Abstract

Dredged sludge is characterized by a high water content, low permeability, and poor load-bearing capacity, which hinder its sustainable utilization as an engineering filler. During the stabilization process using vacuum preloading (VP), fine-grained sludge readily clogs drainage channels, thereby prolonging consolidation duration and compromising drainage efficiency. To address these persistent challenges, this study proposes an improved method that combines electroosmosis, VP, and polyacrylamide (PAM) to enhance the consolidation performance of dredged sludge. Column settling experiments demonstrated that the optimal application dosages of anionic polyacrylamide (APAM) and calcium chloride (CaCl2) were 0.25% and 4.0% of dry sludge mass, respectively. Excessive dosage of either APAM or CaCl2 disturbed the agglomeration and sedimentation of fine-grained particles due to surface charge inversion. Electroosmotic VP (EVP) facilitated the directional movement of pore water, which increased the cumulative water discharge mass by 37.3%. The combination of APAM and CaCl2 enhanced particle flocculation via adsorption and bridging effects, significantly improving soil permeability and dewatering performance. Driven by an electric field, Ca2+ ions transported water molecules toward the cathode. Subsequently, these Ca2+ ions participated in reactions to generate cementitious agents. Compared with VP, this integrated method increased the sludge shear strength by 108.1% and produced a much denser microstructure.

1. Introduction

Dredged sludge is generated in large quantities during urban port and waterway construction. Its sustainable utilization has become one of the common issues in environmental governance and urban development [1]. In recent years, using dredged sludge for land reclamation has emerged as a practical approach to alleviate land shortages in coastal areas [2]. Nevertheless, dredged sludge typically exhibits poor geotechnical properties (high water content, low permeability, and insufficient bearing capacity), and requires consolidation treatment prior to its application in land reclamation projects [3]. Conventional techniques for reinforcing soft soils, including jet grouting [4], deep cement mixing (DCM) [5], compacted granular piles [6], and prefabricated vertical drains (PVDs) [7], are often found to be ineffective for dredged sludge, primarily due to its distinctive properties. Firstly, the high water content of dredged sludge impedes cement hydration, which in turn diminishes the reinforcing effect of jet grouting and DCM. Secondly, dredged sludge fails to provide sufficient confining pressure to form effective drainage channels [8]. Furthermore, its poor permeability limits the drainage efficiency of PVDs. Since water content is crucial in determining the shear strength of dredged sludge, accelerating drainage consolidation is necessary to improve its bearing capacity. Among existing improvement methods, vacuum preloading (VP) has been widely employed to reinforce soft soil [9,10,11]. The VP technique imposes negative pressure to increase the hydraulic gradient inside the soil, thus facilitating pore water extraction and promoting soil consolidation. However, many practical applications found that VP exerts a limited effect on consolidating fine-grained soils. The main reasons focus on two aspects: first, the VP technique can only remove free water from soil pores and cannot extract weakly bound water [12]; second, the seepage force caused by vacuum pressure drives fine particles to migrate and accumulate around drainage boards, blocking drainage channels and generating low-permeability “soil columns” [13]. These issues seriously impede the transfer of vacuum pressure, leading to insufficient consolidation effect and prolonged consolidation durations [14].

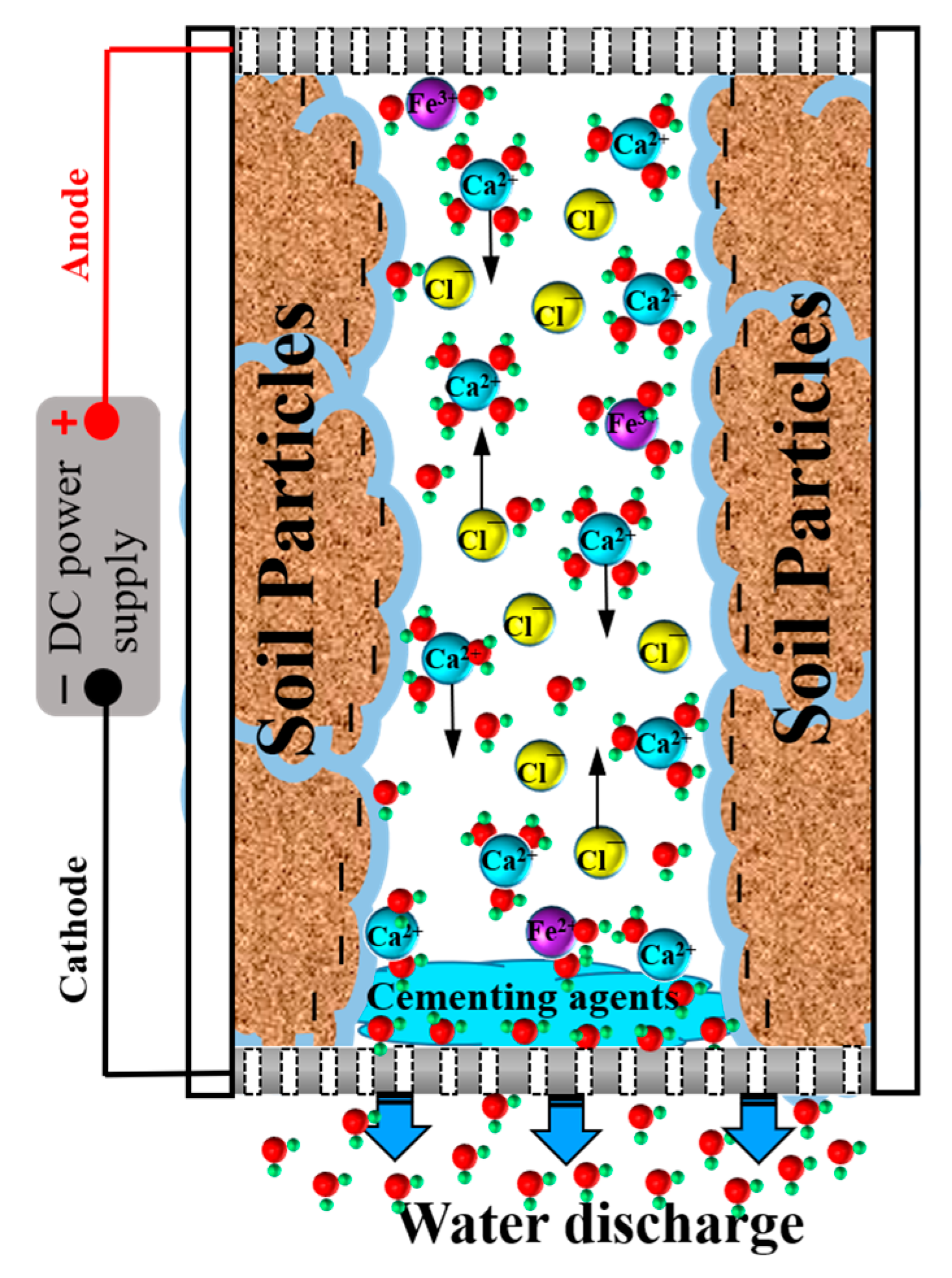

To enhance the efficiency of dredged sludge consolidation treated with VP, electroosmosis has been studied as a complementary method [15]. Due to isomorphous substitution, soil particles carry permanent negative charges on their surfaces, resulting in a large number of free hydrated cations in the pore fluid [16]. When a direct current (DC) is applied across the soil, electromigration drives these hydrated cations to move from anode to cathode, while electroosmosis induces the directional flow of the associated pore water in the same direction. This efficiently extracts weakly bound water, with the electroosmotic permeability coefficients (ke) ranging from 10−8 to 10−9 m2·s−1·V−1 [17,18]. Importantly, this coefficient is unaffected by soil particle size and is significantly greater than the hydraulic permeability coefficient of dredged sludge [19]. However, EVP fails to effectively reduce the aggregation of fine soil particles near drainage boards, which impairs long-term consolidation performance [20].

Recently, flocculants have drawn increasing interest in soil consolidation due to their ability to enhance soil properties through microstructural modification [21,22]. Soil is a typical particulate material, with its physical and mechanical properties essentially determined by interparticle interactions [23]. Flocculants aggregate fine soil particles into large flocs via electrostatic adsorption and/or van der Waals forces, thereby increasing soil permeability and strengthening interparticle bonding [24]. Notably, polyacrylamide (PAM) has attracted growing interest [25]. Based on charge properties, PAM is categorized into anionic (APAM), nonionic (NPAM), and cationic (CPAM) types. APAM is widely employed in engineering practices because of its economic efficiency and superior flocculation with soil particles [26]. Moreover, previous research has shown that calcium chloride (CaCl2) addition further activates APAM’s flocculation performance and enhances electroosmotic drainage [27,28]. Yet, the optimal dosage ratio of APAM to CaCl2 for treating dredged sludge remains undetermined, and previous studies have predominantly determined their proportions empirically [29].

To overcome the difficulties in consolidating dredged sludge, this study proposed a composite method that integrates electroosmosis, VP, and APAM-CaCl2. This method was designed to achieve three synergistic functions: (1) EVP for removing both free water and weakly bound water from the sludge, (2) APAM for aggregating fine soil particles into flocs to mitigate drainage channel clogging, and (3) CaCl2 for enhancing electroosmotic drainage and flocculation efficiency. To verify the above-mentioned hypothesis, we monitored the temporal evolution of water discharge, vacuum pressure, and surface settlement during the consolidating process. After consolidation, sludge’s shear strength, water content, and microstructure were analyzed to explore the mechanisms of dredged sludge consolidation by combined EVP and APAM-CaCl2.

