Energy Consumption of Transfer Points in Passive and Plus-Energy Warehouses—A Systemic Approach to Internal Transport

Abstract

1. Introduction

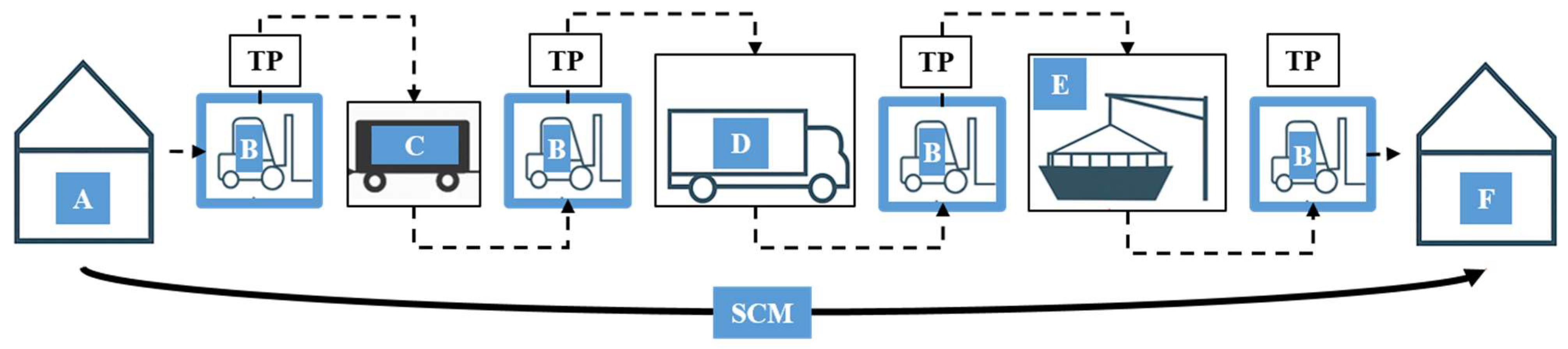

2. Intralogistics and Short-Range Transport in Global Supply Chain Management

3. Theoretical Background and Literature Review

- (1)

- Energy consumption in pallet warehousing. Transport of pallets within a warehouse significantly contributes to the total energy balance. The studies show that it is necessary to design closed loops of cargo flow, taking into account the energy intensity of its transfer [14]. The use of alternative vehicles and drives sufficiently influences the achieved savings [15]. The selection of pallet material (e.g., wood vs. plastic) also contributes to the energy characteristics of operations [16]. Other studies emphasise the importance of short-range transport in the entire supply chain [17] and the environmental impact of the load carrier management [18].

- (2)

