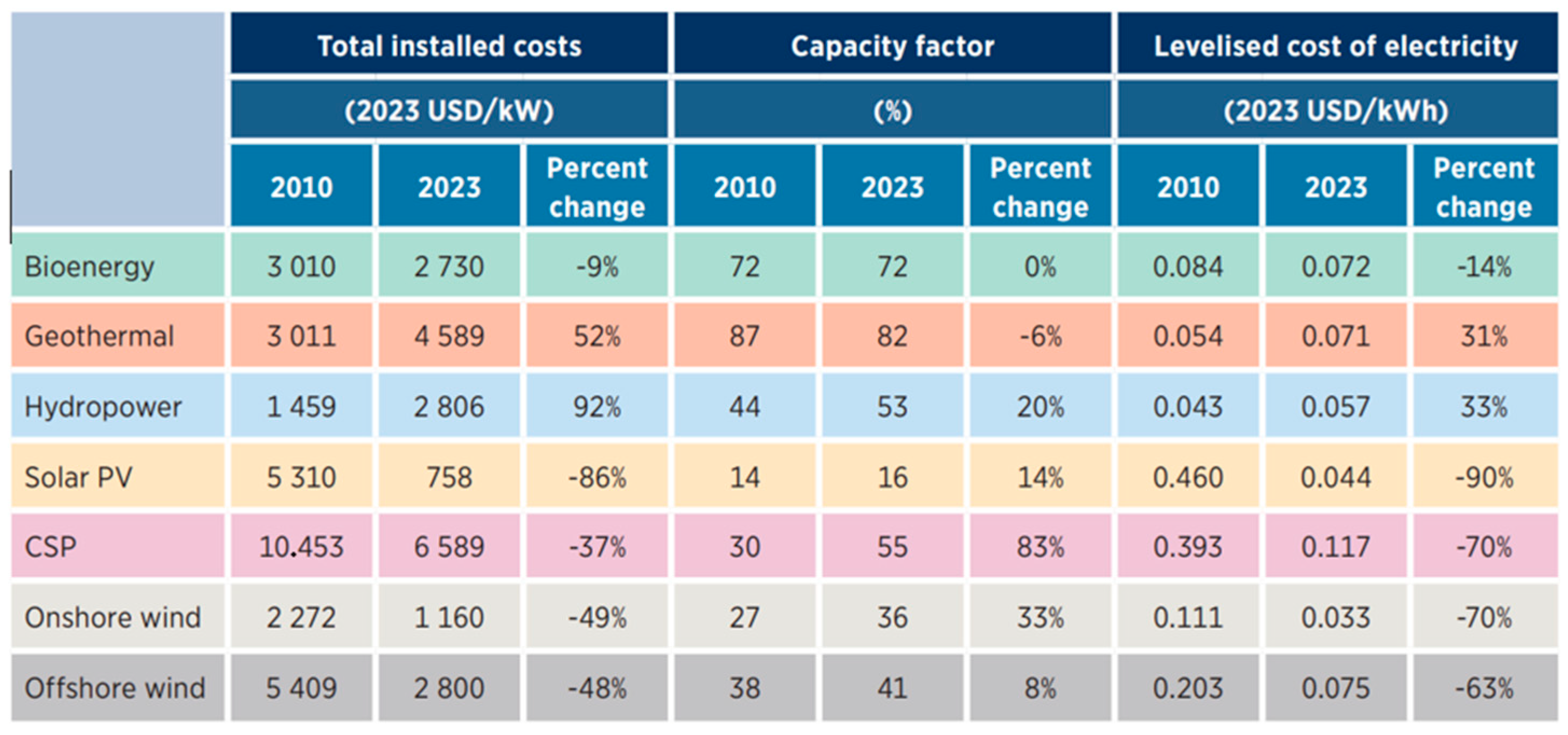

The need to explore innovative solutions for energy generation through renewable and sustainable sources is increasingly evident in the face of environmental challenges and growing demands for electricity worldwide. Solar energy is typically converted to power generation through two technologies: photovoltaic (PV) and concentrated solar power (CSP) [

1]. Although CSP technology offers advantages such as thermal energy storage and enhanced generation stability, its contribution to the global energy matrix remains below 1%, according to the International Energy Agency. In 2023, CSP accounted for ~0.1% of global electricity, versus ~6.9% for PV; installed CSP capacity was ~7 GW compared with ~2200 GW for PV [

1]. It is significantly outpaced by photovoltaic and wind energy sources, which together account for over 90% of the installed renewable energy capacity worldwide. CSP concentrates the sun’s rays using mirrors, allowing heat transfer using a heat transfer fluid. A steam turbine is driven and powered by the high-temperature heat generated [

2]. In this context, the combined use of CSP and PV technologies emerges as a promising and efficient solution, as it leverages the complementarity between photovoltaic generation during daylight hours and the thermal energy storage capabilities of CSP systems. This hybridization enables continuous and dispatchable power supply, even during periods of low solar irradiance or after sunset, thereby enhancing grid reliability and supporting the integration of renewable energy into the energy mix.

