An Integrated Approach to the Development and Implementation of New Technological Solutions

Abstract

1. Introduction

2. Conditions for the Development and Implementation of Technologies in Manufacturing Companies

3. Methods Supporting the Development and Implementation of New Solutions in Manufacturing Companies

3.1. Methods for Developing New Technological Solutions

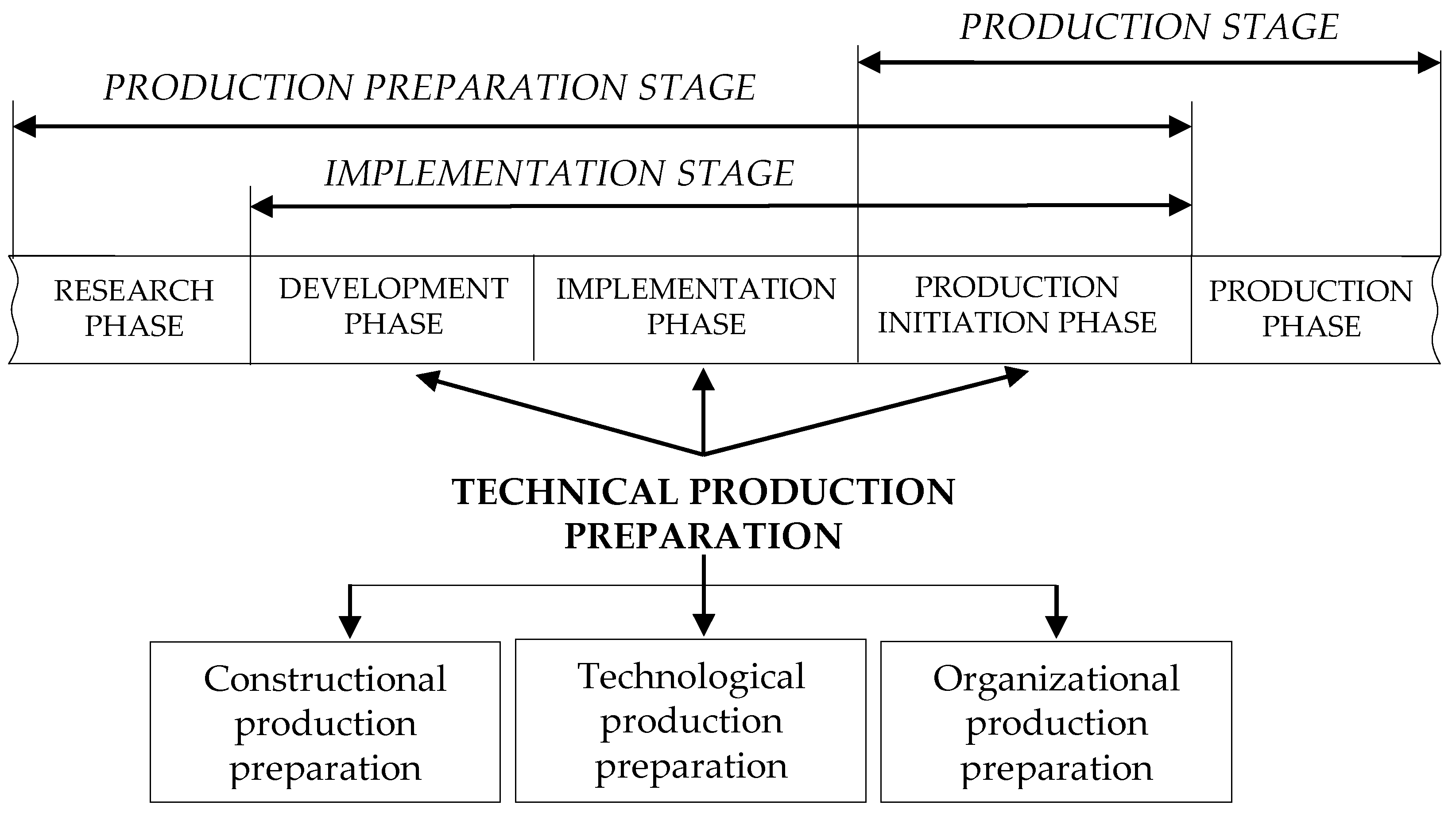

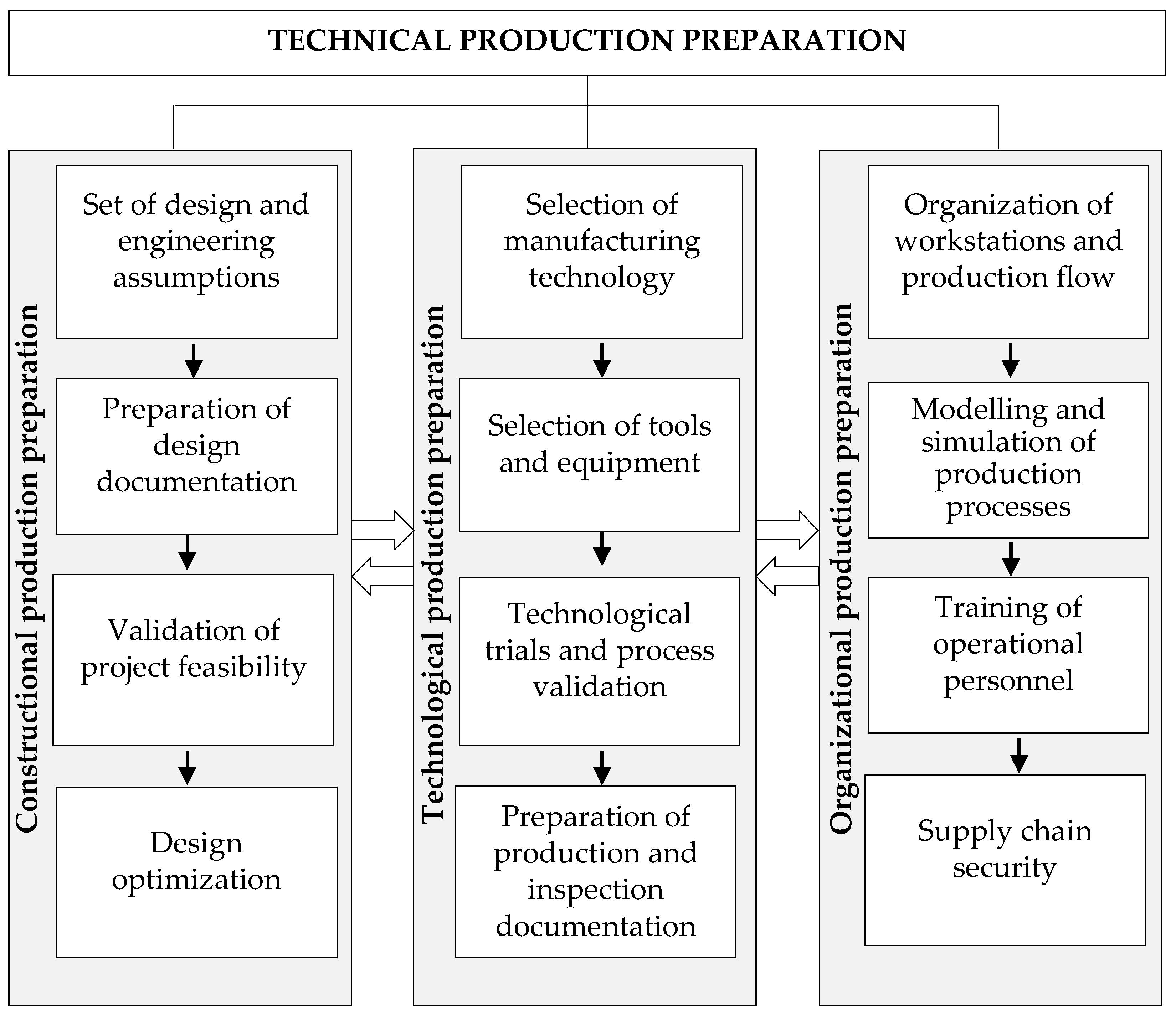

3.2. The Process of Implementing Technological Solutions

4. Practical Implementation of an Integrated Approach to the Deployment of a New Technological Solution

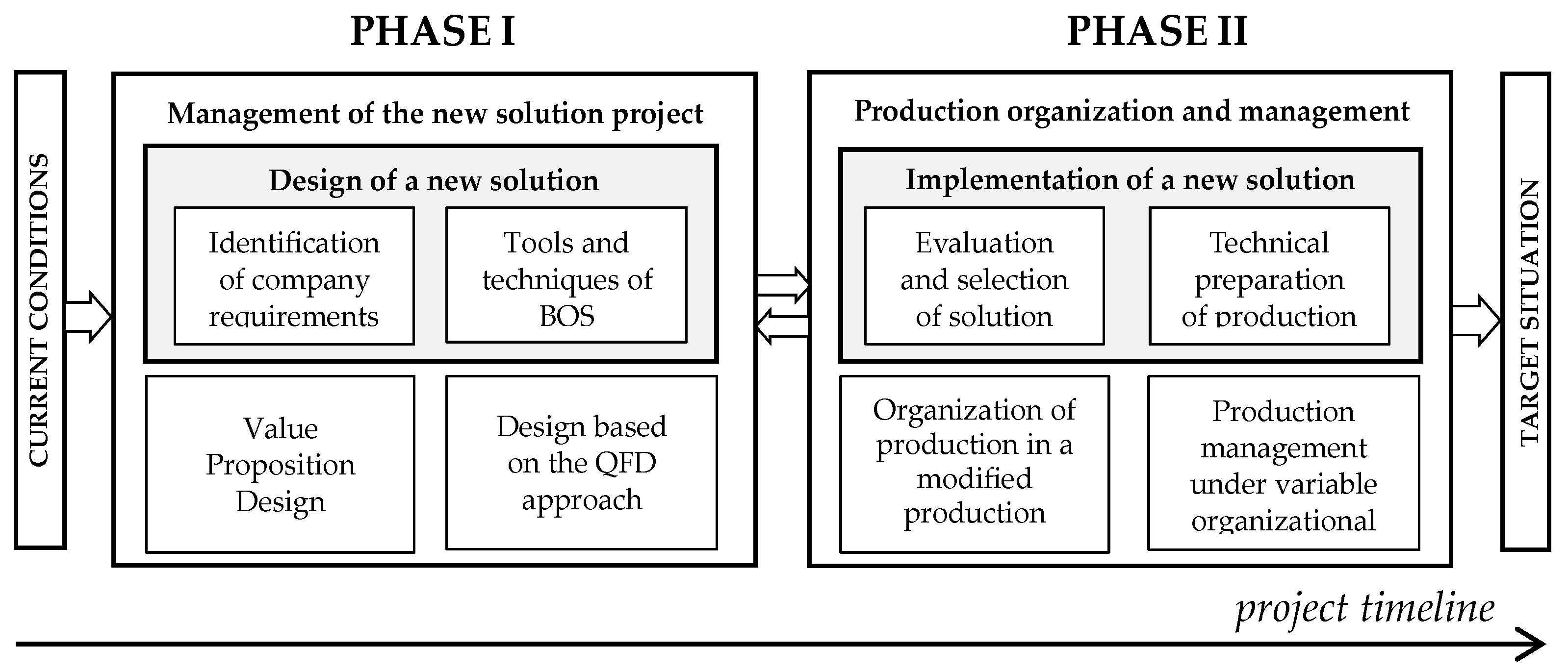

4.1. Assumptions and Concept of the Study

4.2. Research Object

4.3. Management of the Implementation at the Conceptual Design Phase

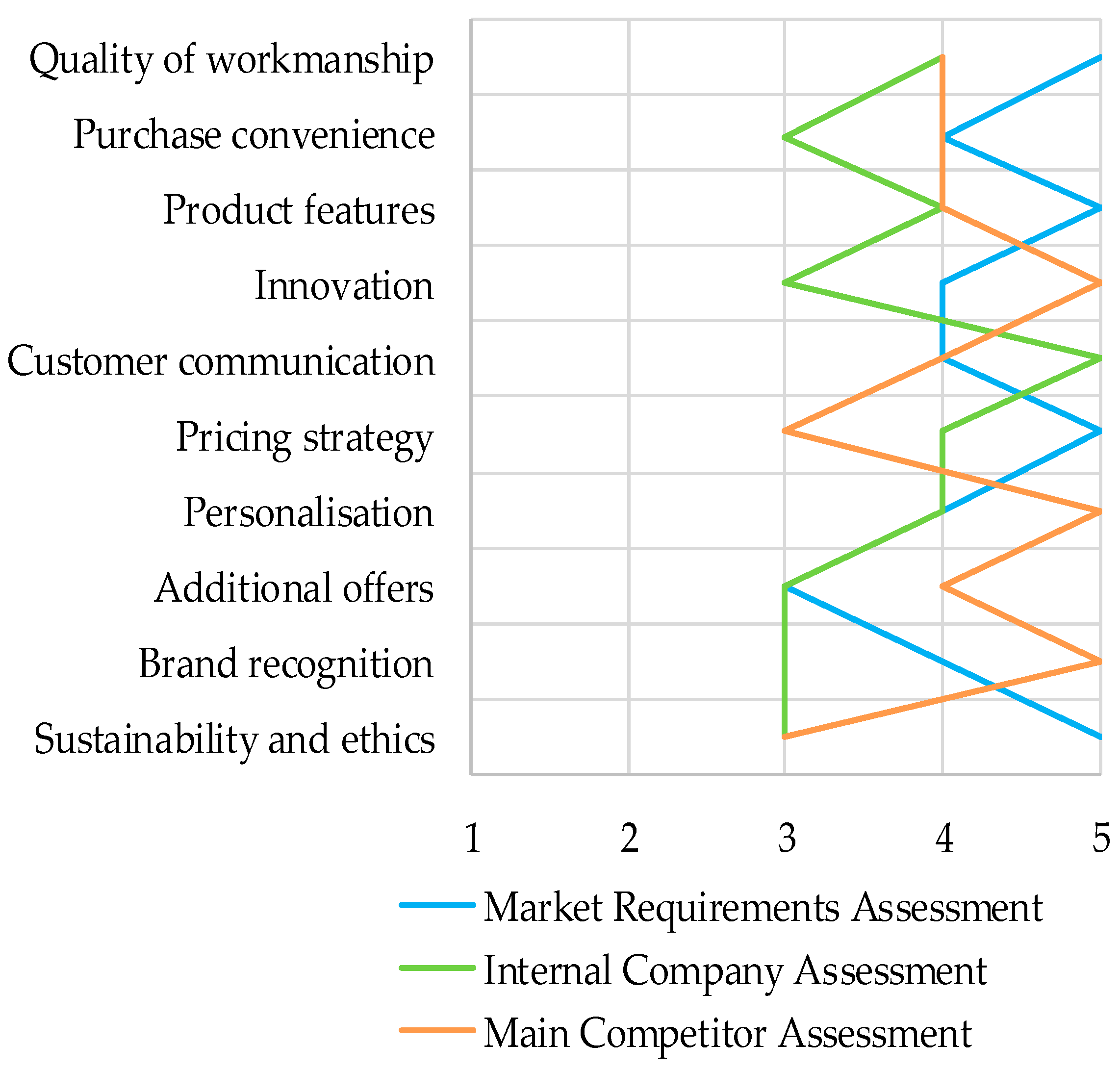

4.3.1. The Competitive Profile of the Company as a Basis for a Sustainable Growth Strategy

- Determining a set of competitiveness factors.

- Conducting a market requirements assessment.

- Conducting an internal performance assessment.

- Conducting a competition assessment.

- Situation analysis.

