1. Introduction

Rising resource scarcity and sustainability concerns are driving manufacturers to develop innovative strategies for efficient product design and manufacturing. Companies are creating green co-products to reduce resource consumption and exploring how consumer green awareness affects profitability [

1]. Integrating sustainability into project management and manufacturing involves adopting standardized norms, such as ISO standards, lean thinking, and green supplier selection methodologies [

2]. The intelligence-connected era presents opportunities for complex product manufacturing, with advanced information systems and smart factories enabling more timely and accurate decision-making [

3].

As a result, the need for Life Cycle Assessment (LCA) has become significantly more prominent, as firms now must measure and document the environmental impacts of their products and processes [

4]. However, ecological metrics must be complemented by economic considerations to inform decision-makers about both sustainability and profitability. Life Cycle Costing (LCC) offers a valuable perspective by mapping the development of costs over the entire lifecycle of a product [

5]. Combining LCA and LCC creates a more holistic framework, enabling companies to gain insights into both the ecological and financial consequences of their strategic choices [

6]. This dual approach supports long-term decision-making and operational adjustments, particularly in rapidly evolving markets where supplier choices, production technologies, and overall financial performance are subject to frequent fluctuations.

Despite its potential, integrating LCA and LCC comes with several challenges:

Shortage of suitable methods and high-quality data [

7].

Lack of real-world case studies [

8]

Obstacles with effective results communication [

9].

Focusing exclusively on LCA, without factoring in LCC, can severely limit the relevance of the findings for company management. Businesses should implement a robust data management system that ensures consistent access to both ecological and economic information about a product. Preferably, this data should be gathered in real time to reflect the considerable dynamism of markets and supply chains. Rapid shifts in supplier availability, volatile pricing, and changing regulatory requirements can make static assessments quickly outdated. By employing real-time data, through, for example, RFID systems, sensor networks, or automated tracking solutions, companies can capture changing conditions as they happen [

10]. This, in turn, enables them to adapt their sustainability and cost analyses immediately, ensuring that the output remains accurate and actionable. Such agile data management provides a strategic advantage, as decisions are rooted in the most current, context-specific information available [

11]. This raises a series of questions: How, precisely, should data for LCA and cost calculations be gathered? Through which processes can such data be reliably processed? How can real-time analysis be structured to effectively integrate dynamic market and technological changes? Finally, how can results be visualized and communicated to become a robust decision-making tool?

In this paper, a conceptual framework is proposed, designed to address these core questions:

How can real-time data for LCA, LCC, and cost analysis be collected?

What processes ensure that these data are properly processed?

What strategies enable a clear and straightforward presentation of results?

What are the advantages and benefits of using real-time LCA and LCC calculations?

By outlining practical methods and identifying key integration points, the framework aims to bridge the gap between sustainability objectives and market-driven imperatives, enabling companies to pursue both ecological and economic goals simultaneously.

2. Materials and Methods

2.1. Materials

The framework of this paper is based on the current concepts of LCA and LCC, along with the possibilities and advantages of combining LCA and LCC and performing a dynamic LCA/LCC analysis. This paper incorporates 62 references, which serve as the foundation for both the Material and the conceptual design of the proposed framework.

2.1.1. LCA and LCC

LCA is a method used to evaluate the environmental impacts of a product or process across its entire lifespan, from raw material extraction to disposal [

12]. The ISO standards 14040 [

13] and 14044 [

14] serve as the basis for conducting LCAs. These standards define the overall framework for the analysis. LCA consists of the following four main components:

Goal and Scope Definition: where the purpose of the LCA and the scope of the study are specified, including system boundaries and functional units [

15].

Inventory Analysis (LCI, Life Cycle Inventory): which involves collecting and quantifying all relevant input and output data across the entire life cycle of the product or service [

16].

Impact Assessment (LCIA): where the data gathered in the inventory analysis are examined to evaluate potential environmental impacts [

17].

Results and Interpretation: which involves examining the LCA results to derive well-founded conclusions and recommendations [

13].

The LCC is a comprehensive tool for analyzing costs over the entire life cycle of a product, including production, operation, maintenance, and disposal [

18]. It aims to minimize total costs and support decision-making by considering both internal and external costs associated with a product or system [

19]. Despite its broad acceptance as a valuable instrument, the practical application of LCC still faces challenges, including organizational weaknesses, limited cost estimation models, and unreliable databases [

7,

20].

The following three variations of LCC have been identified:

Conventional LCC (cLCC): which focuses on a purely economic assessment and typically considers only direct costs from the perspective of the producer or consumer, often disregarding external costs or end-of-life (EoL) disposal [

21].

Environmental LCC (eLCC): which applies the exact system boundaries as LCA and considers the entire life cycle. It complements LCA by monetarily evaluating all direct costs, including internalized external effects [

21].

Societal LCC (sLCC): which takes a broader macroeconomic perspective and accounts for long-term costs affecting all involved parties, including indirect stakeholders influenced by externalities [

22].

2.1.2. Combination of LCA and LCC

Improving eco-efficiency has become a necessary measure for dealing with intensifying resource and environmental pressures while maintaining competitiveness [

23]. Eco-efficiency is conceived as an indicator expressing the ratio between a product’s added value and its environmental impacts. According to ISO 14045 [

24], eco-efficiency is thus an element of product management and evaluation, underscoring the concept’s importance in combined LCA and LCC analyses.

Eco-efficiency is growing in importance, as companies must increasingly consider both economic and environmental aspects in their decision-making processes to achieve a certain level of environmental performance [

25]. By integrating LCC into the LCA methodology, both financial and environmental performance can be evaluated simultaneously, resulting in a more comprehensive and balanced analysis [

26].

The three leading methods for assessing both ecological and economic aspects in a product’s life cycle are BASF’s Eco-Efficiency Analysis (EEA), the PROSA method [

27], and the combination of LCA and LCC under LSCA [

7]. EEA has undergone the most empirical testing and has been extensively tested and applied in numerous case studies across various industries [

28]. In the context of this study, EEA plays a vital role because it provides answers to the research questions 3 and 4.

BASF’s EEA method was introduced in 1996 to address sustainability evaluation challenges and to offer a methodology for improved decision-making within the company [

29]. It compares environmental impacts relative to the cost efficiency of a product [

30]. Essentially, the technique enables a comparative evaluation of the environmental and cost performance of multiple alternatives for a specific functional unit. The assessments include detailed ecological data, showing how different life cycle phases contribute to each impact category, such as greenhouse effect, human toxicity, aquatic ecotoxicity, acidification, and eutrophication, as well as aggregated information on the overall eco-efficiency [

31]. In this way, a company’s environmental performance is measured via LCA, while LCC captures its economic performance. The process begins by defining the functional unit, identifying the product or process in question, and setting system boundaries and pertinent life cycle phases for the analysis. These definitions apply to both LCA and LCC [

19]. Once calculations are completed, the results are interpreted in an eco-efficiency portfolio [

28].

Although BASF’s EEA method has proven to be a robust framework for comparing the ecological and economic performance of different alternatives, recent developments highlight the need for more flexible and responsive approaches. Growing market volatility, real-time data availability, and evolving supply chain complexities have spurred interest in dynamic LCA and LCC methodologies, which can capture changing conditions over time [

32].

