Enhancing Concrete Durability and Resource Efficiency Through Rice Husk Ash Incorporation: A Data-Driven Approach

Abstract

1. Introduction

2. Development of the Rice Husk Ash (RHA) Database

3. Data Analysis

| Constituent Materials | CO2 Emission Factor (kg CO2/kg of the Material) | Cost (Local Price in $) |

|---|---|---|

| Portland Cement | 0.82 (Collins et al., 2010) [51] | $0.11/kg |

| Coarse Aggregates | 0.0459 (Flower and Sanjayan, 2007) [61] | $0.008/kg |

| Fine Aggregates | 0.0139 (Flower and Sanjayan, 2007) [61] | $0.0075/kg |

| Rice Husk Ash (RHA) | 0.1032 (Alnahhal et al., 2018) [64] | $0.015/kg |

| Silica Fume | 0.028 King (2012) [67] | $0.095/kg |

| Metakaolin | 0.330–0.423 (Hammond and Jones (2008), Heath et al. (2014), Black (2016)) [68,70,74] | $0.093/kg |

| Fly Ash | 0.004–0.027 (Flower and Sanjayan, 2007) [61] | $0.080/kg |

| Slag | 0.052–0.143 (Flower and Sanjayan, 2007) [61] | $0.072/kg |

4. Results and Discussion

4.1. Assessment of the Database

4.1.1. Replacement Level of RHA

4.1.2. Replacement Type of RHA

4.1.3. The Use of RHA with Pozzolans

4.1.4. Models Defined for Life Cycle Assessment

- Compressive Strength: Compressive strength values below 20 MPa and above 100 MPa were excluded, as they fall outside the practical range for typical construction applications.

- Durability Indicators: The increase in RHA replacement level led to a substantial decrease in both chloride penetration, mass loss after sulfuric acid exposure, electrical resistivity, and porosity, as well as water absorption, improving the durability of concrete. This trend was particularly evident up to 30% replacement.

- Use of Pozzolans: The addition of pozzolans to RHA-based concrete enhanced its durability by further reducing chloride penetration and porosity. The most effective pozzolans were identified to be metakaolin, slag, fly ash, and silica fume and were found to be effective at 15–30% replacement levels, with the most pronounced improvements occurring when pozzolans replaced cement rather than sand.

