Abstract

Reverse Logistics (RL) plays a fundamental role in supply by addressing returns, undelivered or damaged products, exchanges, and environmental concerns, directly contributing to more sustainable supply chain practices. Although firms recognize the importance and benefits of this concept, their supply chain remains focused on direct logistics, often overlooking RL’s potential to enhance sustainability performance. The aim of this article is to analyse the interaction between the barriers that challenge or prevent the implementation of RL in Small and Medium-sized Enterprises (SMEs). First, a literature review identified 22 barriers to developing RL in SMEs. Then, through experts’ opinions gathered in a Focus Group (FG), an Interpretive Structural Modeling (ISM) model was used to understand the hierarchy relations between barriers, and a Matrix Cross Impact Matrix Multiplication (MICMAC) analysis was carried out to aggregate the barriers in four categories according to their influencing power and dependence. Applying the methodology to the Portuguese case resulted in an ISM model with seven hierarchical levels and a MICMAC diagram without dependent barriers. Moreover, six key barriers emerged, namely, Lack of adequate organizational structure and support for RL practices, Lack of corporate social responsibility, Complexity of the operation, Lack of shared understanding of best practices, Difficulty with members of the supply chain, and Lack of support from supply chain players, which proved to be the most critical as they are positioned at the highest hierarchical levels of the ISM model and fall within the independent variable quadrant of the MICMAC analysis, thus revealing a strong driving power over the other barriers. The findings highlight that overcoming these barriers is crucial for SMEs to unlock the full sustainability potential of RL and transition towards supply chain models that are greener through a reduced carbon footprint, improved resource efficiency, and the adoption of circular economy practices. Academically, this research advances the literature by applying the ISM–MICMAC approach to SMEs, offering novel insights into the structural role of barriers in reverse logistics implementation.

1. Introduction

Due to the growing demand for ecological products and the pressure exerted by customers and other stakeholders throughout the supply chain, emphasizing environmental awareness and sustainable management, many companies have come to recognize the importance of applying sustainable supply chain management concepts in their activities [1].

In light of evolving market requests, a novel logistics paradigm has emerged, focusing on product reuse, reconditioning, and recycling, commonly referred to as Reverse Logistics (RL). While conventional logistics involves moving products from origin to consumption points, RL introduces a paradigm shift by promoting reverse flows. This allows products to be returned for reuse, reconditioning, recycling or deposition on landfill, thereby contributing to a more sustainable and circular economy [2]. The concept has gained global traction, influencing all tiers of supply chain operations across diverse industry sectors. Efficient RL strategies can potentially increase revenues and reduce costs significantly [3].

Recognized as a crucial component of supply chain management, implementing RL is challenging due to several barriers. Many efforts have been made to explore these barriers, but investigations are still minimal. There is still a lack of quantitative research based on the investigation of participant opinions, revealing the importance of each barrier [4].

It is fundamentally important to analyze the interaction between these key barriers that challenge or prevent the application of RL [5].

This is because these barriers inevitably interact with each other, and a particular barrier could be mitigated by removing other barriers that affect it [6]. In addition, the interrelationships among barriers could influence the importance of each barrier because a particular barrier may become an important threat to the ISM through its interaction with other barriers, although this barrier cannot directly have a significant impact [7]. However, few studies have explored the interaction of these barriers and their integrative effects.

Some barriers influence others, so monitoring the system that can determine these key barriers and understanding how their influence spreads and impacts RL is essential. Identifying the key barriers and modelling how they affect others can support the design of appropriate decision-making to overcome those barriers and restrictions [3].

Aiming to understand the relations among the barriers hindering the implementation of RL, Interpretive Structural Modelling (ISM) can be a supporting tool to consider. It can identify and summarise relations between specific variables defining a problem or issue [8]. ISM and Matrix Cross-Impact Matrix Multiplication (MICMAC 3) have been adopted in similar studies on adopting innovative technologies and practices. The literature review shows that ISM has been carefully used by researchers in various areas such as construction [9], RL suppliers [10], the health system [11], the supply chain [12], entrepreneurship [13], education [14], e-commerce [15], the lean system [16], six sigma [17], and agriculture [18].

However, few studies have explored the interaction of these barriers and their integrative effects [19], for example Waehrens et al. [20], Karim et al. [21] and Ali et al. [22].

The main objective of this article is to identify and analyse the key obstacles to the implementation of RL in SMEs. This study represents a new contribution to the literature, as the combined ISM-MICMAC analysis approach is not normally used to identify the barriers to RL implementation in SMEs, although the ISM-MICMAC approach has previously been used successfully to analyse the adoption of RL in large industries [4,23,24]. This research focuses on the Portuguese context and offers a new insight by identifying the barriers to RL implementation in SMEs through a combined ISM-MICMAC approach, supported by focus groups. The Portuguese context is particularly relevant for this research as SMEs dominate not only in the textile and footwear sectors, which play a central role in the country’s economy and are under increasing pressure to improve their sustainability practices, but also in other industries such as pharmaceuticals and information technology, where reverse logistics poses distinct yet equally pressing challenges [25]. Moreover, Portugal presents structural challenges such as limited financial resources and organizational constraints within SMEs, which may intensify the barriers to RL implementation compared to other European regions. This makes Portugal a distinctive and insightful case to study, while also providing lessons that can be adapted to similar contexts [26,27].

Thus, this study aims to contribute by identifying barriers that can assist decision-makers in making informed decisions to mitigate the obstacles to the implementation of RL in SMEs.

The article is structured in six distinct parts. The first presents a general view of RL. The second reviews the literature, addressing the fundaments of RL and the methodology adopted in the research. The methodology is presented in great detail in the third part, being divided into three stages: a review of the literature referring to the barriers to implementation of RL; application of the ISM model; and the MICMAC analysis. The last part contains the conclusions, addresses the study’s limitations and suggests future research paths.

2. Literature Review

2.1. Reverse Logistics

Companies have turned their attention to RL, using it as a strategic tool to satisfy customer needs and stimulate profit. An efficient reverse distribution structure can create significant return on investment and lead to a considerable increase in market competitiveness [28]. Due to economic development and growing competition in the market, companies are more motivated to find modern solutions to improve their commercial activity, and RL can be the path to higher performance.

RL consists of a number of operations to manage products returned by customers to suppliers, generally for recycling, repair, elimination or reuse and always at the lowest possible cost [29].

Driven by market competition and economic growth, businesses are more motivated than ever to modernize their operations, and RL often serves as a path to improved performance. Recent findings support this trend. For instance, Saglam [30] demonstrates that RL capabilities significantly enhance firms’ environmental, economic, and social outcomes—even more so when supported by a strong sustainability culture. Similarly, Appiah & Owusu-Bio [31] reveal that RL can have a positive effect on financial performance in developing economies when firms possess advanced analytics capabilities, which mitigate the cost challenges typically associated with RL implementation.

Therefore, RL is recognized as a fundamental aspect of environmental protection, having been adopted by international companies as part of a strategy to improve economic and environmental performance [32].

According to El Boudali et al. [33], RL management is a fundamental aspect of supply chain management, reducing costs and generating value for the firm. Appropriate RL implementation helps develop an ecological supply chain, increase customer satisfaction and gain a competitive advantage [34].

As a central topic in the academic debate in environmental performance and business sustainability, it has been recognized in various studies as an effective strategy for companies, the environment and sustainable development. RL is fundamental due to several factors, such as mitigating environmental problems, cost control and competitive advantage. However, despite its importance, the area of RL has not yet been sufficiently explored and several questions remain to be studied [35].

In spite of the progress made in recent years, RL is still a challenge for many developed countries and especially for developing ones [36]. Companies face several complications and challenges when carrying out RL activities due to the various barriers that hinder the process [37].

2.2. ISM and MICMAC

ISM is a computational method to develop graphic representations of the composition and structure of systems. It originated in the belief of Warfield [38] about the need to establish a relation between science and politics. The author recognized the importance of communication tools that were scientifically robust and accessible to the general public. An advantage of this methodology is that it describes the order and direction of relations between a system’s elements [23].

The ISM model has been used by researchers in the last decade to analyze barriers. This methodology is widely used in ecological supply change management strategies to develop and analyze the variables hindering more sustainable supply chains [39].

The ISM approach is a technique that helps to understand and simplify complex problems. The model is particularly useful for interpreting rooted variables and transforming unclear models into visible, well-defined ones.