2.1.3. LCA/LCC in Logistics: State of the Art and Open Issues

In freight logistics, LCA and LCC are increasingly combined to evaluate eco-efficiency across services and networks, yet most operational studies still depend on static inventories (average emission factors, representative routes, annualized loads), limiting decision relevance under variable traffic, payloads, and regional energy mixes [

33,

34]. This static approach limits how precisely and frequently data can be updated, making results less useful when conditions change within a day (like traffic, weather, or engine performance) or across seasons (like demand or fuel prices). New research shows that dynamic inventories using telematics and IoT data (e.g., GPS, OBD, fuel flow, engine load) can significantly reduce uncertainty and allow real-time or near-real-time impact updates. However, challenges remain with ensuring data quality, connecting these data streams to LCA tools, and developing consistent methods to translate high-frequency signals into LCI/LCIA data [

33,

35,

36]. On the cost side, recent LCC research has improved consistency in defining system boundaries and cost categories. However, differences in how factors like driver time, empty trips, tolls, and vehicle end-of-life are handled still make it difficult to conduct fully integrated eco-efficiency analyses in logistics [

7]. New logistics telematics platforms show that it’s possible to combine and interpret data from many sources for sustainability analysis. This strengthens the argument for using integrated, dynamic LCA/LCC approaches, especially in road freight and last-mile operations [

37].

2.1.4. Dynamic LCA/LCC

Dynamic LCA/LCC marks a significant evolution from the conventional, static approach, which typically assumes fixed system boundaries, stable market conditions, and unchanging resource flows. Dynamic LCA addresses the limitations of static LCA by incorporating temporal variations in parameters and processes, providing more accurate environmental impact assessments [

38]. This approach considers time-dependent factors, such as changing energy mixes, technological advancements, and fluctuating emissions profiles [

39]. It demonstrates that these factors can significantly influence both environmental impacts and cost structures over time. Dynamic LCA methodologies involve creating temporally differentiated inventories and applying time-dependent characterization factors to calculate real-time impact scores [

38]. Studies have shown significant differences between static and dynamic LCA results, potentially altering conclusions about environmental impacts and policy decisions [

39]. The dynamic approach has been applied to various sectors, including buildings, biofuels, and integrated steel and methanol production, revealing key drivers of temporal uncertainty in environmental impacts [

39,

40,

41] and enabling stakeholders to make more informed decisions that better reflect shifting conditions in real-world supply chains and production processes.

Dynamic LCA/LCC, starts with defining temporal system boundaries alongside functional units, enabling time sensitive modelling of energy, material and cost flows. [

42]. For instance, the carbon intensity of electricity can vary hourly, while transportation routes or production volumes might change seasonally or in response to market demand. By factoring in such shifts, the LCI becomes a dynamic dataset where inputs and outputs are updated according to the relevant time steps. Correspondingly, the LCIA applies time-specific factors for categories like climate change or acidification, accounting for variations in emission profiles or regional environmental sensitivities. On the economic side, a dynamic LCC examines cost fluctuations, such as changing fuel prices, labor costs, or maintenance schedules, assigning these to the same temporal scale as the environmental data.

However, challenges remain in implementing dynamic LCA/LCC, including defining the temporal scope, utilizing calendar-specific information, and selecting an appropriate temporal resolution [

42]. One of the main challenges is obtaining and processing the real-time or near-real-time data required for dynamic modeling. Advanced sensor technologies, radio-frequency identification (RFID) tags, and Internet of Things (IoT) devices can facilitate continuous data collection along supply chains [

10]. At the same time, powerful database systems can store and preprocess high volumes of incoming information. Automated interfaces, such as application programming interfaces (APIs), then feed these data into specialized software capable of recalculating LCA and LCC values at specified intervals or upon detection of critical trigger events (e.g., surpassing a certain cost threshold or deviating from an expected emission profile) [

41,

43].

The benefits of such a dynamic approach are multifold. First, it highlights periods or events where environmental and cost hotspots emerge, allowing companies to quickly implement mitigation strategies or reconfigure supply chains [

10]. Second, it supports real-time decision-making within highly volatile contexts, such as global commodity markets or time-sensitive logistics. Finally, dynamic LCA/LCC fosters a deeper alignment of operational strategies with sustainability targets, as both ecological and financial indicators become continuously monitored and more transparently connected to a product’s lifecycle [

39].

Nevertheless, implementing dynamic LCA/LCC also raises technical and organizational challenges. Data availability and quality must be ensured at every step to avoid magnifying uncertainties [

42]. Raising the frequency of data updates demands more computing resources, as well as a robust software architecture. Additionally, to gain widespread adoption, companies may need clear frameworks, standards, or best-practice guidelines tailored for dynamic assessments. Overcoming these hurdles, however, can lead to a more adaptive and responsive sustainability management strategy, ultimately enhancing both environmental performance and economic resilience.

2.2. Methods

This section outlines the methodological approach taken to design the dynamic LCA/LCC framework. It describes the underlying process models, data integration strategies, and analytical methods that informed the development of the framework.

2.2.1. Framework Development Approach

To address the challenges identified in the introduction and bridge the gap between separate theoretical methodologies and their combined application, an initial conceptual framework was developed. This framework aims to integrate dynamic LCA/LCC principles with robust data management solutions and clear operational guidelines, facilitating real-time decision-making while minimizing complexity and uncertainty.

The framework development process consists of:

Reviewing existing process modelling methodologies (e.g., SCOR) and dynamic LCA approaches.

Identifying the requirements for integrating real-time data (e.g., RFID technology).