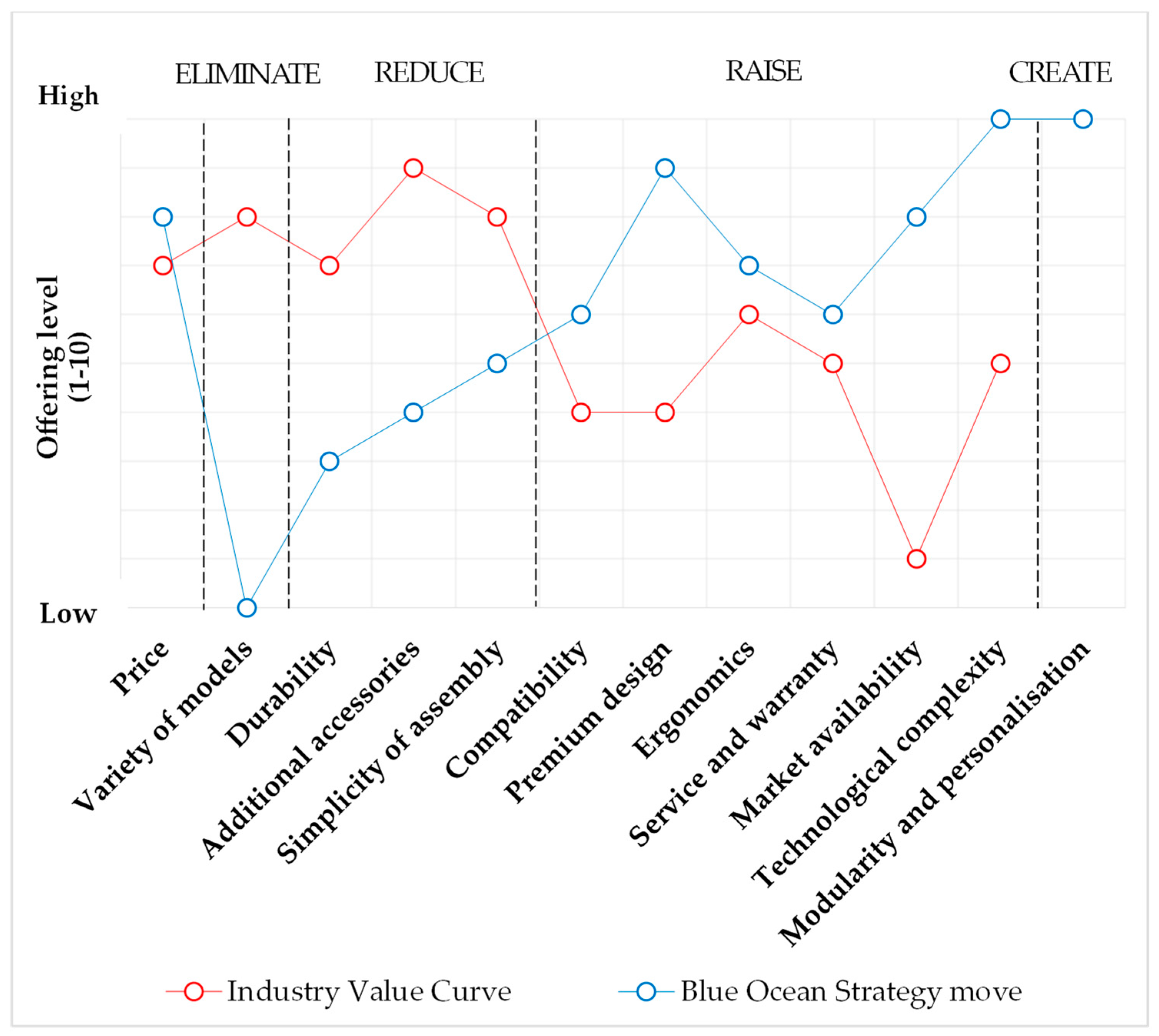

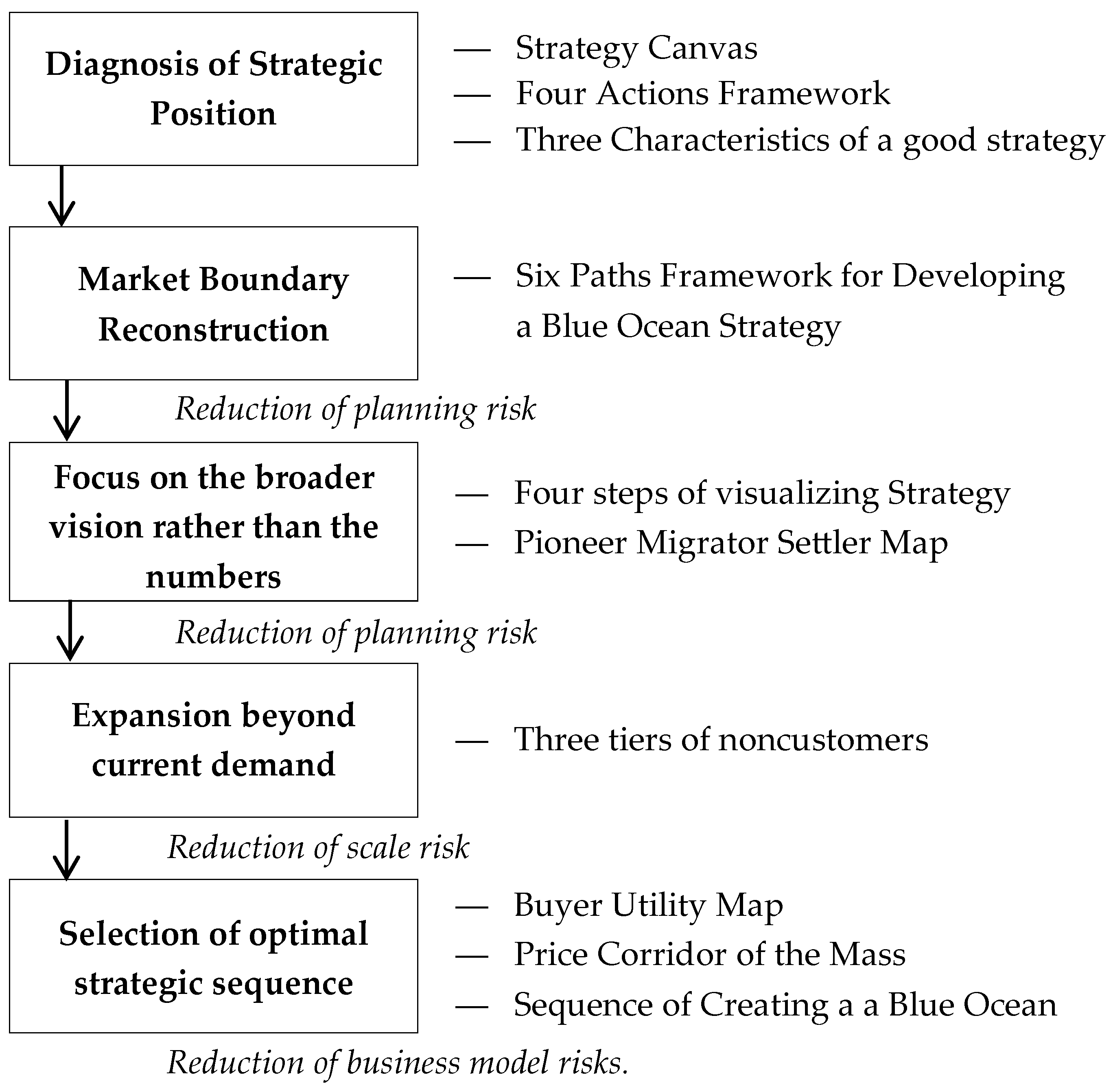

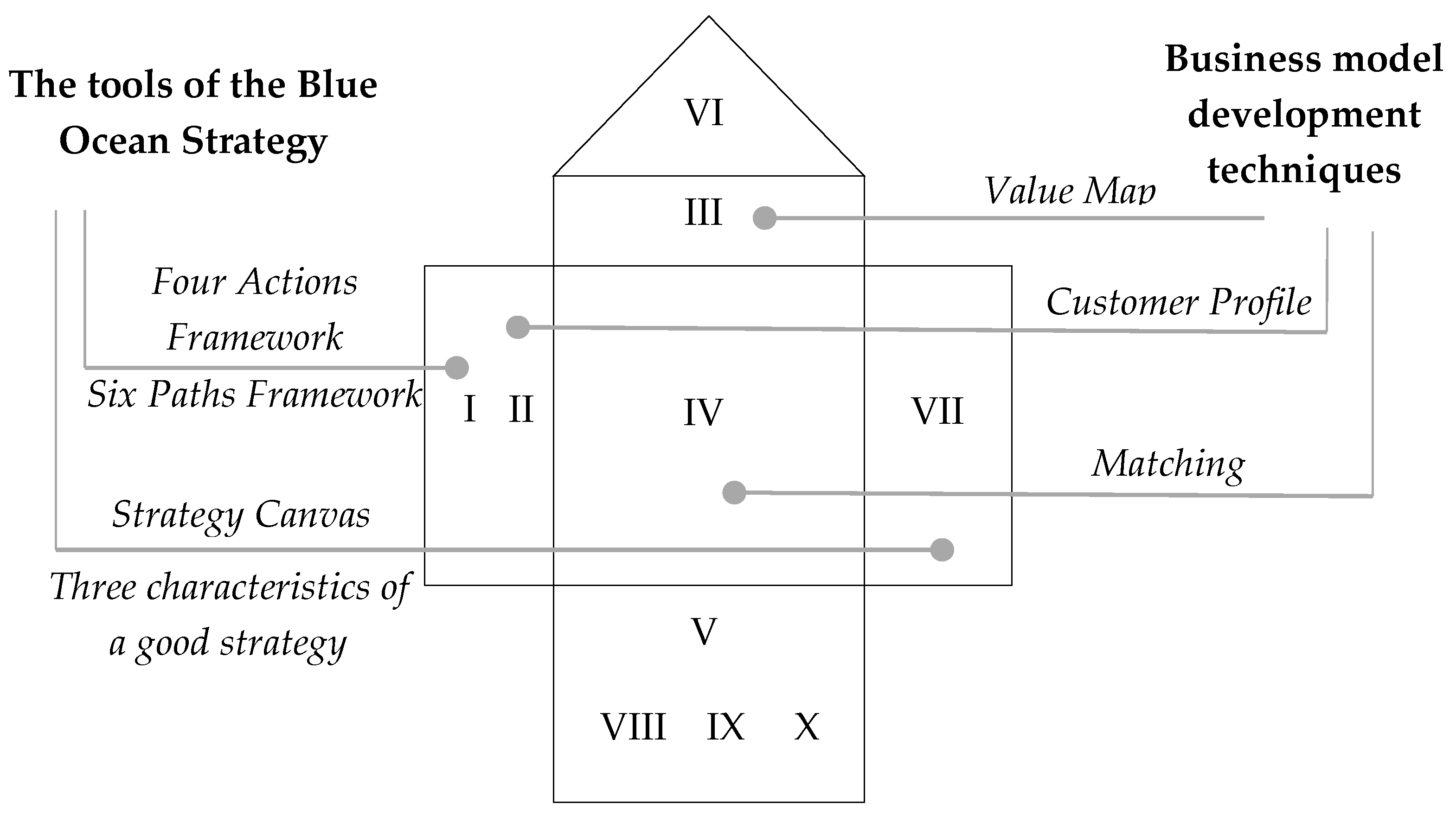

4.3.2. Application of the Blue Ocean Strategy in the Process of Designing New Solution Concepts

4.3.3. Management of the New Solution Development Project

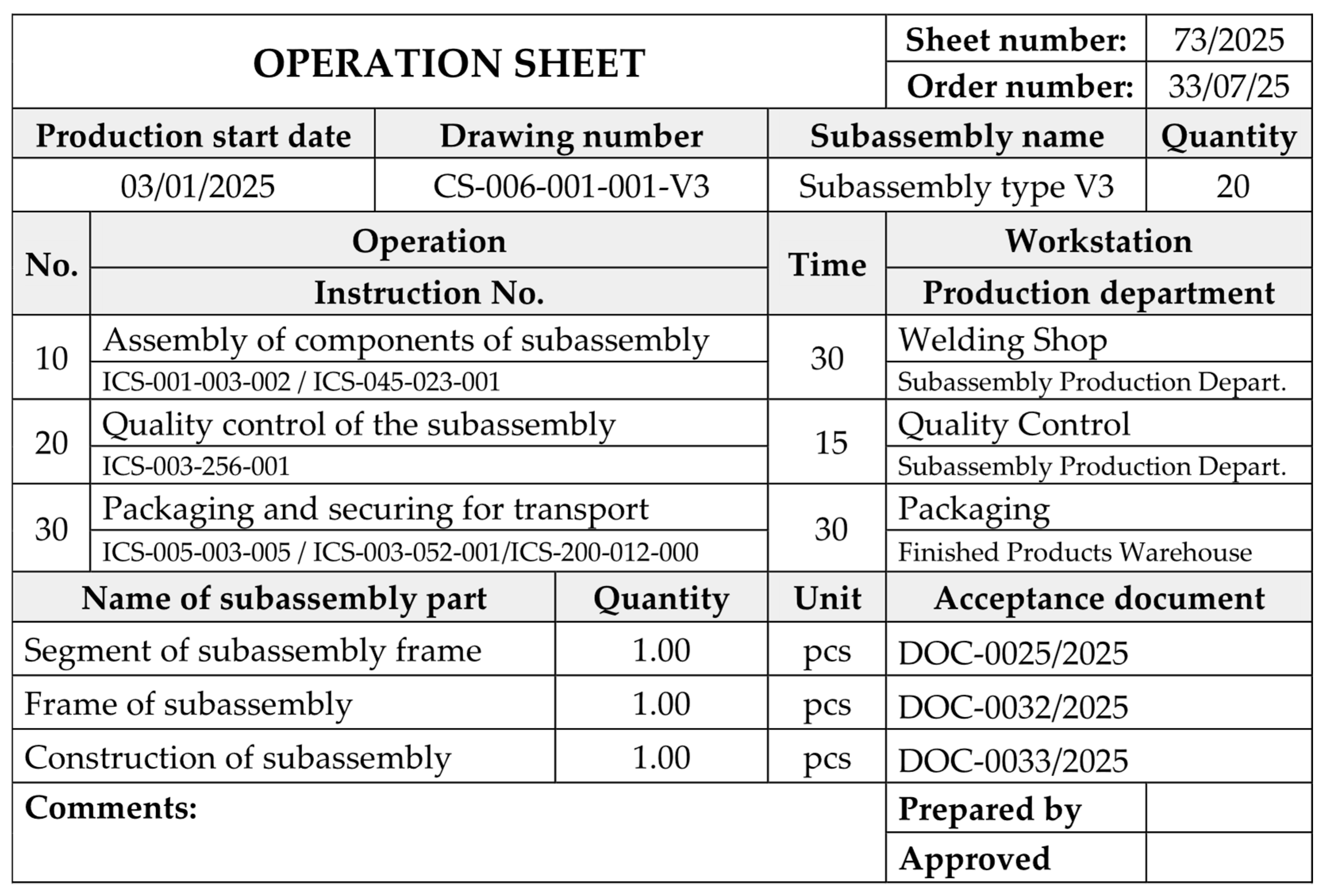

4.4. Organizational and Production Conditions for the Implementation Process of a New Technological Solution

4.4.1. Organizational Aspects of Implementing New Technological Solutions in a Manufacturing Company

- the hierarchy of criteria and the assignment of appropriate weights reflecting the company’s strategic goals and market expectations of customers,

- precise comparison of options not only in terms of meeting requirements but also their usability,

- identification of trade-offs between the interests of different stakeholders.

- if criterion is considered more important than criterion , it is assigned a value . Consequently, criterion receives a weight ,

- when two criteria are assessed as equally important, they are both assigned the value 1,

- the elements on the main diagonal of the comparison matrix are also equal to 1, as each criterion is compared with itself.

- The weights of the criteria in the matrix are calculated by multiplying all values in row . From the resulting product, the root of the degree equal to the number of criteria considered is then extracted. Subsequently, a normalization process is carried out to rescale the weights so that their sum equals one.

- Partial scores for each variant with respect to each criterion are calculated as the product of the point score and the weight according to the formula . The total score for each variant was computed separately for the three groups of criteria, which allowed obtaining independent partial evaluations. This can be expressed as: Normalization of the scores was performed independently for each group of criteria, according to the relation: .

