1. Introduction—From the Extractive Paradigm to the Centrality of Matter

The modern economic paradigm—founded on the pursuit of unlimited growth and the exploitation of natural resources—has revealed its limitations in guaranteeing environmental and social sustainability. Fifty years after the publication of The Limits to Growth by the Club of Rome [

1], the scenarios it predicted are increasingly becoming tangible realities: climate change, biodiversity loss, and the growing accumulation of waste. The dominant response has largely consisted in replacing depleted resources with new raw materials, without a fundamental rethinking of production and consumption models [

2]. This logic has led to a rupture with nature’s regenerative cycles, in which the very notion of waste is absent—every element participates in an interdependent and cyclical system [

3]. In contrast, waste in industrial societies is the product of a linear model [

4], emblematic of the Anthropocene and symbolic of humanity’s capacity to irreversibly alter the environment [

5,

6]. Over time, however, a gradual shift in perspective has taken place: rather than something to be eliminated, waste is increasingly recognised as a potential resource [

7], capable of supporting the transition from a take–make–waste model to a regenerative system [

8]. In this context, designing with and for waste entails not only a critique of the current system [

9], but also the capacity to envision alternatives that are mindful of material, social, and ecological constraints. Since the 1990s, the design field has increasingly emphasised the need to “close the loop” [

10], acknowledging that every product consumes resources and generates waste—waste that, however, can be reintegrated as new raw materials [

11].

This reversal of perspective calls for a fundamental shift in how production is conceived: no longer as a linear and fragmented sequence, but as a complex and interconnected system. Whereas in the past products were primarily designed in response to market demands and cost-efficiency, the redefinition of current models requires materials—and waste in particular—to become the starting point of the design process. This shift brings materials and transformation processes to the forefront, along with the need for interdisciplinary forms of knowledge. Due to their aptitude for innovation and propensity for experimentation, designers are increasingly called upon to move between disciplines, technical skills, and design sensibilities, even when these are divergent. It is essential to move beyond sequential and sector-specific approaches, in favour of models grounded in collaboration and cross-disciplinary exchange between fields of knowledge. Within this framework, new approaches and methodologies are emerging that challenge the traditional role of materials—no longer seen merely as technical supports or functional elements, but as living matter capable of informing and guiding design decisions. In recent years, a range of material-driven approaches have been developed to support design practices. Some emphasise the centrality of the material as the starting point of the creative process; others investigate material properties through exploratory and experimental methods; while still others focus on application and commercial potential, with the goal of facilitating transferability to the industrial sphere.

This article seeks to contribute to this evolving landscape by exploring the potential of waste as a design resource and examining material-driven methodologies that place materials at the core of the creative process. In particular, it presents the Waste Driven Design (WDD) methodology, developed as part of a doctoral research project [

12] of the PNNR research programme of the iNEST-Spoke 3 ecosystem at the IUAV University of Venice and applied in experimental contexts at the CTRL+Junk Lab research centre and the Design Differente spin-off of the same university. Through concrete case studies such as the Marble Cap project, in which mixed food packaging waste, neither sorted nor pre-selected, is transformed into new die-cast slabs suitable for processing with subtractive technologies, a critical reinterpretation of material-driven methodologies and the notion of waste as a resource is proposed. This reinterpretation places waste at the intersection of ecological awareness, transformative potential, and experimental design practice [

13].

2. Material-Driven Approaches and Methodologies

The culture of materials in design is undergoing a profound transformation, shifting from approaches that primarily emphasise functional or aesthetic attributes to more holistic perspectives that integrate concerns related to sustainability, circularity, and socio-environmental impact. This shift has given rise to new lines of inquiry in which designers play an active role—not merely as users of materials, but as agents capable of activating meaning and enabling change. In recent years, a “bottom-up” design approach has emerged—drawing inspiration from informal workshops, rediscovered craft techniques, natural processes, and practices less constrained by disciplinary boundaries [

14]—which has fostered a renewed relationship between process, material, and context. According to Fiorani, this openness enables designers to recognise both the performative dimension of materials and their symbolic and social significance [

15]. In line with this perspective, Ribul (2014) introduces the notion of material activism [

16], which advocates for the democratic development of materials through low-tech processes and an open-source ethos, encouraging widespread experimentation and the creation of new material languages.

This vision has contributed to redefining the role of the designer in relation to matter, now understood as a living archive of the interaction between humans and the planet [

17]. As Barati and Karana (2019) argue, designers can no longer limit themselves to interpreting material data; rather, they must actively engage in uncovering the potential of materials, in dialogue with science, anthropology, and material history [

18]. As materials become increasingly central to the rethinking of production processes, various methodologies have emerged that place materials at the heart of the design process. In this context, material design is no longer confined to selecting the “right material”; instead, it becomes material-driven, with the material itself activating pathways of knowledge, experimentation, and innovation. The evolution of these methodologies reveals how the complexity of materials—particularly from a circularity perspective—demands an increasingly interdisciplinary approach, one that integrates design, technical, economic, and scientific dimensions. Among the first of these to be developed is Material Driven Design (MDD) by Karana et al. (2015) [

19], which places the material at the centre of the design process, challenging the notion of material as a passive entity to be shaped. In this model, the material guides and informs design choices from the earliest stages, through a direct and sensory relationship that generates knowledge.

Similarly, DIY Materials, as theorised by Rognoli et al. (2015) [

20], introduces a pedagogical and relational dimension between designers, technologies, and production processes. In this approach, experimentation is activated through artisanal and alternative practices, where manual skills, practical intelligence, and personal fabrication serve as cognitive and heuristic tools. Both of these methodologies, albeit in different ways, are grounded in the idea that “doing in order to understand” is essential for opening up new material and design scenarios. Workshops thus become spaces of training and learning, where knowledge is acquired through direct experience rather than abstract deduction. However, while this initial exploratory phase is crucial, it is not sufficient to fully express the applicative, strategic, and transformative potential of materials. It is in this direction that Lecce and Ferrara’s Design-driven Material Innovation Methodology (2016) [

21] positions itself—seeking to link material development with coherent and concrete application scenarios. In this model, the material is not only the object of exploration but becomes a strategic component in the construction of product-service systems and in the generation of market value. The integration of a scenario-based dimension marks a first step toward evaluating the design potential of materials.

A further methodological development is offered by the work of Tubito et al. (2019) [

22], which presents a methodology structured into three iterative cycles designed to facilitate knowledge transfer between design, materials science, and manufacturing. The first cycle focuses on the co-creation of application scenarios; the second develops materials in response to realistic design requirements; the third optimises materials in relation to specific product concepts. Each phase culminates in the creation of prototypes that demonstrate the effective integration of diverse forms of expertise. This methodology reinforces the systemic dimension of material-driven design and anchors it within industrial innovation processes. The growing awareness that design experimentation must inherently engage with sustainability has led to the development of a third family of approaches, which incorporate tools for environmental validation and assessment. An example of this is Bak-Andersen’s Material Driven Design for Sustainability (2018) [

23], which integrates indicators such as circularity, environmental and social impact, chemical composition, biodegradability, and recyclability in order to evaluate the alignment of materials with circular economy principles. These are complemented by more subjective dimensions—such as the cultural and symbolic significance of materials—which are fundamental to ensuring their longevity, acceptance, and integration into broader socio-material systems.

