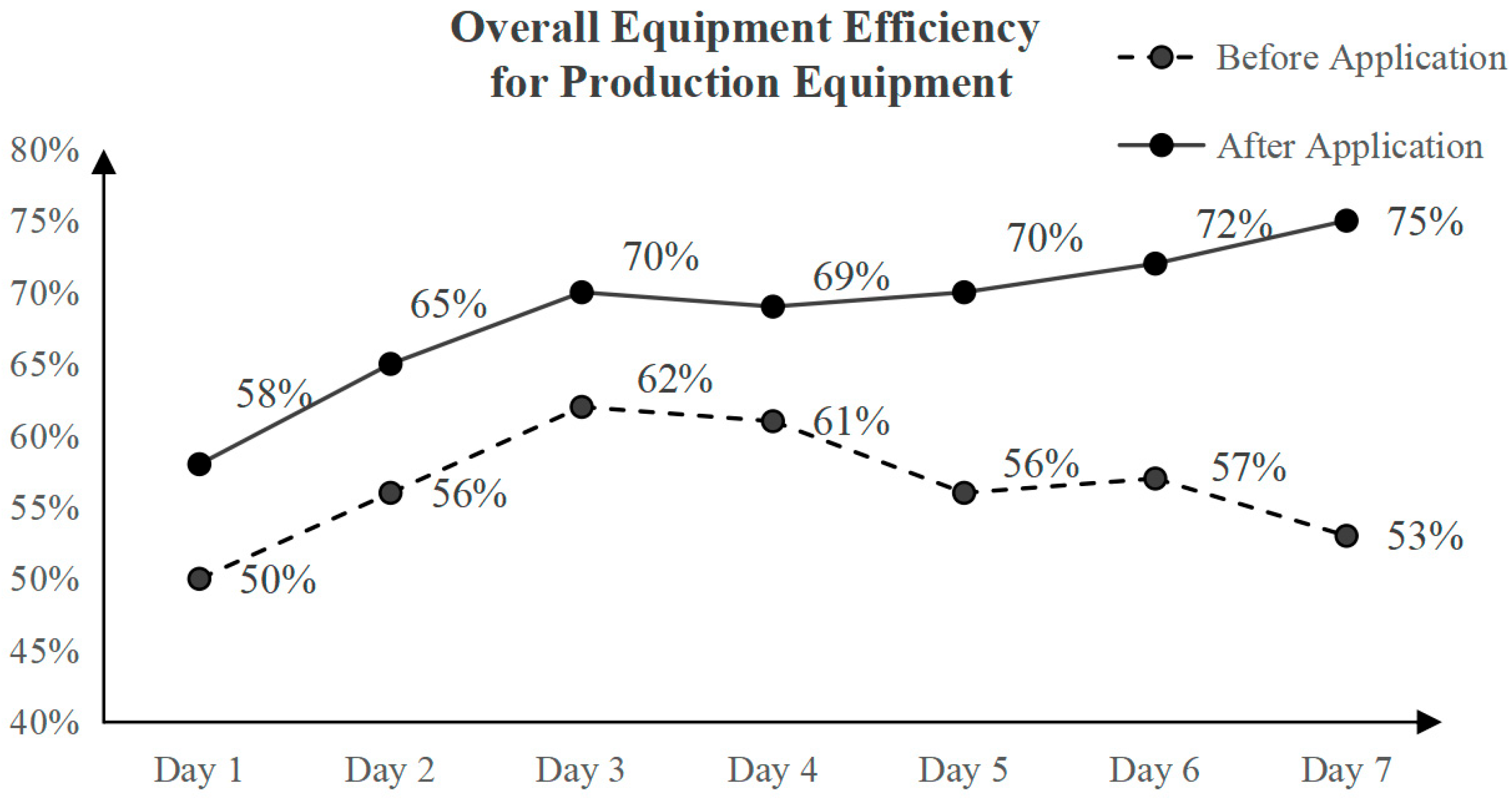

Figure 1.

Standard-based classification of business activities for production equipment operation and control.

The first category places greater emphasis on asset value management of production equipment. For example, international standards such as the IEC 63278 Asset Administration Shell for Industrial Applications [27], ISO 55001 Asset Management—Overview, Principles, and Terminology [28], and ISO 55010 Asset Management—Guidance on the Alignment of Financial and Non-Financial Functions in Asset Management Activities [29] provide specifications for business activities related to production equipment asset management.

The second category focuses primarily on the application management of production equipment manufacturing capabilities, involving the scheduling, assignment, and execution of tasks on the basis of production equipment. Typical international standards include IEC 62264 enterprise control system integration [30], IEC 61512 batch control [31], and SIMA (Reference Architecture for Manufacturing System Integration) [32]. These international standards and reference architectures specify business activities related to production equipment application management.

The third category concentrates on the maintenance management of the production equipment’s own structure, which is also a key task for equipment-related managers in current manufacturing enterprises, that is, ensuring the normal and efficient operation of equipment. Examples of relevant international standards include IEC 62264 Enterprise-Control System Integration [9,10], IDM (IEC TR 63082-1 Intelligent Device Management) [33], and OSA-CBM (ISO 13374 Condition Monitoring and Diagnostics of Machines, Data Processing, Communication and Presentation) [34]. These standards provide specifications for business activities related to the maintenance of production equipment.

3.2. Theoretical Model Construction

In the total productive maintenance (TPM) model, the overall equipment efficiency (OEE), the comprehensive performance evaluation indicator for production equipment operation and control, considers three dimensions: the equipment availability rate, performance efficiency, and quality rate. It can fully and accurately reflect the operation and control level of production equipment and support the continuous monitoring, optimization, and improvement of production equipment operation and control performance. Therefore, this study selects “overall equipment efficiency” as the outcome variable for evaluating production equipment operation and control performance.