Kumar et al. [40] underline that ISM offers a simplified way to solve complex problems, providing orientations in interpreting rooted objectives. This approach gives a clearer, more structured analysis of problems, facilitating identification of their inter-relations and providing a broader view. Furthermore, Jha et al. [41] state that ISM helps in transforming badly segmented and unclear rational models into more visible, well-defined ones. This means that the technique not only simplifies the understanding of the system, but also makes them more tangible, facilitating the decision-making process and the implementation of effective solutions.

For more thorough knowledge about the barriers, combining ISM with the Matrice d’Impacts Croisés Multiplication Appliquée à un Classement (MICMAC) analysis is fundamental. Combining MICMAC with ISM gives a holistic approach to the analysis of complex problems, allowing a deeper understanding of the relations between the variables involved and facilitating decision-making [42].

MICMAC analysis is based on the principle of matrix multiplication properties, and one of the main objectives of this analysis is to examine and categorize the variables of interest in terms of driving power and dependence power where all variables are classified into four specified clusters [43].

The final hierarchical model of the ISM, associated with the MICMAC analysis, improves understanding of the variables considerably and increase the methodological rigor [44,45].

2.3. Justification of the Methodology Proposed for RL Development

During constant economic development and increasing market competition, enterprises are compelled to seek modern solutions to enhance their business activities, with RL potentially providing an answer to these aspirations for improved performance. However, the decision to implement RL processes within a company is not an easy one. Such investments can encounter numerous barriers and obstacles that are difficult to overcome, effectively hindering the successful implementation of RL [29].

In this context, Govindan Hasanagic [46] identified the barriers that prevent or complicate the implementation of RL in companies using multivariate descriptive and inferential statistics. Abdulrahman et al. [47] proposed a theoretical model to empirically identify significant barriers to RL concerning management, finance, policies, and infrastructure in manufacturing industries.

Lamba et al. [48] employed an analytic hierarchy process-based methodology to identify lack of investment in RL, lack of knowledge of best practices, and uncertainty regarding returns and demand as the three main obstacles to RL.

Sirisawat & Kiatcharoenpol [49] used a methodology based on the fuzzy analytic hierarchy process and the fuzzy technique for order preference by similarity to an ideal solution to classify the barriers.

Bouzon et al. [50] used a Multi-Criteria Decision-Making tool named grey-based Decision-Making Trial and Evaluation Laboratory to extract perspectives from multiple company–customer–government associations on the barriers to implementing RL.

Over the years, many efforts have been made to explore these barriers, but investigations remain minimal. Quantitative research based on participants opinions, revealing the importance of each barrier, is still lacking [6]. Furthermore, the interrelationships between obstacles systematically affect the importance of each one in implementing RL. It is crucial to classify them according to their dependency and driving powers. While previous studies have explored these barriers, few have analyzed their complex interrelationships [7,51].

Some variables, which in this study are referred to as barriers, affect the implementation of RL practices, so analysing the direct and indirect relationships between them can give a holistic view of the situation, rather than just considering the individual variable in isolation.

The effectiveness of the ISM model lies in its capacity to portray the structure of a complex problem using a carefully conceived standard combining graphs and words [28].

The basic idea of ISM is to break down a complicated system into various sub-systems, using specialists’ practical experience and knowledge to construct a multi-level structural model.

ISM can be used to identify and analyze the relations between specific variables defining a problem or issue [38]. Mishra et al. [52] applied ISM methodology to identify and model the obstacles to the internationalization of SMEs in the automobile sector in the context of emerging markets. Talib and Rahman [53] used the methodology to identify the potential obstacles to telecommunication services and to develop relations between them. Dube &Gawande [54] developed the model to identify the contextual relation between ecological supply chain management obstacles. Orji [55] used the modelling technique to examine the barriers to organizational change towards sustainability and the factors supporting sustainable performance. Sarkar et al. [56] used ISM to build a structured model of the factors leading to the adoption of green businesses in emerging economies.

Therefore, this research intends to apply the ISM methodology to understand the reciprocal influences among the barriers hindering or preventing RL implementation in SMEs and identify the stimulating barriers that can aggravate others and the dependent barriers that are most affected by the stimulating barriers.

3. Methodology

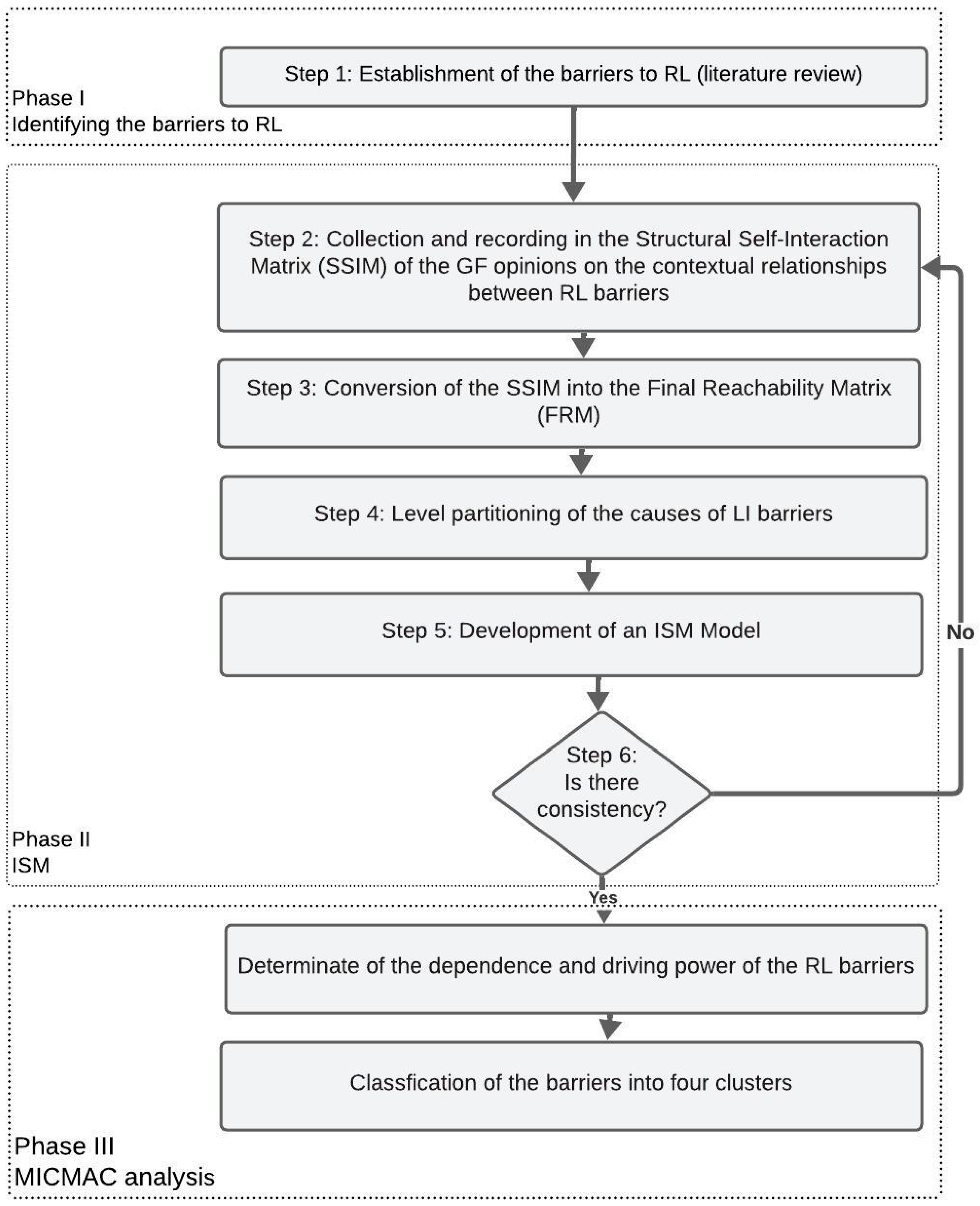

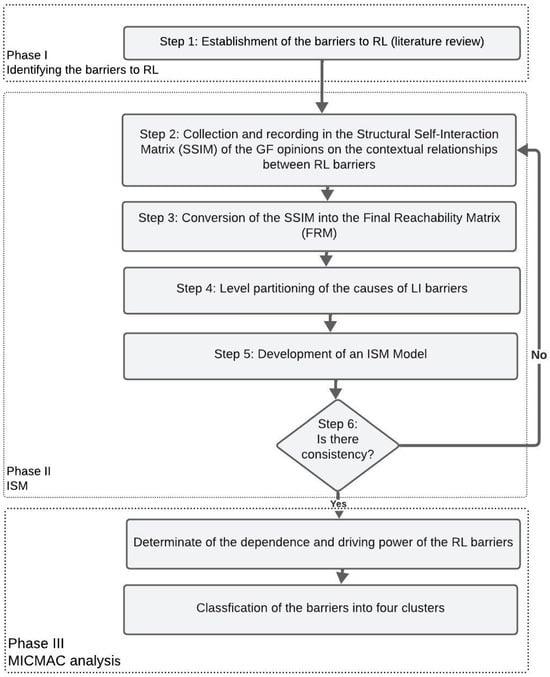

This research’s methodological approach consists of three phases, as presented in Figure 1: I—Determining the critical barriers; II–ISM; and III—MICMAC analysis.