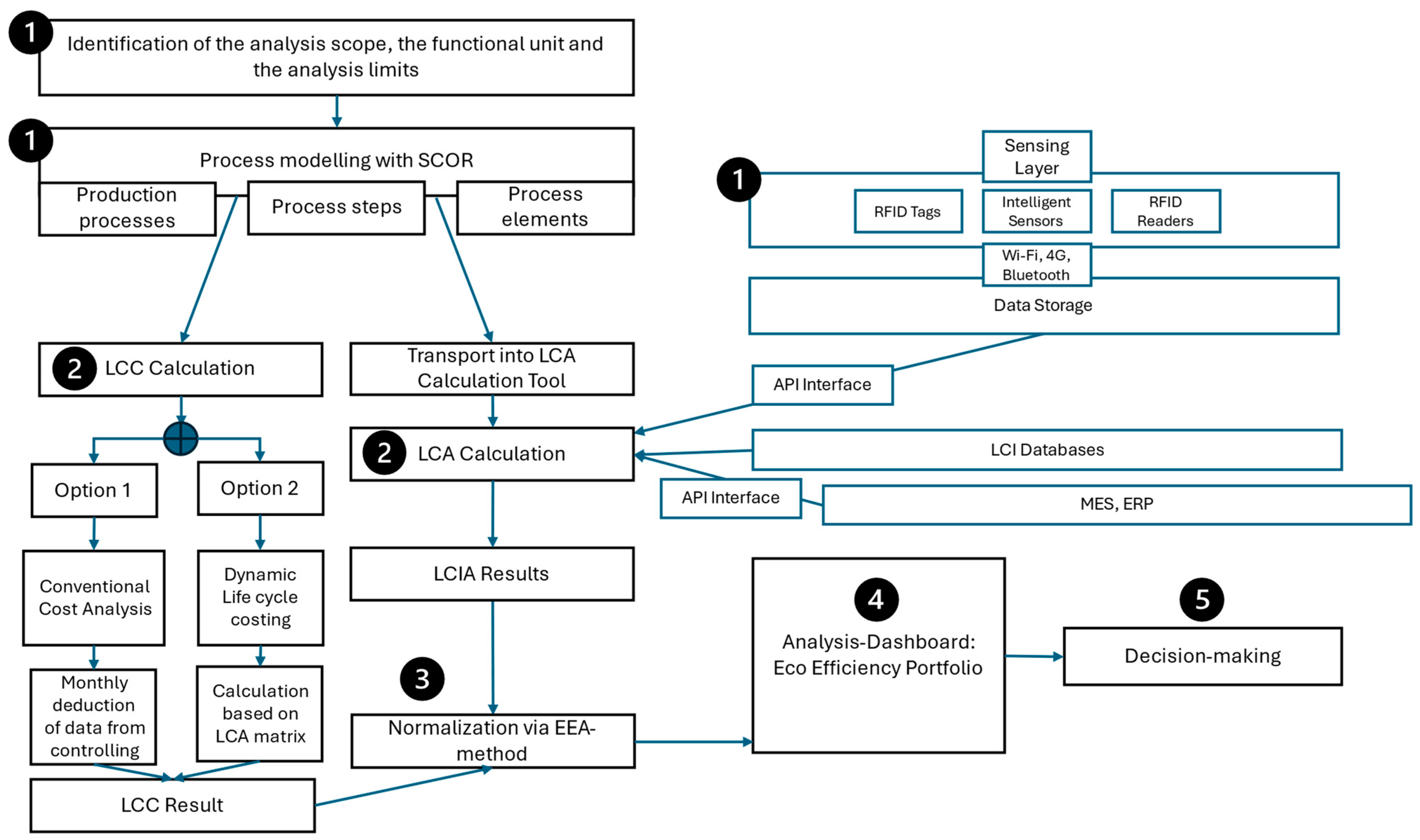

Structuring the framework into five sequential steps: Framework Definition & Data Strategy, Baseline Analysis & Impact Calculation, Results Normalization, Visualization & Decision Support, and Strategic Integration & Policy Development (

Figure 1).

2.2.2. Digital Process Model

To achieve a truly dynamic approach to LCA and LCC, the initial priority is to develop a supply chain and production model that can be updated in real-time. This model must reflect various elements, suppliers, manufacturing sites, transportation routes, warehousing locations, and any other critical components of the supply chain. Equally important is to ensure that this model directly correlates or maps onto the structures used in the chosen LCA software, so that data flows seamlessly from real-world operations into the LCA calculation tool without the need for extensive manual reformatting. A highly effective way to establish this roadmap is to start with a preliminary feasibility or exploratory study based on the SCOR (Supply Chain Operations Reference) model, which provides a standardized framework for diagnosing, documenting, and improving supply chain processes [

44]. By following SCOR, organizations can effectively break down complex chains into individual process steps, such as Plan, Source, Make, Deliver, and Return, and document relevant data streams that can later be aligned with LCA software requirements [

45].

Below is an outline of the recommended process in four key steps:

Define the goal and boundaries of the LCA and align them with a thorough SCOR-based analysis of existing supply chain and production processes. This entails assessing which parts of the chain need to be included (e.g., cradle-to-gate, gate-to-gate, or cradle-to-grave) and identifying the scope of environmental impacts that are to be measured.

Based on these results, identify specific “process stages” within each SCOR module. For instance, if the SCOR model identifies a “Source” stage, determine the detailed sub-processes such as raw material procurement, quality checks, or inventory management.

Develop a detailed breakdown for each identified stage. This involves specifying process inputs, outputs, resource flows, and any relevant performance metrics, aligning these details with the data fields and formats required by the LCA software.

Finally, transfer the resulting structure into the LCA tool, effectively reconstructing the blueprint of both production and supply processes within the software environment. By doing so, it is ensured that the LCA model accurately mirrors real-world operations and tracks all pertinent factors, such as material usage, emissions, or costs, across various stages of the supply chain.

Following these steps allows for a more precise and dynamic integration of industrial processes into an LCA framework. Additionally, because SCOR systematically breaks down processes from high-level supply chain management activities to very granular operational tasks, it eases the alignment between practical operations and analytical models. In turn, this sets the basis for real-time LCA and LCC calculations, providing stakeholders with continuous, up-to-date insights into both environmental and economic performance.

2.2.3. Data Transport

Second, the system must support event-based calculations using current data, which can be triggered either automatically on a defined schedule, such as daily, weekly, or monthly, or manually in response to specific changes in the supply chain. This design ensures that any shifts in production, supplier availability, or transportation routes are promptly captured in LCA and LCC calculations, keeping the results as accurate and relevant as possible.

A key part of this mechanism involves reliable data transport and aggregation. To facilitate automatic and event-based calculations, several data sources must be integrated:

LCI Databases: These are repositories of standard environmental impact data for materials and processes. Examples include ecoinvent, Sphera Databases, and similar platforms that provide baseline values for emissions, resource use, and other impacts. Linking these databases via APIs or local synchronization routines enables the LCA software to retrieve up-to-date, region-specific LCI information on demand.

Sensor Networks: Real-time sensors and RFID tags can be deployed across the supply chain to track operational metrics, including energy consumption, throughput rates, and transportation distances. These sensors transmit live data, via wireless protocols, Ethernet, or other communication channels, to a centralized server or data warehouse. From there, automated scripts can verify, clean, and format this information before passing it on to the LCA/LCC software.

Other Internal Systems (ERP, MES, etc.): Enterprise Resource Planning (ERP) systems and Manufacturing Execution Systems (MES) often hold critical details about inventory levels, production schedules, and associated costs. By establishing data bridges, or APIs, between these internal systems and the analytical environment, the LCA tool can incorporate real-world financial and operational data.

When a calculation event is triggered, whether by a time-based schedule or a manual intervention, the software automatically retrieves the necessary inputs from the various data sources. It then updates the LCA and LCC models accordingly, performing the required calculations to produce new results. This workflow may also involve predefined scripts or services that check for data completeness, perform normalization steps, and export the updated outputs to dashboards or reporting platforms. Such an infrastructure ensures that LCA/LCC models are always running on the most recent inputs, allowing decision-makers to respond swiftly and confidently to any observed changes in performance or operational conditions.

2.2.4. Calculation Methods

Once the data is collected, it should be transferred to the LCA/LCC calculation tool. Several software solutions are available for performing LCA and LCC calculations, including SimaPro 9.5.0 [

46], Sphera [

47] (GaBi 10.7), openLCA 2.0) [

48], Umberto 11 [

49], and Brightway2 2.5.1 [

50].