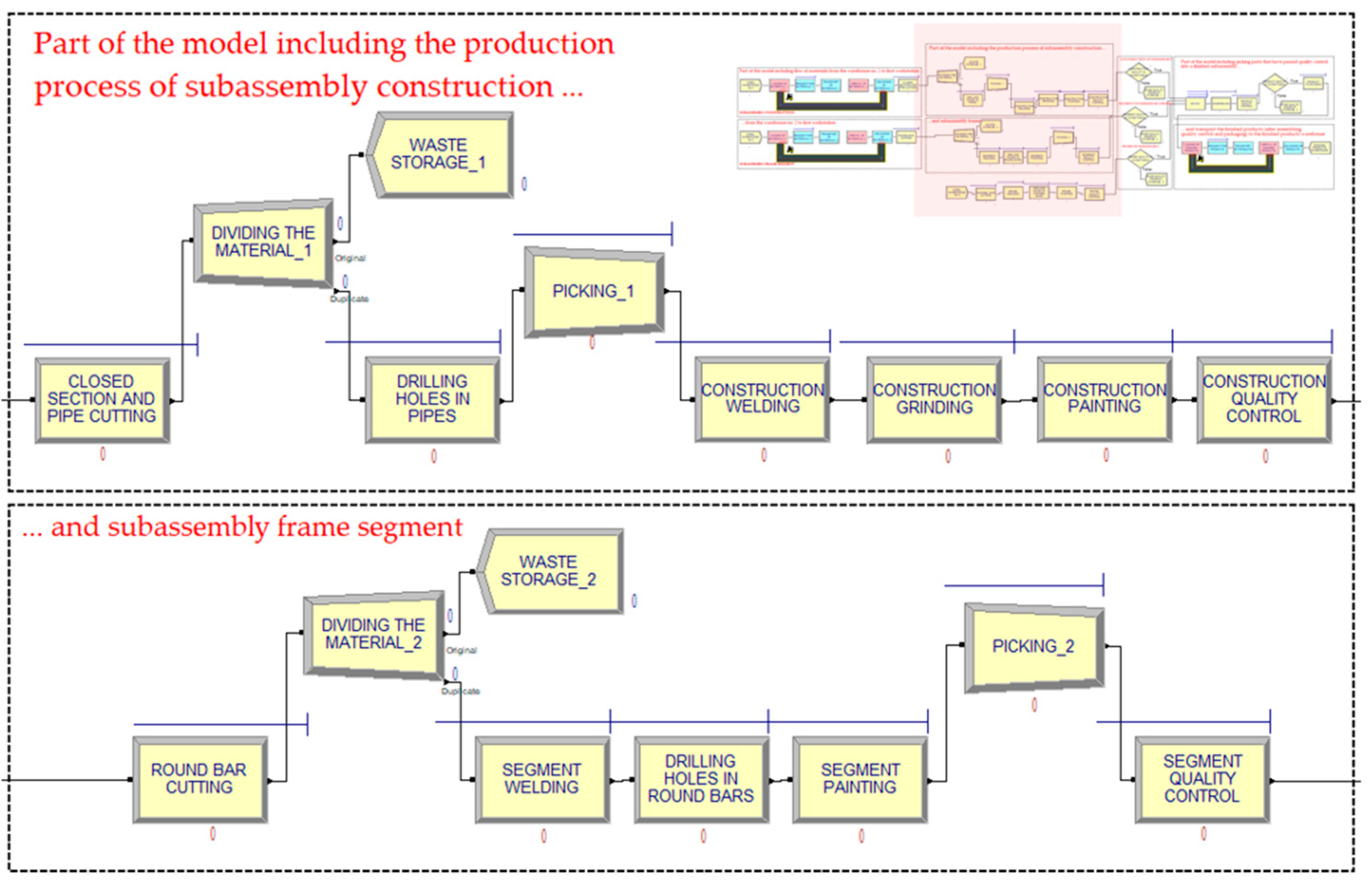

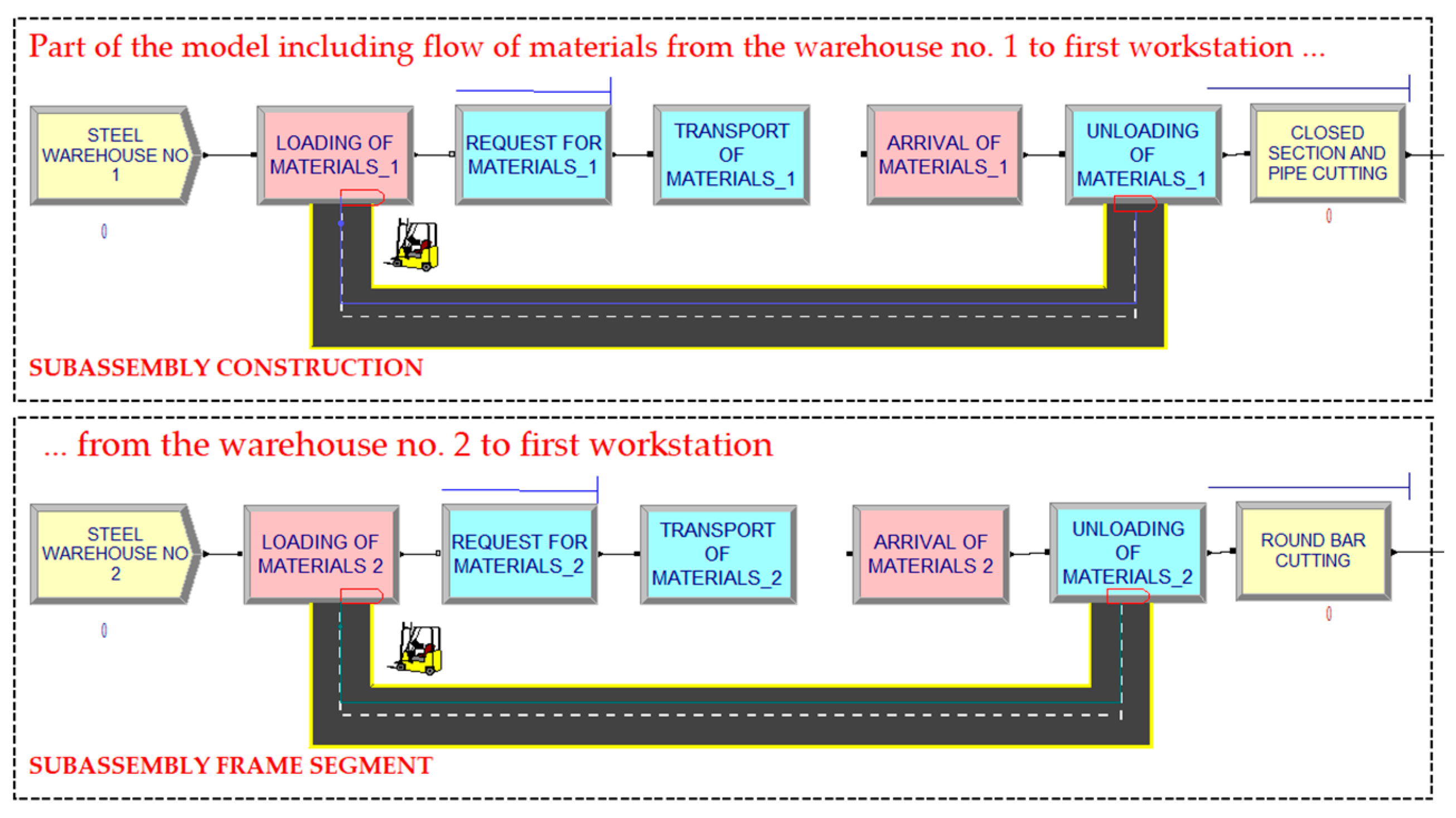

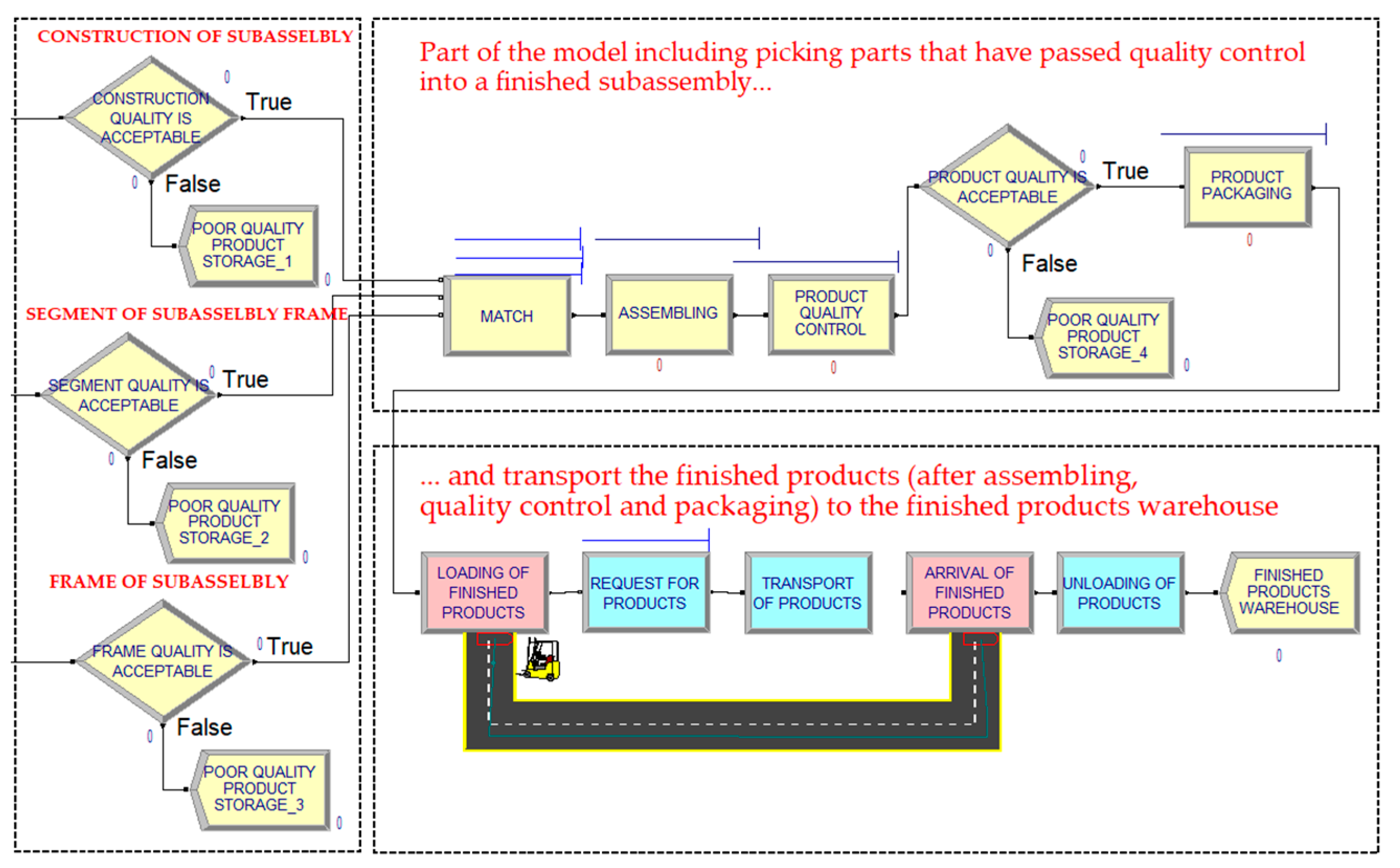

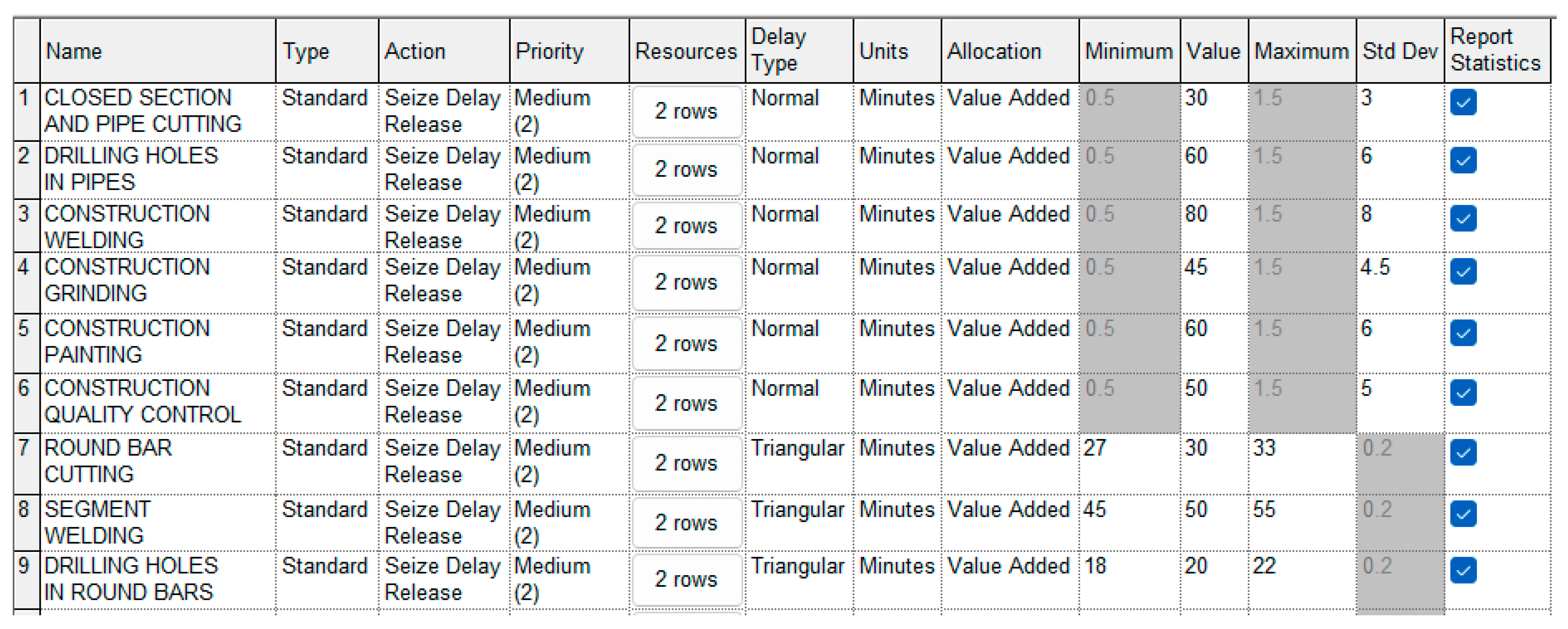

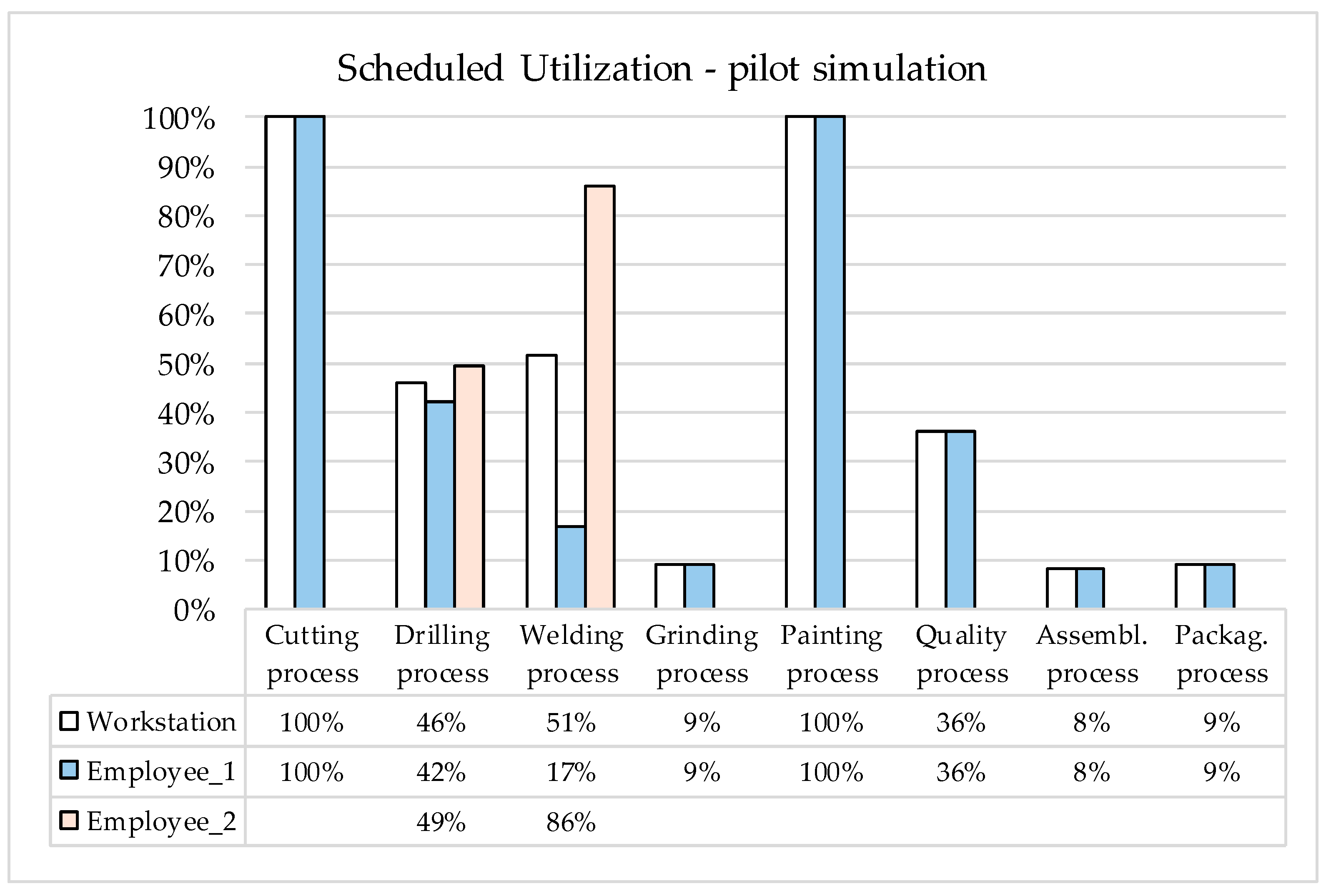

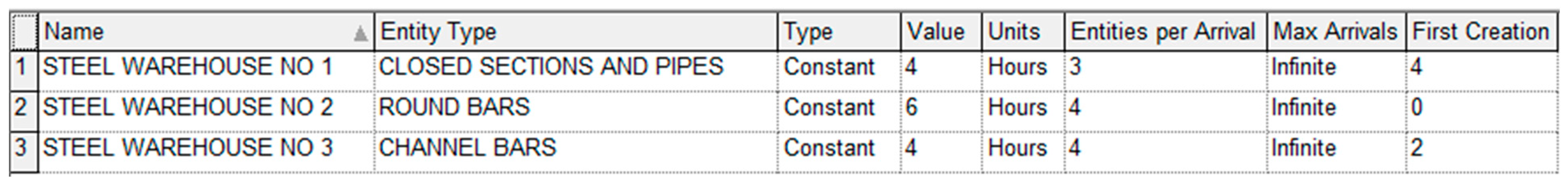

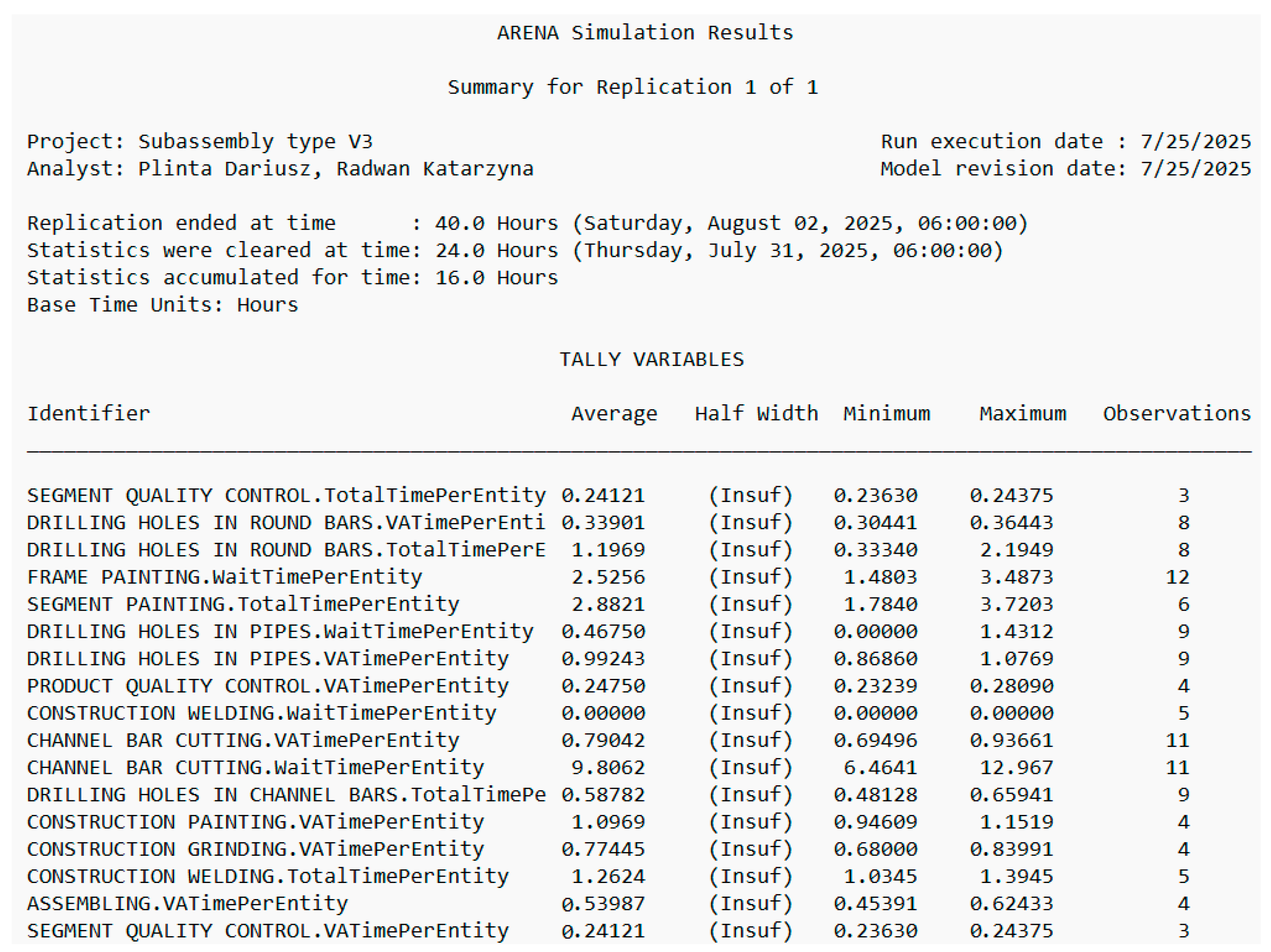

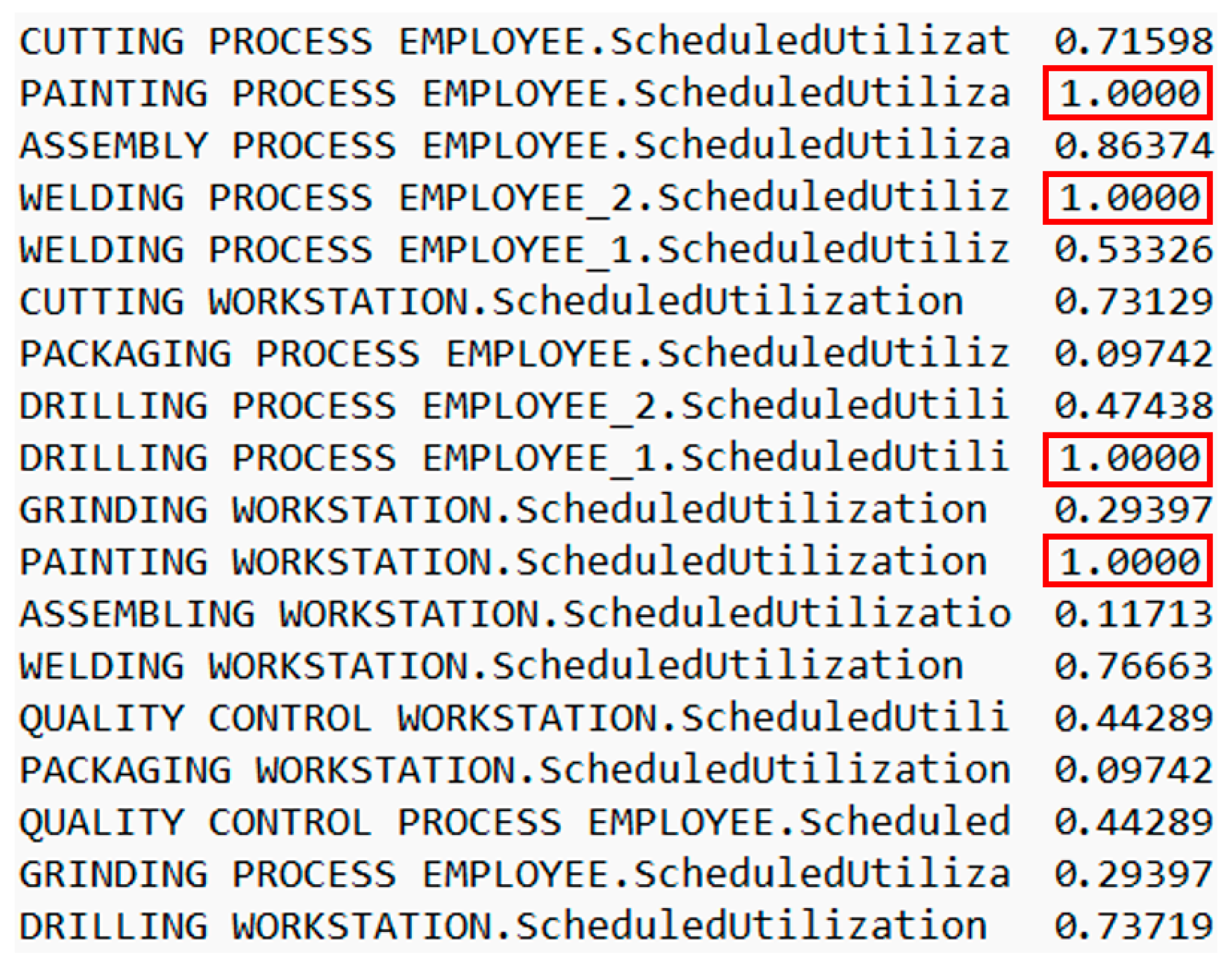

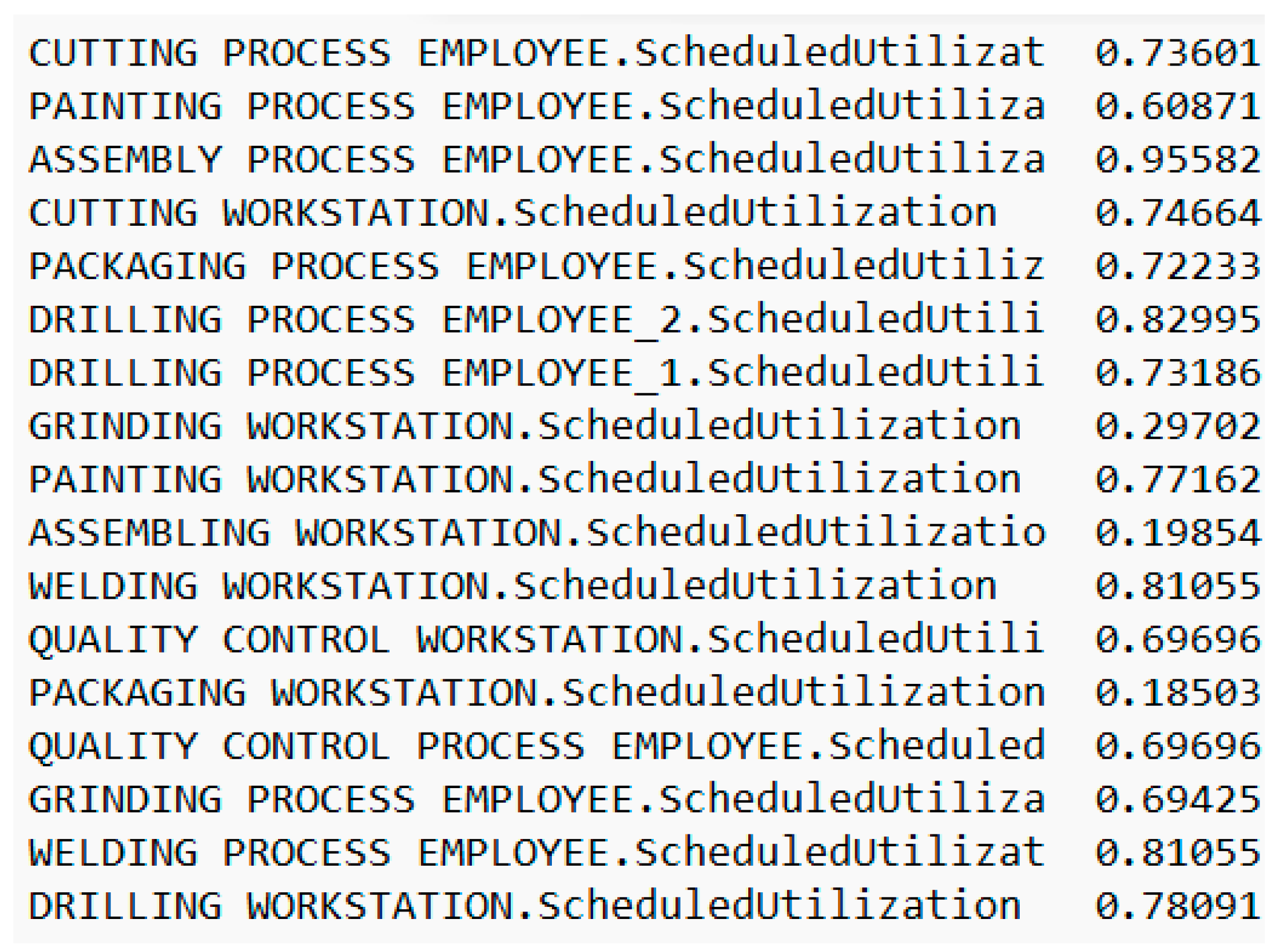

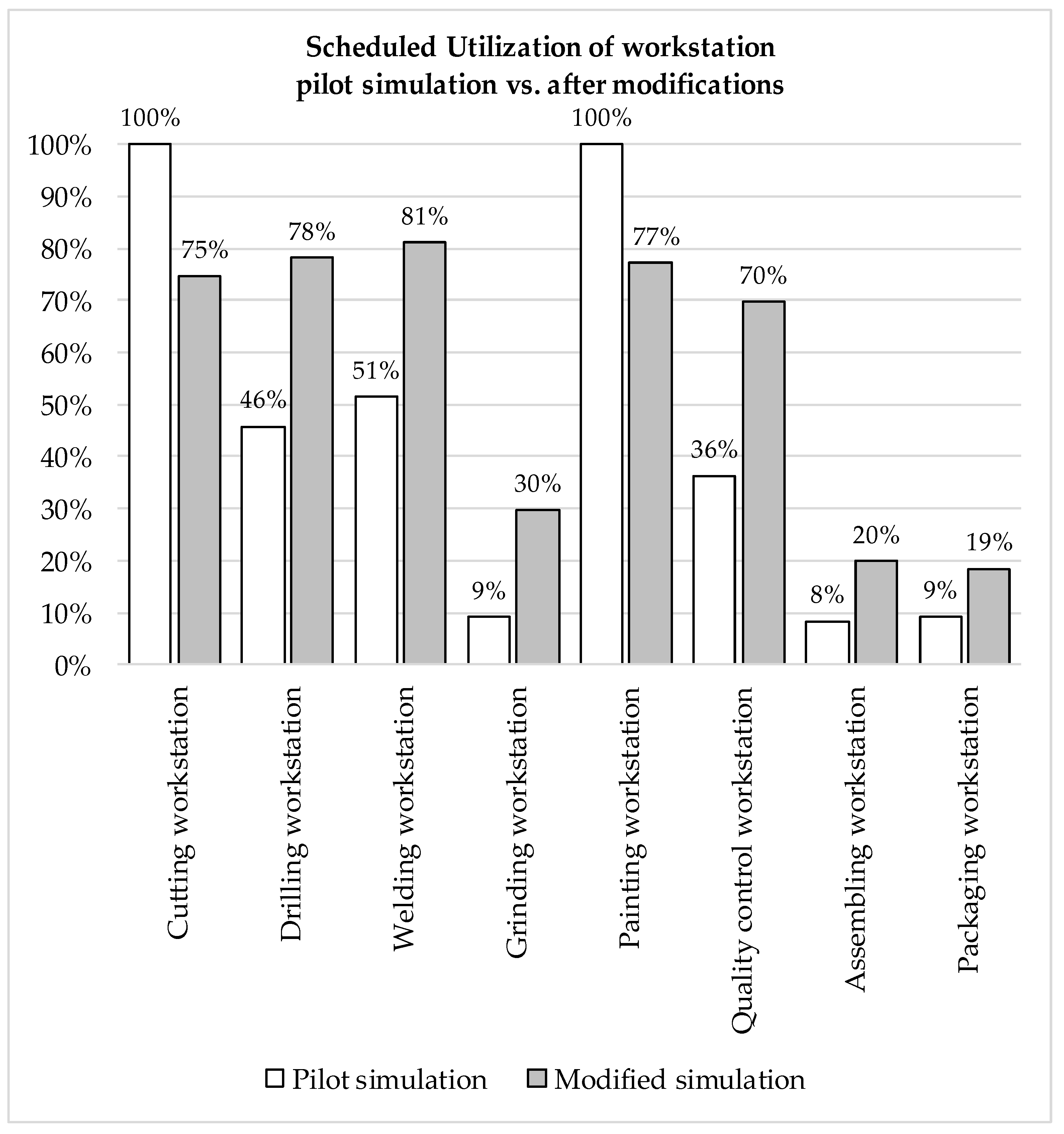

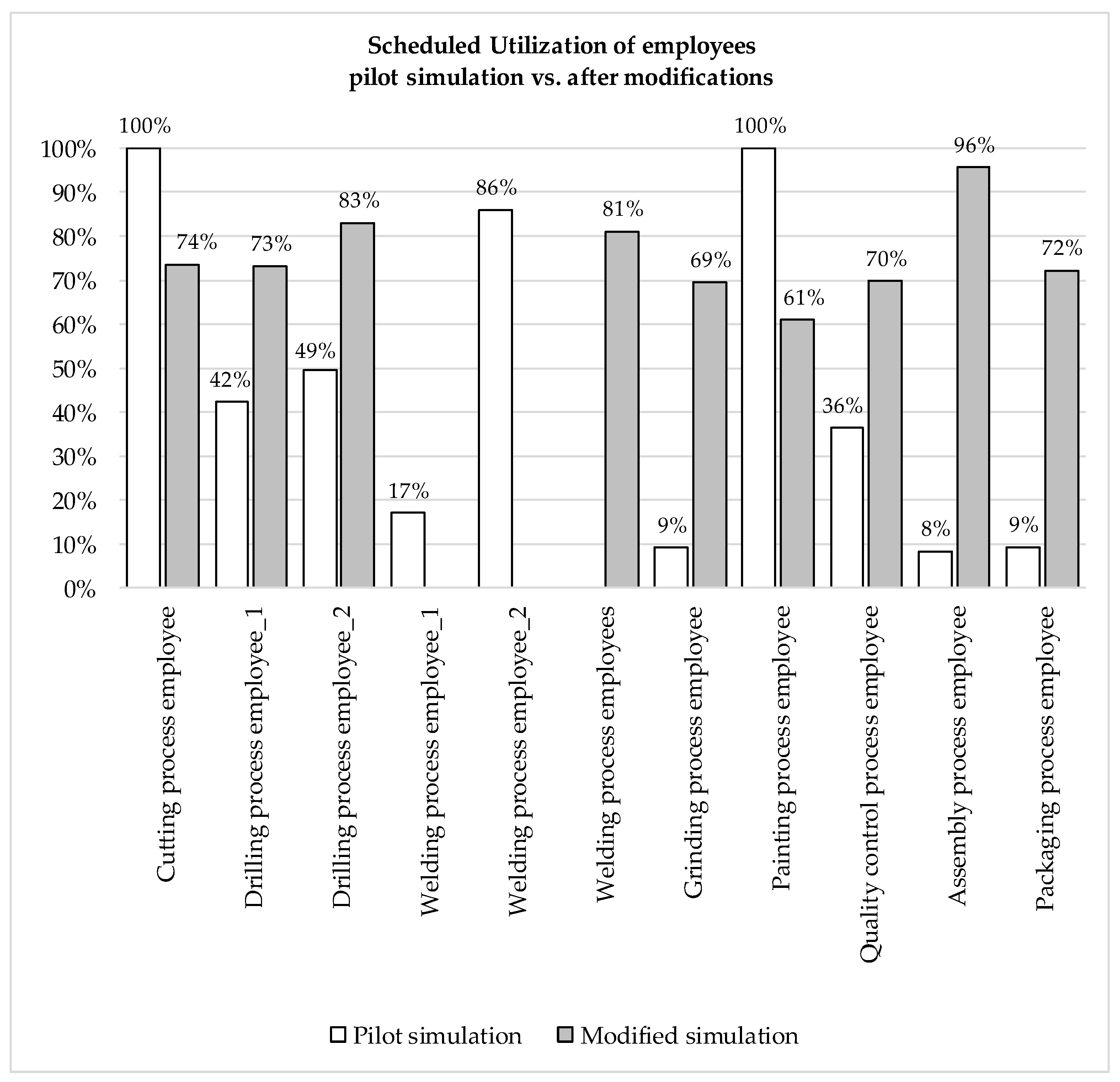

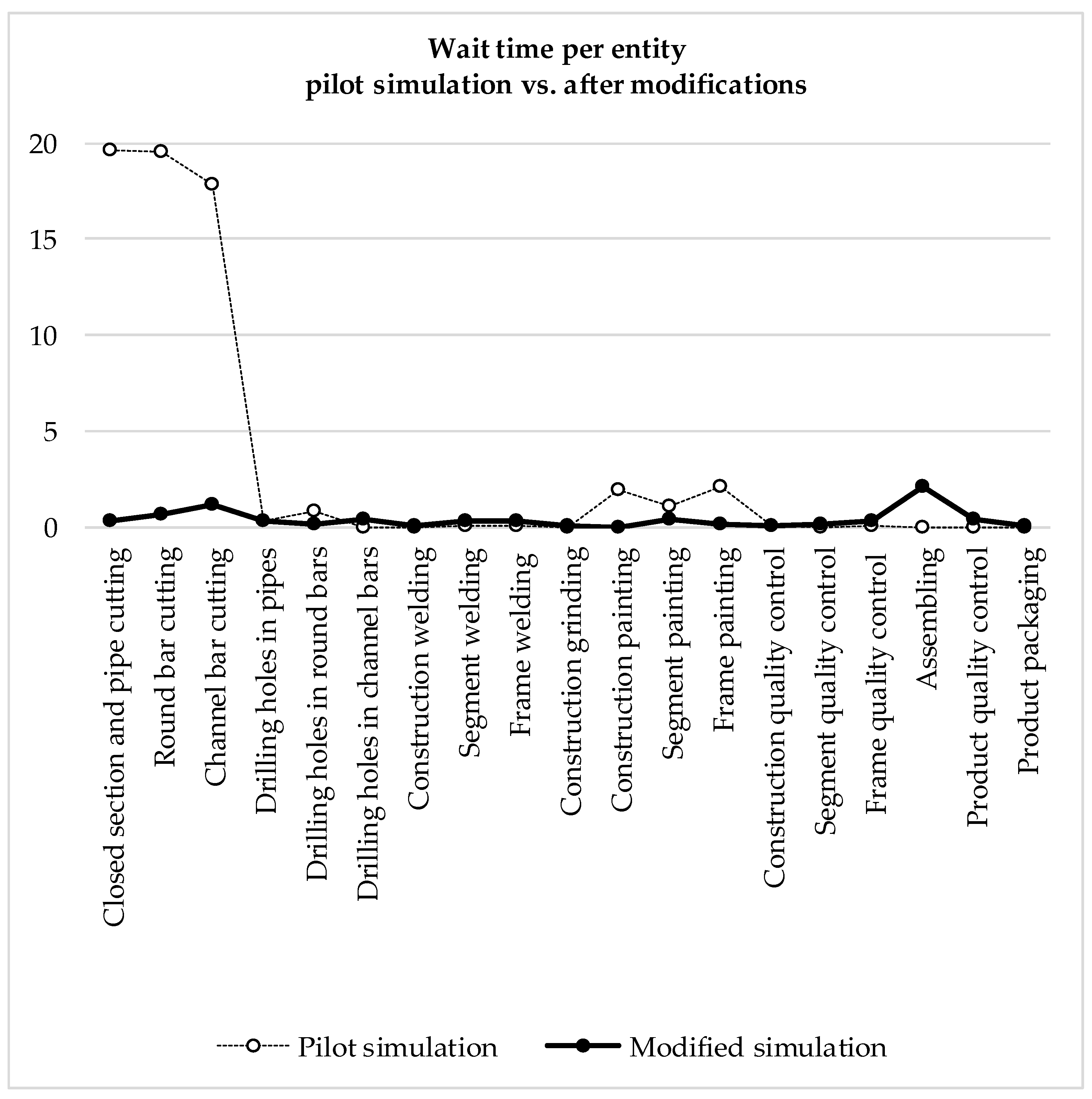

4.4.2. The Use of Simulation Environments to Support Implementation Decisions

- μ—mean value (average operation duration),

- σ—standard deviation,

- x—specific operation time value.

- a—minimum value,

- b—maximum value,

- c—most likely value.

5. Results of Adapting the Process to Changing Organizational Factors

6. Discussion

- ○

- Organizational: clearly defined production processes, the ability to implement organizational changes, staff readiness to collaborate during the implementation of new solutions, and management support in the decision-making process.

- ○

- Technical: basic digital infrastructure (ERP systems, CAD/CAM software, such as AutoCAD and Solid Works, sufficiently powerful computers), the ability to collect and analyze production data, and access to simulation tools.

- ○

- Economic: availability of a budget for implementing simulation tools, personnel training, and potential support from external consultants or technical experts.

7. Conclusions

- ○

- The development of a comprehensive and integrated approach that supports the effective implementation of new technological solutions under real manufacturing conditions.

- ○

- The demonstration of the advantages resulting from the combination of creative design methods, analytical evaluation, and simulation tools, which jointly facilitate risk identification and improve the accuracy of decision-making processes.

- ○

- The empirical confirmation that the proposed model contributes to reducing implementation time, lowering costs, and minimizing the risk of production downtime.

- ○

