Decarbonising Agriculture with Green Hydrogen: A Stakeholder-Guided Feasibility Study

Abstract

1. Introduction

2. Evidence Synthesis

2.1. Techno-Economic Review of Green H2 in Agriculture

2.2. Social and Regulatory Perspectives of Green H2 Implementation

- What are the techno-economic conditions under which green hydrogen becomes feasible at the farm and cluster scales in UK agriculture?

- How do farmers, developers, and sector experts perceive the opportunities and barriers to hydrogen adoption in rural contexts?

- Which business models (e.g., on-farm refuelling, ammonia-based fertiliser, or cooperative hubs) are most feasible?

3. Materials and Methods

- Techno-economic assessment (quantitative)—to evaluate the cost-effectiveness of green H2 systems through LCOH calculations under different farm-based scenarios.

- Stakeholder analysis (qualitative)—to explore the socio-institutional dimensions of H2 integration in farming, through semi-structured interviews and an expert workshop with professionals and practitioners.

3.1. Techno-Economic Assessment Methodology

3.1.1. Conceptualisation of Green H2 Systems

3.1.2. Proposition of Scenarios for H2 Usage in Farms

- (i)

- H2 consumed by selected farms only

- (ii)

- H2 consumed by heavy vehicles in the surrounding area

3.1.3. Optimisation Model for H2 System Sizing

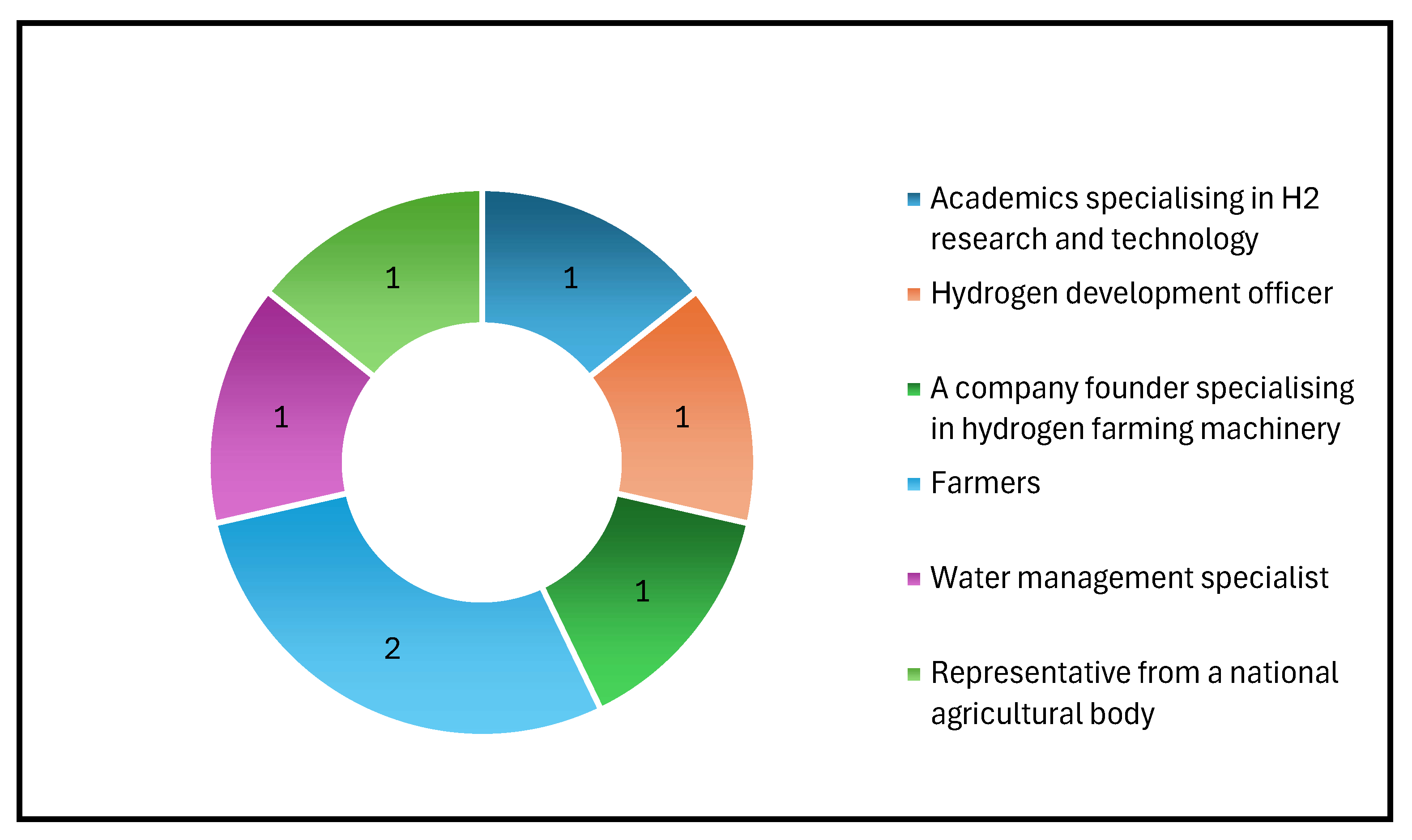

3.2. Qualitative Data Analysis

4. Results and Discussion

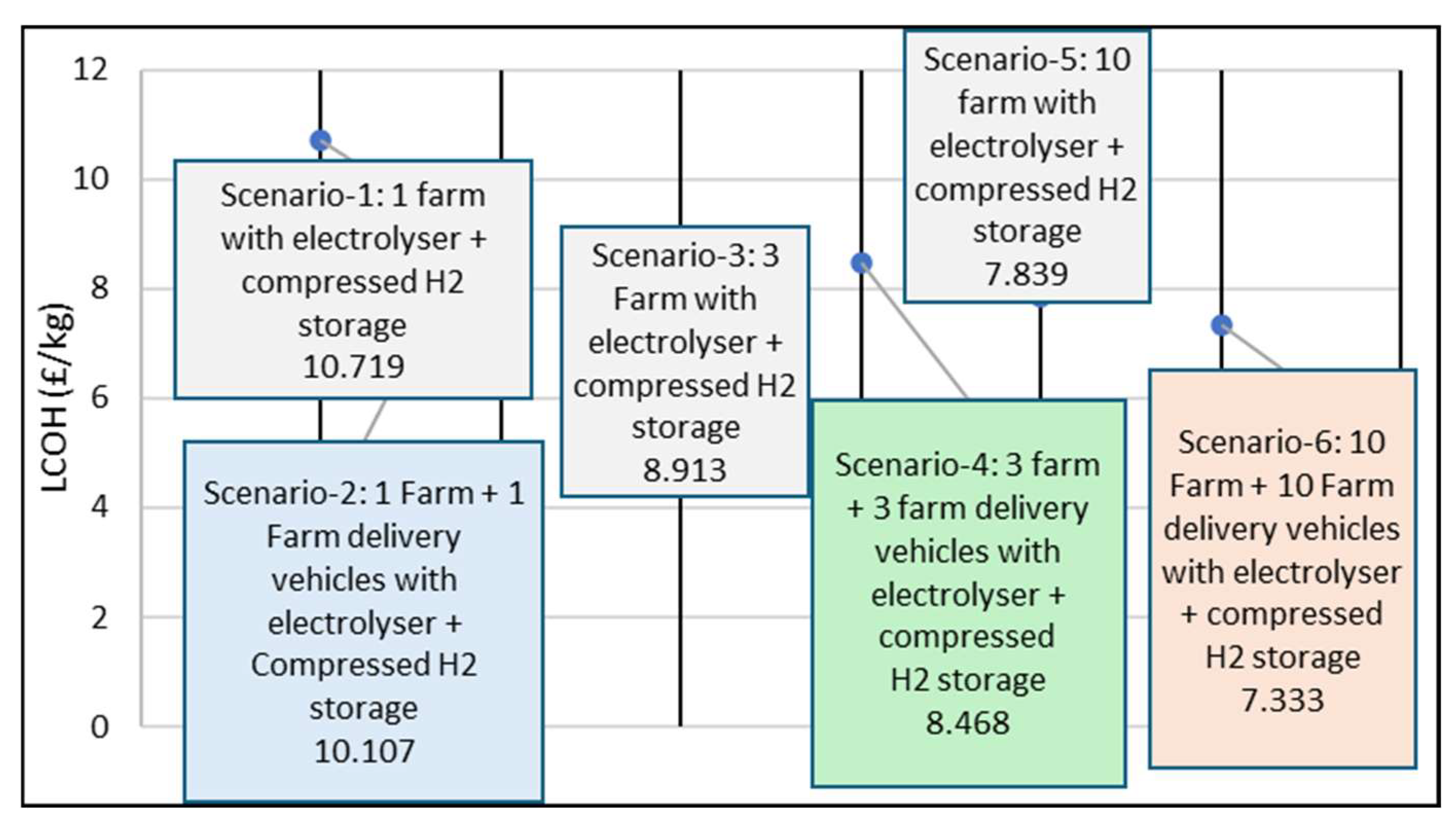

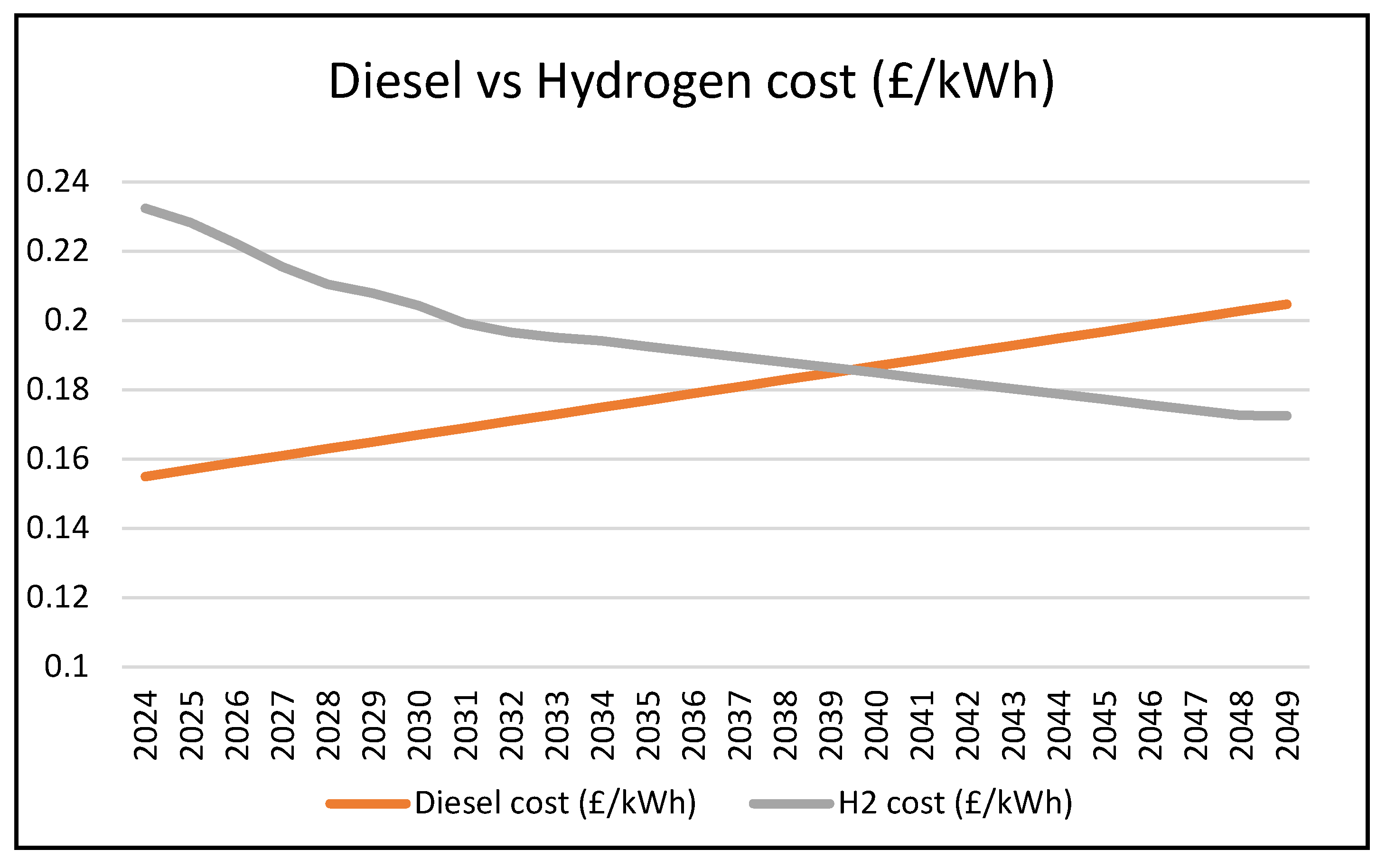

4.1. Techno-Economic Analysis

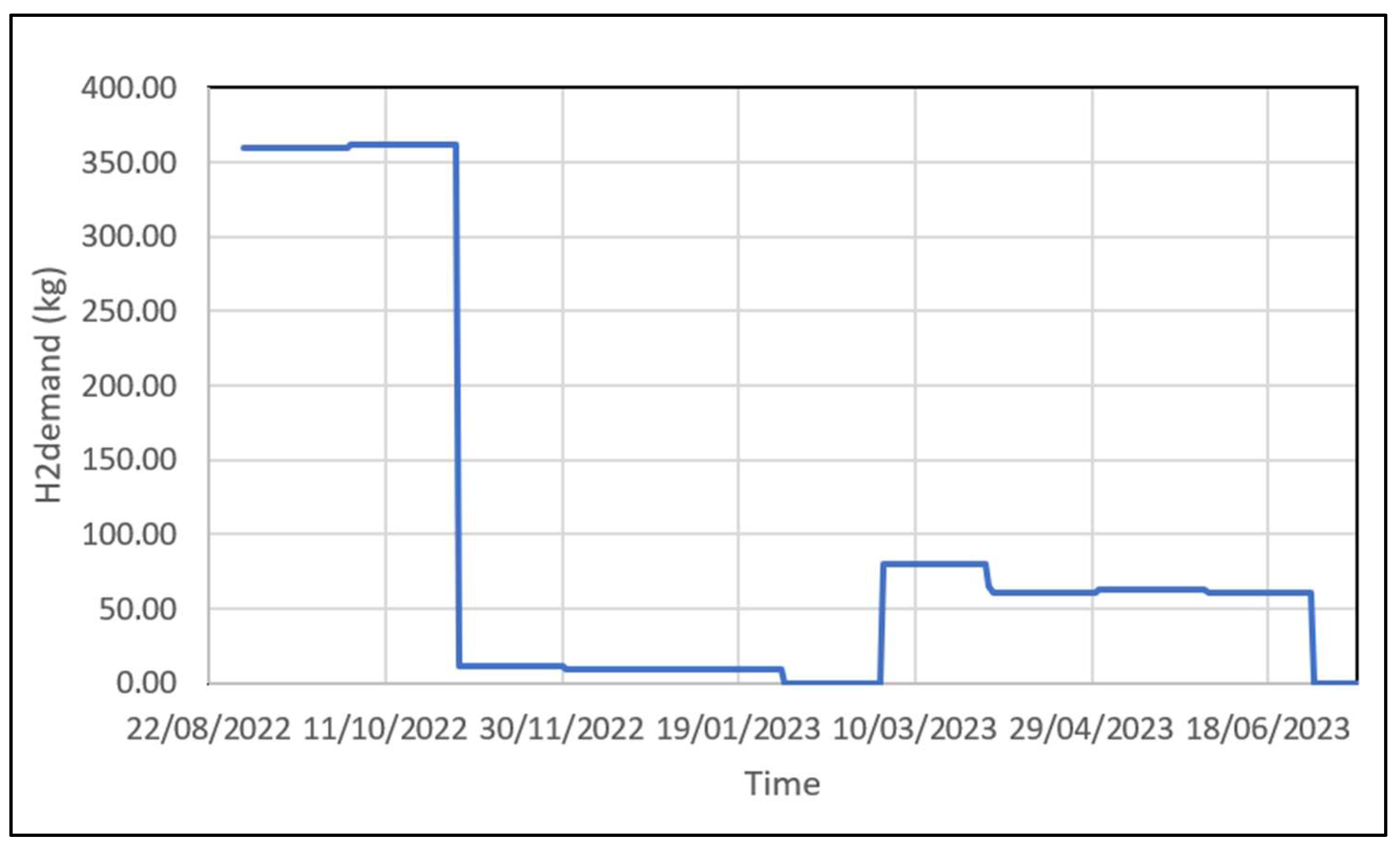

4.1.1. Case Study Setup and Data Collection

4.1.2. Case Study Results

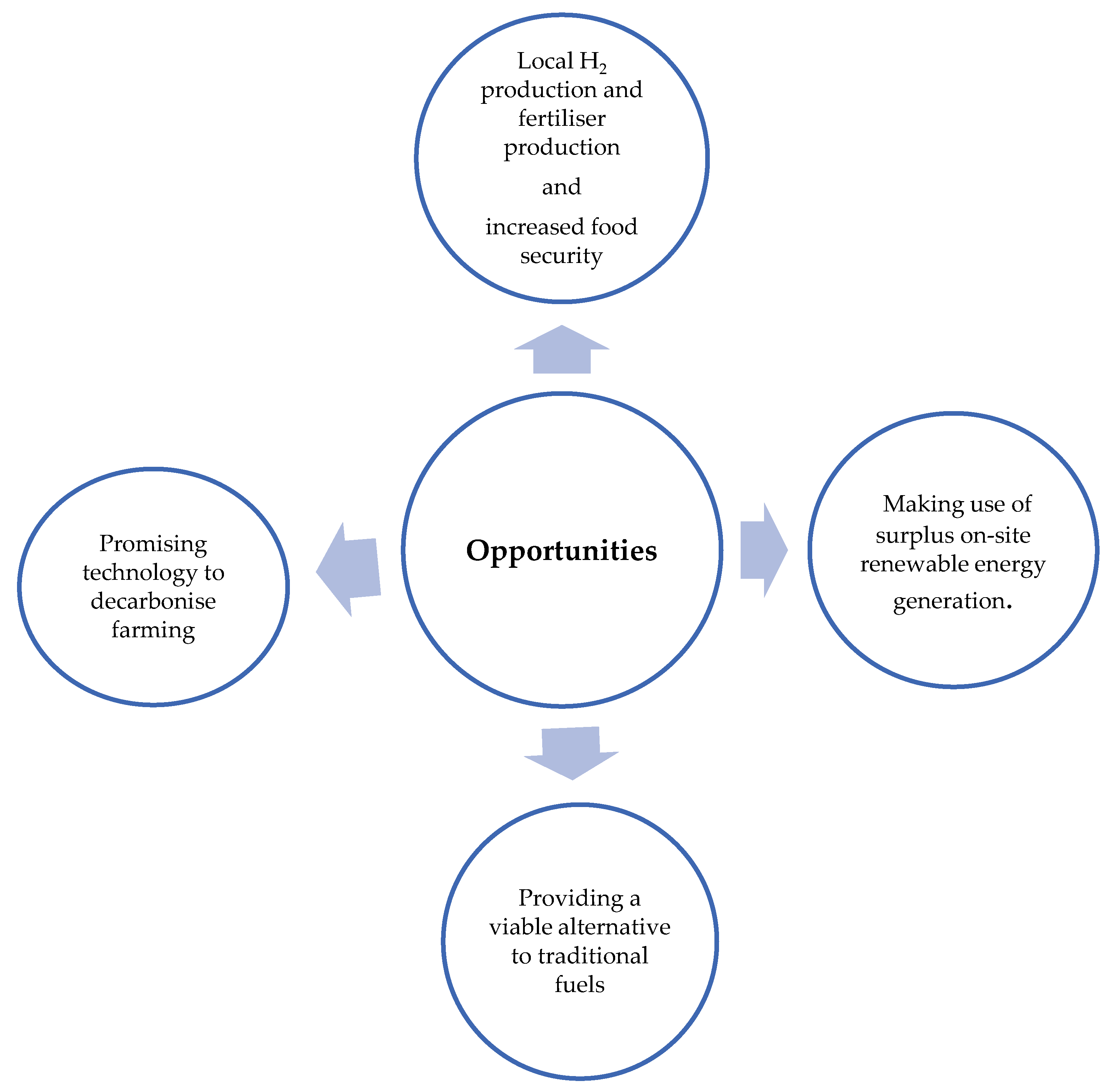

4.2. Key Opportunities from Producing Green H2 in Farming

“I believe H2 gas produced through green electrolysis is the most promising technology for decarbonising the farming sector”.(i1, Farmer A)

“The two biggest expenses on the farm have been fuel and fertiliser. Now, hydrogen has the potential to address both of these costs and could significantly alleviate the problem of high expenses on fuel and fertiliser …Fertiliser prices have been massively inflated by the fertiliser companies. With the added impact of the Ukraine war and other factors, it became almost unaffordable two years ago. This situation poses a serious threat to our food security”.(i1, Farmer A)

