Research on the Sustainable Indicator System for Multi-Coal Seam Mining: A Case Study of the Buertai Coal Mine in China

Abstract

1. Introduction

2. Methodology

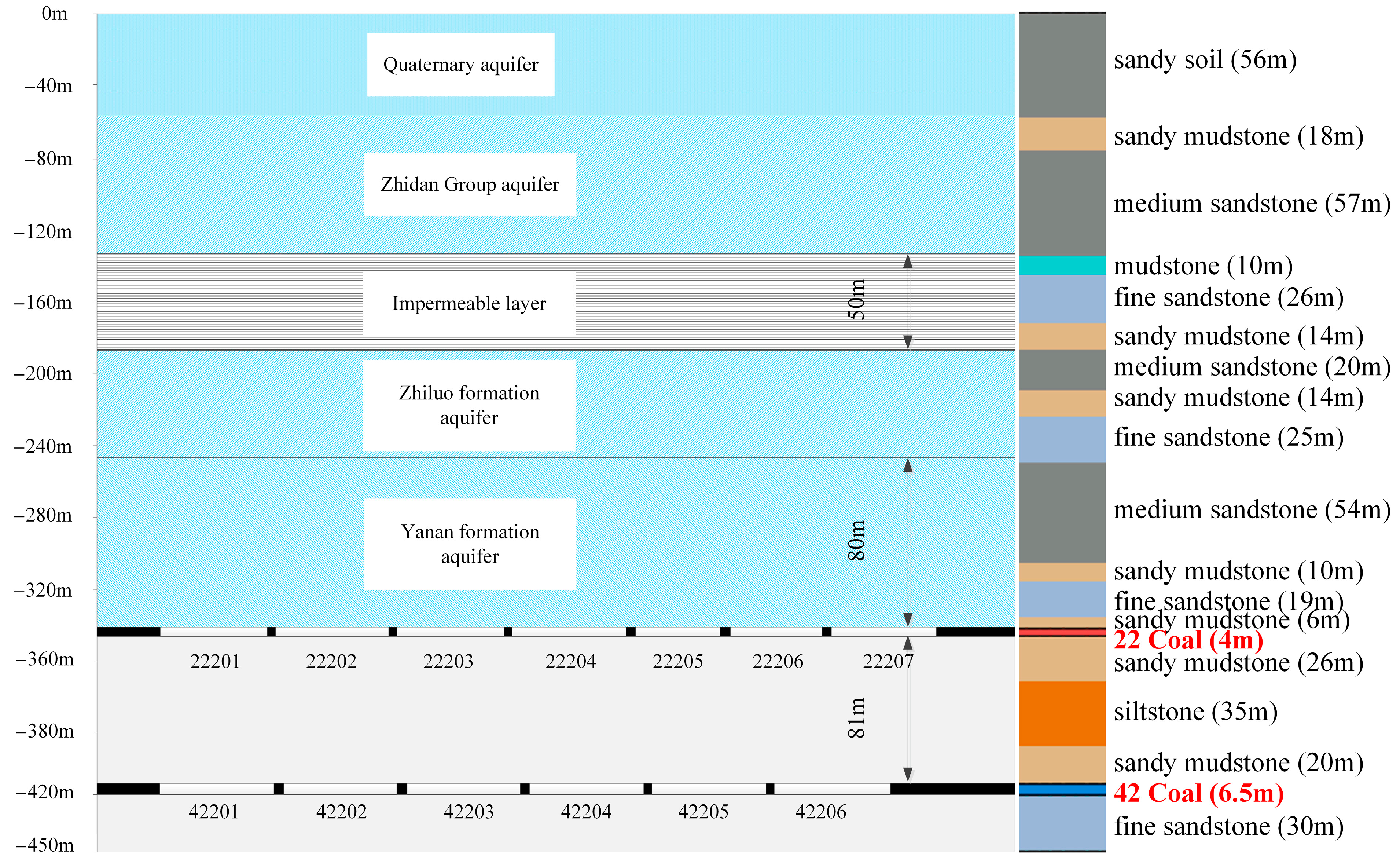

2.1. Project Overview

2.2. Plastic Damage–Seepage Coupling Model

2.3. Numerical Model

2.4. Sustainability Indicator Framework

- (1)

- Groundwater Loss Index (GLI)

- (2)

- Aquifer Protection Efficiency (APE)

- (3)

- Sustainability Trade-off Index (STI)