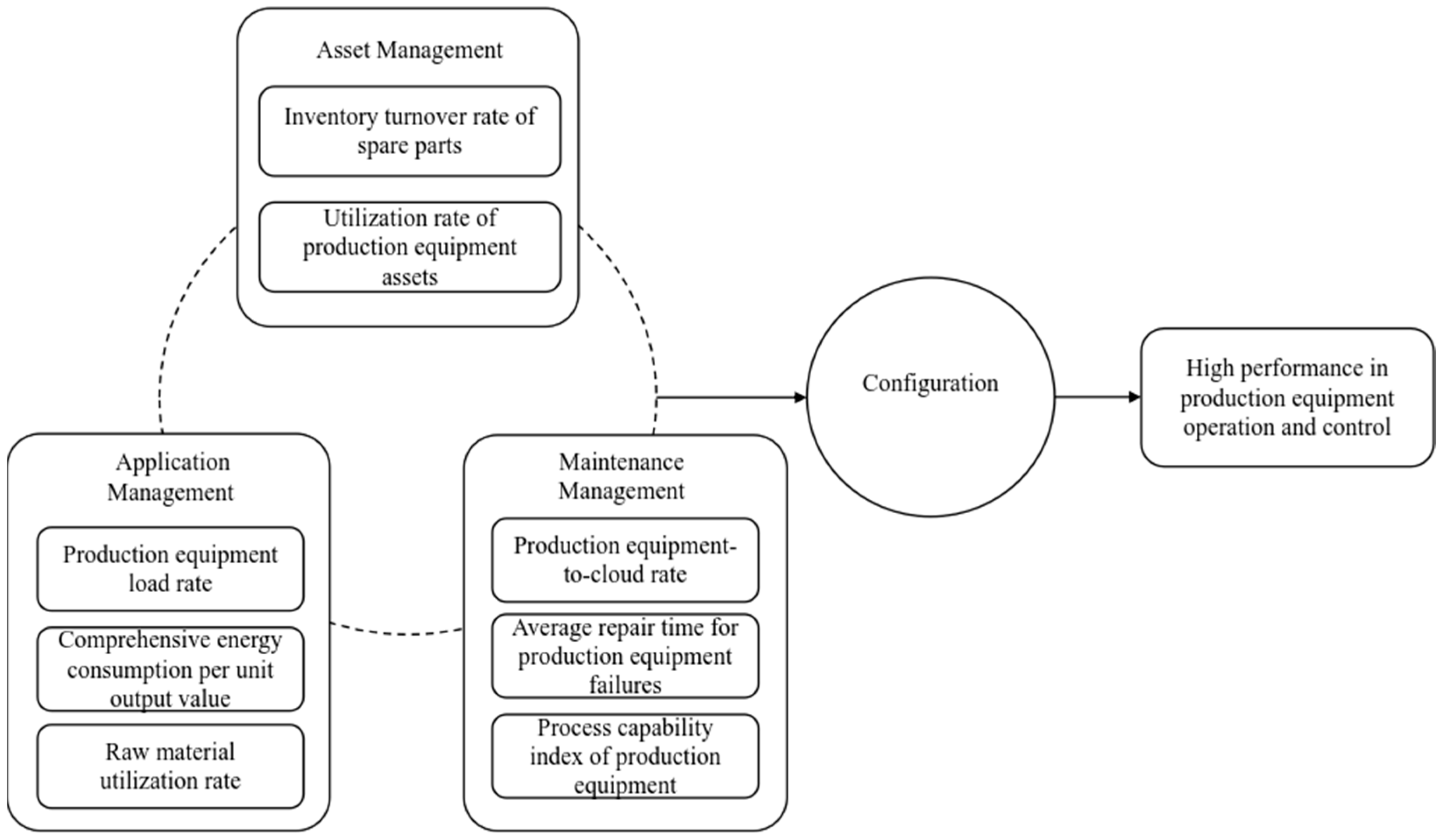

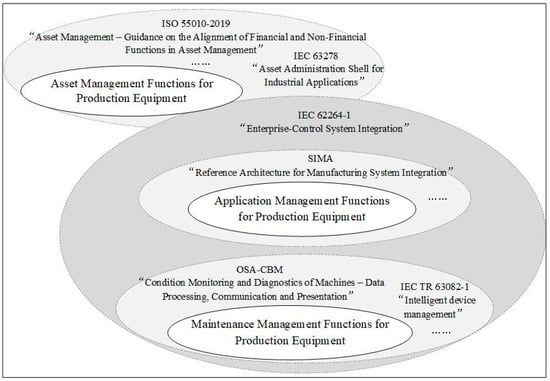

To define the boundary of production equipment operation and control and clarify the mechanism of action between elements, this study constructs a conceptual model in which assets, applications, and maintenance management synergistically influence equipment performance (see Figure 2). The details are as follows.

Figure 2.

Theoretical model of the factors influencing production equipment operation and control performance.

Equipment asset management: This is primarily carried out by equipment managers and involves activities such as registration, transfer, maintenance, loans, commissioning, decommissioning, and disposal of equipment assets. These activities support equipment maintenance and application management.

Equipment maintenance management: This is implemented mainly by equipment maintenance personnel; it includes daily maintenance, periodic maintenance, predictive maintenance, and emergency maintenance of equipment. It leverages services provided by asset management activities to ensure the normal operation of application management activities.

Equipment application management: Equipment operators primarily operate equipment for manufacturing production. It relies on the services provided by asset management activities and invokes supportive auxiliary services from maintenance management.

Asset management focuses on value acquisition and resource allocation throughout the equipment lifecycle, application management centers on the actual operational efficiency of equipment and its resource conversion capability, and maintenance management is responsible for condition diagnosis, abnormal response, and extension of service life. Through the dynamic coupling of the “configuration-utilization-guarantee” closed-loop process, the three dimensions synergistically determine the operational performance of equipment and serve as conditional variables influencing the overall equipment efficiency of production equipment.

3.2.1. Asset Management

In terms of production equipment asset management, with reference to international and national standards such as IEC 63278-1:2023 Asset Administration Shell for Industrial Applications-Part 1: Structure of the Asset Administration Shell [27] and GB/T 33173-2016 Asset Management-Management Systems-Requirements [35], and considering the role of humans in processes including equipment asset planning, asset tracking, and scrap disposal, the “utilization rate of production equipment assets” and “inventory turnover rate of spare parts” are selected as conditional variables to measure the level of production equipment asset management.

The utilization rate of production equipment assets, as a core indicator for measuring the degree of matching between the actual usage capacity of assets and potential production capacity, serves as a key factor for the efficient operation of the asset management system. This reflects the efficiency of allocation of an enterprise’s equipment resources. These changes affect operational performance through two core mechanisms. First, increasing the equipment output and operating rate directly increases the output value per unit time. Second, reducing resource idleness and redundant investment indirectly optimizes the cost structure and maintenance load. An excessively high utilization rate may lead to overloaded operations and increased failure risks, whereas excessively low utilization rates indicate an imbalance in asset allocation, which impairs the input–output ratio of equipment [36]. Therefore, this indicator is set as a core condition in the fsQCA model, not only on the basis of its widespread role as a cost and efficiency measurement factor in existing research but also on its characteristic of exhibiting nonlinear interaction effects on management and control performance.

The inventory turnover rate of spare parts is a core indicator that reflects the liquidity of an enterprise’s spare part assets and the efficiency of capital utilization, which represents the dynamic turnover level of spare part resources from procurement and storage to usage. In asset management practice, this indicator affects equipment operational performance through two main mechanisms. First, improving the response speed of spare parts enhances maintenance support capabilities and shortens the downtime caused by failures. Second, reducing the inventory scale lowers warehousing and capital occupation costs, thereby optimizing the inventory structure [37]. There are two-way risk boundaries for the turnover rate level: an excessively low turnover rate is often accompanied by a backlog of slow-moving inventory, resulting in resource waste and capital immobilization; in contrast, an excessively high turnover rate may indicate insufficient safety stock, which increases the operational risk of “production shutdown due to material shortage” and reveals a structural mismatch between inventory allocation and maintenance rhythm. Therefore, in the analysis of equipment operation management and control performance, setting the inventory turnover rate of spare parts as a core condition has clear management value and a theoretical basis. On the one hand, this indicator runs through the whole-life cycle management of spare parts and balances the dual goals of “support” and “control”; on the other hand, it exhibits significant non-linear interaction effects with other capability elements in scenarios such as digital inventory management and predictive maintenance.

3.2.2. Application Management

In terms of production equipment application management, with reference to national standards such as GB/T 20720.3-2010 Enterprise-Control System Integration-Part 3: Activity Models of Manufacturing Operations Management [38], GB/T 29116-2012 General Rules for Calculation of Raw Material Consumption in Industrial Enterprises [39], and GB/T 2589-2020 General Rules for Calculation of Comprehensive Energy Consumption [40], and considering the role of humans in equipment operation and product manufacturing processes, “Production equipment load rate”, “Raw material utilization rate”, and “Comprehensive energy consumption per unit output value” are selected as conditional variables to measure the level of production equipment application management.