“There are many farmers, particularly in Scotland, who have existing wind turbines that are frequently curtailed, meaning they’re not fully utilising the renewable electricity they generate on-site. This presents a viable option for these farms to act as hubs for H2 production, similar to a microgrid model. In this setup, the curtailed energy can be used to produce something valuable rather than being wasted. Wind farms that face curtailment could be particularly suited for hydrogen production, helping to ensure that renewable electricity isn’t wasted”.(I6, a hydrogen development officer)

“Hydrogen can be used to power a combustion engine, though further development is still needed for these engines, which is why it hasn’t yet gone mainstream. However, using hydrogen in combustion engines is a realistic option, especially if the hydrogen is produced through electrolysis on the farm, which is relatively straightforward. This process requires a renewable energy source to power the electrolyser, making on-farm renewable energy crucial for hydrogen production”.(i5, hydrogen farming machinery specialist)

4.3. Barriers to Green H2 Production Across the Farming Sector

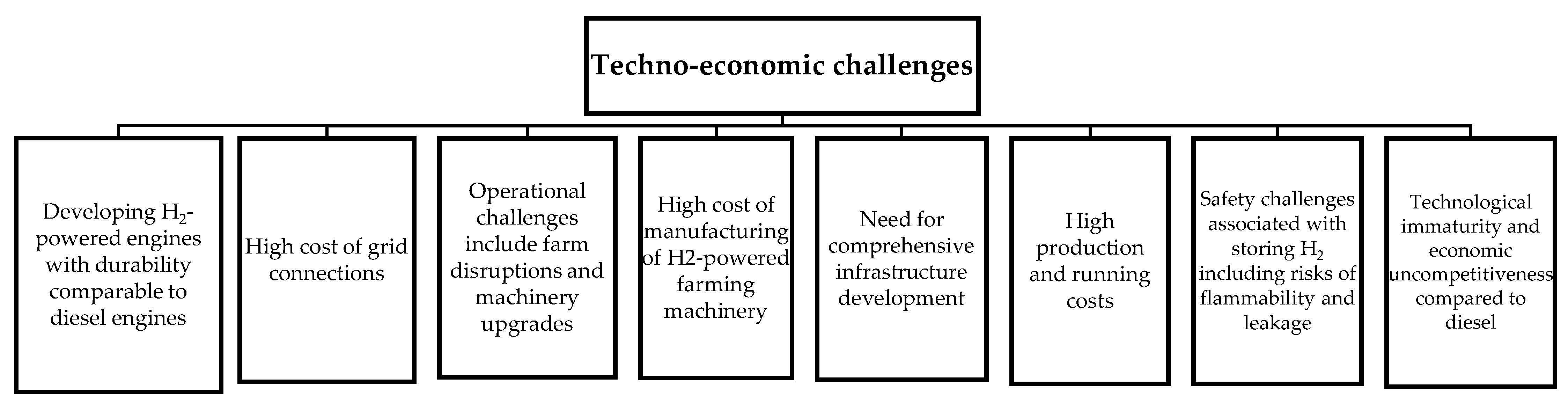

4.3.1. Techno-Economic Challenges

“Farm machinery and other equipment powered entirely by hydrogen is feasible, but current costs are slightly too high. Additionally, there are still very few hydrogen engines available”.(i1, a farmer)