3. Results

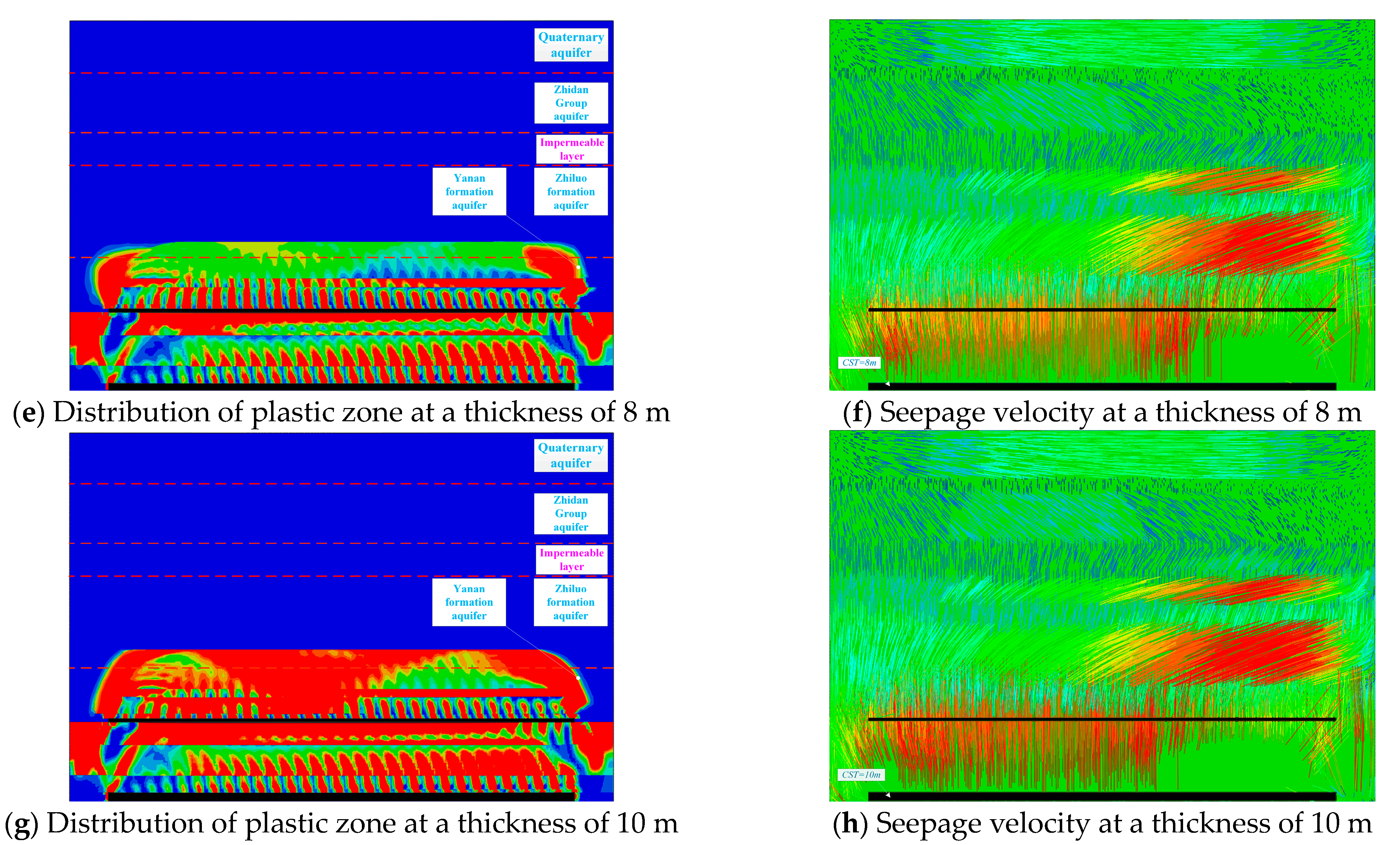

3.1. The Impact of Coal Seam Thickness

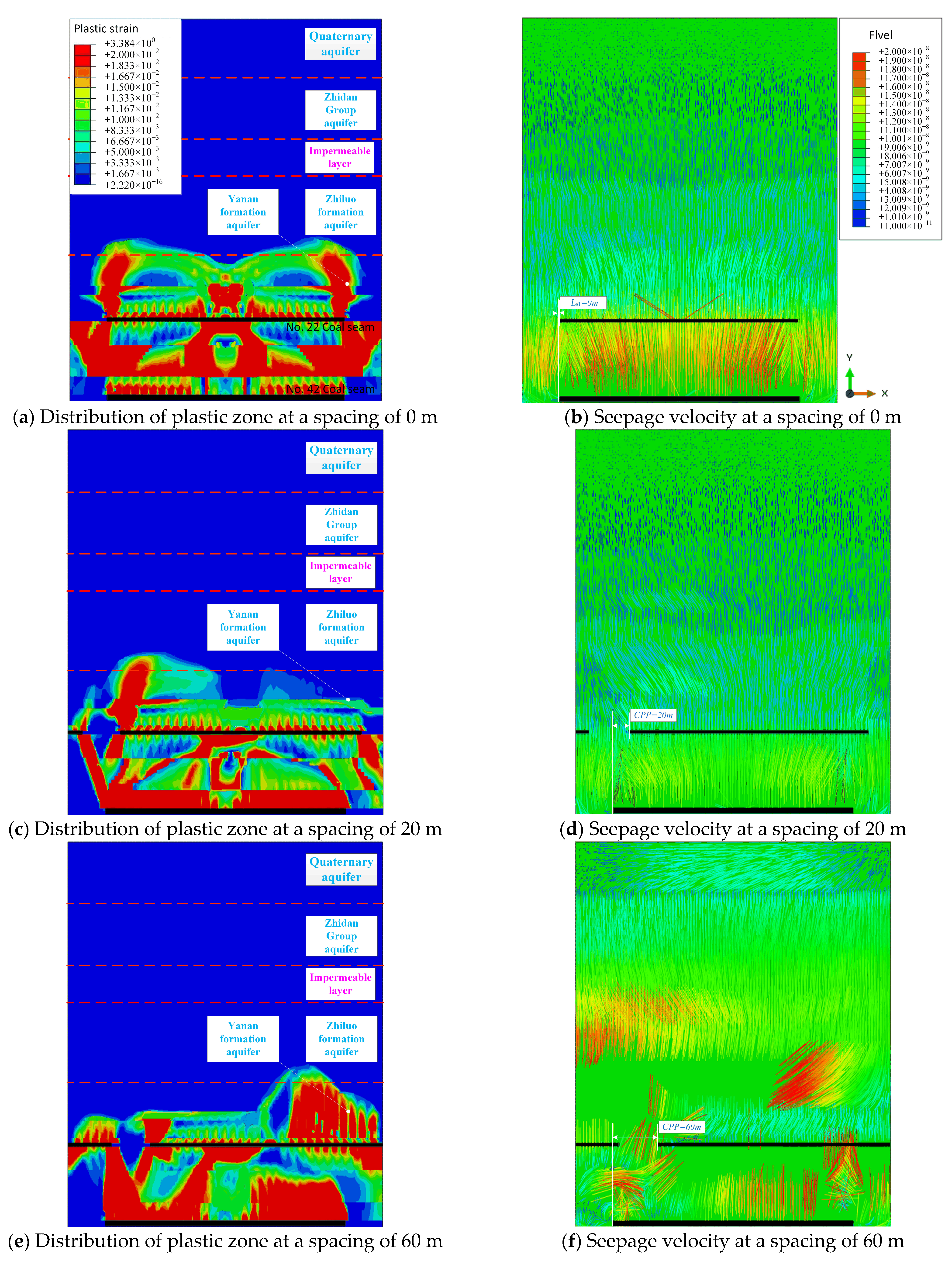

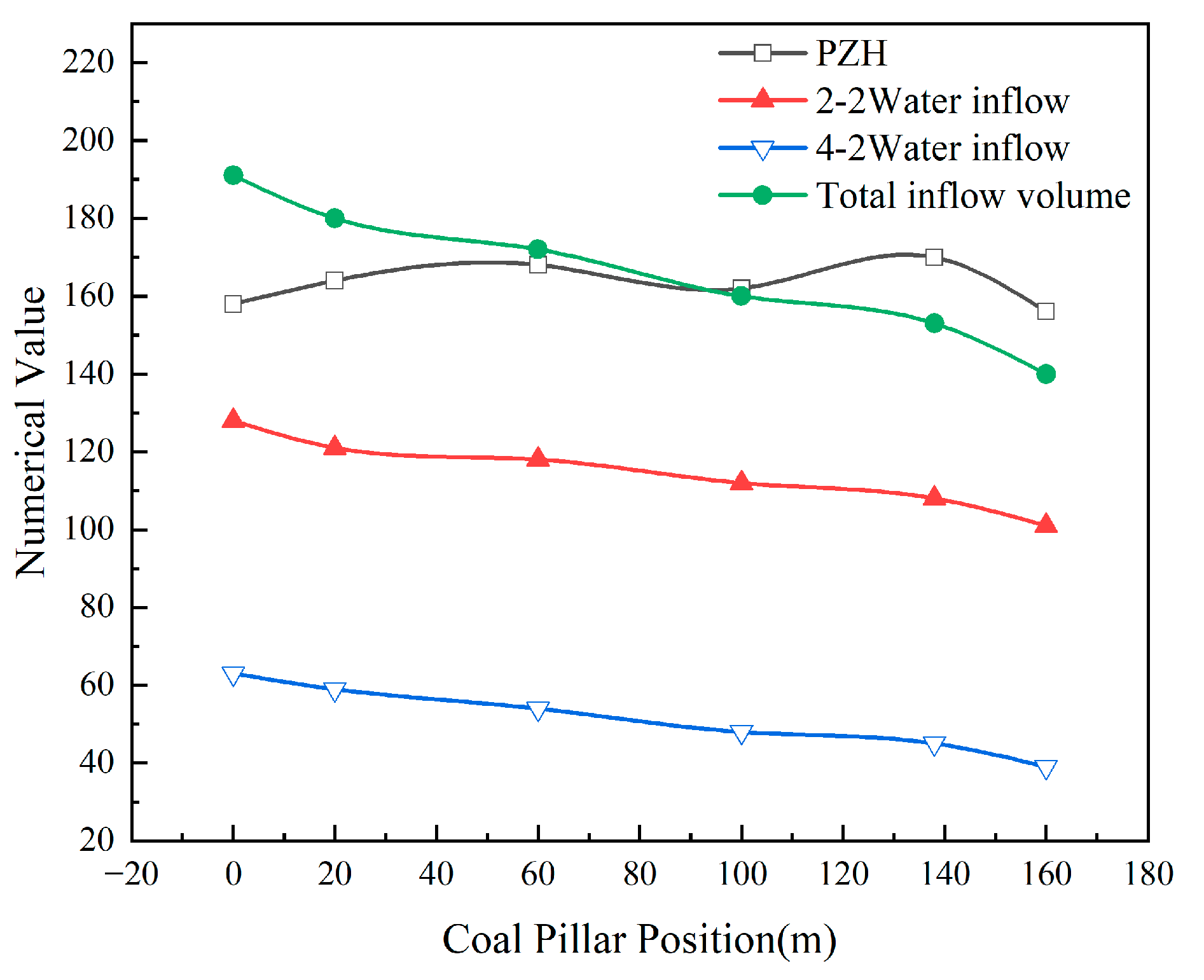

3.2. The Impact of Coal Pillar Position

3.3. Experimental Verification

3.4. Sustainability Indicator Analysis

4. Discussion

4.1. Meaning of Sustainability

4.2. Comparison with Previous Studies

4.3. Support for Policies and Management

- GLI Threshold: When GLI ≥ 1.5, it may indicate that groundwater extraction is at an unsustainable risk level. This threshold can serve as an early warning reference for implementing measures such as recharge, supplementation, or controlled drainage to maintain aquifer stability.

- APE Standard: The misalignment arrangement can achieve APE ≈ 27%. Based on this, it is recommended that APE ≥ 20% be used as a preliminary evaluation benchmark for green and efficient mines, providing policymakers with a quantitative standard to promote environmentally friendly mining.

- STI Optimization: Through STI, the optimal balance point for coal recovery and water resource protection can be identified, providing a scientific basis for mine planning.

- Global coherence: The indicator system proposed in this article is highly aligned with the United Nations Sustainable Development Goals (SDGs), particularly SDG 6, 12, and 13. Although its applicability in different mining areas still needs further verification, this framework provides an innovative reference for incorporating sustainability indicators into environmental impact assessments and mining approval processes.

4.4. Limitations and Prospects

5. Conclusions