The production equipment load rate (PELR) is a critical indicator for measuring the matching degree between the actual load of the equipment and its theoretical design load, reflecting the capacity utilization intensity of the equipment within a unit time [41]. As a core regulatory parameter in equipment application management, the load rate embodies the operational status of the equipment in terms of resource allocation, scheduling arrangement, and capacity release. These changes have a direct impact on equipment operational performance: a relatively low load rate usually indicates equipment idleness and capacity waste, exposing the imbalance between production planning and resource allocation; conversely, an excessively high or continuously overloaded rate may lead to equipment overoperation, intensified wear and tear, increased failure probability, and increased maintenance and downtime costs. During the application management process, changes in the load rate prompt enterprises to dynamically adjust their management strategies—for instance, by optimizing order coordination, process allocation, or the pace of preventive maintenance—to maintain the efficiency and stability of equipment operation. Therefore, there is a sufficient basis for designating the load rate as a key condition in the fsQCA model. On the one hand, it directly characterizes the dynamic balance between equipment operational efficiency and system load, enabling the capture of the effectiveness of organizational scheduling capabilities; on the other hand, this indicator exhibits significant complementary and substitutive relationships with other capability elements, facilitating the identification of multipath coexisting models for equipment performance improvement.

The raw material utilization rate (RMUR) is deeply integrated into the equipment application management system through the equipment–material adaptation relationship, and its level directly reflects the collaborative efficiency of equipment operation and production processes. As a key parameter in equipment application management, this indicator is deeply embedded in the dynamic coupling relationship between the equipment and material systems, influencing both output efficiency and restricting operational stability [42]. From the perspective of the mechanism of action, a low raw material utilization rate usually stems from issues such as insufficient equipment precision, deviation of operating parameters from process standards, or improper operation, which leads to increased material waste, higher raw material consumption per unit product, and further triggers the risks of cost control failure and production interruption. These issues often drive enterprises to adopt interventions and optimizations such as equipment debugging, parameter calibration, and operational training. The raw material utilization rate is also related to the collaborative efficiency of equipment and supply chain systems; its decline often signals an imbalance between raw material allocation and consumption rhythm, thereby promoting the management system to redesign processes among planning, procurement, and application. Therefore, the raw material utilization rate is an intuitive reflection of the quality of equipment process execution, embodying the ability to use material resources accurately. It has significant interactive influences on factors such as equipment load and maintenance frequency, contributing to the identification of composite paths for improving the operational performance of equipment. There is sufficient rationality for setting this as a core condition in the fsQCA model.

The comprehensive energy consumption per unit output value (CEC/UV) is a composite indicator for measuring the energy consumed by equipment in the process of creating unit economic output, which centrally reflects the energy efficiency level and value-creation capacity of equipment. In the equipment application management system empowered by the Industrial internet, this indicator serves not only as an important tool for operational cost optimization but also as a core guiding variable for driving intelligent energy consumption governance. Relatively high energy consumption often indicates problems such as equipment aging, unreasonable operating parameters, or prolonged idling, pushing management strategies to focus on energy-saving transformation, intelligent monitoring deployment, and operational process optimization. On the basis of real-time tracking of energy consumption data, it is possible to implement time-phased energy management and dynamic load adjustment, thereby improving the allocation efficiency and response flexibility of energy resources [43]. The optimization of the unit energy consumption indicator can not only directly reduce the energy consumption cost per unit output value and improve the financial performance of enterprises but also indirectly enhance equipment energy efficiency, reduce failure probability, extend service life, and further strengthen the stability and predictability of equipment operation. Therefore, this indicator has dual functions of cost control and risk management and exhibits significant configuration interactions with elements such as equipment scheduling and maintenance strategies, making it an important path variable for explaining performance heterogeneity.

3.2.3. Maintenance Management

In terms of production equipment maintenance management, with reference to international and national standards such as IEC 63082-1 Smart Device Management-Part 1: Concepts and Definitions [33] and GB/T 40571-2021 Smart Services-Predictive Maintenance-General Requirements [44], human behaviors (including equipment repair, maintenance, and patrol inspection) during the equipment maintenance process, production equipment-to-cloud rate, process capability index of production equipment, and average repair time for production equipment failures were selected as conditional variables to measure the level of production equipment maintenance management.

The production equipment-to-cloud rate is a key indicator for measuring an enterprise’s ability to connect equipment to cloud platforms for real-time monitoring, remote operation, and maintenance in the industrial internet environment. It represents the evolution of the equipment maintenance management model from a “passive response” to a “proactive prediction”. A relatively high equipment-to-cloud rate means that the operating status of more equipment can be monitored in real time, and cloud platforms can identify potential anomalies through data mining and fault modeling, thereby providing support for condition-driven predictive maintenance and reducing the probability of unplanned downtime and sudden maintenance costs. Relying on the cross-organizational data-sharing capability of cloud platforms, unified scheduling of maintenance resources and collaborative configuration of spare parts can be realized, improving the efficiency of cross-regional technical response and the accuracy of maintenance decision-making. This data-driven upgrading path for maintenance management can fundamentally improve the stability, continuity, and availability of equipment operations [45]. Particularly in equipment-intensive manufacturing scenarios, improving the equipment-to-cloud rate can simultaneously achieve visualization of the equipment management process, advance early warning mechanisms, and refine performance control. Therefore, designating the equipment-to-cloud rate as a core condition in the fsQCA model not only reflects its practical necessity as the fundamental support for modern maintenance capabilities but also aligns with its characteristic of interactive synergy with other capability elements, endowing it with significant capabilities in configuration identification and path differentiation.

The process capability index of production equipment (CPK) is a core indicator for measuring an equipment’s ability to continuously produce qualified products under given process conditions, reflecting the comprehensive level of equipment operation stability and process parameter adaptability. Within the equipment maintenance management system, CPK serves as a critical signal variable for quality control and equipment efficiency evaluation, directly guiding the precision of management strategies [46]. Its mechanism of action is as follows. A low CPK usually indicates severe accuracy deviation or process variation in the equipment, which may be caused by mechanical wear, parameter drift, or aging of the control system. In-depth interventions, such as equipment calibration, replacement of key components, and resetting of process parameters, are needed in such cases. The optimization of CPK can not only improve output quality by reducing product defect rates and rework costs but also support production continuity and cycle balance by enhancing process stability. Additionally, dynamic monitoring based on CPK can serve as a feedback tool for the effectiveness of maintenance strategies, forming a closed-loop mechanism of “monitoring-intervention-evaluation” to facilitate the continuous improvement of equipment efficiency. Therefore, in the fsQCA path analysis, CPK is reasonably qualified as a core condition, as it can reveal the key role of equipment quality control capabilities and maintenance response mechanisms in the performance configuration.

The average repair time for production equipment failures (MTTR) is a core indicator for measuring the time required for equipment to recover from failure to normal operation (from diagnosis to restoration), reflecting the response speed and execution efficiency of an enterprise’s maintenance system [47]. In maintenance management practice, MTTR is not only an intuitive reflection of the efficiency of operation and maintenance processes but also a key basis for evaluating an organization’s emergency response capabilities and resource coordination capabilities. A relatively high MTTR often reveals management shortcomings, such as insufficient fault diagnosis capabilities, inadequate spare part support, or inefficient organization of maintenance processes. This prompts enterprises to optimize operation and maintenance processes, for example, by introducing intelligent work order systems, establishing data-based spare part early warning mechanisms, and strengthening the training and multiskill allocation of maintenance personnel. Conversely, effectively reducing the MTTR can significantly reduce equipment downtime, alleviate production capacity fluctuations, and improve the overall availability and operational continuity of equipment. Moreover, analysis based on MTTR data can identify key equipment with high maintenance frequency and high repair difficulty, assisting decision makers in allocating resources, optimizing personnel configurations, and upgrading equipment. This forms a maintenance resource allocation mechanism centered on efficiency-driven principles. Therefore, setting the MTTR as a core condition in the fsQCA model has sufficient theoretical and practical justification; it is not only a quantitative expression of fault recovery capabilities but also a key mediating variable connecting maintenance process quality and equipment performance, capable of revealing the functional modes of different maintenance management configurations in performance improvement paths.