There are various options available, and the choice of which one to use depends on the characteristics of the system being modeled. If one of the programs offers more detailed or straightforward modeling capabilities, that program should be prioritized. Once the data sources have been identified, they need to be transferred to the software model via an API connection. This setup automatically updates the model with current data and generates real-time results. Using API connections enables the required data to flow into the software model, allowing for real-time monitoring of changes within the supply chain and production process. The software can then output the results via API, which enables swift reporting and effective decision-making based on current information.

2.2.5. Data Management

Another critical task involves selecting the methodology and technology for data collection. Several options exist for collecting real-time information for LCA and LCC. One is the use of barcodes, which are read optically to capture product or material data. However, barcodes have notable limitations, including restricted data storage capabilities and an inability to accommodate programmatic updates. The second option is Radio Frequency Identification (RFID). This method enables the identification of products or materials using radio waves. RFID offers several advantages, including high data storage capacity, programmability, and the ability to read information in real-time [

51]. Optical Character Recognition (OCR) is yet another option. It recognizes text and scans product or material information optically. However, OCR also has constraints, including limited data storage and a lack of programming functionality [

52,

53].

RFID technology offers significant potential for optimizing supply chains and improving environmental sustainability. particularly due to its real-time capability, ability to store and transmit detailed data, and compatibility with IoT systems. Passive and active RFID tags enable real-time data collection, supporting better decision-making and automation across various sectors [

47]. In the food industry, RFID implementation can reduce waste and environmental impacts, with the benefits generally outweighing the environmental costs of the tags [

48]. The construction sector has explored RFID applications; however, successful adoption requires a more integrated, life-cycle-oriented approach [

49]. In wood supply chains, RFID enhances traceability, helps combat illegal logging, minimizes waste, and provides detailed product information. Thanks to its accuracy, low cost, and programmability, RFID remains one of the most appropriate solutions for real-time data collection in support of life cycle assessment (LCA) and life cycle costing (LCC) [

50].

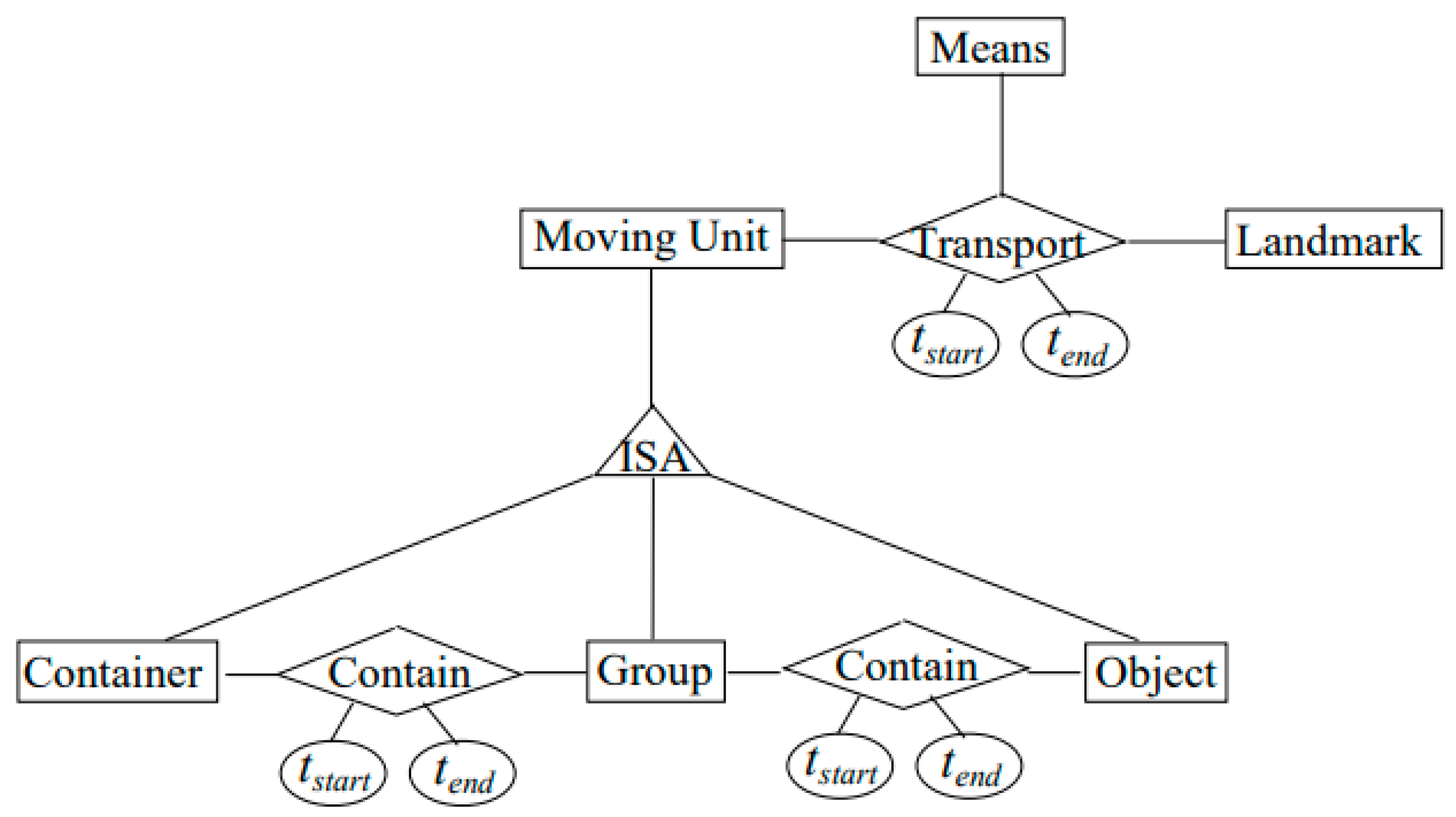

The following describes a possible system for storing and transmitting this data. A well-structured chain of data collection, storage, transformation, and transmission must be established to process real-time information about products, materials, and manufacturing processes. The initial stage involves collecting information using RFID chips embedded in the product or material. For this purpose, a data model is used that assigns two types of information to each unit: transportation and the unit itself, as shown in

Figure 2 [

54].

This division enables the application of the multi-table method, significantly reducing the cost of storing information, the size of databases, and, consequently, the retrieval speed.

So, reading devices record identifiers and other parameters encoded on the chips through radio-frequency interaction. The data is then transmitted in real time to a data management system, where it is stored in a central database [

55]. In the proposed framework, initial data filtering and validation occur primarily within the data management system, after raw data is collected from distributed RFID readers, IoT sensors, and other data sources. While some basic checks (such as communication errors or device malfunctions) may be flagged at the device or edge layer, most data cleaning and transformation are centralized to ensure consistency and traceability. Within the data management system, raw input data undergo several steps:

Outlier Detection and Noise Filtering: Statistical methods such as Z-score analysis or the Interquartile Range (IQR) rule can be applied to detect and exclude anomalous measurements [

51]. For example, measurements that deviate beyond ±3 standard deviations from the mean (using a moving window for time series data) are flagged as outliers and either removed or subject to further review.

