1. Introduction

Businesses today operate in fierce and hypercompetitive markets that are characterized by intense rivalry, uncertainty, and growing sophistication [

1]. For many firms, responding to these challenges and introducing innovations is a difficult task [

2]. Yunus [

3] observed that organizations in win–win environments often face significant pressure, and not all are able to achieve optimal outcomes. This raises an important question: is innovation always advantageous [

4]? The tendency to imitate competitors, often described as the “me-too” habit, can generate both notable successes and costly failures [

1,

5]. In this situation, innovation is no longer an option. Firms that desire long-term survival recognize the importance of sustainable business practices. It provides greater resilience than reliance on traditional business practices [

6,

7].

Supply chain collaboration is a powerful response to the challenges suppliers and retailers face. Mofokeng and Chinomona [

8] emphasized that SCC strengthens relationships, reduces risks, and capitalizes on the advantages of partnership to enhance sustainability [

9,

10]. Collaboration may occur with the customers, suppliers and even in-team members. According to Akam et al. [

11], it is very important for bringing together resources to improve both operational and sustainability performance. By exchanging information and resources, firms can develop integrated systems that support innovativeness and make them more competitive [

12,

13].

Collaboration has clear benefits in the real world. Collaborating firms can reduce costs and increase profits while enhancing sales forecast accuracy and improving logistics control [

14,

15,

16]. According to Kumar et al. [

17], partnerships can lead to shorter lead times, decreased bullwhip effects, improved skill development, greater flexibility, and increased customer satisfaction. The ability of a synchronized supply chain to produce value for end consumers is important for competitiveness [

9,

18]. Working relationship enhances replenishment plans, forecasts and techniques, which improves performance efficiencies and responsiveness [

19].

Being innovative, or the ability to learn, adapt, and make things part of the culture [

20], is very relevant for supply chain innovations (SCI) and performance [

21]. SCC enables both upstream and downstream partners to access knowledge, encourages the creation of new knowledge, and shortens R&D cycles [

22]. SCC drives SCI through these processes. The process of transforming an idea into a new and better product, service or process is known as SCI. According to Uddin and Akhter [

23], SCI not only brings firms commercial competitiveness but also sustainability goals.

A collaboration that generates new solutions builds resilient supply chains. According to [

24], SCCs foster spaces that allow people to work together flexibly and efficiently. Partnerships stimulate ideas that produce new technologies and processes. This means that these lower risks and increase flexibility while helping sustainability goals. These types of innovative ideas are beneficial for the economy, society, and the environment [

18,

25]. As per a recent study by Jum’a et al. [

13], the world’s economy has drastically changed as a result of customer expectations being continuously raised.

As there is a growing interest in this relationship, there are still considerable gaps in research [

23,

26,

27,

28]. Although prior studies have explored how SCC and innovation influence sustainability in various global contexts, limited attention has been paid to how these dynamics unfold within developing economies such as Jordan, where manufacturing firms face distinct institutional, environmental, and resource constraints that challenge innovation and sustainability adoption [

3,

13]. The manufacturing sector in Jordan remains a vital yet under-researched domain for understanding how collaborative innovation can enhance resilience and sustainable performance amid supply disruptions, resource scarcity, and evolving regulatory frameworks [

18,

23]. Hence, examining the mediating role of supply chain innovation (SCI) in the relationship between SCC and sustainability performance in this local context is both timely and essential, as it provides insights into how Jordanian manufacturers can leverage collaborative capabilities to achieve long-term competitiveness and sustainability outcomes [

10,

29,

30].

This research analyzes how SCC and SCI influences performance sustainability to help tackle existing gaps. The research seeks to answer the subsequent three core issues—Do end-users and supplier collaboration along with internal stakeholders affect SCI? How does collaboration affect sustainability performance? What is the role of SCI in the relationship between collaboration and sustainability outcomes?