Figure 1.

Research Methodology.

The FG technique was fundamental to the operationalisation of stages II and VI of this study’s methodology.

FG has a fundamental role in ISM, since the whole process and the result depend on its contribution [57], the FG is a research method of an exploratory nature that gathers qualitative data from the group’s interaction in relation to a topic presented by the moderator. The group should represent all those involved in the scope of the problem, with special attention being paid to size, specialization and diversity. They should have solid experience in the area and specialized knowledge of the variables studied [44].

The FG stimulates discussion among specialists about their perceptions, opinions, attitudes and beliefs with regard to a product, service, theory or concept, extending and improving the existing information about a topic and creating new perceptions [58].

According to [59], FG should be formed of 4 to 12 participants. Therefore, the FG that built the SSIM (Structural Self-Interaction Matrix) for this study was made up of 8 experts with knowledge of RL and more than 5 years’ experience. The focus group was composed of eight experts with more than five years of professional experience in reverse logistics. The experts represented different sectors of the Portuguese economy, namely footwear, textiles, waste management, and technology. This diversity ensured that the analysis incorporated perspectives from industries where SMEs play a central role and where reverse logistics practices face distinct operational and organizational challenges. In the meeting, held using the Zoom video-conferencing application, the barriers to implementing RL were presented and explained, and the ISM-MICMAC logic was addressed.

Although the FG sessions were conducted online via Zoom, specific measures were adopted to preserve the quality of interaction and consensus building, such as the use of structured moderation, clear presentation of the barriers and ISM-MICMAC logic, and active facilitation to ensure balanced participation among all experts.

The meeting was moderated by one of the researchers to ensure a clear understanding of the obstacles to implementing RL, stimulate debate, and ensure that the discussion transitioned from general to specific topics to promote sincerity and reduce biases [60].

The study used the principle of “majority rules” [7] when the specialists had diverging opinions. The meeting, held using the Zoom video-conferencing application, presented and explained the barriers to implementing RL and addressed the ISM-MICMAC logic.

3.1. Phase I—Identifying the Barriers to RL

Step 1—Identification of the barriers

This study uses the barriers validated previously (Table 1). In that study, the literature review focused on the Scopus and Web of Science databases, using the terms of ‘Reverse Logistics’ and ‘Barriers’, analyzing 330 scientific articles published in international journals. That process identified 61 barriers that were subsequently grouped in seven categories. Then, the Fuzzy Delphi Method was used to obtain a critical list of barriers, with the collaboration of 20 specialists in the area. Of the 61 barriers identified, the specialists validated 22. The set of 22 barriers validated in the study was adopted without modifications, since they were considered sufficiently comprehensive and applicable to the Portuguese SME context.

Table 1.

Barriers to implementation of RL.

The study serves as the basis for Phase I, wherein 22 barriers to the implementation of RL were identified and, subsequently, the authors determined both the fuzzy score and priority level associated with each of these barriers.

3.2. Phase II—ISM

In the present study, ISM was employed to identify and evaluate the interactions between critical barriers to the implementation of RL. This approach allowed for a graphical and hierarchical representation of the connections between these barriers and facilitated the identification of the main barriers that need to be mitigated.

Step 2—Contextual relationships between the critical barriers.

The 22 critical barriers to RL generated 22 × 21/2 = 231 different inter-relations. The FG specialists were asked to express the contextual inter-relations between a pair of barriers (Bi and Bj), obtaining four different types:

- -

- V: Bi helps to achieve or influences Bj;

- -

- A: Bj helps to achieve or influences Bi;

- -

- X: Bi helps to achieve or influences Bj and vice versa;

- -

- O: There is no inter-relation between Bi and Bj.

The SSIM elaborated by the 8 specialists is presented in Table 2. As mentioned, the study used the principle of “majority rules” when the specialists had diverging opinions.

Table 2.

Structural self-intersection matrix.

Step 3—Converting the SSIM into the Final Reachability Matrix

Initially, the SSIM was transformed into the initial reachability matrix (IRM), a binary matrix representing the direct relationships between the barriers, which was accomplished by replacing the letters with 1 s and 0 s.

If the (i, j) entry is V in SSIM, the (w, z) entry in the IRM becomes 1 and the (i, j) entry becomes 0.

If the (i, j) entry is A in SSIM, the (w, z) entry in the IRM becomes 0 and the (i, j) entry becomes 1.

If the (i, j) entry is X in SSIM, the (w, z) entry in the IRM becomes 1 and the (i, j) entry becomes 1.

If the (i, j) entry is O in SSIM, the (w, z) entry in the IRM becomes 0 and the (i, j) entry becomes 0.

Then, the IRM was checked for transitivity, giving way to the FRM. If barrier i influences barrier j and barrier j influences barrier k, then barrier i indirectly influences k through barrier j, and if the entry (i,k) in the IRM is 0, then it must be changed to 1*. Before calculating the FRM, the matrix IRM_I was obtained by adding the IRM to identity matrix I. The FRM was then obtained through the Boolean operation, which involved self-multiplication of IRM_I until it reached a stable state, as indicated in Equation (1) [9]:

IRM_I ≠ IRM_I2 ≠ … ≠ IRM_In−1 ≠ IRM_In = IRM_In+1 = FRM

Step 4—Level partitioning of the barriers.

After completing the reachability matrix, the barriers are divided into levels. To establish the relevance of each barrier, they are divided into various levels, and three sets are created to divide the barriers efficiently. These are the sets of intersection, reachability and antecedents. The set of reachability includes the barrier in question and all the barriers that depend on it. The antecedent set includes the barrier and all those that affect or influence it. Finally, the intersection set combines the sets of reachability and antecedents, representing the barriers that depend on and affect the original variable. In the ISM hierarchy, the barriers with the same reachability and intersection are designated as Level I or higher-level barriers. The process of determining the remaining levels is iterative, with the variables of the previous level being eliminated until all have been attributed to a level. Level I barriers are at the top of the ISM hierarchy and do not influence the other barriers. In the higher levels, the barriers are in the lower part of the ISM hierarchy and have a greater influence on the other variables [44,61].

Step 5—Development of the ISM model.

The ISM model was constructed by creating a diagram based on the FRM and the hierarchical level of each barrier. First, the conical matrix of the FRM was built, grouping barriers of the same hierarchical level in the rows and columns of the matrix to facilitate the creation of the ISM model. Second, a preliminary diagram was developed by placing the barriers vertically according to their level partitioning and connecting the barriers with arrows as per the conical matrix. Third, indirect links between the barriers were eliminated to obtain the ISM model.

Step 6—Consistency check.

Finally, the GF experts were asked to verify the conceptual consistency of the hierarchical structure and the interrelations of barriers to the implementation of RL in the obtained ISM model. The experts were instructed to check for any ambiguities in the ISM model and to ensure that it accurately represented their mental model of the system of barriers affecting the implementation of RL.

3.3. Phase III—MICMAC

For a more thorough analysis of the main barriers to implementing RL, as defined in phase III of the methodology, we perform a MICMAC analysis, exploring these barriers’ power of influence and dependence.

The MICMAC analysis was developed by [62] based on the matrices’ multiplication properties. MICMAC is a technique to classify variables. The variables are mapped on a two-dimensional grid based on their values of dependence and stimulating strength, represented on the horizontal and vertical axes, respectively. The interval of these values varies between 1 and the total number of variables, and the axis are bifurcated at the mid-points, resulting in four quadrants. Each 1 or 1* in the entry (i,j) of the FRM shows that barrier i has an influence on barrier j and the other way around, meaning that barrier j is affected by barrier i. Thus, the dependence power of a barrier is obtained by adding up the values in its column, while the driving power is determined by adding up the values in its row. These quadrants classify the variables in autonomous, dependent, connecting and independent categories. The autonomous variables are not linked to the rest of the system of variables, whereas the linking variables are sensitive and are strongly connected to the independent and dependent variables.