Time Synchronization and Alignment: Records from different sensors may be asynchronous; thus, all incoming data is time-stamped and resampled [

52] (using windowing) at a consistent temporal resolution suitable for downstream LCA/LCC analysis. This can prevent gaps due to communication delays.

Missing Value Imputation: When data gaps occur—such as RFID readers failing to scan or a sensor briefly disconnecting—imputation methods fill in missing values. Common approaches include Last Observation Carried Forward (LOCF), Linear Interpolation (between adjacent valid values), or even Simple Moving Average [

53,

54]. The chosen method could depend on the frequency and importance of missingness for the particular parameter.

Data Consistency Checks: The system may apply logical rules (e.g., material flow balances, known minimum/maximum process limits) to flag implausible values for manual or automated correction [

55].

All filtered, inputted, and validated data is logged along with a data-quality flag and, if possible, the original (“raw”) value, to allow for auditing and future algorithmic refinement. Centralizing these processes within the data management system allows for unified error handling, versioning, and transparent data lineage, which are crucial for robust and repeatable sustainability assessments in dynamic environments.

From this database, the data is sent directly to the business layer. In this case, this business layer is the LCA calculation tool. Within the LCA, the data must be linked to the corresponding objects in the model to fill in these empty or partially filled data fields with data from LCIA, ERP, and MES objects. The use of standard digital integration approaches (e.g., REST APIs, OPC UA) ensures that the origin of each object in the system, its material, path, and method of transportation are as accurate and standardized as possible [

56]. There are examples of frameworks that propose the use of RFID in ERP and MES [

56,

57,

58]. Using the models proposed, it is possible to simplify the concept by integrating data from ERP and MES into the deduction process. This can be achieved through a simple interface between ERP or MES and the LCA calculation tool, with the necessary mapping tables. However, to make the method more versatile, the direct connection of databases obtained from RFID chips to the calculation process has to be considered. This connection in this framework is necessary only for LCA, since LCC calculation is either solely dependent on financial data (when calculated from data from monthly accounting reports) or entirely reliant on the LCA matrix. Thus, integrating dynamic data from RFID into the cost analysis was an unnecessary complication.

2.2.6. Evaluation Methods

To integrate LCA and LCC into a single analysis, a normalization procedure is required [

57] to better represent and analyse the results in the same coordinate system. Furthermore, normalization is a suitable measure for comparing product alternatives. In LCA, the results are normalized by comparing a products or process’s environmental impacts to a reference value, such as the total environmental output of a country or region [

57]. This is reflected in Equation (1), as shown in

Table 1.

The costs identified in the LCC are similarly normalized by comparing them to economic indicators such as a country’s or region’s gross domestic product [

59]. This approach is shown in Equation (2) (

Table 1).

Following the normalization step, environmental impacts and costs are combined into a ratio (

RE,c) that reflects the relationship between their normalized environmental impacts and normalized costs (Equation (3),

Table 1).

A ratio greater than one indicates that environmental impacts are higher relative to costs. This ratio is a central element of eco-efficiency analysis, as it clarifies the balance between environmental and economic performance. The results of this normalization are often depicted in the form of a portfolio, where products or services are visualized according to their environmental and cost impacts [

29].

The most eco-efficient products, those with the best ratio of environmental to cost efficiency, are located in the upper-right corner of the diagram. In contrast, products with lower eco-efficiency appear toward the bottom left, as shown in

Figure 3.

The eco-efficiency portfolio is advantageous because it visually unites environmental impacts and cost results in a single, intuitive diagram. Mapping products or processes along two axes—one for environmental performance and one for economic efficiency—enables quick comparisons and prioritization of different alternatives. This holistic perspective highlights trade-offs or synergies between ecological and financial dimensions, which can be more challenging to grasp numerically. Additionally, the portfolio simplifies the complexity of multi-indicator analyses by consolidating crucial metrics into a straightforward visual format. Finally, decision-makers from both technical and managerial backgrounds find it accessible and actionable, making it one of the most effective methods for communicating and interpreting assessment outcomes [

29].

The methodological structure of the proposed framework aligns with the core principles of the European Safe-and-Sustainable-by-Design (SSbD) approach. The European Commission’s SSbD framework calls for life-cycle thinking, integration of environmental, economic, and social dimensions, traceable data flows, and iterative improvement cycles throughout the design and assessment process [

58,

59]. The present framework operationalises these requirements by integrating ISO 14040/44–based Life Cycle Assessment (LCA) and Life Cycle Costing (LCC) within a single dynamic decision-support system [

13,

14]. Real-time data streams from RFID, IoT devices, and ERP/MES systems enable continuous monitoring of environmental and economic hotspots, while the eco-efficiency portfolio supports multi-criteria evaluation of design alternatives. In line with SSbD principles, this structure links product and process design with systematic sustainability assessment and strategic decision-making. Although intrinsic safety assessment (e.g., hazard and exposure analysis) is not yet included, the framework provides the sustainability assessment component of the SSbD methodology and can be coupled with upstream safety modules in future applications [

60].

3. Results

This section presents the proposed dynamic LCA/LCC framework, which integrates the methodological elements described in the previous section. The framework is designed to enable real-time environmental and economic assessment within supply chains by combining RFID-based data collection, automated calculation processes, and advanced visualization tools. In this logistics use case, the framework is applied to a road freight network that includes a main transport corridor between two regional hubs and connected last-mile delivery routes.

A visual representation of the overall procedure is provided in

Figure 4 Conceptually, the process can be divided into five steps, each comprising multiple elements that must be fulfilled to achieve the desired outcome and proceed to the subsequent level:

3.1. Step 1: Framework Definition & Data Strategy

Defining the research framework, research objectives, and functional unit constitutes the first step of the analysis. The result of the first step is a digital model of the process to be investigated. This model, as well as the functional unit, is identical for both the life cycle cost analysis and the environmental impact analysis. The model within the scope of the pre-study is based on the SCOR methodology, due to its reputation as the standard approach to displaying a production model. For logistics, the SCOR elements correspond to transport planning, hub operations, long-distance transport, last-mile delivery, and returns or empty backhauls. The functional unit is defined as one tonne-kilometre (tkm) delivered to the customer for line-haul operations and one parcel delivered for last-mile delivery. Furthermore, in the first step, it is essential to understand what data for future LCA analysis can be obtained from classical databases and what data needs to be created by a dynamic model based on RFID sensors transmitting information about the material, transportation path, and other relevant data. Telematics (GPS/OBD), RFID at gates, and TMS/ERP trip records provide dynamic route distance, payload, idle time, stop density, and energy/fuel use needed for LCI and LCC. It is also possible to measure temperature, humidity, and other storage conditions using auxiliary sensors, which may be particularly helpful for specific industries. For cold-chain freight, these sensors parameterize refrigeration set-points and energy draw.

