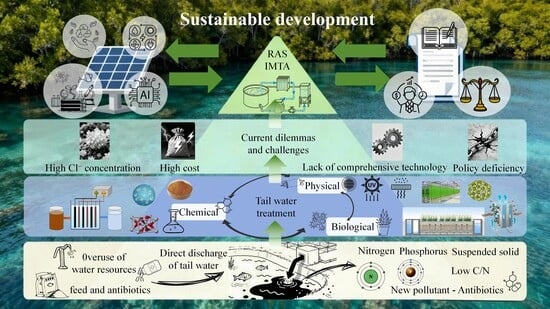

The Dilemmas and Challenges of Tail Water Treatment Technology for Land-Based Marine Aquaculture in China: A Review

Abstract

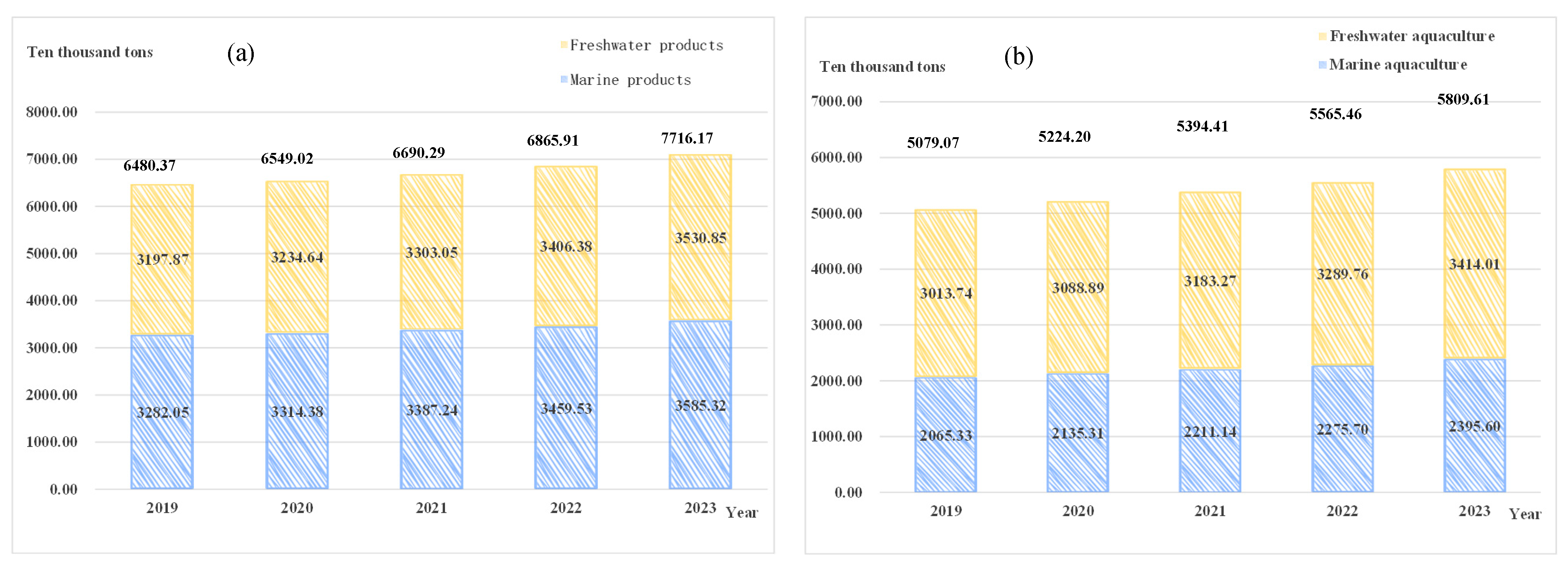

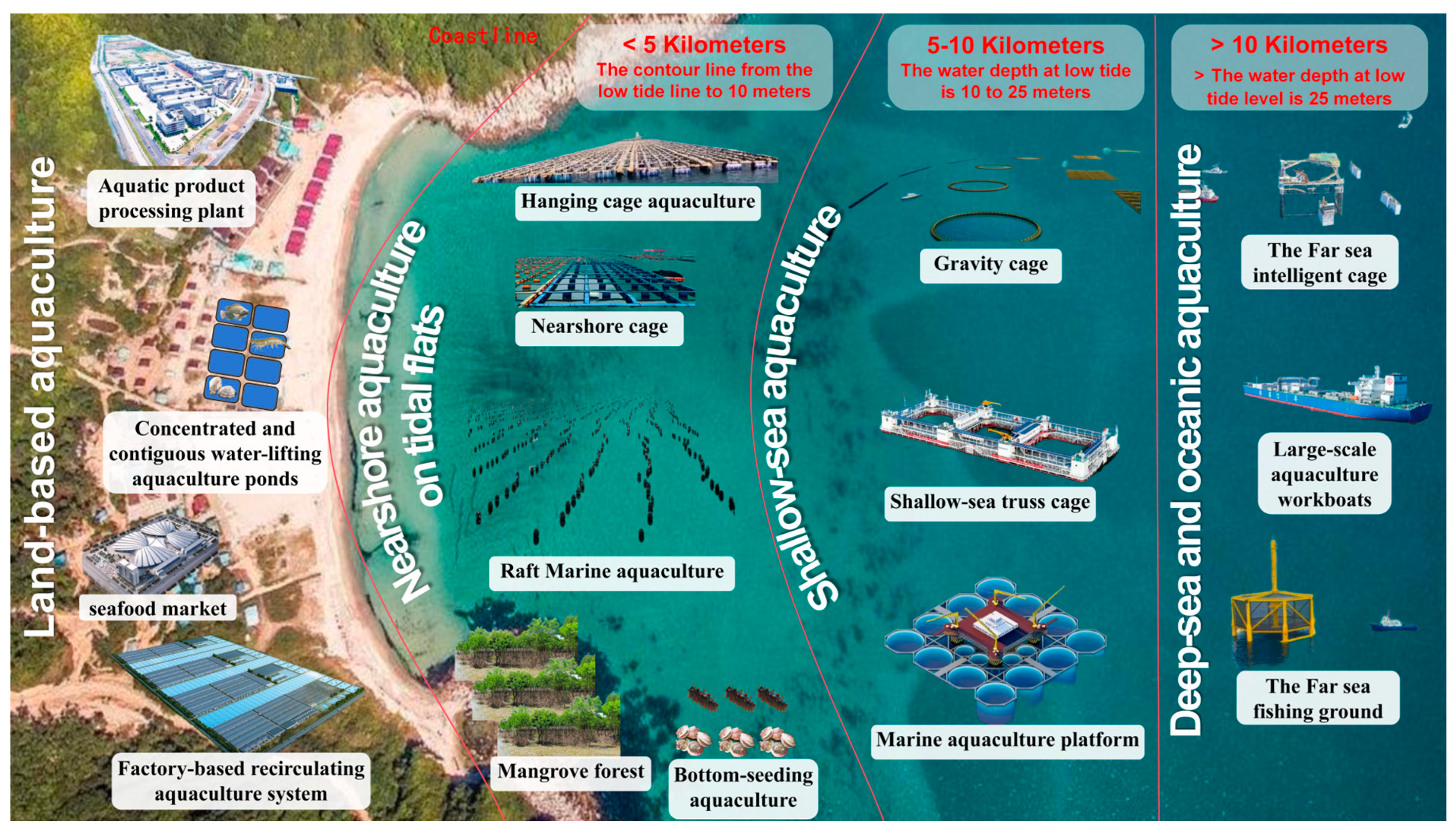

1. Introduction

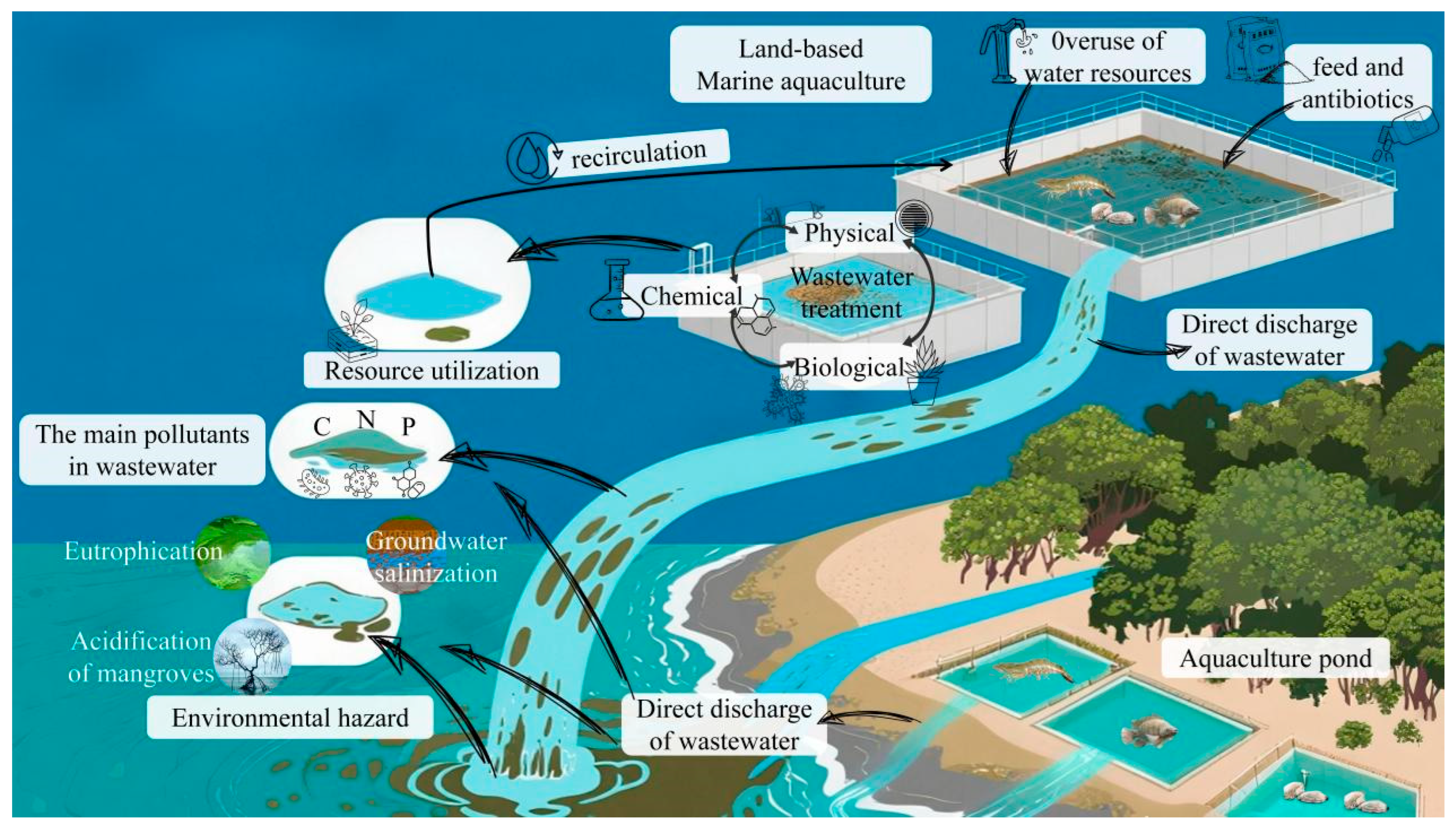

2. Marine Aquaculture Tail Water

2.1. Aquaculture Tail Water Pollution

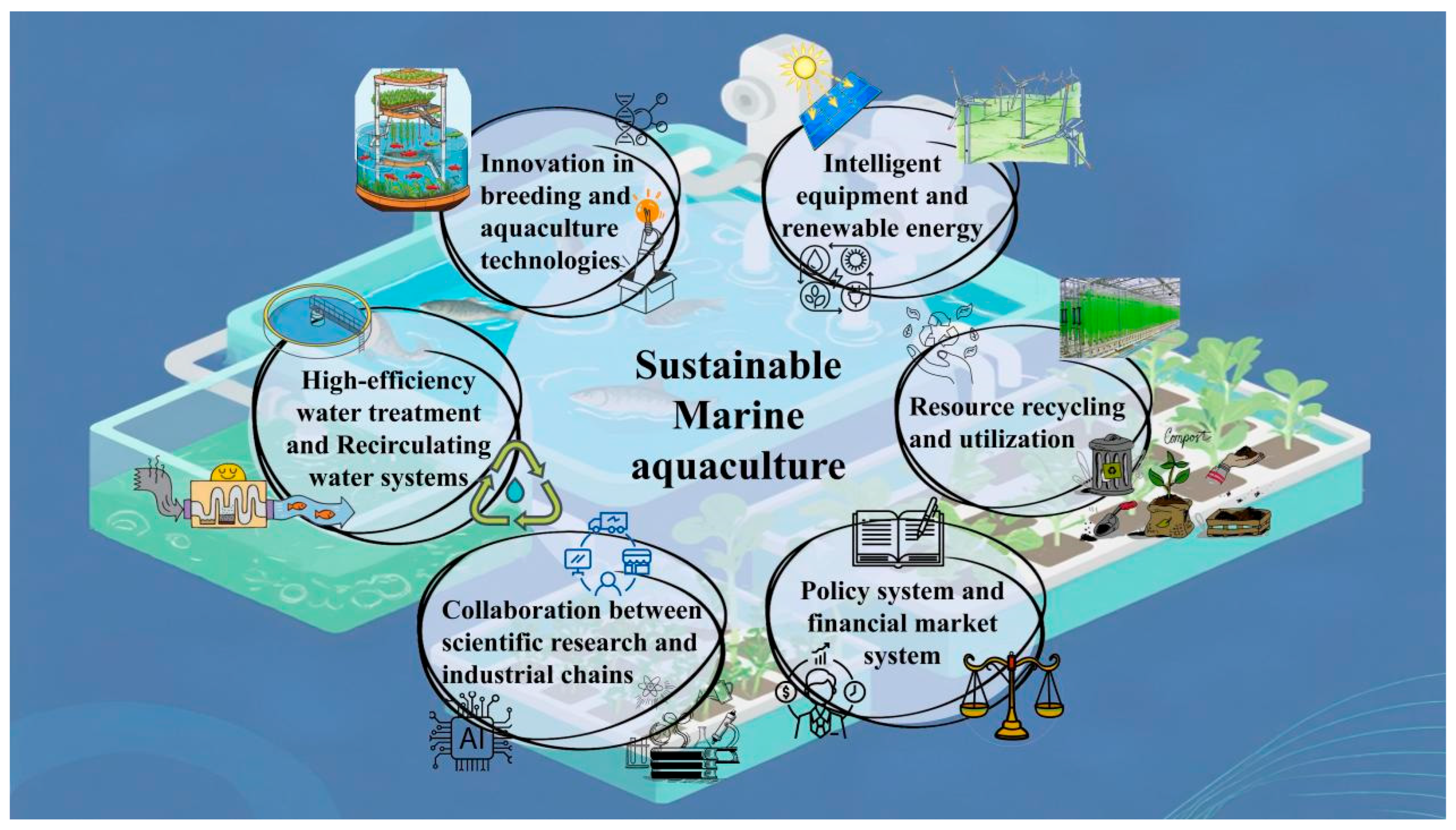

2.2. The Environmental Impact of Marine Aquaculture Tail Water

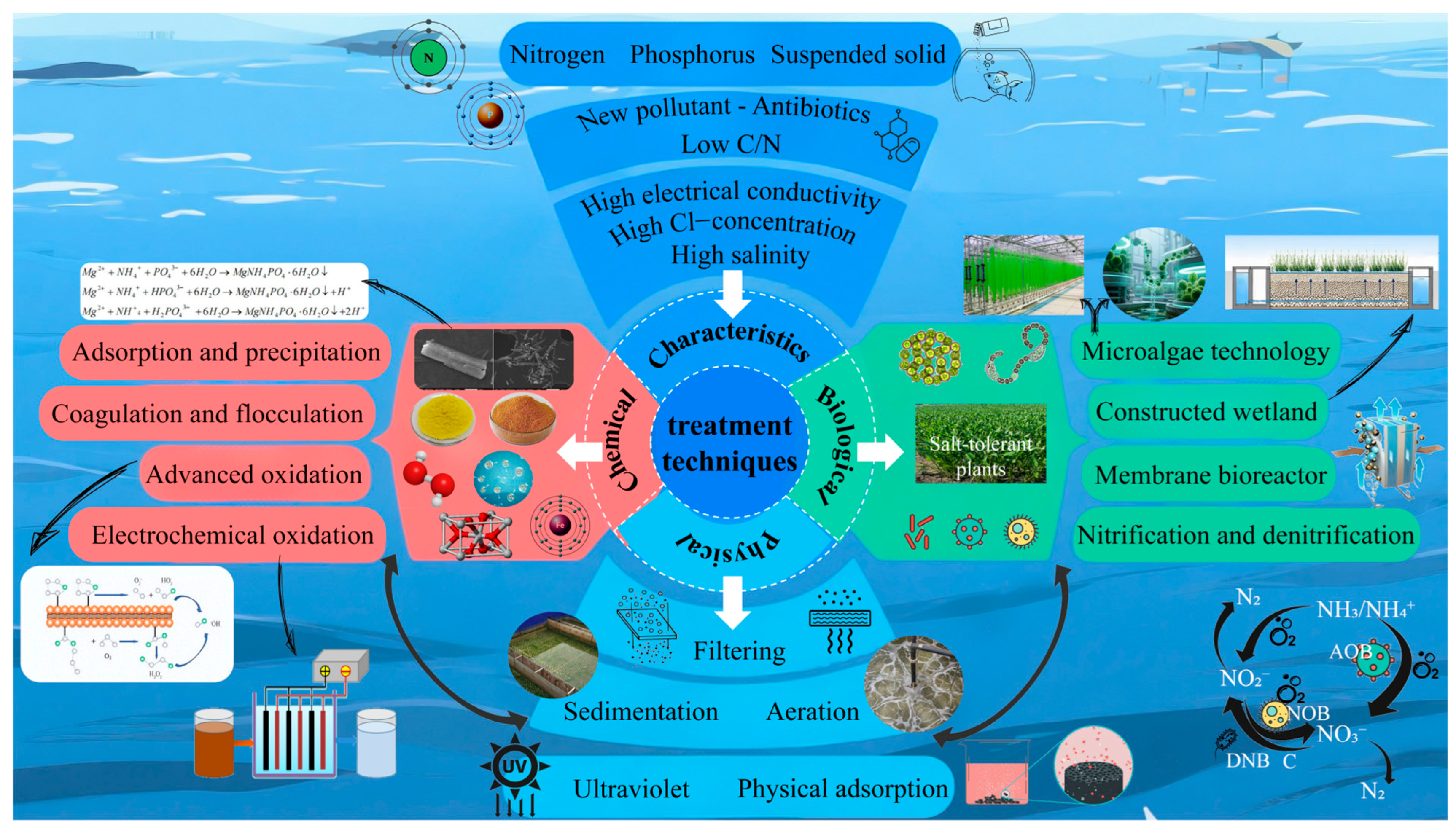

3. The Dilemma of the Existing Tail Water Treatment Technology

3.1. Physical Technology

3.2. Chemical Technology

3.3. Biotechnology

4. The Main Challenges Faced in Tail Water Treatment

5. Countermeasures and Suggestions

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- FAO. World Food and Agriculture—Statistical Yearbook 2024; FAO: Rome, Italy, 2024; pp. 1–76. [Google Scholar]

- FAO. The State of World Fisheries and Aquaculture 2024—Blue Transformation in Action; FAO: Rome, Italy, 2024; pp. 1–82. [Google Scholar]

- Ji, J.; Sun, Y.; Xu, L.; Xu, Y. Research on the influencing factors and configuration path of environmental technological progress bias in China’s mariculture industry. Aquac. Int. 2025, 33, 357. [Google Scholar] [CrossRef]

- Qiao, S.; Yin, W.; Liu, Y.; Li, D. The evolution of food and nutrition supply patterns of marine capture and mariculture in China and its transformation coping strategies. Front. Mar. Sci. 2024, 11, 1478631. [Google Scholar] [CrossRef]