4. Results

4.1. Phase II: ISM

The ISM model was developed by following steps 3 to 6 of phase II of the methodology (Figure 1). In step 2, the SSIM was initially converted into the IRM (Table 3). Next, in step 3, the IRM was checked for transitivity, resulting in the FRM (Table 4) with the help of a VBA program in Microsoft Excel. The driving power and dependence of each barrier were also determined, with the former representing the sum of the respective row and the latter the sum of the respective column in the FRM.

Table 3.

Initial Reachability Matrix.

Table 4.

Final Reachability Matrix.

In stage 3, the process of partitioning the levels of barriers to implementing IL resulted in seven iterations and the corresponding seven hierarchical levels, as shown in Table 5.

Table 5.

Level partitioning.

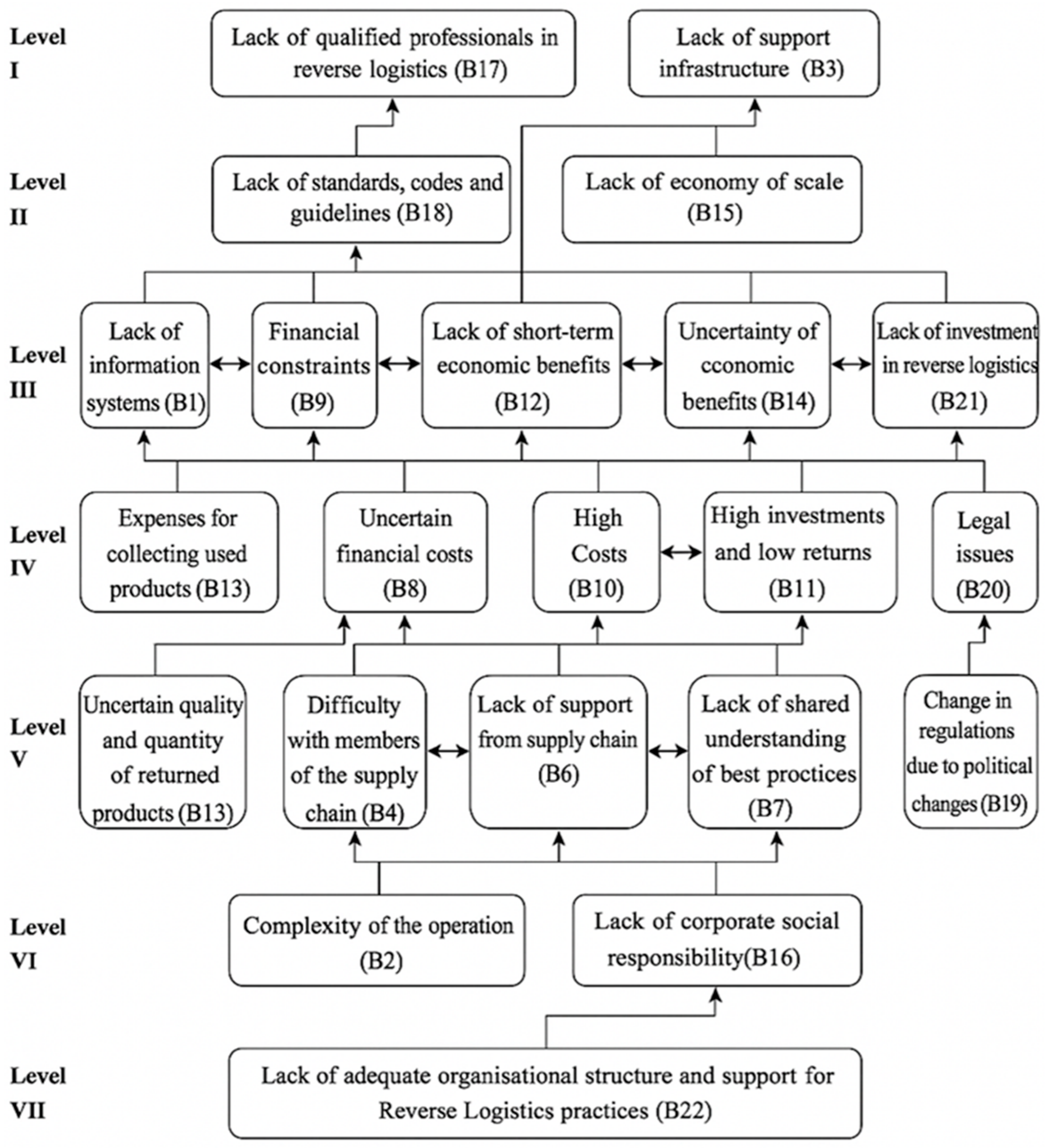

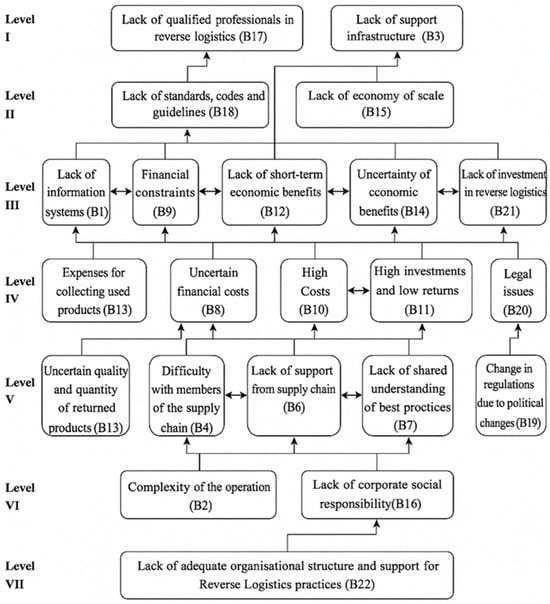

In stage 5, the ISM model was established using the conical matrix of the FRM and is presented in Figure 2. Finally, in stage 6, this model was discussed in the GF, where experts were asked to verify any potential inconsistencies. The experts agreed on the consistency of the ISM model. Thus, the model was deemed appropriate, highlighting both the hierarchical structure and the interrelationships of the barriers to implementing RL.

Figure 2.

ISM model of the barriers to RL in Portugal.

Analysis of Figure 2 shows that Lack of support infrastructure (B17) and Lack of qualified professionals in RL (B3) are at the top of the table, since they were considered Level I barriers. These barriers do not exert an influence on the others but are strongly influenced by other barriers. Barriers positioned at Level I are not classified as “influential” because they do not drive other barriers; rather, they are the most “influenced” by the rest of the system.

Levels II to V are considered intermediate levels in the model. Level II includes Lack of economy of scale (B15) and Lack of standards, codes and guidelines (B18). Level III includes Lack of information systems (B1), Financial constraints (B9), Lack of short-term economic benefits (B12), Uncertainty of economic benefits (B14) and Lack of investment in RL (B21). Level IV includes High costs (B10), Uncertain financial costs (B8), Legal issues (B20, High investments and low returns (B11) and Expenses for collecting used products (B13). Level V includes Uncertain quality and quantity of returned products (B5), Difficulty with members of the supply chain (B6), Lack of support from supply chain players (B7), Lack of shared understanding of best practices (B8) and Change in regulations due to political changes (B19).

Figure 2 also reveals that barriers in the category of Economic-related issues are concentrated in Levels III and IV, and those in the category of Governance and supply chain process-related issues in Level V.

The barriers attributed to the intermediate levels influence the barriers of the lower hierarchical levels and are also influenced by the barriers of the higher hierarchical levels.

Finally, the barriers at the highest level are positioned in the lower part of the ISM model and are considered the main barriers to implementing RL in Portugal. Level VI includes Complexity of the operation (B2) and Lack of corporate social responsibility (B17) and Level VII, the highest level, includes Lack of adequate organizational structure and support for RL practices (B22).