3.2. Step 2: Baseline Analysis & Impact Calculation

The second step involves calculating the product or process cost and environmental impact for the selected impact categories. In the context of LCA, this step first includes the Life Cycle Inventory (LCI) phase, which involves the collection and quantification of input and output data—such as energy use, raw materials, emissions, and waste flows—throughout the product system. The accuracy and completeness of the LCI data determine the reliability of the subsequent logistics results. Data sources may include primary process data, supplier information, and secondary data from other sources. Data validation and consistency checks are essential to ensure comparability across different scenarios.

For LCA, the LCIA is calculated using a traditional methodology that incorporates supply chain data to maximize accuracy and provide accurate information about production materials, as well as complete transparency of the supply chain pathway. Several paths can be proposed for costing, which differ in convenience rather than quality. The first option is the provision of data by the controlling or accounting department, based on monthly, quarterly, and annual reports. The primary challenge in this case is to align the calculation with the functional unit or to tailor the variable report to the study’s boundaries. For example, if the functional unit refers to “per tonne-kilometre of transported material flows,” but the available data are aggregated as “total transported quantities and costs per quarter,” the data need to be converted or adjusted to ensure consistency between the two. Another possibility is calculating the LCC based on the resource matrix used in LCA, i.e., directly using the resource inputs from each process in the LCA model—such as electricity, materials, and fuels—to calculate costs, thereby ensuring structural consistency between the LCC and LCA frameworks. This method is not widely used in practice, but it guarantees a complete correspondence between the analysis framework in life cycle costing and LCA analysis. The method has been extensively discussed in the works of Weidema [

61], Heijungs [

62], and Bachmann [

7]. Both methods are possible. The choice is driven solely by the preferences of the adapting individual. The outputs of the second step are the calculated value of the functional unit and the calculated impact of the functional unit on the selected impact categories. For the logistics case, the impact assessment includes greenhouse gas emissions from fuel use and production, as well as acidification and particulate matter impacts. The cost assessment includes expenses for fuel or energy, driver wages, maintenance, tolls, hub handling, waiting time, empty trips, and vehicle depreciation per ton-kilometer or parcel.

3.3. Step 3: Results Normalization

The third step is to process the obtained results and bring them to a common denominator. For this purpose, a normalization approach is used, proposed in the EEA method. This step is key to a comprehensive evaluation of a product or process and is necessary to finalize the decision-making policy based on the proposed analysis. In logistics, environmental results for each route or delivery tour are adjusted to make them comparable across different service routes and delivery areas. Costs are adjusted using regional economic and capacity factors to enable fair comparison between different transport routes. Normalization is explained in more detail in

Section 2.2.6.

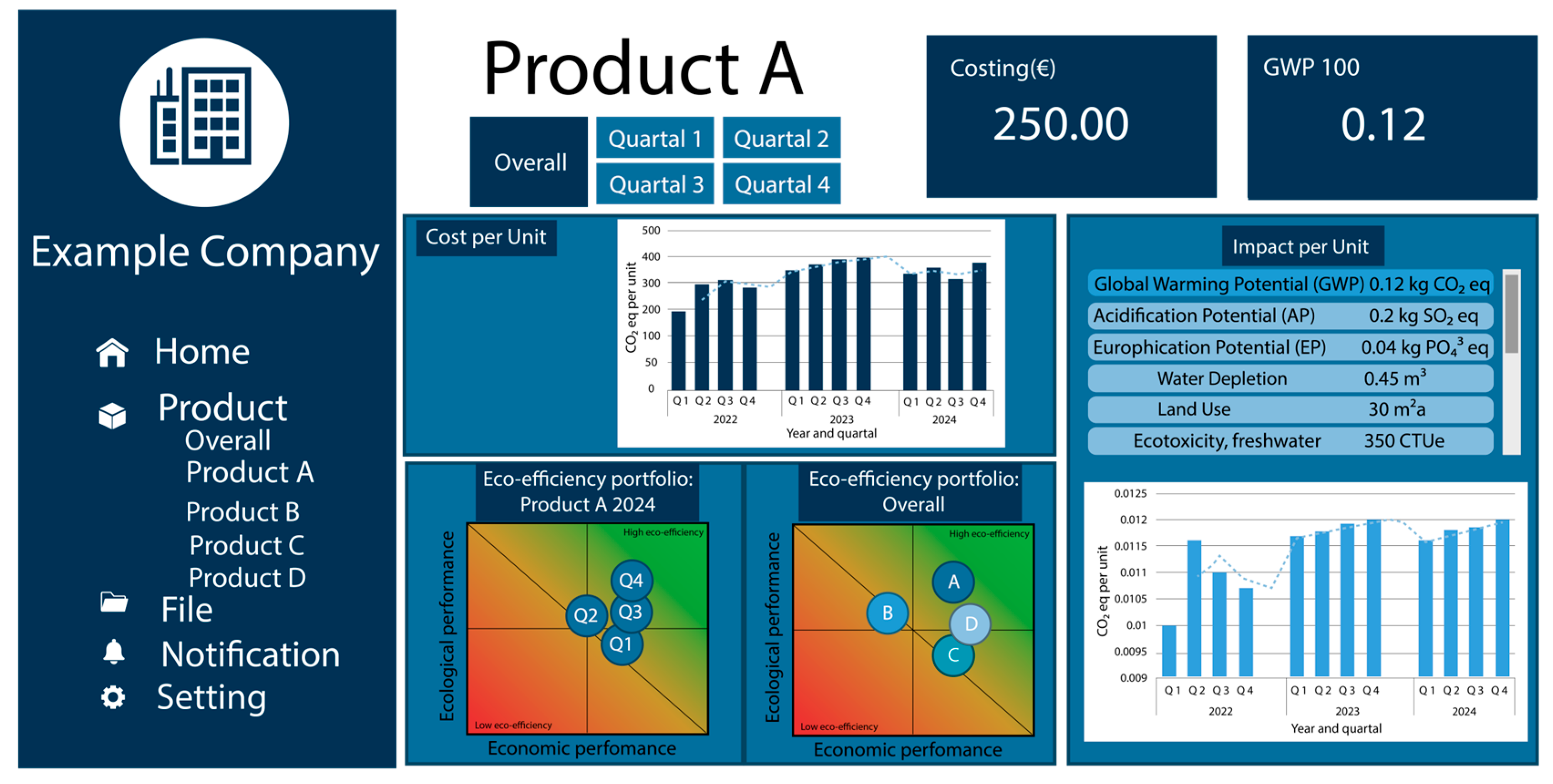

3.4. Step 4: Visualization & Decision Support

In Step 4, the results obtained in Steps 2 and 3 need to be evaluated. A possible solution for presenting these results is to compile a dynamic dashboard that displays the most relevant data for informed decision-making.

Figure 5 illustrates an example of the dashboard of this framework.

Different types of analysis can be applied to the obtained data. However, the following indicators are essential:

LCC per functional unit with historical data: tracking by month, quarter, and year. It allows for a critical examination of the decisions made, market conditions, changes in own or key supplier policies, and their impact on the cost.

LCC with allocated cost items: R&D, Marketing, Maintenance, EoL, etc. An auxiliary value to help track cost changes in individual cost items. It allows for identifying growth potential and examining the cost structure in more detail.