Photovoltaic solar energy has experienced remarkable growth in Brazil, driven by supportive public policies and a geographic location that naturally favors this form of energy generation [

2,

4]. However, hybrid photovoltaic energy with a CSP system is becoming increasingly present in literature. In 2023, Brazil rose in the world ranking of installed photovoltaic solar generation capacity, occupying 6th place with 37.4 GW, only behind China (609.3 GW), the United States (137.7 GW), Japan (87.1 GW), Germany (81.7 GW) and India (72.7 GW).

1.1. Literature Review on Hybrid PV/CSP Systems

According to EPE (Energy Research Company) [

5], hybrid plants combine multiple energy sources to generate electricity. These systems, especially those integrating renewable sources like solar, wind, and biomass are gaining importance due to their higher reliability and capacity factor, despite potentially higher initial costs. Technologies like CSP also offer flexibility by allowing the use of alternative fuels to enhance performance.

Cocco & Petrollese [

6] demonstrated that an improvement in power dispatch ability can be achieved with an appropriate integration of concentrated solar power (CSP) and photovoltaic (PV) plants to mitigate the effects of solar power variability and intermittency. This hybridization can increase the overall capacity factor of the plant by allowing thermal energy to be stored while the PV plant is in production and thus help achieve a fully dispatchable solar electricity generation system.

In another work, Giaconia and Grena [

7] presented a CSP system with thermal storage coupled to a PV system without storage. They concluded that the PV field provides most of the electricity needed during the day and that the CSP provides energy, especially at night, exploring storage.

Pilotti et al. [

8] state that projects carried out with stand-alone technologies (only CSP or PV plus battery) show that hybrid solutions can achieve similar or better dispatch levels with a lower electricity cost (LCOE reduction between 30% and 50%). Other forms of hybridization with CSP have already been studied, such as wind [

9], biomass [

10,

11], nuclear [

12], and geothermal [

13], but there is a gap when we apply these installations to the current tariff market of each country, in the case of this work, Brazil.

Economic assessments of hybrid solar plants consider seasonal generation, costs, and revenues from energy sales. Financial viability requires covering CAPEX and OPEX with returns evaluated using discounted cash flow, Net Present Value (NPV), and Levelized Cost of Energy (LCOE) [

14,

15,

16,

17,

18].

In a study for the decarbonization of LNG (Liquefied Natural Gas) plants using heat and power from hybrid CSP/PV plants in locations with DNI (Direct Normal Irradiation) values greater than 2000 kWh/m

2/year, Hasni & Platzer [

19] conducted a techno-economic assessment considering the price of electricity in Australia and Qatar. The results indicate that purchasing electricity would be more expensive for Australia than investing in a PV/CSP plant. In Qatar, the LCOE range of US

$93–110/MWh is not competitive with the price of electricity, mainly due to energy subsidies.