“The biggest barrier to any new technology is often its cost. The key question is how the cost compares to existing solutions”.(i7, representative from an agriculture body)

“The main issue now is reducing costs to improve efficiency and make H2 competitive with diesel.”(i5, founder specialising in hydrogen-powered farming machinery)

“It can be very dangerous if in the wrong hands, but so can certain fuels we use today. Handling things under very high pressure is difficult. Where do we source it from? How does it arrive on the farm? Are we going to produce it ourselves, or will we form collaborations?”(i3, farmer)

“Farmers are unlikely to immediately discard their current equipment and replace it with new technology. The transition would likely occur over time, as the existing equipment reaches the end of its working life and requires replacement”.(i7, representative from an agriculture body)

“The design, construction, or operation of the hydrogen infrastructure should not impact the day-to-day workings of the farm... we’re working closely with our farm manager to mitigate that risk and ensure clear communication about when certain buildings are in use throughout the year”.(i6, hydrogen development officer)

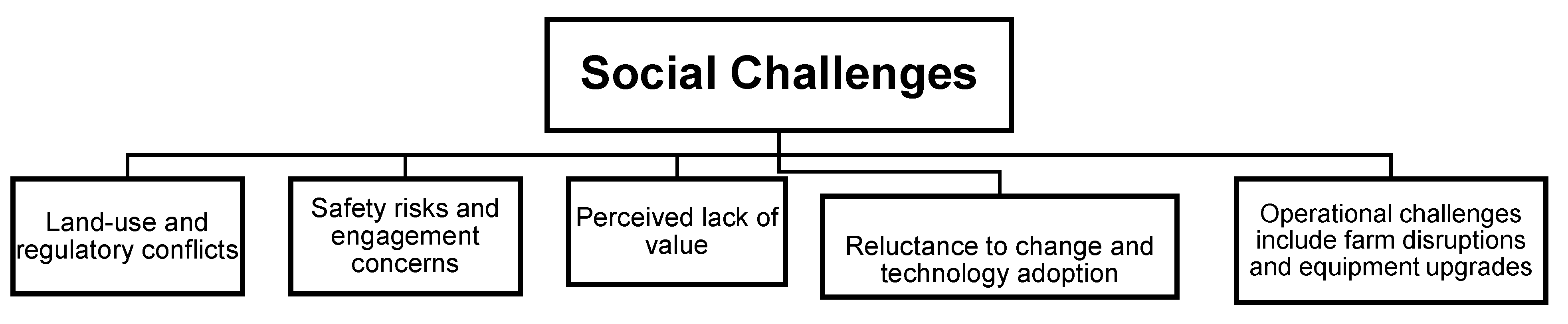

4.3.2. Social Challenges

“I think initially, there would be some reluctance, some scepticism. Farmers, or a group—groups of farmers—tend to be slow to adapt to different techniques, different technologies. But having said that, there are other farmers, other groups of farmers, who are very quick to adapt them and seize new opportunities. And so, if there is a significant benefit”.(i7, representative from an agriculture body)

“Key part of stakeholder engagement is to really hit home about this safety piece as well, because also that’s a concern for some farmers is that you’re storing what is deemed as a, you know, highly explosive flammable gas on an agricultural site, and it’s really just making sure that those safety measures are in place, but also say that when they are in place that there isn’t, there’s quite reduced risk”.(I6, a H2 development officer)

“If you said to someone when they were paying 8 pence per unit for electricity, ‘How would you feel if you had to pay 30 pence per unit?’ they would say, ‘Oh, that’s ridiculous, we wouldn’t have a business, life would grind to a halt.’ And here we are. We’re there, and life is difficult, but it hasn’t ground to a halt.”(i3; a farmer)

4.3.3. Environmental Challenges

“When using non-public water supply sources, farmers’ ability to abstract water is often seasonal. There’s typically more water available in winter, which means you need to consider the amount of storage required”.(i2, a water management specialist)

“If you can store water and take advantage of greater solar energy availability during summer, hydrogen production becomes easier during that period”.(i2, a water management specialist)

4.3.4. Institutional and Legal Challenges

If we really want to implement hydrogen adoption, the government must be involved. Policies need to make hydrogen or green energy more affordable, for example, by cutting taxes for those using these technologies in crop production. Offering incentives, such as tax breaks, would make it more attractive for people to install electrolysers and other hydrogen-related equipment, thereby facilitating the transition to green energy.(i4, an academic specialising in hydrogen research and technology)

“I think it becomes more of an issue when you need to balance agricultural land use for hydrogen energy production instead of food production. That then becomes a much more complex decision.”

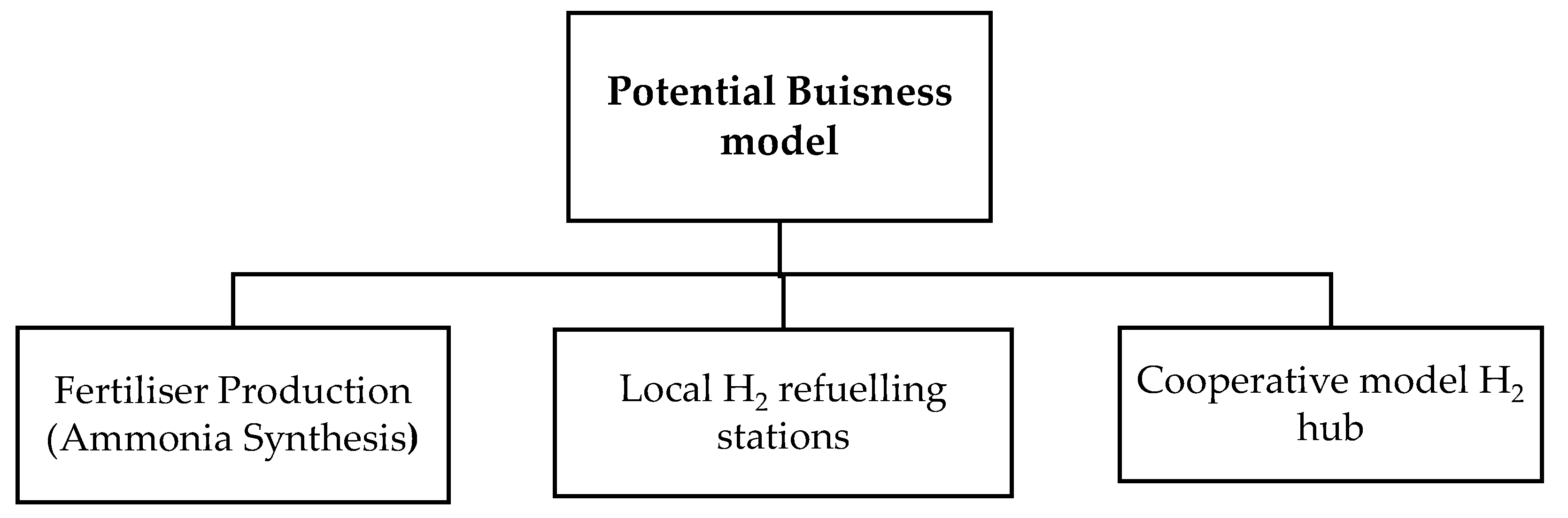

4.4. Alternative Stakeholder-Driven Business Models for Green H2 Deployment

- High Capital Cost and Reliability: Hydrogen refuelling stations are expensive, often costing millions for a single installation. They are complex, bespoke systems, with even advanced designs achieving only about 95% uptime, making rural investment financially challenging [96].

- Regulatory and Planning Hurdles: Strict safety regulations and lengthy approval processes for hydrogen infrastructure can delay projects for years, particularly in remote areas where permitting and compliance are more complex [97].

- Demand Uncertainty and Underutilisation Risks: Demand uncertainty in sparsely populated rural areas poses a significant risk to hydrogen refuelling infrastructure, as insufficient local demand can lead to underutilisation, higher unit costs, and poor economic viability. Studies indicate that small on-farm H2 stations are unlikely to be viable without a consistent baseload demand [97,98].

| Business Model | Advantages | Challenges | Source |

|---|---|---|---|

| Cooperative-Owned Hydrogen Infrastructure |

|

| [91,101] |

| Local H2 Refuelling on Farms |

|

| [96,102,103] |

| On-site Ammonia/Fertiliser Production |

|

| [104,105] |

5. Conclusions and Recommendations

- Techno-economic assessment demonstrates that multi-user systems improve the utilisation rate of hydrogen production systems and therefore reduce the LCOH, making cooperative ownership more attractive than isolated farm systems.