In summary, on the basis of the dynamic coupling of the “configuration-utilization-guarantee” closed-loop process, this study focuses on three types of business activities (production equipment asset management, application management, and maintenance management) and identifies eight performance indicators across three categories. These indicators serve as important conditional variables influencing the overall equipment efficiency (OEE) of production equipment, and a theoretical model of the influencing factors for production equipment operation and control performance was constructed (see Figure 2).

4. Research Design

4.1. Research Method

Fuzzy-set qualitative comparative analysis (fsQCA) is an empirical research method based on set theory and configurational thinking. It combines qualitative and quantitative approaches to investigate multiple concurrent causal relationships between sets of influencing condition variables and a particular outcome variable from a holistic perspective. This method can identify multiple equivalent pathways leading to the same outcome. In recent years, fsQCA has been widely applied in performance evaluation and influencing factor studies. Therefore, this study employed fsQCA to explore the key influencing factors and configurational effects of integrated performance in production equipment operation management with the software fsqca (verson 4.1). The findings provide guidance for the functional combination and invocation of industrial internet platforms in various production equipment operation scenarios, thereby helping enterprises enhance their performance in production equipment operation management.

4.2. Sample Selection and Data Sources

The data collection in this study was primarily conducted via online questionnaires. As the indicators involve different internal departments of manufacturing enterprises, the respondents were required to be enterprise managers to ensure the accuracy of the performance data on production equipment operation management. The content of the questionnaire mainly includes performance data on production equipment operation management in manufacturing enterprises, covering specific values of indicators such as over all equipment efficiency, the utilization rate of production equipment assets, the inventory turnover rate of spare parts, the production equipment load rate, the raw material utilization rate, comprehensive energy consumption per unit output value, the production equipment-to-cloud rate, the average repair time for production equipment failure, and the process capability index of production equipment. On this basis, the research team distributed questionnaires point-to-point to manufacturing enterprises in equipment-intensive industries in May 2024 and collected their performance data for 2023. A total of 85 questionnaires were distributed and recovered. After incomplete and homogeneous responses were excluded, 82 valid responses were obtained, yielding an effective response rate of approximately 96.47%. The sample size was in the medium range and met the requirements of the fsQCA. The 82 sample enterprises were from industries such as aerospace, automotive, rail transit, and electronics. Their operational management performance data covered 125 factories/workshops and 85,673 units of production equipment, including CNC machine tools, robots, inspection equipment, stamping equipment, and other types of manufacturing equipment. Therefore, the sample has strong representativeness. The sample distributions of the 82 manufacturing enterprises are presented in Table 1.

Table 1.

Distribution of 82 manufacturing enterprise samples.

On the basis of the performance evaluation framework of production equipment operation management provided in Figure 1, this study conducted a statistical analysis of 2023 performance sample data from 82 manufacturing enterprises. The results are presented in Table 2.

Table 2.

Statistical results for sample data from 82 manufacturing enterprises.

4.3. Variable Definition and Calibration

4.3.1. Outcome Variable

This study adopted OEE as the outcome variable to represent the performance of production equipment operation management. The OEE of the production equipment during the statistical period was used as the evaluation criterion. The calculation formula is as follows:

where TOR denotes the time operation rate, POR denotes the performance operation rate, and OR denotes the quality rate during the statistical period. The calculation methods are as follows:

Here, OT is the actual operating time of the equipment, LT is the planned load time, NOT is the effective running time, QP is the number of qualified products produced, and PQ is the total number of products produced during the statistical period.

4.3.2. Condition Variables

A total of eight indicators, including the production equipment asset utilization rate, spare parts inventory turnover rate, production equipment load rate, raw material utilization rate, comprehensive energy consumption of unit output value, production equipment cloud adoption rate, average repair time for production equipment failures, and production equipment process capability index, are selected as the set of conditional variables for production equipment operation control, denoted as . The main focus is to analyze the degree of influence and mechanism of various combinations of these conditional variables on the performance result variable OEE of production equipment operation control, as detailed in Table 3.

Table 3.

Definition and measurement of the condition variables.

4.3.3. Condition Calibration

As described above, this study involved one outcome variable and eight condition variables with inconsistent dimensions. Therefore, dimensionless processing was applied to the data. Because there is no established reference for fuzzy membership, this study applies the direct calibration method by setting three anchor points for fuzzy membership: full membership (75%), crossover points (50%), and full non-membership (25%). The calibration anchors are listed in Table 4.

Table 4.

Calibration anchors for outcome and condition variables.

5. Data Analysis

5.1. Necessity Analysis of Single-Condition Variables

On the basis of the definition and calibration of the condition and outcome variables, this study employs consistency and coverage indicators to analyze the necessity of each condition variable for the outcome. If the consistency score is greater than 0.9, with relatively high coverage, the condition can be considered to significantly influence the performance of production equipment operation management with sufficient sample support. If the consistency is greater than 0.9 but the coverage is low, the condition variable is still necessary, but with limited sample representation, further exploration of its mechanisms is needed in subsequent studies. Conversely, if the consistency is less than 0.9, the association between the condition and the outcome is considered weak, and the interaction effects among multiple condition variables need to be considered in the configurational analysis.

As shown in Table 5, none of the condition variables constitute a necessary condition for high production equipment operation management performance.

Table 5.

Results of the necessity analysis of variables related to the performance of production equipment operation control.

5.2. Sufficiency Analysis of the Configurations of Multiple Condition Variables

Sufficiency analysis uses consistency as the primary criterion. Following Ragin et al. [48], only when the consistency score of a configuration with respect to the outcome variable is ≥0.8 can it be identified as a sufficient condition. In this study, OEE was used as the outcome variable, with the raw consistency threshold set to 0.8, the PRI threshold set to 0.75, and the frequency threshold set to 1.

The results of the configurational analysis are listed in Table 6. Three configurations were found to lead to high performance in production equipment operation management, each with different condition variables. Overall, the intermediate solution yielded an overall consistency of 0.932 and a coverage of 0.516. At the individual configuration level, the consistency and raw coverage values of the three solutions satisfied the standard requirements for fsQCA [49].

Table 6.

Configuration results of operational control performance for high-production equipment.

5.3. Robustness Test

To ensure the accuracy of the research findings, the calibration thresholds for the non-crossover points were adjusted, the full membership threshold was set at 80%, and the full non-membership threshold was set at 20%. After adjustment, three configurations were obtained, which were largely consistent with the original results. This demonstrates that the research findings are robust (Table 7).

Table 7.

Results of the robustness test on the configuration of the operational control performance for high-production equipment.