2. Materials and Methods

2.1. Materials

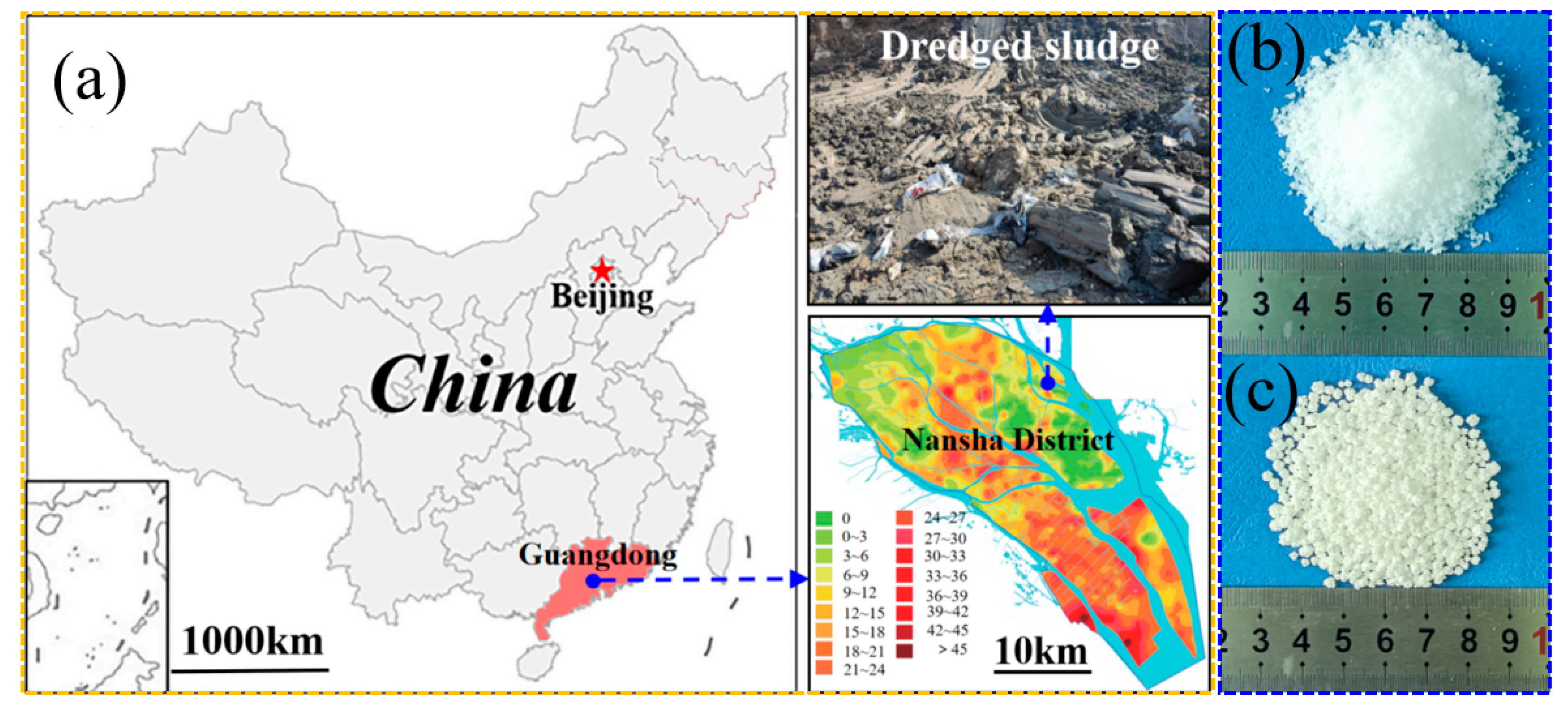

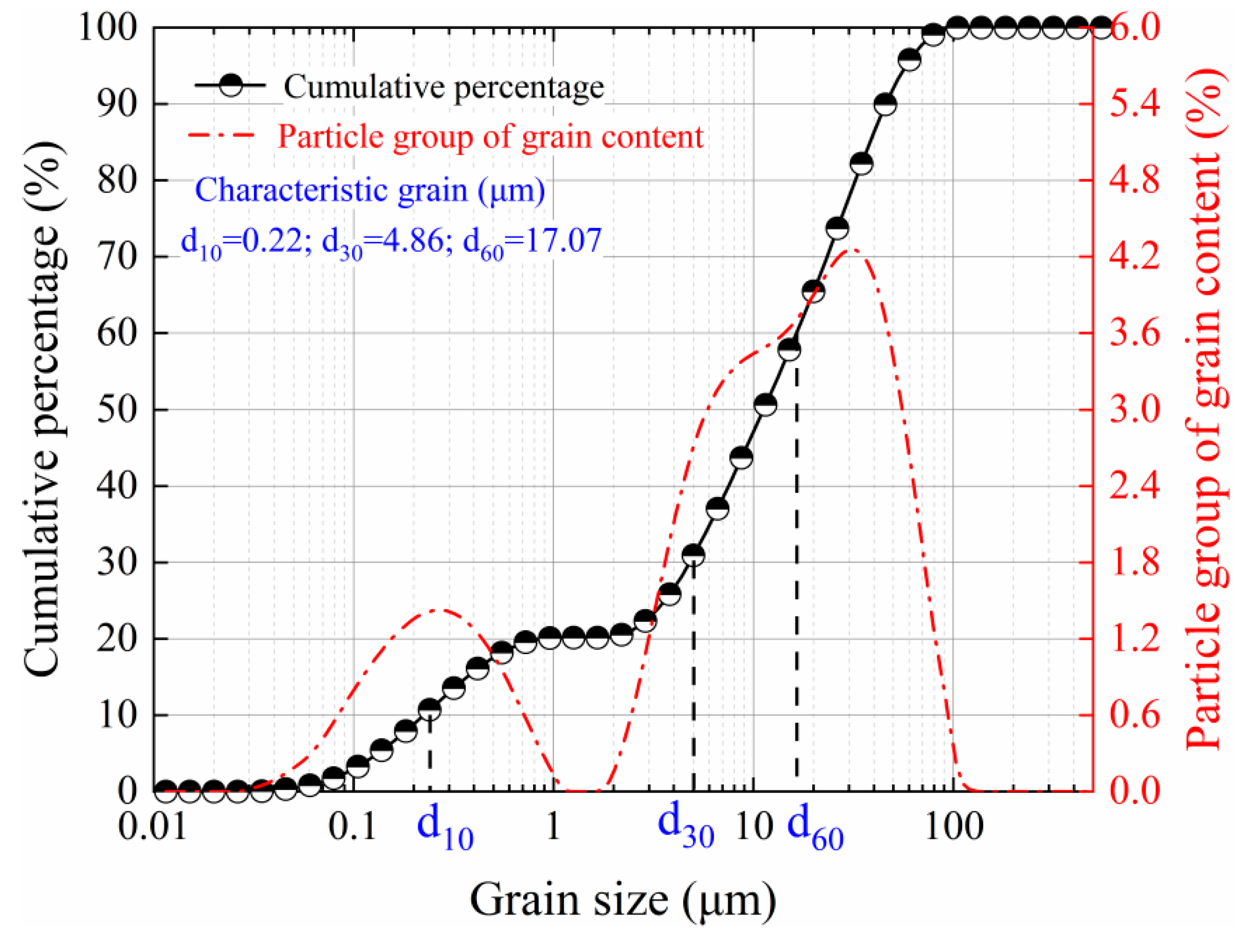

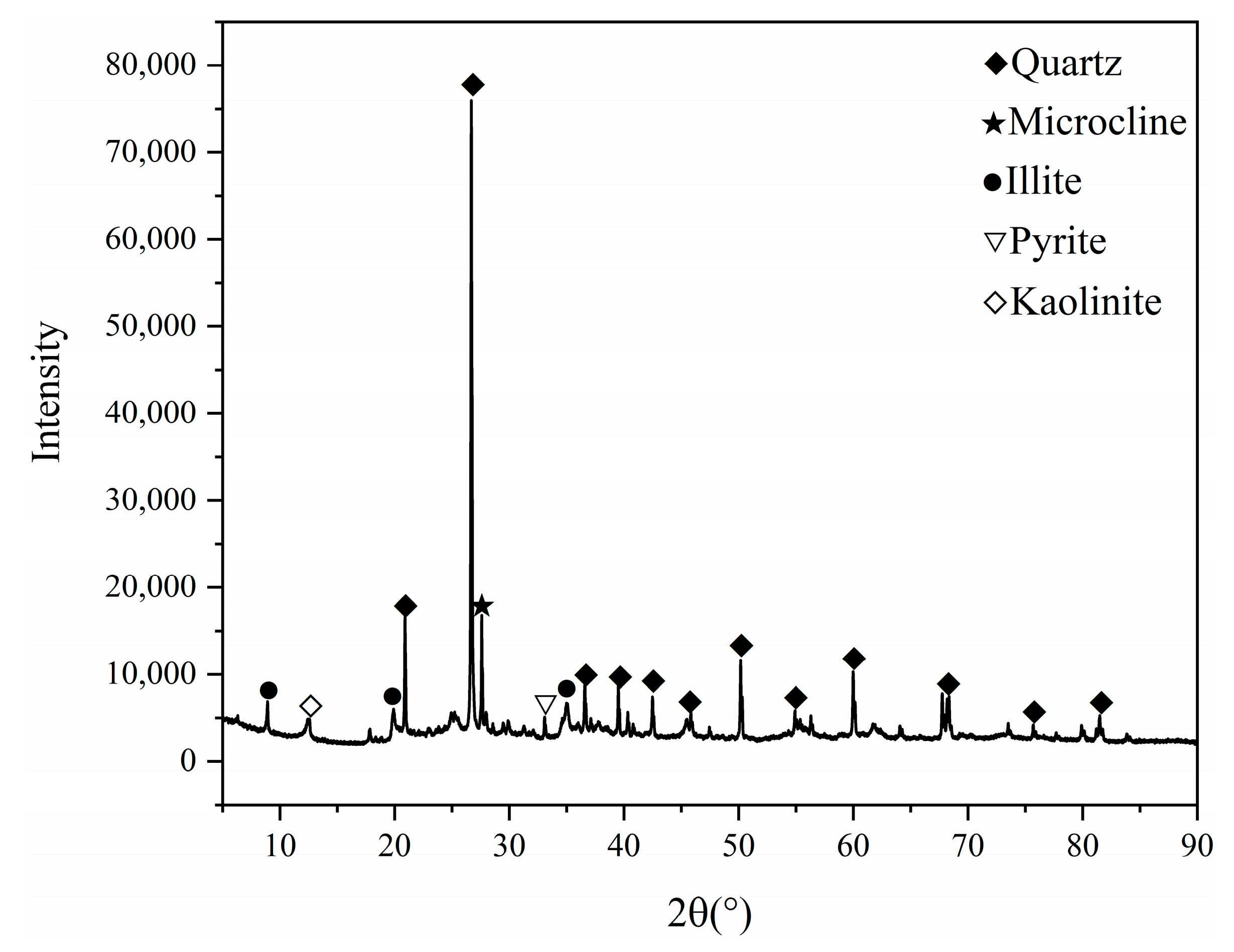

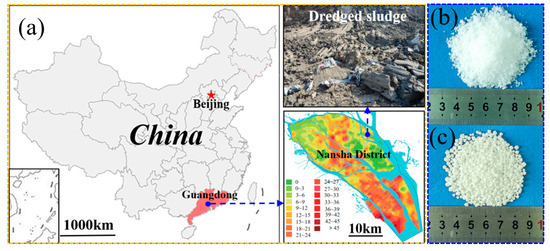

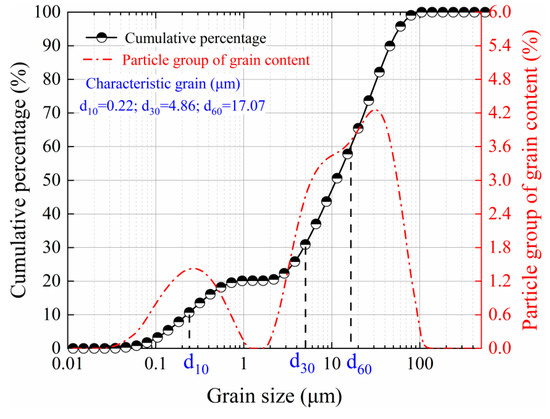

Dredged sludge was sampled from Nansha District (22°50′47″ N, 113°32′35″ E) in Guangdong, China—a coastal area with extensive sludge deposits, as shown in Figure 1a [30]. Prior to conducting laboratory research, the natural sludge was subjected to immersion and filtration processes to ensure uniformity and remove impurities. The pretreated sludge was then transferred to a forced-air oven and dried at 105 °C for 24 h. Subsequently, the dried sludge was ground into a fine and homogeneous powder using a ball mill. To prepare reconstituted sludge of target water content, a predefined mass of sludge powder was placed in a mechanical stirrer and mixed with deionized water for 15 min. The basic physical properties of the reconstituted sludge were summarized in Table 1. Its liquid limit and plastic limit, determined using the Casagrande method and thread rolling, were 42.6% and 20.2%, respectively [31]. The corresponding plasticity index (PI) and liquidity index (LI) were 22.4 and 2.26. Additional physical properties were measured, such as density (1.62 g·cm−3), specific gravity (2.71), void ratio (1.92), and saturation (100%). Notably, the initial water content of the sludge was 70.8%, 1.66 times the liquid limit, suggesting the sludge was in a flowing plastic state. Its particle size distribution (PSD) was analyzed using laser diffraction (Mastersizer 2000). The PSD results (Figure 2) revealed that the sludge was composed of 1.5% sand (particle size > 75 μm), 77.9% silt (particle size 2~75 μm), and 20.6% clay (particle size < 2 μm). This composition indicates that fine-grained particles accounted for 98.5% of the sludge. According to the Unified Soil Classification System (USCS) [32], this sludge was classified as low-plasticity clay (CL). The mineral composition of the sludge was analyzed using X-ray diffraction (XRD; Bruker D8 Advance), as shown in Figure 3. Five crystalline minerals were detected, with their relative contents as follows: quartz (35.7%), illite (25.4%), microcline (19.5%), kaolinite (16.1%), and pyrite (3.2%). Additionally, APAM and CaCl2 were purchased from Sinopharm Chemical Reagent Co., Ltd. (Shanghai, China). Both reagents were used directly without further purification or modification, as shown in Figure 1b,c.

Figure 1.

The materials used in this study: (a) In situ dredged sludge; (b) APAM; (c) CaCl2.

Table 1.

Basic physical properties of the sludge used in laboratory experiments.

Figure 2.

Grain size distribution of the studied sludge.

Figure 3.

XRD intensity counts for sludge sample.

2.2. Column Settling Experiment

Prior to the consolidation process, the column settling experiment was conducted to explore the optimal mass ratio of flocculant to sludge. If flocculant dosage is insufficient, it cannot aggregate fine soil particles into larger flocs; whereas excessive dosage will adhere to soil particle surfaces, resulting in charge inversion and particle redispersion. As such, optimizing the flocculant dosage is essential for achieving effective sludge consolidation.