This reinforces the idea that material design cannot be separated from a robust system of evaluation, drawing from scientific and environmental disciplines. The level of interdisciplinary integration is further advanced in the Material-Driven Textile Design (MDTD) methodology developed by Ribul et al. (2021) [

24], which aims to merge practices and tools from materials science with those of design. Here, design is directly embedded within laboratory processes, while scientific practice is, in turn, informed by design thinking. This establishes a shared research space in which designers and scientists collaborate in the development of new materials, effectively dissolving traditional boundaries between art, science, and industry.

In summary, the analysis of the main material-driven approaches (

Table 1) highlights how each methodology presents different application domains and varying levels of maturity. Material Driven Design (MDD) [

19] is employed for the development of biocomposites from agri-food waste, bio-based materials, 3D-printed textiles, and flexible OLEDs, while the DIY Materials [

20] approach remains primarily confined to the laboratory context, proposing “recipes” for materials derived from food, textile, or plastic waste without direct reference to specific industries or markets. Design-driven Material Innovation Methodology [

21] does not mention specific materials or application areas, focusing instead on the definition of application scenarios and product–service systems, while the Design Driven Material Innovation (DDMI) [

22] identifies concrete applications in the textile, plastic, furniture, and automotive sectors. Material Driven Design for Sustainability [

23] focuses on bio-based materials derived from biodegradable waste, mainly intended for packaging and product design. Finally, the Material-Driven Textile Design (MDTD) [

24] methodology, although originally tested on textile waste, demonstrates a high potential for transferability, as it is based on collaboration between designers and materials scientists, making it applicable to other types of post-consumer waste and industrial contexts. The evolution of these approaches—despite their methodological differences—reveals a common trajectory: each methodology not only introduces new variables to address the complexity of materials, but also demands tools and languages from multiple disciplines. It is within this scenario that the Waste Driven Design (WDD) methodology is situated. Developed in the context of a doctoral research project [

12] and experimental activities promoted by IUAV University of Venice—within the CTRL+Junk Lab research centre and the Design Differente spin-off—WDD contributes to this interdisciplinary landscape by proposing a material-centred approach focused on the transformative potential of post-consumer waste.

Waste Driven Design (WDD) can be understood as a summative methodology—one that builds upon previous approaches and integrates them into a design framework centred on transforming waste into neomaterials that are workable, replicable, and scalable. The starting material—waste—is examined not only for its physical properties, but also as a catalyst for meaning: a form of material for invention [

25] that embodies transformability, ecological urgency, and social value [

26]. Unlike earlier methodologies, WDD explicitly positions the design project as its central operational matrix. It is the project—understood as the space in which desirable futures are imagined—that orchestrates and synthesises environmental assessments, economic evaluations, technical feasibility, and production scalability. In this sense, WDD constitutes not only a methodological advancement, but also an epistemological stance: it positions design as a site of convergence between experiential knowledge and scientific rigour, between creative imagination and systemic responsibility. In doing so, it articulates a model that, while emerging from the material and waste crisis, is oriented toward a regenerative future.

In this context, the designer plays a central role, acting as a link and mediator between complementary skills and disciplines. It is precisely through this mediating function that these methodologies and approaches demonstrate their value, which lies not only in their theoretical dimension but above all in their ability to be translated into design practices capable of generating contextual and transferable solutions, intervening at different stages of the process—from experimentation and education to market validation, to environmental assessment and interdisciplinary collaboration.

As previously noted, this form of material activism has given rise to tangible design practices and experimental projects, many of which are being developed within design universities. A notable example is Design Differente, a spin-off of IUAV University of Venice, which has made this approach visible through documented practices and applied projects. This orientation aligns with a broader vision of regenerative economics, in which systems of resource supply, waste management, and product end-of-life are fundamentally reimagined [

26]. Within this framework, a particularly fertile area of experimentation is that of so-called new materials [

27]—that is, materials developed from waste streams that fall outside conventional recycling systems due to technological or regulatory constraints. The concept of neomaterials, or waste-based materials, has emerged within this context [

28]. These include materials derived from organic, industrial, or unconventional waste sources that, although initially excluded from production cycles, are re-evaluated and transformed into valuable resources [

29]. In this process, designers play a critical role in identifying and activating the most appropriate supply chains and use scenarios to unlock the potential of these materials.

This is precisely where the concept of Waste Driven Design (WDD) [

30] becomes relevant. As discussed above, WDD is a design approach that begins with waste and its material potential to generate new productive and cultural opportunities. This paradigm translates into tangible initiatives at the local level, as demonstrated by European projects promoted by IUAV University of Venice: Waste Design [

31] (Interreg Italy–Slovenia 2014–2020) and Waste Design 2.0 [

32] (Interreg 2021–2026), alongside other notable initiatives such as Da Cosa Nasce Cosa, promoted by Repubblica del Design in Milan (2021–2022) [

33], and Zero Waste Design, a European project supported by the Tuscany Region [

34].

This process—at the intersection of design research and industry—is fostering the emergence of new professional profiles and generating both economic and cultural spin-offs. A significant example is the Waste Driven Design exhibition (

Figure 1), curated by Davide Crippa for Design Differente during Milan Design Week 2023, which showcased the theoretical and experimental work carried out by the CTRL+JUNK LAB research group at IUAV.

The exhibition, hosted at the spin-off’s headquarters in Via Grazioli 73 in Milan, transformed a former industrial site into an exhibition space built almost entirely from locally sourced waste and discarded materials. The exhibition was organised into several sections, beginning with a permanent courtyard installation in which old advertising signs from well-known national and international brands were regenerated and reused in their lettering to create a reinterpretation of the Universal Declaration of Human Rights. This symbolic gesture simultaneously re-signified both the objects themselves and our everyday actions.

Inside the exhibition space, the phrase

dal rifiuto un nuovo oggetto (“from waste to a new object”) (

Figure 2), together with an installation curated by Fercam Ecolab showcasing the reuse of pallets for outdoor furniture (

Figure 3), exemplified the systemic and relational design approach applied to the issue of waste. At the core of the exhibition were three collections, each dedicated to a specific waste stream—wood, plasterboard, and Forex/Poliplat. These collections presented objects resulting from material transformation processes that turn discarded matter into design opportunities. The design of the exhibition space itself, developed according to the same principles, stood as a tangible demonstration of how constraints can be reimagined as resources, and waste as value.