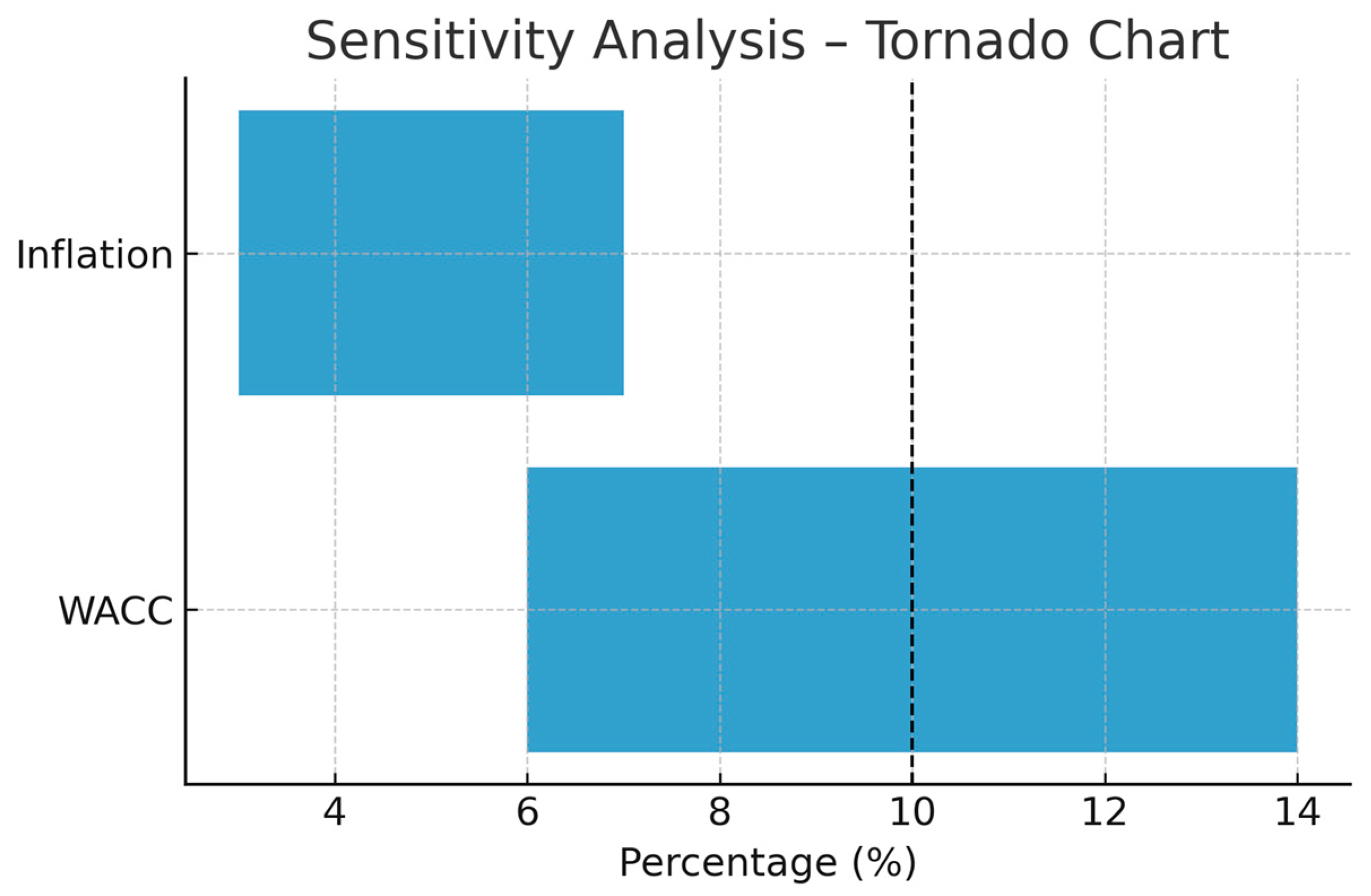

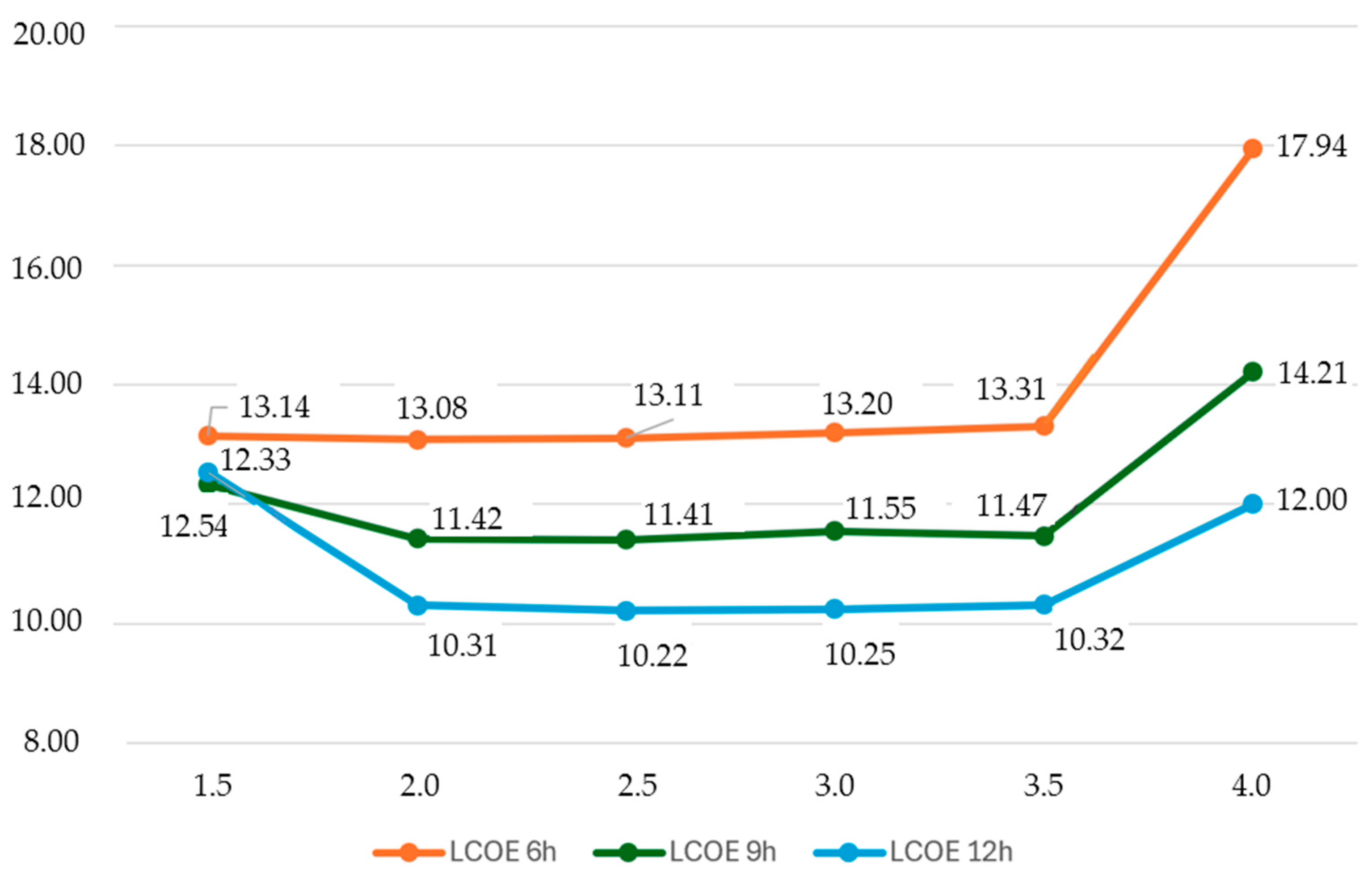

Seeking to investigate the feasibility of CSP in Tanzania by modeling parabolic trough and solar tower CSP technologies, Aly et al. [

20] the LCOE for solar tower plants ranges from 11.6 to 12.5 ¢/kWh, and for parabolic trough plants from 13.0 to 14.4 ¢/kWh. Higher interest rates significantly increase LCOE, reaching up to 25.9 ¢/kWh in private-sector projects. Therefore, CSP project viability in the country relies heavily on favorable financing conditions and supportive political mechanisms to lower investment risk.