- Mohiuddin, A.K. Nutritional Value and Associated Potentials Risks of Seafood Consumption. Biomed. J. Sci. Tech. Res. 2019, 19, 14456–14459. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, Z.; Yang, X.; Wang, S.; Liu, X.; Liu, B.; Zhang, J.; Meng, D.; Ding, K.; Gao, K.; et al. Changes in the spatial distribution of mariculture in China over the past 20 years. J. Geogr. Sci. 2023, 33, 2377–2399. [Google Scholar] [CrossRef]

- Liu, Y.; Yang, X.; Wang, Z.; Liu, B.; Zhang, J.; Liu, X.; Meng, D.; Gao, K.; Zeng, X.; Yu, G.; et al. Mapping the fine spatial distribution of global offshore surface seawater mariculture using remote sensing big data. Int. J. Digit. Earth 2024, 17, 1. [Google Scholar] [CrossRef]

- Clawson, G.; Kuempel, C.D.; Frazier, M.; Blasco, G.; Cottrell, R.S.; Froehlich, H.E.; Metian, M.; Nash, K.L.; Többen, J.; Verstaen, J.; et al. Mapping the spatial distribution of global mariculture production. Aquaculture 2022, 553, 738066. [Google Scholar] [CrossRef]

- Ministry of Ecology and Environment. Bulletin on the State of Marine Ecological Environment in China in 2022. Environ. Prot. 2023, 51, 70–82. [Google Scholar] [CrossRef]

- Bambaranda, B.V.A.S.M.; Tsusaka, T.W.; Chirapart, A.; Salin, K.R.; Sasaki, N. Capacity of Caulerpa lentillifera in the Removal of Fish Culture Effluent in a Recirculating Aquaculture System. Processes 2019, 7, 440. [Google Scholar] [CrossRef]