- The formulation of a universal framework that can be adapted to the specific requirements of different industrial sectors and flexibly adjusted to dynamic market and technological conditions.

- ○

- The incorporation of real-time data integration and digital twin technologies in order to enhance predictive accuracy and system adaptability.

- ○

- The validation of the framework through studies carried out across a wide spectrum of industrial sectors.

- ○

- The extension of the approach to incorporate sustainability assessment metrics, allowing evaluation of environmental and social impacts.

- ○

- The application of advanced artificial intelligence and machine learning methods to strengthen predictive analytics and to support more autonomous management of the implementation process.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cakmak, Z. Adapting to Environmental Change: The Importance of Organizational Agility in the Business Landscape. Florya Chron. Political Econ. 2023, 9, 67–87. [Google Scholar] [CrossRef]

- Scharmer, V.M.; Vernim, S.; Horsthofer-Rauch, J.; Jordan, P.; Maier, M.; Paul, M.; Schneider, D.; Woerle, M.; Schulz, J.; Zaeh, M.F. Sustainable Manufacturing: A Review and Framework Derivation. Sustainability 2024, 16, 119. [Google Scholar] [CrossRef]

- Schutselaars, J.; Romme, A.G.L.; Bell, J.; Bobelyn, A.S.A.; van Scheijndel, R. Designing and Testing a Tool That Connects the Value Proposition of Deep-Tech Ventures to SDGs. Designs 2023, 7, 50. [Google Scholar] [CrossRef]

- Al Maazmi, A.; Piya, S.; Araci, Z.C. Exploring the Critical Success Factors Influencing the Outcome of Digital Transformation Initiatives in Government Organizations. Systems 2024, 12, 524. [Google Scholar] [CrossRef]

- Adewumi, A.; Ewim, S.E.; Sam-Bulya, N.J.; Ajani, O.B. Strategic innovation in business models: Leveraging emerging technologies to gain a competitive advantage. Int. J. Manag. Entrep. Res. 2024, 6, 3372–3398. [Google Scholar] [CrossRef]

- Frank, A.G.; Dalenogare, L.S.; Ayala, N.F. Industry 4.0 Technologies: Implementation Patterns in Manufacturing Companies. Int. J. Prod. Econ. 2019, 210, 15–26. [Google Scholar] [CrossRef]