- Impact of coal seam thickness: The thickness of the coal seam is a major driver of groundwater depletion. While increasing coal seam thickness is economically attractive, it could lead to a significant rise in groundwater loss at the Buertai coal mine, especially with a notable increase in water inflow from deeper coal seams, reaching up to 1.8 times. The proposed Groundwater Loss Index (GLI) successfully quantifies this risk, providing a scientific measurement for identifying mining plans with high environmental impact.

- Optimizing coal pillar layout: Optimizing the arrangement of coal pillars, especially using staggered layouts, can effectively reduce the roof cracking in the Buertai coal mine and significantly lower the underground water inflow in the Buertai coal mine, with a maximum reduction of 26.7%. The aquifer protection efficiency (APE) provides a practical benchmark for green mining design, and optimizing coal pillar layout helps to enhance groundwater protection and reduce the risk of water disasters.

- Sustainability Trade-offs: The Sustainability Trade-off Index (STI) provides a framework for balancing production, safety, and environmental protection in the design of the Buertai coal mine. The STI helps identify operational windows for achieving synergistic optimization among these goals, going beyond traditional single-objective planning and promoting the development of the Buertai coal mine towards a more sustainable direction.

- Policy Relevance: The proposed GLI, APE, and STI indicators show potential for application in environmental impact assessments, mining approval processes, and sustainability certification systems. These quantitative indicators may provide a useful scientific basis for aligning mining practices with national green development goals and international sustainability frameworks (such as the SDGs). However, their applicability under different geological and mining conditions still needs to be further verified through field investigations and long-term monitoring.

- Sustainable Mining Recommendations: To reduce environmental impact and improve management efficiency, it is recommended to: first, optimize coal pillar design based on APE thresholds, balancing recovery rates with aquifer protection; then, incorporate GLI and STI early warning systems into mine planning and safety monitoring platforms to achieve real-time risk control; and finally, establish an interdisciplinary monitoring network that integrates hydrogeology, rock mechanics, and ecological data to enable full-process sustainable assessment.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hamilton, C.; Song, J.; Cui, R.; Olson, C.; Cui, D. Evaluating provincial-level employment challenge during the coal transition in China. Adv. Clim. Change Res. 2022, 13, 729–737. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, F.; Kou, M.; Li, M. A Review of Stability of Dam Structures in Coal Mine Underground Reservoirs. Water 2024, 16, 1856. [Google Scholar] [CrossRef]

- Audin, J. The coal transition in Datong: An ethnographic perspective. Made China J. 2020, 5, 34–43. [Google Scholar] [CrossRef]

- Yuan, Z.; Yan, D.; Yang, Z.; Yin, J.; Yuan, Y. Research on temporal and spatial change of 400 mm and 800 mm rainfall contours of China in 1961–2000. Adv. Water Sci. 2014, 25, 494–502. [Google Scholar]