- Bannister, R.J.; Johnsen, I.A.; Hansen, P.K.; Kutti, T.; Asplin, L. Near- and far-field dispersal modelling of organic waste from Atlantic salmon aquaculture in fjord systems. ICES J. Mar. Sci. 2016, 73, 2408–2419. [Google Scholar] [CrossRef]

- Wu, L.; Ren, L.; Li, J.; Li, X.; Yang, S.; Song, Y.; Li, X. Novel maricultural-solid-waste derived biochar for removing eutrophic nutrients and enrofloxacin: Property, mechanism, and application assessment. J. Hazard. Mater. 2022, 427, 128147. [Google Scholar] [CrossRef]

- Liu, F.; Lu, T.; Zhang, Y. Performance assessment of constructed wetland-microbial fuel cell for treatment of mariculture wastewater containing heavy metals. Process Saf. Environ. Prot. 2022, 168, 633–641. [Google Scholar] [CrossRef]

- Liu, X.; Steele, J.C.; Meng, X.-Z. Usage, residue, and human health risk of antibiotics in Chinese aquaculture: A review. Environ. Pollut. 2017, 223, 161–169. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Hasunuma, T.; Shiung Lam, S.; Kondo, A.; Ho, S.-H. Salinity-induced microalgal-based mariculture wastewater treatment combined with biodiesel production. Bioresour. Technol. 2021, 340, 125638. [Google Scholar] [CrossRef]

- Lang, Z.; Zhou, M.; Zhang, Q.; Yin, X.; Li, Y. Comprehensive treatment of marine aquaculture wastewater by a cost-effective flow-through electro-oxidation process. Sci. Total Environ. 2020, 722, 137812. [Google Scholar] [CrossRef] [PubMed]

- Xu, J.; Han, L.; Yin, W. Research on the ecologicalization efficiency of mariculture industry in China and its influencing factors. Mar. Policy 2022, 137, 104935. [Google Scholar] [CrossRef]

- Li, N.; Hu, C.; Wang, K.; Du, J.; He, J.; Wu, J. Research Progress on Prevention and Control Technology of Mariculture Wastewater: A Review. Fish. Sci. 2023, 42, 911–920. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, Z.; Wang, W.; Wang, D.; Sun, L. The treatment effects of “Three ponds and two dams” on the wastewater from Litopenaeus vannamei industrialized mariculture. Mar. Environ. Sci. 2023, 42, 720–728. [Google Scholar] [CrossRef]

- Tan, L.; Liu, Y.; Ren, J.S.; Zhang, J. The sources and burial fluxes of sedimentary organic carbon from the intensive mariculture zone in Haizhou Bay, China. Mar. Pollut. Bull. 2025, 218, 118168. [Google Scholar] [CrossRef]

- Wang, Y.; Guo, X.; Wang, G.; Wang, L.; Huang, T.; Li, Y.; Wang, Z.; Dai, M. Assessment of nutrient cycling in an intensive mariculture system. Mar. Pollut. Bull. 2024, 209, 117085. [Google Scholar] [CrossRef]

- He, Q.; Zhang, D.; Main, K.; Feng, C.; Ergas, S.J. Biological denitrification in marine aquaculture systems: A multiple electron donor microcosm study. Bioresour. Technol. 2018, 263, 340–349. [Google Scholar] [CrossRef]

- Wang, Q.; Liu, H.; Sui, J. Mariculture: Developments, Present Status and Prospects. In Aquaculture in China; Wiley Blackwell: Hoboken, NJ, USA, 2018; pp. 38–54. [Google Scholar]

- Castilla-Gavilán, M.; Guerra-García, J.M.; Hachero-Cruzado, I.; Herrera, M. Understanding Carbon Footprint in Sustainable Land-Based Marine Aquaculture: Exploring Production Techniques. J. Mar. Sci. Eng. 2024, 12, 1192. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, Z.; Yang, X.; Wang, S.; Liu, X.; Liu, B.; Zhang, J.; Meng, D.; Ding, K.; Gao, K.; et al. Changes in mariculture and offshore seawater quality in China during the past 20 years. Ecol. Indic. 2023, 157, 111220. [Google Scholar] [CrossRef]

- Liu, X.; Shao, Z.; Cheng, G.; Lu, S.; Gu, Z.; Zhu, H.; Shen, H.; Wang, J.; Chen, X. Ecological engineering in pond aquaculture: A review from the whole-process perspective in China. Rev. Aquac. 2021, 13, 1060–1076. [Google Scholar] [CrossRef]

- Xu, L.; Yang, Y.; Cui, Z.; Wang, Q. Carbon dynamics in seawater and sediment: A case study of shellfish and seaweed mariculture systems. Mar. Environ. Res. 2025, 204, 106897. [Google Scholar] [CrossRef]

- Huang, J.; Wang, D.; Gong, F.; Bai, Y.; He, X. Changes in Nutrient Concentrations in Shenzhen Bay Detected Using Landsat Imagery between 1988 and 2020. Remote Sens. 2021, 13, 3469. [Google Scholar] [CrossRef]

- Anh, P.T.; Kroeze, C.; Bush, S.R.; Mol, A.P.J. Water pollution by intensive brackish shrimp farming in south-east Vietnam: Causes and options for control. Agric. Water Manag. 2010, 97, 872–882. [Google Scholar] [CrossRef]

- Zhao, Z.; Wei, Y.; Wang, Y.; Peng, G.; Zeng, E.Y.; Yu, K.; Xu, X.-R.; Li, R. Fate and drivers of mariculture-derived microplastics from ponds to mangrove forests. Environ. Pollut. 2024, 361, 124790. [Google Scholar] [CrossRef]

- Liu, M.; Lian, Q.; Zhao, Y.; Ni, M.; Lou, J.; Yuan, J. Treatment effects of pond aquaculture wastewater using a Field-scale Combined Ecological Treatment System and the associated microbial characteristics. Aquaculture 2023, 563, 739018. [Google Scholar] [CrossRef]

- Xiong, Y.; Gao, L.; Qu, L.; Xu, J.; Ma, Z.; Gao, G. The contribution of fish and seaweed mariculture to the coastal fluxes of biogenic elements in two important aquaculture areas, China. Sci. Total Environ. 2023, 856, 159056. [Google Scholar] [CrossRef]

- Du, J.; Yan, Z.; Hu, C.; Wang, K.; Liu, G.; Jiang, B.; Song, L.; Xie, H. Occurrence, distribution and risk assessment of antibiotics and pesticides in mariculture area around Liaodong Peninsula. Mar. Pollut. Bull. 2024, 205, 116588. [Google Scholar] [CrossRef]

- Dong, S.; Liu, D.; Zhu, B.; Zhang, D.; Wang, F. Practice assessment of integrated marine pond aquaculture for increasing benefits and reducing environmental pollution using an ecosystem modeling approach. Sci. Total Environ. 2024, 908, 168408. [Google Scholar] [CrossRef]

- Price, C.; Black, K.D.; Hargrave, B.T.; Morris, J.A. Marine cage culture and the environment: Effects on water quality and primary production. Aquac. Environ. Interact. 2015, 6, 151–174. [Google Scholar] [CrossRef]

- Bouwman, L.; Beusen, A.; Glibert, P.M.; Overbeek, C.; Pawlowski, M.; Herrera, J.; Mulsow, S.; Yu, R.; Zhou, M. Mariculture: Significant and expanding cause of coastal nutrient enrichment. Environ. Res. Lett. 2013, 8, 044026. [Google Scholar] [CrossRef]

- Herbeck, L.S.; Krumme, U.; Nordhaus, I.; Jennerjahn, T.C. Pond aquaculture effluents feed an anthropogenic nitrogen loop in a SE Asian estuary. Sci. Total Environ. 2021, 756, 144083. [Google Scholar] [CrossRef]

- Yu, J.; Wu, S.; Zhang, Y.; Xiao, Y. Fuzzy comprehensive evaluation of seawater quality of Larimichthys Crocea mariculture areas in Zhoushan, China. Mar. Freshw. Res. 2024, 75, MF23151. [Google Scholar] [CrossRef]

- Duan, N.; Yu, X.; Jiang, Z.; Chen, H.; Feng, H.; Kang, Y.; Ma, H.; Zhu, H. Impacts of an intensive traditional mariculture model on offshore environments as evidenced by dissolved organic matter and bacterial communities. Water Res. 2024, 267, 122530. [Google Scholar] [CrossRef]

- Yin, P.; Wang, D.; Zhang, X.; Zhang, G.; Zhao, H.; Zhang, Y.; Yang, H. Effects of KMPS on eutrophic sediment-water interface in pond aquaculture: Based on physicochemical properties, DOM characteristics and microbial community structure. Aquaculture 2026, 612, 743089. [Google Scholar] [CrossRef]

- Bennett, N.J.; Blythe, J.; White, C.S.; Campero, C. Blue growth and blue justice: Ten risks and solutions for the ocean economy. Mar. Policy 2021, 125, 104387. [Google Scholar] [CrossRef]

- Qin, Y.-Y.; Liang, M.-Z.; Liang, S.-C.; Zheng, H.-L. Effect of Shrimp Aquaculture Effluent on Mangrove Sediment in Beibu Bay. Pol. J. Environ. Stud. 2021, 31, 795–802. [Google Scholar] [CrossRef]

- Hu, K.; Huang, Q.; Han, P.; Han, Z.; Yang, Z.; Luo, Q.; Li, P.; Miao, M.; Zeng, Z.; Chen, H.; et al. A Hydrochemical Study of Groundwater Salinization in Qinzhou Bay, Guangxi, Southern China. Earth Space Sci. 2023, 10, e2022EA002565. [Google Scholar] [CrossRef]

- Lu, S.; Wang, Q.; Gao, M.; Zhao, C.; She, Z.; Zhao, Y.; Jin, C.; Guo, L. Effect of aerobic/anoxic duration on the performance, microbial activity and microbial community of sequencing batch biofilm reactor treating synthetic mariculture wastewater. Bioresour. Technol. 2021, 333, 125198. [Google Scholar] [CrossRef]

- Zheng, L.; Liu, Q.; Liu, J.; Xiao, J.; Xu, G. Pollution Control of Industrial Mariculture Wastewater: A Mini-Review. Water 2022, 14, 1390. [Google Scholar] [CrossRef]

- Mook, W.T.; Chakrabarti, M.H.; Aroua, M.K.; Khan, G.M.A.; Ali, B.S.; Islam, M.S.; Abu Hassan, M.A. Removal of total ammonia nitrogen (TAN), nitrate and total organic carbon (TOC) from aquaculture wastewater using electrochemical technology: A review. Desalination 2012, 285, 1–13. [Google Scholar] [CrossRef]

- Zhao, W.; Wang, Y.; Su, S.; Qiu, H.; Wang, K.; Zhang, Y. Research Advances in Mechanism and Process of NH4+-N Removal from Mariculture Tail Water. Technol. Water Treat. 2024, 50, 1–5. [Google Scholar] [CrossRef]