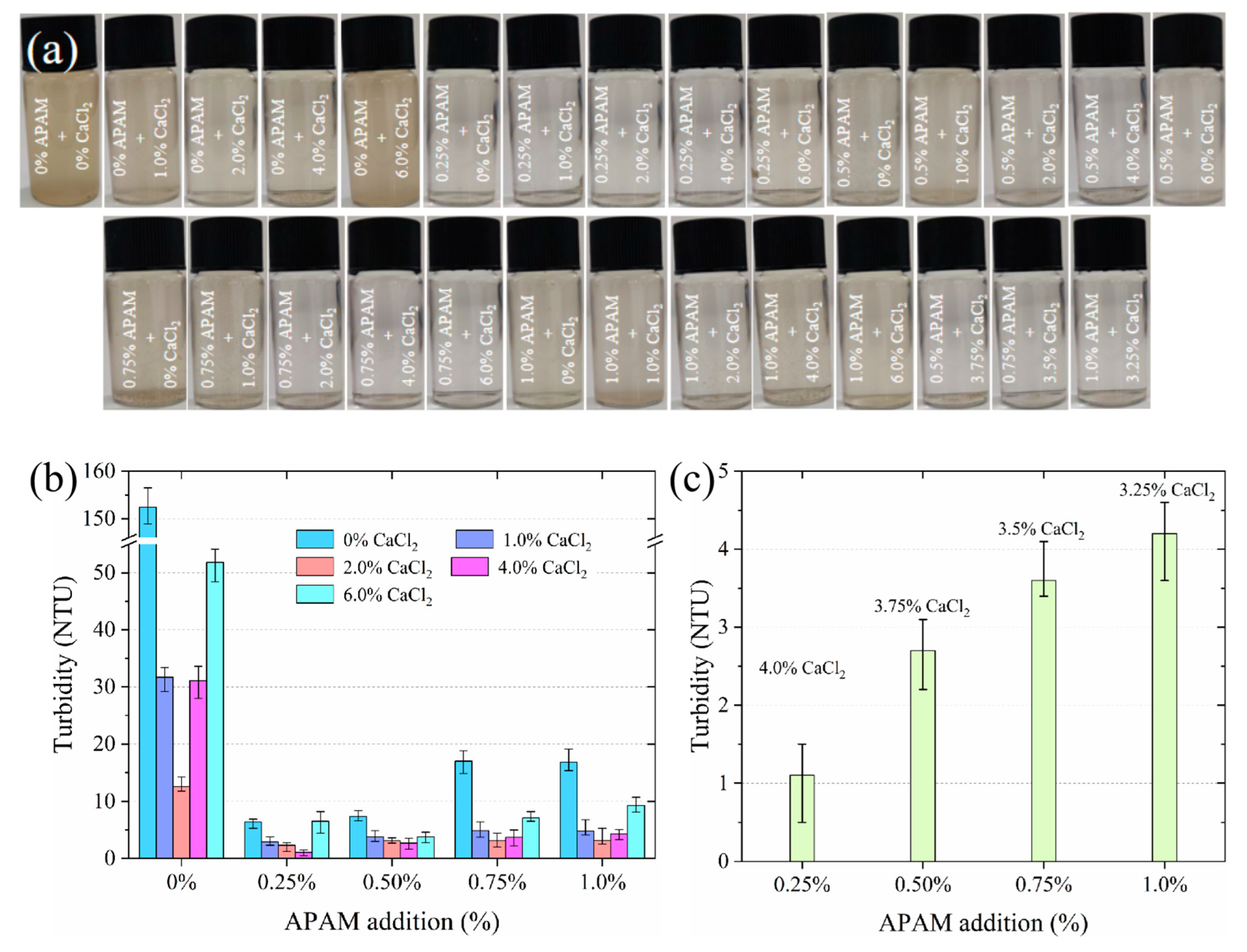

APAM and CaCl2 were incorporated at specific gradient ratios based on the dry sludge mass: APAM at 0%, 0.25%, 0.5%, 0.75%, and 1.0%, and CaCl2 at 0%, 1.0%, 2.0%, 4.0%, and 6.0%. For column settling experiments, 25 sets of sludge samples were prepared using a 5 × 5 matrix design, ensuring all possible combinations of APAM and CaCl2 dosages were included. First, precisely weighed quantities of APAM were dissolved in 31 g deionized water to form approximately 31 mL solutions. Similarly, CaCl2 was dissolved in 40 g deionized water to form approximately 40 mL solutions. Both solutions were stirred using a magnetic stirrer (Joanlba Co., Ltd., Huzhou, China) at 200 rpm for 5 h at room temperature (25 ± 1 °C) to ensure complete dissolution. Subsequently, 100 g dry sludge was mixed with the CaCl2 solution. After 5 min of manual swirling, the prepared APAM solution was added, and the mixture was stirred for another 5 min until uniform dispersion was obtained. The mixed sludge was then transferred to a 300 mL beaker and left to settle undisturbed for 12 h. Supernatant of the sludge samples was extracted using a pipette and transferred into 10 mL glass vials, as shown in Figure 4a. Supernatant turbidity was measured using a turbidimeter with an accuracy of ±0.1 NTU to assess flocculation performance of sludge with different APAM-CaCl2 combinations [33,34]. To ensure the reliability of test results, three parallel samples were prepared for each combination, and the average of three measurements was adopted as the final data.

Figure 4.

Column settling experiments with different flocculant combinations. (a) Supernatant extracted from sludge samples; (b) variations in supernatant turbidity under different flocculant combinations; (c) variations in supernatant turbidity under the fixed total dosage.

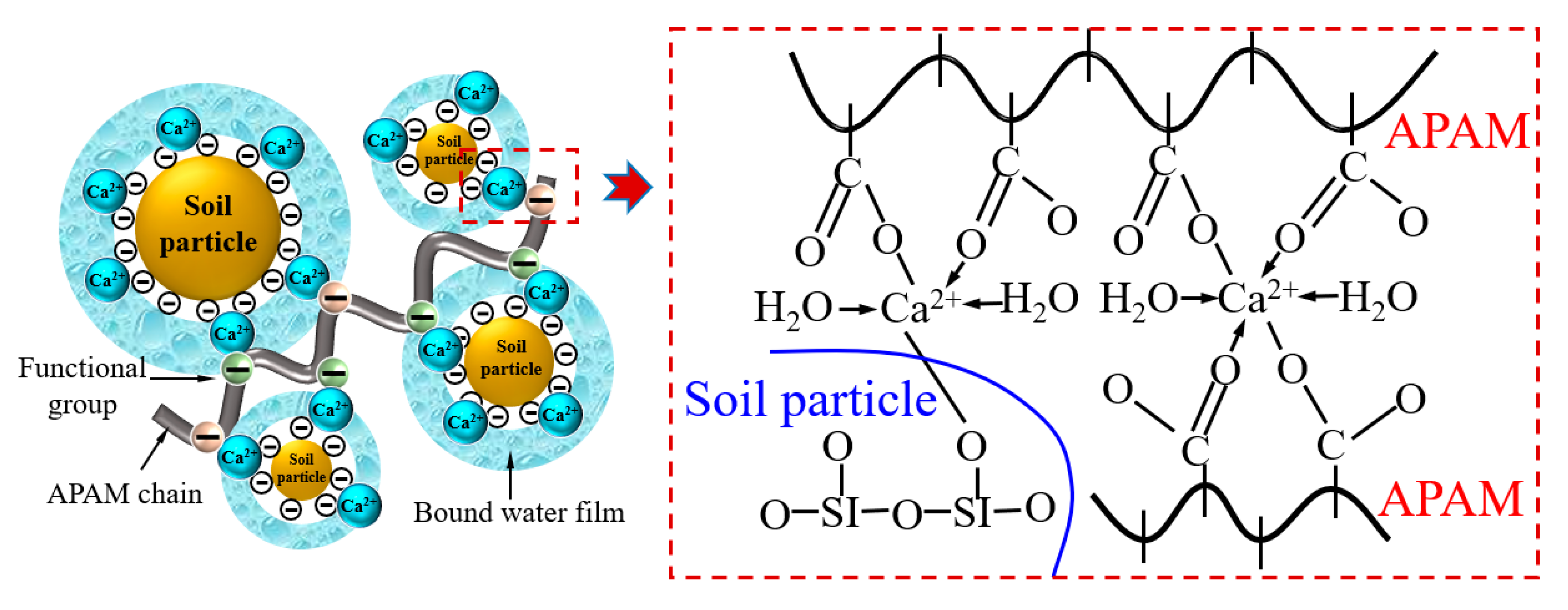

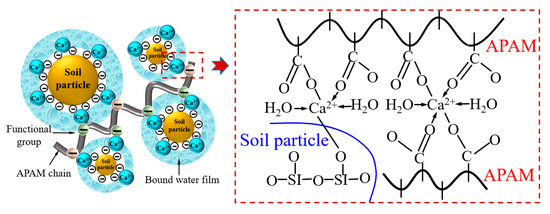

Figure 4b illustrates that when only one flocculant (APAM or CaCl2) was used, the supernatant turbidity first decreased and then increased as the dosage increased. The lowest turbidity—measured at 1.1 ± 0.5 NTU (1 NTU is defined as the turbidity of 1 mg·L−1 formazin solution), was observed when APAM and CaCl2 were added at 0.25% and 4.0%, respectively. To further explore how the total dosage of APAM and CaCl2 influences flocculation behavior, additional turbidity tests were conducted under a fixed total dosage of 4.25%. Three different APAM-CaCl2 combinations were adopted: 0.5% APAM + 3.75% CaCl2, 0.75% APAM + 3.5% CaCl2, and 1.0% APAM + 3.25% CaCl2. As shown in Figure 4c, compared with the 0.25% APAM + 4.0% CaCl2 combination, the supernatant turbidity increased from 1.1 NTU to 2.7 ± 0.5 NTU, 3.6 ± 0.4 NTU, and 4.2 ± 0.5 NTU, respectively, with increasing APAM dosage. The underlying mechanism can be explained as follows: Illite has a 2:1 layered structure and exhibits high surface negative charge density, which readily adsorbs Ca2+ from CaCl2. This adsorption reduces the thickness of electrical double layer (EDL) and enhances the bridging effect of APAM. Upon adding APAM, its anionic functional groups bind to the adsorbed Ca2+ ions, establishing soil particle-Ca2+-APAM linkages as illustrated in Figure 5. When APAM and CaCl2 are used in appropriate ratios and dosages, Ca2+ ions compress the EDL of fine soil particles, while APAM chains form interparticle bridges that aggregate these particles into flocs. By contrast, overuse of either additive disrupts this process: surplus APAM forms a steric layer on particle surfaces, whereas excess Ca2+ triggers surface charge inversion. Under these conditions, the supernatant turbidity increases. Column settling experiments showed that the optimal dosages of APAM and CaCl2 were 0.25% and 4.0% of the dry sludge mass, respectively.

Figure 5.

Schematic diagram of soil particle-Ca2+-APAM bridging. (Ca2+ ions produced by the ionization of CaCl2 act as a medium to bridge APAM and soil particles or APAM and itself, thereby enhancing APAM’s flocculation efficiency.).

2.3. Electroosmotic Vacuum Preloading System

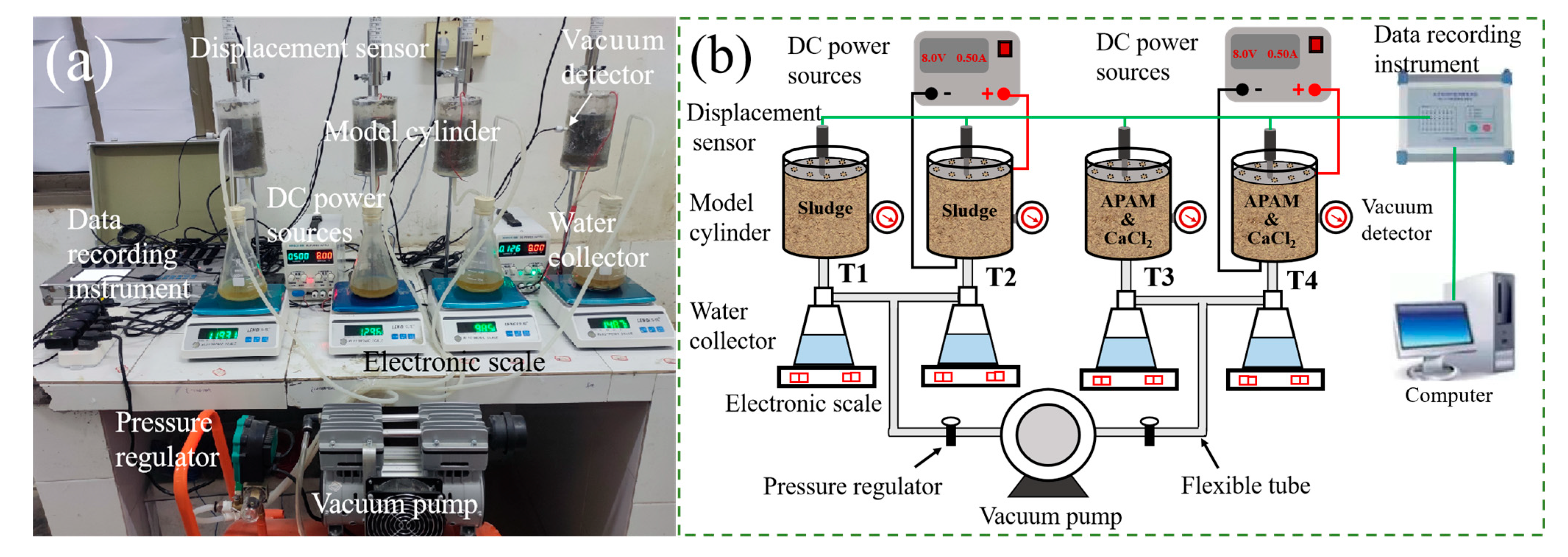

Figure 6 illustrates the EVP system, which comprises a vacuum pump, two DC power sources, four model cylinders, four water collectors, four electronic scales, and a data recording instrument. Detailed information about the apparatus is provided in the following sections.