5.4. Strategy Combinations for Improving Equipment Operation Management Performance

On the basis of the fsQCA results of the influencing factors, the three strategic configurations for enhancing enterprise performance in production equipment operation management can be summarized as follows:

5.4.1. Strategy 1: High-Load Output Mode—Task Allocation × Maintenance

Corresponding to Configuration 1 in Table 6, its core conditions are a high production equipment load rate and high production equipment process capability index, whereas the marginal conditions are a high asset utilization rate of production equipment, high raw material utilization rate, non-high comprehensive energy consumption per unit output, and non-high average repair time for production equipment failure. It focuses on the combined role of production equipment task management and maintenance function modules, which can significantly improve the overall efficiency of production equipment. This strategy indicates that enterprises achieve balanced equipment loads through scientific scheduling of task data and combine real-time adjustment of production takes to maximize the time utilization rate of equipment, avoiding equipment idleness or overload operation caused by uneven task allocation. Simultaneously, supplemented by high-level equipment repair, maintenance, and daily upkeep, the Internet of Things (IoT) and predictive analysis technology can be used to monitor key equipment parameters (such as vibration and temperature), accurately judge the equipment degradation trend, identify potential faults in advance, and automatically trigger maintenance tasks to reduce unplanned downtime. This not only avoids resource waste caused by excessive maintenance but also prevents a sudden drop in efficiency due to insufficient maintenance, ensuring that the equipment is in the best performance state to effectively achieve production task goals and high operational performance.

5.4.2. Strategy 2: Lean Management Mode—Task Allocation × Resource/Process Configuration × Fault Handling

Corresponding to Configuration 2 in Table 6, its core conditions are a high load rate of production equipment, a high raw material utilization rate, and a non-average repair time for production equipment failures. The marginal conditions are a high production equipment-to-cloud rate and non-high comprehensive energy consumption of the unit output value. It mainly focuses on the combined role of functional modules, such as production equipment task management, resource allocation, process management, and fault diagnosis, which can significantly improve the overall efficiency of production equipment. This strategy indicates that enterprises, through the precise alignment of production plans and equipment capacity, establish a full-process scheduling mechanism covering task decomposition, priority ranking, and load balancing to ensure that equipment undertakes production tasks that match its technical characteristics, thereby avoiding efficiency losses caused by task overload or type mismatch. Moreover, through the optimal combination of factors, such as human resources, materials, energy, and time, precise matching and dynamic supply of resources are carried out on the basis of equipment task requirements, avoiding shutdowns and waiting caused by material shortages, mismatched personnel skills, or unstable energy supplies. In addition, through the in-depth coupling of process parameters and equipment performance, operating specifications that meet equipment technical standards are formulated to improve equipment operating efficiency from the perspective of process optimization; reduce equipment idling, losses, or quality defects caused by unreasonable processes; and promptly handle abnormal equipment working conditions and potential faults to ensure stable equipment operating status and stable product performance and quality to achieve high production equipment operating performance.

5.4.3. Strategy 3: Low-Failure Operation Mode—Maintenance × Fault Handling

Corresponding to Configuration 3 in Table 6, its core conditions are a high process capability index of production equipment and a non-high average repair time for production equipment failures. The marginal conditions include a high inventory turnover rate of spare parts, a high load rate of production equipment, and a high production equipment-to-cloud rate. This approach focuses on the combined role of functional modules in production equipment maintenance, fault diagnosis, and condition monitoring, which can significantly improve the OEE of production equipment. This strategy indicates that enterprises, through methods such as connecting equipment to the cloud and platforms, can capture real-time parameter fluctuations and performance degradation signals during equipment operation; establish a dynamic database covering indicators such as rotational speed, load, and energy consumption; and provide real-time data support for equipment health assessment. On the basis of the condition monitoring data, an in-depth analysis of abnormal equipment states can be achieved through a combination of intelligent algorithms and expert knowledge bases. It can not only quickly identify current fault types (such as mechanical faults and electrical faults) but also predict the evolution path of potential faults. On the basis of the equipment operation cycle and condition monitoring data, differentiated maintenance plans were formulated to achieve a paradigm shift from “post-fault maintenance” to “proactive maintenance.” The fault data accumulated during the maintenance process are used to reverse feedback and optimize the condition monitoring model, forming a closed-loop feedback mechanism of “monitoring-diagnosis-maintenance-optimization.” By improving the effective operating rate of the production equipment, high production equipment operation performance can be achieved.

In summary, the three strategies offer enterprises different pathways to enhance production equipment operational management performance. Enterprise managers may choose strategies on the basis of their production models and management needs, with specific implementation in the following aspects:

- Optimization of management processes—refine task flows, activity sequences, and management modes according to strategy focus.

- Customization of management tools: In accordance with the equipment operation and management methods specified in the corresponding strategies and targeting specific business scenarios, the optimization of orchestration strategies and combined invocation of equipment operation management microservices at the industrial internet PaaS layer should be carried out in accordance with the technical route of “scenario external interface design—functional module extraction and combined arrangement—information model design—industrial APP development and deployment.” These microservices are then packaged to form customized APP tools, which are applied to specific equipment operation and management tasks.

- Performance regulation-monitor, assess, and improve key performance indicators corresponding to the core and peripheral condition variables.

6. Strategy Analysis and Case Validation for Improving Equipment Operation Management Performance

6.1. Problem Overview

The aero-engine transmission unit manufacturing workshop of a certain enterprise mainly engages in the processing of shaft gears for the engine transmission units. Originally, this workshop was operated in a traditional non-computer numerical control (CNC) environment, where some old equipment frequently malfunctioned, which not only resulted in low processing efficiency but also made it difficult to ensure the stability of product quality, significantly restricting the improvement of the overall equipment efficiency of the workshop. Facing the urgent need for industrial upgrading and efficiency innovation, the enterprise actively responded to the national strategic initiative of large-scale equipment renewal and introduced a batch of high-performance, high-value CNC equipment with multi-task machining functions to replace the original non-CNC equipment. This transformation is expected to reform the enterprise’s existing production equipment operation and management model and achieve improvements in both the overall equipment efficiency and the product quality of the workshop. After equipment renewal, the workshop is composed of a turning-milling unit, a gear profile machining unit, an internal grinding and surface grinding unit, an external grinding unit, a gear grinding unit, and other units.

In actual production, unexpected downtime frequently occurs in equipment such as five-axis vertical turning-milling machining centers and CNC gear hobbling machines. The analysis revealed that although these machines were equipped with intelligent functions, such as remote control, data transmission, and performance analysis, and even issued early warning signals before failure, the platform exhibited latency in receiving and responding to these warnings. Consequently, no timely measures were taken, leading to production line interruptions.

Although key performance indicators, such as the equipment load rate, raw material utilization rate, and cloud adoption rate, reached their preset targets, the OEE remained at approximately 55%, far below the preset goal of 70%. Further investigation of performance bottlenecks identified the following problems:

- The process capability index of production equipment does not meet expectations: the current process capability index of the workshop equipment is only 1.28, which indicates that the production equipment in this workshop has deficiencies in terms of the stability and consistency of processing performance.

- The fault early warning function of intelligent equipment has not been effectively utilized, and although the workshop is equipped with high-performance CNC equipment with a fault early warning function, the platform fails to receive early warning signals and take timely response measures before equipment failure occurs.

- Unified expression standards for the operation and maintenance information of multi-type and heterogeneous equipment are lacking. There are multiple models and brands of equipment in the current workshop, and the operation and maintenance information of these equipment types shows obvious differences in aspects such as expression formats and interaction methods, making it impossible to realize unified management and interactive analysis on an industrial internet platform.