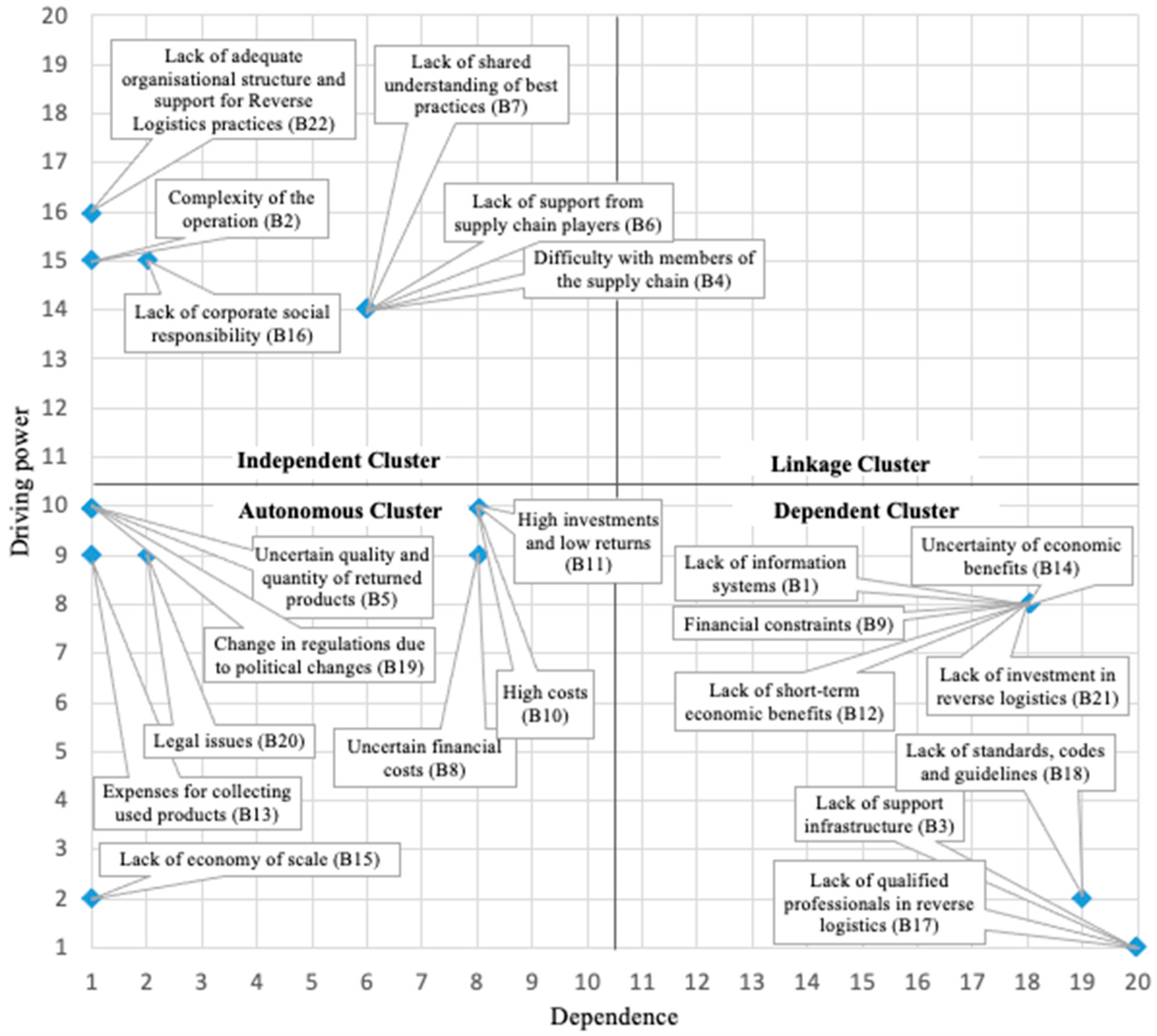

4.2. Phase III: MICMAC Analysis

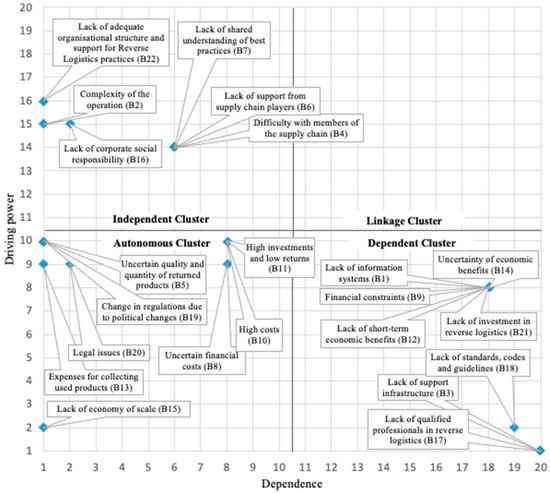

As observed in Figure 3, the barriers to RL are classified in four groups. The first is formed of autonomous variables that have a weak power of influence and weak dependence. These variables are disconnected from the system, with which they have only a few, but strong, links. The second group is formed of the dependent variables that have a weak power of influence but strong dependence. The third cluster contains the linking variables that have a strong power of influence and also strong dependence. These variables are unstable inasmuch as any action on them will have an effect on the others and also a feedback effect on themselves. The fourth group includes the independent variables that have a strong power of influence but weak dependence. It is noted that the variables with a very strong power of influence, called key variables, belong to the category of independent variables.

Figure 3.

MICMAC diagram of the barriers to implementing RL.

5. Discussion

The model based on ISM proposed to identify the obstacles to RL can give decision-makers a realistic representation of the problems involved in implementing RL. This can help them decide on priorities for taking proactive measures to overcome these barriers.

Lack of adequate organizational structure and support for RL practices (B22), at the highest hierarchical level of the ISM model, is the barrier with greatest influence on the system. A lack of conditions and basic functions in the organizational structure limits the adoption of RL practices [63].

According to the results, Lack of adequate organizational structure and support for RL practices directly influences Lack of corporate social responsibility (B21). An appropriate structure could improve the company’s social responsibility (B16), Lack of shared understanding of best practices (B7), Lack of support from supply chain players (B6) and Difficulty with members of the supply chain (B4).

Regarding the MICMAC analysis, we can observe that B5, B8, B10, B11, B13, B15, B19, and B20 are in the autonomous cluster. This means these barriers have low influence and low dependence, indicating no significant relationship with the system due to their weak connection with other barriers. These barriers are outside the barrier system, and they need to be dealt with autonomously.

The analysis also shows that B2, B4, B6, B7, B16, and B22 are classified as independent barriers, as they have a high influence. This implies that these are fundamental barriers for the effective implementation of RL in the supply chain.

Integrating the hierarchical structure and the interrelationships of the barriers (ISM model) with their influence and dependence (MICMAC analysis) contributes to the discussion about the importance of barriers to the implementation of RL in SMEs and their relationships.

It is worth noting that the linkage cluster in the MICMAC diagram is empty, which indicates that none of the identified barriers simultaneously present strong driving and dependence power. This absence suggests that the system of barriers in the Portuguese SME context is more polarized, with barriers acting either primarily as independent drivers or as dependent outcomes, rather than occupying an unstable intermediary position.

The main barriers from the MICMAC analysis (independent cluster) and the main barriers from the ISM model (level VII barriers) are now classified as key barriers to RL in Portugal (specifically barriers B2, B4, B6, B7, B16, and B22).

Compared to other critical barriers, the key barriers have a relatively low ranking in terms of perceived importance by the respondents. This result confirms the need to go beyond merely classifying the barriers when the goal is to adapt mitigation measures to reduce their impact and promote the implementation of RL [64].

We also note that B14, classified as the second most important barrier in the rank, is situated in the dependent cluster. This analysis indicates that B14 significantly depends on the mitigation of other barriers, which are considered less important by the experts. This divergence between the perceived importance of barriers and their structural influence can be hypothesized as a consequence of how experts typically assess obstacles [65]. In practice, decision-makers often prioritize barriers that have a visible and immediate impact, such as financial costs or infrastructure gaps. By contrast, the ISM–MICMAC methodology uncovers the systemic and indirect influence of barriers, revealing hidden causal relationships. As a result, certain barriers may be underestimated in perception-based rankings but emerge as structurally critical once their interdependencies are analyzed. This indicates that less apparent barriers can, in fact, play a fundamental role as root causes that shape the overall system of constraints [20].