- Liu, Y.; Tang, X.; Sun, Z.; Zhang, J.; Wang, G.; Jin, J.; Wang, G. Spatiotemporal precipitation variability and potential drivers during 1961–2015 over the Yellow River Basin, China. Weather 2019, 74, S32–S39. [Google Scholar] [CrossRef]

- Shen, Y.; Hong, Z.; Pan, Y.; Yu, J.; Maguire, L. China’s 1 km merged gauge, radar and satellite experimental precipitation dataset. Remote Sens. 2018, 10, 264. [Google Scholar] [CrossRef]

- Meng, Z.; Shi, X.; Li, G. Deformation, failure and permeability of coal-bearing strata during longwall mining. Eng. Geol. 2016, 208, 69–80. [Google Scholar] [CrossRef]

- Palchik, V. Formation of fractured zones in overburden due to longwall mining. Environ. Geol. 2003, 44, 28–38. [Google Scholar] [CrossRef]

- Bu, W.K.; Mao, X. Research on effect of fault dip on fault activation and water inrush of coal floor. Chin. J. Rock Mech. Eng. 2009, 28, 386–394. [Google Scholar]

- Sui, W.; Liu, J.; Gao, B.; Liang, Y. A review on disaster mechanism of quicksand with a high potential energy due to mining and its prevention and control. China Coal Soc. 2019, 44, 2419–2426. [Google Scholar]

- Xie, H. Research review of the state key research development program of China: Deep rock mechanics and mining theory. J. China Coal Soc. 2019, 44, 1283–1305. [Google Scholar]

- Tati, B.B. Multi-seam coal mining. J. S. Afr. Inst. Min. Metall. 2011, 111, 231–242. [Google Scholar]

- Kunz, N.C. Towards a broadened view of water security in mining regions. Water Secur. 2020, 11, 100079. [Google Scholar] [CrossRef]

- Mahato, M.K.; Singh, P.K.; Singh, A.K.; Tiwari, A.K. Assessment of Hydrogeochemical Processes and Mine Water Suitability for Domestic, Irrigation, and Industrial Purposes in East Bokaro Coalfield, India. Mine Water Environ. 2018, 37, 493–504. [Google Scholar] [CrossRef]

- Gandhe, A.; Venkateswarlu, V.; Gupta, R.N. Extraction of Coal Under a Surface Water Body—A Strata Control Investigation. Rock Mech. Rock Eng. 2005, 38, 399–410. [Google Scholar] [CrossRef]

- Booth, C.J.; Spande, E.D.; Pattee, C.T.; Miller, J.D.; Bertsch, L.P. Positive and negative impacts of longwall mine subsidence on a sandstone aquifer. Environ. Geol. 1998, 34, 223–233. [Google Scholar] [CrossRef]

- Bruns, D.A. Macroinvertebrate response to land cover, habitat, and water chemistry in a mining-impacted river ecosystem: A GIS watershed analysis. Aquat. Sci. 2005, 67, 403–423. [Google Scholar] [CrossRef]

- Candeias, C.; Ávila, P.F.; Ferreira da Silva, E.; Teixeira, J.P. Integrated approach to assess the environmental impact of mining activities: Estimation of the spatial distribution of soil contamination (Panasqueira mining area, Central Portugal). Environ. Monit. Assess. 2015, 187, 135. [Google Scholar] [CrossRef]

- Cooper, D.J.; Sanderson, J.S.; Stannard, D.I.; Groeneveld, D.P. Effects of long-term water table drawdown on evapotranspiration and vegetation in an arid region phreatophyte community. J. Hydrol. 2006, 325, 21–34. [Google Scholar] [CrossRef]

- Newman, C.; Agioutantis, Z.; Leon, G.B.J. Assessment of potential impacts to surface and subsurface water bodies due to longwall mining. Int. J. Min. Sci. Technol. 2017, 27, 57–64. [Google Scholar] [CrossRef]

- He, J.; Li, W.; Fan, K.; Qiao, W.; Wang, Q.; Li, L. A method for predicting the water-flowing fractured zone height based on an improved key stratum theory. Int. J. Min. Sci. Technol. 2023, 33, 61–71. [Google Scholar] [CrossRef]

- Jiang, D.; Tang, Y.; Huang, W.; Hou, K.; Luo, Y.; Liu, J. Research on the height of the water-conducting fracture zone in fully mechanized top coal caving face under combined-strata structure. Sustainability 2022, 14, 13781. [Google Scholar] [CrossRef]

- Wang, W.; Li, Z.; Du, F.; Li, G. Study on fracture characteristics of high key stratum and development law of water and gas transport channels in Datong mining area. Energy Sci. Eng. 2023, 11, 48–61. [Google Scholar] [CrossRef]

- Li, A.; Ding, X.; Yu, Z.; Wang, M.; Mu, Q.; Dai, Z.; Li, H.; Zhang, B.; Han, T. Prediction model of fracture depth and water inrush risk zoning in deep mining coal seam floor. Environ. Earth Sci. 2022, 81, 315. [Google Scholar] [CrossRef]