6.2. Design and Implementation of a Predictive Maintenance Scenario

The engineering issues in equipment operation and management of the shaft gear processing workshop described in the previous section reveal deficiencies in the current enterprise’s equipment maintenance management. Although the equipment in the workshop is fully loaded and connected to the cloud, it fails to detect unexpected shutdowns of equipment, such as five-axis vertical turning-milling compound machining centers and CNC gear hobbing machines, as well as conduct maintenance and disposal. Currently, the overall process capability index of workshop equipment hovers at a low level, resulting in the workshop’s overall equipment efficiency consistently falling below the expected target.

To improve the OEE of the shaft and gear processing workshop, by referring to the three performance improvement strategy combinations of “high-load output, lean management and control, and low-failure operation” provided in Section 5.4, the methods closely related to the equipment process capability index are the two modes of “high-load output” and “low-failure operation”. However, the current focus of an enterprise’s equipment management and control optimization is to reduce the probability of equipment failure. For this reason, the enterprise selected the “low-failure operation mode” as the key strategy to improve the performance of the workshop’s equipment operation management and control. The “low-failure operation mode” focuses primarily on equipment health status. Through dynamic monitoring and real-time perception of the equipment operating status, it conducts predictive maintenance and early warning disposal of the equipment health status on the basis of data. In accordance with the technical route of “scenario external interface design-functional module extraction and combined arrangement-information model design-industrial APP development and deployment-solution application effect analysis,” the overall predictive maintenance solution for production equipment in the shaft gear processing workshop based on the industrial internet platform is designed. This solution further supports the effective operation of the predictive maintenance scenario for production equipment in the shaft gear processing workshop to realize status monitoring, fault early warning, and predictive repair and maintenance of the equipment of the workshop.

On this basis, the enterprise developed an industrial APP for the predictive maintenance of production equipment in the manufacturing workshop of aero-engine transmission units. It includes seven functional modules: asset value evaluation, task execution tracking, production process planning, operation status optimization, equipment fault detection, equipment health assessment, and equipment maintenance disposal. These modules are combined and arranged according to the business logic interaction relationship between them and deployed on the enterprise’s industrial internet platform. This has promoted the implementation of a predictive maintenance solution for cloud-connected equipment and realized the online monitoring of the operation status, fault prediction, and early warning, as well as the predictive repair and maintenance of the production equipment in the manufacturing workshop of aero-engine transmission units.

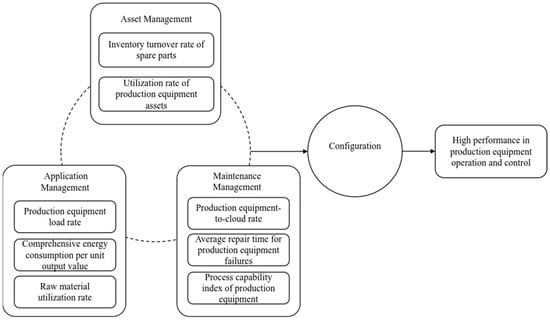

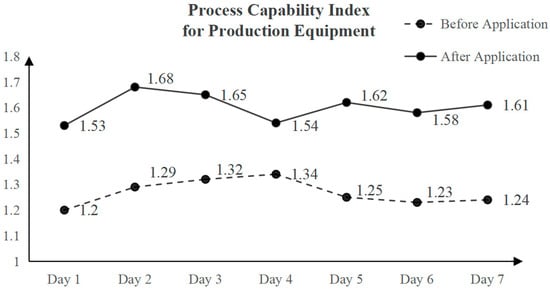

6.3. Comparative Analysis of Production Equipment Operation and Management Performance Before and After the Deployment of the Predictive Maintenance Solution