- Lasaki, B.A.; Maurer, P.; Schönberger, H. Uncovering the reasons behind high-performing primary sedimentation tanks for municipal wastewater treatment: An in-depth analysis of key factors. J. Environ. Chem. Eng. 2024, 12, 112460. [Google Scholar] [CrossRef]

- Kang, P.; Liu, P.; Wang, F. Use of multiple isotopes to evaluate the impact of mariculture on nutrient dynamics in coastal groundwater. Environ. Sci. Pollut. Res. 2019, 26, 12399–12411. [Google Scholar] [CrossRef]

- Wang, C.; Yuan, Z.; Yuan, Y.; Li, X.; Yu, B.; Ying, L. Research progress of biological treatment technology of mariculture wastewater and thoughts on carbon reduction: A review. J. Dalian Ocean Univ. 2022, 37, 1055–1065. [Google Scholar] [CrossRef]

- Ye, M.; Tong, J. Development trend and prospect of tail water treatment technology of shrimp mariculture. J. Huazhong Agric. Univ. 2021, 40, 241–252. [Google Scholar] [CrossRef]

- Nora’aini, A.; Wahab Mohammad, A.; Jusoh, A.; Hasan, M.R.; Ghazali, N.; Kamaruzaman, K. Treatment of aquaculture wastewater using ultra-low pressure asymmetric polyethersulfone (PES) membrane. Desalination 2005, 185, 317–326. [Google Scholar] [CrossRef]

- Zhang, Y.; Wei, M.; Huang, K.; Yu, K.; Liang, J.; Wei, F.; Huang, J.; Yin, X. Inactivation of E. coli and Streptococcus agalactiae by UV/persulfate during marine aquaculture disinfection. Environ. Sci. Pollut. Res. 2022, 29, 45421–45434. [Google Scholar] [CrossRef]

- Kuang, B.; Zhou, L.; Cai, C. Mariculture wastewater treatment using electroactive bacteria-algae biofilm coupled with siphon aeration. Trans. Chin. Soc. Agric. Eng. 2023, 39, 205–212. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, H.; Yao, J.; Cao, S.; Liu, X.; Cheng, G.; Hu, Q.; Wang, F.; Zhang, Z. Hydrodynamic characteristics analysis of series hydraulic cyclone separators for pond aquaculture wastewater purification. Aquac. Eng. 2024, 106, 102436. [Google Scholar] [CrossRef]

- Xu, J.; Du, Y.; Qiu, T.; Zhou, L.; Li, Y.; Chen, F.; Sun, J. Application of hybrid electrocoagulation–filtration methods in the pretreatment of marine aquaculture wastewater. Water Sci. Technol. 2021, 83, 1315–1326. [Google Scholar] [CrossRef] [PubMed]

- Zeng, D.; Lin, F.; Wu, G.; Hu, L.; Shen, K.; Zhou, C.; Xu, Z. Mariculture Wastewater Treatment by Integrated Process of Hybridmesh, Continuous Flow Sand Filter, and Activated Carbon Adsorption. China Water Wastewater 2019, 35, 97–102. [Google Scholar] [CrossRef]

- Huang, B.; Zhou, N.; Yi, P.; Fan, X. Application of Continuous Uf Technique in Water Treatment for Marine Culture. Technol. Water Treat. 2006, 03, 43–45. [Google Scholar] [CrossRef]

- De Jesus Gregersen, K.J.; Pedersen, P.B.; Pedersen, L.-F.; Liu, D.; Dalsgaard, J. UV irradiation and micro filtration effects on micro particle development and microbial water quality in recirculation aquaculture systems. Aquaculture 2020, 518, 734785. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhao, Y.-G.; Hu, Y.; Gao, M.; Guo, L.; Ji, J. Insight in degradation of tetracycline in mariculture wastewater by ultraviolet/persulfate advanced oxidation process. Environ. Res. 2022, 212, 113324. [Google Scholar] [CrossRef]

- Tang, Y.; Wang, T.; Hu, Y.; Wang, X.; Wang, Y.; Zhang, H.; Gao, X.; Li, P. Study of an electrochemical system with dual cathodes for the treatment of mariculture wastewater. Chem. Eng. J. 2024, 498, 155064. [Google Scholar] [CrossRef]

- Sun, J.; Liu, L.; Yang, F. Successful bio-electrochemical treatment of nitrogenous mariculture wastewater by enhancing nitrogen removal via synergy of algae and cathodic photo-electro-catalysis. Sci. Total Environ. 2020, 743, 140738. [Google Scholar] [CrossRef]

- Quan, F.; Zhan, G.; Zhou, B.; Ling, C.; Wang, X.; Shen, W.; Li, J.; Jia, F.; Zhang, L. Electrochemical removal of ammonium nitrogen in high efficiency and N2 selectivity using non-noble single-atomic iron catalyst. J. Environ. Sci. 2023, 125, 544–552. [Google Scholar] [CrossRef]

- Zhou, Y.; Wang, H.; Liu, X.; Zeng, D.; Wang, K.; Zhang, L.; Wang, W. An efficient strategy for selective oxidation of ammonia nitrogen into N2 over BiOCl photocatalyst. Appl. Catal. B Environ. 2021, 294, 120265. [Google Scholar] [CrossRef]

- Chi, Y.; Xu, S.; Li, M.; He, M.; Yu, H.; Li, L.; Yue, Q.; Gao, B. Effective blockage of chloride ion quenching and chlorinated by-product generation in photocatalytic wastewater treatment. J. Hazard. Mater. 2020, 396, 122670. [Google Scholar] [CrossRef] [PubMed]

- Velusamy, K.; Periyasamy, S.; Kumar, P.S.; Vo, D.-V.N.; Sindhu, J.; Sneka, D.; Subhashini, B. Advanced techniques to remove phosphates and nitrates from waters: A review. Environ. Chem. Lett. 2021, 19, 3165–3180. [Google Scholar] [CrossRef]

- Mavhungu, A.; Masindi, V.; Foteinis, S.; Mbaya, R.; Tekere, M.; Kortidis, I.; Chatzisymeon, E. Advocating circular economy in wastewater treatment: Struvite formation and drinking water reclamation from real municipal effluents. J. Environ. Chem. Eng. 2020, 8, 103957. [Google Scholar] [CrossRef]

- Bonisławska, M.; Nędzarek, A.; Rybczyk, A. Assessment of the use of precipitating agents and ceramic membranes for treatment of effluents with high concentrations of nitrogen and phosphorus from recirculating aquaculture systems. Aquac. Res. 2019, 50, 1248–1256. [Google Scholar] [CrossRef]

- Ahmad, A.; Abdullah, S.R.S.; Hasan, H.A.; Othman, A.R.; Kurniawan, S.B. Aquaculture wastewater treatment using plant-based coagulants: Evaluating removal efficiency through the coagulation-flocculation process. Results Chem. 2024, 7, 101390. [Google Scholar] [CrossRef]

- Liao, H.; Wang, W.; Cheng, X.; Chen, S.; Liu, F.; Liu, G. Efficient degradation of inorganic nitrogen in mariculture wastewater by electrochemical methods. J. Hazard. Mater. Adv. 2022, 6, 100093. [Google Scholar] [CrossRef]

- Zhao, L.; Hu, Y.; Zhao, Y.-G.; Mupindu, P. Removal of typical sulfonamide resistance genes by ultraviolet/hydrogen peroxide advanced oxidation process in mariculture wastewater. J. Water Process Eng. 2023, 55, 104262. [Google Scholar] [CrossRef]

- Zhang, X.; Hu, J.; Spanjers, H.; van Lier, J.B. Struvite crystallization under a marine/brackish aquaculture condition. Bioresour. Technol. 2016, 218, 1151–1156. [Google Scholar] [CrossRef]

- Alnawajha, M.M.; Kurniawan, S.B.; Imron, M.F.; Abdullah, S.R.S.; Hasan, H.A.; Othman, A.R. Plant-based coagulants/flocculants: Characteristics, mechanisms, and possible utilization in treating aquaculture effluent and benefiting from the recovered nutrients. Environ. Sci. Pollut. Res. 2022, 29, 58430–58453. [Google Scholar] [CrossRef]

- Zhang, X.; Hu, J.; Spanjers, H.; van Lier, J.B. Performance of inorganic coagulants in treatment of backwash waters from a brackish aquaculture recirculation system and digestibility of salty sludge. Aquac. Eng. 2014, 61, 9–16. [Google Scholar] [CrossRef]

- Yakamercan, E.; Turco, R.F.; Nas, B.; Hussain, A.S.; Aygun, A.; Meador, L.; Simsek, H. Optimizing electrochemical methods for fish wastewater treatment in recirculating aquaculture systems. J. Water Process Eng. 2024, 66, 105891. [Google Scholar] [CrossRef]

- Romano, A.; Ortiz, I.; Urtiaga, A.M. Comprehensive kinetics of electrochemically assisted ammonia removal in marine aquaculture recirculating systems. J. Electroanal. Chem. 2021, 897, 115619. [Google Scholar] [CrossRef]

- Fujihira, M.; Satoh, Y.; Osa, T. Heterogeneous photocatalytic oxidation of aromatic compounds on TiO2. Nature 1981, 293, 206–208. [Google Scholar] [CrossRef]

- Wang, J.; Bai, Z. Fe-based catalysts for heterogeneous catalytic ozonation of emerging contaminants in water and wastewater. Chem. Eng. J. 2017, 312, 79–98. [Google Scholar] [CrossRef]

- Xiao, R.; Liu, K.; Bai, L.; Minakata, D.; Seo, Y.; Kaya Göktaş, R.; Dionysiou, D.D.; Tang, C.-J.; Wei, Z.; Spinney, R. Inactivation of pathogenic microorganisms by sulfate radical: Present and future. Chem. Eng. J. 2019, 371, 222–232. [Google Scholar] [CrossRef]

- Chen, Y.; Duan, X.; Zhou, X.; Wang, R.; Wang, S.; Ren, N.; Ho, S.-H. Advanced oxidation processes for water disinfection: Features, mechanisms and prospects. Chem. Eng. J. 2021, 409, 128207. [Google Scholar] [CrossRef]

- Kanakaraju, D.; Glass, B.D.; Oelgemöller, M. Advanced oxidation process-mediated removal of pharmaceuticals from water: A review. J. Environ. Manag. 2018, 219, 189–207. [Google Scholar] [CrossRef]

- Ong, J.H.; Huang, S.; Hu, X.; Xu, R. Struvite precipitation for low-level ammonium removal in mariculture wastewater: Feasibility study. Bioresour. Technol. 2025, 424, 132270. [Google Scholar] [CrossRef]

- Schleyken, J.; Gumpert, F.; Tränckner, S.; Palm, H.W.; Tränckner, J. Enhanced chemical recovery of phosphorus from residues of recirculating aquaculture systems (RAS). Int. J. Environ. Sci. Technol. 2023, 21, 3775–3788. [Google Scholar] [CrossRef]