- Stakeholder analysis shows that collective ownership can mitigate farmers’ cost sensitivity and risk aversion, ensuring a fairer distribution of costs and benefits.

- Recommendations:

- Provide targeted incentives (capital grants, tax breaks, and contracts-for-difference) to lower upfront costs and de-risk cooperative investment.

- Streamline planning and safety approval processes to accelerate rural hydrogen hub deployment.

- Expand cooperative hydrogen pilots to refine governance, financing, and business models in diverse agricultural contexts.

- Avenues for Further Research

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| Abbreviation | Definition |

| H2 | Hydrogen |

| IRENA | International Renewable Energy Agency |

| kWh | Kilowatt-hour |

| LCOH | Levelised Cost of Hydrogen |

| P | Pence |

References

- IEA. Global Hydrogen Review 2021. Available online: https://iea.blob.core.windows.net/assets/5bd46d7b-906a-4429-abda-e9c507a62341/GlobalHydrogenReview2021.pdf (accessed on 5 September 2025).

- Nnabuife, S.G.; Oko, E.; Kuang, B.; Bello, A.; Onwualu, A.P.; Oyagha, S.; Whidborne, J. The prospects of hydrogen in achieving net zero emissions by 2050: A critical review. Sustain. Chem. Clim. Action 2023, 2, 100024. [Google Scholar] [CrossRef]

- McKinsey & Company. Global Energy Perspective 2023_Hydrogen Outlook_McKinsey; McKinsey & Company: New York, NY, USA, 2023. [Google Scholar]

- Carbonbrief. Climate Justice: The Challenge of Achieving a ‘Just Transition’ in Agriculture. Available online: https://www.carbonbrief.org/gue (accessed on 4 June 2025).

- DEFRA, 2023. Agri-Climate Report 2023. Available online: https://www.gov.uk/government/statistics/agri-climate-report-2023/agri-climate-report-2023 (accessed on 10 June 2025).

- DESNZ. Hydrogen Blending into GB Gas Distribution Networks A Consultation to Further Assess the Case for Hydrogen Blending and Lead Options for its Implementation, If Enabled; Department for Energy Security and Net Zero: London, UK, 2023. [Google Scholar]

- Department for Transport and Anthony Browne. Farming and Construction Vehicles Set for Hydrogen-Powered Revolution; Department for Transport and Anthony Browne: London, UK, 2024. [Google Scholar]

- U.S. Department of Energy. There Are Now More Than 20,000 Hydrogen Fuel Cell Forklifts in Use Across the United States. 2018. Available online: https://www.energy.gov/eere/fuelcells/fact-month-november-2018-there-are-now-more-20000-hydrogen-fuel-cell-forklifts-use? (accessed on 29 September 2025).

- DOE. Hydrogen Fuel Cells in Farm Equipment. 2021. Available online: https://science.osti.gov/-/media/sbir/pdf/Market-Research/HFCT---Hydrogen-Fuel-Cells-in-Farm-Equipment-June-2021-Public.pdf (accessed on 29 September 2025).

- BEIS. UK Hydrogen Strategy. Chem. Ind. 2021, 85, 17. [Google Scholar] [CrossRef]

- IRENA. Renewable Power Generation Costs in 2020. 2020. Available online: https://www.irena.org/-/media/Files/IRENA/Agency/Publication/2018/Jan/IRENA_2017_Power_Costs_2018.pdf (accessed on 3 June 2025).

- Bade, S.O.; Tomomewo, O.S. A review of governance strategies, policy measures, and regulatory framework for hydrogen energy in the United States. Int. J. Hydrog. Energy 2024, 78, 1363–1381. [Google Scholar] [CrossRef]

- Fitton, N.; Alexander, P.; Arnell, N.; Bajzelj, B.; Calvin, K.; Doelman, J.; Gerber, J.; Havlik, P.; Hasegawa, T.; Herrero, M.; et al. The vulnerabilities of agricultural land and food production to future water scarcity. Glob. Environ. Change 2019, 58, 101944. [Google Scholar] [CrossRef]

- Awad, M.; Said, A.; Saad, M.H.; Farouk, A.; Mahmoud, M.M.; Alshammari, M.S.; Alghaythi, M.L.; Aleem, S.H.A.; Abdelaziz, A.Y.; Omar, A.I. A review of water electrolysis for green hydrogen generation considering PV/wind/hybrid/hydropower/geothermal/tidal and wave/biogas energy systems, economic analysis, and its application. Alex. Eng. J. 2024, 87, 213–239. [Google Scholar] [CrossRef]

- Ribeiro, C.; Santos, D.M.F. Transitioning Ammonia Production: Green Hydrogen-Based Haber–Bosch and Emerging Nitrogen Reduction Technologies. Clean Technol. 2025, 7, 49. [Google Scholar] [CrossRef]

- Janke, L.; McDonagh, S.; Weinrich, S.; Nilsson, D.; Hansson, P.-A.; Nordberg, Å. Techno-Economic Assessment of Demand-Driven Small-Scale Green Hydrogen Production for Low Carbon Agriculture in Sweden. Front. Energy Res. 2020, 8, 595224. [Google Scholar] [CrossRef]

- Osorio-Tejada, J.; Tran, N.N.; Hessel, V. Techno-environmental assessment of small-scale Haber-Bosch and plasma-assisted ammonia supply chains. Sci. Total Environ. 2022, 826, 154162. [Google Scholar] [CrossRef]

- Magnino, A.; Marocco, P.; Santarelli, M.; Gandiglio, M. Economic viability and CO2 emissions of hydrogen production for ammonia synthesis: A comparative analysis across Europe. Adv. Appl. Energy 2025, 17, 100204. [Google Scholar] [CrossRef]

- Alban Thurston. Royal Society_Ammonia Could Power Shipping, District Heating and Storage. 2020. Available online: https://theenergyst.com/royal-society-ammonia-could-power-shipping-district-heating-and-storage/#:~:text=The%20Royal%20Society%20says%20’green,existing%20pipes%20and%20distribution%20infrastructure (accessed on 28 August 2025).

- Davenne, T.; Huddart, A.; Cowan, R.; Tallentire, D.; Peters, B.; Smith, J.; Ruddell, A.; Halliday, J.; Reid, A.; Livermore, S.; et al. Ammonia Synthesis Plant from Intermittent Renewable Energy (ASPIRE): Feasibility Study; Frazer-Nash Consultancy: Leatherhead, UK, 2022. [Google Scholar]

- Abdelsalam, R.A.; Mohamed, M.; Farag, H.E.; El-Saadany, E.F. Green hydrogen production plants: A techno-economic review. Energy Convers. Manag. 2024, 319, 118907. [Google Scholar] [CrossRef]

- Al-Sharafi, A.; Sahin, A.Z.; Ayar, T.; Yilbas, B.S. Techno-economic analysis and optimization of solar and wind energy systems for power generation and hydrogen production in Saudi Arabia. Renew. Sustain. Energy Rev. 2017, 69, 33–49. [Google Scholar] [CrossRef]

- Babaei, R.; Ting, D.S.-K.; Carriveau, R. Optimization of hydrogen-producing sustainable island microgrids. Int. J. Hydrog. Energy 2022, 47, 14375–14392. [Google Scholar] [CrossRef]

- Park, J.; Kang, S.; Kim, S.; Kim, H.; Cho, H.-S.; Lee, J.H. Enhancing the economic viability and reliability of renewables based electricity supply through Power-to-Gas-to-Power with green hydrogen. Energy Convers. Manag. 2024, 310, 118485. [Google Scholar] [CrossRef]

- Henry, A.; McStay, D.; Rooney, D.; Robertson, P.; Foley, A. Techno-economic analysis to identify the optimal conditions for green hydrogen production. Energy Convers. Manag. 2023, 291, 117230. [Google Scholar] [CrossRef]