The resource-based view and dynamic capabilities theory (DCT) guided this study. According to the resource-based view of the firm, SCC is an important resource that is not easily replicated by competitors. This is because SCC allows firms to pool together their capabilities, and combine resources such as expertise, technologies and information to enhance clever control [

29]. The innovations that arise from these collaborations become strategic resources that improve efficiency and adaptability while supporting sustainability. From the DCT perspective, SCC enables firms to reconfigure and renew their capabilities in rapidly changing environments [

30]. Collaborative innovation provides firms with the agility to respond to uncertainty, adopt new technologies, and embed sustainability into their strategies, thereby ensuring resilience and long-term performance.

The rest of this paper is organized as follows: The literature review on SCC, innovation, and sustainability will be introduced. The methodology will outline the research design and analysis methods. The results will present key findings. The discussion will interpret these findings, and the conclusion will summarize the main points, contributions, limitations, and future research directions.

5. Discussion

The results of Hypothesis H1 confirmed that customer collaboration has a positive influence on SCI, consistent with previous studies emphasizing customer engagement for product and process innovation through knowledge sharing and responsiveness to customer needs [

3,

40]. This finding suggests that Jordanian manufacturing firms benefit from customer input in developing innovative solutions, yet the extent of customer-driven innovation appears less intensive than in advanced economies. This may be attributed to institutional and cultural factors—such as limited technological readiness, conservative customer expectations, and less mature innovation ecosystems—that restrict co-creation opportunities. Consequently, while customer collaboration provides market insights, its translation into disruptive innovation remains constrained by contextual barriers.

The results of Hypothesis H2 demonstrated that SCI is significantly enhanced through supplier collaboration. This aligns with prior research that found close supplier–buyer relationships positively influence firms’ abilities to develop innovative sourcing and procurement practices [

42,

43]. However, the findings also indicate that supplier collaboration in Jordan tends to focus on operational efficiency and compliance rather than radical innovation. This may reflect the institutional emphasis on cost efficiency and resource optimization typical of developing economies, where suppliers often operate under capacity limitations and lack advanced R&D capabilities. Therefore, while supplier collaboration contributes to incremental innovation, systemic challenges may prevent it from fully supporting strategic innovation initiatives.

The results of Hypothesis H3 showed that internal collaboration has the strongest influence on SCI. This supports the findings of Tarigan et al. [

18] and Solaimani and van der Veen [

31], who emphasized that effective internal communication and planning foster a learning culture and facilitate knowledge transfer. In Jordan’s manufacturing sector, where hierarchical structures and centralized decision-making often dominate, internal collaboration becomes the most reliable and controllable driver of innovation. By promoting internal alignment, firms can leverage internal competencies to overcome institutional rigidity and transform traditional operations into innovation-oriented processes that enhance overall performance.

The results of Hypothesis H4 also confirmed the importance and positive effect of customer collaboration on sustainability performance. Consistent with Ahmed et al. [

25] and Sudusinghe and Seuring [

47], this finding reinforces that engaging customers in sustainability-oriented communication enables firms to better meet expectations for ethical and eco-friendly products. However, in the Jordanian context, customer collaboration often remains at the awareness level rather than deep sustainability co-development. Institutional pressures, such as weak regulatory enforcement and low consumer activism, may explain why customer collaboration directly improves sustainability outcomes but does not operate strongly through SCI.

Hypothesis H5 results showed that supplier collaboration has a significant positive effect on sustainability performance, supporting Jum’a et al. [

50] and Tarigan et al. [

18]. Yet, compared to similar studies in other developing economies, this collaboration appears more compliance-oriented—driven by external standards or donor requirements rather than proactive sustainability innovation. This suggests that suppliers in Jordan play a facilitating rather than transformative role in achieving sustainability, reflecting both resource constraints and the institutional focus on short-term cost advantages.

The results of Hypothesis H6 indicated that internal collaboration enhances sustainability performance, though to a lesser extent than customer and supplier collaboration. Similarly to the work of Shan et al. [

52] and Sudusinghe and Seuring [

47], cross-departmental coordination was found to integrate sustainability goals into operational processes. This outcome demonstrates that sustainability in Jordanian firms is still evolving from a compliance-based to a capability-based approach. Institutional limitations—such as fragmented organizational structures and limited incentives for sustainability innovation—may reduce the overall internal impact, but firms that foster integration across departments can still achieve measurable sustainability gains.