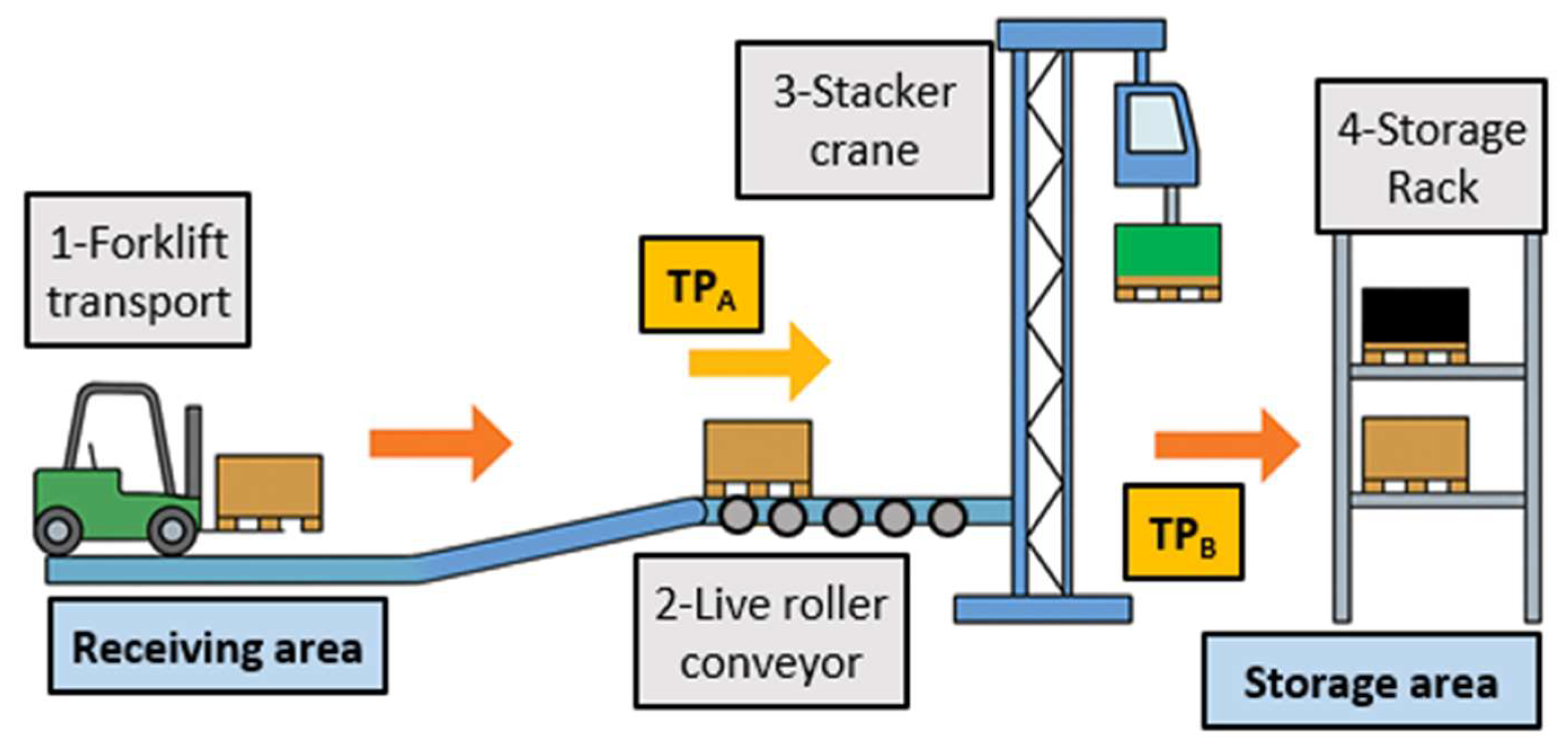

- Energy modelling for transfer points. The TP issue holds a prominent place among model analyses. TPs are locations where a pallet is transferred between devices of different operating characteristics, such as trucks, gantries, stacking cranes, or conveyors. It should be noted that if such locations are omitted in models, this results in a significant underestimation of energy consumption [19]. The importance of the modular warehouse structure [20] and the effects of delays between subsystems [21] are also emphasised. Furthermore, appropriate technological integration may reduce losses resulting from uncoordinated operation of equipment [13], and the geometry of racks contributes to energy consumption in the system [22].

- (1)

- Classification of energy flows and losses. Analyses point to a need to create systematic classifications of energy losses and flows in warehouses. The literature presents frameworks for the evaluation of environmental operations in logistics, in which energy holds a prominent place [23]. Diversified drives that are implemented at random without previous analyses lead to losses of many types, including mechanical, heat, or conversion ones [15]. Options for using the approach known from the commercial power industry, i.e., classification of losses by their source and place of origination, were also identified [24]. Further works expand this approach with intralogistic systems [25] and call for the standardising of energy data [26].

- (2)

- Organisational and technical solutions supporting the reduction in losses. The proposed solutions focus on optimising entire intralogistic systems. Reference [13] discusses green warehousing practices, including automation and coordination of transport and measuring systems. References [13,27,28], in turn, analyse the use of AGVs together with management systems and energy recovery. Ref. [13] points to an option for reducing energy consumption by using adaptive lighting [29]. In their paper, Ref. [28] presents algorithms for scheduling handling tasks from the point of view of their energy intensity [27]. A model developed in paper [30] enables forecasting of energy consumption in AVS/RS systems [30].

- (3)

- Technologies supporting energy efficiency of internal transport. In the analysed sources, the technology was named the essential factor enabling the energy deficiency improvement in warehouse operations. Practices such as the integration of AGV systems, implementation of Industry 4.0 solutions, or the use of smart systems for lighting and monitoring work cycles were considered activities that effectively reduce energy consumption [28,31]. The works also show that optimisation of load transfer points influences not only the cycle time but also energy losses resulting from delays and equipment standby [32,33,34].