- Jang, D.; Kim, K.; Kim, K.-H.; Kang, S. Techno-economic analysis and Monte Carlo simulation for green hydrogen production using offshore wind power plant. Energy Convers. Manag. 2022, 263, 115695. [Google Scholar] [CrossRef]

- Vallejos-Romero, A.; Cordoves-Sánchez, M.; Cisternas, C.; Sáez-Ardura, F.; Rodríguez, I.; Aledo, A.; Boso, Á.; Prades, J.; Álvarez, B. Green Hydrogen and Social Sciences: Issues, Problems, and Future Challenges. Sustainability 2023, 15, 303. [Google Scholar] [CrossRef]

- Itaoka, K.; Saito, A.; Sasaki, K. Public perception on hydrogen infrastructure in Japan: Influence of rollout of commercial fuel cell vehicles. Int. J. Hydrog. Energy 2017, 42, 7290–7296. [Google Scholar] [CrossRef]

- Bellaby, P.; Upham, P.; Flynn, R.; Ricci, M. Unfamiliar fuel: How the UK public views the infrastructure required to supply hydrogen for road transport. Int. J. Hydrog. Energy 2016, 41, 6534–6543. [Google Scholar] [CrossRef]

- Bögel, P.; Oltra, C.; Sala, R.; Lores, M.; Upham, P.; Dütschke, E.; Schneider, U.; Wiemann, P. The role of attitudes in technology acceptance management: Reflections on the case of hydrogen fuel cells in Europe. J. Clean. Prod. 2018, 188, 125–135. [Google Scholar] [CrossRef]

- Gordon, J.A.; Balta-Ozkan, N.; Nabavi, S.A. Beyond the triangle of renewable energy acceptance: The five dimensions of domestic hydrogen acceptance. Appl. Energy 2022, 324, 119715. [Google Scholar] [CrossRef]

- Wolsink, M. Social acceptance revisited: Gaps, questionable trends, and an auspicious perspective. Energy Res. Soc. Sci. 2018, 46, 287–295. [Google Scholar] [CrossRef]

- Wüstenhagen, R.; Wolsink, M.; Bürer, M.J. Social acceptance of renewable energy innovation: An introduction to the concept. Energy Policy 2007, 35, 2683–2691. [Google Scholar] [CrossRef]

- Gordon, J.A.; Balta-Ozkan, N.; Haq, A.; Nabavi, S.A. Coupling green hydrogen production to community benefits: A pathway to social acceptance? Energy Res. Soc. Sci. 2024, 110, 103437. [Google Scholar] [CrossRef]

- Bentsen, H.L.; Skiple, J.K.; Gregersen, T.; Derempouka, E.; Skjold, T. In the green? Perceptions of hydrogen production methods among the Norwegian public. Energy Res. Soc. Sci. 2023, 97, 102985. [Google Scholar] [CrossRef]

- Carr-Cornish, S.; Lamb, K.; Rodriguez, M.; Gardner, J. Social Science for a Hydrogen Energy Future A Review of Existing Knowledge, Potential Risks from Society’s Response, and Science Pathways for Social Responsibility; Commonwealth Scientific and Industrial Research Organisation: Canberra, Australia, 2019. [Google Scholar]

- IRENA. Making the Breakthrough Green Hydrogen Policies and Technology Costs. 2021. Available online: https://www.irena.org/-/media/Files/IRENA/Agency/Publication/2020/Nov/IRENA_Green_Hydrogen_breakthrough_2021.pdf?la=en&hash=40FA5B8AD7AB1666EECBDE30EF458C45EE5A0AA6 (accessed on 25 July 2025).

- Anthony, K.; Hellström, M.; Spohr, J. Techno-economic assessment of hydrogen application in cereal crop farming. Front. Energy Res. 2025, 13, 1479212. [Google Scholar] [CrossRef]

- Lin, N.; Wang, H.; Moscardelli, L.; Shuster, M. The dual role of low-carbon ammonia in climate-smart farming and energy transition. J. Clean. Prod. 2024, 469, 143188. [Google Scholar] [CrossRef]

- Roy, T.K. Techno-economic and environmental assessment of green hydrogen production in multiple Australian regions using different electrolyzer technologies. Renew. Energy 2025, 256, 123879. [Google Scholar] [CrossRef]

- Wolf, N.; Neuber, R.; Mädlow, A.; Höck, M. Techno-economic analysis of green hydrogen supply for a hydrogen refueling station in Germany. Int. J. Hydrog. Energy 2025, 106, 318–333. [Google Scholar] [CrossRef]

- Tunn, J.; Kalt, T.; Müller, F.; Simon, J.; Hennig, J.; Ituen, I.; Glatzer, N. Green hydrogen transitions deepen socioecological risks and extractivist patterns: Evidence from 28 prospective exporting countries in the Global South. Energy Res. Soc. Sci. 2024, 117, 103731. [Google Scholar] [CrossRef]

- Hahn, C.; Lindkvist, E.; Magnusson, D.; Johansson, M. The role of agriculture in a sustainable energy system—The farmers’ perspective. Renew. Sustain. Energy Rev. 2025, 213, 115437. [Google Scholar] [CrossRef]

- Multi-Criteria Decision Analysis. Multi-Criteria Decision Analysis. 2023. Available online: https://www.1000minds.com/decision-making/what-is-mcdm-mcda (accessed on 2 September 2025).

- Department for Environment Food & Rural Affairs. Chapter 7: Crops. 2022. Available online: https://www.gov.uk/government/statistics/agriculture-in-the-united-kingdom-2022/chapter-7-crops (accessed on 20 September 2024).

- Gordon, J.A.; Balta-Ozkan, N.; Nabavi, S.A. Gauging public perceptions of blue and green hydrogen futures: Is the twin-track approach compatible with hydrogen acceptance? Int. J. Hydrog. Energy 2023, 49, 75–104. [Google Scholar] [CrossRef]

- Guest, G.; Bunce, A.; Johnson, L. How Many Interviews Are Enough?: An Experiment with Data Saturation and Variability. Field Methods 2006, 18, 59–82. [Google Scholar] [CrossRef]

- Lumivero (2024) NVivo (Version 14). Available online: https://lumivero.com/products/nvivo/ (accessed on 20 July 2024).

- Praveenkumar, S.; Agyekum, E.B.; Ampah, J.D.; Afrane, S.; Velkin, V.I.; Mehmood, U.; Awosusi, A.A. Techno-economic optimization of PV system for hydrogen production and electric vehicle charging stations under five different climatic conditions in India. Int. J. Hydrog. Energy 2022, 47, 38087–38105. [Google Scholar] [CrossRef]

- DESNZ. Quarterly Energy Prices. 2023. Available online: https://www.gov.uk/government/collections/quarterly-energy-prices (accessed on 20 September 2025).

- International Renewable Energy Agency, Renewable Power Generation Costs in 2021. 2022. Available online: https://www.irena.org/-/media/Files/IRENA/Agency/Publication/2022/Jul/IRENA_Power_Generation_Costs_2021.pdf (accessed on 11 July 2025).

- IRENA. Green Hydrogen Cost Reduction Scaling up Electrolysers to Meet the 1.5 °C Climate Goal H2O2. 2020. Available online: www.irena.org/publications (accessed on 10 August 2025).

- IRENA. Hydrogen; Blackwell Publishing: Oxford, UK, 2022; Available online: https://www.irena.org/Energy-Transition/Technology/Hydrogen (accessed on 23 April 2025).