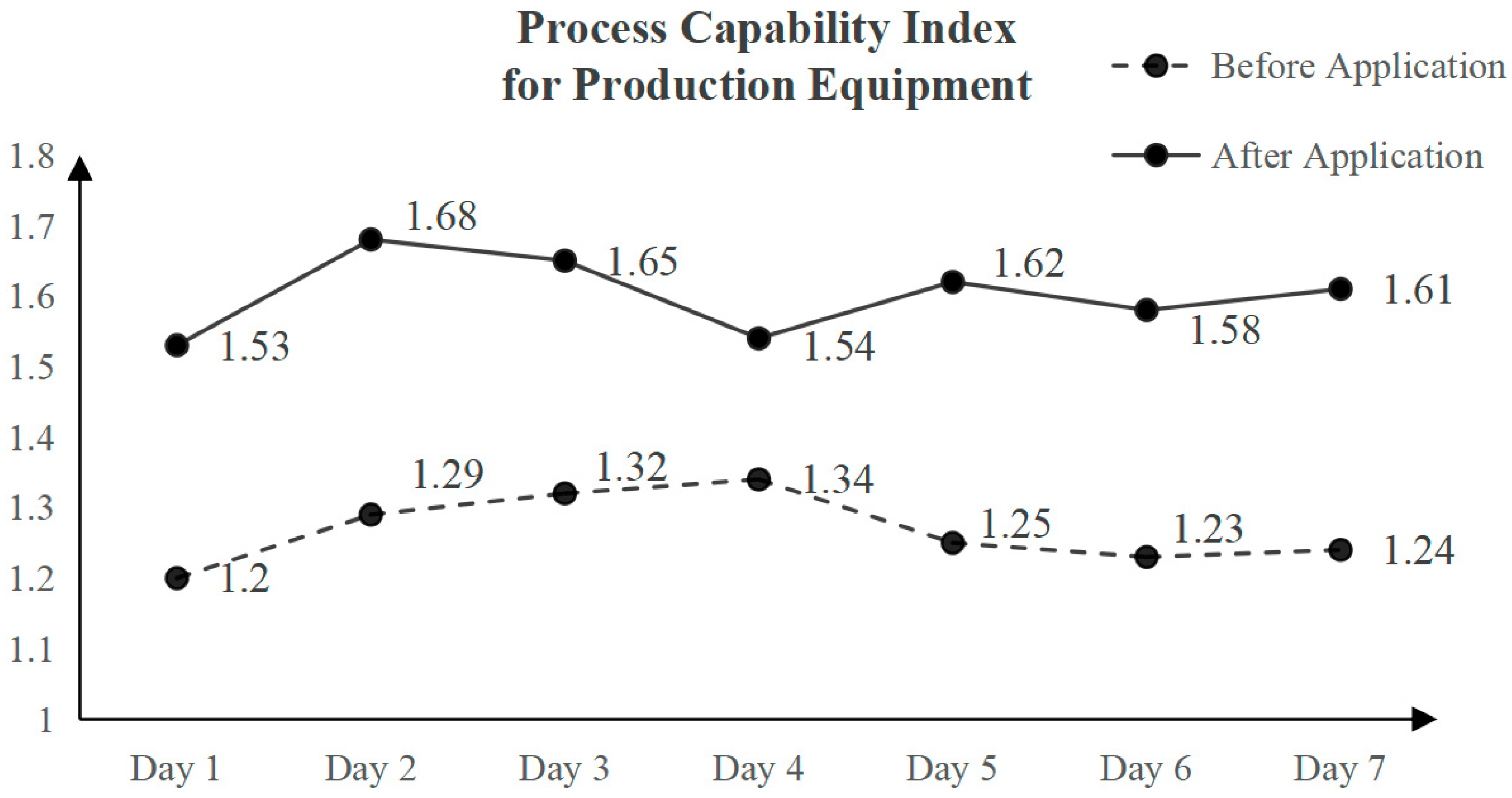

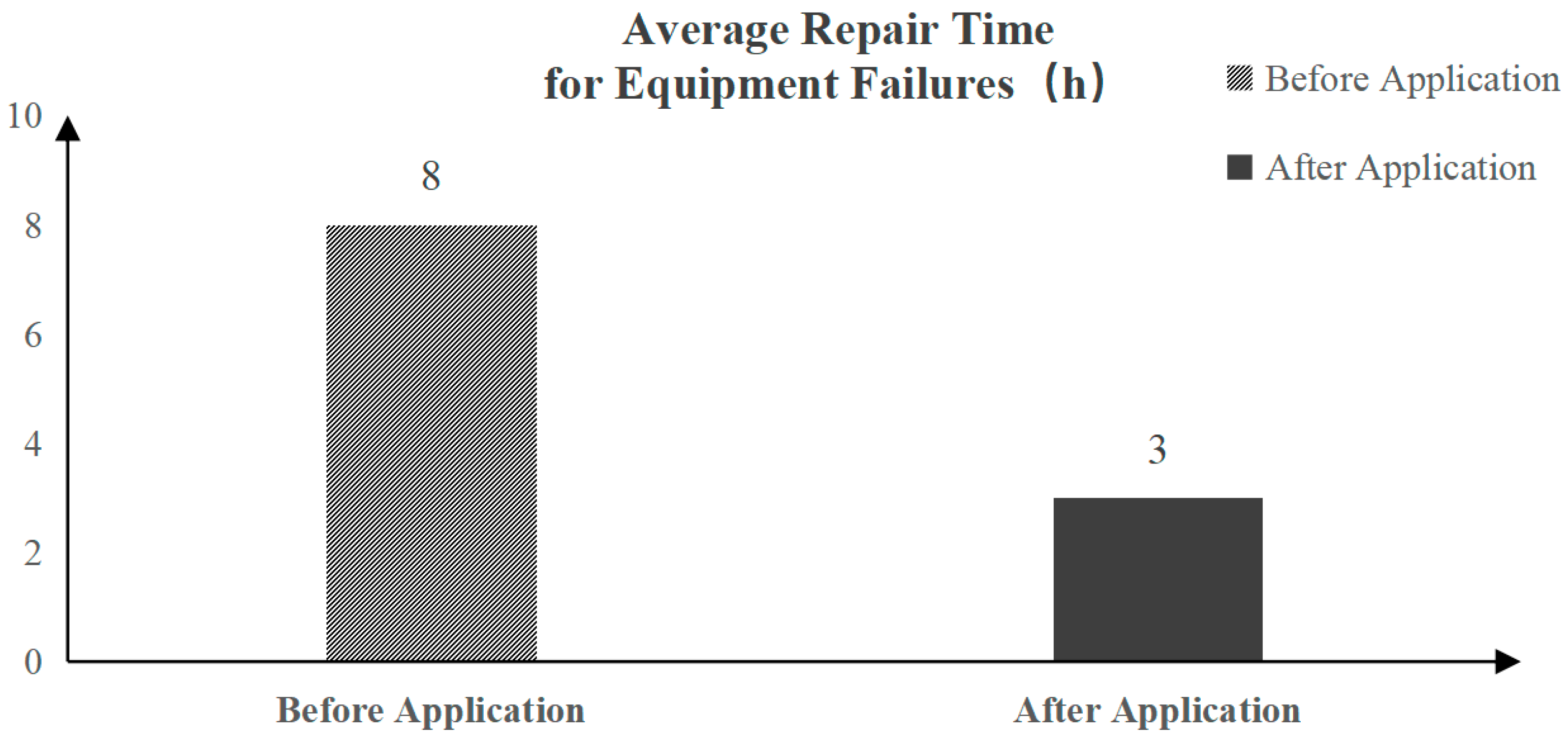

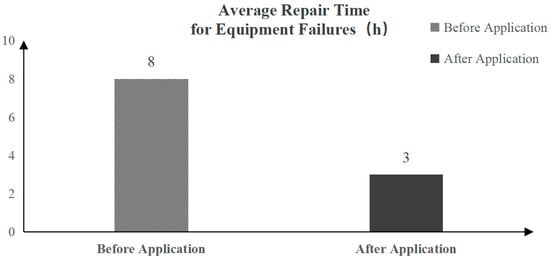

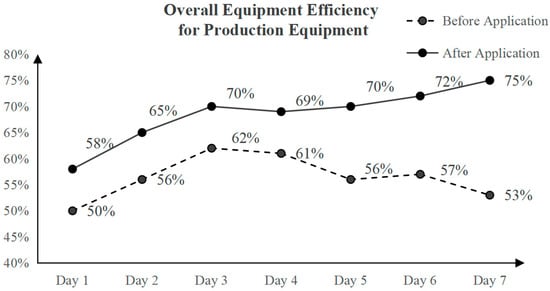

After the deployment and application of the industrial APP for equipment predictive maintenance, the performance of the enterprise’s equipment operation management and control significantly improved. The average value of the production equipment process capability index in the workshop increased from 1.28 to approximately 1.60 (Figure 3.), the average repair time of the production equipment faults decreased from 8 to 3 h (Figure 4). The average value of the OEE of the production equipment increased from 56.43% to 68.57% (Figure 5). This result shows that by applying the functional model for the equipment predictive maintenance scenario, the two key indicators of the equipment process capability index and the average repair time of equipment faults have been significantly improved, effectively enhancing the continuity and stability of the production process and promoting a substantial improvement in the OEE of the production equipment in this workshop.

Figure 3.

Comparison of the process capability indices of production equipment before and after deployment and application of the predictive maintenance APP for production equipment.

Figure 4.

Comparison of the average repair time for production equipment failure before and after deployment and application of the predictive maintenance APP for production equipment.

Figure 5.

Comparison of the overall equipment efficiency of production equipment before and after deployment and application of the predictive maintenance APP for production equipment.

7. Conclusions and Future Works

7.1. Conclusions

This study comprehensively analyzed domestic and international standards and specifications, theoretical models, and architectural frameworks related to production equipment and operation management. From the three dimensions of asset management, application management, and maintenance management, an analytical framework under the “capability-performance” logic is constructed. On the basis of sample data from 82 manufacturing enterprises, the fuzzy set qualitative comparative analysis (fsQCA) method was adopted to identify three types of high-performance paths for equipment operation, providing reference guidance for sustainable development of enterprises. The results show that there are multiple complementary relationships among different capability elements, corresponding to three configurational paths: “High-Load Output”, “Lean Management and Control”, and “Low-Fault Operation”. Among them, the “High-Load Output Path” relies on a relatively high equipment asset utilization rate and production rhythm matching capability; the “Lean Management and Control Path” highlights the synergistic effect of the cloud connection rate and energy consumption control; and the “Low-Fault Operation Path” emphasizes maintenance timeliness and the response rate. In addition to previous studies that suggested that the degree of digitization affects equipment performance (Xu H., et al., 2025; Jiang T., et al., 2025) [50,51], this study indicates that the operational performance of production equipment is not driven by a single factor but rather by a composite outcome formed by the synergistic effect among capability structures. This finding verifies the applicability of theories of equifinality and causal complexity in the context of manufacturing operations and maintenance. On this basis, the study further verifies the influencing factors and improvement strategies of production equipment operation management performance through practical applications in the aero-engine transmission unit manufacturing workshop of a certain enterprise.