- Ali, H.; Chen, T.; Hao, Y. Sustainable Manufacturing Practices, Competitive Capabilities, and Sustainable Performance: Moderating Role of Environmental Regulations. Sustainability 2021, 13, 10051. [Google Scholar] [CrossRef]

- Jamwal, A.; Agrawal, R.; Sharma, M.; Giallanza, A. Industry 4.0 Technologies for Manufacturing Sustainability: A Systematic Review and Future Research Directions. Appl. Sci. 2021, 11, 5725. [Google Scholar] [CrossRef]

- Li, Q.; Tang, W.; Li, Z. Leveraging Industry 4.0 for Sustainable Manufacturing: A Quantitative Analysis Using FI-RST. Appl. Sci. 2024, 14, 9545. [Google Scholar] [CrossRef]

- Woźniak, M.; Duda, J.; Gąsior, A.; Bernat, T. Relations of GDP growth and development of SMEs in Poland. Procedia Comput. Sci. 2019, 159, 2470–2480. [Google Scholar] [CrossRef]

- Sołoducho-Pelc, L.; Sulich, A. Between Sustainable and Temporary Competitive Advantages in the Unstable Business Environment. Sustainability 2020, 12, 8832. [Google Scholar] [CrossRef]

- Zhang, A.; Zhang, W. Network orientation, organisational improvisation and innovation: An empirical examination. Syst. Res. Behav. Sci. 2022, 39, 668–678. [Google Scholar] [CrossRef]

- Onufrey, K.; Bergek, A. Transformation in a mature industry: The role of business and innovation strategies. Technovation 2021, 105, 102190. [Google Scholar] [CrossRef]

- Wojtaszek, H.; Miciuła, I. Analysis of Factors Giving the Opportunity for Implementation of Innovations on the Example of Manufacturing Enterprises in the Silesian Province. Sustainability 2019, 11, 5850. [Google Scholar] [CrossRef]

- Kumar, A.; Nayyar, A. Si3-Industry: A Sustainable, Intelligent, Innovative, Internet-of-Things Industry. In A Roadmap to Industry 4.0: Smart Production, Sharp Business and Sustainable Development; Springer: Cham, Switzerland, 2020; pp. 1–21. [Google Scholar]

- Breque, M.; De Nul, L.; Petridis, A. Industry 5.0: Towards a Sustainable, Human-Centric and Resilient European Industry; European Commission, Directorate-General for Research and Innovation: Luxembourg, LU, USA, 2021. [Google Scholar]

- Ahangar, M.N.; Farhat, Z.A.; Sivanathan, A. AI Trustworthiness in Manufacturing: Challenges, Toolkits, and the Path to Industry 5.0. Sensors 2025, 25, 4357. [Google Scholar] [CrossRef]