- Letelier-Gordo, C.O.; Fernandes, P.M. Coagulation of phosphorous and organic matter from marine, land-based recirculating aquaculture system effluents. Aquac. Eng. 2021, 92, 102144. [Google Scholar] [CrossRef]

- Li, S.; Meng, D.; Zhang, G.; Yang, F. Periodic polarity reversal triggered sequential electrochemical redox of blue TiO2 nanotube arrays for efficient removal of antibiotics and inorganic nitrogen from actual mariculture wastewater. Chem. Eng. J. 2024, 499, 156651. [Google Scholar] [CrossRef]

- Wei, Y.; Sun, Z.; Song, X.; Sun, G.; Li, M. Mariculture wastewater treatment using electrochemically assisted submerged fixed bed bioreactor (E-SFBBR): Potential performance and pathways of nitrogen removal. J. Water Process Eng. 2021, 40, 101904. [Google Scholar] [CrossRef]

- Xue, W.; Zhang, C.; Zhou, D. Positive and negative effects of recirculating aquaculture water advanced oxidation: O3 and O3/UV treatments improved water quality but increased antibiotic resistance genes. Water Res. 2023, 235, 119835. [Google Scholar] [CrossRef]

- Huang, Y.; Zhang, S.; Chen, L.; Kou, X.; Hou, Y.; Wu, Z.; Wu, J.; Li, S.; Zou, J. Removal of ammonia nitrogen in maricultural wastewater with Cl−/peroxymonosulfate process: Performances and mechanism. J. Environ. Chem. Eng. 2025, 13, 115549. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhao, M.; Huang, Y.; Hu, Y.-L.; Wang, L. Efficient chlorination reaction of Pt/RuO2/g-C3N4 under visible light irradiation for simultaneous removal of ammonia and bacteria from mariculture wastewater. J. Environ. Sci. 2025, 150, 490–502. [Google Scholar] [CrossRef]

- You, X.; Zhang, Z.; Guo, L.; Liao, Q.; Wang, Y.; Zhao, Y.; Jin, C.; Gao, M.; She, Z.; Wang, G. Integrating acidogenic fermentation and microalgae cultivation of bacterial-algal coupling system for mariculture wastewater treatment. Bioresour. Technol. 2021, 320, 124335. [Google Scholar] [CrossRef]

- Dildar, T.; Cui, W.; Ikhwanuddin, M.; Ma, H. Aquatic Organisms in Response to Salinity Stress: Ecological Impacts, Adaptive Mechanisms, and Resilience Strategies. Biology 2025, 14, 667. [Google Scholar] [CrossRef]

- Neoh, C.H.; Noor, Z.Z.; Mutamim, N.S.A.; Lim, C.K. Green technology in wastewater treatment technologies: Integration of membrane bioreactor with various wastewater treatment systems. Chem. Eng. J. 2016, 283, 582–594. [Google Scholar] [CrossRef]

- Shahid, A.; Malik, S.; Zhu, H.; Xu, J.; Nawaz, M.Z.; Nawaz, S.; Asraful Alam, M.; Mehmood, M.A. Cultivating microalgae in wastewater for biomass production, pollutant removal, and atmospheric carbon mitigation; a review. Sci. Total Environ. 2020, 704, 135303. [Google Scholar] [CrossRef]

- Wu, H.; Zhang, J.; Ngo, H.H.; Guo, W.; Hu, Z.; Liang, S.; Fan, J.; Liu, H. A review on the sustainability of constructed wetlands for wastewater treatment: Design and operation. Bioresour. Technol. 2015, 175, 594–601. [Google Scholar] [CrossRef]

- Duan, J.; Fang, H.; Su, B.; Chen, J.; Lin, J. Characterization of a halophilic heterotrophic nitrification–aerobic denitrification bacterium and its application on treatment of saline wastewater. Bioresour. Technol. 2015, 179, 421–428. [Google Scholar] [CrossRef]

- Pinheiro, I.; Carneiro, R.F.S.; Vieira, F.d.N.; Gonzaga, L.V.; Fett, R.; Costa, A.C.d.O.; Magallón-Barajas, F.J.; Seiffert, W.Q. Aquaponic production of Sarcocornia ambigua and Pacific white shrimp in biofloc system at different salinities. Aquaculture 2020, 519, 734918. [Google Scholar] [CrossRef]

- Jang, D.; Hwang, Y.; Shin, H.; Lee, W. Effects of salinity on the characteristics of biomass and membrane fouling in membrane bioreactors. Bioresour. Technol. 2013, 141, 50–56. [Google Scholar] [CrossRef] [PubMed]

- Ma, Y.; Zhang, C.; Wang, D.; Cheng, K.; Lu, Y.; Dai, C.; Guo, J. Co-activation of peroxymonosulfate activation with sunlight and tailored catalytic MnFe2O4/MWCNTs membrane to mitigate membrane fouling caused by NOM and synergistic oxidation mechanism analysis. J. Membr. Sci. 2024, 707, 123030. [Google Scholar] [CrossRef]

- Liu, Y.; Zhu, J.; Li, W.; Xie, B.; Zhang, G.; Ding, Y.; Liu, F.; Tan, H.; Jia, Y.; You, H.; et al. Mechanism of membrane fouling mitigation by microalgae biofilm formation for low C/N mariculture wastewater treatment: EPS characteristics, composition and interfacial interaction energy. J. Environ. Chem. Eng. 2024, 12, 114146. [Google Scholar] [CrossRef]

- Böpple, H.; Kymmell, N.L.E.; Slegers, P.M.; Breuhaus, P.; Kleinegris, D.M.M. Water treatment of recirculating aquaculture system (RAS) effluent water through microalgal biofilms. Algal Res. 2024, 84, 103798. [Google Scholar] [CrossRef]

- Zhao, J.; Peng, L.; Ma, X. Innovative microalgae technologies for mariculture wastewater treatment: Single and combined microalgae treatment mechanisms, challenges and future prospects. Environ. Res. 2025, 266, 120560. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, G.; Li, W.; Ding, Y.; You, H.; Zhu, J.; Leng, H.; Xu, C.; Xing, X.; Xu, J.; et al. The characteristic evolution and formation mechanism of hybrid microalgae biofilm and its application in mariculture wastewater treatment. J. Environ. Chem. Eng. 2023, 11, 109645. [Google Scholar] [CrossRef]

- Han, P.; Lu, Q.; Fan, L.; Zhou, W. A Review on the Use of Microalgae for Sustainable Aquaculture. Appl. Sci. 2019, 9, 2377. [Google Scholar] [CrossRef]

- Zhang, Q.; Li, N.; Wang, B.-L.; Zhang, T.; Ma, P.-F.; Zhang, W.-X.; Nusrat Zahan, S.; Ma, Z.; Zhang, Y.-Q.; Ying, L. Capabilities and mechanisms of microalgae on nutrients and florfenicol removing from marine aquaculture wastewater. J. Environ. Manag. 2022, 320, 115673. [Google Scholar] [CrossRef]

- Vymazal, J.; Zhao, Y.; Mander, Ü. Recent research challenges in constructed wetlands for wastewater treatment: A review. Ecol. Eng. 2021, 169, 106318. [Google Scholar] [CrossRef]

- Li, M.; Liang, Z.; Callier, M.D.; Roque d’orbcastel, E.; Sun, G.; Ma, X.; Li, X.; Wang, S.; Liu, Y.; Song, X. Nutrients removal and substrate enzyme activities in vertical subsurface flow constructed wetlands for mariculture wastewater treatment: Effects of ammonia nitrogen loading rates and salinity levels. Mar. Pollut. Bull. 2018, 131, 142–150. [Google Scholar] [CrossRef]

- Fu, G.; Zhao, L.; Huangshen, L.; Wu, J. Isolation and identification of a salt-tolerant aerobic denitrifying bacterial strain and its application to saline wastewater treatment in constructed wetlands. Bioresour. Technol. 2019, 290, 121725. [Google Scholar] [CrossRef]

- Ning, M.; Li, X.; Lu, Z.; Yang, Y.; Liu, W. Heterotrophic nitrification-aerobic denitrification (HNAD) in marine aquaculture wastewater treatment: Nitrogen removal performance, mechanism and microbial community characteristics. J. Water Process Eng. 2025, 70, 107006. [Google Scholar] [CrossRef]

- Di Capua, F.; Pirozzi, F.; Lens, P.N.L.; Esposito, G. Electron donors for autotrophic denitrification. Chem. Eng. J. 2019, 362, 922–937. [Google Scholar] [CrossRef]

- Liu, X.; Yu, J.; Wang, H.; Jin, C.; Zhao, Y.; Guo, L. Effect of magnetic powder (Fe3O4) on heterotrophic-sulfur autotrophic denitrification efficiency and electron transport system activity for marine recirculating aquacultural wastewater treatment. J. Environ. Manag. 2024, 370, 122749. [Google Scholar] [CrossRef]

- Beyer, C.P.; Gómez, S.; Lara, G.; Monsalve, J.P.; Orellana, J.; Hurtado, C.F. Sarcocornia neei: A novel halophyte species for bioremediation of marine aquaculture wastewater and production diversification in integrated systems. Aquaculture 2021, 543, 736971. [Google Scholar] [CrossRef]

- Doncato, K.B.; Costa, C.S.B. Growth and Mineral Composition of Two Lineages of The Sea Asparagus Sarcocornia Ambigua Irrigated With Shrimp Farm Saline Effluent. Exp. Agric. 2018, 54, 399–416. [Google Scholar] [CrossRef]

- Fan, X.-Y.; Zhou, S.-L.; Yang, Y.; Cao, S.-B.; Niu, Y.; Zheng, M.-Y.; Zhao, J.-R. Impact of carbon/nitrogen ratio on sequencing batch biofilm reactors initiated with different seed sludges for treating actual mariculture effluents. Bioresour. Technol. 2025, 417, 131838. [Google Scholar] [CrossRef] [PubMed]

- Ma, X.; Yin, R.; Yang, C.; Cai, C.; Zhao, J.; Lv, C.; Wang, X.; Chen, S.; Ren, J.; Zhang, B. Application of a biofilm-enhanced A2O system in the treatment of wastewater from mariculture. Front. Mar. Sci. 2024, 11, 1408774. [Google Scholar] [CrossRef]

- Zhang, H.; Zhou, C.; Shangguan, M.; Peng, Z.; An, Z. Simultaneous removal of organic pollutants and nutrients from mariculture wastewater using a rotating algal biofilm system. J. Water Process Eng. 2024, 57, 104598. [Google Scholar] [CrossRef]

- Ding, W.; Zhou, X.; He, M.; Jin, W.; Chen, Y.; Sun, J. Pollutant removal and resource recovery of co-cultivated microalgae Chlorella sp. and Phaeodactylum tricornutum for marine aquaculture wastewater. J. Water Process Eng. 2024, 67, 106182. [Google Scholar] [CrossRef]