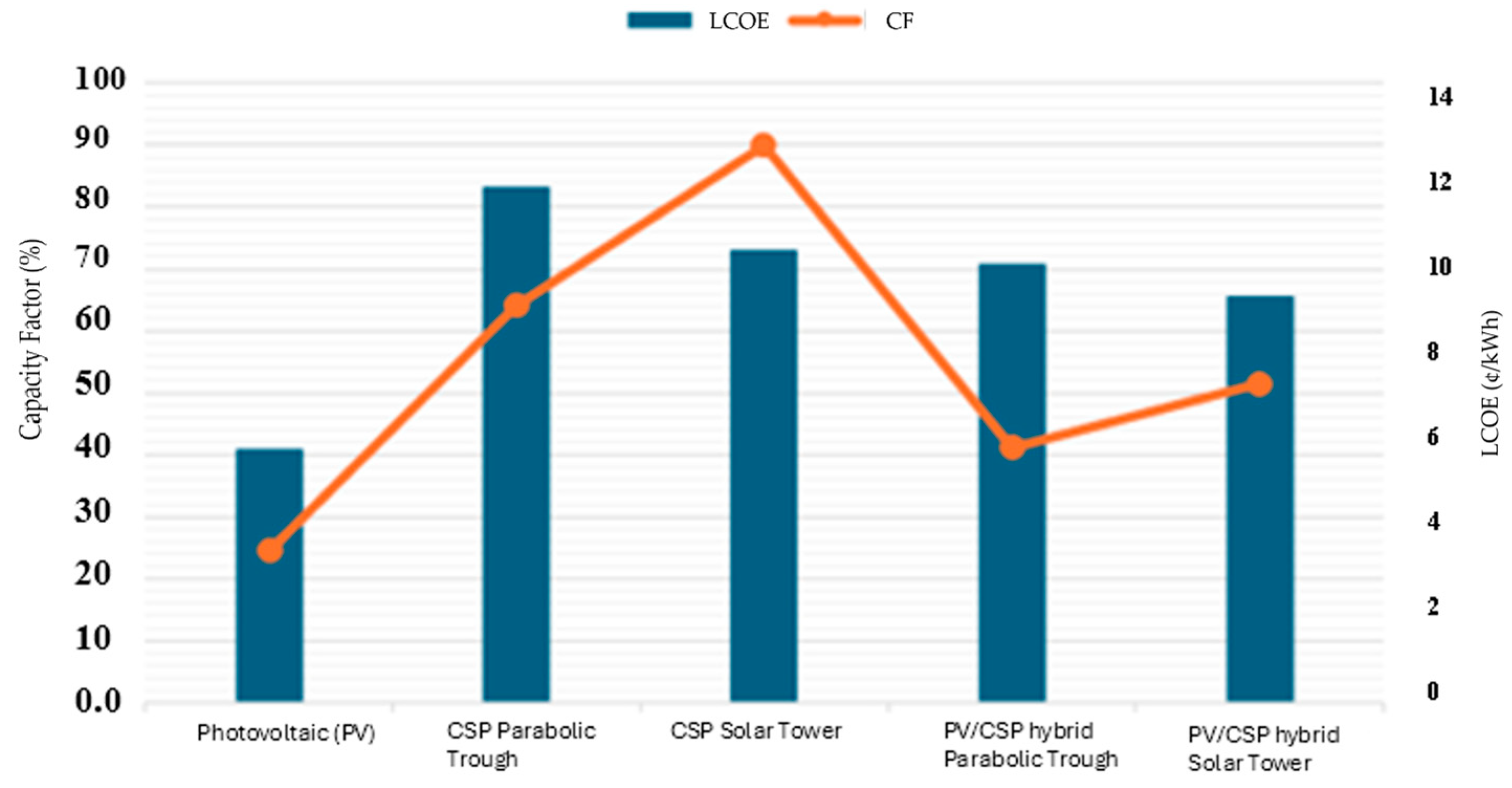

Boreti & Castelleto [

21] and Ziyati et al. [

22] compared PV and CSP plants over 100 MW in the U.S. and showed that PV dominates due to lower costs and more mature technology, while CSP, particularly solar tower systems, remains less common. Their study also used model predictions to explore the optimal long-term complementary use of both technologies.