Therefore, key-cause mitigation measures are more effective than those based solely on importance. For instance, in the case of SMEs facing the barrier “Lack of adequate organizational structure and support for RL practices” (B22), a key-cause mitigation measure could involve establishing a dedicated reverse logistics unit, even if on a small scale, by reallocating existing resources rather than creating a fully new department. This structural adjustment could also be complemented by training programs to address the “Lack of qualified professionals in RL” (B3). By focusing on these root-cause barriers, SMEs can create internal capabilities that in turn reduce the impact of dependent barriers, such as uncertainty of economic benefits or lack of shared understanding of best practices, thereby triggering a positive cascading effect throughout the system [66].

Identifying the six key barriers—lack of adequate organizational structure, lack of corporate social responsibility, complexity of operations, lack of shared understanding of best practices, difficulty with supply chain members, and lack of support from supply chain players—offers decision-makers a structured view of where to intervene first.

From a managerial perspective, the lack of organizational structure (B22) indicates that SMEs should begin by assigning clear responsibilities for reverse flows, even if through small dedicated teams or cross-functional task forces. Without such structural adjustments, other initiatives tend to fail. Likewise, corporate social responsibility (B16) emerges as a driver of both internal and external change: SMEs that explicitly integrate sustainability goals into their strategies are more likely to secure cooperation from supply chain partners and to meet customer expectations [67].

The complexity of reverse operations (B2) suggests that managers need to simplify processes by adopting digital solutions, outsourcing specialized activities, or forming partnerships with logistics providers. In turn, the lack of shared understanding of best practices (B7) reveals an urgent need for benchmarking and training initiatives. SMEs can benefit from participating in industry associations, clusters, or EU-funded projects that disseminate circular economy practices adapted to their scale.

Barriers related to the supply chain (B4 and B6) highlight that reverse logistics is not an isolated function but a collaborative effort. Managers must invest in building trust and formal agreements with distributors, retailers, and waste management operators [68]. Practical measures include establishing standardized return policies, cost-sharing mechanisms, and joint investment in infrastructure.

At the policy level, the Portuguese context reinforces the need for support instruments that enable SMEs to invest in reverse flows, such as fiscal incentives, targeted training, and sector-specific guidelines. These measures would not only reduce barriers at the firm level but also strengthen collective capabilities across industries like textiles, footwear, pharmaceuticals, IT, and waste management.

6. Conclusions

A duly planned and well-managed RL network is crucial to increase a company’s income and customer satisfaction. To concentrate on the business’s main operations and achieve good cost effectiveness, companies need to organize their RL activities correctly. Consequently, identifying barriers is a challenge for both decision-makers and managers.

In this study, the barriers to implementing RL activities were identified through a review of the literature and introduced in the ISM model to develop a contextual relation between the selected barriers and to establish the hierarchical structure of the barriers, identifying those with the greatest influence and their dependence.

The ISM converted the perception of 8 RL specialists, in the Portuguese context, into a clear, structured map deciphering the contextual relations among the barriers to implementing reverse flows.

Besides the ISM model, a MICMAC analysis was performed to determine the dependence and strength of influence of the variables identified. This analysis helped to determine the factors that can be worked on immediately and those requiring most attention.

Application of the ISM and MICMAC analysis revealed that Lack of adequate organizational structure and support for RL practices stimulates Lack of corporate social responsibility, which in turn and jointly with Complexity of the operation, influences the barriers of the Governance and supply chain process-related issues category. The barriers of the Economic-related issues category are at the intermediate level, meaning that they influence the lower levels, but these barriers are also greatly influenced by the higher levels. This analysis reveals that these barriers depend significantly on mitigation of the higher-level barriers.

The research also showed that Lack of adequate organizational structure and support for RL practices, Lack of corporate social responsibility, Complexity of the operation, Lack of shared understanding of best practices, Difficulty with members of the supply chain and Lack of support from supply chain players are the key barriers to implementing RL. This observation suggests it is crucial to mitigate these barriers, as they exert a significant influence on the others.

Lack of support infrastructure and Lack of qualified professionals in RL were found to be lower-level barriers, which indicates they are influenced by most of the other barriers.

The results underline the importance of mitigating barriers related to management, corporate social responsibility and the complexity of operations.

The findings of this research reinforce and expand upon previous studies on barriers to RL implementation. For example, Ravi and Shankar [24] and Bouzon et al. [69] identified operational complexity and uncertain costs as critical factors, which is consistent with this study’s emphasis on the complexity of operations and the uncertainty of economic benefits. On the other hand, recent works such as Saglam [70] and Appiah & Owusu-Bio [31] highlight the importance of internal capabilities, such as a strong sustainability culture and analytics, to overcome RL barriers. This perspective resonates with our results, which stress the need for SMEs to establish dedicated structures and invest in training qualified professionals. Therefore, this study contributes to the existing literature by applying the ISM–MICMAC approach in the Portuguese SME context, uncovering a hierarchical system of barriers that has not been previously explored in this type of organization.

By giving priority to these barriers and taking appropriate measures, those involved can overcome the obstacles and promote effective adoption of RL practices.

This research contributes to the existing body of academic knowledge and provides valuable guidelines so that professionals and policy-makers can strengthen sustainability. Future research efforts can focus on developing strategies and interventions to address the barriers identified and assess their effectiveness in facilitating RL implementation. There should also be a focus on mitigating the key barriers found here and determining whether the barriers have the same impact in different industrial sectors.

While this study has made significant contributions, it is important to recognize some limitations. Firstly, the sample used was relatively small, which can limit generalization of the results beyond the group studied. Moreover, the results referred to the Portuguese context, and so care is necessary in extrapolating them to other European markets with different characteristics.

Future research could explore whether the barriers identified in this study manifest differently across specific industrial sectors, such as electronics, food and beverage, or textile industries, where reverse logistics plays a critical yet distinct role. Additionally, applying complementary methodologies, such as longitudinal case studies, simulation modelling, or hybrid approaches combining ISM–MICMAC with methods like DEMATEL or fuzzy logic, could provide deeper insights into the dynamic interactions between barriers. Such sector-specific and methodologically diverse studies would strengthen the generalizability and practical applicability of the findings.

Author Contributions

Conceptualization, M.S.; formal analysis, M.S.; investigation, M.S.; writing—original draft preparation, M.S.; funding acquisition, M.S.; supervision, A.d.P. and A.B. writing—review and editing, A.d.P. and A.B.; methodology, A.A.; software, A.A. All authors have read and agreed to the published version of the manuscript.

Funding

This work is supported by FCT—Fundação para a Ciência e Tecnologia, I.P. by project reference UIDP/04728/2020.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Some or all of the data, models, or codes that support the findings of this study are available from the corresponding author upon reasonable request.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Sirisawat, P.; Kiatcharoenpol, T. A study of correlation for reverse logistics barriers to solutions using structural equation modelling. Int. J. Product. Qual. Manag. 2019, 26, 139–159. [Google Scholar] [CrossRef]

- Calmon, A.P.; Graves, S.C.; Lemmens, S. Warranty Matching in a Consumer Electronics Closed-Loop Supply Chain. Manuf. Serv. Oper. Manag. 2021, 23, 1314–1331. [Google Scholar] [CrossRef]

- Sari, D.P.; Ulkhaq, M.M.; Rinawati, D.I.; Rasyida, D.R. Barriers of Reverse Logistics Implementation: A Case Study in a Car Battery Industry in Indonesia, 2018. Available online: https://www.scopus.com/inward/record.uri?eid=2-s2.0-85060877023&partnerID=40&md5=60d79fdfb591cc95ee0173ae2f7f42b5 (accessed on 12 January 2025).