- Chen, L.; Ou, Q.; Peng, Z.; Wang, Y.; Chen, Y.; Tian, Y. Numerical simulation of abnormal roof water-inrush mechanism in mining under unconsolidated aquifer based on overburden dynamic damage. Eng. Fail. Anal. 2022, 133, 106005. [Google Scholar] [CrossRef]

- Han, Y.; Wang, Q.; Li, W.; Yang, Z.; Gu, T.; Wang, Z. Predicting the height of the water-conducting fractured zone in fully mechanized top coal caving longwall mining of very thick jurassic coal seams in western China based on the NNBR model. Mine Water Environ. 2023, 42, 121–133. [Google Scholar] [CrossRef]

- Li, J.; He, Z.; Piao, C.; Chi, W.; Lu, Y. Research on Subsidence Prediction Method of Water-Conducting Fracture Zone of Overlying Strata in Coal Mine Based on Grey Theory Model. Water 2023, 15, 4177. [Google Scholar] [CrossRef]

- Lei, W.; Chai, J.; Zhang, Y.; Ding, G.; Yao, R.; Chen, Y.; Wang, Z.; Ma, C. Study on pressure relief effect of upper protective coal seam mining based on distributed optical fiber sensing monitoring. Opt. Fiber Technol. 2022, 68, 102830. [Google Scholar] [CrossRef]

- Guarneri, M.; Ceccarelli, S.; Francucci, M.; de Collibus, M.F.; Ciaffi, M.; Gusella, V.; Liberotti, R.; La Torre, M. Multi-sensor analysis for experimental diagnostic and monitoring techniques at san bevignate templar church in perugia. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2023, 48, 693–700. [Google Scholar] [CrossRef]

- Lu, C.; Xu, J.; Li, Q.; Zhao, H.; He, Y. Research on the Development Law of Water-Conducting Fracture Zone in the Combined Mining of Jurassic and Carboniferous Coal Seams. Appl. Sci. 2022, 12, 11178. [Google Scholar] [CrossRef]

- Wang, X.; Li, H. Failure height and fracture evolution pattern of overburden rock in fully mechanized cave mining. Arab. J. Geosci. 2022, 15, 443. [Google Scholar] [CrossRef]

- Panza, E.; Berto, C.; Luzi, E.; Agosta, F.; Zambrano, M.; Tondi, E.; Prosser, G.; Giorgioni, M.; Janiseck, J.M. Structural architecture and Discrete Fracture Network modelling of layered fractured carbonates (Altamura Fm., Italy). Ital. J. Geosci. 2015, 134, 409–422. [Google Scholar] [CrossRef]

- Vyazmensky, A.; Stead, D.; Elmo, D.; Moss, A. Numerical analysis of block caving-induced instability in large open pit slopes: A finite element/discrete element approach. Rock Mech. Rock Eng. 2010, 43, 21–39. [Google Scholar] [CrossRef]

- Fan, H.; Luo, F.; Gao, S.; Li, M.; Lv, Z.; Sun, G. Evolution law of mining-induced overburden stratum stress and fracture fields in inclined coal seam. World J. Eng. 2024, 21, 475–486. [Google Scholar] [CrossRef]

- Munjiza, A.; Owen, D.; Bicanic, N. A combined finite-discrete element method in transient dynamics of fracturing solids. Eng. Comput. 1995, 12, 145–174. [Google Scholar] [CrossRef]

- Munjiza, A.; Andrews, K.R.F.; White, J.K. Combined single and smeared crack model in combined finite-discrete element analysis. Int. J. Numer. Methods Eng. 1999, 44, 41–57. [Google Scholar] [CrossRef]

- Mai, L.; Li, H. Finite–Discrete Element Method Simulation Study on Development of Water-Conducting Fractures in Fault-Bearing Roof under Repeated Mining of Extra-Thick Coal Seams. Sustainability 2024, 16, 5177. [Google Scholar] [CrossRef]

- Liu, J.; Zhao, Y.; Tan, T.; Zhang, L.; Zhu, S.; Xu, F. Evolution and modeling of mine water inflow and hazard characteristics in southern coalfields of China: A case of Meitanba mine. Int. J. Min. Sci. Technol. 2022, 32, 513–524. [Google Scholar] [CrossRef]

- Li, H.; Tang, S.; Ma, L.; Bai, H.; Kang, Z.; Wu, P.; Miao, X. Continuous-discrete coupling simulation of progressive failure of mining overburden rock. Chin. J. Rock Mech. Eng. 2022, 41, 2299–2310. [Google Scholar]

- Zhang, Y.; Yang, L. A novel dynamic predictive method of water inrush from coal floor based on gated recurrent unit model. Nat. Hazards 2021, 105, 2027–2043. [Google Scholar] [CrossRef]

- Cao, J.; Dou, L.; Konietzky, H.; Zhou, K.; Zhang, M. Failure mechanism and control of the coal bursts triggered by mining-induced seismicity: A case study. Environ. Earth Sci. 2023, 82, 168. [Google Scholar] [CrossRef]