3.1. Packaging Influence on Energy Intensity

3.2. Design and Mechanical Aspects of Transfer Points

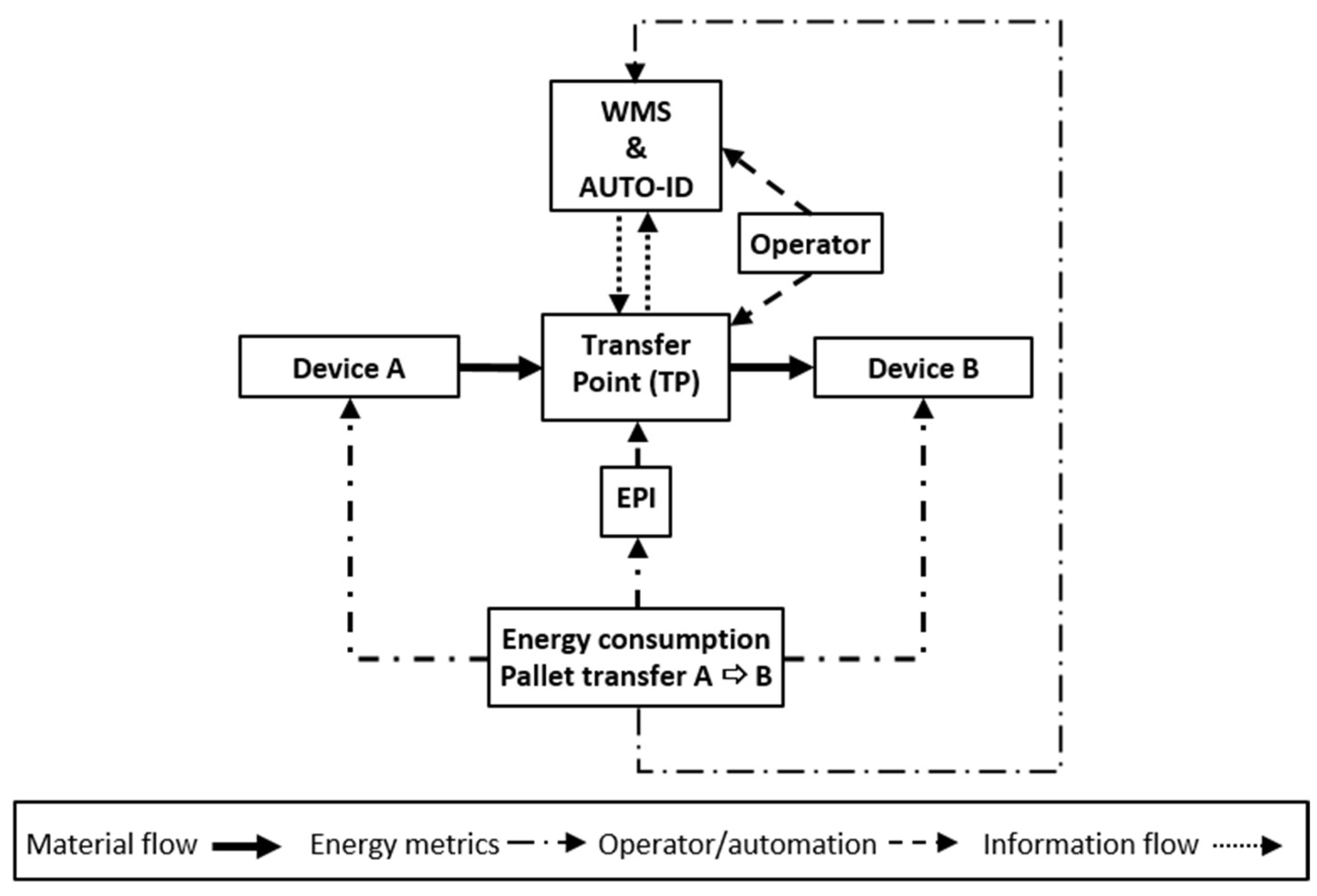

4. Concept of Energy Intensity of Transfer Points

4.1. Warehouse Energy Intensity Model Considering TPS

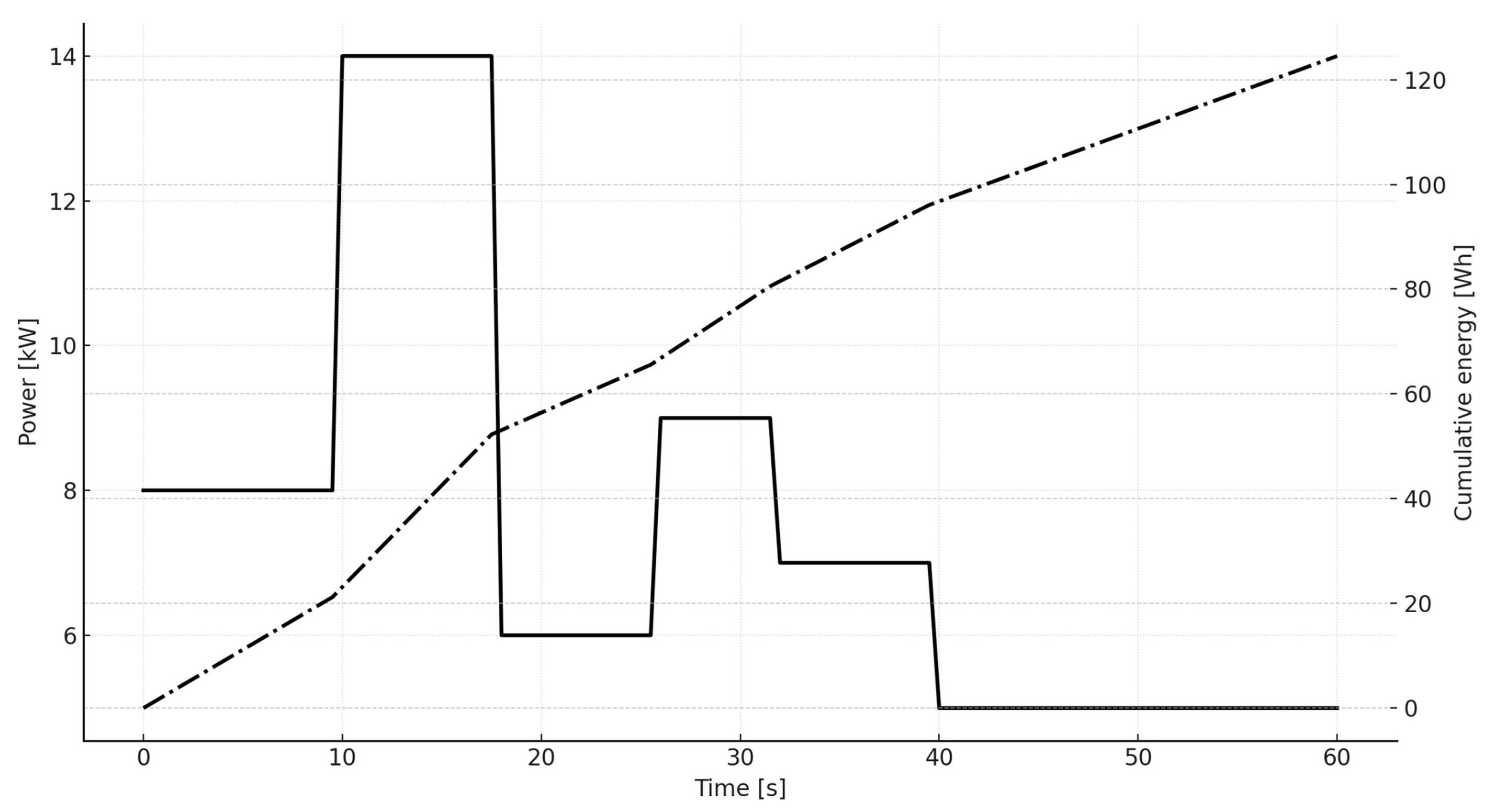

4.2. Verification of a Research Problem—An Experimental Study

5. Modelling Energy Intensity of Short-Range Transport, with TPs Considered

5.1. Research Methodology

5.2. A Balance Between the Analysis Level and the Underestimation of Energy Intensity

5.3. Energy Intensity Assessment, EPI Usefulness

5.4. Design or Quantitative Energy Intensity Ratio

6. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Symbol/Abbreviation | Description |

| TP | Transfer Point (pallet handover point) |

| AGV | Automated Guided Vehicle |

| EPI | Energy Performance Index |

| LCA | Life Cycle Assessment |

| AVS/RS | Autonomous Vehicle Storage and Retrieval System |

| AUTO-ID | Automatic Identification System |

| ERP | Enterprise Resource Planning |

| WMS | Warehouse Management System |

| HVAC | Heating, Ventilation, and Air Conditioning |

| HACCP | Hazard Analysis and Critical Control Points |

| TRL | Technology Readiness Level |

| MS ADAMS | Automated Dynamic Analysis of Mechanical Systems |

References

- Lewczuk, K.; Kłodawski, M.; Gepner, P. Energy consumption in a distributional warehouse facility in Poland—Case study. Energies 2021, 14, 2709. [Google Scholar] [CrossRef]

- Directive 2010/31/EU of the European Parliament and of the Council of 19 May 2010 on the Energy Performance of Buildings. Available online: http://data.europa.eu/eli/dir/2010/31/oj (accessed on 17 August 2025).

- Directive 2003/87/EC of the European Parliament and of the Council of 13 October 2003 Establishing a Scheme for Greenhouse Gas Emission Allowance Trading Within the Community and Amending Council Directive 96/61/EC (Text with EEA Relevance). Available online: https://eur-lex.europa.eu/PL/legal-content/summary/eu-emissions-trading-system.html (accessed on 17 August 2025).