- Plinta, D.; Radwan, K. Improving material flow in a modified production system. Appl. Comput. Sci. 2023, 19, 95–106. [Google Scholar] [CrossRef]

- Kim, W.C.; Mauborgne, R. Value innovation: The strategic logic of high growth. Harv. Bus. Rev. 1997, 82, 172–180. [Google Scholar]

- Kim, W.C.; Mauborgne, R. Blue Ocean Strategy, Expanded Edition: How to Create Uncontested Market Space and Make the Competition Irrelevant; Harvard Business Review Press: Brighton, MA, USA, 2017. [Google Scholar]

- Kim, W.C. Blue Ocean Strategy: From Theory to Practice. Calif. Manag. Rev. 2005, 47, 105–121. [Google Scholar] [CrossRef]

- Kim, W.C.; Mauborgne, R. Blue Ocean Shift: Beyond Competing—Proven Steps to Inspire Confidence and Seize New Growth; Hachette Books: New York, NY, USA, 2017. [Google Scholar]

- Hajar, M.A.; Alkahtani, A.A.; Ibrahim, D.N.; Darun, M.R.; Al-Sharafi, M.A.; Tiong, S.K. The Approach of Value Innovation towards Superior Performance, Competitive Advantage, and Sustainable Growth: A Systematic Literature Review. Sustainability 2021, 13, 10131. [Google Scholar] [CrossRef]

- Gupta, V.; Fernandez-Crehuet, J.M.; Hanne, T. Fostering Continuous Value Proposition Innovation through Freelancer Involvement in Software Startups: Insights from Multiple Case Studies. Sustainability 2020, 12, 8922. [Google Scholar] [CrossRef]

- Sassanelli, C.; Terzi, S. Building the Value Proposition of a Digital Innovation Hub Network to Support Ecosystem Sustainability. Sustainability 2022, 14, 11159. [Google Scholar] [CrossRef]

- Osterwalder, A.; Pigneur, Y. Business Model Generation: A Handbook for Visionaries, Game Changers, and Challengers (The Strategyzer Series); John Wiley and Sons: Hoboken, NJ, USA, 2010. [Google Scholar]

- Osterwalder, A.; Pigneur, Y.; Bernarda, G.; Smith, A. Value Proposition Design: How to Create Products and Services Customers Want, 1st ed.; Wiley: Hoboken, NJ, USA, 2014. [Google Scholar]

- Brown, T. Design Thinking. Harv. Bus. Rev. 2008, 86, 1–10. Available online: https://readings.design/PDF/Tim%20Brown,%20Design%20Thinking.pdf (accessed on 20 October 2025).