- Zhang, L.; Yan, X.; Yang, X.; Tian, Z.; Yang, H. An elastoplastic model of collapse pressure for deep coal seam drilling based on Hoek–Brown criterion related to drilling fluid loss to reservoir. J. Pet. Sci. Eng. 2015, 134, 205–213. [Google Scholar] [CrossRef]

- Zhang, W.; Li, S.; Wei, J.; Zhang, Q.; Liu, R.; Zhang, X.; Yin, H. Grouting rock fractures with cement and sodium silicate grout. Carbonates Evaporites 2018, 33, 211–222. [Google Scholar] [CrossRef]

- Li, L.; Xie, D.; Wei, J.; Yin, H.; Li, G.; Man, X.; Zhang, W. Analysis and control of water inrush under high-pressure and complex karstic water-filling conditions. Environ. Earth Sci. 2020, 79, 493. [Google Scholar] [CrossRef]

- Zhou, X.; Ouyang, Z.; Zhou, R.; Ji, Z.; Yi, H.; Tang, Z.; Chang, B.; Yang, C.; Sun, B. An Approach to Dynamic Disaster Prevention in Strong Rock Burst Coal Seam under Multi-Aquifers: A Case Study of Tingnan Coal Mine. Energies 2021, 14, 7287. [Google Scholar] [CrossRef]

- Ma, Q.; Liu, X.; Tan, Y.; Wang, Y.; Wang, R.; Wang, E.; Liu, X.; Zhao, Z.; Ren, D.; Xie, W.; et al. Monitoring and evaluation of disaster risk caused by linkage failure and instability of residual coal pillar and rock strata in multi-coal seam mining. Geohazard Mech. 2023, 1, 297–307. [Google Scholar] [CrossRef]

- Liu, X.; Wang, J.; Du, S.; Deng, K.; Chen, G.; Qin, X. Monitoring and Law Analysis of Secondary Deformation on the Surface of Multi-Coal Seam Mining in Closed Mines. Remote Sens. 2024, 16, 3223. [Google Scholar] [CrossRef]

- Wang, X.; Tan, C.; Wang, X. Study on the damage risk assessment of mining geological aquifer based on remote sensing monitoring method. Fresenius Environ. Bull. 2022, 31, 10513–10522. [Google Scholar]

- Deveci, M.; Varouchakis, E.A.; Brito-Parada, P.R.; Mishra, A.R.; Rani, P.; Bolgkoranou, M.; Galetakis, M. Evaluation of risks impeding sustainable mining using Fermatean fuzzy score function based SWARA method. Appl. Soft Comput. 2023, 139, 110220. [Google Scholar] [CrossRef]

- Mirzehi, M.; Afrapoli, A.M. A novel framework for integrating environmental costs and carbon pricing in open-pit mine plans: Towards sustainable and green mining. J. Clean. Prod. 2024, 468, 143059. [Google Scholar] [CrossRef]

- Al Heib, M.M.; Franck, C.; Djizanne, H.; Degas, M. Post-Mining Multi-Hazard Assessment for Sustainable Development. Sustainability 2023, 15, 8139. [Google Scholar] [CrossRef]

- Li, H.; Liang, W.; Li, G.; Bai, J.; Wang, J.; Wu, P. Ductile failure-seepage coupling constitutive equations of broken soft coal and its verification in indirect fracturing engineering. J. China Coal Soc. 2021, 46, 924–936. [Google Scholar]

- Ghavidel, A.; Mousavi, S.R.; Rashki, M. The Effect of FEM Mesh Density on the Failure Probability Analysis of Structures. KSCE J. Civ. Eng. 2018, 22, 2371–2383. [Google Scholar] [CrossRef]

- Zabolotnii, E.; Morgenstern, N.R.; Ward Wilson, G. Mesh sensitivity in numerical models of strain-weakening systems. Comput. Geotech. 2021, 136, 104253. [Google Scholar] [CrossRef]

- Liu, H.; Tang, C.; Rui, Y. Numerical simulation of strata failure process with multi-coal strata mined. Chin. J. Rock Mech. Eng. 2001, 20, 190–196. [Google Scholar]

- Ning, W.J.; Tao, L.W.; Cheng, S.W. Numerical Simulation and Test Analysis of Development Height of Fractured Zone in Overlying Strata. Coal Technol. 2017, 36, 149–151. [Google Scholar]

- Li, H.; Bai, H.; Wu, J.; Ma, Z.; Ma, K.; Wu, G.; Du, Y.; He, S. A Cascade Disaster Caused by Geological and Coupled Hydro-Mechanical Factors—Water Inrush Mechanism from Karst Collapse Column under Confining Pressure. Energies 2017, 10, 1938. [Google Scholar] [CrossRef]

- Hajiabdolmajid, V.; Kaiser, P. Brittleness of rock and stability assessment in hard rock tunneling. Tunn. Undergr. Space Technol. 2003, 18, 35–48. [Google Scholar] [CrossRef]

- Ma, Q.; Liu, X.; Qian, R.; Tan, Y.; Li, B.Q.; Liu, X. Progressive failure processes and mechanisms of disasters caused by interrelated failure of residual coal pillars and rock strata. Sci. Total Environ. 2024, 954, 176181. [Google Scholar] [CrossRef] [PubMed]