Among the most significant examples showcased in the exhibition, the Negativo–Positivo collection, dedicated to wood waste (

Figure 4), introduces an innovation in the production process: the simultaneous use of both the “positive” (the desired configurations) and “negative” (residues remaining in flat sheets) components of the cut material, effectively reducing waste to zero. This outcome is made possible through the use of nesting techniques in DeltaCAM software, which enables the optimised layout of the elements to be cut. The resulting aesthetics are intrinsically tied to the process itself, illustrating how efficiency and form can coexist within a coherent design language.

Similarly, the Sedimenti collection—produced from waste and debris recovered from plasterboard construction sites (

Figure 5)—offers another example of innovation in waste transformation. In this case, the salvaged material is kept visible, dry-assembled and reworked into a series of limited-edition furniture pieces, whose distinctive aesthetic emerges directly from the material’s nature and the specific processes employed in its reuse.

This approach not only valorises materials that would otherwise be destined for disposal, but also proposes a new design language in which matter, form, and narrative are deeply interwoven. The objects on display do not simply offer a new aesthetic for waste; they function as material manifestos, embodying a design methodology rooted in experience and oriented toward a critical and transformative understanding of matter—“a matter that contains clues, stories and potentialities for establishing new trajectories of meaning” ([

2], p. 109).

3. What Is Waste-Driven Design (WDD)?

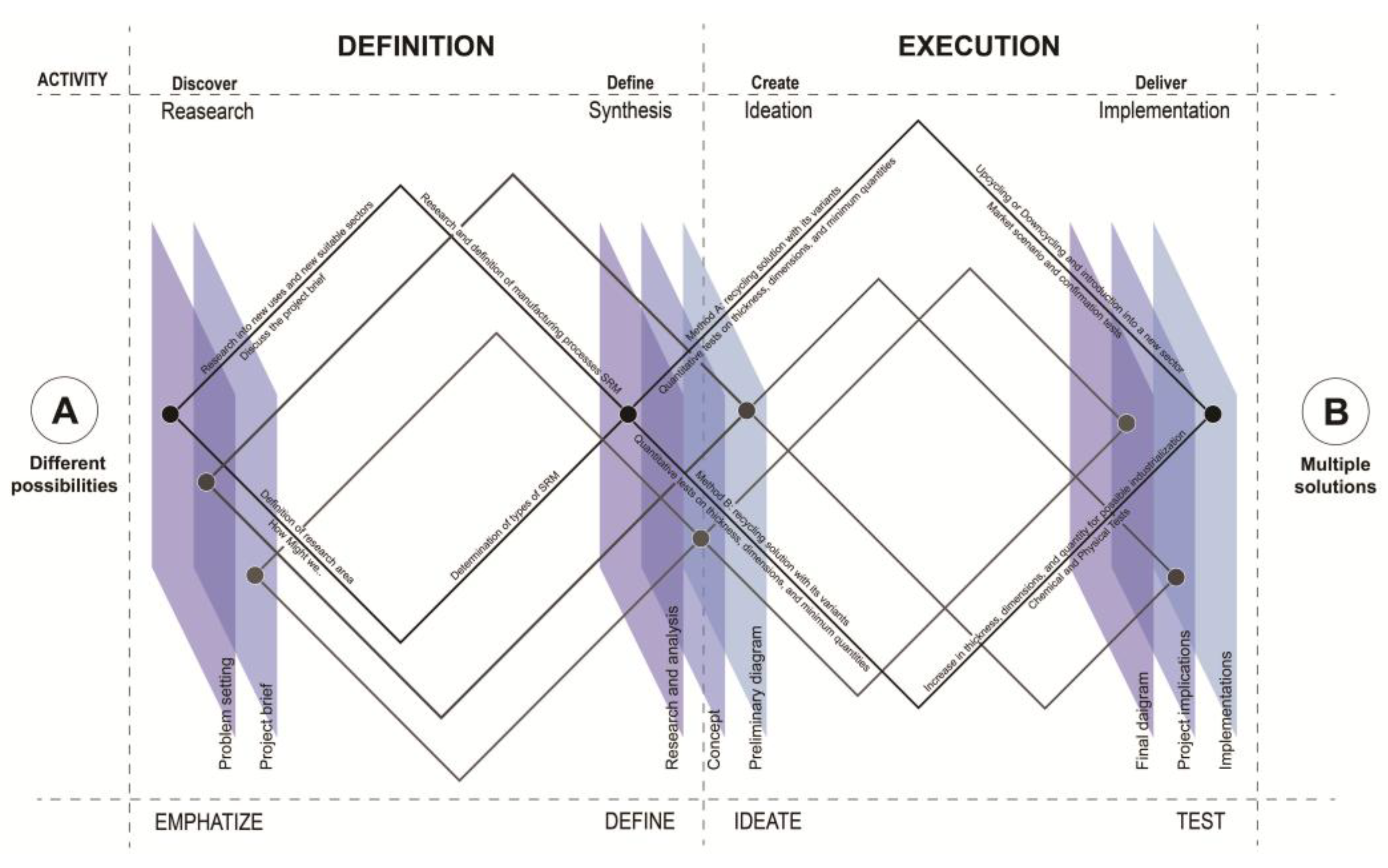

The aforementioned Waste-Driven Design (WDD) (

Figure 6), which also gives its name to the exhibition described above, is a design process rooted in design expertise but characterised by a divergent approach—essential for developing innovative solutions. It draws upon practices and tools from the hard sciences, integrating them into the creative and speculative process typical of design [

30]. WDD is not confined to simple interdisciplinarity; rather, it aspires to full transdisciplinarity, transcending disciplinary boundaries to shape a design figure capable of combining practical and technical skills with scientific and experimental knowledge.

At the heart of WDD lies the re-design of waste, with a dual focus on reuse—aimed at generating new products—and recycling, through the development of new materials to be reintegrated into production cycles. The method unfolds through a sequence of phases that include the collection and analysis of waste, the evaluation of its potential for reuse or transformation, technical experimentation, the development of future scenarios, and the assessment of industrial feasibility and production scalability. These steps are accompanied by the creation of material samples and the verification of design impact through prototypes and application testing.

WDD is conceived as a layered system, in which researchers can move fluidly between phases—progressing or returning to previous stages depending on the nature of the problem. This iterative movement, characteristic of design practice [

35], is reinforced by the integration of tools from the hard sciences, which allow decisions to be assessed in relation to specific end goals. As a result, the structure of the method ensures that the design direction remains coherent and traceable, without compromising the flexibility required for exploratory processes. To make this methodology operational, hybrid spaces are essential—such as the aforementioned Design Differente spin-off of IUAV University of Venice. This laboratory, equipped with technologies for in situ experimentation of recycling processes, operates as a vertical fablab entirely dedicated to the circular economy. It enables the verification of semi-industrial production feasibility, the testing of new materials, and the development of technical and design competencies.