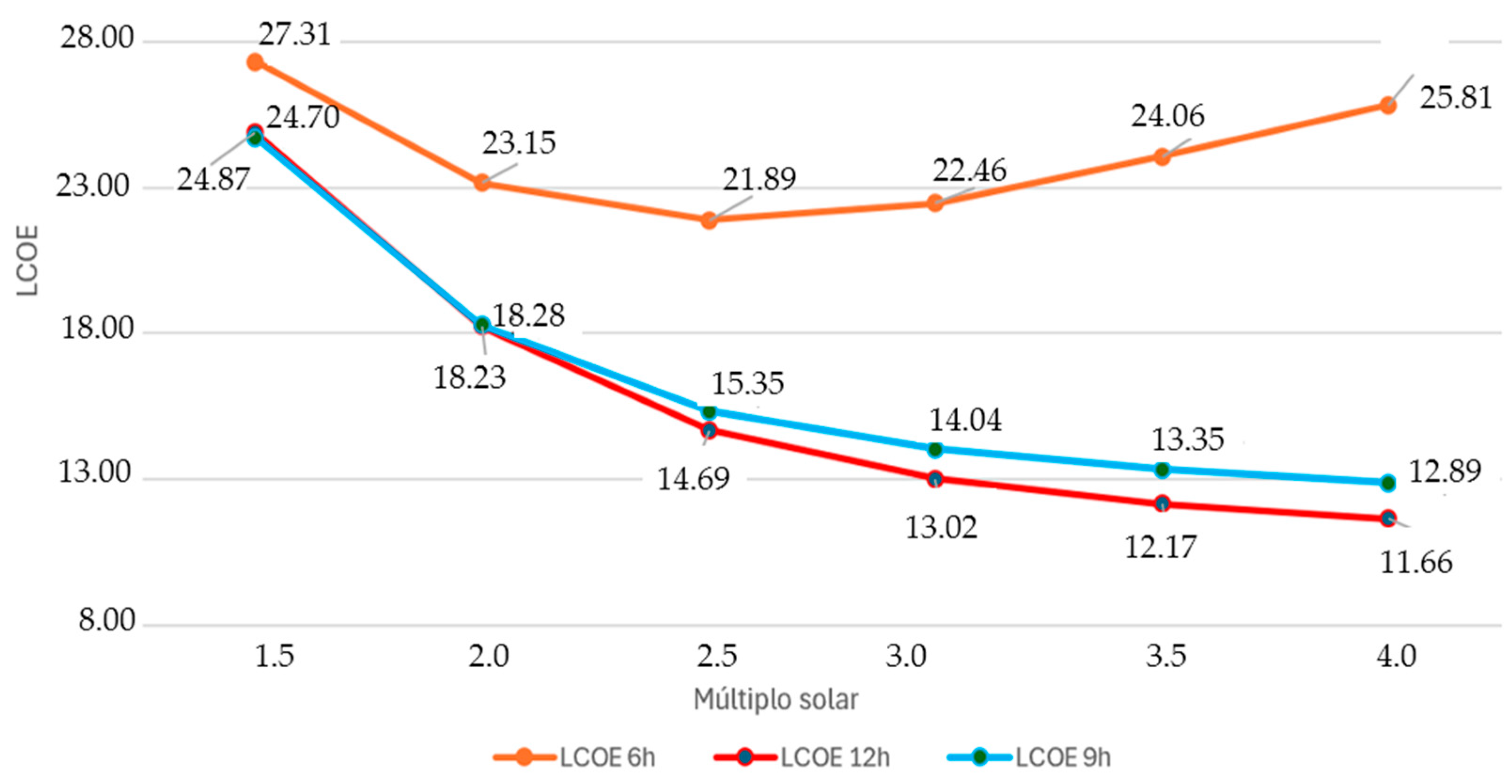

Hassani & Mezrhab [

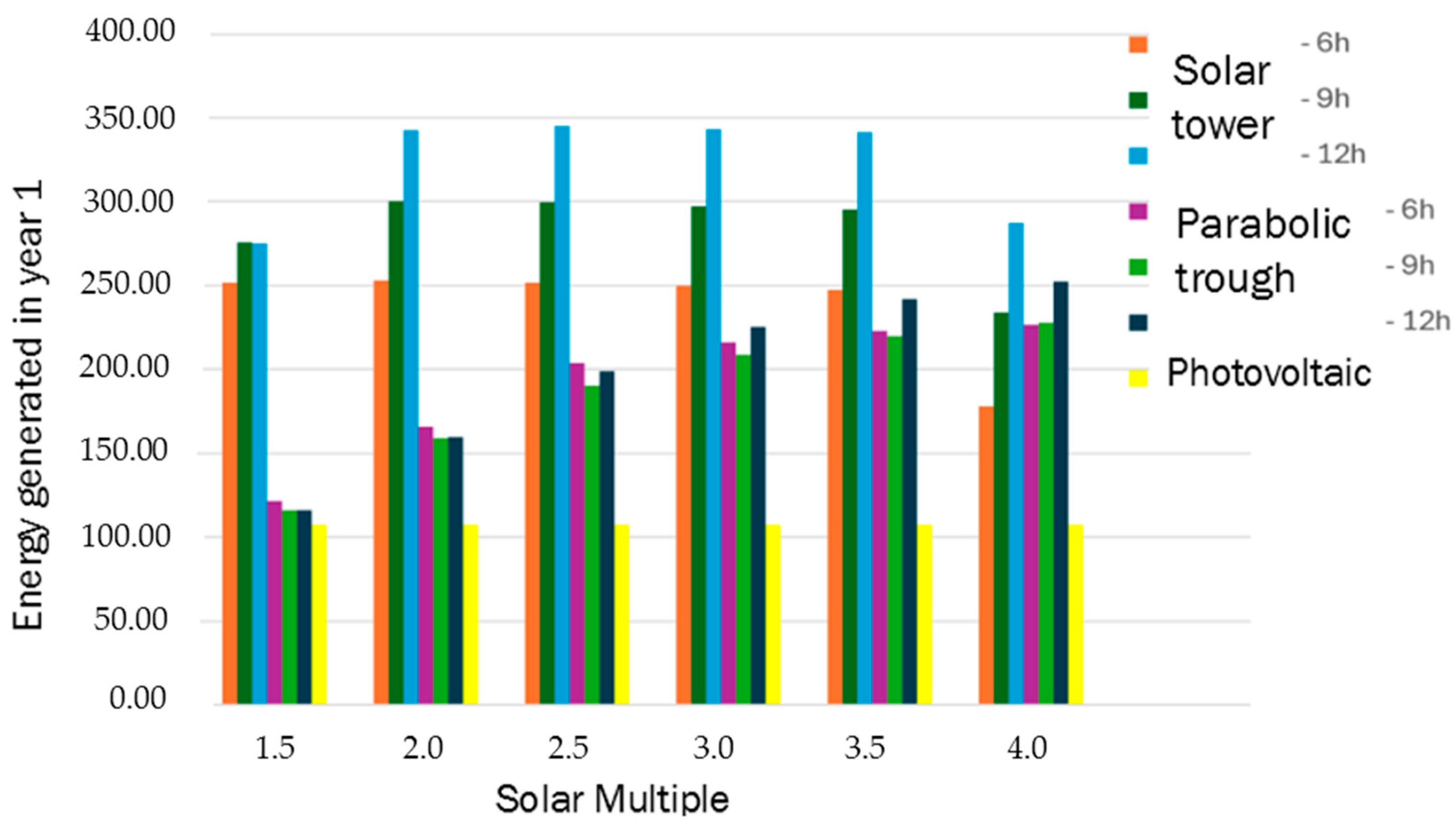

23] conducted a parametric study examining the effects of varying tilt angles, solar multiples (SM), and thermal storage durations on annual energy output and the levelized cost of energy (LCOE). Their technical and economic analysis indicated that fixing solar PV panels at a 30° tilt yields optimal performance, delivering higher annual energy generation alongside a reduced LCOE. Moreover, as anticipated, the findings reveal that hybrid power plants enable more flexible energy dispatch and achieve a lower LCOE compared to concentrated solar power (CSP) systems. Notably, when the solar multiple exceeds 3.5 and thermal storage extends beyond 16 h—given its significantly lower cost relative to battery storage—the system’s capacity factor can surpass 90%.

By investigating two Saudi Arabian cities with hybrid CSP/PV plants with three different operating strategies, Sumayli et al. [