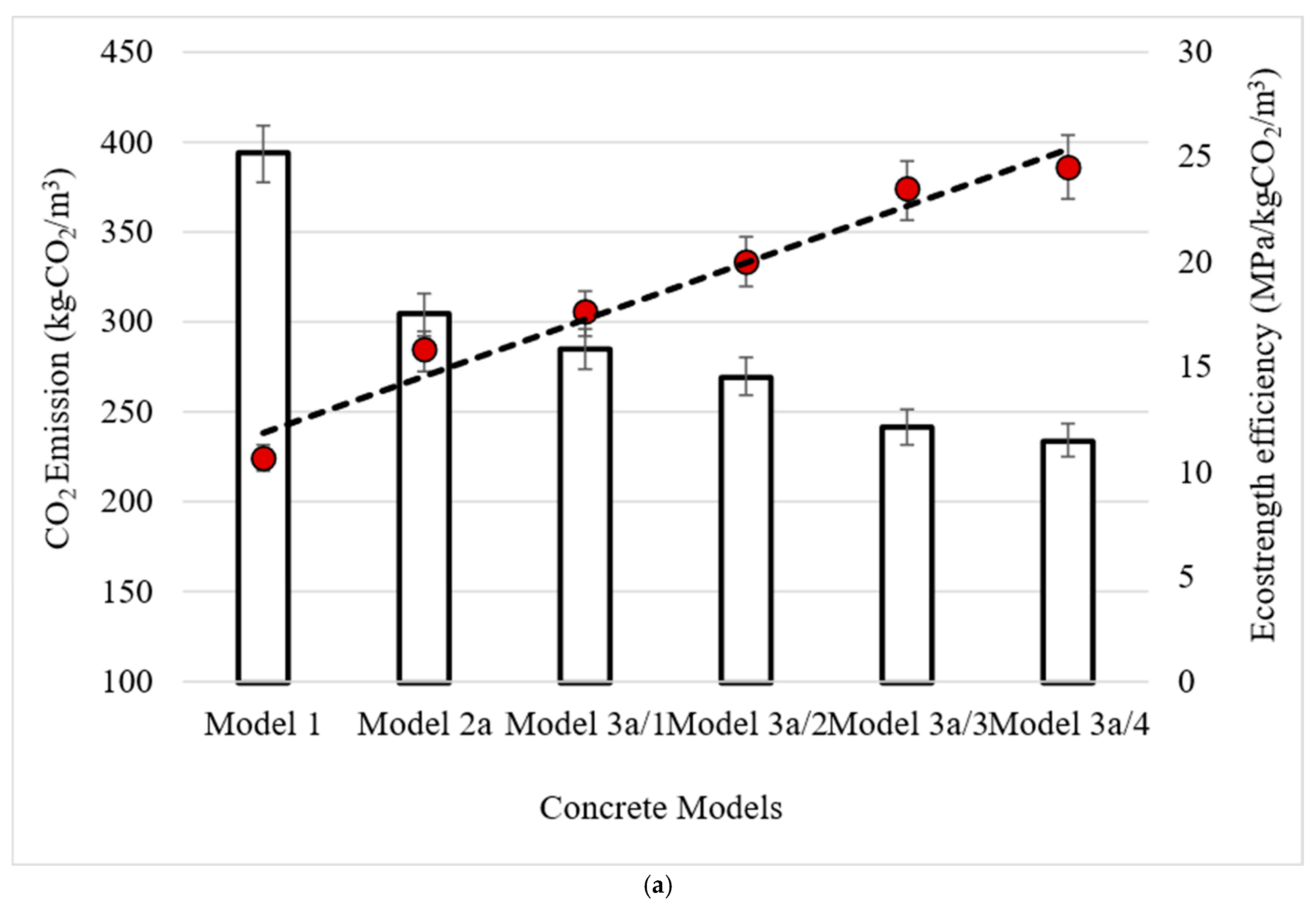

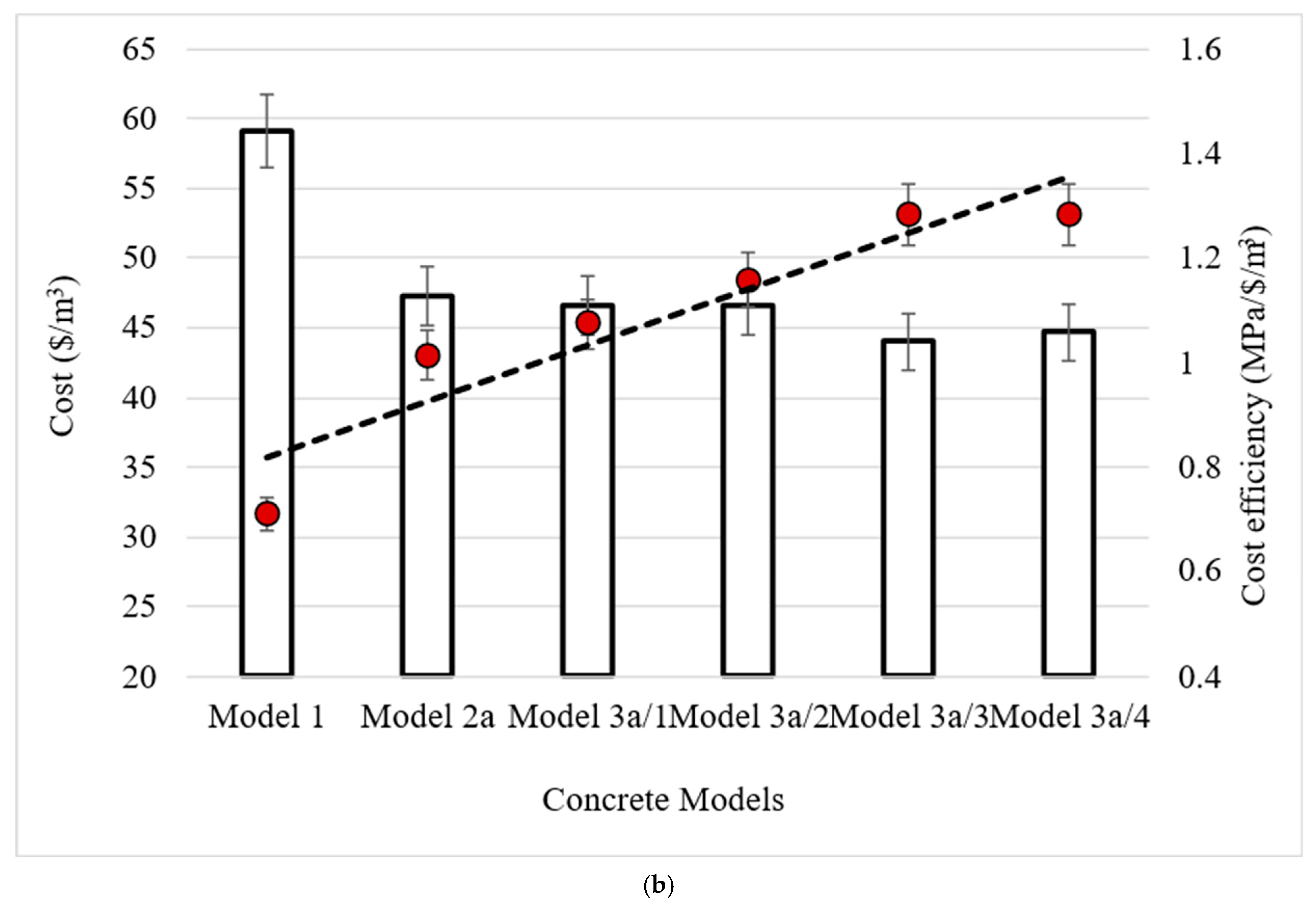

4.2. Sustainability Assessment

4.2.1. RHA Used as Cement Replacement

4.2.2. RHA Used as Sand Replacement

4.2.3. Comparative Analysis of RHA

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- What Is Agriculture’s Share of the Overall U.S. Economy?|Economic Research Service. Available online: https://www.ers.usda.gov/data-products/chart-gallery/chart-detail?chartId=58270&utm_source=chatgpt.com (accessed on 23 June 2025).

- Rice|USDA Foreign Agricultural Service. Available online: https://www.fas.usda.gov/data/production/commodity/0422110 (accessed on 17 April 2025).

- Khassaf, S.I.; Jasim, A.T.; Mahdi, F.K. Investigation the Properties of Concrete Containing Rice Husk Ash to Reduction the Seepage in Canals. Int. J. Sci. Technol. Res. 2014, 3, 348–354. [Google Scholar]

- Muthadhi, A.; Kothandaraman, S. Optimum Production Conditions for Reactive Rice Husk Ash. Mater. Struct. 2010, 43, 1303–1315. [Google Scholar] [CrossRef]

- Khan, R.; Jabbar, A.; Ahmad, I.; Khan, W.; Khan, A.N.; Mirza, J. Reduction in Environmental Problems Using Rice-Husk Ash in Concrete. Constr. Build. Mater. 2012, 30, 360–365. [Google Scholar] [CrossRef]

- Sampaio, D.O.A.; Tashima, M.M.; Costa, D.; Quinteiro, P.; Dias, A.C.; Akasaki, J.L. Evaluation of the Environmental Performance of Rice Husk Ash and Tire Rubber Residues Incorporated in Concrete Slabs. Constr. Build. Mater. 2022, 357, 129332. [Google Scholar] [CrossRef]

- Ahsan, M.B.; Hossain, Z. Supplemental Use of Rice Husk Ash (RHA) as a Cementitious Material in Concrete Industry. Constr. Build. Mater. 2018, 178, 1–9. [Google Scholar] [CrossRef]

- International Agency for Research on Cancer. Silica and Some Silicates. In IARC Monographs on the Evaluation of the Carcinogenic Risk of Chemicals to Humans; International Agency for Research on Cancer: Lyon, France, 1987; Volume 42. [Google Scholar]

- International Agency for Research on Cancer. IARC Monographs on the Evaluation of Carcinogenic Risks to Humans; Solar and Ultraviolet Radiation; International Agency for Research on Cancer: Lyon, France, 1992; Volume 55. [Google Scholar]

- An, D.; Guo, Y.; Zhu, Y.; Wang, Z. A Green Route to Preparation of Silica Powders with Rice Husk Ash and Waste Gas. Chem. Eng. J. 2010, 162, 509–514. [Google Scholar] [CrossRef]

- Wong, S.; Mah, A.X.Y.; Nordin, A.H.; Nyakuma, B.B.; Ngadi, N.; Mat, R.; Amin, N.A.S.; Ho, W.S.; Lee, T.H. Emerging Trends in Municipal Solid Waste Incineration Ashes Research: A Bibliometric Analysis from 1994 to 2018. Environ. Sci. Pollut. Res. 2020, 27, 7757–7784. [Google Scholar] [CrossRef]

- Benassi, L.; Franchi, F.; Catina, D.; Cioffi, F.; Rodella, N.; Borgese, L.; Pasquali, M.; Depero, L.E.; Bontempi, E. Rice Husk Ash to Stabilize Heavy Metals Contained in Municipal Solid Waste Incineration Fly Ash: First Results by Applying New Pre-Treatment Technology. Materials 2015, 8, 6868–6879. [Google Scholar] [CrossRef] [PubMed]

- Oanh, N.T.K. Rice Straw Open Burning: Emissions, Effects and Multiple Benefits of Non-Burning Alternatives. Vietnam J. Sci. Technol. Eng. 2021, 63, 79–85. [Google Scholar] [CrossRef]

- Xu, W.; Huang, J. Utilization of Contaminated Biowaste. In Low Carbon Stabilization and Solidification of Hazardous Wastes; Elsevier: Amsterdam, The Netherlands, 2022; pp. 395–405. [Google Scholar] [CrossRef]

- Wae AbdulKadir, W.A.F.; Che Omar, R.; Shamsudin, M.S. Ammoniacal Nitrogen—A Critical Contaminant in Leachate Composition: Characteristics, Potential Risk, and Adsorption Treatment Innovations. J. Water Process Eng. 2024, 62, 105424. [Google Scholar] [CrossRef]

- CEMBUREAU. Key Facts & Figures; The European Cement Association: Brussels, Belgium, 2024. [Google Scholar]