The spin-off hosts a multidisciplinary team and collaborates with institutions beyond the field of design—such as the School of Industrial and Information Engineering at Politecnico di Milano, particularly with researchers specialising in materials science and technology, and the Laboratory of Technical and Environmental Physics (FISTEC) at IUAV, which focuses on analysing the acoustic, thermal, and lighting performance of materials. This hybrid setup enables the rapid and targeted testing and validation of mechanical recycling processes, allowing for the identification of the most promising strategies for integrating new ideas into existing systems. The possibility of developing new materials and prototypes directly within the lab makes it possible to critically assess design hypotheses, bridging the gap between research and application, and accelerating market adoption.

WDD thus combines the systematic, scientific analysis of process variables—essential for validation and reproducibility—with an iterative design approach that supports the continuous exploration of alternative scenarios based on ongoing experimentation. The method constantly shifts between vertical thinking, aimed at logical and systemic analysis, and lateral thinking, focused on the discovery of unconventional solutions [

36,

37]. Its primary objective is to uncover, starting from the experimental phase, the latent potential of waste as new material, while envisioning its productive, cultural, and aesthetic applications.

Given all these connotations outlined above—and above all because of its unique focus on waste rather than materials in general—the following paragraph will examine this WDD approach as applied to a specific case study promoted by the CAP Group, a wholly public company that manages the integrated water service for the metropolitan city of Milan.

4. A Virtuous Example of Application: The Marble CAP Case

4.1. The Project Challenge

To fully understand and assess the effectiveness of the Waste Driven Design (WDD) method, the Marble CAP case offers a strategic example. As one of the first projects initiated—and among the most fully developed—within the broader research programme, this case provides a concrete opportunity to test the method’s replicability, challenging both its initial insights and their sustainability over time. As with any process guided by anticipatory logic, it is essential to begin with a hypothesis and an opportunity—that is, from a scientific assumption to be validated and a contingency, sometimes determined by fortuitous circumstances, capable of triggering lateral thinking. In this case, the critical assumption concerned the potential synergy—in line with the principles of industrial symbiosis, understood as a collaborative approach based on the exchange of resources and materials among actors operating in different sectors [

38]—that could be established between companies in different product sectors but guided by the same goals, namely the following: the optimisation of their production processes and the definition of new cycles dedicated to environmental sustainability through the elimination of waste. The “circumstance” was the (seemingly risky) connection between distant supply chains that were not particularly inclined to collaborate, but which in reality proved to be extremely complementary. The project is part of the research programme entitled ‘CAPitoli urbani-Circular economy projects for the recycling of plastic waste for the benefit of the community’, promoted by CAP and carried out by the Politecnico di Milano (places + group) in collaboration with the IUAV Design Differente spin-off. The research programme consisted of the study, experimentation, and codification of a new process for the production of sheets made from unsorted plastic material mixed with other material residues (e.g., aluminium, Tetra Pak, paper, cardboard). The aim was therefore to experiment with a process innovation in plastic waste recycling with a view to achieving a complete circular economy.

Specifically, the initial waste consisted of bottles and containers still full of organic material (such as yoghurt and other dairy products), close to or just past their expiry date, supplied by food companies and used by CAP as valuable biogas feedstock at the Sesto San Giovanni plant in Milan. The final waste—the specific subject of the research—consisted solely of containers, the inorganic fraction that remained with CAP as non-reusable waste, i.e., as a non-amortisable cost.

The company’s request was to start a virtuous recycling process, to find a second life for this waste, starting with washing equipment already at their disposal, without having to manually sort the individual parts of the containers (whose lids introduced spurious materials). The challenge was therefore one of recycling and circularity, but first and foremost, it was to consider material heterogeneity not as a problem to be avoided (as in most current recycling experiments, which are typically mono-material), but as a resource to be exploited. As highlighted by Geyer and Zink (2021) [

39], mixed-material waste streams—particularly food packaging plastics—are often subjected to downcycling due to contamination and loss of properties, hindering their reintegration into closed material loops. This limitation underscores the importance of exploring alternative approaches that embrace heterogeneity as a design driver for the development of new material solutions.

In this context of expectations and opportunities, the universities involved—in collaboration with Social Factory as a laboratory structure supporting waste management, prototype creation, and machinery testing—tested a non-standard and as yet uncodified process that involved producing the material (which was not sorted or pre-selected) in pressed sheets that could be machined using subtractive technology according to an innovative production process. The aim was to understand the potential and problems of such an uneven material, to verify its reproducibility and its technical and aesthetic characteristics (quality verification). Obviously, this study was limited to the recycling of non-bulky waste.

4.2. Thinking Lateral: “The Right Side of Leftover”

Assuming that expired food containers represented a significant obstacle to the circularity of the process, precisely because of the absence of automated material separation procedures (

Figure 7), the project was rooted in a lateral intuition: rather than separating all the components of the packaging, it proposed keeping them together—abandoning a purely technical logic in favour of a design-oriented vision. Composite materials and complex products, such as food packaging, present well-documented challenges in terms of separation and recyclability [

40].

After ruling out reuse options for these containers, recycling was explored, but adopting an alternative approach to the traditional one based on separation [

41,

42,

43]. Unlike the most common processes, therefore, an attempt has been made to avoid sorting individual types of waste, a costly and complex step that often contributes to the failure of the recycling process. Inspired by the concept of plastiglomerate [

40], the design intuition shifted the focus to composition rather than decomposition, consisting of the following: a material that incorporates rather than divides, enhancing material complexity and suggesting new strategies for recycling design [

44]. This approach is similar to what nature itself already does, integrating plastic waste into the environment spontaneously and organically, without expelling it, but including it [

45]. This lateral thinking ultimately triggered a more systematic, typically scientific process, which transformed an initial intuition into a semi-finished product.