- Zhao, L.; Tang, J.; Xu, Y.; Zhang, Y.; Song, Z.; Fu, G.; Hu, Z. A vertical-flow constructed wetland–microalgal membrane photobioreactor integrated system for treating high-pollution-load marine aquaculture wastewater: A lab-scale study. Sci. Total Environ. 2024, 919, 170465. [Google Scholar] [CrossRef]

- Zhao, Z.; Liu, Y.; Dong, X.; Jiang, Q.; Wang, J.; Yang, X.; Chen, J.; Lei, Z. Unveiling the role of ferrous ion in driving microalgae granulation from salt–tolerant strains for mariculture wastewater treatment. Sci. Total Environ. 2024, 923, 171315. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Gao, M.; Zhao, Y.; Guo, L.; Jin, C.; Ji, J.; She, Z. Nitrogen and sulfamethoxazole removal in a partially saturated vertical flow constructed wetland treating synthetic mariculture wastewater. Bioresour. Technol. 2022, 358, 127401. [Google Scholar] [CrossRef] [PubMed]

- Zhao, L.; Fu, G.; Pang, W.; Li, X.; Pan, C.; Hu, Z. A novel autotrophic denitrification and nitrification integrated constructed wetland process for marine aquaculture wastewater treatment. Chemosphere 2023, 321, 138157. [Google Scholar] [CrossRef]

- Ma, X.; Li, X.; Li, J.; Ren, J.; Chi, L.; Cheng, X. Iron-carbon could enhance nitrogen removal in Sesuvium portulacastrum constructed wetlands for treating mariculture effluents. Bioresour. Technol. 2021, 325, 124602. [Google Scholar] [CrossRef]

- Wang, L.; Liu, J.; Lin, X.; Liu, Z.; Cui, H.; Zhang, Y. Simultaneous removal of nitrogen and phosphorus from mariculture wastewater by mixotrophic-denitrification biofilm process based on pyrite and poly-3-hydroxybutyrate-co-hyroxyvelate. J. Water Process Eng. 2024, 68, 106414. [Google Scholar] [CrossRef]

- Liu, H.; Du, Y.; Chen, Y.; Huang, Z.; Ji, J.; Gao, M.; Zhao, Y.; Jin, C. Nitrogen removal via solid carbon source-driven heterotrophic nitrification and aerobic denitrification in marine aquaculture wastewater. J. Water Process Eng. 2025, 73, 107697. [Google Scholar] [CrossRef]

- Feng, Y.; Wang, L.; Yin, Z.; Cui, Z.; Qu, K.; Wang, D.; Wang, Z.; Zhu, S.; Cui, H. Comparative investigation on heterotrophic denitrification driven by different biodegradable polymers for nitrate removal in mariculture wastewater: Organic carbon release, denitrification performance, and microbial community. Front. Microbiol. 2023, 14, 1141362. [Google Scholar] [CrossRef] [PubMed]

- Jiang, S.; Huang, H.; Chen, Y.; Xiong, J.; Lin, Z.; Wang, S. Optimizing Nitrogen Removal Through Coupled Simultaneous Nitrification-Denitrification and Sulfur Autotrophic Denitrification: Microbial Community Dynamics and Functional Pathways in Mariculture Tailwater Treatment. Water 2025, 17, 683. [Google Scholar] [CrossRef]

- Xu, Y.; Zhang, Y.; Ji, J.; Xu, L.; Liang, Y. What drives the growth of China’s mariculture production? An empirical analysis of its coastal regions from 1983 to 2019. Environ. Sci. Pollut. Res. 2023, 30, 111397–111409. [Google Scholar] [CrossRef]

- Liang, Y.; Cheng, X.; Zhu, H.; Shutes, B.; Yan, B.; Zhou, Q.; Yu, X. Historical Evolution of Mariculture in China During Past 40 Years and Its Impacts on Eco-environment. Chin. Geogr. Sci. 2018, 28, 363–373. [Google Scholar] [CrossRef]

- Xu, C.; Feng, Y.; Li, H.; Li, Y.; Yao, Y.; Wang, J. Constructed wetlands for mariculture wastewater treatment: From systematic review to improvement measures and insights. Desalination 2024, 579, 117505. [Google Scholar] [CrossRef]

- Cooney, R.; de Sousa, D.B.; Fernández-Ríos, A.; Mellett, S.; Rowan, N.; Morse, A.P.; Hayes, M.; Laso, J.; Regueiro, L.; Wan, A.H.L.; et al. A circular economy framework for seafood waste valorisation to meet challenges and opportunities for intensive production and sustainability. J. Clean. Prod. 2023, 392, 136283. [Google Scholar] [CrossRef]

- Castine, S.A.; McKinnon, A.D.; Paul, N.A.; Trott, L.A.; de Nys, R. Wastewater treatment for land-based aquaculture: Improvements and value-adding alternatives in model systems from Australia. Aquac. Environ. Interact. 2013, 4, 285–300. [Google Scholar] [CrossRef]

- Lahav, O.; Ben Asher, R.; Gendel, Y. Potential applications of indirect electrochemical ammonia oxidation within the operation of freshwater and saline-water recirculating aquaculture systems. Aquac. Eng. 2015, 65, 55–64. [Google Scholar] [CrossRef]

- Bhatt, P.; Huang, J.-Y.; Brown, P.; Shivaram, K.B.; Yakamercan, E.; Simsek, H. Electrochemical treatment of aquaculture wastewater effluent and optimization of the parameters using response surface methodology. Environ. Pollut. 2023, 331, 121864. [Google Scholar] [CrossRef]

- Wang, X.; Cuthbertson, A.; Gualtieri, C.; Shao, D. A Review on Mariculture Effluent: Characterization and Management Tools. Water 2020, 12, 2991. [Google Scholar] [CrossRef]

- Li, W.; Zhang, X.; Zhao, B.; Cui, Y.; Antwi, P.; Li, R.; Zhou, A.; Li, J.; Yue, X. Advancing the treatment of low carbon-to-nitrogen ratio municipal wastewater using a novel microaerobic sludge bed approach: Insights into enhanced performance and functional microbial community. Environ. Res. 2024, 258, 119461. [Google Scholar] [CrossRef] [PubMed]

- Yu, M.; Lu, H.; Wu, D.; Zhao, Q.; Meng, F.; Wang, Y.; Hao, X.; Chen, G.-H. Effects of carbon-to-sulfur (C/S) ratio and nitrate (N) dosage on Denitrifying Sulfur cycle-associated Enhanced Biological Phosphorus Removal (DS-EBPR). Sci. Rep. 2016, 6, 23221. [Google Scholar] [CrossRef]

- Zhang, W.; Liu, B.; Sun, Z.; Wang, T.; Tan, S.; Fan, X.; Zou, D.; Zhuang, Y.; Liu, X.; Wang, Y.; et al. Comparision of nitrogen removal characteristic and microbial community in freshwater and marine recirculating aquaculture systems. Sci. Total Environ. 2023, 878, 162870. [Google Scholar] [CrossRef]

- Kumar, N.; Thorat, S.T.; Chavhan, S.R.; Reddy, K.S. Understanding the molecular mechanism of arsenic and ammonia toxicity and high-temperature stress in Pangasianodon hypophthalmus. Environ. Sci. Pollut. Res. 2024, 31, 15821–15836. [Google Scholar] [CrossRef]

- Ding, R.; Yang, R.; Fu, Z.; Zhao, W.; Li, M.; Yu, G.; Ma, Z.; Zong, H. Changes in pH and Nitrite Nitrogen Induces an Imbalance in the Oxidative Defenses of the Spotted Babylon (Babylonia areolata). Antioxidants 2023, 12, 1659. [Google Scholar] [CrossRef]

- Enwereuzoh, U.O.; Harding, K.G.; Low, M. Fish farm effluent as a nutrient source for algae biomass cultivation. South Afr. J. Sci. 2021, 117, 22–30. [Google Scholar] [CrossRef]

- Nguyen, T.T.; Zhang, Z.; Wang, R.; Sawada, K.; Soda, S. Greywater treatment using lab-scale systems combining trickling filters and constructed wetlands with recycled foam glass and water spinach. Bioresour. Technol. Rep. 2024, 27, 101915. [Google Scholar] [CrossRef]

- Li, M.; Callier, M.D.; Blancheton, J.-P.; Galès, A.; Nahon, S.; Triplet, S.; Geoffroy, T.; Menniti, C.; Fouilland, E.; Roque d’orbcastel, E. Bioremediation of fishpond effluent and production of microalgae for an oyster farm in an innovative recirculating integrated multi-trophic aquaculture system. Aquaculture 2019, 504, 314–325. [Google Scholar] [CrossRef]

- Zhang, R.; Chen, T.; Wang, Y.; Short, M. An optimisation approach for the design and operation of recirculating aquaculture systems integrated with sustainable hybrid energy systems. J. Clean. Prod. 2024, 477, 143860. [Google Scholar] [CrossRef]

- Dong, J.; Shen, M.; Yu, X. Study on the eco-economic efficiency of China’s mariculture based on undesirable output. Front. Mar. Sci. 2023, 10, 1254537. [Google Scholar] [CrossRef]

- Yin, Z.; Liu, Z.; Sun, X.; Li, F. The blue economy: Assessing the comprehensive benefits and future development trends of China’s marine aquaculture industry. Aquac. Int. 2025, 33, 185. [Google Scholar] [CrossRef]

| Treatment Method | Material/Strain | Treatment Efficiency | Advantages | Disadvantages | References |

|---|---|---|---|---|---|

| Siphon aeration | Electroactive bacteria-algae biofilm coupled with siphon aeration | COD: 83.49%, TP: 93.56%, NH3-N: 91.26%, NO3−-N: 96.54%, NO2−-N: 86.11%, TN: 92.03% | Aeration can enhance the activity of microorganisms. Siphonic aeration reduces energy loss and provides an alternating aerobic and anaerobic environment, ensuring oxidation-reducing reactions and improving the degradation efficiency of organic matter. | The operation requirements are high, aeration equipment may become clogged and the cost is relatively high. | [54] |

| Solid- liquid separation | A three-dimensional two-phase model of these hydraulic cyclone separators | Under the optimal conditions, the efficiency of solid–liquid separation can reach 83.16% to 100% | It provides a reference for the design and optimization of series hydrocyclones in pond aquaculture wastewater treatment. The established model can be used to predict the hydrodynamic behavior and separation performance of series hydrocyclones. | Adjusting the optimal conditions of the series hydrocyclone separator may result in excessive energy consumption. | [55] |

| Filtration | Continuous flow electro- coagulation (EC)–filtration system | COD: 48.99%, TN: 55.26%, NH3-N: 57.06%, NO3−-N: 34.09%, NO2−-N: 18.47%, Energy consumption: 26.25 ± 4.95 × 10−3 kWh/m3 | Continuous flow electrocoagulation can significantly improve the processing efficiency of filtration equipment. Increasing the hydraulic retention time and reducing the pore size of the filter have a more obvious reinforcing effect on the filter. | The impact of the scale and energy consumption of subsequent water treatment units still requires further research. | [56] |