- Khalil, E.; AbouZeid, M. A Global Assessment Tool for Cement Plants Improvement Measures for the Reduction of CO2 Emissions. Results Eng. 2025, 26, 104767. [Google Scholar] [CrossRef]

- Juenger, M.C.G.; Snellings, R.; Bernal, S.A. Supplementary Cementitious Materials: New Sources, Characterization, and Performance Insights. Cem. Concr. Res. 2019, 122, 257–273. [Google Scholar] [CrossRef]

- Barbhuiya, S.; Das, B.B.; Adak, D.; Kapoor, K.; Tabish, M. Low Carbon Concrete: Advancements, Challenges and Future Directions in Sustainable Construction. Discov. Concr. Cem. 2025, 1, 3. [Google Scholar] [CrossRef]

- Luo, B.; Su, Y.; Ding, X.; Chen, Y.; Liu, C. Modulation of Initial CaO/Al2O3 and SiO2/Al2O3 Ratios on the Properties of Slag/Fly Ash-Based Geopolymer Stabilized Clay: Synergistic Effects and Stabilization Mechanism. Mater. Today Commun. 2025, 47, 113295. [Google Scholar] [CrossRef]

- THE 17 GOALS|Sustainable Development. Available online: https://sdgs.un.org/goals (accessed on 25 June 2025).

- Mosaberpanah, M.A.; Umar, S.A. Utilizing Rice Husk Ash as Supplement to Cementitious Materials on Performance of Ultra High Performance Concrete: A Review. Mater. Today Sustain. 2020, 7–8, 100030. [Google Scholar] [CrossRef]

- Antiohos, S.K.; Papadakis, V.G.; Tsimas, S. Rice Husk Ash (RHA) Effectiveness in Cement and Concrete as a Function of Reactive Silica and Fineness. Cem. Concr. Res. 2014, 61–62, 20–27. [Google Scholar] [CrossRef]

- Al-saffar, F.Y.; Wong, L.S.; Paul, S.C. An Elucidative Review of the Nanomaterial Effect on the Durability and Calcium-Silicate-Hydrate (C-S-H) Gel Development of Concrete. Gels 2023, 9, 613. [Google Scholar] [CrossRef]

- Wang, Z.; Li, B.; Othman, A.; Zhang, Z. Endogenous Alkali Silica Reaction Evaluation of Rice Husk Ash in Mortar. J. Build. Eng. 2023, 75, 106970. [Google Scholar] [CrossRef]

- Madandoust, R.; Ranjbar, M.M.; Moghadam, H.A.; Mousavi, S.Y. Mechanical Properties and Durability Assessment of Rice Husk Ash Concrete. Biosyst. Eng. 2011, 110, 144–152. [Google Scholar] [CrossRef]

- Hwang, C.-L.; Bui, L.A.-T.; Chen, C.-T. Effect of Rice Husk Ash on the Strength and Durability Characteristics of Concrete. Constr. Build. Mater. 2011, 25, 3768–3772. [Google Scholar] [CrossRef]

- Sahoo, S.; Parhi, P.K.; Chandra Panda, B. Durability Properties of Concrete with Silica Fume and Rice Husk Ash. Clean. Eng. Technol. 2021, 2, 100067. [Google Scholar] [CrossRef]

- Gill, A.S.; Siddique, R. Durability Properties of Self-Compacting Concrete Incorporating Metakaolin and Rice Husk Ash. Constr. Build. Mater. 2018, 176, 323–332. [Google Scholar] [CrossRef]

- Muthukrishnan, S.; Gupta, S.; Kua, H.W. Application of Rice Husk Biochar and Thermally Treated Low Silica Rice Husk Ash to Improve Physical Properties of Cement Mortar. Theor. Appl. Fract. Mech. 2019, 104, 102376. [Google Scholar] [CrossRef]

- Jindal, A.; Ransinchung, G.D. Behavioural Study of Pavement Quality Concrete Containing Construction, Industrial and Agricultural Wastes. Int. J. Pavement Res. Technol. 2018, 11, 488–501. [Google Scholar] [CrossRef]

- Fernandes, I.J.; Calheiro, D.; Kieling, A.G.; Moraes, C.A.M.; Rocha, T.L.A.C.; Brehm, F.A.; Modolo, R.C.E. Characterization of Rice Husk Ash Produced Using Different Biomass Combustion Techniques for Energy. Fuel 2016, 165, 351–359. [Google Scholar] [CrossRef]

- Nair, D.G.; Fraaij, A.; Klaassen, A.A.K.; Kentgens, A.P.M. A Structural Investigation Relating to the Pozzolanic Activity of Rice Husk Ashes. Cem. Concr. Res. 2008, 38, 861–869. [Google Scholar] [CrossRef]

- Zhang, J.X.; Guo, Y.T.; Zhuang, S.Y.; Lou, H.Q.; Li, Y. The Effect of Adding Rice Husk Ash (RHA) and Calcined Shell Powder (CSP) on the Properties of Cement Mortar. Case Stud. Constr. Mater. 2025, 22, e04426. [Google Scholar] [CrossRef]

- Kang, S.H.; Hong, S.G.; Moon, J. The Use of Rice Husk Ash as Reactive Filler in Ultra-High Performance Concrete. Cem. Concr. Res. 2019, 115, 389–400. [Google Scholar] [CrossRef]

- Saraswathy, V.; Song, H.W. Corrosion Performance of Rice Husk Ash Blended Concrete. Constr. Build. Mater. 2007, 21, 1779–1784. [Google Scholar] [CrossRef]

- Safiuddin, M.; West, J.S.; Soudki, K.A. Hardened Properties of Self-Consolidating High Performance Concrete Including Rice Husk Ash. Cem. Concr. Compos. 2010, 32, 708–717. [Google Scholar] [CrossRef]

- Ali, T.; Saand, A.; Khan Bangwar, D.; Salam Buller, A.; Ahmed, Z.; Ali, T.; Saand, A.; Bangwar, D.K.; Buller, A.S.; Ahmed, Z.; et al. Mechanical and Durability Properties of Aerated Concrete Incorporating Rice Husk Ash (RHA) as Partial Replacement of Cement. Crystals 2021, 11, 604. [Google Scholar] [CrossRef]

- Ma, W.; Lv, B.; Wang, Y.; Huang, L.; Yan, L.; Kasal, B. Freeze-Thaw, Chloride Penetration and Carbonation Resistance of Natural and Recycled Aggregate Concrete Containing Rice Husk Ash as Replacement of Cement. J. Build. Eng. 2024, 86, 108889. [Google Scholar] [CrossRef]

- Hamada, H.M.; Abed, F.; Binti Katman, H.Y.; Humada, A.M.; Al Jawahery, M.S.; Majdi, A.; Yousif, S.T.; Thomas, B.S. Effect of Silica Fume on the Properties of Sustainable Cement Concrete. J. Mater. Res. Technol. 2023, 24, 8887–8908. [Google Scholar] [CrossRef]

- Sua-iam, G.; Makul, N. Effect of Limestone Powder on the Properties of Self-Consolidating Concrete Mixed with Rice Husk Ash. Res. Dev. J. 2012, 23, 18–26. [Google Scholar]

- Chopra, D.; Siddique, R. Kunal Strength, Permeability and Microstructure of Self-Compacting Concrete Containing Rice Husk Ash. Biosyst. Eng. 2015, 130, 72–80. [Google Scholar] [CrossRef]