Figure 6.

(a) Experimental setup; (b) Schematic configuration of the EVP system.

The model cylinder has a diameter of 80 mm and height of 160 mm, with an 8 mm-diameter hole drilled at the bottom. Its inner wall was coated with a thin layer of Vaseline to minimize wall-adjacent friction. A porous stainless-steel plate (76 mm diameter) was wrapped with geotextile and then placed at the bottom of the model cylinder. The steel plate serves as the cathode, and the geotextile functions as a sludge filter. Subsequently, the prepared sludge samples were poured into the cylinder in layers, and continuous vibration was applied to remove air bubbles. A steel plate was placed on top of the sludge to act as the anode. The model cylinder was then covered with a geotextile and a geomembrane to maintain a sealed environment. A YWC displacement sensor (Jincheng Test Equipment Co., Ltd., Liyang, China), with a measuring range of 0–100 mm and an accuracy of ±0.01 mm, was fixed on the upper surface of the anode plate to record its settlement. The electrode plates were connected to the two poles of the power supply using wires, while the model cylinder was connected to the water collector via a flexible tube. A vacuum detector was embedded 80 mm deep into the sludge sample to monitor vacuum pressure variations. A regulator was employed to control the output vacuum pressure, with an accuracy of ±1 kPa. After the installation was completed, the EVP system was left undisturbed for 12 h to ensure sufficient contact between the sludge samples and electrodes. Thereafter, a vacuum pressure of −85 kPa was applied to initiate drainage consolidation. Electroosmosis was activated when the drainage rate was ≤0.5 g/h and sustained for at least 3 consecutive hours [7]. A stable voltage of 8 V was applied, corresponding to a voltage gradient of 0.5 V·cm−1, which is consistent with previous studies [35,36]. Throughout the experimental process, the vacuum pressure was kept constant.

2.4. Sludge Sample Preparation

Initially, 2 g APAM and 32 g CaCl2 were separately dissolved in 350 g and 220 g deionized water, and stirred with a magnetic stirrer to obtain homogeneous solutions. Subsequently, 800 g sludge powder was mechanically mixed with the CaCl2 solution at 200 rpm for 5 min. The APAM solution was then added and mixed for another 5 min to reach the target mass ratios. The resulting sludge had a water content of approximately 71%, which was consistent with that of natural sludge. In this study, sludge samples were divided into four groups and consolidated using different methods, as specified in Table 2. Each group contained three parallel samples to ensure the reliability of results, with average values reported. After drainage consolidation was completed, sludge samples from specific locations were selected for analyzing water content, shear strength, and microstructure. Water content was measured via oven-drying, shear strength was assessed using a portable vane shear apparatus (SZB-2.0), and microstructure was examined through scanning electron microscopy (SEM).

Table 2.

Summary of dredged sludge consolidation test schemes.

3. Results and Discussion

3.1. Water Discharge and Current

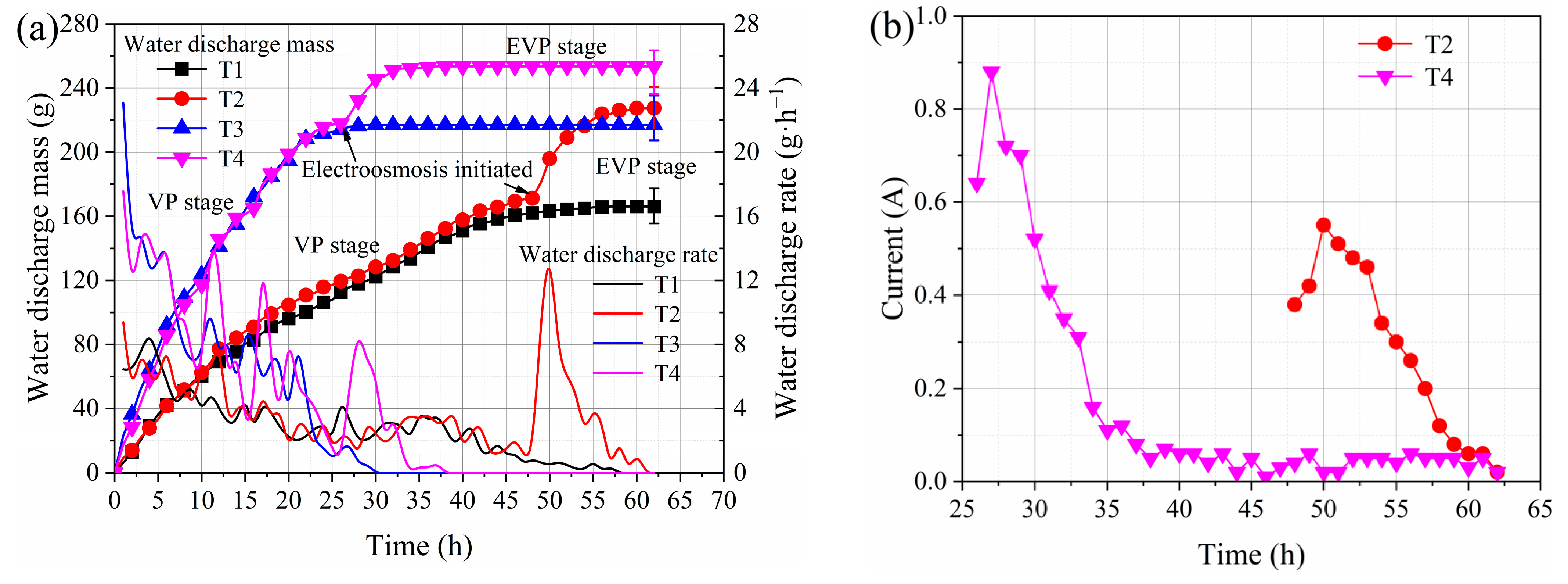

Water discharge plays a critical role in evaluating the dewatering performance and efficiency of sludge. As plotted in Figure 7a, the water discharge curves can be divided into two stages based on the applied consolidation methods, namely the VP stage and the EVP stage. In T1 (VP alone), the discharged water mass accumulated at decreasing rate, reaching 166 ± 11 g at the 57th hour, which was equivalent to 29.2% of the total water mass in sludge sample. The variation in the water discharge curve in T2 (EVP alone) was nearly identical to that in T1 during the VP stage. However, after electroosmosis was activated, the water discharge increased abruptly. The cumulative water discharge mass reached 228 ± 18 g at the 60th hour, which was 37.3% higher than that in T1. In T3 (VP + APAM-CaCl2), due to the addition of APAM-CaCl2, the initial discharge rate reached 23 g·h−1. The cumulative water discharge mass was 217 ± 16 g at the 29th hour, which was 30.7% higher than that in T1 but 4.8% lower than that in T2, and the drainage time was reduced by 49.1% compared to that in T1. During the VP stage, the variation in the water discharge curve in T4 (EVP + APAM-CaCl2) was nearly identical to that in T3. Once electroosmosis was activated, the water discharge increased abruptly, and the cumulative water discharge mass stabilized at 254 ± 15 g—17.1% higher than that in T3.

Figure 7.

(a) Variations in water discharge; (b) Variations in current of T2 and T4.

Figure 7b presents the current curves of T2 and T4 sludge samples during the EVP stage. It can be observed that both current curves first increase and then decrease, which is primarily attributed to the formation of stable seepage channels within the sludge. Due to the addition of APAM-CaCl2, the initial current of T4 was 0.64 A, representing a 68.4% increase compared to that of T2. Additionally, the peak current of T4 reached 0.88 A, approximately 60% higher than that of T2, and occurred 1 h earlier. Furthermore, we calculated the electroosmotic energy consumption per tonne of sludge via Equation (1).

where U represents the applied voltage (V), G is the sludge mass (t), ∆t is the measurement interval (h), and Ij is the current value during ∆t (A). ∆t was set to 1 h in this study.

The results show that the energy consumption of T4 sludge sample is 35.7 kWh·t−1, which is approximately 52% higher than that of T2 (23.5 kWh·t−1).

Analysis of the differences in water discharge and current revealed that VP alone was insufficient for effective sludge consolidation [37]. In contrast, EVP enhanced sludge consolidation by increasing electroosmotic drainage, which is consistent with the findings of Wang et al. [38], who observed that the cumulative water discharge mass of EVP was nearly twice that of VP alone. APAM-CaCl2 enhanced sludge permeability (3.98 × 10−5 cm·s−1) through forming stable seepage channels and facilitated pore water discharge under VP [39]. Moreover, adsorbed Ca2+ ions compressed the EDL thickness, thereby increasing the proportion of free water. Under the applied electric field, Ca2+ ions carried a large number of water molecules to migrate toward the cathode for discharge, further accelerating the drainage consolidation of sludge. Obviously, the additional water migration correspondingly increased the electrical energy consumption.