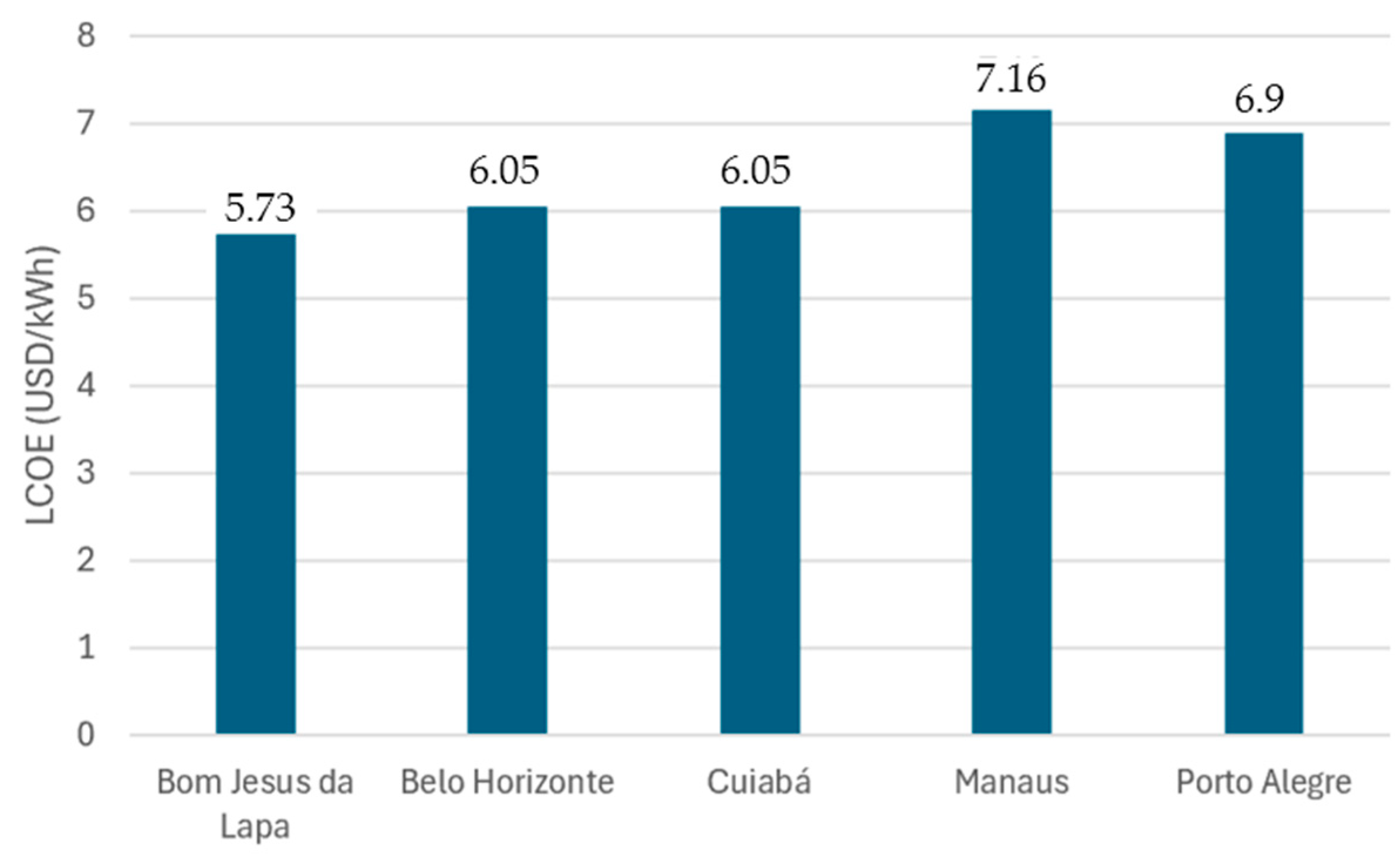

24], show that for a target capacity factor of 79%, the hybrid concept with a PV plant added to the original CSP baseload plant shows a reduction in LCOE of 18% for Riyadh and 7% for Tabuk. Thus, the LCOE was reduced by hybridization in both locations. Therefore, it is important to study hybridization for an individual city based on its meteorological data.

The sizing of grid-connected photovoltaic systems through energy cost indicators was evaluated by Aguilar et al. [

14] in Mexico. It presents an operational and economic study that compares the hybrid system to that used in the microgrid. The results show that the levelized cost of energy (LCOE) for the PV/CSP hybrid system is USD 0.524/kWh, only 2% higher than the LCOE of the photovoltaic battery, which is USD 0.51/kWh. However, in a scenario where the PV/CSP system is deployed in a community with a 50% increase in energy demand, the levelized cost of energy (LCOE) rises to USD 0.506/kWh. Conversely, if the community’s energy demand surpasses 500 kW, the LCOE of the PV-CSP system decreases by 26%, highlighting the economic advantage of scaling up the system.

Hasni & Platzer [

19] investigated a new concept for supplying heat and power from a hybrid PV and CSP plant to meet the energy demand of an LNG export terminal. The results indicate that the hybrid PV/CSP plant significantly accelerates the decarbonization of the energy supply to the “all-electric” LNG plant.

Although environmental assessments of CSP technologies remain limited, key studies such as Gasa et al. [

25] and Klein & Rubin [

26] have demonstrated that thermal energy storage significantly reduces life cycle greenhouse gas emissions and enhances dispatchability. These findings, while not the focus of this techno-economic assessment, underscore the broader sustainability potential of CSP systems. Additionally, policy analyses by Kumar et al. [

27], Pan & Dinter [

28], and Ling-Zhi et al. [

16] highlight how national incentive programs influence CSP adoption, offering context for future integration strategies.

Caldas & Santos [

2] state that current regulations, such as REN (Normative Resolution) 687 [

4] are partially adequate to support the growth of the solar energy market in Brazil. There is a need for regulatory improvements aimed at reducing costs and improving financing conditions in the implementation of distributed generation systems in the residential, commercial, and industrial markets, as well as greater freedom and flexibility so that the consumer can effectively become a customer in the Brazilian energy market.

In Brazil, there are no studies that deal with hybrid CSP/PV plants; only studies on hybridization with CSP appear, those by Soria et al. [

10] and Fichter et al. [

29], both of which use biomass in the country’s semiarid region. According to Soria et al. [

10], the hybridization of biomass in a CSP plant with a solar multiple (SM) of 1.2 and a biomass fill fraction of 30% can generate electricity at 110 USD/MWh.

1.2. SAM—System Advisor Model

The System Advisor Model (SAM) is software developed by National Renewable Energy Laboratory—NREL [

30], a laboratory of the United States Department of Energy (DOE), with over 35 years of experience in energy efficiency and renewable energy. SAM collaborates with Sandia National Laboratories on photovoltaic modeling and has collaborated with the University of Wisconsin on concentrated solar power (CSP) modeling.

SAM performs annual cash flow and performance analyses based on user-defined parameters. It uses TRNSYS, a time-series simulation tool developed by the University of Wisconsin, to calculate hourly energy generation for PV, CSP, and other renewable sources based on local solar resource data. Through SAM, it is possible to simulate photovoltaic, wind, biomass, geothermal, and water heating plants, various CSP technologies, and a generic model where it is possible to combine results from two or more technologies in a single plant to obtain results from hybrid plants [

30].

Elbeh & Sleiti [

31] reviewed concentrated solar power (CSP) technology to design and optimize a CSP tower plant for arid climate regions such as Qatar. SAM was used to validate technical and financial data from a solar power tower project, confirming the plant’s feasibility. Key findings showed peak energy production in July (3,621,950 kWh) and the highest energy surplus in March (2,946,965 kWh).