| Filtration | Integrated process of screen mesh, sand filtration and adsorption | COD: 46.00% BOD5: 35.25% TIN: 62.94% Active phosphate: 84.34% SS: 84.73% | The inclined plane hydraulic screen can remove over 90% of the total suspended solids without affecting the drainage rate. The continuous flow sand filter does not require the pool to be shut down for backwashing. | There may be problems such as filter clogging and adsorption saturation. | [57] |

| Sedimentation | Sedimentation, aeration and a biological multi-stage treatment process | The removal rate of pollutants in the sedimentation tank: TSS: 71.9%; TN:55.6%; TP: 35.3%. | The technology is simple, easy to promote and the cost of infrastructure construction is low. | The volume of aquaculture wastewater is prone to exceeding the maximum load of the process. | [19] |

| Membrane technology | Continuous ultrafiltration and ultraviolet technology | SS > 73% BOD5: 35.25% COD: 40.00% Colibacillus:100% | The technology is simple, the operating cost is low, and the water change cycle is extended, which is conducive to water conservation. | Membrane fouling problem. | [58] |

| Ultraviolet treatment | Ultraviolet and microfiltration | Microparticle numbers: 74%; micro particle surface area: 54%; COD: 34%; microbial activity:89%. | Cartridge filtration appeared to reduce the build-up of micro particles by directly removing bacteria and bacterial substrate. Ultraviolet rays reduce the number of particles by reducing the dissolved matrix. | Filtration with a 1 μm filter element is difficult to apply; high energy consumption. | [59] |

| Ultraviolet treatment | Tetracycline (TC) is treated by ultraviolet/peroxymonosulfate (UV/PS) process | When the dosage of UV/PS was 5 mg/L, the removal rate of TC reached 95.73% after 30 min. | The main contributor to TC degradation by UV/PS in mariculture wastewater was reactive bromine species, followed by free chlorine. UV/PS process proved to have great potential for the harmless treatment of mariculture wastewater. | Cl− in mariculture wastewater slightly inhibited TC degradation by scavenging free radicals. | [60] |

| Treatment Method | Material/Strain | Treatment Efficiency | Advantages | Disadvantages | References |

|---|---|---|---|---|---|

| Adsorption precipitation | Struvite (magnesium ammonium phosphate hexahydrate, MgNH4PO4·6H2O) precipitation | Struvite precipitation effectively reduces the ammonium concentration in marine aquaculture wastewater from 10 mg/L to less than 1 mg/L. | The use of waste phosphate can reduce costs. The precipitated products can be used as flame retardants and anti-corrosion coatings for steel structures. | Large-scale implementation poses challenges, such as the design and maintenance of pumping and filtration systems. | [82] |

| Chemical precipitation | Sulfuric acid, nitric acid and citric acid. Sodium hydroxide is used to regulate the pH of water. | Sulfuric acid, nitric acid and citric acid can achieve a recovery rate of 71–86% of phosphorus content in sludge. Phosphorus re-dissolution with citric acid requires the highest amount of acid per g dry matter. | The processing steps are simple, the properties of the additives are simple, and they are widely available on the global market. Compared with inorganic acids, citric acid is cost-effective. | An economic assessment is required to determine the type, quantity and pH of the acid in order to estimate the actual feasibility. | [83] |

| Flocculation and coagulation | FeCl3 and AlSO4 Fe: PO43−-P = 2.6:1; Al: PO43−-P = 5.7:1 | The removal rates of TCOD, TSS and TP were all above 89%. When the ratio of Fe: PO43−-P was 2.6:1, the removal rate of PO43−-P was 90%. | Higher water ion strength has an interaction effect on the removal of P. Salinity also improves the interaction between Fe3+ and P. | Pre-sedimentation treatment is required before adding any coagulant. | [84] |

| Electrochemical oxidation | Flow-through electrochemical oxidation process | The removal rates of NH3-N and NO2−-N can reach 90%. Antibiotics such as sulfamethazine and norfloxacin can be completely removed, with an energy consumption of only 0.054 kWh/g. | It has a good application prospect in the removal and sterilization of ammonia nitrogen and nitrite nitrogen. | The removal efficiency of total phosphorus and COD is relatively low, and disinfection by-products are produced. | [16] |

| Electrochemical oxidation | A bipolar system with Ti/BTNAs as the anode and cathode | The removal rate of NH3-N reached 97.6%, the residual total inorganic nitrogen was only 0.63 mg/L, and the minimum energy consumption was 0.043 kWh/g. | It is a long-lasting and low-consumption comprehensive strategy for removing organic pollutants and inorganic nitrogen from marine aquaculture wastewater. | The removal of active phosphate pollutants was not taken into account, and the types of antibiotic removal were relatively few. | [85] |

| Electrochemical oxidation | The electro-Fenton synergistic electrocatalytic system with dual cathodes | The removal rate of COD was 100%, and the removal rates of NH3-N, NO3-N and TN were 100%, 100% and 99.83% respectively. | Under the optimal operating conditions, the treatment cost is low and the effluent meets the first-level discharge standard. | The service life and the removal of active phosphate pollutants remain to be further studied. | [61] |

| Electrochemistry | Electrochemical-assisted submerged fixed-bed bioreactor (E-SFBBR) | The TN removal rate of E-SFBBR under electrical stimulation was 2.95–3.43 g N m−2 d−1. When the current density was 0.10 mA m−2, the removal effect on TN was better. | The N removal pathways related to the transformation of S and Fe in E-SFBBR were proposed. | The interaction between the S cycle, autotrophic denitrification and N transformation remains to be studied. | [86] |

| Advanced oxidation | Ozone (O3) treatment and ozone/ultraviolet (O3/UV) treatment | After treatment, the concentration of dissolved organic carbon in the aquaculture water was reduced by 40%, and NH3-N and NO2−-N were completely removed. | The O3 and O3/UV treatments have significantly improved the water quality of recirculating aquaculture and can also promote the growth of farmed fish. | Highly saturated intermediate products induce antibiotic resistance genes, presenting potential biological risks. | [87] |

| Advanced oxidation | Chloride ions (Cl−) promote the peroxymonosulfate (PMS) process (Cl−/PMS) | Under the condition of pH 8.0, the degradation rates of NH3-N and TN by the Cl−/PMS process reached 100% and 97%, respectively, within 15 min. | The Cl−/PMS process has a good anti-interference ability for the substrate of marine aquaculture wastewater. The intermediate product is green and non-toxic. | The simulation experiment awaits entering the application stage. | [88] |

| Advanced oxidation | Graphitic carbon nitride composite polymetallic doping was used to produce the photocatalyst (Pt/RuO2/g-C3 N4) | 1.0 g/L Pt/RuO2/g-C3N4 photocatalyst can degrade 81% NH3-N. The higher Cl− concentration in real wastewater promotes the removal of NH3-N and sterilization. | In real water bodies, Pt/RuO2/g-C3N4 has a good removal effect on NH3-N and bacteria, and has good economy and feasibility. | The sterilization effect on bacteria other than Escherichia coli remains to be further studied. | [89] |

| Treatment Method | Material/Strain | Treatment Efficiency | Advantages | Disadvantages | References |

|---|---|---|---|---|---|

| Membrane Bioreactor | Sequencing batch biofilm reactors started with sludge inoculated at different C/N ratios | When the C/N ratio was 30, the average removal rates of NH3-N and TN were 95% and 73%. The high C/N ratio promoted the secretion of tightly bound extracellular polymers. | Membrane bioreactors inoculated with a high C/N ratio significantly enhance the positive interactions among dominant groups and promote the relative abundance of dominant bacteria. | The technical requirements are high, and the C/N ratio of biofilm sludge must be strictly controlled. | [113] |

| Biofilm technology | An A2O system enhanced by biofilm with specific bacterial strains added | The removal efficiencies of CODMn, NH3-N, TN and TP in the A2O system were approximately 86.3–90.8%, 97.7–99.5%, 94.6–95.2% and 97.0–98.1%. | The biofilm-enhanced A2O system can independently provide organic carbon sources, has strong salt tolerance, occupies a small area and has high treatment efficiency. | The technical requirements are high, and the service life of the biofilm needs further research. | [114] |

| Membrane Bioreactor | A rotating algal biofilm (RAB) system attached to seawater Chlorella sp. | The removal rates of TOC, NH3-N and PO43− reached 80%, 96% and 99%, respectively. Prolonging the retention time of algal biofilms can enhance the removal efficiency. | Algal biofilms can secrete a large amount of extracellular polymers. These substances promote the efficient removal of pollutants and help protect the biofilms from toxic substances. | The operating energy consumption is relatively high and the hydraulic retention time is long. | [115] |

| Microalgae technology | The microalgae co-culture system of Chlorella sp. and Phaeodactylum tricornutum | Under the optimal operating conditions, the removal rates of NH3-N, TN and TP were 100%, 93.26% and 96.12%, respectively. | The microalgae co-culture system can increase the total biological yield and achieve efficient removal of pollutants through interspecific interactions. | In actual operation, the environmental complexity is high and the operation difficulty is relatively large. | [116] |

| Microalgae technology | Microalgae membrane photobioreactor (MPBR) and autotrophic denitrification—nitrification integrated constructed Wetland (ADNI-CW) | The removal rates of TN and TP by the ADNI-CW-MPBR system were 92.63% ± 2.8% and 77.46% ± 8.41%, respectively. The biomass of microalgae was 54.58 ± 6.8 mg/L/d. | It has solved the problem of low efficiency in treating marine aquaculture wastewater by constructed wetlands, and has high-value biomass production. The synergistic effect between bacteria and chlorella ensures the efficient denitrification and phosphorus removal of the MPBR system. | The optimal reaction conditions need to be strictly controlled. The interaction between microalgae and bacteria requires further study. | [117] |

| Microalgae technology | Utilize Fe2+ to promote the granulation of pure algal strains into microalgae-bacterial granular sludge (MBGS) | Fe2+ can induce the formation of Fe precipitates and promote the adhesion of microbial cells. The removal rates of DOC, PO43−-P and NH3-N reached 98%, 98% and 87%, respectively. | The accumulation of exogenous heterotrophic bacteria and the enhanced expression of functional genes related to N and P metabolism significantly promoted the improvement of the nutrient salt removal rate. | Both insufficient and excessive Fe2+ concentrations can lead to a decrease in the ability to remove nutrients. | [118] |

| Constructed wetland | Partially saturated vertical flow constructed wetlands (PS-VFCW) at different saturation zone depths (SZD) | When the SZD was 60 cm, the removal rate of TN was as high as 97.3%, and the removal rate of the antibiotic sulfamethoxazole (SMX) reached its highest at 70 cm. The change in SZD has a significant impact on the structure of the bacterial community. | This technology can enhance the denitrification technology. The abundances of ammonia-oxidizing bacteria, nitrite-oxidizing bacteria, nitrifying bacteria and SMX-degrading bacteria show an increasing trend along the depth. | The technical requirements are high, and it is necessary to add exogenous carbon sources to improve its removal rate. | [119] |