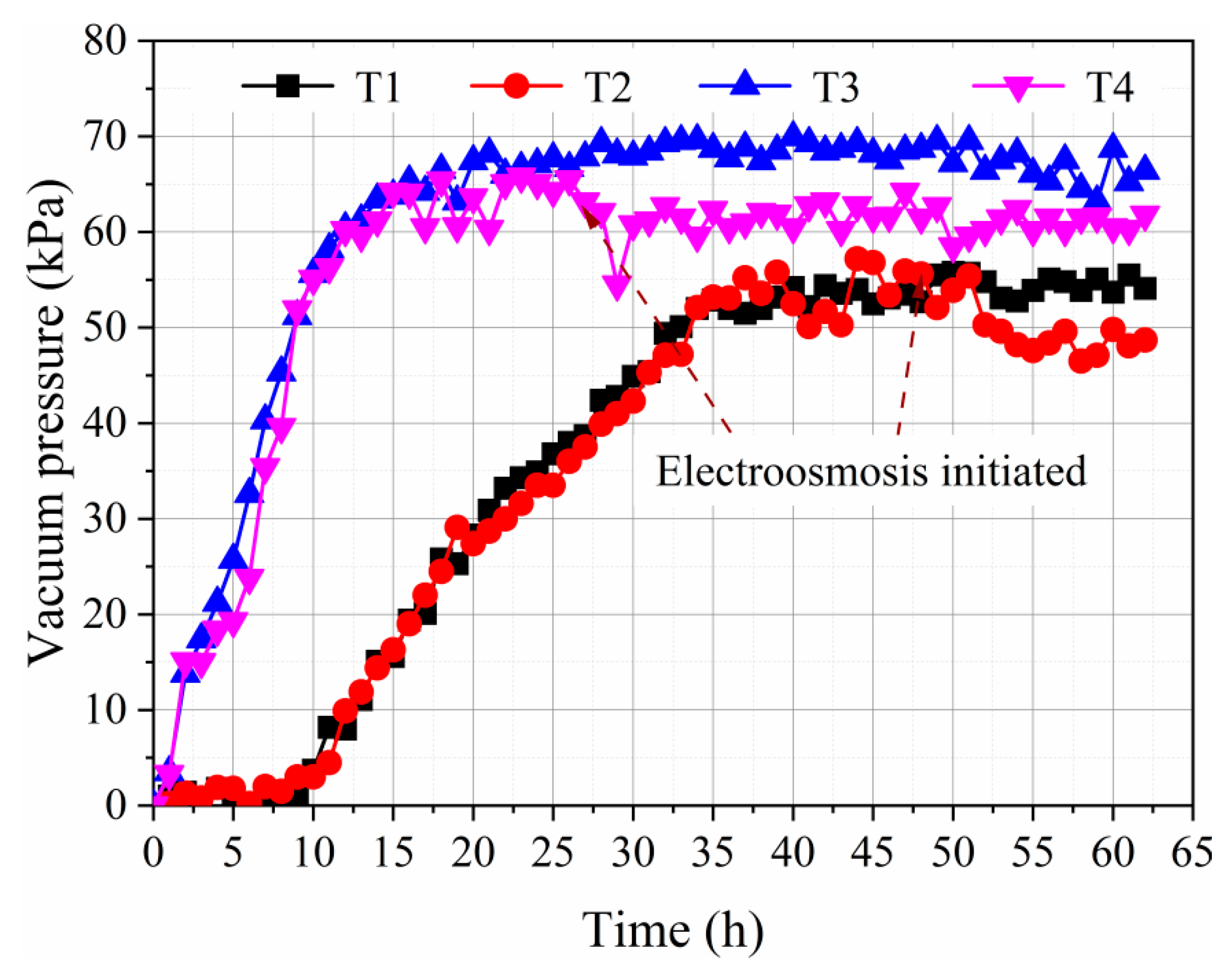

3.2. Vacuum Pressure

Figure 8 depicts the temporal evolution of vacuum pressure in sludge during the consolidation process, with the detection point located at a depth of 80 mm. It can be observed that consolidation methods significantly impact the vacuum pressure transmission. For the sludge without APAM-CaCl2 pretreatment, obvious changes in the vacuum pressure curve only occurred after approximately 9 h, which was mainly caused by the low permeability (3.16 × 10−6 cm·s−1). Lei et al. [23] also found the lag in vacuum pressure transmission during test process. In T1, the vacuum pressure eventually fluctuated around 54 kPa after 39 h. Before the activation of electroosmosis, the vacuum pressure curve of T2 almost overlapped with that of T1. After activation, the vacuum pressure gradually decreased to approximately 48 kPa, which reduced by 11.1% compared to T1. For the sludge pretreated with APAM-CaCl2, the vacuum pressure curve increased rapidly and stabilized at the 20th hour, representing a 48.7% reduction in the time required to reach a steady state compared to the untreated sludge. Further, the final vacuum pressure in T3 fluctuated around 68 kPa, which increased by 25.9% compared with T1. In contrast, the final vacuum pressure in T4 stabilized at approximately 61 kPa, representing a 10.3% decrease compared to that of T3. Previous studies have demonstrated a strong correlation between vacuum pressure transmission and hydraulic conductivity [36]. VP, EVP, and APAM-CaCl2 affect the hydraulic conductivity by altering the microstructure of dredged sludge, thereby leading to significant differences in vacuum pressure transmission.

Figure 8.

Temporal variation in vacuum pressure in dredged sludge during consolidation (detection point: 80 mm depth).

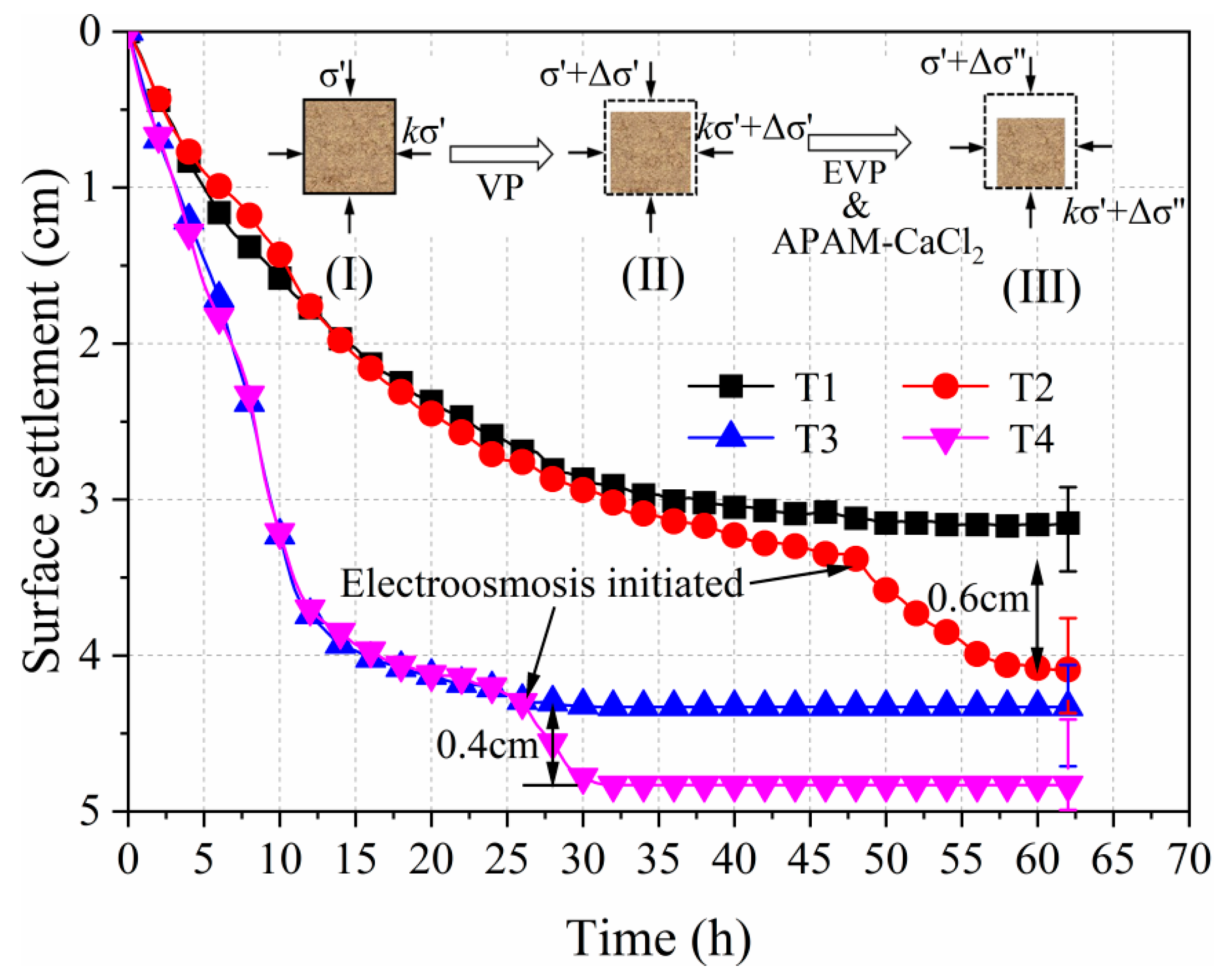

3.3. Surface Settlement

Surface settlement is a key indicator reflecting the degree of soil consolidation. Figure 9 shows the variation in surface settlement over time, with a trend similar to that of water discharge curves. Before the activation of electroosmosis, the settlement curves of T1 and T2 remained almost consistent. Once electroosmosis was activated, the settlement of T2 gradually increased to 4.1 ± 0.3 cm due to additional electroosmotic drainage, representing a 28.1% increase compared to that of T1. Pretreatment with APAM-CaCl2 significantly accelerated the settlement process of dredged sludge. The surface settlement of T3 reached 4.3 ± 0.3 cm at the 24th hour, which represented a 34.4% increase in settlement and a 20% reduction in the time required compared to T1. The variation in settlement of T4 was consistent with that of T3 during the VP stage, while electroosmosis induced an additional 11.6% increase in settlement of T4 compared to T3. The final settlement of T4 reached 4.8 ± 0.4 cm.

Figure 9.

The variation in surface settlement versus time. (I: initial stress state; II: stress state under VP; III: stress state under EVP + APAM-CaCl2).

The mentioned variations in settlement are primarily attributed to different soil stress states induced by applied consolidation methods. According to Terzaghi’s Effective Stress Principle, the soil consolidation degree is determined by effective stress (σ′), defined as σ′ = σ − μ (where σ represents the total stress and μ denotes the pore water pressure). Therefore, a reduction in μ directly translates to an increase in σ′. Prior to the application of any consolidation method, soil elements are in equilibrium under the vertical and horizontal In Situ stresses. VP imposes negative pressure on the soil element and squeezes out pore water, inducing the dissipation of pore water pressure (Δμ′) and an increase in effective stress (Δσ′ ≈ Δμ′). The synergistic application of EVP and APAM-CaCl2 accelerates the pore water extraction, inducing a higher incremental effective stress (Δσ″ > Δσ′), thereby further enhancing dredged sludge consolidation.

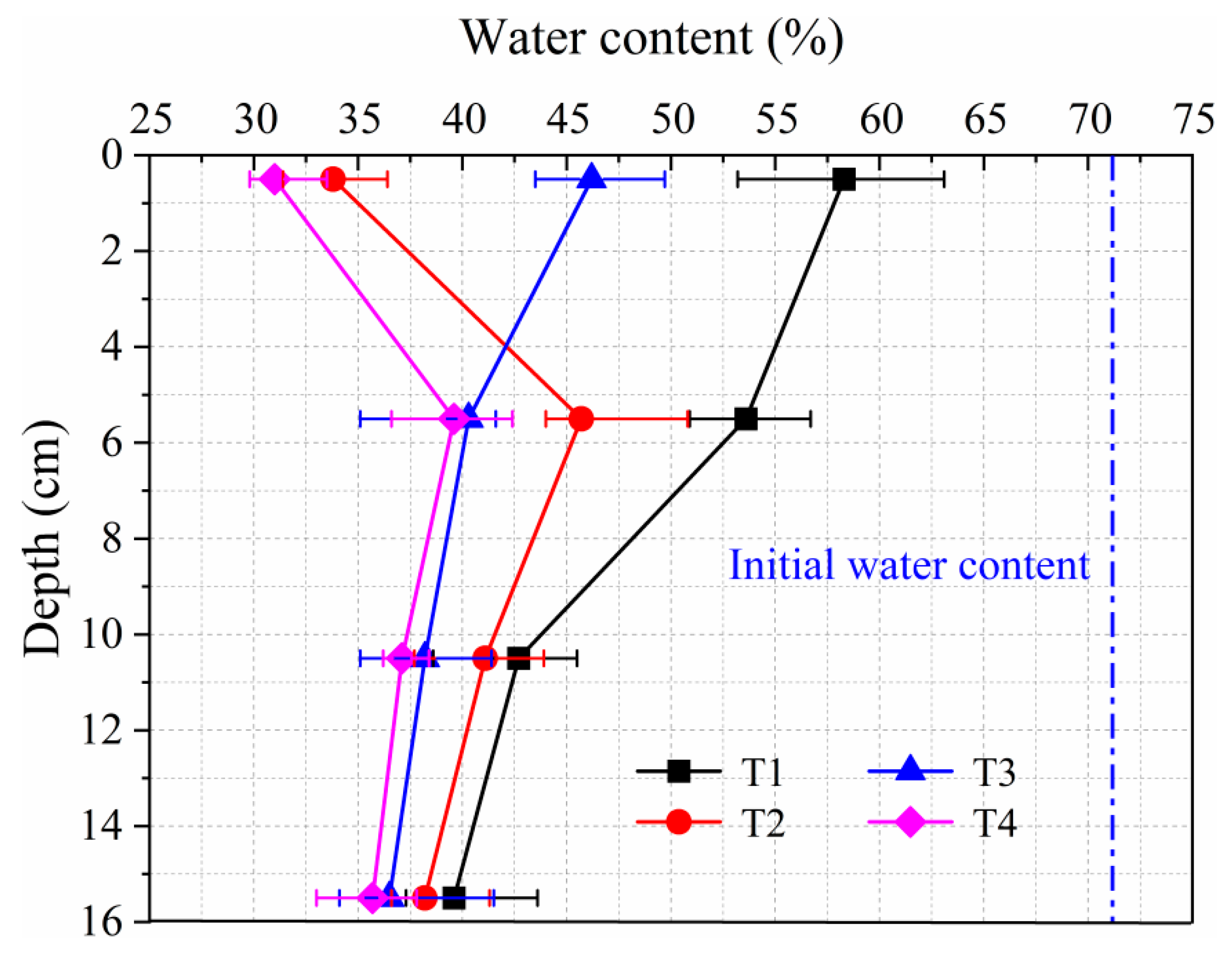

3.4. Water Content

Upon completion of the consolidation process, sludge samples were collected from four predetermined vertical positions (0.5 cm, 5.5 cm, 10.5 cm, and 15.5 cm) for water content measurement and vane shear strength testing. Figure 10 presents the variations in water content as a function of depth. The results reveal that consolidation methods notably affected the sludge dewaterability. For instance, the water content of T1 dropped from 58.3 ± 5.0% to 39.6 ± 3.5% as depth increased, which resulted from the progressive reduction in vacuum pressure along the depth direction. T2 exhibited lower water contents across all measured depths than T1, with minimum values achieved near the electrodes. Specifically, the sludge water content in the anode (33.8 ± 2.5%) and cathode (38.2 ± 2.8%) regions was 9.6% and 5.2% lower than that in the middle region (43.4 ± 3.1%), respectively. This non-uniform moisture distribution is attributed to synergistic mechanisms. First, pore water migrates to the cathode under electroosmosis, resulting in a significant reduction in the water content of the anodic sludge. Second, strong vacuum suction near the cathode facilitates the removal of accumulated pore water. T3 exhibited a similar water content variation pattern to T1 along the depth direction, but its water content was 3.1% to 12.1% lower. As detailed in Section 3.1, APAM-CaCl2 promotes the flocculation of fine particles, thereby enhancing sludge permeability. Owing to the migration of Ca2+ ions further improving dewatering efficiency, T4 exhibited the lowest water content (31.0 ± 2.2%~39.6 ± 2.4%) at all measured depths.