- Zajac, P.; Dragasius, E.; Roik, T. Energy consumption when transporting pallet loads using a forklift with an anti-slip pad preventing damage. Energies 2021, 14, 8423. [Google Scholar] [CrossRef]

- Korzen, Z. Logistics Systems of Internal Transport and Storage; ILIM: Poznań, Poland, 1999; ISBN 83-87344-40-0. [Google Scholar]

- Fijalkowski, J. Internal Transport in Logistics Systems: Selected Issues; Publishing House of Warsaw University of Technology: Warsaw, Poland, 2003; ISBN 83-7207-412-7. [Google Scholar]

- Zajac, P. Evaluation Method of Energy Consumption in Logistic Warehouse Systems; Springer International Publishing: Cham, Switzerland, 2015. [Google Scholar]

- Zajac, P. The Energy Consumption in Refrigerated Warehouses; Springer International Publishing: Cham, Switzerland, 2016. [Google Scholar]

- Bujak, A.; Zajac, P. Monitoring of cargo in logistic systems of transport and storage. In Activities of Transport Telematics, Proceedings of the 13th International Conference on Transport Systems Telematics, TST 2013, Katowice, Poland, 23–26 October 2013; Springer: Berlin/Heidelberg, Germany, 2013; pp. 361–369. [Google Scholar]

- Bujak, A.; Zajac, P. Can the increasing of energy consumption of information interchange be a factor that reduces the total energy consumption of a logistic warehouse system? In Telematics in the Transport Environment, Proceedings of the 12th International Conference on Transport Systems Telematics, TST 2012, Katowice, Poland, 10–13 October 2012; Springer: Berlin/Heidelberg, Germany, 2012; pp. 199–210. [Google Scholar]

- Werbińska-Wojciechowska, S.; Zajac, P. Use of delay-time concept in modelling process of technical and logistics systems maintenance performance. Case study. Eksploat. Niezawodn. 2015, 17, 174–185. [Google Scholar] [CrossRef]

- Zajac, P.; Kwasniowski, S. Zero energy buildings in the logistics warehouse systems. E3S Web Conf. 2017, 22, 198. [Google Scholar] [CrossRef]

- Cannava, L.; Javan, F.D.; Najafi, B.; Perotti, S. Green warehousing practices: Assessing the impact on energy efficiency. Sustain. Energy Technol. Assess. 2024, 72, 104054. [Google Scholar] [CrossRef]

- Elia, V.; Gnoni, M.G. Designing an effective closed loop system for pallet management: A case study. Int. J. Prod. Econ. 2015, 170, 730–740. [Google Scholar] [CrossRef]

- Mızrak, F. An Evaluation for the Use of Alternative Vehicles in Warehouse Operations. In Contributions to Economics; Springer: Cham, Switzerland, 2022; pp. 159–171. [Google Scholar] [CrossRef]

- Dotelli, G.; Gallo Stampino, P.; Simonetti, E. Pallet Use and Transport in Italy: Comparing the Energy Impacts of Wood and Plastic Solutions. Appl. Sci. 2025, 15, 2032. [Google Scholar] [CrossRef]

- McKinnon, A.C. Reducing energy consumption and emissions in the supply chain. In Energy, Transport, & the Environment; Springer: London, UK, 2011; pp. 521–537. [Google Scholar] [CrossRef]

- Mazeika Bilbao, A.; Carrano, A.L.; Thorn, B.K.; Hewitt, M. Environmental impact analysis of pallets management. In IISE Annual Conference, Proceedings of the Industrial Engineering Research Conference, IERC 2010, Cancun, Mexico, 5–9 June 2010; Fairfield University: Bridgeport, CT, USA, 2010. [Google Scholar]

- Chari, N.; Venkatadri, U.; Diallo, C. Orbital warehouse design for an extra-terrestrial logistics support system. Int. J. Perform. Eng. 2013, 9, 609–618. [Google Scholar]

- Akerma, M.; Hoang, H.M.; Leducq, D.; Flinois, C.; Rulliere, R. Demand response in refrigerated warehouse. In Proceedings of the 2018 IEEE International Smart Cities Conference (ISC2), Kansas City, MO, USA, 16–19 September 2018. [Google Scholar] [CrossRef]

- Jeon, H.-W.; Ebrahimi, A.; Lee, G.-H. A Simulation-Based Experimental Design for Analyzing Interaction Effects in Automated Warehouse Systems. Sustainability 2023, 15, 14891. [Google Scholar] [CrossRef]

- Ilesaliev, D.; Samatov, G.; Sarvirova, N.; Mustanov, R.; Nurmukhametov, T. Influence of racking equipment parameters on the energy consumption of storage processes. E3S Web Conf. 2023, 460, 10004. [Google Scholar] [CrossRef]

- Yu, Y.; Zhu, W.; Tian, Y. Green supply chain management, environmental dynamics and firm performance: Evidence from China. Discret. Dyn. Nat. Soc. 2021, 2021, 5179964. [Google Scholar] [CrossRef]