- Khan, A.Q.; Muhammad, S.G.; Raza, A.; Pimanmas, A. Advanced Machine Learning Techniques for Predicting Mechanical Properties of Eco-Friendly Self-Compacting Concrete. J. Road Eng. 2025, 5, 213–229. [Google Scholar] [CrossRef]

- Miao, X.; Zhu, J.X.; Zhu, W.B.; Wang, Y.; Peng, L.; Le Dong, H.; Xu, L.Y. Intelligent Prediction of Comprehensive Mechanical Properties of Recycled Aggregate Concrete with Supplementary Cementitious Materials Using Hybrid Machine Learning Algorithms. Case Stud. Constr. Mater. 2024, 21, e03708. [Google Scholar] [CrossRef]

- Alaneme, G.U.; Olonade, K.A.; Esenogho, E.; Lawan, M.M.; Dintwa, E. Artificial Intelligence Prediction of the Mechanical Properties of Banana Peel-Ash and Bagasse Blended Geopolymer Concrete. Sci. Rep. 2024, 14, 26151. [Google Scholar] [CrossRef]

- Fu, K.; Xue, Y.; Qiu, D.; Wang, P.; Lu, H. Multi-Channel Fusion Prediction of TBM Tunneling Thrust Based on Multimodal Decomposition and Reconstruction. Tunn. Undergr. Space Technol. 2026, 167, 107061. [Google Scholar] [CrossRef]

- Niu, Y.; Wang, W.; Su, Y.; Jia, F.; Long, X. Plastic Damage Prediction of Concrete under Compression Based on Deep Learning. Acta Mech. 2024, 235, 255–266. [Google Scholar] [CrossRef]

- Ozturk, E.; Ince, C.; Derogar, S.; Ball, R. Factors Affecting the CO2 Emissions, Cost Efficiency and Eco-Strength Efficiency of Concrete Containing Rice Husk Ash: A Database Study. Constr. Build. Mater. 2022, 326, 126905. [Google Scholar] [CrossRef]

- Nwaokete, D.; Ince, C.; Derogar, S.; Nicolaides, D.; Ball, R.J. Environmental Impact and Sustainable Development of Pozzolanic Concrete Incorporating Polypropylene Fibers: A Database Study. Resour. Conserv. Recycl. 2025, 215, 108142. [Google Scholar] [CrossRef]

- Tural, H.G.; Ozarisoy, B.; Derogar, S.; Ince, C. Investigating the Governing Factors Influencing the Pozzolanic Activity through a Database Approach for the Development of Sustainable Cementitious Materials. Constr. Build. Mater. 2024, 411, 134253. [Google Scholar] [CrossRef]

- Collins, F. Inclusion of Carbonation during the Life Cycle of Built and Recycled Concrete: Influence on Their Carbon Footprint. Int. J. Life Cycle Assess. 2010, 15, 549–556. [Google Scholar] [CrossRef]

- Turner, L.K.; Collins, F.G. Carbon Dioxide Equivalent (CO2-e) Emissions: A Comparison between Geopolymer and OPC Cement Concrete. Constr. Build. Mater. 2013, 43, 125–130. [Google Scholar] [CrossRef]

- Diego, M.E.; Arias, B.; Abanades, J.C. Analysis of a Double Calcium Loop Process Configuration for CO2 Capture in Cement Plants. J. Clean. Prod. 2016, 117, 110–121. [Google Scholar] [CrossRef]

- Geng, Y.; Wang, Z.; Shen, L.; Zhao, J. Calculating of CO2 Emission Factors for Chinese Cement Production Based on Inorganic Carbon and Organic Carbon. J. Clean. Prod. 2019, 217, 503–509. [Google Scholar] [CrossRef]

- Debbarma, S.; Ransinchung, G.D.; Singh, S.; Sahdeo, S.K. Utilization of Industrial and Agricultural Wastes for Productions of Sustainable Roller Compacted Concrete Pavement Mixes Containing Reclaimed Asphalt Pavement Aggregates. Resour. Conserv. Recycl. 2020, 152, 104504. [Google Scholar] [CrossRef]

- Sheheryar, M.; Rehan, R.; Nehdi, M.L. Estimating CO2 Emission Savings from Ultrahigh Performance Concrete: A System Dynamics Approach. Materials 2021, 14, 995. [Google Scholar] [CrossRef]

- Huntzinger, D.N.; Eatmon, T.D. A Life-Cycle Assessment of Portland Cement Manufacturing: Comparing the Traditional Process with Alternative Technologies. J. Clean. Prod. 2009, 17, 668–675. [Google Scholar] [CrossRef]

- Benhelal, E.; Zahedi, G.; Shamsaei, E.; Bahadori, A. Global Strategies and Potentials to Curb CO2 Emissions in Cement Industry. J. Clean. Prod. 2013, 51, 142–161. [Google Scholar] [CrossRef]

- Huang, W.; Kazemi-Kamyab, H.; Sun, W.; Scrivener, K. Effect of Replacement of Silica Fume with Calcined Clay on the Hydration and Microstructural Development of Eco-UHPFRC. Mater. Des. 2017, 121, 36–46. [Google Scholar] [CrossRef]

- Murmu, A.L.; Dhole, N.; Patel, A. Stabilisation of Black Cotton Soil for Subgrade Application Using Fly Ash Geopolymer. Road Mater. Pavement Des. 2020, 21, 867–885. [Google Scholar] [CrossRef]

- Flower, D.J.M.; Sanjayan, J.G. Green House Gas Emissions Due to Concrete Manufacture. Int. J. Life Cycle Assess. 2007, 12, 282–288. [Google Scholar] [CrossRef]

- Quattrone, M.; Angulo, S.C.; John, V.M. Energy and CO2 from High Performance Recycled Aggregate Production. Resour. Conserv. Recycl. 2014, 90, 21–33. [Google Scholar] [CrossRef]

- Turk, J.; Cotič, Z.; Mladenovič, A.; Šajna, A. Environmental Evaluation of Green Concretes versus Conventional Concrete by Means of LCA. Waste Manag. 2015, 45, 194–205. [Google Scholar] [CrossRef]

- Alnahhal, M.F.; Alengaram, U.J.; Jumaat, M.Z.; Abutaha, F.; Alqedra, M.A.; Nayaka, R.R. Assessment on Engineering Properties and CO2 Emissions of Recycled Aggregate Concrete Incorporating Waste Products as Supplements to Portland Cement. J. Clean. Prod. 2018, 203, 822–835. [Google Scholar] [CrossRef]

- Shackley, S.; Carter, S.; Knowles, T.; Middelink, E.; Haefele, S.; Sohi, S.; Cross, A.; Haszeldine, S. Sustainable Gasification–Biochar Systems? A Case-Study of Rice-Husk Gasification in Cambodia, Part I: Context, Chemical Properties, Environmental and Health and Safety Issues. Energy Policy 2012, 42, 49–58. [Google Scholar] [CrossRef]

- Yang, K.H.; Seo, E.A.; Tae, S.H. Carbonation and CO2 Uptake of Concrete. Environ. Impact Assess. Rev. 2014, 46, 43–52. [Google Scholar] [CrossRef]

- King, D. The Effect of Silica Fume on the Properties of Concrete as Defined in Concrete Society Report 74, Cementitious Materials. In Proceedings of the 37th Conference on our world in concrete and structures, Singapore, 29–31 August 2012; pp. 29–31. [Google Scholar]