- BEIS. Electricity Generation Cost Report 2020; Department for Energy Security and Net Zero and Department for Business, Energy & Industrial Strategy: London, UK, 2020; p. 69. [Google Scholar]

- Karagöz, Y.; Sandalcı, T.; Yüksek, L.; Dalkılıç, A.S.; Wongwises, S. Effect of hydrogen-diesel dual-fuel usage on performance, emissions and diesel combustion in diesel engines. Adv. Mech. Eng. 2016, 8, 1687814016664458. [Google Scholar] [CrossRef]

- Bika, A.S.; Franklin, L.M.; Kittelson, D.B. Emissions effects of hydrogen as a supplemental fuel with diesel and biodiesel. SAE Int. J. Fuels Lubr. 2009, 1, 283–292. [Google Scholar] [CrossRef]

- IRENA. Green Hydrogen: A Guide to Policy Making; International Renewable Energy Agency: Masdar City, Abu Dhabi, 2020. [Google Scholar]

- Maganza, A.; Gabetti, A.; Pastorino, P.; Zanoli, A.; Sicuro, B.; Barcelò, D.; Cesarani, A.; Dondo, A.; Prearo, M.; Esposito, G. Toward Sustainability: An Overview of the Use of Green Hydrogen in the Agriculture and Livestock Sector. Animals 2023, 13, 2561. [Google Scholar] [CrossRef]

- Hailes, O. From guano to green hydrogen: Food security and fertilizer disputes in international energy law. J. Int. Econ. Law 2023, 26, 663–683. [Google Scholar] [CrossRef]

- Nallapaneni, A.; Sood, S. Green Hydrogen Adoption in Fertilizer Manufacturing: Opportunities and Challenges. 2023. Available online: https://wri-india.org/blog/green-hydrogen-adoption-fertilizer-manufacturing-opportunities-and-challenges (accessed on 19 September 2025).

- IBISWorld. Fertiliser Prices. 2024. Available online: https://www.ibisworld.com/uk/bed/fertiliser-prices/44250/#:~:text=In (accessed on 20 September 2025).

- Drax. Renewable Curtailment and the Role of Long Duration Storage. 2022. Available online: https://www.drax.com/wp-content/uploads/2022/06/Drax-LCP-Renewable-curtailment-report-1.pdf (accessed on 17 October 2024).

- Carbontracker. Britain Wastes Enough Wind Generation to Power 1 Million Homes Related Report Media Resources Gone with the Wind? 2023. Available online: https://carbontracker.org/britain-wastes-enough-wind-generation-to-power-1-million-homes/#:~:text=Overall%2C (accessed on 23 September 2025).

- Yue, M.; Lambert, H.; Pahon, E.; Roche, R.; Jemei, S.; Hissel, D. Hydrogen energy systems: A critical review of technologies, applications, trends and challenges. Renew. Sustain. Energy Rev. 2021, 146, 111180. [Google Scholar] [CrossRef]

- Browne, A. Farming and Construction Vehicles Set for Hydrogen-Powered Revolution. 2024. Available online: https://www.gov.uk/government/news/farming-and-construction-vehicles-set-for-hydrogen-powered-revolution (accessed on 16 October 2025).

- Rameez, P.; Ibrahim, M.M. A comprehensive review on the utilization of hydrogen in low temperature combustion strategies: Combustion, performance and emission attributes. J. Energy Inst. 2024, 113, 101511. [Google Scholar] [CrossRef]

- Lopez, V.M.; Ziar, H.; Haverkort, J.; Zeman, M.; Isabella, O. Dynamic operation of water electrolyzers: A review for applications in photovoltaic systems integration. Renew. Sustain. Energy Rev. 2023, 182, 113407. [Google Scholar] [CrossRef]

- Bade, S.O.; Tomomewo, O.S.; Meenakshisundaram, A.; Ferron, P.; Oni, B.A. Economic, social, and regulatory challenges of green hydrogen production and utilization in the US: A review. Int. J. Hydrogen Energy 2024, 49, 314–335. [Google Scholar] [CrossRef]

- Kumar, S.S.; Lim, H. An overview of water electrolysis technologies for green hydrogen production. Energy Rep. 2022, 8, 13793–13813. [Google Scholar] [CrossRef]

- IRENA Green Hydrogen Cost Reduction 2020. Available online: https://www.irena.org/publications/2020/Dec/Green-hydrogen-cost-reduction (accessed on 25 September 2025).

- Pallares, C. The Barriers for a Hydrogen Economy. 2012. Available online: https://papers.ssrn.com/sol3/papers.cfm?abstract_id=2060304 (accessed on 16 October 2025).

- Chung, D.; Kwon, Y.; Kim, Z. Technology life cycle and commercialization readiness of hydrogen production technology using patent analysis. Int. J. Hydrog. Energy 2023, 48, 12139–12154. [Google Scholar] [CrossRef]

- Optimas. Hydrogen Powered Farm Machinery. Available online: https://optimas.com/en_gb/blog/hydrogen-powered-farm-machinery/ (accessed on 15 August 2025).

- Salimi, M.; Hosseinpour, M.; N.Borhani, T. The Role of Clean Hydrogen Value Chain in a Successful Energy Transition of Japan. Energies 2022, 15, 6064. [Google Scholar] [CrossRef]

- Tashie-Lewis, B.C.; Nnabuife, S.G. Hydrogen Production, Distribution, Storage and Power Conversion in a Hydrogen Economy—A Technology Review. Chem. Eng. J. Adv. 2021, 8, 100172. [Google Scholar] [CrossRef]

- Calabrese, M.; Portarapillo, M.; Di Nardo, A.; Venezia, V.; Turco, M.; Luciani, G.; Di Benedetto, A. Hydrogen Safety Challenges: A Comprehensive Review on Production, Storage, Transport, Utilization, and CFD-Based Consequence and Risk Assessment. Energies 2024, 17, 1350. [Google Scholar] [CrossRef]

- JCB. JCB’s Hydrogen-Fuelled Combustion Engine Examined. Available online: https://www.fwi.co.uk/machinery/technology/jcbs-hydrogen-fuelled-combustion-engine-examined#:~:text=Comparatively%2C (accessed on 25 September 2025).

- Halder, P.; Babaie, M.; Salek, F.; Shah, K.; Stevanovic, S.; Bodisco, T.A.; Zare, A. Performance, emissions and economic analyses of hydrogen fuel cell vehicles. Renew. Sustain. Energy Rev. 2024, 199, 114543. [Google Scholar] [CrossRef]

- Hienuki, S.; Hirayama, Y.; Shibutani, T.; Sakamoto, J.; Nakayama, J.; Miyake, A. How knowledge about or experience with hydrogen fueling stations improves their public acceptance. Sustainability 2019, 11, 6339. [Google Scholar] [CrossRef]

- Robles, J.O.; Azzaro-Pantel, C.; Garcia, G.M.; Lasserre, A.A. Social cost-benefit assessment as a post- optimal analysis for hydrogen supply chain design and deployment: Application to Occitania (France). Sustain. Prod. Consum. 2020, 24, 105–120. [Google Scholar] [CrossRef]

- Dahncke, H. Combining environmental education with experience of industry in teacher education. Eur. J. Teach. Educ. 2006, 20, 151–159. [Google Scholar] [CrossRef]

- Glanz, S.; Schönauer, A.-L. Towards a low-carbon society via hydrogen and carbon capture and storage: Social acceptance from a stakeholder perspective. J. Sustain. Dev. Energy Water Environ. Syst. 2021, 9, 1080322. [Google Scholar] [CrossRef]

- Hadebe, S.T.; Modi, A.T.; Mabhaudhi, T. Drought Tolerance and Water Use of Cereal Crops: A Focus on Sorghum as a Food Security Crop in Sub-Saharan. Afr. J. Agron. Crop. Sci. 2017, 203, 177–191. [Google Scholar] [CrossRef]

- Ward, J.; Wentworth, J. Water Supply Resilience and Climate Change. 2021. Available online: https://researchbriefings.files.parliament.uk/documents/POST-PB-0040/POST-PB-0040.pdf (accessed on 29 October 2024).

- Rey, D.; Holman, I.P.; Knox, J.W. Developing drought resilience in irrigated agriculture in the face of increasing water scarcity. Reg. Environ. Change 2017, 17, 1527–1540. [Google Scholar] [CrossRef] [PubMed]

- Department for Energy Security & Net Zero. Net Zero Hydrogen Fund Strands 1 and 2. 2022. Available online: https://apply-for-innovation-funding.service.gov.uk/competition/1540/overview/9c2c00ea-5749-42af-abd5-c7026d0e4f64 (accessed on 27 September 2025).

- Department for Energy Security & Net Zero. Hydrogen Production Business Model. 2022. Available online: https://www.gov.uk/government/publications/hydrogen-production-business-model (accessed on 26 September 2025).