4.3. Process Experimentation

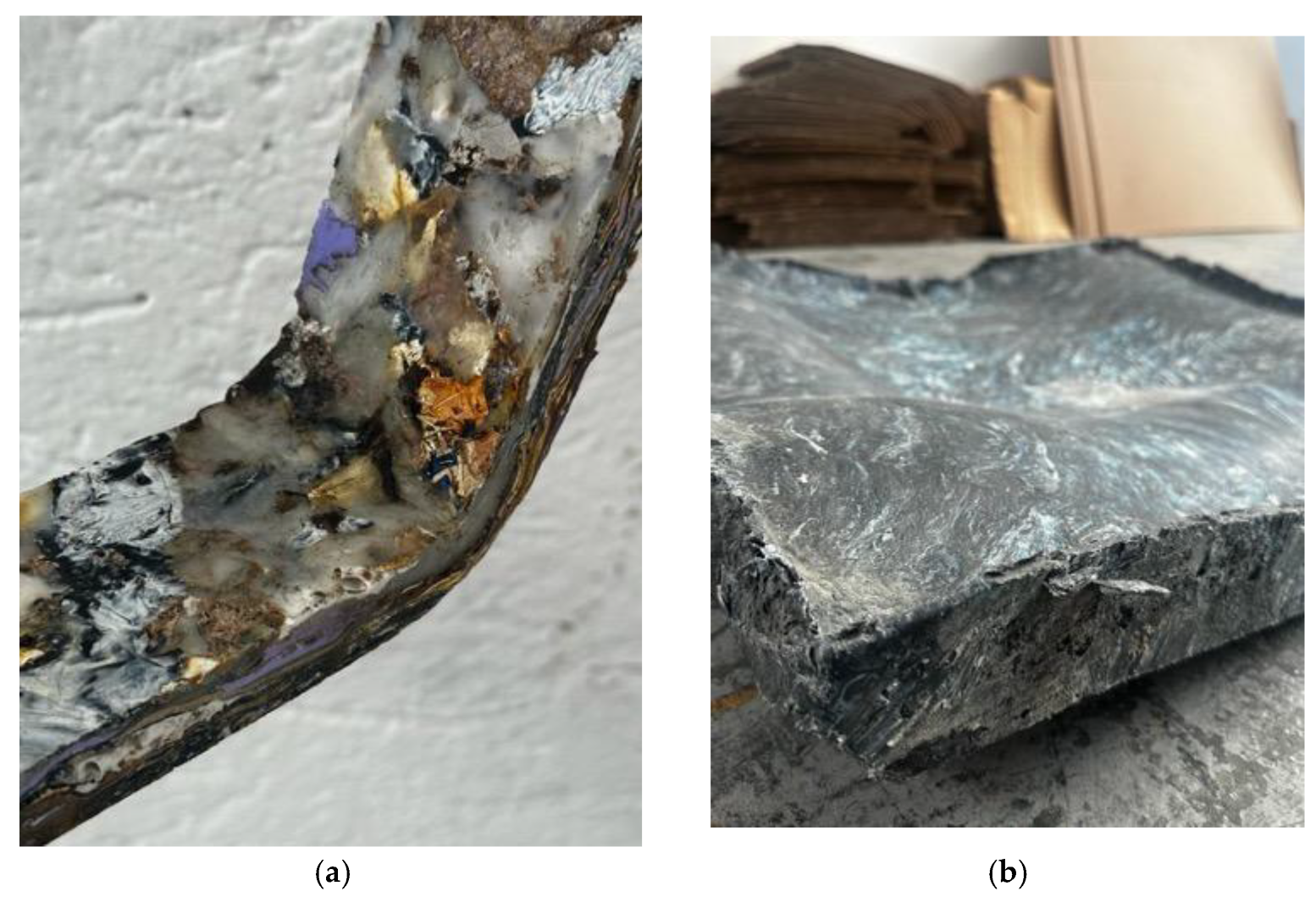

After an initial trial with waste collected in the early stages, it was decided to use waste recovered over a whole year to obtain a larger sample and check for any unexpected material variables, a crucial aspect in mixed-waste recycling where input composition can significantly affect output quality and reproducibility [

39]. Subsequently, the reception and systematic cataloguing of waste (using reception codes) was planned and, starting from the first result obtained (

Figure 8a,b), the process was repeated, gradually introducing different process variables to verify any improvements.

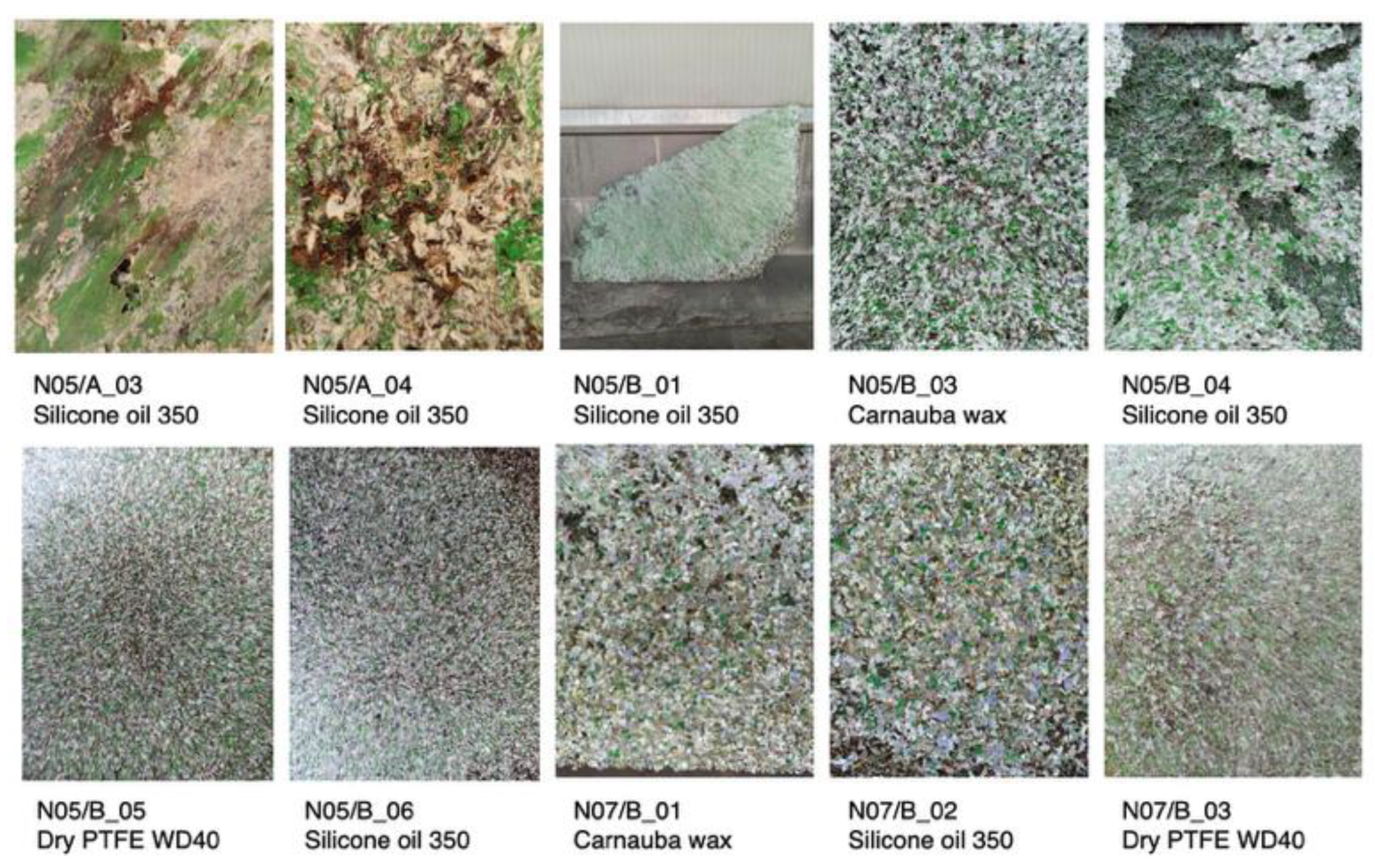

Various production methods (both additive and subtractive) were tested, with different levels of shredding of the plastic waste supplied; samples were produced with different material mixes and different thicknesses to test their variable behaviour; a special machine was built for the production of medium/large pressure-moulded sheets. Different melting temperatures were tested, also differentiating the two planes of the press. Different release agents were used so as not to compromise the samples produced, and the samples themselves were subjected to multiple surface treatments (sanding, planing, milling) in order to obtain the best possible finish.