Figure 10.

Evolution of the water content with depth.

A comparison of the drainage efficiency (De) reveals that most consolidation methods without electroosmosis or flocculant pretreatment exhibit poor performance in consolidating sludge (De: 0.05%·h−1 ~ 0.55%·h−1) [27,40,41,42,43]. In contrast, the combination of EVP and APAM-CaCl2 integrates the advantages of both electroosmosis and flocculants, achieving a drainage efficiency of 1.06%·h−1. Drainage efficiency is derived using Equation (2).

where w0 is the initial water content (%), w1 is the water content after consolidation (%), and T is the consolidation time (h).

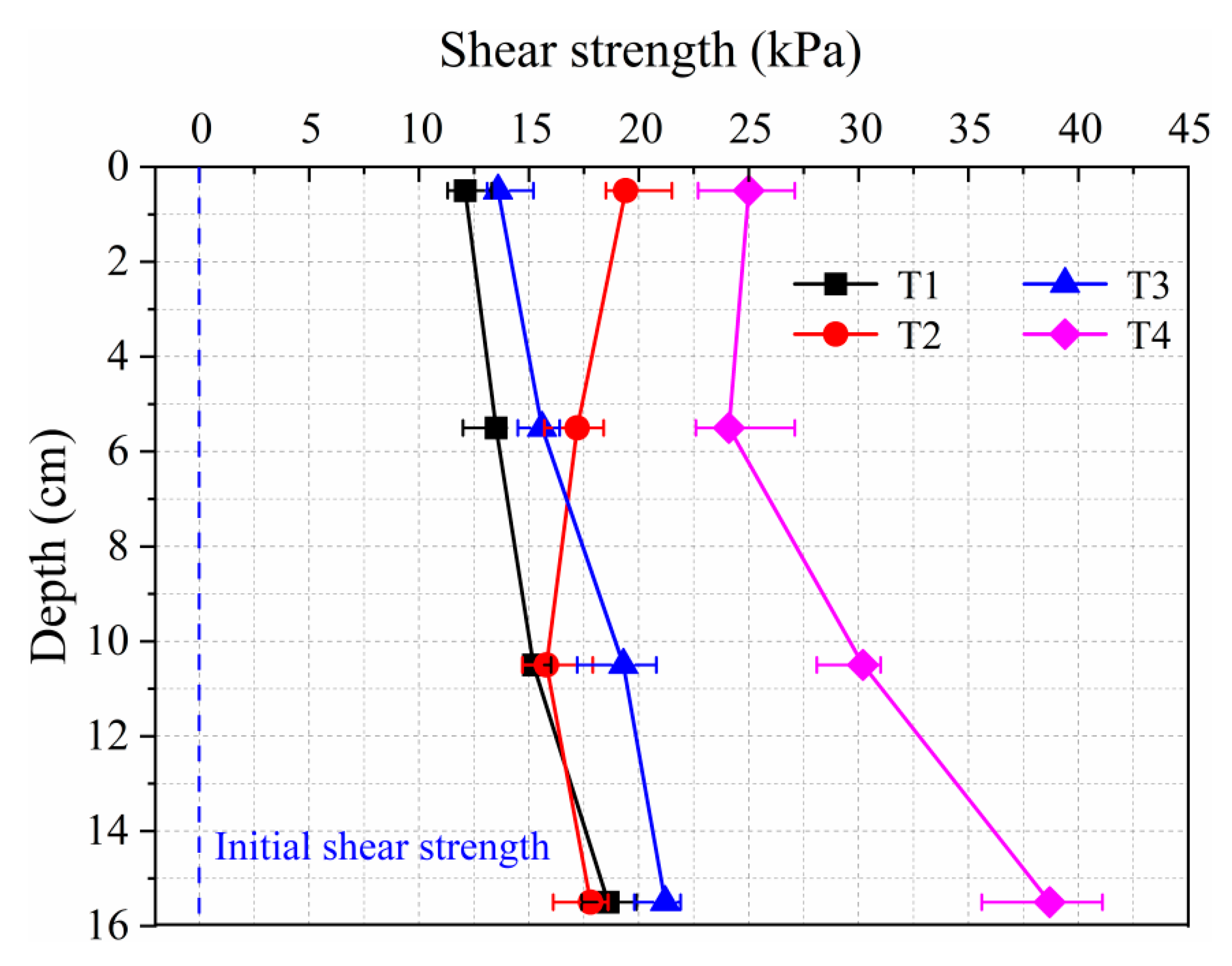

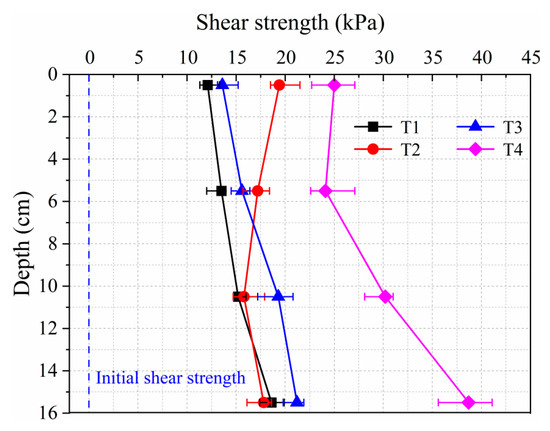

3.5. Vane Shear Strength

The variation in vane shear strength with depth is shown in Figure 11. In T1, the shear strength increased from 12.1 ± 1.1 kPa to 18.6 ± 1.3 kPa with depth due to the growing vacuum suction. In comparison, T2 exhibited greater shear strength near the regions of anode (19.4 ± 1.8 kPa) and cathode (17.8 ± 0.8 kPa) than its mid-section (16.5 ± 1.8 kPa). For sludge pretreated with APAM-CaCl2, the shear strength of T3 increased from 13.6 ± 1.4 kPa to 21.2 ± 1.2 kPa with depth, which represents a 12.4% to 14.0% increment over T1. Notably, the shear strength of anodic and cathodic sludge in T4 reached 25.0 ± 2.2 kPa and 38.7 ± 2.3 kPa, respectively, representing 28.9% and 117.4% increases compared to those of T2. Based on the above analysis, it is evident that both EVP and APAM-CaCl2 enhance the strength of sludge, and the combined use of EVP and APAM-CaCl2 exhibits a stronger reinforcement effect. Additionally, Zhang et al. [19] concluded that Ca2+ ions arriving at the cathode react with hydroxide ions (OH−) to form the cementitious substance (Ca(OH)2), which enhances the cohesion between particles. Furthermore, excess Ca2+ ions react with soluble silicates to generate calcium silicate hydrate (C-S-H), which coats the particle surfaces and increases interparticle friction. These findings provide a good explanation for the significant increase in shear strength of the cathodic sludge observed in this study. The specific chemical reaction equations are provided as follows. These chemical processes significantly improve the sludge’s shear strength, as illustrated in Figure 12.

Figure 11.

Evolution of the vane shear strength with depth.

Figure 12.

Mechanism of synergistic action of EVP and APAM-CaCl2 for dredged sludge consolidation.

At the anodic region:

Fe → Fe2+ + 2e−

Fe2+ → Fe3+ + e−

2H2O → O2 (g) + 4H+ + 4e−

At the cathodic region:

2H2O + 2e− → H2 (g) + 2OH−

Fe3+ + 3OH− → Fe(OH)3 (gel)

Ca2+ + 2OH− → Ca(OH)2 (gel)

Ca2+ + SiO32− + H2O → C-S-H

3.6. Microstructure and XRD Pattern

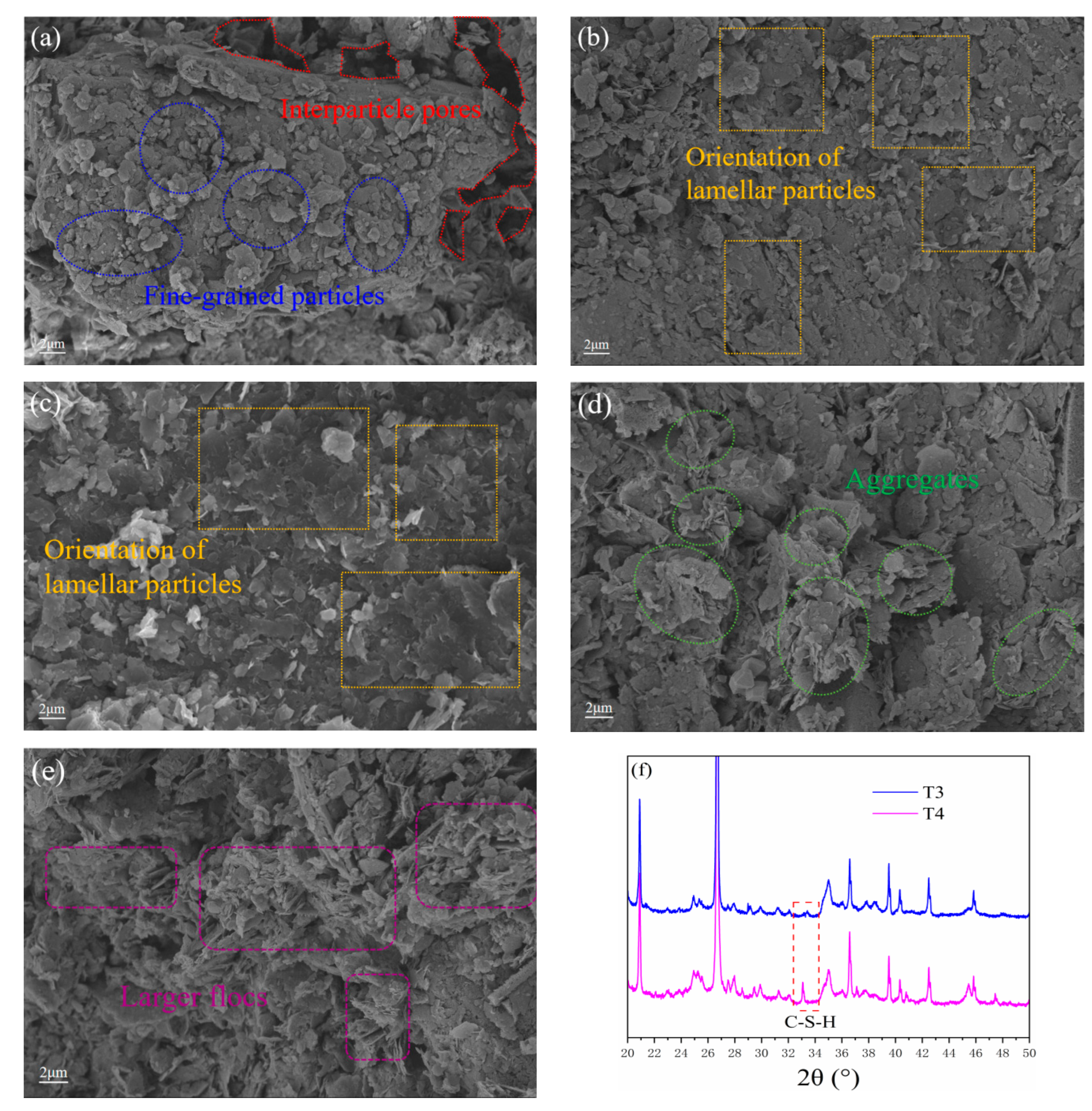

To further verify the mentioned results, representative sludge samples collected at a depth of 15.5 cm (i.e., the cathodic region) were selected for microstructure and mineral analysis. Figure 13a presents the microstructure of natural dredged sludge, which is composed of numerous fine-grained particles with weak interparticle bonds. Figure 13b shows the microstructure of sludge treated solely with VP, and more platy faces of the soil particles are observed. VP primarily increases the hydraulic gradient within the soil by applying negative pressure, thereby extracting free water from macropores. Due to weak interparticle bonds and strong vacuum suction, the soil particles tend to orient their platy faces perpendicular to the direction of vacuum pressure. Such particle orientation serves as the primary factor contributing to the subsequent reduction in vacuum consolidation efficiency [44]. The comparison of Figure 13b,c reveals that the two samples exhibit no significant difference in microstructure which aligns with the results reported in Section 3.5. EVP induces electroosmosis in addition to vacuum drainage, accelerating the removal of weakly bound water. However, for the cathodic soil, electroosmosis causes the accumulation of water, while vacuum suction remains the primary driving force for water drainage. Notably, the sludge pretreated with APAM-CaCl2 exhibits a significantly denser microstructure (without obvious particle orientation) and contains numerous aggregates, as illustrated in Figure 13d. Initially, Ca2+ ions compress the EDL by neutralizing surface negative charges on soil particles, reducing interparticle distance. APAM adsorbs onto particle surfaces via forming interparticle bridges, stabilizing fine-grained sludge into larger aggregates. VP then efficiently drains water from the interconnected macropores within these aggregates. The combined application of electroosmosis further facilitates water discharge and the formation of cementitious substances, which in turn strengthens the consolidation behavior of the sludge. Furthermore, Ca2+ ions improve the flocculation efficiency of APAM, resulting in the formation of extensive flocculent structures, as shown in Figure 13e. Figure 13f presents the XRD patterns of sludge samples in T3 and T4. A careful comparison revealed that the T4 sludge sample exhibited a new peak at 2θ = 33.1°. The peak roughly corresponds to the crystalline products of calcium silicate hydrate (C-S-H) [24]. These observations provide additional insights into the significant differences in shear strength among sludge samples consolidated by different methods.