- Niste, D.F.; Tîrnovan, R.; Pavel, S.; Beleiu, H.; Culea, M.; Bogdan, I. Electricity Losses in Focus: Detection and Reduction Measures. Appl. Sci. 2025, 15, 3517. [Google Scholar] [CrossRef]

- Hafner, N.; Lottersberger, F. Intralogistics systems–optimization of energy consumption. FME Trans. 2016, 44, 256–262. [Google Scholar]

- Aidarova, A.B.; Demessinova, A.A.; Moldogaziyeva, D.B.; Imanbekova, S.Y.; Aimagambetov, M.M. Improving transport energy statistics of the transport sector of the economy of Kazakhstan. Izvestiya Vysshikh Uchebnykh Zavedenii. Seriya Energ. 2020, 388, 10–13. [Google Scholar]

- Carli, R.; Dotoli, M.; Digiesi, S.; Facchini, F.; Mossa, G. Sustainable scheduling of material handling activities in labor-intensive warehouses: A decision and control model. Sustainability 2020, 12, 3111. [Google Scholar] [CrossRef]

- Ellithy, K.; Salah, M.; Fahim, I.S.; Shalaby, R. AGV and Industry 4.0 in warehouses: A comprehensive review. Int. J. Adv. Manuf. Technol. 2024, 134, 15–38. [Google Scholar] [CrossRef]

- Cannava, L.; Perotti, S.; Najafi, B.; Rinaldi, F. Assessing the impact of smart lighting systems on warehouse energy consumption. In Proceedings of the International Conference on Harbour, Maritime and Multimodal Logistics Modelling and Simulation, Athens, Greece, 18–20 September 2023. [Google Scholar] [CrossRef]

- D’Antonio, G.; Bruno, G.; Traini, E.; Lombardi, F. An analytical model to estimate AVS/RS energy consumption. IFAC Pap. 2019, 52, 24–29. [Google Scholar] [CrossRef]

- Dadras Javan, F.; Campodonico Avendano, I.A.; Najafi, B.; Perotti, S. Machine-Learning-Based Prediction of HVAC-Driven Energy Consumption in Warehouses Using Environmental Factors. Energies 2023, 16, 5407. [Google Scholar] [CrossRef]

- Zajac, P.; Kwasniowski, S. Modeling forklift truck movement in the VDI cycle and the possibility of energy recovery. In Proceedings of the 23rd International Conference on Engineering Mechanics, Svratka, Czech Republic, 15–18 May 2017; pp. 1094–1097. [Google Scholar]

- Prasetya, B.; Wahono, D.R.; Dewantoro, A.; Anggundari, W.C. The role of Energy Management System based on ISO 50001 for Energy-Cost Saving and Reduction of CO2-Emission: A review of implementation, benefits, and challenges. IOP Conf. Ser. Earth Environ. Sci. 2021, 926, 012077. [Google Scholar] [CrossRef]

- Tošić, B. ISO 14000 Standards Series. In Encyclopedia of Sustainable Management; Springer International Publishing: Cham, Switzerland, 2023; pp. 2058–2064. [Google Scholar]

- Hruzík, L.; Struž, J.; Trochta, M.; Klapetek, L.; Piek, D. Modern Design of Carrier for Overhead Conveyor. Appl. Sci. 2024, 14, 5352. [Google Scholar] [CrossRef]

- Carli, R.; Digiesi, S.; Dotoli, M.; Facchini, F. A control strategy for smart energy charging of warehouse material handling equipment. Procedia Manuf. 2020, 42, 503–510. [Google Scholar] [CrossRef]

- Cannava, L.; Ferraro, S.; De Carlo, F.; Perotti, S. Pioneering Green and Energy-Efficient Material Handling: A Decision Support System for Battery Charging Strategy Selection in Warehouse Operations. In Proceedings of the Summer School Francesco Turco; University of Salento: Lecce, Italy, 2024. [Google Scholar]

- Katzel, J.; Robbins, R. Silver Bullet; Packaging Digest: Oak Brook, IL, USA, 2009; Volume 46, pp. 40–41. [Google Scholar]

- Early, C.; Kidman, T.; Menvielle, M.; Geyer, R.; McMullan, R. Informing packaging design decisions at Toyota Motor sales using life cycle assessment and costing. J. Ind. Ecol. 2009, 13, 592–606. [Google Scholar] [CrossRef]

- Chenjie, G.; Feng, X.; Senyi, W.; Kaiwang, X. The material selection method for functional packaging of electromechanical products based on low carbon and cost constraint. Int. J. Low Carbon Technol. 2024, 19, 996–1002. [Google Scholar] [CrossRef]

- ten Klooster, R.; De Koeijer, B. Utilising the potential of design briefs in sustainable packaging development. In Proceedings of the IAPRI 2016-20th World Conference on Packaging: Innovation, Development and Sustainability in Packaging, Campinas, Brazil, 12–15 June 2016; Volume 2016, pp. 200–207. [Google Scholar]