The production process continued through trial and error, gradually approaching the final result, which also saw the creation of a series of slabs that were not optimal in terms of internal density, presence of material gaps, imprecise edges, and excessive malleability. In addition, problems were sometimes encountered due to concentrations of other materials (e.g., paper, aluminium) in certain areas, which resulted in uneven performance in some panels. To ensure objective analysis and comparable results, samples taken from the various big bags were always mapped so that their yield could be tracked and verified, both in terms of appearance and performance.

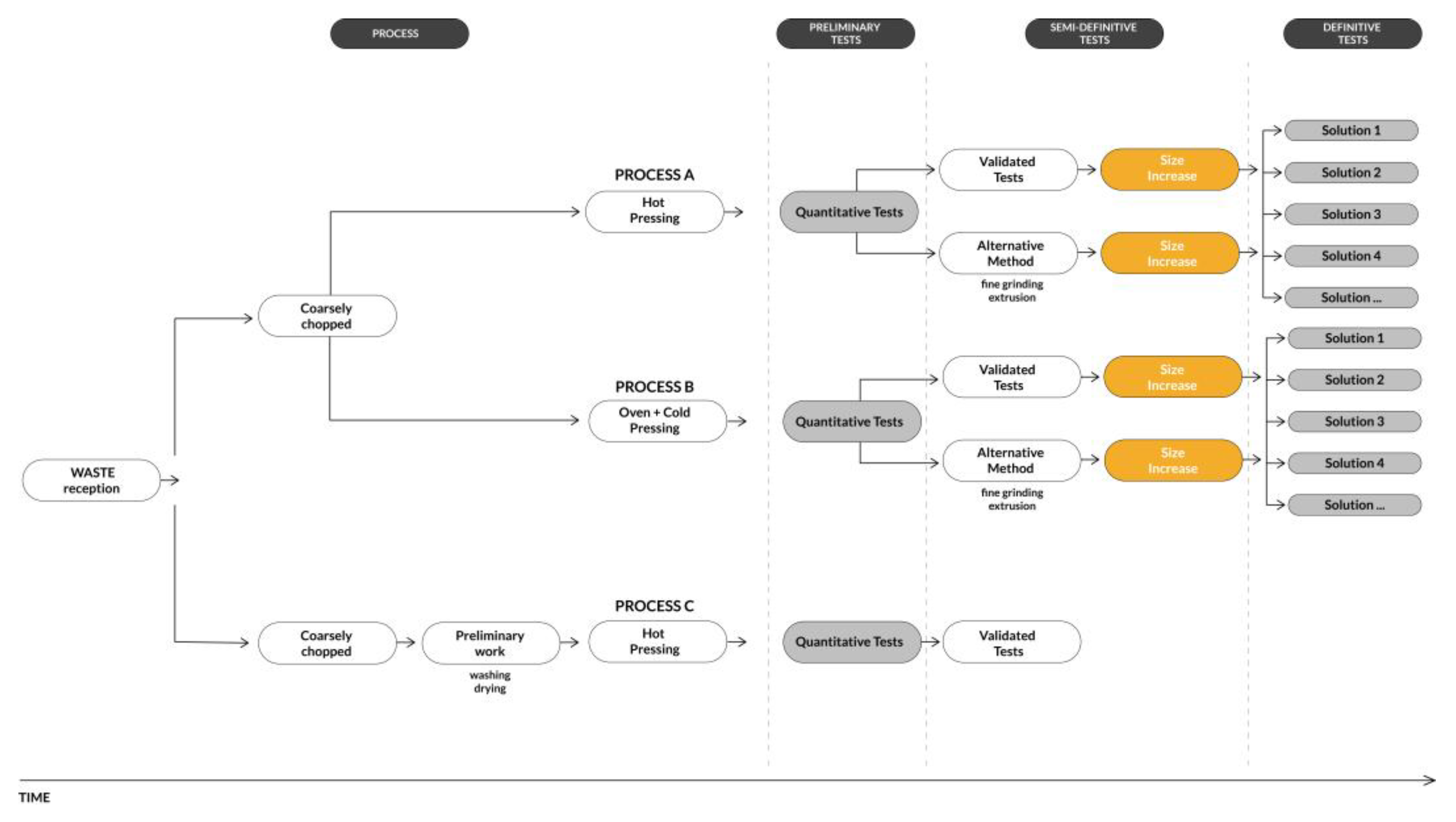

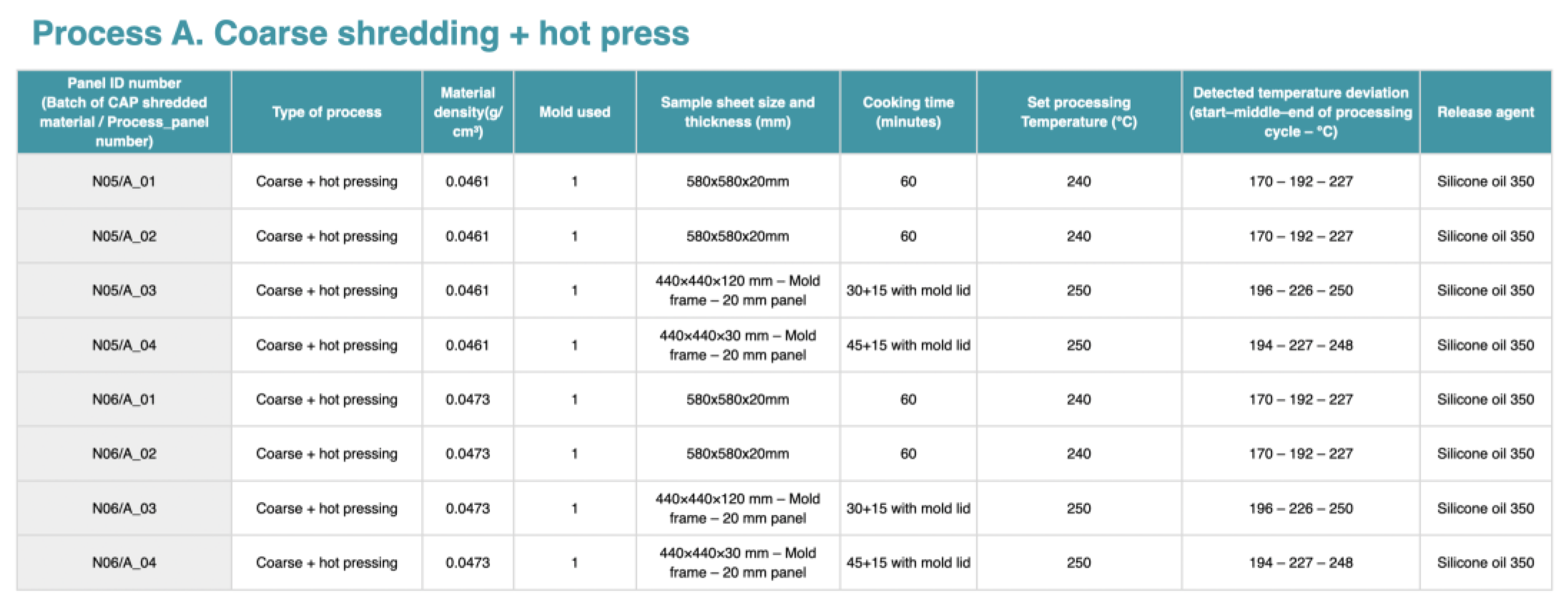

In particular, two different processing technologies were tested: die-casting and extrusion. Between them, die-casting yielded the more promising results. Washing and drying procedures were also evaluated in collaboration with chemical engineers; however, testing revealed that the benefits were marginal in relation to the increased complexity introduced by these additional steps. The process was subsequently refined and articulated into three distinct procedures (

Figure 9), tested on progressively larger formats—up to 1200 × 2500 mm, a standard size for wooden panels. Process A used coarsely shredded material and a hot press (version A1), while the alternative method tried using finely shredded material (5 