Figure 13.

SEM images of sludge samples taken at a magnification of 3000×: (a) natural dredged sludge; (b) T1; (c) T2; (d) T3; (e) T4; (f) XRD patterns.

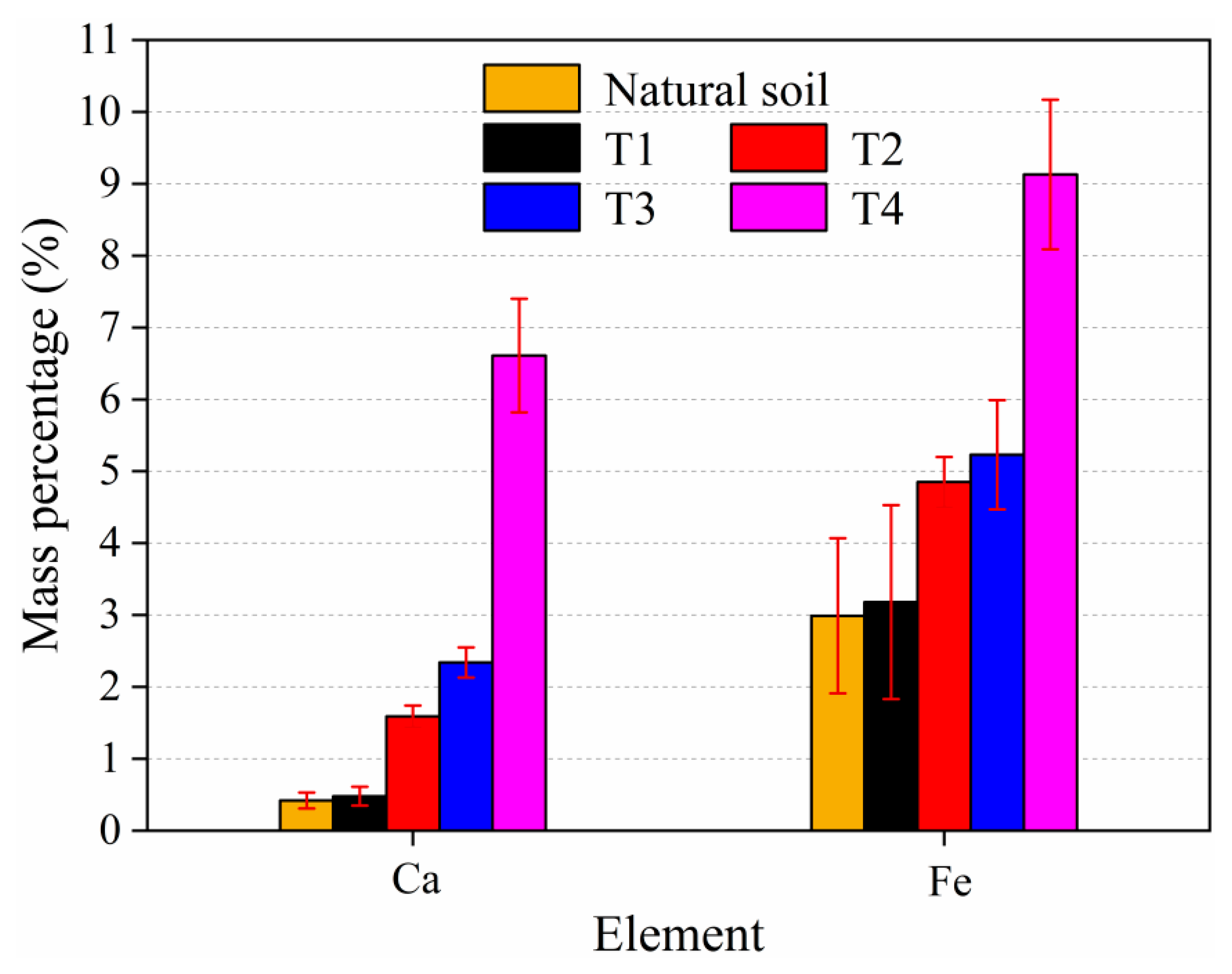

Figure 14 presents the differences in Ca and Fe contents in cathodic sludge detected via energy-dispersive spectroscopy (EDS). It can be observed that the elemental contents in T1 show negligible differences compared to those in natural dredged sludge, indicating that VP exerts a minimal impact on elemental distribution. By contrast, Ca and Fe contents in T2 increased by 1.11% and 1.67%, respectively, demonstrating that electroosmosis induces the accumulation of these elements near the cathode. Furthermore, Ca and Fe contents in T3 increased to 2.34% and 5.23%, while those in T4 increased to 6.61% and 9.13%, respectively. Both T3 and T4 were pretreated with APAM-CaCl2, introducing a large amount of Ca2+ into the sludge—this is the primary source of the increased Ca content. T4 retained more Ca than T3 due to electrokinetic acceleration of Ca2+ migration and precipitation, significantly reducing Ca2+ loss during drainage. The increased Fe content in T3 and T4 arose from the electrode corrosion and the differential transport mechanisms. APAM-CaCl2 enhanced the electrical conductivity of the sludge, reducing the resistance of the electrochemical cell formed on the electrode surface. This lowered the energy barrier for electron transfer, accelerating both anodic iron dissolution and cathodic reactions, thereby increasing the rate of Fe2+ release into the sludge. Moreover, the external electric field aggravated anode corrosion in T4, generating large amounts of Fe2+ that migrate to the cathode via electromigration. This process significantly increased the Fe content in T4. Ultimately, the distribution of these elements provides additional evidence for the aforementioned mechanisms underlying the consolidation of dredged sludge by EVP and APAM-CaCl2.

Figure 14.

Variations in Ca and Fe content in cathodic sludge.

4. Sustainability and Economic Evaluation

In addition to the superiority at flocculating fine-grained sludge, APAM-CaCl2 poses negligible environmental risks. APAM exhibits low bioavailability owing to its large molecular size (~12 million Da in this study). This characteristic prevents its absorption by plants, soil microorganisms, and soil animals. Additionally, APAM forms stable “soil particle-Ca2+-APAM” bridging, further limiting its mobility in sludge. APAM is inherently non-toxic. Its potential environmental risks are solely attributed to residual acrylamide (AMD) monomers, remaining from the synthesis process. However, AMD is easily metabolized by microorganisms in soil, with a half-life of merely tens of hours. It is also not absorbed by plant tissues and breaks down swiftly upon contact with living plant matter [45,46].

CaCl2 is a commonly used inorganic salt. Its environmental behavior is primarily governed by natural soil elemental cycling processes and the maintained Ca2+ concentrations. In the treated sludge, Ca2+ predominantly exists in two forms: (1) adsorbed onto the soil particle surface through cation exchange; and (2) precipitated as stable mineral phases, specifically Ca(OH)2 and C-S-H. Only a minor fraction of Ca2+ remains in the free ionic state. Moreover, this free Ca2+ is readily taken up by plants as an essential nutrient and does not undergo bioaccumulation in the food chain, further mitigating environmental risks.

The direct costs of the EVP + APAM-CaCl2 method were estimated based on local industrial prices in Guangzhou, China, combined with experimental data on additive usage and energy consumption.

- (1)

- With the real-time electricity price at 0.08$ per kilowatt-hour (kWh), the additional energy cost for sludge treatment is 2.9$·t−1 (calculated as: 35.7 kWh·t−1 × 0.08$·kWh−1 ≈ 2.9$·t−1).

- (2)

- For industrial-grade additives, APAM is priced at 100$·t−1 and CaCl2 at 170$·t−1. Based on optimal dosages identified in experiments (0.25% APAM and 4.0% CaCl2), the additive cost per tonne of dry sludge is approximately 7.05 $ (calculated as: 100$·t−1 × 0.0025 + 170$·t−1 × 0.04 ≈ 7.1$·t−1).

Compared to the VP method, the proposed combined method increases treatment costs by approximately 10$ per tonne of dry sludge. However, it offers substantial advantages: water discharge is enhanced by 53%, and average shear strength is improved by 98.6%, significantly reducing subsequent sludge treatment expenses. Moreover, for equivalent water discharge, the consolidation period is shortened by approximately 67% compared to VP. Thus, the combined method demonstrates significant economic benefits and promising application potential.

5. Conclusions

A series of laboratory studies were conducted on dredged sludge to investigate the synergistic effects of EVP combined with APAM. Initially, the optimal mass ratio and dosage of APAM and CaCl2 were determined through column settling experiments. Laboratory model tests were then performed using different consolidation methods. By comparing the differences in water discharge, surface settlement, and vacuum pressure during the consolidation process, as well as the water content, vane shear strength, and microstructure of the sludge after consolidation, the following conclusions were drawn:

- The combination of APAM and CaCl2 exhibits more efficient flocculation performance than their individual use. For the dredged sludge studied in this research, the optimal dosages of APAM and CaCl2 were confirmed to be 0.25% and 4.0% of the dry sludge mass, respectively.

- The EVP method simultaneously extracts free water and weakly bound water from sludge, thereby further increasing vacuum drainage mass and enhancing sludge consolidation efficiency. Notably, the consolidation degree in the vicinity of the electrodes is higher compared to other regions.

- Compared to the sole VP treatment, the combined application of APAM-CaCl2 significantly improves sludge permeability through aggregating fine particles into large flocs, increasing the vacuum drainage mass by 30.7% and the average shear strength by 17.3%.

- The combination of EVP and APAM-CaCl2 further enhances the efficiency and effectiveness of sludge consolidation. Specifically, EVP accelerates water discharge and promotes the synthesis of cementitious substances, APAM-CaCl2 improves sludge permeability and strengthens the bonding force between particles. As a result, the final drainage mass and the shear strength of the sludge are increased by 53% and 108%, respectively.

The combination of EVP and APAM-CaCl2 enables sustainable sludge management by accelerating dredged sludge consolidation and enhancing its geotechnical properties, promoting eco-friendly utilization in land reclamation. For practical applications, it is recommended to maintain a constant potential gradient (0.5 V·cm−1) instead of a fixed voltage. The electrode spacing is appropriately controlled at 2–4 m to reduce additional energy consumption. Meanwhile, a stepped vacuum preloading should be adopted to minimize clogging of drainage channels. Since the electromigration distance is positively correlated with time, the electric treatment period needs to be extended to 10–20 days to ensure sufficient Ca2+ delivery to target regions. In addition, sensors should be installed to monitor changes in sludge water content, electrical conductivity, and pH value, facilitating dynamic adjustment of operational parameters.

Author Contributions

Conceptualization, H.Z.; methodology, H.Z.; writing—original draft, H.Z.; project administration, C.T.; formal analysis, C.T.; data curation, C.H.; funding acquisition, H.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the National Natural Science Foundation of China (Grant No. 52308354), Guangdong Provincial Characteristic Innovation Projects for Ordinary Universities (Grant No. 2025KTSCX161), and the Doctoral Scientific Research Foundation of Wuyi University (Grant No. BSQD2404).