Your works by Soria et al. [

32] and Parent et al. [

33] used SAM to analyze the influence of variation in the storage capacity of heat and hybridization on the levelized cost of energy (LCOE), the capacity factor, and the annual energy production in a solar thermal power generation system, respectively.

Liaqat et al. [

34] presented the design of a hybrid power plant using CSP and PV technologies in Pakistan, a country with high solar capacity. A 150 MW hybrid system (100 MW CSP and 50 MW PV) with 12 h thermal storage showed an 18.5% reduction in LCOE compared to stand-alone CSP, while maintaining dispatchability. The system was modeled using SAM.

In Brazil, Malagueta et al. [

35] using SAM and an optimization model, the study assessed CSP potential in Brazil and its long-term integration by 2040. It concluded that CSP is not yet competitive without tariff support, though future cost reductions and international incentive programs suggest promising prospects.

The data used in SAM for the solar plant simulations described in the literature are presented in

Table 1.

The CSP and PV plants simulated in this study are based on the solved physical models by mathematical equations, which serve as the basis for the standard arrangement present in SAM version 2021.12.2 and the variations made possible by the software.

The novelty of this study lies in providing a Brazil-focused techno-economic benchmark for PV/CSP hybrids, filling a gap in the literature that has so far addressed hybridization mainly in other regions, and by explicitly comparing parabolic trough and solar tower configurations under local solar resource and financial assumptions.

Although this study focuses on Brazil, the modeling setup was designed to be flexible. By separating hourly solar data and financial inputs by country, the same SAM-based approach can be easily adapted to other Latin American regions with similar solar potential.

1.3. CSP Generation in Brazil

Unlike the generation of photovoltaic energy that is growing, supported by REN 687/2015, CSP energy is not yet present in Brazilian soil when it comes to electrical energy. However, for heat generation, we have the company Kraft Foods in its subsidiary in Recife, where a parabolic cylinder solar field can provide pressurized water at temperatures of 110 °C, used for cooking, cleaning, drying, and pasteurizing food [

36].

Aiming at the dissemination of knowledge and development of CSP technology in Brazil, ANEEL (National Electric Energy Agency) developed a strategic research and development project, which resulted in public call no. 19/2015—Strategic Project for the Development of National Technology for Solar Thermal Generation of Electric Energy [

36]. In this call, the Regulatory Agency observed that the country’s existing industrial capacities offered good conditions for insertion into the global production chains of geothermal technology. Thus, its main objective was to identify technical and commercial arrangements for generating electricity through this technology, in addition to seeking public policy designs capable of driving the nationalization of technology and component manufacturing. The call anticipated that projects could include the installation of pilot plants or parts of a solar thermal installation.

Among other requirements, it required the implementation of an irradiation measurement campaign and recommended the carrying out of exchanges with international experts. In total, 5 projects were selected to participate in ANEEL’s Strategic PD program, as shown in

Table 2. As published by the publisher Brasil Energia, all envisaged the installation of pilot projects of CSP plants. Although some of the projects are already in the final stage, none have yet managed to complete the installation of the plants, with CESP (São Paulo Energy Company, Sao Paulo, Brazil) being the most advanced to date.

CSP technology provides firm power, ancillary services, and zero emissions, but is undervalued in Brazil’s cost-focused auctions, making it currently uncompetitive. Therefore, evaluating the economic viability of CSP, especially hybrid systems and modeling their impact on the electricity matrix and tariffs, is essential for future competitiveness.

1.4. CSP Technologies

The parabolic cylindrical solar collector uses concave mirrors and an absorber tube through which a thermal fluid heated by the sun’s rays circulates, which subsequently generates steam for the Rankine cycle. The central tower CSP plant uses heliostats to reflect sunlight to a receiver on a tower, heating the thermal fluid. Fresnel concentrators use flat mirrors, reflecting sunlight to a fixed tube, which is less expensive but also less efficient. Parabolic disk concentrators use independent mirrors that concentrate heat at a focal point to operate a Stirling engine and are efficient, but with power limited to small generators [

37].

Table 3 provides a comparative overview of the two technologies within the CSP family.

Clearly, from a technological perspective, Sumayli et al. [

24] emphasize the importance of analyzing hybridization strategies tailored to the specific meteorological conditions of each city. They argue that integrating photovoltaic (PV) systems into concentrated solar power (CSP) plant designs should be considered universally, as this approach can significantly reduce the cost of solar-based baseload energy supply.

Although they have already been made in Saudi Arabia [

24], Iran [

38], India [

27,

39], Spain [

18,

33], Egypt [

40], Morocco [

23], Malaysia [

41], Mexico [

14], Chile [

42,

43], China [

16], Ghana [

44], Tanzania [

20], and Pakistan [

34], there is no detailed estimate in the literature of an economic analysis of hybrid CSP/PV plants in Brazil considering different solar multiples (SM) and different thermal storages, even with the country’s large solar potential.

This study addresses a gap in the literature by evaluating different solar plant scenarios across various Brazilian regions, considering their climatic and solar potential. Using PV and multiple CSP configurations, it aims to identify the optimal hybrid setup based on energy generation and LCOE.