- Verghese, K.L.; Horne, R.; Carre, A. PIQET: The design and development of an online streamlined LCA tool for sustainable packaging design decision support. Int. J. Life Cycle Assess. 2010, 15, 608–620. [Google Scholar] [CrossRef]

- Rossi, M.; Cappelletti, F.; Manuguerra, L.; Mundo, M.; Germani, M. Ecodesign Strategies for Packaging: A Simplified Approach to Evaluate Environmental Benefits. Procedia CIRP 2024, 122, 330–335. [Google Scholar] [CrossRef]

- Church, E.; Dull, L. Responsible packaging by design process guide. In Proceedings of the 18th IAPRI World Packaging Conference; DEStech Publications: Lancaster, PA, USA, 2012; pp. 321–326. [Google Scholar]

- Giudice, F. Eco-packaging development: Integrated design approaches. In Handbook of Sustainable Engineering; Springer: Dordrecht, The Netherlands, 2013; pp. 323–350. [Google Scholar] [CrossRef]

- Topcic, A.; Selo, R.; Cerjakovic, E. Optimisation of reloading segments of internal transportation systems. Tech. Technol. Educ. Manag. 2010, 5, 259–270. [Google Scholar]

- Zajac, P.; Rozic, T. Energy consumption of forklift versus standards, effects of their use and expectations. Energy 2022, 239, 122187. [Google Scholar] [CrossRef]

- Zajac, P.; Kwasniowski, S. The reliability problems of reading RFID tags in logistics warehouse systems. MATEC Web Conf. 2017, 112, 05012. [Google Scholar] [CrossRef]

- Zajac, P.; Kwasniowski, S. Reliability of automatic identification systems in logistics systems. In Proceedings of the 23rd International Conference Engineering Mechanics, Svratka, Czech Republic, 15–18 May 2017; pp. 15–18. [Google Scholar]

- Zajac, P. Evaluation of automatic identification systems according to ISO 50001: 2011. In Progress in Automation, Robotics and Measuring Techniques, Proceedings of the International Conference on Automation, Warsaw, Poland, 18–20 March 2015; Springer International Publishing: Cham, Switzerland, 2015; pp. 345–355. [Google Scholar]

- Cantini, A.; De Carlo, F.; Tucci, M. Towards Forklift Safety in a Warehouse: An Approach Based on the Automatic Analysis of Resource Flows. Sustainability 2020, 12, 8949. [Google Scholar] [CrossRef]

- Mohamed, I.S.; Capitanelli, A.; Mastrogiovanni, F.; Rovetta, S.; Zaccaria, R. Detection, localisation and tracking of pallets using machine learning techniques and 2D range data. arXiv 2018, arXiv:1803.11254. [Google Scholar] [CrossRef]

- Borisoglebskaya, L.N.; Provotorova, E.N.; Sergeev, S.M.; Khudyakov, A.P. Automated storage and retrieval system for Industry 4.0 concept. IOP Conf. Ser. Mater. Sci. Eng. 2019, 537, 032036. [Google Scholar] [CrossRef]

- Buckow, F.; Heitsch, H.; Kurz, S. Integrated pallet retrieval and processing in warehouses under uncertainty. OR Spectr. 2025, 47, 817–855. [Google Scholar] [CrossRef]

- Syu, J.-L.; Li, H.-T.; Chiang, J.-S.; Hsia, C.-H.; Wu, P.-H.; Hsieh, C.-F.; Li, S.-A. A computer vision assisted system for autonomous forklift vehicles in real factory environment. Multimed. Tools Appl. 2017, 76, 18387–18407. [Google Scholar] [CrossRef]

- ISO 50001:2018; Energy Management Systems–Requirements with Guidance for Use. International Organization for Standardization: Geneva, Switzerland, 2018.

- ISO 14001:2015; Environmental Management Systems–Requirements with Guidance for Use. International Organization for Standardization: Geneva, Switzerland, 2015.