mm—version A2); Process B used coarsely shredded material (version B1) and finely shredded material (version B2) preheated in an oven and with a cold press; Process C used coarsely shredded material, testing preliminary processes such as washing (with sodium bicarbonate or bleach) and drying (in a ventilated oven or dryer) and a hot press. Tests also explored the use of different release agents, as well as the evaluation of material density at various stages—raw, shredded, and post-processing. Drying operations were performed using two techniques—forced ventilation and hot air recirculation—but neither showed a significant effect on the final material properties.

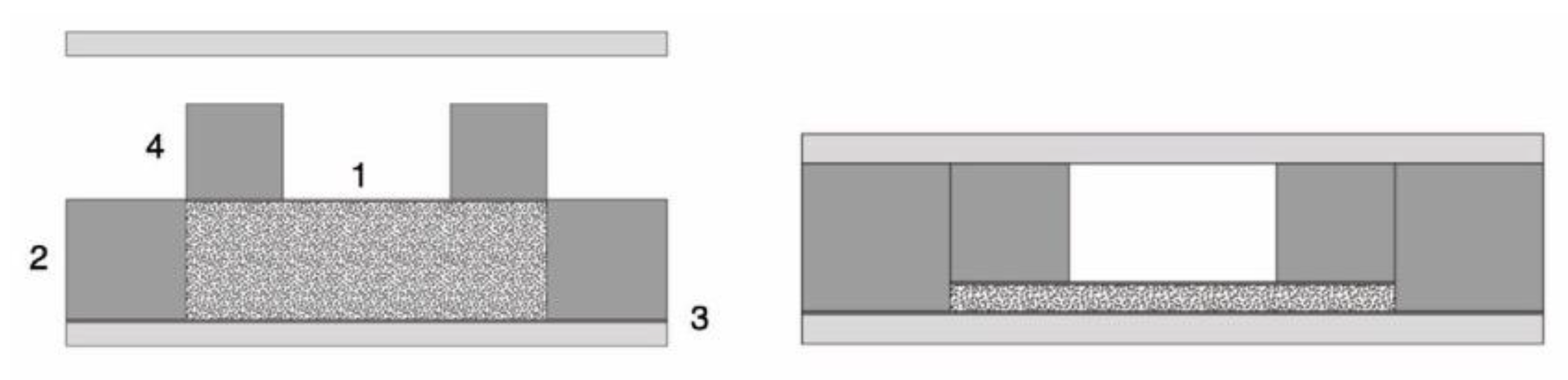

The optimal mould setup was identified as a container equipped with an oversized counter-mould (

Figure 10), which was tested across the three processes. Each phase was analysed according to the following specific parameters: processing time, temperature, grain size, and type of pressing. One of the main criticalities encountered was the formation of air bubbles, which was resolved only through manual mixing of the material. All relevant information for each individual sample was collected and archived in a summary sheet, which includes details such as sample number, material density, type of mould used, sample dimensions, processing temperature, temperature differentials within the press, and the release agent applied (

Figure 11 and

Figure 12).