- Bouzon, M.; Govindan, K.; Rodriguez, C.M.T. Reducing the extraction of minerals: Reverse logistics in the machinery manufacturing industry sector in Brazil using ISM approach. Resour. Policy 2015, 46, 27–36. [Google Scholar] [CrossRef]

- Waqas, M.; Dong, Q.-L.; Ahmad, N.; Zhu, Y.; Nadeem, M. Critical barriers to implementation of reverse logistics in the manufacturing industry: A case study of a developing country. Sustainability 2018, 10, 4202. [Google Scholar] [CrossRef]

- Xu, X.; Zou, P.X.W. Analysis of factors and their hierarchical relationships influencing building energy performance using interpretive structural modelling (ISM) approach. J. Clean. Prod. 2020, 272, 122650. [Google Scholar] [CrossRef]

- Shen, L.; Song, X.; Wu, Y.; Liao, S.; Zhang, X. Interpretive Structural Modeling based factor analysis on the implementation of Emission Trading System in the Chinese building sector. J. Clean. Prod. 2016, 127, 214–227. [Google Scholar] [CrossRef]

- Mandal, A.; Deshmukh, S.G. Vendedor Selection Using Interpretive Structural Modelling (ISM). Stud. Syst. Decis. Control 1993, 336, 311–324. [Google Scholar] [CrossRef]

- Ribeiro, A.M.; Arantes, A.; Cruz, C.O. Barriers to the Adoption of Modular Construction in Portugal: An Interpretive Structural Modeling Approach. Buildings 2022, 12, 1509. [Google Scholar] [CrossRef]

- Govindan, K.; Palaniappan, M.; Zhu, Q.; Kannan, D. Analysis of third party reverse logistics provider using interpretive structural modeling. Int. J. Prod. Econ. 2012, 140, 204–211. [Google Scholar] [CrossRef]

- Santosh, K.; Roopali, S. Key Barrier in Growth of Rural Health Care: An ISM MICMAC Approach. Benchmarking Int. J. 2018, 25, 2169–2183. [Google Scholar] [CrossRef]

- Mor, R.S.; Bhardwaj, A.; Singh, S. Benchmarking the interactions among barriers in dairy supply chain: An ism approach. Int. J. Qual. Res. 2018, 12, 385–404. [Google Scholar] [CrossRef]

- Tripathi, K.A.; Singh, S. Analysis of barriers to women entrepreneurship through ISM and MICMAC: A case of Indian MSMEs. J. Enterprising Communities-People Places Glob. Econ. 2018, 12, 346–373. [Google Scholar] [CrossRef]

- Kinker, P.; Swarnakar, V.; Singh, A.R.; Jain, R. Identifying and evaluating service quality barriers for polytechnic education: An ISM-MICMAC approach. Mater. Today-Proc. 2021, 46, 9752–9757. [Google Scholar] [CrossRef]

- Rana, N.P.; Dwivedi, Y.K.; Hughes, D.L. Analysis of challenges for blockchain adoption within the Indian public sector: An interpretive structural modelling approach. Inf. Technol. People 2022, 35, 548–576. [Google Scholar] [CrossRef]

- Abu-Salim, T.Y.; Agarwal, P.; Elrub, E.A.; Haoum, L.; Almashgari, M.H. Investigation and modelling lean six sigma barriers in service industries: A hybrid ISM-Fuzzy MICMAC approach. Meas. Bus. Excell. 2023, 27, 379–402. [Google Scholar] [CrossRef]

- Kumar, S.; Luthra, S.; Govindan, K.; Kumar, N.; Haleem, A. Barriers in green lean six sigma product development process: An ISM approach. Prod. Plan. Control 2016, 27, 604–620. [Google Scholar] [CrossRef]

- Kumar, S.; Sarkar, B.; Kumar, A. Fuzzy reverse logistics inventory model of smart items with two warehouses of a retailer considering carbon emissions. Rairo-Oper. Res. 2021, 55, 2285–2307. [Google Scholar] [CrossRef]

- Wu, M.; Wu, Y.; He, J.; Xu, M.; Zhang, T.; Liu, F. Barrier identification, analysis and solutions of hydrogen energy storage application in multiple power scenarios based on improved DEMATAL-ISM approach. Int. J. Hydrogen. Energy 2022, 47, 30329–30346. [Google Scholar] [CrossRef]

- Jensen, S.F.; Kristensen, J.H.; Uhrenholt, J.N.; Rincon, M.C.; Adamsen, S.; Waehrens, B.V. Unlocking Barriers to Circular Economy: An ISM-Based Approach to Contextualizing Dependencies. Sustainability 2022, 14, 9523. [Google Scholar] [CrossRef]

- Hossain, S.; Hassan, S.; Karim, R. Assessment of Critical Barriers to Industry 4.0 Adoption in Manufacturing Industries of Bangladesh: An ISM-Based Study. Braz. J. Oper. Prod. Manag. 2023, 20, 1797. [Google Scholar] [CrossRef]

- Shoaib, M.; Zhang, S.; Ali, H. Assessment of sustainable green logistics enablers: A robust framework using fuzzy DEMATEL and ISM approach. Int. J. Environ. Sci. Technol. 2023, 20, 11407–11426. [Google Scholar] [CrossRef]

- Ravi, V.; Shankar, R. Analysis of interactions among the barriers of reverse logistics. Technol. Forecast. Soc. Change 2005, 72, 1011–1029. [Google Scholar] [CrossRef]

- Ravi, V.; Shankar, R. An ISM-based approach analyzing interactions among variables of reverse logistics in automobile industries. J. Model. Manag. 2017, 12, 36–52. [Google Scholar] [CrossRef]

- Ramesh, B.; Dieguez, T.; Ferreira, L.P.; Silva, F.J.G. A Strategy to Reinforce the Textile and Clothing Sector Cluster in Portugal. In Transdisciplinary Engineering Methods for Social Innovation of Industry 4.0; Peruzzini, M., Pellicciari, M., Bil, C., Stjepandic, J., Wognum, N., Eds.; Advances in Transdisciplinary Engineering; IOS PRESS: Amsterdam, The Netherlands, 2018; Volume 7, pp. 459–468. [Google Scholar] [CrossRef]

- das Virgens, N.; Silva, S.; Laranjeira, E. Applications of the circular economy to the second-hand textile and clothing market: The case of Humana in Portugal. Int. J. Fash. Des. Technol. Educ. 2023, 16, 214–223. [Google Scholar] [CrossRef]

- Santos, E.; Castanho, R.A. The Impact of Size on the Performance of Transnational Corporations Operating in the Textile Industry in Portugal during the COVID-19 Pandemic. Sustainability 2022, 14, 717. [Google Scholar] [CrossRef]

- Sharma, S.K.; Mahapatra, S.S.; Panda, B.N.; Sahu, S. An Interpretive Structural Modeling Approach for Analysis of Interactions among the Barriers in Reverse Logistics. In Mechanical and Aerospace Engineering, Pts 1–7; Fan, W., Ed.; Applied Mechanics and Materials; Trans Tech Publications LTD.: Durnten-Zurich, Switzerland, 2012; Volumes 110–116, 2699p. [Google Scholar] [CrossRef]

- Starostka-Patyk, M. The use of information systems to support the management of reverse logistics processes. In Knowledge-Based and Intelligent Information Engineering Systems (KSE 2021); Watrobski, J., Salabun, W., Toro, C., Zanni-Merk, C., Howlett, R.J., Jain, L.C., Eds.; Procedia Computer Science; Elsevier Science BV: Amsterdam, The Netherlands, 2021; Volume 192, pp. 2586–2595. [Google Scholar] [CrossRef]

- Saglam, Y.C. Analyzing sustainable reverse logistics capability and triple bottom line: The mediating role of sustainability culture. J. Manuf. Technol. Manag. 2023, 34, 1162–1182. [Google Scholar] [CrossRef]

- Appiah, L.O.; Owusu-Bio, M.K. Reverse logistics and financial performance in a developing country context: The moderating role of analytics capability. J. Responsible Prod. Consum. 2024, 1, 81–106. [Google Scholar] [CrossRef]

- Liu, Q.; Yang, L.; Yang, M. Digitalisation for Water Sustainability: Barriers to Implementing Circular Economy in Smart Water Management. Sustainability 2021, 13, 11868. [Google Scholar] [CrossRef]

- El Boudali, J.; Mansouri, K.; Qbadou, M. Modelling the design of the reverse logistics network for metal waste. In Proceedings of the 2022 2nd International Conference on Innovative Research in Applied Science, Engineering and Technology (IRASET’2022), Meknes, Morocco, 3–4 March 2022; Benhala, B., Mansouri, K., Raihani, A., Qbadou, M., Eds.; IEEE: New York, NY, USA, 2022; pp. 664–668. [Google Scholar]

- Bajar, K.; Kamat, A.; Shanker, S.; Barve, A. Blockchain technology: A catalyst for reverse logistics of the automobile industry. Smart Sustain. Built Environ. 2024, 13, 133–178. [Google Scholar] [CrossRef]

- Sharma, H. Identifying determinants of refurbished apparel adoption: An attribution theory perspective. J. Consum. Behav. 2024, 23, 3–14. [Google Scholar] [CrossRef]

- Acimovic, S.; Mijuskovic, V.; Rajic, V. The impact of reverse logistics onto green supply chain competitiveness evidence from Serbian consumers. Int. J. Retail Distrib. Manag. 2020, 48, 1003–1021. [Google Scholar] [CrossRef]