Furthermore, the results of Hypothesis H7 confirmed that SCI significantly enhances sustainability performance. This aligns with Jum’a et al. [

13], Fontoura and Coelho [

10], and Zhao et al. [

54], who found that adopting digitalization, circular economy models, and advanced technologies improve environmental, social, and economic outcomes. However, compared with firms in more industrialized contexts, Jordanian manufacturers face cultural and financial barriers that limit the diffusion of such innovations. These contextual challenges emphasize the need for institutional support mechanisms—such as innovation grants, digital infrastructure, and collaborative R&D platforms—to fully harness SCI’s sustainability potential.

The rejection of Hypothesis H8a suggests that SCI does not mediate the relationship between customer collaboration and sustainability performance. One possible explanation is that customer collaboration in this context emphasizes product adaptation and responsiveness rather than innovation-driven sustainability initiatives [

41]. Customers may provide feedback that enhances performance but does not necessarily drive innovation toward sustainability. Similarly, Hypothesis H8b was not supported, showing no mediating role of SCI between supplier collaboration and sustainability performance, contradicting prior works that highlighted supplier-driven innovation [

22,

42]. This divergence may stem from the institutional and cultural realities of Jordan’s supply base, where sustainability practices are often externally imposed rather than internally driven.

Finally, Hypothesis H8c confirmed that SCI mediates the relationship between internal collaboration and sustainability performance. Consistent with Afraz et al. [

34] and Junaid et al. [

55], this finding reveals that internal collaboration creates an environment conducive to learning and innovation, allowing sustainability objectives to be translated into tangible outcomes. Within Jordan’s context, this result highlights the unique importance of internal innovation mechanisms as firms rely more on internal resources than external networks to drive sustainability. Thus, innovation acts as a bridge through which internal synergies are transformed into sustained value creation, offering a distinctive theoretical contribution that emphasizes internal collaboration specificity in developing-country manufacturing sectors.

5.1. Managerial Implications

The study concludes by emphasizing the role of customer collaboration as a key enabler of innovation’ activities and enhancing sustainability performance. This implies that managers of Jordanian manufacturing companies need to engage customers in product design processes, feedback loops, and initiatives to reduce their company’s environmental impact. Companies should establish formal mechanisms for identifying the needs of customers, particularly for environmentally friendly products, and use this feedback for decision-making. Doing so enables manufacturers to not only generate new ideas faster, but they can also build trust with customers and make the market more competitive.

It was also found that collaboration with suppliers was extremely important for innovation performance and sustainability performance. Many Jordanian companies should establish long-term relationships with suppliers built on honesty, shared sustainability objectives and trust. Practical examples of actions to be implemented are provided, such as in situ training programs, supplier development programs or collaborative investments in green technologies. These types of partnerships will not only make purchasing more efficient but will also build the resilience of the supply chain and reduce environmental and social risks prevalent in the region.

Collaboration between companies was found to be very important for promoting sustainable, innovative development. Managers need higher levels of collaboration between functions like production, procurement, research and development, and sustainability. Cross-functional teams can help ensure that sustainability priorities are aligned with daily practice. This will help to ensure that practices such as resource conservation, waste reduction and innovation are embedded in the organizational culture. This will allow Jordanian companies to develop dynamic skills and attract creative and environmentally sound workers.

As per the study, supply chain innovation can enhance sustainability in supply chain management. In other words, it shows that managers should invest in technologies, processes, and systems. This means they need to digitize and automate. Also, they need to invest in the circular economy. In Jordan, manufacturers can boost efficiency, engine savings, and assess long-term impact by using these new ideas. Viewing innovation as a means of compliance will promote faster and lower-cost adaptation to stricter international sustainability standards.