- Smorch, P. Nine steps to greater profitability, sustainability. Packaging Digest 2007, 44, 46–48. [Google Scholar]

| 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|

| 2 | Study area | Pallet warehouse (without air conditioning) | Pallet warehouse (with air conditioning) | Pallet warehouse (cold store) |

| 3 | Lighting | 24.0% | 7.0% | 9.0% |

| 4 | Air Conditioning and Ventilation | 15.0% | 55.0% | 0.0% |

| 5 | Process Automation | 5.0% | 4.0% | 1.0% |

| 6 | Cargo Technologies | 2.0% | 1.0% | 1.0% |

| 7 | Transport Systems in a Pallet Warehouse | 50.0% | 29.0% | 23.0% |

| 9 | Cold Store | 0.0% | 0.0% | 62.0% |

| 11 | Warehouse Management Systems (WMS) | 2.0% | 1.0% | 1.0% |

| 12 | Monitoring and Data Analysis | 2.0% | 3.0% | 3.0% |

| 100.00% | 100.00% | 100.00% |

| 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|

| 2 | Equipment configuration | TP energy (Wh/unit) | Cycle time (s) | Operational notes |

| 3 | Forklift truck → roller conveyor | 40–80 | 8–15 | Manual positioning, limit sensors |

| 4 | Forklift truck → stacking crane | 70–120 | 12–20 | Active buffer, precise centring |

| 5 | Conveyor → stacking crane | 50–90 | 8–12 | Full automation, low energy consumption on rollers |

| 6 | Conveyor → gantry | 80–140 | 12–25 | Synchronisation of drives, blocking signals |

| 7 | AGV → conveyor | 90–150 | 15–25 | Standby, wireless communication |

| 8 | Gantry → stacking crane | 100–160 | 18–30 | Precise stopping, dynamic buffer |

| 9 | Truck → AGV | 60–100 | 10–20 | Operator supported by sensors |

| 1 | 2 | 3 | 4 |

|---|---|---|---|

| 2 | Modelling scenario | Cycle energy (Wh/pallet) | Notes |

| 3 | Simplified model | 700 | Only main movement of the device |

| 4 | Model considering TPs | 980 | Transfers, idle time, adjustments, standby |

| Cycle Stage | Stage Name | Average Consumption [Wh/Pallet] | Operational Notes |

|---|---|---|---|

| 1 | Horizontal transport on the conveyor | 200 | Speed of 0.4 m/s, average time of 70 s |

| 2 | Transfer: conveyor → stacking crane | 90 | Positioning, stopping, sensors, standby |

| 3 | Vertical transport—stacking crane | 420 | Elevator with a partial recovery |

| 4 | Transfer: stacking crane → rack | 70 | Moving out, centring, active rollers |

| 5 | Total with TPs | 780 Wh | - |

| 6 | Total without TPs | 490 Wh | With intermediate operations omitted |

| 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|

| 2 | Point type | Description | Relationship | Integration |

| 3 | Manual | Manual transfer of load | Forklift truck → operator | None or basic |

| 4 | Semi-automated | One device is controlled, the other is passive | Truck → conveyor | Signalisation or sensors |

| 5 | Automated simple | Both devices are automated, no full synchronisation | Conveyor → gantry | Transmitters, blockades, limiting sensors |

| 6 | Integrated smart | Full two-directional exchange of signals and synchronisation | AGV → stacking crane | Logical interface, scheduled cycles |

| 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|

| 2 | Class | Consumption level | Energy features | Consumption [Wh/pallet] | Potential for improvement |

| 3 | E1 | Low consumption | Short cycle time, no standby | <60 Wh | limited |

| 4 | E2 | Average consumption | Buffering or position adjustments | 60–120 Wh | moderate |

| E3 | High consumption | Idle time, unsynchronised drives | >120 Wh | high |

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

|---|---|---|---|---|---|---|---|---|---|

| 2 | Point | N operations | EPI quantitative | EPI design | Interpretation/decision | Discrepancy | |||

| 3 | A (Truck → conveyor) | 2 | 2 | 40 | 20 | 2.0 | 2.0 | Moderate effectiveness | None |

| 4 | B (AGV → stacking crane) | 3 | 4 | 108 | 30 | 3.6 | 3.6 | High losses—optimisation is required | None |

| 5 | C (conveyor → gantry) | 2 | 3 | 52 | 20 | 2.6 | 2.6 | Technological improvement is required | None |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zajac, P. Energy Consumption of Transfer Points in Passive and Plus-Energy Warehouses—A Systemic Approach to Internal Transport. Sustainability 2025, 17, 9419. https://doi.org/10.3390/su17219419

Zajac P. Energy Consumption of Transfer Points in Passive and Plus-Energy Warehouses—A Systemic Approach to Internal Transport. Sustainability. 2025; 17(21):9419. https://doi.org/10.3390/su17219419

Chicago/Turabian StyleZajac, Pawel. 2025. "Energy Consumption of Transfer Points in Passive and Plus-Energy Warehouses—A Systemic Approach to Internal Transport" Sustainability 17, no. 21: 9419. https://doi.org/10.3390/su17219419

APA StyleZajac, P. (2025). Energy Consumption of Transfer Points in Passive and Plus-Energy Warehouses—A Systemic Approach to Internal Transport. Sustainability, 17(21), 9419. https://doi.org/10.3390/su17219419