- Prajapati, H.; Kant, R.; Shankar, R. Prioritizing the solutions of reverse logistics implementation to mitigate its barriers: A hybrid modified SWARA and WASPAS approach. J. Clean. Prod. 2019, 240, 118219. [Google Scholar] [CrossRef]

- Warfield, J.N. Developing Subsystem Matrices in Structural Modeling. IEEE Trans. Syst. Man. Cybern. 1974, SMC-4, 74–80. [Google Scholar] [CrossRef]

- Mathiyazhagan, K.; Haq, A.N. Analysis of the influential pressures for green supply chain management adoption-an Indian perspective using interpretive structural modeling. Int. J. Adv. Manuf. Technol. 2013, 68, 817–833. [Google Scholar] [CrossRef]

- Kumar, A.; Mangla, S.K.; Luthra, S.; Rana, N.P.; Dwivedi, Y.K. Predicting changing pattern: Building model for consumer decision making in digital market. J. Enterp. Inf. Manag. 2018, 31, 674–703. [Google Scholar] [CrossRef]

- Jha, M.K.; Raut, R.D.; Gardas, B.B.; Raut, V. A sustainable warehouse selection: An interpretive structural modelling approach. Int. J. Procure. Manag. 2018, 11, 201–232. [Google Scholar] [CrossRef]

- Patel, M.N.; Pujara, A.A.; Kant, R.; Malviya, R.K. Assessment of circular economy enablers: Hybrid ISM and fuzzy MICMAC approach. J. Clean. Prod. 2021, 317, 128387. [Google Scholar] [CrossRef]

- Agrawal, N.M. Modeling Deming’s quality principles to improve performance using interpretive structural modeling and MICMAC analysis. Int. J. Qual. Reliab. Manag. 2019, 36, 1159–1180. [Google Scholar] [CrossRef]

- Ahmad, N.; Qahmash, A. SmartISM: Implementation and Assessment of Interpretive Structural Modeling. Sustainability 2021, 13, 8801. [Google Scholar] [CrossRef]

- Bianco, D.; Filho, M.G.; Osiro, L.; Ganga, G.M.D.; Tortorella, G.L. The driving and dependence power between Lean leadership competencies: An integrated ISM/fuzzy MICMAC approach. Prod. Plan. Control 2023, 34, 1037–1061. [Google Scholar] [CrossRef]

- Govindan, K.; Hasanagic, M. A systematic review on drivers, barriers, and practices towards circular economy: A supply chain perspective. Int. J. Prod. Res. 2018, 56, 278–311. [Google Scholar] [CrossRef]

- Abdulrahman, M.D.; Gunasekaran, A.; Subramanian, N. Critical barriers in implementing reverse logistics in the Chinese manufacturing sectors. Int. J. Prod. Econ. 2014, 147, 460–471. [Google Scholar] [CrossRef]

- Lamba, D.; Yadav, D.K.; Barve, A.; Panda, G. Prioritizing barriers in reverse logistics of E-commerce supply chain using fuzzy-analytic hierarchy process. Electron. Commer. Res. 2020, 20. [Google Scholar] [CrossRef]

- Sirisawat, P.; Kiatcharoenpol, T. Fuzzy AHP-TOPSIS approaches to prioritizing solutions for reverse logistics barriers. Comput. Ind. Eng. 2018, 117, 303–318. [Google Scholar] [CrossRef]

- Bouzon, M.; Govindan, K.; Rodriguez, C. Evaluating barriers for reverse logistics implementation under a multiple stakeholders’ perspective analysis using grey decision making approach. Resour. Conserv. Recycl. 2018, 128, 315–335. [Google Scholar] [CrossRef]

- Hsu, C.-H.; Yu, R.-Y.; Chang, A.-Y.; Liu, W.-L.; Sun, A.-C. Applying Integrated QFD-MCDM Approach to Strengthen Supply Chain Agility for Mitigating Sustainable Risks. Mathematics 2022, 10, 552. [Google Scholar] [CrossRef]

- Saraswat, C.; Mishra, B.K.; Kumar, P. Integrated urban water management scenario modeling for sustainable water governance in Kathmandu Valley, Nepal. Sustain. Sci. 2017, 12, 1037–1053. [Google Scholar] [CrossRef]

- Talib, F.; Rahman, Z. Modeling the barriers of Indian telecom services using ISM and MICMAC approach. J. Asia Bus. Stud. 2017, 11, 188–209. [Google Scholar] [CrossRef]

- Dube, A.S.; Gawande, R.R. Analysis of green supply chain barriers using integrated ISM-fuzzy MICMAC approach. Benchmarking Int. J. 2016, 23, 1558–1578. [Google Scholar] [CrossRef]

- Orji, I.J. Examining barriers to organizational change for sustainability and drivers of sustainable performance in the metal manufacturing industry. Resour. Conserv. Recycl. 2019, 140, 102–114. [Google Scholar] [CrossRef]

- Sarkar, A.; Qian, L.; Peau, A.K.; Shahriar, S. Modeling drivers for successful adoption of green business: An interpretive structural modeling approach. Environ. Sci. Pollut. Res. 2021, 28, 1077–1096. [Google Scholar] [CrossRef]

- Morgan, D.; Focus Groups. Doing Social Psychology Research; John Wiley & Sons: New York, NY, USA, 1996; pp. 344–376. [Google Scholar]

- Marshall, C.; Gretchen, R. Designing Qualitative Research, 6th ed.; Sage Publications: New York, NY, USA, 2015. [Google Scholar]

- Kitzinger, J. Qualitative Research: Introducing focus groups. BMJ 1995, 311, 299–302. [Google Scholar] [CrossRef]

- Larson, K.; Grudens-Schuck, N.; Allen, B. Can You Call It a Focus Group? Methodol. Brief 2004, 1–4. Available online: https://dr.lib.iastate.edu/server/api/core/bitstreams/ae91cfd9-b0da-4a9a-b8ae-c7eb588add50/content (accessed on 13 October 2025).

- Pedrosa, M.; Arantes, A.; Cruz, C.O. Barriers to Adopting Lean Methodology in the Portuguese Construction Industry. Buildings 2023, 13, 2047. [Google Scholar] [CrossRef]

- Duperrin, J.-C.; Godet, M.; CEA. Hierarchization Method for the Elements of a System. An Attempt to Forecast a Nuclear Energy System in Its Societal Context; Dept. des Programmes: Paris, France, 1973; pp. 45–51. [Google Scholar]

- Kiatcharoenpol, T.; Sirisawat, P. A selection of barrier factors affecting reverse logistics performance of thai electronic industry. Int. J. Intell. Eng. Syst. 2020, 13. [Google Scholar] [CrossRef]

- Ni, Z.; Zhang, Q.; Hao, J.L.; Liu, X. Toward a better understanding of China’s e-waste reverse logistics implementation barriers: A certified disassembler’s perspective. Sustain. Chem. Pharm. 2024, 41, 101660. [Google Scholar] [CrossRef]

- Arantes, A.; Ferreira, L.M.D.F. Development of delay mitigation measures in construction projects: A combined interpretative structural modeling and MICMAC analysis approach. Prod. Plan. Control 2024, 35, 1164–1179. [Google Scholar] [CrossRef]

- Gorane, S.J.; Kant, R. Modelling the SCM implementation barriers an integrated ISM-fuzzy MICMAC approach. J. Model. Manag. 2015, 10, 158–178. [Google Scholar] [CrossRef]

- Thakur, P.; Wilson, V.H. Analysis of barriers affecting the adoption of community solar from consumer’s perspective: A hybrid ISM-DEMATEL approach. Energy Environ. 2024, 35, 113–141. [Google Scholar] [CrossRef]

- Naseem, M.H.; Yang, J.; Xiang, Z. Prioritizing the solutions to reverse logistics barriers for the e-commerce industry in pakistan based on a fuzzy ahp-topsis approach. Sustainability 2021, 13, 12743. [Google Scholar] [CrossRef]

- Govindan, K.; Bouzon, M. From a literature review to a multi-perspective framework for reverse logistics barriers and drivers. J. Clean. Prod. 2018, 187, 318–337. [Google Scholar] [CrossRef]

- Saglam, Y.C. Does green intellectual capital matter for reverse logistics competency? The role of regulatory measures. J. Intellect. Cap. 2023, 24, 1227–1247. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).