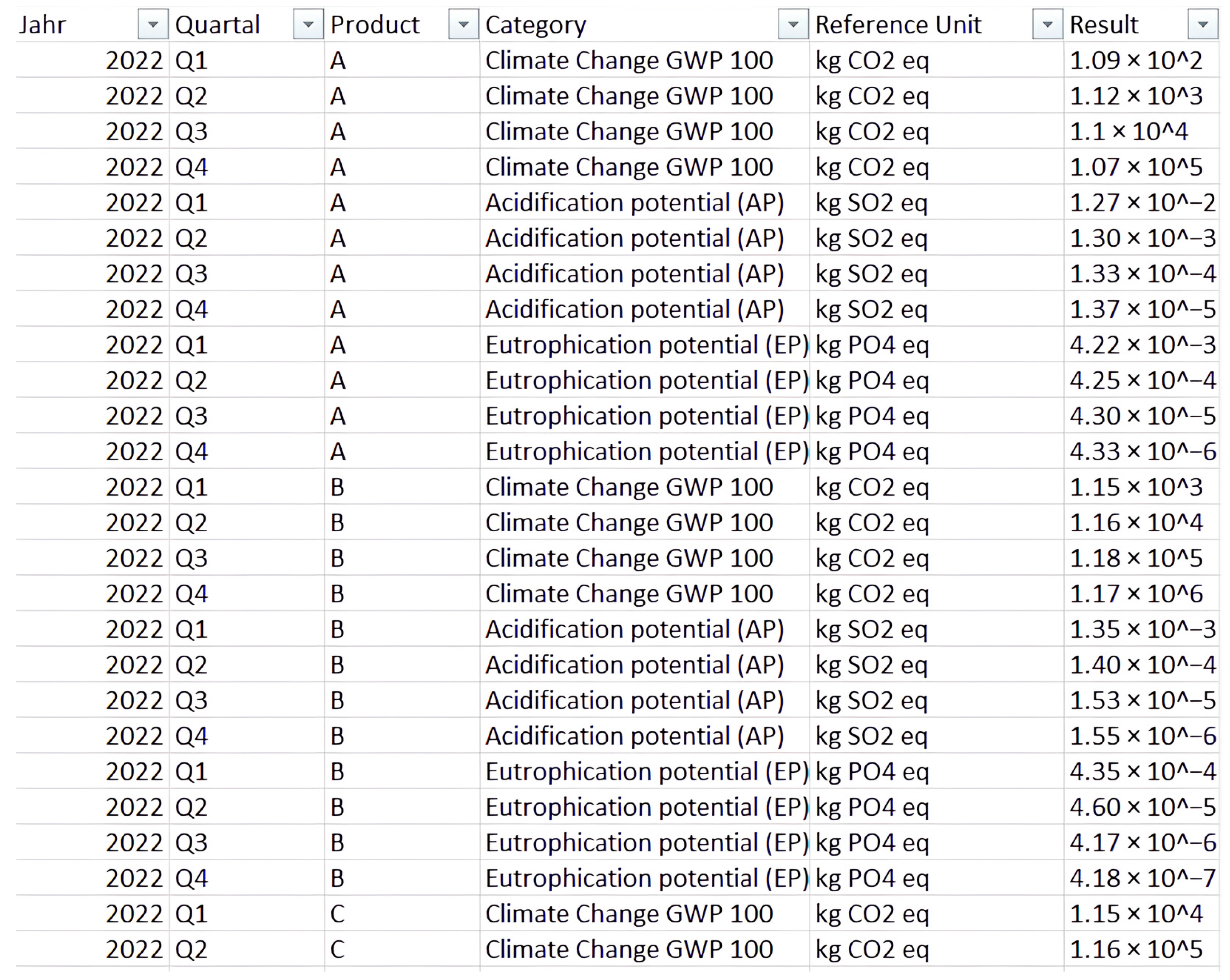

Similar markers for individual LCIA categories. Total value, as well as separate graphs for each product, for each time period, and for each of the available impact categories. As an example, shown in

Figure 6 of the database structure:

A dynamic portfolio of eco-efficiency of products to evaluate the full range of the company’s products and determine further development strategy.

Historical values of the eco-efficiency portfolios of different products are observed to track changes, assess the degree of influence of previous decisions, and evaluate the resulting development or decline in the performance of individual products within the portfolio. In logistics, the dashboard can be filtered by route, vehicle type, and delivery pattern. It shows 7- and 30-day rolling eco-efficiency for long-distance and last-mile operations, highlights problem areas such as low load factors or urban congestion and allows testing of “what-if” scenarios for re-routing or load consolidation.

3.5. Step 5: Strategic Integration & Policy Development

In the fifth step, the presented indicators should be turned into a strategic policy for the company. The KPIs in the dashboard should become indicators around which a sustainability strategy can be built. The proposed method provides an opportunity to quantify the company’s aspirations, making adherence to the plan more focused, traceable, and, consequently, controllable. It is essential to realize that a dynamic approach is necessary, as a single analysis does not allow for benchmarking within its processes and, consequently, is practically inapplicable for making operational and strategic decisions in this format. In logistics, policy measures include prioritizing routes for fleet renewal (for example, using zero-emission trucks on high-traffic corridors), setting load-factor targets, placing small local hubs for last-mile delivery, providing eco-driving training for drivers, and including contract terms that share fuel or energy risks while rewarding proven improvements in eco-efficiency.

The purpose of the proposed framework is precisely to extend the applicability of LCA and LCC, to show the economic incentives for implementing these analyses in real economic conditions and, consequently, to draw more attention to the topic of sustainability and make it more tangible by introducing a straightforward calculation approach.

Unlike traditional methods, the implication of eco-efficiency results can be much more intensive due to the regular possibility of comparing results on identical parameters. This makes it possible to establish clear KPIs in the company’s overall strategy, moving away from qualitative assessments and aspirations. In this way, the transparency of companies’ sustainability aspirations increases, which can also be used in marketing companies to gain more trust from customers.

4. Discussion

This chapter revisits the key research questions raised at the beginning of the study and explains how the proposal framework addresses them.

Traditional LCA/LCC assessments are typically static, episodic, and reliant on periodic manual data entry, limiting their responsiveness to operational changes. Recent methods such as BASF’s Eco-Efficiency Analysis or PROSA offer more holistic, but still largely static, assessments. The proposed framework surpasses these by enabling dynamic, event-driven inventory and impact updates using direct sensor and ERP/MES integration. This closes the loop between real-world operations and analytical insights, allowing for agile adaptations and more robust sustainability management across volatile supply chains.

One significant aspect is the collection of real-time data for LCA and LCC analyses. The developed framework leverages RFID technology to collect real-time data along the entire supply chain and production process. RFID tags, whether passive, active, or chip-based, are embedded in products or materials, allowing continuous tracking of their location, status, or quantity through radio-frequency interaction. These data points are automatically transmitted to a secure central database via an SFTP server, ensuring both speed and security. Additionally, API connections enable this data management system to integrate with various LCA/LCC calculation tools (e.g., SimaPro 9.5.0, Sphera GaBi 10.7, Brightway2 2.5.1). The model can also trigger event-based updates, either automatically (e.g., every 24 h) or manually, to capture changes such as production shifts or supply chain disruptions when they happen. The frequency of data update and analysis can be defined according to the dynamics of the production system and the criticality of decision-making timeframes: from real-time (minutes/hours) for rapidly changing environments (e.g., energy, logistics), to daily or weekly for less time-sensitive contexts. The chosen interval balances the value of up-to-date insight with computational and IT resource requirements.