- Hammond, G.P.; Jones, C.I. Embodied Energy and Carbon in Construction Materials. Proc. Inst. Civ. Eng. Energy 2008, 161, 87–98. [Google Scholar] [CrossRef]

- Cassagnabère, F.; Mouret, M.; Escadeillas, G.; Broilliard, P.; Bertrand, A. Metakaolin, a Solution for the Precast Industry to Limit the Clinker Content in Concrete: Mechanical Aspects. Constr. Build. Mater. 2010, 24, 1109–1118. [Google Scholar] [CrossRef]

- Heath, A.; Paine, K.; McManus, M. Minimising the Global Warming Potential of Clay Based Geopolymers. J. Clean. Prod. 2014, 78, 75–83. [Google Scholar] [CrossRef]

- Campos, H.F.; Klein, N.S.; Marques Filho, J.; Bianchini, M. Low-Cement High-Strength Concrete with Partial Replacement of Portland Cement with Stone Powder and Silica Fume Designed by Particle Packing Optimization. J. Clean. Prod. 2020, 261, 121228. [Google Scholar] [CrossRef]

- Ince, C.; Derogar, S.; Gurkaya, K.; Ball, R.J. Properties, Durability and Cost Efficiency of Cement and Hydrated Lime Mortars Reusing Copper Mine Tailings of Lefke-Xeros in Cyprus. Constr. Build. Mater. 2021, 268, 121070. [Google Scholar] [CrossRef]

- Ayasgil, D.; Ince, C.; Derogar, S.; Ball, R.J. The Long-Term Engineering Properties and Sustainability Indices of Dewatering Hydrated Lime Mortars through Jacaranda Seed Pods. Sustain. Mater. Technol. 2022, 32, e00435. [Google Scholar] [CrossRef]

- Black, L. Low Clinker Cement as a Sustainable Construction Material. In Sustainability of Construction Materials; Elsevier: Amsterdam, The Netherlands, 2016; pp. 415–457. [Google Scholar] [CrossRef]

- Danjuma, T.; Yohanna Adamu, A.; Mbishida, M.A.; Yusuf Mailafiya, B.; Building, N. Assessment of Concrete Elements of A Collapsed Building Using Ultrasonic Pulse Velocity Test. SSRG Int. J. Recent Eng. Sci. 2021, 8, 16–19. [Google Scholar] [CrossRef]

- Hasbullah, M.A.; Yusof, R.; Rahman, M.N.Y.A. Evaluating the Strength of Concrete Structure on Terrace Houses. AIP Conf. Proc. 2016, 1761, 020043. [Google Scholar] [CrossRef]

- Pathak, N.; Siddique, R. Properties of Self-Compacting-Concrete Containing Fly Ash Subjected to Elevated Temperatures. Constr. Build. Mater. 2012, 30, 274–280. [Google Scholar] [CrossRef]

- ASTM C 1202-97; Standard Test Method for Electrical Indication of Concrete’s Ability to Resist Chloride Ion Penetration 1. ASTM International: West Conshohocken, PA, USA, 2006; Volume 4.

- Kannan, V.; Ganesan, K. Chloride and Chemical Resistance of Self Compacting Concrete Containing Rice Husk Ash and Metakaolin. Constr. Build. Mater. 2014, 51, 225–234. [Google Scholar] [CrossRef]

- Chatveera, B.; Lertwattanaruk, P. Durability of Conventional Concretes Containing Black Rice Husk Ash. J. Environ. Manag. 2011, 92, 59–66. [Google Scholar] [CrossRef]

- Ganesan, K.; Rajagopal, K.; Thangavel, K. Rice Husk Ash Blended Cement: Assessment of Optimal Level of Replacement for Strength and Permeability Properties of Concrete. Constr. Build. Mater. 2008, 22, 1675–1683. [Google Scholar] [CrossRef]

- Ambedkar, B.; Alex, J.; Dhanalakshmi, J. Enhancement of Mechanical Properties and Durability of the Cement Concrete by RHA as Cement Replacement: Experiments and Modeling. Constr. Build. Mater. 2017, 148, 167–175. [Google Scholar] [CrossRef]

- Koushkbaghi, M.; Kazemi, M.J.; Mosavi, H.; Mohseni, E. Acid Resistance and Durability Properties of Steel Fiber-Reinforced Concrete Incorporating Rice Husk Ash and Recycled Aggregate. Constr. Build. Mater. 2019, 202, 266–275. [Google Scholar] [CrossRef]

- Siddika, A.; Al Mamun, M.A.; Alyousef, R.; Mohammadhosseini, H. State-of-the-Art-Review on Rice Husk Ash: A Supplementary Cementitious Material in Concrete. J. King Saud. Univ.-Eng. Sci. 2021, 33, 294–307. [Google Scholar] [CrossRef]

- Balapour, M.; Ramezanianpour, A.A.; Hajibandeh, E. An Investigation on Mechanical and Durability Properties of Mortars Containing Nano and Micro RHA. Constr. Build. Mater. 2017, 132, 470–477. [Google Scholar] [CrossRef]

- Kaur, R.; Kothiyal, N.C.; Arora, H. Studies on Combined Effect of Superplasticizer Modified Graphene Oxide and Carbon Nanotubes on the Physico-Mechanical Strength and Electrical Resistivity of Fly Ash Blended Cement Mortar. J. Build. Eng. 2020, 30, 101304. [Google Scholar] [CrossRef]

- Rao, S.K.; Sravana, P.; Rao, T.C. Experimental Studies in Ultrasonic Pulse Velocity of Roller Compacted Concrete Pavement Containing Fly Ash and M-Sand. Int. J. Pavement Res. Technol. 2016, 9, 289–301. [Google Scholar] [CrossRef]

- Rum, R.H.M.; Jaini, Z.M.; Boon, K.H.; Khairaddin, S.A.A.; Rahman, N.A. Foamed Concrete Containing Rice Husk Ash as Sand Replacement: An Experimental Study on Compressive Strength. IOP Conf. Ser. Mater. Sci. Eng. 2017, 271, 012012. [Google Scholar] [CrossRef]

- Albiajawi, M.I.; Embong, R.; Muthusamy, K. An Overview of the Utilization and Method for Improving Pozzolanic Performance of Agricultural and Industrial Wastes in Concrete. Mater. Today Proc. 2022, 48, 778–783. [Google Scholar] [CrossRef]

- Mohamad, N.; Lakhiar, M.T.; Samad, A.A.A.; Mydin, M.A.O.; Jhatial, A.A.; Sofia, S.A.; Goh, W.I.; Ali, N. Innovative and Sustainable Green Concrete—A Potential Review on Utilization of Agricultural Waste. IOP Conf. Ser. Mater. Sci. Eng. 2019, 601, 012026. [Google Scholar] [CrossRef]

- Edwards, D.D.; Allen, G.C.; Ball, R.J.; El-Turki, A. Pozzolanic Properties of Glass Fines in Lime Mortars. Adv. Appl. Ceram. 2007, 106, 309–313. [Google Scholar] [CrossRef]

- Gursel, A.P.; Maryman, H.; Ostertag, C. A life-cycle approach to environmental, mechanical, and durability properties of “green” concrete mixes with rice husk ash. J. Clean. Prod. 2016, 112, 823–836. [Google Scholar] [CrossRef]