- Shabanimashcool, M.; Li, C.C. Numerical modelling of longwall mining and stability analysis of the gates in a coal mine. Int. J. Rock Mech. Min. Sci. 2012, 51, 24–34. [Google Scholar] [CrossRef]

- Suchowerska, A.; Merifield, R.S.; Carter, J.P. Vertical stress changes in multi-seam mining under supercritical longwall panels. Int. J. Rock Mech. Min. Sci. 2013, 61, 306–320. [Google Scholar] [CrossRef]

- Wu, C.; Wu, X.; Zhu, G.; Qian, C. Predicting mine water inflow and groundwater levels for coal mining operations in the Pangpangta coalfield, China. Environ. Earth Sci. 2019, 78, 130. [Google Scholar] [CrossRef]

- Li, X.; Du, S.; Hu, S.; Dong, D.; Jiang, D.; Cao, C.; Lin, G.; Fu, J. Simulation of surface water–groundwater interaction in coal mining subsidence areas: A case study of the Kuye River Basin in China. J. Hydrol. 2025, 659, 133243. [Google Scholar] [CrossRef]

- Heidar, M.R.; Ardejani, F.D.; Taherdangkoo, R.; Shokri, B.J.; Butscher, C. A Novel Empirical-Analytical Model for Predicting Groundwater Inflow into an Open Pit Partially Penetrating an Unconfined Aquifer. Mine Water Environ. 2025, 44, 631–640. [Google Scholar] [CrossRef]

| E0/GPa | c/MPa | φ/° | knd/(m/s) | kd/(m/s) | np/% | |

|---|---|---|---|---|---|---|

| Coal | 1.63 | 2.7 | 27 | 1.3 × 10−11 | 5.6 × 10−9 | 3.1 |

| Mudstone | 3.58 | 4.3 | 32 | 1.1 × 10−11 | 3.2 × 10−9 | 2.6 |

| Sandy mudstone | 7.22 | 6.5 | 38 | 4.2 × 10−10 | 2.9 × 10−7 | 4.6 |

| Medium sandstone | 14.35 | 10.3 | 42 | 7.6 × 10−9 | 1.2 × 10−6 | 12.7 |

| Fine sandstone | 12.33 | 11.1 | 40 | 2.8 × 10−9 | 3.3 × 10−6 | 10.3 |

| Siltstone | 17.54 | 8.4 | 37 | 8.1 × 10−10 | 1.1 × 10−6 | 8.3 |

| Scenario (CST, CPP) | PZH/m | TIV (m3/h) | GLI | APE/% | STI (w = 1/3) |

|---|---|---|---|---|---|

| 4 m, 0 m | 155 | 161 | 1.00 | 28.1 | 0.67 |

| 6 m, 0 m | 160 | 170 | 1.06 | 24.1 | 0.60 |

| 8 m, 0 m | 164 | 190 | 1.18 | 15.2 | 0.50 |

| 10 m, 0 m | 168 | 224 | 1.39 | 0.0 | 0.33 |

| Scenario (CST, CPP) | PZH/m | TIV (m3/h) | GLI | APE/% | STI (w = 1/3) |

|---|---|---|---|---|---|

| 4 m, 0 m | 158 | 191 | 1.36 | 0.0 | 0.29 |

| 4 m, 20 m | 164 | 180 | 1.29 | 5.8 | 0.22 |

| 4 m, 60 m | 168 | 172 | 1.23 | 9.9 | 0.17 |

| 4 m, 100 m | 162 | 160 | 1.14 | 16.2 | 0.39 |

| 4 m, 138 m | 170 | 153 | 1.09 | 19.9 | 0.25 |

| 4 m, 160 m | 156 | 140 | 1.00 | 26.7 | 0.67 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qi, T.; Li, H.; Kang, Z.; Yang, D.; Zhou, Z. Research on the Sustainable Indicator System for Multi-Coal Seam Mining: A Case Study of the Buertai Coal Mine in China. Sustainability 2025, 17, 9512. https://doi.org/10.3390/su17219512

Qi T, Li H, Kang Z, Yang D, Zhou Z. Research on the Sustainable Indicator System for Multi-Coal Seam Mining: A Case Study of the Buertai Coal Mine in China. Sustainability. 2025; 17(21):9512. https://doi.org/10.3390/su17219512

Chicago/Turabian StyleQi, Tianshuo, Hao Li, Zhiqin Kang, Dong Yang, and Zhengjun Zhou. 2025. "Research on the Sustainable Indicator System for Multi-Coal Seam Mining: A Case Study of the Buertai Coal Mine in China" Sustainability 17, no. 21: 9512. https://doi.org/10.3390/su17219512

APA StyleQi, T., Li, H., Kang, Z., Yang, D., & Zhou, Z. (2025). Research on the Sustainable Indicator System for Multi-Coal Seam Mining: A Case Study of the Buertai Coal Mine in China. Sustainability, 17(21), 9512. https://doi.org/10.3390/su17219512