Finally, the mediating effect of SCI was supported only in the relationship between internal collaboration and sustainability performance. This implies that while customer and supplier collaboration directly improve sustainability, internal collaboration requires innovation to translate into sustainable outcomes. Managers should therefore focus on fostering an internal culture that promotes experimentation, creativity, and the adoption of new technologies. Encouraging employees to contribute innovative ideas and supporting them with the necessary resources will help ensure that internal collaboration leads to measurable sustainability gains.

5.2. Theoretical Implications

The findings of this study provide several theoretical implications. First, they extend the resource-based view by showing that customer, supplier, and internal collaboration represent valuable resources that enhance innovation and sustainability performance. Second, the results enrich the dynamic capabilities theory by demonstrating how firms in dynamic environments such as Jordanian manufacturing can reconfigure their resources through collaboration and innovation to achieve sustainable outcomes. Third, the study highlights the mediating role of SCI, particularly in the relationship between internal collaboration and sustainability performance, which advances understanding of the mechanisms through which collaboration translates into long-term sustainability. Fourth, the study contributes to literature by integrating collaboration, innovation, and sustainability into a single framework, offering a comprehensive explanation of how firms can align operational strategies with sustainability goals. Finally, unlike previous studies conducted in developing-country manufacturing contexts, which often report a generalized mediating role of SCI across different collaboration dimensions [

15,

16,

26,

27,

34], this study demonstrates that the mediating effect of SCI is specific to internal collaboration rather than universal. This finding suggests that in Jordan’s manufacturing sector, innovation outcomes depend more on intra-organizational coordination and knowledge integration than on external partnerships with customers or suppliers [

18,

31]. Such “internal collaboration specificity” contrasts with evidence from other developing economies, where supplier- or customer-driven innovation tends to dominate [

19,

36]. This highlights the contextual influence of organizational culture, resource structures, and institutional environments, which shape how collaborative innovation translates into sustainability outcomes [

7,

10,

13]. Therefore, the study contributes theoretically by refining the understanding of how collaborative innovation mechanisms operate under resource-constrained and institutionally distinct settings typical of developing countries [

23,

30,

34].