- Ndi, F.A. Land acquisition, renewable energy development, and livelihood transformation in rural Kenya: The case of the Kipeto wind energy project. Energy Res. Soc. Sci. 2024, 112, 103530. [Google Scholar] [CrossRef]

- Borders Machinery Ring. Machinery Ring History. Available online: https://www.bordersmachineryring.co.uk/our-history?utm_source=chatgpt.com (accessed on 27 August 2025).

- Tom MacMillan & George Cusworth. Farmer Cooperation in the UK. 2019. Available online: https://www.uk.coop/sites/default/files/2020-11/farmer_co-operation_in_the_uk_report.pdf?utm_source=chatgpt.com (accessed on 27 August 2025).

- James Hutton Institute. HydroGlen Renewable Hydrogen Powered Farm. 2021. Available online: https://www.hutton.ac.uk/ (accessed on 26 September 2025).

- Prism. Sustainability. Financing Models for Energy Cooperatives in Underserved Regions. 2025. Available online: https://prism.sustainability-directory.com/scenario/financing-models-for-energy-cooperatives-in-underserved-regions (accessed on 26 September 2025).

- Mirzania, P.; Balta-Ozkan, N.; Ford, A. An innovative viable model for community-owned solar PV projects without FIT: Comprehensive techno-economic assessment. Energy Policy 2020, 146, 111727. [Google Scholar] [CrossRef]

- Lister, M. Home-Made Hydrogen_West Sussex Farm Fuels Riversimple Rasa—Driving Hydrogen. Available online: https://drivinghydrogen.com/2025/06/13/home-made-hydrogen-west-sussex-farm-fuels-riversimple-rasa/#:~:text=%E2%80%9CEngas%20Global%20Steyning%20is%20demonstrating,%E2%80%9D (accessed on 27 August 2025).

- Sussex World. Horsham Company Helps Pioneer Next Generation of Hydrogen Electric Cars. Available online: https://www.sussexexpress.co.uk/business/consumer/horsham-company-helps-pioneer-next-generation-of-hydrogen-electric-cars-5179553#:~: (accessed on 27 August 2025).

- Cenex. Hydrogen Farm of the Future; Cenex: Inver Grove Heights, MN, USA, 2025. [Google Scholar]

- Ove Arup & Partner. Aberdeen City Region Hydrogen Refuelling Study. 2024. Available online: https://www.nestrans.org.uk/wp-content/uploads/2024/11/Arup-Hydrogen-Refueller-Study-Final-Report-Apr-24.pdf#:~:text=A%20major%20challenge%20to%20deploying,path%20forward%20for%20further%20hydrogen (accessed on 27 August 2025).

- Li, Y.; Kool, C.; Engelen, P.-J. Analyzing the business case for hydrogen-fuel infrastructure investments with endogenous demand in the Netherlands: A real options approach. Sustainability 2020, 12, 5424. [Google Scholar] [CrossRef]

- H2 Station Maps. Costs and Financing_H2 Station Maps. 2025. Available online: https://h2stationmaps.com/costs-and-financing? (accessed on 26 September 2025).

- Interreg Europe. Public-Private Collaboration to Develop a Broad Green Hydrogen Ecosystem and Roadmap in Mallorca. 2025. Available online: https://www.interregeurope.eu/good-practices/public-private-collaboration-to-develop-a-broad-green-hydrogen-ecosystem-and-roadmap-in-mallorca-0#:~:text=This%20holistic%20approach%20with%20its,covers%20the%20whole%20value%20chain (accessed on 26 September 2025).

- Sołtysik, M.; Kozakiewicz, M.; Jasiński, J. The Potential for the Use of Hydrogen Storage in Energy Cooperatives. Appl. Sci. 2024, 14, 9753. [Google Scholar] [CrossRef]

- Fuel Cells Works. There is No Chicken and Egg Paradox—And This Farm in West Sussex is Showing Us Why. 2025. Available online: https://fuelcellsworks.com/2025/06/16/fuel-cells/there-is-no-chicken-and-egg-paradox-and-this-farm-in-west-sussex-is-showing-us-why?utm_source=chatgpt.com (accessed on 27 August 2025).

- Farming. Green Growth Hydrogen Role in Powering the Future of Agriculture. 2024. Available online: https://farming.co.uk/news/green-growth-hydrogen-role-in-powering-the-future-of-agriculture?utm_source=chatgpt.com (accessed on 27 August 2025).

- Atchison, J. Talus Renewables: Modular, Renewable Fertilizers in Kenya & Iowa. 2023. Available online: https://ammoniaenergy.org/articles/talus-renewables-modular-renewable-fertilizers-in-kenya-iowa/?utm_source=chatgpt.com (accessed on 27 August 2025).

- Talus Renewables. How Our Green Ammonia System Works: Modular, Containerized, Autonomous. 2024. Available online: https://www.talusag.com (accessed on 27 August 2025).

- de la Hera, G.; Ruiz-Gutiérrez, G.; Viguri, J.R.; Galán, B. Flexible Green Ammonia Production Plants: Small-Scale Simulations Based on Energy Aspects. Environments 2024, 11, 71. [Google Scholar] [CrossRef]

- Tonelli, D.; Rosa, L.; Gabrielli, P.; Parente, A.; Contino, F. Cost-competitive decentralized ammonia fertilizer production can increase food security. Nat. Food 2024, 5, 469–479. [Google Scholar] [CrossRef]

- Wiskich, A.; Rapson, T. Economics of Emerging Ammonia Fertilizer Production Methods—A Role for On-Farm Synthesis? ChemSusChem 2023, 16, e202300565. [Google Scholar] [CrossRef]

- Chen, C.; Zhou, Y.; Fang, H.; Peng, X.; Jiang, L. Progress and challenges in energy storage and utilization via ammonia. Surf. Sci. Technol. 2023, 1, 13. [Google Scholar] [CrossRef]

- HyDeploy. Hydrogen is Vital to Tackling Climate Change—HyDeploy. 2023. Available online: https://hydeploy.co.uk/app/uploads/2024/01/22951_CADENT_HYDEPLOY_REPORT_JAN24_FINAL.pdf (accessed on 20 July 2025).

- Green Hydrogen Organisation. Fiscal Terms and Incentives Green Hydrogen Organisation. 2022. Available online: https://gh2.org/sites/default/files/2022-12/GH2_Contracting%20Guidance_Fiscal%20Terms%20and%20Incentives_2022.pdf (accessed on 15 June 2025).

| Name | Description | Value |

|---|---|---|

| Capital cost of a single unit solar PV | 712,000 GBP/MW | |

| Capital cost of a single unit 500 kW wind turbine | 654,000 GBP/unit | |

| Capital cost of a single unit of H2 storage | 500 GBP/kg | |

| Capital cost of a dispenser | 71,000 GBP/unit | |

| Price of grid electricity | 240.6 GBP/MWh | |

| Price of exported electricity | 0 | |

| Operating capacity of an electrolyser | 2.708 kg/hr | |

| Power consumption of compressor | 0.0063 MWh/kg | |

| Electrolyser efficiency | 58% | |

| Lower heating value of hydrogen | 120 MJ/kg |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mirzania, P.; Huo, D.; Balta-Ozkan, N.; Panigrahi, N.; Knox, J.W. Decarbonising Agriculture with Green Hydrogen: A Stakeholder-Guided Feasibility Study. Sustainability 2025, 17, 9298. https://doi.org/10.3390/su17209298

Mirzania P, Huo D, Balta-Ozkan N, Panigrahi N, Knox JW. Decarbonising Agriculture with Green Hydrogen: A Stakeholder-Guided Feasibility Study. Sustainability. 2025; 17(20):9298. https://doi.org/10.3390/su17209298

Chicago/Turabian StyleMirzania, Pegah, Da Huo, Nazmiye Balta-Ozkan, Niranjan Panigrahi, and Jerry W. Knox. 2025. "Decarbonising Agriculture with Green Hydrogen: A Stakeholder-Guided Feasibility Study" Sustainability 17, no. 20: 9298. https://doi.org/10.3390/su17209298

APA StyleMirzania, P., Huo, D., Balta-Ozkan, N., Panigrahi, N., & Knox, J. W. (2025). Decarbonising Agriculture with Green Hydrogen: A Stakeholder-Guided Feasibility Study. Sustainability, 17(20), 9298. https://doi.org/10.3390/su17209298