In terms of theoretical contributions, this study breaks through the traditional linear hypothetical path, adopts a configurational perspective to systematically identify the combinatorial effects among capability elements, and incorporates the three-dimensional structure of assets, application, and maintenance management into a unified performance model for the first time. Moreover, it identifies multiple paths through the fsQCA method, which enriches the theoretical explanation of the causal mechanism in equipment management performance research. In addition, this study introduces typical equipment characteristics and data elements in the industrial internet scenario, providing new empirical support for the “capability-performance” theory in the digital context.

In terms of practical implications, this study proposes three types of targeted management action suggestions and operable steps: (1) enterprises with low equipment utilization but strong equipment configuration capabilities should optimize the production scheduling rhythm and equipment distribution to improve the asset utilization rate and load coordination; (2) enterprises that have completed cloud deployment should establish an equipment cloud connection status monitoring ledger, identify unconnected equipment and data silos, focus on energy consumption monitoring and data-driven precise scheduling management, and promote the maximization of resource efficiency; and (3) flexibility-oriented manufacturing enterprises should strengthen the construction of condition perception and maintenance response mechanisms and establish maintenance response KPIs (e.g., mean time to repair) to conduct closed-loop evaluation of the effectiveness of maintenance mechanisms, thereby improving equipment reliability. The above suggestions are all derived from the characteristic summary of different paths with strong situational adaptability and operability, facilitating the implementation of differentiated strategy deployment on the basis of enterprise types and strategic positioning, enhancing the sustainable development capability of the enterprise.

7.2. Limitations and Future Work

In terms of limitations, the samples of this study are concentrated in manufacturing enterprises in some regions of China; therefore, the regional representativeness and industry universality are still limited. The three types of configurational paths identified in this study have been verified in Chinese manufacturing enterprises, but their applicability to enterprises in different countries remains to be further explored. Although fsQCA was used to reveal the combinatorial effects of variables, the longitudinal temporal dimension was not incorporated, making it impossible to identify the dynamic evolution mechanism of the paths. In addition, the model does not consider the impact of macro factors such as corporate culture and external policies.

Future research can be expanded in the following three ways. First, we expand the sample coverage and introduce cross-border or cross-industry data. Considering the differences in operation modes, regulatory environments, and resource endowments among manufacturing enterprises, future research should use cross-border samples to conduct fsQCA path comparisons to test the stability and generalizability of each path and enhance the external applicability of the theory. Second, we combine the dynamic fsQCA method to explore the path evolution process. Third, the institutional environment and organizational characteristics are introduced as moderating variables to enrich the model’s boundary conditions.

Author Contributions

Conceptualization, J.L. (Jun Li) and K.D.; methodology, J.L. (Jun Li), K.D. and J.L. (Jinsong Liu); validation, K.D. and J.L. (Jinsong Liu); formal analysis, J.L. (Jinsong Liu) and Y.Z.; investigation, J.L. (Jun Li); resources, J.L. (Jun Li); writing—original draft preparation, K.D., J.L. (Jinsong Liu), Y.Z. and Q.L.; writing—review and editing, J.L. (Jun Li) and Q.L.; supervision, J.L. (Jun Li); funding acquisition, J.L. (Jun Li). All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported in part by the National Key R&D Program of China (2021YFB1715300) and the National Natural Science Foundation of China (62172425).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author. The data are not publicly available due to the confidential data related to the enterprise that have not been released to the public.

Acknowledgments

The authors thank all the personnel who either provided technical support or helped with data collection. We also acknowledge all the reviewers for their useful comments and suggestions.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Singh, S.; Batheri, R.; Dias, J. Predictive Analytics: How to Improve Availability of Manufacturing Equipment in Automotive Firms. IEEE Eng. Manag. Rev. 2023, 51, 157–168. [Google Scholar] [CrossRef]

- Yu, M.; Ruan, W.; Zhou, Y.; Zhao, Y. Flow Shop Scheduling for Prefabricated Components Production Considering Parallel Machines and Buffer Constraints. J. Constr. Eng. Manag. 2025, 151, 04025010. [Google Scholar] [CrossRef]

- Li, C. The Effect of Plant Management Capability on Plant Performance Based on Manufacturing Enterprises. Master’s Thesis, Xiamen University, Xiamen, China, 2019. [Google Scholar]

- Jia, Y.; Wang, J.; Han, X.; Tang, H.; Xiao, X. Application and Performance Evaluation of Industrial Internet Platform in Power Generation Equipment Industry. Sustainability 2023, 15, 15116. [Google Scholar] [CrossRef]

- Wang, J.; Xu, C.; Zhang, J.; Bao, J.; Zhong, R. A Collaborative Architecture of the Industrial Internet Platform for Manufacturing Systems. Robot. Comput.-Integr. Manuf. 2019, 61, 101854. [Google Scholar] [CrossRef]

- Wang, L.; Li, T.; Xu, Y.; Xiang, F.; Zhang, X.; Zuo, Y. A Hybrid Graph Neural Network-Based Federated Learning Method for Personalized Manufacturing Service Composition Recommendation. Int. J. Comput. Integr. Manuf. 2025, 1–23. [Google Scholar] [CrossRef]

- Tao, F.; Zhang, Y.; Cheng, Y.; Ren, J.; Wang, D.; Qi, Q.; Li, P. Digital Twin and Blockchain Enhanced Smart Manufacturing Service Collaboration and Management. J. Manuf. Syst. 2020, 62, 903–914. [Google Scholar] [CrossRef]

- Nakajima, S. Introduction to TPM: Total Productive Maintenance; Productivity Press: New York, NY, USA, 1988. [Google Scholar]

- IEC 62264-2:2013; Enterprise-Control System Integration—Part 2: Objects and Attributes for Enterprise-Control System Integration. International Electrotechnical Commission (IEC): Geneva, Switzerland, 2013.

- IEC 62264-3:2016; Enterprise-Control System Integration—Part 3: Activity Models of Manufacturing Operations Management. International Electrotechnical Commission (IEC): Geneva, Switzerland, 2016.

- ISO 22400-2:2014; Automation Systems and Integration—Key Performance Indicators (KPIs) for Manufacturing Operations Management Part 2: Definitions and Descriptions. International Organization for Standardization (ISO): Geneva, Switzerland, 2014.

- GB/T 23023-2022; Integration of Informatization and Industrialization Management Systems—Assessment Indicator Set for Production Equipment Operational Performance. State Administration for Market Regulation: Beijing, China, 2022.

- Wan, G.Y.; Pu, F.Y.; Li, Z.C.; Cao, Y. Impact of Marketing Capability and Production Operation Capability on Firms’ Financial Performance. Chin. J. Manag. Sci. 2024, 32, 275–285. [Google Scholar]

- Li, T.; Cheng, H.S.; Zhao, W.; Liu, L.; Zhang, Y. Research on the Impact of Green Innovation on Firm Performance. Syst. Eng.—Theory Pract. 2025, 45, 1812–1827. [Google Scholar]

- Zhao, Y.P.; Li, J.Y.; Liu, D.P.; Cheng, S. Digital Leadership and Enterprise Digital Transformation Performance: An Institutional Entrepreneurship Perspective. J. Manag. Sci. China 2025, 28, 15–30. [Google Scholar]

- Yu, C.P.; Li, Z.F.; Lin, C.P.; Liao, Y. The Impact of Digital Innovation Network Embeddedness on New Product Development Performance of Manufacturing Enterprises. J. Manag. World 2024, 40, 154–176. [Google Scholar]