- Le, H.T.; Nguyen, S.T.; Ludwig, H.M. A study on high performance fine-grained concrete containing rice husk ash. Int. J. Concr. Struct. Mater. 2014, 8, 301–307. [Google Scholar] [CrossRef]

- Givi, A.N.; Rashid, S.A.; Aziz, F.N.A.; Salleh, M.A.M. Assessment of the effects of rice husk ash particle size on strength, water permeability and workability of binary blended concrete. Constr. Build. Mater. 2010, 24, 2145–2150. [Google Scholar] [CrossRef]

- Makul, N. Combined use of untreated-waste rice husk ash and foundry sand waste in high-performance self-consolidating concrete. Results Mater. 2019, 1, 100014. [Google Scholar] [CrossRef]

- Sathawane, S.H.; Vairagade, V.S.; Kene, K.S. Combine effect of rice husk ash and fly ash on concrete by 30% cement replacement. Procedia Eng. 2013, 51, 35–44. [Google Scholar] [CrossRef]

- Salas, A.; Delvasto, S.; de Gutierrez, R.M.; Lange, D. Comparison of two processes for treating rice husk ash for use in high performance concrete. Cem. Concr. Res. 2009, 39, 773–778. [Google Scholar] [CrossRef]

- Zerbino, R.; Giaccio, G.; Isaia, G.C. Concrete incorporating rice-husk ash without processing. Constr. Build. Mater. 2011, 25, 371–378. [Google Scholar] [CrossRef]

- Makul, N.; Sua-iam, G. Effect of granular urea on the properties of self-consolidating concrete incorporating untreated rice husk ash: Flowability, compressive strength and temperature rise. Constr. Build. Mater. 2018, 162, 489–502. [Google Scholar] [CrossRef]

- Venkatanarayanan, H.K.; Rangaraju, P.R. Effect of grinding of low-carbon rice husk ash on the microstructure and performance properties of blended cement concrete. Cem. Concr. Compos. 2015, 55, 348–363. [Google Scholar] [CrossRef]

- Le, H.T.; Ludwig, H.M. Effect of rice husk ash and other mineral admixtures on properties of self-compacting high performance concrete. Mater. Des. 2016, 89, 156–166. [Google Scholar] [CrossRef]

- Talsania, S.; Pitroda, J.; Vyas, C.M. Effect of rice husk ash on properties of pervious concrete. Int. J. Adv. Eng. Res. Stud. 2015, 296, 299. [Google Scholar]

- Mahmud, H.B.; Bahri, S.; Yee, Y.W.; Yeap, Y.T. Effect of rice husk ash on strength and durability of high strength high performance concrete. Int. J. Civil. Environ. Eng. 2016, 10, 390–395. [Google Scholar]

- Lertwattanaruk, P.; Sua-Iam, G.; Makul, N. Effects of calcium carbonate powder on the fresh and hardened properties of self-consolidating concrete incorporating untreated rice husk ash. J. Clean. Prod. 2018, 172, 3265–3278. [Google Scholar] [CrossRef]

- Olutoge, F.A.; Adesina, P.A. Effects of rice husk ash prepared from charcoal-powered incinerator on the strength and durability properties of concrete. Constr. Build. Mater. 2019, 196, 386–394. [Google Scholar] [CrossRef]

- Foong, K.Y.; Alengaram, U.J.; Jumaat, M.Z.; Mo, K.H. Enhancement of the mechanical properties of lightweight oil palm shell concrete using rice husk ash and manufactured sand. J. Zhejiang Univ.-Sci. A 2015, 16, 59–69. [Google Scholar] [CrossRef]

- Patel, Y.J.; Shah, N. Enhancement of the properties of ground granulated blast furnace slag based self compacting geopolymer concrete by incorporating rice husk ash. Constr. Build. Mater. 2018, 171, 654–662. [Google Scholar] [CrossRef]

- Chatveera, B.; Lertwattanaruk, P. Evaluation of nitric and acetic acid resistance of cement mortars containing high-volume black rice husk ash. J. Environ. Manag. 2014, 133, 365–373. [Google Scholar] [CrossRef]

- Chatveera, B.; Lertwattanaruk, P. Evaluation of sulfate resistance of cement mortars containing black rice husk ash. J. Environ. Manag. 2009, 90, 1435–1441. [Google Scholar] [CrossRef]

- Cordeiro, G.C.; Toledo Filho, R.D.; Tavares, L.M.; Fairbairn, E.M.R. Experimental characterization of binary and ternary blended-cement concretes containing ultrafine residual rice husk and sugar cane bagasse ashes. Constr. Build. Mater. 2012, 29, 641–646. [Google Scholar] [CrossRef]

- Zareei, S.A.; Ameri, F.; Bahrami, N.; Dorostkar, F. Experimental evaluation of eco-friendly light weight concrete with optimal level of rice husk ash replacement. Civ. Eng. J. 2017, 3, 972. [Google Scholar] [CrossRef]

- Muthadhi, A.; Kothandaraman, S. Experimental investigations of performance characteristics of rice husk ash–blended concrete. J. Mater. Civ. Eng. 2013, 25, 1115–1118. [Google Scholar] [CrossRef]

- Gastaldini, A.L.G.; Isaia, G.C.; Saciloto, A.P.; Missau, F.; Hoppe, T.F. Influence of curing time on the chloride penetration resistance of concrete containing rice husk ash: A technical and economical feasibility study. Cem. Concr. Compos. 2010, 32, 783–793. [Google Scholar] [CrossRef]

- Padhi, R.S.; Patra, R.K.; Mukharjee, B.B.; Dey, T. Influence of incorporation of rice husk ash and coarse recycled concrete aggregates on properties of concrete. Constr. Build. Mater. 2018, 173, 289–297. [Google Scholar] [CrossRef]

- Kunchariyakun, K.; Asavapisit, S.; Sinyoung, S. Influence of partial sand replacement by black rice husk ash and bagasse ash on properties of autoclaved aerated concrete under different temperatures and times. Constr. Build. Mater. 2018, 173, 220–227. [Google Scholar] [CrossRef]

- Huang, H.; Gao, X.; Wang, H.; Ye, H. Influence of rice husk ash on strength and permeability of ultra-high performance concrete. Constr. Build. Mater. 2017, 149, 621–628. [Google Scholar] [CrossRef]

- Raisi, E.M.; Amiri, J.V.; Davoodi, M.R. Influence of rice husk ash on the fracture characteristics and brittleness of self-compacting concrete. Eng. Fract. Mech. 2018, 199, 595–608. [Google Scholar] [CrossRef]

- Tangchirapat, W.; Buranasing, R.; Jaturapitakkul, C.; Chindaprasirt, P. Influence of rice husk–bark ash on mechanical properties of concrete containing high amount of recycled aggregates. Constr. Build. Mater. 2008, 22, 1812–1819. [Google Scholar] [CrossRef]

- Gastaldini, A.L.G.; Isaia, G.C.; Hoppe, T.F.; Missau, F.; Saciloto, A.P. Influence of the use of rice husk ash on the electrical resistivity of concrete: A technical and economic feasibility study. Constr. Build. Mater. 2009, 23, 3411–3419. [Google Scholar] [CrossRef]