| Constructed wetland | Autotrophic denitrifying—nitrification integrated constructed wetland (ADNI-CW) for mangrove plant cultivation | Under different hydraulic retention times, the nitrification rate of the autotrophic nitrifying constructed wetland unit (AN-CW) exceeded 92%, and the COD removal rate exceeded 96%. | ADNI-CW has the potential to couple sulfate reduction and sulfide-driven autotrophic denitrification in one device. The growth of various microorganisms in the constructed wetland system can enhance the removal of N. | The increase in the concentration of NO3−-N in the influent will lead to a decrease in the amount of sulfides and also affect the efficiency of autotrophic denitrification. | [120] |

| Constructed wetland | Constructed wetland of Sesuvium portulacastrum enhanced by iron–carbon microelectrolysis method | The presence of iron–carbon and seahorse teeth can increase the denitrification efficiency by 20–30% and 15–30% respectively. And they can all significantly change and improve the microbial community structure. | In this system, plant absorption, nitrification, denitrification and anaerobic ammonium oxidation all participate in the denitrification process of wastewater, and it has a good denitrification effect on wastewater with insufficient carbon sources. | The accumulation of intermediate products in the early stage may increase the toxicity of the effluent. | [121] |

| Nitrification and denitrification | Pyrite-driven autotrophic denitrification (PAD) and pyrite/poly-3-hydroxybutyrate-co-hydroxyvalerate-driven mixotrophic denitrification (PPMD) | The PPMD reactor has a better removal effect on NO3−N, but a poorer removal effect on PO43--P. When the influent NO3−N concentration is 25 mg/L, the removal rates of the PAD and PPMD reactors are 69.8% ± 5.6% and 82.3% ± 3.7%, respectively. | PAD also plays a key role in the PPMD reactor. Compared with the single PAD bioreactor, the synergistic effect between heterotrophic and autotrophic denitrification in the mixed nutrient denitrification bioreactor can promote nitrate removal. | The concentration and temperature of the influent NO3−-N will significantly affect the removal performance of NO3−-N and PO43− P in the PAD and PPMD reactors. | [122] |

| Nitrification and denitrification | Heterotrophic nitrification and aerobic denitrification (HNAD) processes based on solid carbon sources (SCSs) | The performance of SCS’s corn cobs is superior to that of peanut shells. The maximum removal efficiencies of NO3−-N and TIN were 99.71% and 96.72%, respectively, and the content of NO2−-N was always lower than 0.3 mg/l. | Corn cobs have a good denitrification effect. Compared with other carbon sources, they are low in price and do not cause secondary pollution. The pores formed by carbon release are conducive to the adhesion and growth of microorganisms. | The service life of corn cobs as a solid carbon source awaits further research to determine the service life of this system. | [123,124] |

| Nitrification and denitrification | A coupled system of simultaneous nitrification and denitrification (SND)—sulfur autotrophic denitrification (SAD) with an added carbon source | Under the condition of a C/N ratio of 1.2, the removal rates of NO3--N, TN and NH3-N reached 93.48%, 95.06% and 95.06%, respectively, and remained stable at 99.00% during steady-state operation. | The addition of carbon sources enhances the denitrification effect by simultaneously strengthening the SND and SAD processes, making it a cost-effective and sustainable denitrification technology for low C/N wastewater. | Sulfur element needs to be added externally as an electron donor, and its practical value in large-scale water bodies is relatively low. | [125] |

| Aquaponics | The removal of inorganic components in wastewater and their accumulation in Sarcocornia neei by sand substrate systems and deep-water systems | Sarcocornia neei is a halophyte with strong salt tolerance and great growth potential under seawater irrigation conditions. It has the highest removal rates of ammonia nitrogen (0.68 ± 0.41 g/m2/day−1) and total phosphorus (0.44 ± 0.34 g/m2/day−1) in sand substrate treatment. | Sarcocornia neei achieves a 100% plant survival rate, and the contents of organic nitrogen and organophosphorus in the plant biomass increase significantly. Therefore, it is a very good biological filter for marine aquaculture wastewater. | Further research is needed on the effects of adding essential micronutrients and different planting densities on its growth rate and nutrient removal efficiency. | [111] |

| Type of Technology | Economic Cost | Advantage | Dilemmas |

|---|---|---|---|

| Physical technology | A set of integrated equipment that integrates precipitation, filtration and other physical processes, its tail water treatment cost is about 0.4–0.5 yuan/ton. | Simple and direct, no chemical reagents or biological treatment media are required. The processing effect is stable and controllable. It is applicable to the pretreatment of large-scale aquaculture tail water treatment. | The processing cost is relatively high and requires energy consumption (such as pumping, filtration, etc.). It is unable to remove dissolved organic matter and certain pollutants in water. The equipment maintenance requirements are high, and it may cause secondary pollution to the environment. |

| Chemical technology | The cost for treating wastewater with a TAN concentration of 10 mgN/L is approximately 6.67 cents/m3 [131]. | It can remove most of the toxic and harmful substances in water, especially dissolved substances (such as heavy metals, organic pollutants, etc.). The treatment process is highly efficient and can respond quickly to changes in pollutant concentrations. | Chemical reagents need to be used, which may cause secondary pollution. The treated waste (such as chemical precipitation) requires further processing. The high cost of chemicals and their corrosiveness to equipment [132]. |

| Biotechnology | The cost is about 240–300 yuan/m3 of water, saving about 50% of the traditional factory’s circulating water system. The energy consumption is approximately 0.002–0.006 kW·h/m3. | Biodegradation can remove organic matter from water, with good treatment effects and environmental friendliness. It has strong selectivity and can handle complex pollutants. It is environmentally friendly and causes little secondary pollution. | The processing speed is slow and it may take a relatively long time. It has high requirements for environmental conditions (such as temperature, pH, etc.), is difficult to control, and is easily affected by changes in aquaculture water quality. It is necessary to cultivate a relatively stable biological population. |

| Comprehensive technology | The cost of a traditional factory recirculating aquaculture system is about 400–600 yuan/m3 of water. | The combination of multiple technologies can better comprehensively utilize their respective advantages and improve processing efficiency. It can be flexibly adjusted and used according to the specific water quality conditions, reducing the limitations of a single technology. It is expected to achieve relatively stable long-term effects. | The system is complex, and the construction and operation costs are relatively high. It is necessary to coordinate the workflow of different technologies, which may increase the management difficulty. System maintenance is rather complicated and requires regular inspection and adjustment. |

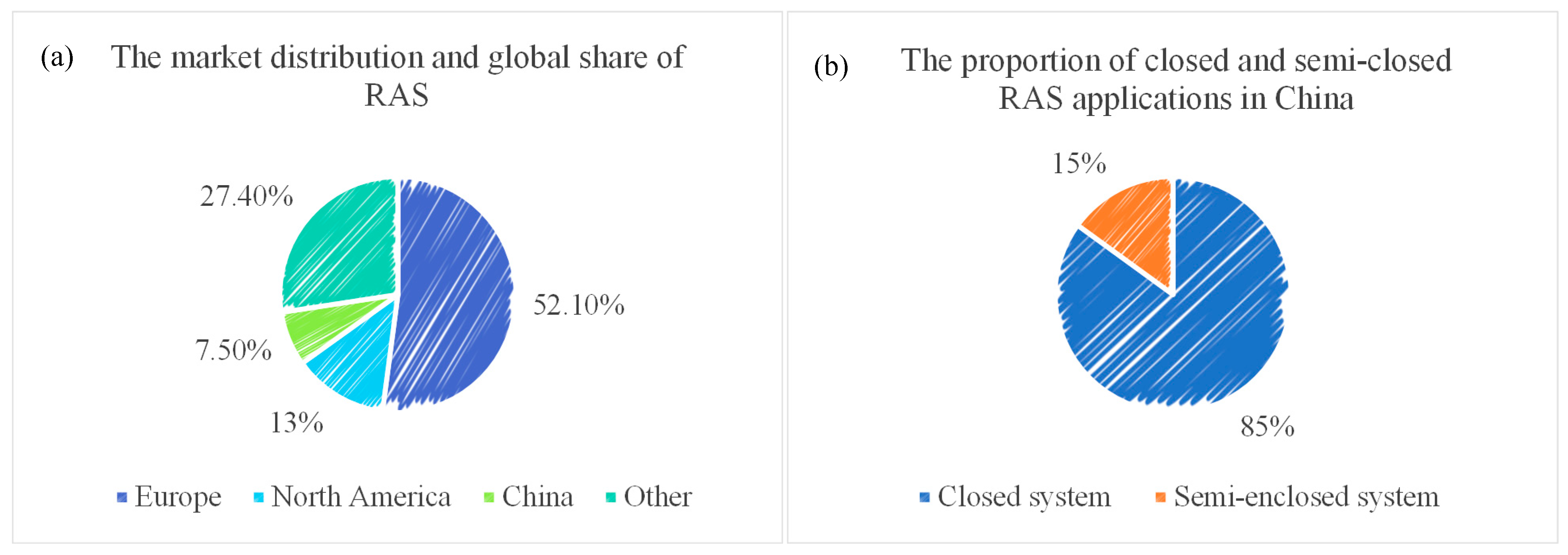

| Dimension of Comparison | International (Mainly European and American) | China |

|---|---|---|

| Size of market | Europe accounted for 52.1% of the world, followed by North America. | China accounts for 7.5%, with a fast growth rate. |

| Technology Maturity | Highly automated, integrating biofiltration and energy recovery technologies. | The closed system is the main type (85%), and indoor applications account for 70% |

| The main breeding species | High-value fish such as salmon and trout. | Litopenaeus vannamei (accounting for 40%), salt field shrimp, oysters, etc. |

| Driven by environmental protection policies | The strict emission standards of the European Union drive technological upgrades. | Policies such as the comprehensive management of the Bohai Sea have promoted the popularization of tail water treatment. |

| Extension of the industrial chain | Combine renewable energy sources (such as wind energy and solar energy). | The “breeding and cultural tourism” model. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Deng, S.; Pan, W. The Dilemmas and Challenges of Tail Water Treatment Technology for Land-Based Marine Aquaculture in China: A Review. Sustainability 2025, 17, 9593. https://doi.org/10.3390/su17219593

Deng S, Pan W. The Dilemmas and Challenges of Tail Water Treatment Technology for Land-Based Marine Aquaculture in China: A Review. Sustainability. 2025; 17(21):9593. https://doi.org/10.3390/su17219593

Chicago/Turabian StyleDeng, Shengjie, and Wenbin Pan. 2025. "The Dilemmas and Challenges of Tail Water Treatment Technology for Land-Based Marine Aquaculture in China: A Review" Sustainability 17, no. 21: 9593. https://doi.org/10.3390/su17219593

APA StyleDeng, S., & Pan, W. (2025). The Dilemmas and Challenges of Tail Water Treatment Technology for Land-Based Marine Aquaculture in China: A Review. Sustainability, 17(21), 9593. https://doi.org/10.3390/su17219593