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author(s).

Acknowledgments

The authors would like to thank the reviewers for their critical reviews and suggestions on how to improveing the quality of this manuscript.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Svensson, N.; Norén, A.; Modin, O.; Fedje, K.K.; Rauch, S.; Strömvall, A.-M.; Andersson-Sköld, Y. Integrated cost and environmental impact assessment of management options for dredged sediment. Waste Manag. 2022, 138, 30–40. [Google Scholar] [CrossRef] [PubMed]

- Anda, R.; Fu, H.T.; Wang, J.; Lei, H.Y.; Hu, X.Q.; Ye, Q.; Cai, Y.Q.; Xie, Z.W. Effects of pressurizing timing on air booster vacuum consolidation of dredged slurry. Geotext. Geomembr. 2020, 48, 491–503. [Google Scholar] [CrossRef]

- Chen, H.; Chu, J.; Guo, W.; Wu, S. Land reclamation using the horizontal drainage enhanced geotextile sheet method. Geotext. Geomembr. 2023, 51, 131–150. [Google Scholar] [CrossRef]

- Chen, D.S.; Wu, Y.D.; Liu, Y.; Wu, H.G.; Zhu, Y.Y. Sensitivity Analysis of the Factors Affecting the Ground Heave Caused by Jet Grouting. Buildings 2024, 14, 2610. [Google Scholar] [CrossRef]

- Wu, P.C.; Feng, W.Q.; Yin, J.H. Numerical study of creep effects on settlements and load transfer mechanisms of soft soil improved by deep cement mixed soil columns under embankment load. Geotext. Geomembr. 2020, 48, 331–348. [Google Scholar] [CrossRef]

- Tan, X.; Zhao, M.H.; Chen, W. Numerical Simulation of a Single Stone Column in Soft Clay Using the Discrete-Element Method. Int. J. Geomech. 2018, 18, 04018176. [Google Scholar] [CrossRef]

- Mesri, G.; Khan, A.Q. Ground Improvement Using Vacuum Loading Together with Vertical Drains. J. Geotech. Geoenvironmental Eng. 2012, 138, 680–689. [Google Scholar] [CrossRef]

- Sexton, B.G.; Sivakumar, V.; McCabe, B.A. Creep improvement factors for vibro-replacement design. Proc. Inst. Civ. Eng.-Ground Improv. 2017, 170, 35–56. [Google Scholar] [CrossRef]

- Indraratna, B.C.; Rujikiatkamjorn, R.K.; Buys, H. Soft soil foundation improved by vacuum and surcharge loading. Proc. Inst. Civ. Eng.-Ground Improv. 2012, 165, 87–96. [Google Scholar] [CrossRef]

- Lei, H.; Toma, A.; Bo, Y.; Wang, L.; Wu, H. Reinforcement effect of the stepped-alternating vacuum preloading method on dredged fills. Int. J. Geomech. 2024, 24, 04023272. [Google Scholar] [CrossRef]

- Zhang, X.; Ye, P.; Wu, Y.J. Enhanced technology for sewage sludge advanced dewatering from an engineering practice perspective: A review. J. Environ. Manag. 2022, 321, 115938. [Google Scholar] [CrossRef]

- Zhang, X.D.; Huang, T.W.; Wu, Y.J. Soil drainage clogging mechanism under vacuum preloading: A review. Transp. Geotech. 2024, 45, 101178. [Google Scholar] [CrossRef]

- Liu, S.; Cai, Y.; Sun, H.; Geng, X.; Shi, L.; Pan, X. Consolidation considering clogging effect under uneven strain assumption. Int. J. Geomech. 2021, 21, 04020239. [Google Scholar] [CrossRef]

- Zhou, Y.; Chen, S.; Guo, W.; Ren, Y.; Xu, G. Recent developments in the vacuum preloading technique in China. Sustainability 2022, 14, 13897. [Google Scholar] [CrossRef]

- Hu, J.; Li, X.; Zhang, D.; Wang, J.; Hu, X.; Cai, Y. Experimental Study on the Effect of Additives on Drainage Consolidation in Vacuum Preloading Combined with Electroosmosis. KSCE J. Civ. Eng. 2020, 24, 2599–2609. [Google Scholar] [CrossRef]

- Zhang, G. Soil Nanoparticles and Their Influence on Engineering Properties of Soils. Adv. Meas. Model. Soil Behav. ASCE 2007, 173, 1–13. [Google Scholar] [CrossRef]

- Liu, X.Y.; Zhuang, Y.F. Evaluation of Electroosmotic Permeability Using Different Models and Investigation of Its Effect on Chromium Removal. Sustainability 2023, 15, 12706. [Google Scholar] [CrossRef]

- Zhou, J.; Gan, Q.; Tao, Y. Electro-osmotic permeability model based on ions migration. Acta Geotech. 2022, 17, 2379–2393. [Google Scholar] [CrossRef]

- Zhang, H.; Lu, S.C.; Tu, C.Z.; Guo, L.F. Experimental study on synergistic effects of electroosmosis and CaCl2 on inhibiting the expansion behaviors of sodium sulfate saline soil. Case Stud. Constr. Mat. 2025, 22, e04906. [Google Scholar] [CrossRef]

- Wang, J.; Zhao, R.; Cai, Y.Q. Vacuum preloading and electro-osmosis consolidation of dredged slurry pre-treated with flocculants. Eng. Geol. 2018, 246, 123–130. [Google Scholar] [CrossRef]

- Latifi, N.; Marto, A.; Eisazadeh, A. Physicochemical behavior of tropical laterite soil stabilized with non-traditional additive. Acta Geotech. 2016, 11, 433–443. [Google Scholar] [CrossRef]

- Dwari, R.K.; Angadi, S.I.; Tripathy, S.K. Studies on flocculation characteristics of chromite’s ore process tailing: Effect of flocculants ionicity and molecular mass. Colloid. Surface. A. 2018, 537, 467–477. [Google Scholar] [CrossRef]

- Lei, H.Y.; Xu, Y.G.; Li, X.; Jiang, M.J.; Liu, L.Z. Effect of Polyacrylamide on Improvement of Dredger Fill with Vacuum Preloading Method. J. Mater. Civ. Eng. 2019, 31, 04019193. [Google Scholar] [CrossRef]

- Latifi, N.; Meehan, C.L.; Majid, M.Z.A.; Horpibulsuk, S. Strengthening montmorillonitic and kaolinitic clays using a calcium-based non-traditional additive: A micro-level study. Appl. Clay Sci. 2016, 132, 182–193. [Google Scholar] [CrossRef]

- Lee, K.E.; Teng, T.T.; Morad, N.; Poh, B.T.; Mahalingam, M. Flocculation activity of novel ferric chloride-polyacrylamide (FeCl3-PAM) hybrid polymer. Desalination 2011, 266, 108–113. [Google Scholar] [CrossRef]

- Kang, X.; Bate, B.; Chen, R.P.; Yang, W.; Wang, F. Physicochemical and Mechanical Properties of Polymer-Amended Kaolinite and Fly Ash-Kaolinite Mixtures. J. Mater. Civ. Eng. 2019, 31, 04019064. [Google Scholar] [CrossRef]

- Wang, J.; Huang, G.; Fu, H.T.; Cai, Y.Q.; Hua, X.X.; Lou, X.M.; Jing, Y.W.; Hai, J.; Ni, J.F.; Zou, J. Vacuum preloading combined with multiple-flocculant treatment for dredged fill improvement. Eng. Geol. 2019, 259, 105194. [Google Scholar] [CrossRef]

- Zhang, H.; Ma, Q.G.; Su, W.J. On the dewatering of electroosmotic soil using intermittent current incorporated with calcium chloride. Dry. Technol. 2021, 42, 468–478. [Google Scholar] [CrossRef] [PubMed]

- Chang, T.H.; Chang, H.W. Improvement of Liquefaction Resistance of Reclaimed Sand in Water—An Experimental Study. J. Geo-Eng. 2010, 5, 39–49. [Google Scholar] [CrossRef]

- Zhang, H.; Guo, L.; Tu, C. Experimental Investigation on the Improvement of Dredged Sludge Using Air-Booster Vacuum Preloading with Polyacrylamide Addition. Materials 2025, 18, 2065. [Google Scholar] [CrossRef] [PubMed]

- D4318-10; Standard Test Methods for Liquid Limit, Plastic Limit, and Plasticity Index of Soils. ASTM International: West Conshohocken, PA, USA, 2010. [CrossRef]

- D2487-10; Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System). ASTM International: West Conshohocken, PA, USA, 2010. [CrossRef]

- Choi, Y.I.; Jung, B.G.; Son, H.J.; Jung, Y.J. Determination of optimum coagulants (ferric chloride and alum) for arsenic and turbidity removal by coagulation. J. Environ. Sci. Int. 2010, 19, 931–940. [Google Scholar] [CrossRef]

- Wong, S.S.; Teng, T.T.; Ahmad, A.L.; Zuhairi, A.; Najafpour, G. Treatment of pulp and paper mill wastewater by polyacrylamide (PAM) in polymer induced flocculation. J. Hazard. Mater. 2006, 135, 378–388. [Google Scholar] [CrossRef]

- Tao, Y.; Zhou, J.; Gong, X.; Chen, Z. Influence of polarity reversal and current intermittence on electro-osmosis. In Proceedings of the Geo-Shanghai in Ground Improvement and Geosynthetics, ASCE, Shanghai, China, 22 May 2014; Volume 238, pp. 198–208. [Google Scholar] [CrossRef]

- Chai, J.; Hong, Z.; Shen, S. Vacuum-drain consolidation induced pressure distribution and ground deformation. Geotext. Geomembr. 2010, 28, 525–535. [Google Scholar] [CrossRef]

- Cao, Y.; Zhang, R.; Xu, G.; Xu, J. Axisymmetric large strain consolidation by vertical drains considering well resistance under vacuum pressure. Arab. J. Geosci. 2021, 14, 2016. [Google Scholar] [CrossRef]

- Wang, J.; Ma, J.; Liu, F.; Mi, W.; Cai, Y.; Fu, H. Experimental study on the improvement of marine clay slurry by electroosmosis-vacuum preloading. Geotext. Geomembr. 2016, 44, 615–622. [Google Scholar] [CrossRef]

- Jiao, Y.; He, J.; Zhou, P.; Cao, Z. Potential of Flocculant-Aided Soil Slurry Dewatering in Land Reclamation: Laboratory Investigations. Adv. Civ. Eng. 2018, 2018, 8040193. [Google Scholar] [CrossRef]

- Wang, J.; Shi, W.; Wu, W.; Liu, F.; Fu, H.; Cai, Y. Influence of composite flocculant FeCl3-APAM on vacuum drainage of river-dredged sludge. Can. Geotech. J. 2019, 56, 868–875. [Google Scholar] [CrossRef]

- Liu, F.; Li, Z.; Yuan, G.; Hu, X.; Zhang, D.; Du, Y. Improvement of dredger fill by stepped vacuum preloading combined with stepped voltage electro-osmosis. Mar. Georesour. Geotechnol. 2020, 39, 822–831. [Google Scholar] [CrossRef]

- Hu, X.; Gao, Z.; Liu, F.; Tao, Y.; Xu, D.; Du, Y. The optimal combination form of vacuum pre-loading combined with electro-osmosis and with dynamic compaction method on the improvement of dredged slurry. Mar. Georesour. Geotechnol. 2020, 39, 1192–1204. [Google Scholar] [CrossRef]

- Wu, J.; Liu, X.; Luo, X.; Fu, H.; Li, X.; Cai, Y. Improvement of marine slurry by vacuum preloading and air-booster via a reverse prefabricated vertical drain. Mar. Georesour. Geotechnol. 2022, 42, 149–160. [Google Scholar] [CrossRef]

- Xu, B.H.; He, N.; Jiang, Y.B.; Zhou, Y.Z.; Zhan, X.J. Experimental study on the clogging effect of dredged fill surrounding the PVD under vacuum preloading. Geotext. Geomembr. 2020, 48, 614–624. [Google Scholar] [CrossRef]

- Sojka, R.E.; Bjorneberg, D.L.; Entry, J.A.; Lentz, R.D.; Orts, W.J. Polyacrylamide (PAM) in agriculture and environmental land management. Adv. Agron. 2007, 92, 75–162. [Google Scholar] [CrossRef]

- Xiong, B.; Loss, R.D.; Shields, D.; Pawlik, T.; Hochreiter, R.; Zydney, A.L.; Kumar, M. Polyacrylamide degradation and its implications in environmental systems. Npj Clean Water 2018, 1, 17. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).