This combination of RFID hardware, secure data transmission, and event-based triggers ensures that the correct data is gathered in real-time for accurate environmental and cost analyses.

Another important consideration is how these data are processed to ensure their quality and suitability for further analysis. After the data is recorded by RFID readers and transmitted via SFTP, it undergoes a preliminary verification and integrity check in the data management system. This processing includes format standardization to ensure the data is compatible with LCA/LCC software, as well as validation steps to flag and discard erroneous entries. Dedicated algorithms compare real-time measurements with expected thresholds, checking for inconsistencies or anomalies that might indicate sensor errors. After this verification step, the data is automatically fed into the chosen LCA/LCC software via an API. There, further automated algorithms incorporate relevant components such as energy use, emissions, and disposal costs. Results are then relayed back to the data management system or to higher-level enterprise resource planning (ERP) or manufacturing execution systems (MES), ensuring a closed-loop flow of verified information.

To present results clearly and effectively, the framework uses an eco-efficiency portfolio, which visually combines environmental and cost metrics in a two-dimensional diagram. Environmental impacts (normalized using reference values such as national annual emissions) are plotted against normalized costs (e.g., relative to GDP), with each product or process represented as a point. This allows for intuitive comparison of trade-offs, highlighting, for example, options with low ecological impact but higher costs, or vice versa. The use of standardized normalization formulas (see Formulas (1) and (3) in

Table 1) ensures consistency and facilitates direct comparison of multiple alternatives, making the relative eco-efficiency of each option immediately visible.

It is also important to note that the environmental impact and cost of RFID tag production, use, and disposal should be incorporated as separate inventory processes and cost entries within the LCA and LCC models, ensuring that the digitalization footprint is explicitly accounted for.

Ultimately, the benefits of utilizing real-time LCA and LCC calculations become clear in this context. Moving from static to real-time calculations offers several key advantages. First, it provides immediate insight into environmental and cost performance whenever supply chain or production factors change, thereby enabling swift course corrections and proactive decision-making. Second, the presence of connected RFID systems and automatically updated databases enhances transparency, allowing stakeholders to see precisely where inefficiencies or hotspots (environmental or economic) arise at any given moment. Third, real-time data ensures more accurate modelling over a product’s life cycle, because assumptions about resource consumption or emission levels can be fine-tuned as inputs evolve. Fourth, with event-based triggers, abrupt incidents, such as supply chain interruptions or spikes in energy prices, can be factored in immediately, allowing the entire organization to react quickly. Finally, this agile, data-driven feedback loop drives continual improvement. As soon as a process optimization shows success in either cost savings or reduced environmental impact, that benefit is instantly reflected in the eco-efficiency portfolio, encouraging further iterative enhancements to processes and products.

Despite its potential, the proposed framework has several limitations. First, as a conceptual study, it lacks comprehensive empirical validation in real industrial contexts. Future applications should test data flows, temporal modelling, and API integrations under operational conditions. Second, the framework assumes high-quality, temporally resolved, and interoperable data across all supply chain partners, which may not always be available, leading to uncertainties and boundary inconsistencies in LCA and LCC. Third, it relies on advanced digital infrastructures (e.g., sensor networks, ERP/MES integration) that are not universally present, particularly in SMEs or global supply chains. Finally, the current approach focuses mainly on environmental and economic indicators, without integrating social dimensions or addressing the scalability challenges of maintaining dynamic models over time.

To automate data cleaning, imputation, and anomaly detection, artificial intelligence (AI) and machine learning approaches can be utilized. These technologies also enable the identification of optimization opportunities within complex data sets. Although not implemented in the current framework, the integration of AI-driven analytics is recognized as a promising direction for further enhancing process efficiency and minimizing the need for manual intervention. The use of these technologies can be further elaborated upon following research into relevant use cases.

5. Conclusions

The proposed dynamic LCA/LCC framework integrates real-time data acquisition, automated impact calculation, and decision-support visualization into a cohesive process, addressing the limitations of static assessments by providing real-time, data-driven insights. By harnessing RFID-enabled sensor networks and API-driven exchanges with ERP/MES systems, organizations can continuously generate normalized eco-efficiency metrics, enabling them to respond swiftly to changes in resource consumption and cost drivers. This approach enhances transparency across the product life cycle and delivers actionable insights for balancing environmental and economic performance under volatile market conditions.

Although the framework can offer clear practical benefits, its implementation presupposes mature digital infrastructures—specifically, reliable sensor networks and deeply integrated ERP/MES platforms—that may not be universally available. Inconsistent data standards across supply chain partners create challenges for seamless information sharing and may compromise the comparability of LCA/LCC results. The upfront technical complexity and financial investment required could also deter small and medium-sized enterprises that lack dedicated IT and sustainability resources.

While the proposed dynamic framework can most seamlessly be adopted by organizations with mature digital infrastructure, its modular design permits partial deployment suitable for SMEs. SMEs may begin by targeting the highest-impact or highest-value segments of their supply chain, and may rely on more cost-effective solutions such as passive RFID tags or barcode scanning. Moreover, leveraging shared cloud platforms and standardized dashboard templates reduces both setup costs and technical complexity. Sector-wide initiatives or collaborative platforms may further aid in resource sharing and reduce individual firm burden, accelerating digital and sustainability transitions even in resource-constrained contexts. Initial implementation case studies in representative SMEs are recommended as a future research focus.

Recognizing the inherent uncertainty in both real-time data and impact modeling, the framework can also be extended with basic sensitivity and uncertainty analyses. Key variables (such as resource intensities, emission factors, or cost inputs) can be systematically varied to assess their effect on results. Monte Carlo simulations or scenario analyses can be incorporated to provide confidence intervals for both LCA and LCC results. While a comprehensive exploration of uncertainty is outside the primary scope of this study, the integration of such tools represents a promising direction for future implementations, especially as database and algorithmic maturity develop.

Future research could broaden the framework’s applicability and robustness by incorporating additional environmental and social indicators, such as water footprint, biodiversity impacts, and social well-being metrics, thereby demanding more advanced data collection and processing techniques. Or analysing multistage or distributed production processes. In cases where supply chains are global in scope and involve multiple participants, establishing unified standards and protocols for data sharing, while considering commercial and competitive constraints, would further strengthen the approach. Also, improving mechanisms to account for stakeholder preferences. Methods for setting weighting factors need to be refined, and the toolkit for analysis personalization expanded, so that stakeholders can better align their financial, environmental, and social priorities. Finally, developing lightweight, cost-effective implementations tailored to the needs and constraints of smaller enterprises will be essential for ensuring that dynamic LCA/LCC becomes a scalable tool for sustainable decision-making across diverse industrial contexts.