- Horsakulthai, V.; Phiuvanna, S.; Kaenbud, W. Investigation on the corrosion resistance of bagasse-rice husk-wood ash blended cement concrete by impressed voltage. Constr. Build. Mater. 2011, 25, 54–60. [Google Scholar] [CrossRef]

- Bahri, S.; Mahmud, H.B.; Shafigh, P.; Majuar, E. Mechanical and durability properties of high strength high performance concrete incorporating rice husk ash. IOP Conf. Ser. Mater. Sci. Eng. 2019, 536, 012028. [Google Scholar] [CrossRef]

- Raisi, E.M.; Amiri, J.V.; Davoodi, M.R. Mechanical performance of self-compacting concrete incorporating rice husk ash. Constr. Build. Mater. 2018, 177, 148–157. [Google Scholar] [CrossRef]

- Mahmud, H.B.; Malik, M.F.A.; Kahar, R.A.; Zain, M.F.M.; Raman, S.N. Mechanical properties and durability of normal and water reduced high strength grade 60 concrete containing rice husk ash. J. Adv. Concr. Technol. 2009, 7, 21–30. [Google Scholar] [CrossRef]

- Madandoust, R.; Ghavidel, R. Mechanical properties of concrete containing waste glass powder and rice husk ash. Biosyst. Eng. 2013, 116, 113–119. [Google Scholar] [CrossRef]

- Modarres, A.; Hosseini, Z. Mechanical properties of roller compacted concrete containing rice husk ash with original and recycled asphalt pavement material. Mater. Des. 2014, 64, 227–236. [Google Scholar] [CrossRef]

- Sua-iam, G.; Sokrai, P.; Makul, N. Novel ternary blends of Type 1 Portland cement, residual rice husk ash, and limestone powder to improve the properties of self-compacting concrete. Constr. Build. Mater. 2016, 125, 1028–1034. [Google Scholar] [CrossRef]

- Ameri, F.; Shoaei, P.; Bahrami, N.; Vaezi, M.; Ozbakkaloglu, T. Optimum rice husk ash content and bacterial concentration in self-compacting concrete. Constr. Build. Mater. 2019, 222, 796–813. [Google Scholar] [CrossRef]

- Bui, D.D.; Hu, J.; Stroeven, P. Particle size effect on the strength of rice husk ash blended gap-graded Portland cement concrete. Cem. Concr. Compos. 2005, 27, 357–366. [Google Scholar] [CrossRef]

- Nehdi, M.; Duquette, J.; El Damatty, A. Performance of rice husk ash produced using a new technology as a mineral admixture in concrete. Cem. Concr. Res. 2003, 33, 1203–1210. [Google Scholar] [CrossRef]

- Siddique, R.; Singh, K.; Singh, M.; Corinaldesi, V.; Rajor, A. Properties of bacterial rice husk ash concrete. Constr. Build. Mater. 2016, 121, 112–119. [Google Scholar] [CrossRef]

- Zareei, S.A.; Ameri, F.; Dorostkar, F.; Ahmadi, M. Rice husk ash as a partial replacement of cement in high strength concrete containing micro silica: Evaluating durability and mechanical properties. Case Stud. Constr. Mater. 2017, 7, 73–81. [Google Scholar] [CrossRef]

- Zhang, M.H.; Lastra, R.; Malhotra, V.M. Rice-husk ash paste and concrete: Some aspects of hydration and the microstructure of the interfacial zone between the aggregate and paste. Cem. Concr. Res. 1996, 26, 963–977. [Google Scholar] [CrossRef]

- Rahman, M.E.; Muntohar, A.S.; Pakrashi, V.; Nagaratnam, B.H.; Sujan, D. Self compacting concrete from uncontrolled burning of rice husk and blended fine aggregate. Mater. Des. 2014, 55, 410–415. [Google Scholar] [CrossRef]

- Kannan, V. Strength and durability performance of self compacting concrete containing self-combusted rice husk ash and metakaolin. Constr. Build. Mater. 2018, 160, 169–179. [Google Scholar] [CrossRef]

- Gill, A.S.; Siddique, R. Strength and micro-structural properties of self-compacting concrete containing metakaolin and rice husk ash. Constr. Build. Mater. 2017, 157, 51–64. [Google Scholar] [CrossRef]

- Abalaka, A.E. Strength and some durability properties of concrete containing rice husk ash produced in a charcoal incinerator at low specific surface. Int. J. Concr. Struct. Mater. 2013, 7, 287–293. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Homwuttiwong, S.; Jaturapitakkul, C. Strength and water permeability of concrete containing palm oil fuel ash and rice husk–bark ash. Constr. Build. Mater. 2007, 21, 1492–1499. [Google Scholar] [CrossRef]

- de Sensale, G.R. Strength development of concrete with rice-husk ash. Cem. Concr. Compos. 2006, 28, 158–160. [Google Scholar] [CrossRef]

- Praveenkumar, T.R.; Vijayalakshmi, M.M.; Meddah, M.S. Strengths and durability performances of blended cement concrete with TiO2 nanoparticles and rice husk ash. Constr. Build. Mater. 2019, 217, 343–351. [Google Scholar] [CrossRef]

- Gastaldini, A.L.G.; Da Silva, M.P.; Zamberlan, F.B.; Neto, C.M. Total shrinkage, chloride penetration, and compressive strength of concretes that contain clear-colored rice husk ash. Constr. Build. Mater. 2014, 54, 369–377. [Google Scholar] [CrossRef]

- Cordeiro, G.C.; Toledo Filho, R.D.; de Moraes Rego Fairbairn, E. Use of ultrafine rice husk ash with high-carbon content as pozzolan in high performance concrete. Mater. Struct. 2009, 42, 983–992. [Google Scholar] [CrossRef]

- Sua-iam, G.; Makul, N. Use of unprocessed rice husk ash and pulverized fuel ash in the production of self-compacting concrete. IERI Procedia 2013, 5, 298–303. [Google Scholar] [CrossRef]

- Anwar, M.; Miyagawa, T.; Gaweesh, M. Using Rice Husk Ash as a Cement Replacement Material in Concrete; Waste Management Series; Elsevier: Amsterdam, The Netherlands, 2000; Volume 1, pp. 671–684. [Google Scholar]

- Sua-iam, G.; Makul, N. Utilization of high volumes of unprocessed lignite-coal fly ash and rice husk ash in self-consolidating concrete. J. Clean. Prod. 2014, 78, 184–194. [Google Scholar] [CrossRef]

- Sua-Iam, G.; Makul, N. Utilization of limestone powder to improve the properties of self-compacting concrete incorporating high volumes of untreated rice husk ash as fine aggregate. Constr. Build. Mater. 2013, 38, 455–464. [Google Scholar] [CrossRef]

- Chalee, W.; Sasakul, T.; Suwanmaneechot, P.; Jaturapitakkul, C. Utilization of rice husk–bark ash to improve the corrosion resistance of concrete under 5-year exposure in a marine environment. Cem. Concr. Compos. 2013, 37, 47–53. [Google Scholar] [CrossRef]

- Sua-iam, G.; Makul, N.; Cheng, S.; Sokrai, P. Workability and compressive strength development of self-consolidating concrete incorporating rice husk ash and foundry sand waste–A preliminary experimental study. Constr. Build. Mater. 2019, 228, 116813. [Google Scholar] [CrossRef]