6. Conclusions

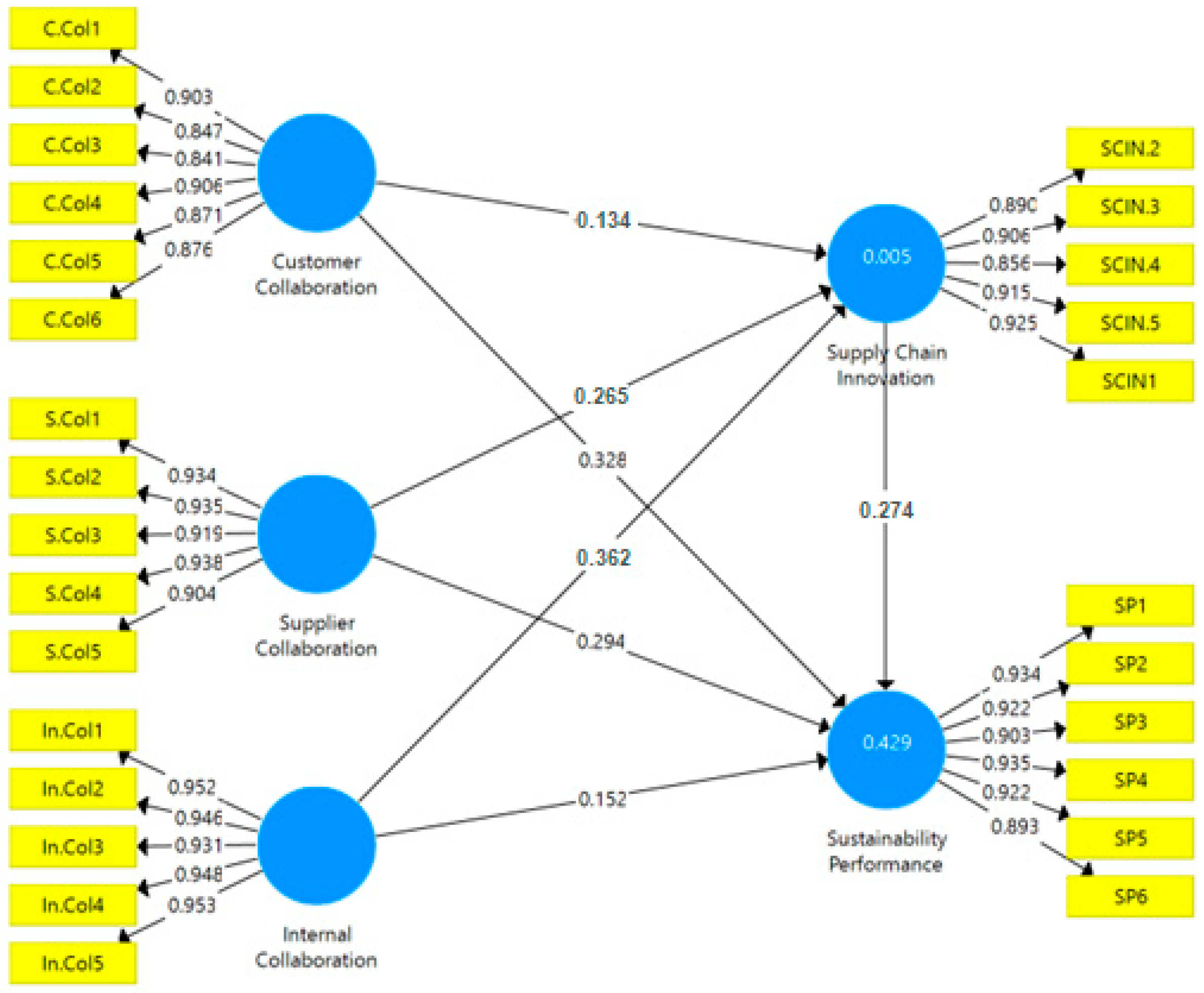

The main aim of this study was to examine the influence of SCC on SCI and sustainability performance in the context of manufacturing firms in Jordan. The study also investigated the mediating role of SCI in the relationship between different forms of collaboration and sustainability outcomes. To achieve this aim, data were collected through a structured questionnaire administered to employees from multiple management levels across organizations in Amman. Using SmartPLS software, the data were analyzed through partial least squares structural equation modeling.

The results showed that customer, supplier, and internal collaboration all had significant positive effects on SCI. These three forms of collaboration also positively influenced sustainability performance, with customer and supplier collaboration showing stronger effects compared to internal collaboration. SCI was found to directly enhance sustainability performance and to mediate the relationship between internal collaboration and sustainability performance. However, the mediating role of innovation was not supported in the cases of customer and supplier collaboration.

The managerial implications of these findings suggest that firms in Jordan should strengthen collaboration with customers and suppliers to improve innovation and sustainability outcomes, while also fostering internal collaboration to build a culture of innovation that supports sustainable practices. The theoretical implications highlight the importance of the resource-based view and dynamic capabilities theory in explaining how collaboration and innovation serve as pathways for achieving sustainability in dynamic environments.

This study has some limitations. The data were collected only from organizations in Amman, which may restrict the generalizability of the results to other regions in Jordan or different industries. The study also relied on cross-sectional data, which limits the ability to capture long-term causal effects. In addition, the use of self-reported survey responses may introduce bias. Another limitation of this study is the gender imbalance in the sample, with males accounting for 91.7% and females only 8.3%. This reflects the current composition of Jordan’s manufacturing workforce but may limit the generalizability of the findings.

Future studies should aim for a more gender-balanced sample to enhance representativeness. Moreover, future studies should expand the sample to include other cities and industries in Jordan to provide broader insights. Longitudinal research designs are recommended to examine how collaboration, innovation, and sustainability evolve over time. Future research could also incorporate objective performance data or case studies to complement survey findings and reduce potential bias. Finally, comparative studies across different countries could provide deeper insights into the role of cultural and institutional contexts in shaping the collaboration–innovation–sustainability nexus.