- Altshuller, G. The Innovation Algorithm: TRIZ, Systematic Innovation, and Technical Creativity, 2nd ed.; Technical Innovation Center: Worcester, MA, USA, 2007. [Google Scholar]

- Cooper, R. Stage-Gate Systems: A New Tool for Managing New Products. Bus. Horiz. 1990, 33, 44–54. [Google Scholar] [CrossRef]

- Schwaber, K.; Sutherland, J. The Scrum Guide: The Definitive Guide to Scrum—The Rules of the Game. 2020. Available online: https://scrumguides.org/docs/scrumguide/v2020/2020-Scrum-Guide-US.pdf#zoom=100 (accessed on 20 October 2025).

- Da Silva, L.B.L.; Ferreira, E.B.; Ferreira, R.J.P.; Frej, E.A.; Roselli, L.R.P.; De Almeida, A.T. Paradigms, Methods, and Tools for Multicriteria Decision Models in Sustainable Industry 4.0 Oriented Manufacturing Systems. Sustainability 2023, 15, 8869. [Google Scholar] [CrossRef]

- Knosala, R.; Boratynska-Sala, A.; Jurczyk-Bunkowska, M.; Moczała, A. Zarzadzanie Innowacjami; Polskie Wydawnictwo Ekonomiczne: Warszawa, Poland, 2014. [Google Scholar]

- Ďurica, L.; Gregor, M.; Vavrík, V.; Marschall, M.; Grznár, P.; Mozol, Š. A Route Planner Using a Delegate Multi-Agent System for a Modular Manufacturing Line: Proof of Concept. Appl. Sci. 2019, 9, 4515. [Google Scholar] [CrossRef]

- Gola, A. Economic Aspects of Manufacturing Systems Design. Actual Probl. Econ. 2014, 156. Available online: https://www.researchgate.net/publication/263660093_Economical_Aspects_of_Manufacturing_Systems_Design (accessed on 20 October 2025).

- Novikov, K.; Hořejší, P.; Kubr, J.; Dvořák, M.; Bednář, M.; Krákora, D.; Krňoul, M.; Šimon, M. Methodology for Rationalization of Pre-Production Processes Using Virtual Reality Based Manufacturing Instructions. Machines 2024, 12, 2. [Google Scholar] [CrossRef]

- Areth Koroth, R.; Elgh, F.; Lennartsson, M.; Raudberget, D. A Method to Capture and Share Production Requirements Supporting a Collaborative Production Preparation Process. Proc. Des. Soc. 2023, 3, 273–282. [Google Scholar] [CrossRef]

- Pająk, E. Zarządzanie Produkcją—Produkt, Technologia, Organizacja; Wydawnictwo Naukowe PWN: Warszawa, Poland, 2021. [Google Scholar]

- Areth Koroth, R.; Elgh, F.; Lennartsson, M.; Raudberget, D. Aligning production requirements with product and production maturities: Enhancing production preparation during product development. Proc. Des. Soc. 2024, 4, 195–204. [Google Scholar] [CrossRef]

- Mahmoodi, E.; Fathi, M.; Ghobakhloo, M. The impact of Industry 4.0 on bottleneck analysis in production and manufacturing: Current trends and future perspectives. Comput. Ind. Eng. 2022, 174, 108801. [Google Scholar] [CrossRef]

- Dulina, L.; Zuzik, J.; Furmannova, B.; Kukla, S. Improving Material Flows in an Industrial Enterprise: A Comprehensive Case Study Analysis. Machines 2024, 12, 308. [Google Scholar] [CrossRef]

- Grznár, P.; Gregor, M.; Krajčovič, M.; Mozol, Š.; Schickerle, M.; Vavrík, V.; Ďurica, L.; Marschall, M.; Bielik, T. Modeling and Simulation of Processes in a Factory of the Future. Appl. Sci. 2020, 10, 4503. [Google Scholar] [CrossRef]

- Wtorkowski, N.; Musioł, T. Simulation as a Method of Hazard Identification with the MHT (Maximum Holding Time) Indicator at the Booth of the Spray Booth Operator in the Automotive Industry. Zesz. Nauk. Wyż. Szkoły Zarządz. Ochr. Pracy w Katowicach 2018, 1, 181–192. [Google Scholar] [CrossRef]

- Łatuszyńska, M. Modelowanie i Symulacja w Zarządzaniu Produkcją. Przegl. Organiz. 2015, 12, 51–57. [Google Scholar] [CrossRef]

- Burduk, A.; Łapczyńska, D.; Popiel, P. Simulation Modeling in Production Effectiveness Improvement—Case Study. Manag. Prod. Eng. Rev. 2021, 12, 75–85. [Google Scholar] [CrossRef]

- Breznik, M.; Buchmeister, B.; Vujica Herzog, N. Assembly Line Optimization Using MTM Time Standard and Simulation Modeling—A Case Study. Appl. Sci. 2023, 13, 6265. [Google Scholar] [CrossRef]

- Rojek, I.; Macko, M.; Mikołajewski, D.; Sága, M.; Burczyński, T. Modern methods in the field of machine modelling and simulation as a research and practical issue related to industry 4.0. Bull. Pol. Acad. Sci. 2021, 69, 136717. [Google Scholar] [CrossRef]

- Plinta, D.; Radwan, K. Implementation of Technological Innovation in a Manufacturing Company. Appl. Sci. 2023, 13, 6068. [Google Scholar] [CrossRef]

- Krenczyk, D.; Paprocka, I. Integration of Discrete Simulation, Prediction, and Optimization Methods for a Production Line Digital Twin Design. Materials 2023, 16, 2339. [Google Scholar] [CrossRef]

- Butean, A.; Cutean, I.; Barbero, R.; Enriquez, J.; Matei, A. A Review of Artificial Intelligence Applications for Biorefineries and Bioprocessing: From Data-Driven Processes to Optimization Strategies and Real-Time Control. Processes 2025, 13, 2544. [Google Scholar] [CrossRef]

- Peta, K.; Żurek, J. Prediction of Air Leakage in Heat Exchangers for Automotive Applications Using Artificial Neural Networks. In Proceedings of the 2018 9th IEEE Annual Ubiquitous Computing, Electronics & Mobile Communication Conference (UEMCON), New York, NY, USA, 8–10 November 2018; pp. 721–725. [Google Scholar] [CrossRef]

- Ahmmed, M.S.; Isanaka, S.P.; Liou, F. Promoting Synergies to Improve Manufacturing Efficiency in Industrial Material Processing: A Systematic Review of Industry 4.0 and AI. Machines 2024, 12, 681. [Google Scholar] [CrossRef]

| Factor | Assessment of Competitiveness Factor with Justification | |||||

|---|---|---|---|---|---|---|

| Price | Competitive pricing remains an important factor in attracting potential buyers. However, the market is increasingly recognizing the added value of products and services, as well as aspects beyond price alone. | |||||

| 1 | 2 | 3 | 4 | 5 | ||

| Perceived value relative to price | X | |||||

| Price flexibility | X | |||||

| Price competitiveness | X | |||||

| Assessment of the Competitiveness Factor | 4 | |||||

| Technical consulting | Professional technical consulting enables customers to better understand the products or services offered by a company. Well-informed customers are able to compare competing offers more effectively and make more conscious choices, contributing to the company’s success in the market. | |||||

| 1 | 2 | 3 | 4 | 5 | ||

| Availability of technical support | X | |||||

| Quality of technical advice provided | X | |||||

| Customer satisfaction with the technical support | X | |||||

| Assessment of the Competitiveness Factor | 5 | |||||

| The Six Stages of Buyer Experience Cycle | |||||||

|---|---|---|---|---|---|---|---|

| Purchase | Delivery | Use | Supplements | Maintenance | Disposal | ||

| The six utility levers | Productivity | O | X | O | |||

| Simplicity | X | ||||||

| Convenience | |||||||

| Risk Reduction | X | ||||||

| Reputation | X | ||||||

| Environmental impact | X | X | |||||

| Group of Criteria | Enterprise Perspective | Customer Perspective |

|---|---|---|

| Technical | Ease of integration with existing processes | Quality of workmanship |

| Degree of innovation and uniqueness of the solution | Reliability and durability in use | |

| Production scalability | Functionality of the solution | |

| Economic | Unit production cost | Purchase price |

| Financial risk of implementation | Operating costs | |

| Storage and logistics costs | Warranty conditions | |

| Ergonomic | Ergonomics of workstations | Ease of use |

| Ease of adaptation to changing working conditions | Comfort of use in daily operation | |

| Training requirements for personnel | Availability of support and user manuals |

| Name of Resource | Comments | |

| Workstation | Cutting process | One workstation |

| Drilling process | Two workstations | |

| Welding process | Two workstations | |

| Painting process | One workstation | |

| Quality control | One workstation | |

| Grinding process | One workstation | |

| Assembly process | One workstation | |

| Packaging process | One workstation | |

| Employee | Cutting process | One employee operates three workstations |

| Drilling process | Employee no. 1 operates drilling holes in pipes and round bars | |

| Employee no. 2 operates drilling holes in channel bars | ||

| Welding process | Employee no. 1 operates construction welding | |

| Employee no. 2 operates segment and frame welding | ||

| Painting process | One employee operates three workstations | |

| Quality control | One employee operates four workstations | |

| Grinding process | One employee operates one workstation | |

| Assembly process | One employee operates one workstation | |

| Packaging process | One employee operates one workstation | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Plinta, D.; Radwan, K. An Integrated Approach to the Development and Implementation of New Technological Solutions. Sustainability 2025, 17, 9434. https://doi.org/10.3390/su17219434

Plinta D, Radwan K. An Integrated Approach to the Development and Implementation of New Technological Solutions. Sustainability. 2025; 17(21):9434. https://doi.org/10.3390/su17219434

Chicago/Turabian StylePlinta, Dariusz, and Katarzyna Radwan. 2025. "An Integrated Approach to the Development and Implementation of New Technological Solutions" Sustainability 17, no. 21: 9434. https://doi.org/10.3390/su17219434

APA StylePlinta, D., & Radwan, K. (2025). An Integrated Approach to the Development and Implementation of New Technological Solutions. Sustainability, 17(21), 9434. https://doi.org/10.3390/su17219434