- Rattanachu, P.; Toolkasikorn, P.; Tangchirapat, W.; Chindaprasirt, P.; Jaturapitakkul, C. Performance of recycled aggregate concrete with rice husk ash as cement binder. Cem. Concr. Compos. 2020, 108, 103533. [Google Scholar] [CrossRef]

- Kusbiantoro, A.; Nuruddin, M.F.; Shafiq, N.; Qazi, S.A. The effect of microwave incinerated rice husk ash on the compressive and bond strength of fly ash based geopolymer concrete. Constr. Build. Mater. 2012, 36, 695–703. [Google Scholar] [CrossRef]

- Krishna, N.K.; Sandeep, S.; Mini, K.M. Study on concrete with partial replacement of cement by rice husk ash. IOP Conf. Ser. Mater. Sci. Eng. 2016, 149, 012109. [Google Scholar] [CrossRef]

- Bansal, S.; Antil, Y. Effect of rice husk on compressive strength of concrete. Int. J. Emerg. Technol. 2015, 6, 144. [Google Scholar]

- Prayuda, H.; Monika, F.; Cahyati, M.D. Fresh properties and compressive strength of self compacting concrete with fines aggregate replacement using red brick powder and rice husk ash. World J. Eng. 2020, 17, 473–480. [Google Scholar] [CrossRef]

- Zubairu, I.; Ibrahim, H.; Kabir, N. Investigation into the use of rice husk ash and local dye residue (Katsi) as partial replacement for cement. Glob. Sci. J. 2018, 6, 106–115. [Google Scholar]

- Deepa, N.G.; Sivaraman, K.; Job, T. Mechanical Properties of Rice Husk Ash (RHA)-High Strength Concrete. 2013. Available online: https://dyuthi.cusat.ac.in/xmlui/handle/purl/4643 (accessed on 13 August 2021).

- Hussain, Z.; Noor, N.M.; Caronge, M.A. Workability and compressive strength of seawater-mixed concrete containing rice husk ash as supplementary cementitious material. Int. J. Integr. Eng. 2019, 11, 192–200. [Google Scholar]

- Amin, M.N.; Hissan, S.; Shahzada, K.; Khan, K.; Bibi, T. Pozzolanic reactivity and the influence of rice husk ash on early-age autogenous shrinkage of concrete. Front. Mater. 2019, 6, 150. [Google Scholar] [CrossRef]

- Vieira, A.P.; Toledo Filho, R.D.; Tavares, L.M.; Cordeiro, G.C. Effect of particle size, porous structure and content of rice husk ash on the hydration process and compressive strength evolution of concrete. Constr. Build. Mater. 2020, 236, 117553. [Google Scholar] [CrossRef]

- Das, S.K.; Mishra, J.; Singh, S.K.; Mustakim, S.M.; Patel, A.; Das, S.K.; Behera, U. Characterization and utilization of rice husk ash (RHA) in fly ash–Blast furnace slag based geopolymer concrete for sustainable future. Mater. Today: Proc. 2020, 33, 5162–5167. [Google Scholar] [CrossRef]

- Lun, L.T. Effects of Rice Husk Ash (RHA) Produced From Different Temperatures on The Performance of Concrete; Universiti Tunku Abdul Rahman: Kampar, Malaysia, 2015. [Google Scholar]

- Brown, D.K. Unprocessed Rice Husk Ash as a Partial Replacement of Cement for Low-Cost Concrete. Ph.D. Thesis, Massachusetts Institute of Technology, Boston, MA, USA, 2012. [Google Scholar]

| Model | Sub-Model | Model Name | Optimum Replacement Level of RHA (%) | Optimum Replacement Level of Pozzolans (%) |

|---|---|---|---|---|

| Model 1 | Model 1 | Control | - | - |

| Model 2 | Model 2a | RHA used as cement replacement | 30% RHA | - |

| Model 2b | RHA used as sand replacement | 20% RHA | - | |

| Model 3 | Model 3a/1 | RHA cement replacement with silica fume | 30% RHA | 15% MK |

| Model 3a/2 | RHA cement replacement with fly ash | 15% SF | ||

| Model 3a/3 | RHA cement replacement with metakaolin | 30% Slag | ||

| Model 3a/4 | RHA cement replacement with slag | 30% FA | ||

| Model 3b/1 | RHA sand replacement with silica fume | 20% RHA | 15% MK | |

| Model 3b/2 | RHA sand replacement with fly ash | 15% SF | ||

| Model 3b/3 | RHA sand replacement with metakaolin | 30% Slag | ||

| Model 3b/4 | RHA sand replacement with slag | 30% FA |

| Model | Water kg/m3 | Cement kg/m3 | RHA kg/m3 | Type of Pozzolan | Pozzolan kg/m3 | Fine Aggregate kg/m3 | Coarse Aggregate kg/m3 |

|---|---|---|---|---|---|---|---|

| Model 1 | 174.5 | 414.3 | - | - | - | 826.4 | 918.7 |

| Model 2a | 174.5 | 290 | 124.3 | - | - | 826.4 | 918.7 |

| Model 2b | 174.5 | 414.3 | 165.3 | - | - | 661.1 | 918.7 |

| Model 3a/1 | 174.5 | 246.5 | 124.3 | MK | 43.5 | 826.4 | 918.7 |

| Model 3a/2 | 174.5 | 246.5 | 124.3 | SF | 43.5 | 826.4 | 918.7 |

| Model 3a/3 | 174.5 | 203 | 124.3 | Slag | 87 | 826.4 | 918.7 |

| Model 3a/4 | 174.5 | 203 | 124.3 | FA | 87 | 826.4 | 918.7 |

| Model 3b/1 | 174.5 | 352.2 | 165.3 | MK | 62.1 | 661.1 | 918.7 |

| Model 3b/2 | 174.5 | 352.2 | 165.3 | SF | 62.1 | 661.1 | 918.7 |

| Model 3b/3 | 174.5 | 290 | 165.3 | Slag | 124.3 | 661.1 | 918.7 |

| Model 3b/4 | 174.5 | 290 | 165.3 | FA | 124.3 | 661.1 | 918.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Öztürk, E.; Ince, C.; Borgianni, Y.; Derogar, S.; Forster, A.M.; Ball, R.J. Enhancing Concrete Durability and Resource Efficiency Through Rice Husk Ash Incorporation: A Data-Driven Approach. Sustainability 2025, 17, 9382. https://doi.org/10.3390/su17219382

Öztürk E, Ince C, Borgianni Y, Derogar S, Forster AM, Ball RJ. Enhancing Concrete Durability and Resource Efficiency Through Rice Husk Ash Incorporation: A Data-Driven Approach. Sustainability. 2025; 17(21):9382. https://doi.org/10.3390/su17219382

Chicago/Turabian StyleÖztürk, Ece, Ceren Ince, Yuri Borgianni, Shahram Derogar, Alan M. Forster, and Richard James Ball. 2025. "Enhancing Concrete Durability and Resource Efficiency Through Rice Husk Ash Incorporation: A Data-Driven Approach" Sustainability 17, no. 21: 9382. https://doi.org/10.3390/su17219382

APA StyleÖztürk, E., Ince, C., Borgianni, Y., Derogar, S., Forster, A. M., & Ball, R. J. (2025). Enhancing Concrete Durability and Resource Efficiency Through Rice Husk Ash Incorporation: A Data-Driven Approach. Sustainability, 17(21), 9382. https://doi.org/10.3390/su17219382