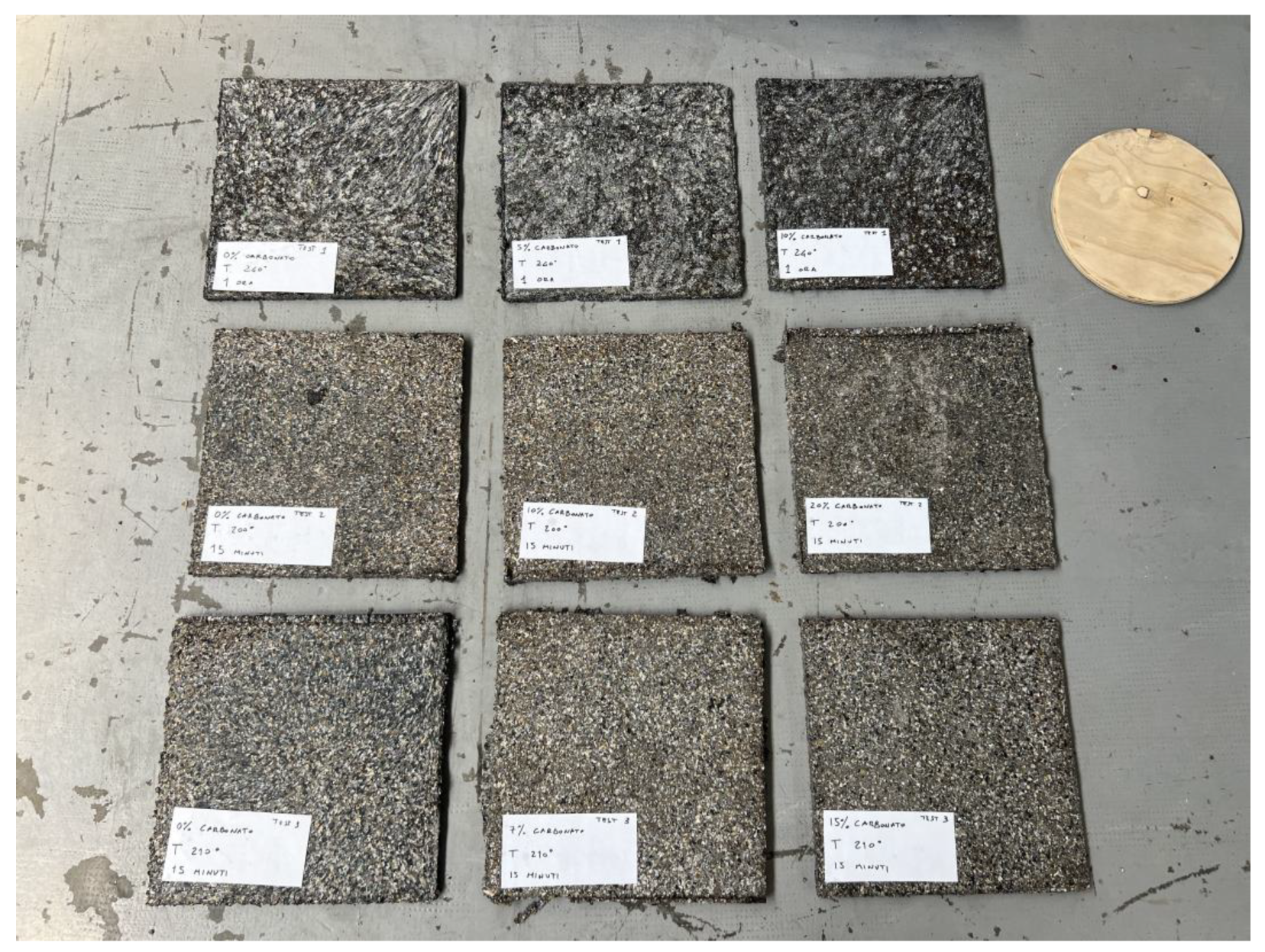

Following this, the possibility of producing thicker panels (24–30 mm)—more suitable for retail and furnishing applications—was explored. Experiments were conducted on green-toned samples from the initial batches (

Figure 13), adjusting pressing time and pressure. Some tests involved the addition of calcium carbonate to enhance mechanical resistance, in line with the documented use of mineral fillers in recycled polymers to improve stiffness and dimensional stability [

46,

47], though this compromised the material’s aesthetic qualities (

Table 2). The definitive solution finally emerged through the development of a double-finish process, resulting in a new line of materials with visual characteristics reminiscent of cipollino marble and granite (

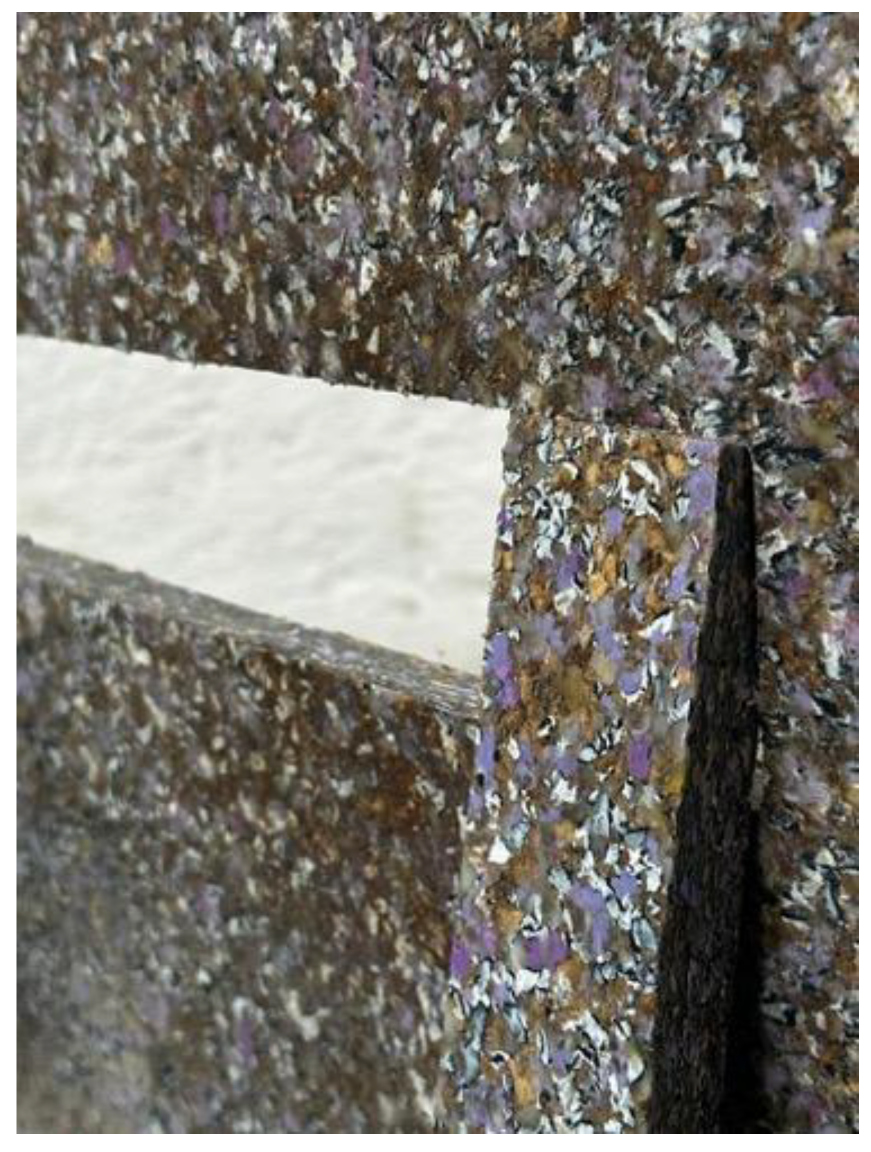

Figure 14a,b). Qualitative and tactile assessments confirmed the material’s performance, paving the way for certification procedures. Simultaneously, the steps described above have led to the definition of a replicable production process capable of generating slabs up to 110 × 210 cm with a standardised thickness of 18 mm—potentially suitable for industrial-scale manufacturing.

4.4. The Final Outcomes and Results Achieved

The final result is a new material with aesthetic qualities reminiscent of marble (

Figure 15), but which is lighter, easier to work with, and thermoformable. Although the material visually resembles marble, it retains its plastic and thermoplastic properties, enabling processing techniques not typically associated with high-end materials: at low thicknesses, the material can be laser cut (

Figure 16), while thicker formats are suitable for machining using either manual or computer numerical control (CNC) milling (

Figure 17). This versatility makes it appropriate for the production of shaped furniture elements, digital fabrication components, or engraved surfaces to modify them with designs that change their texture and appearance. Moreover, by exploiting its thermoplastic behaviour, the material can undergo thermoforming processes to produce three-dimensional profiles and complex geometries (

Figure 18a,b). These characteristics allow for convincing results from both an aesthetic and mechanical point of view.

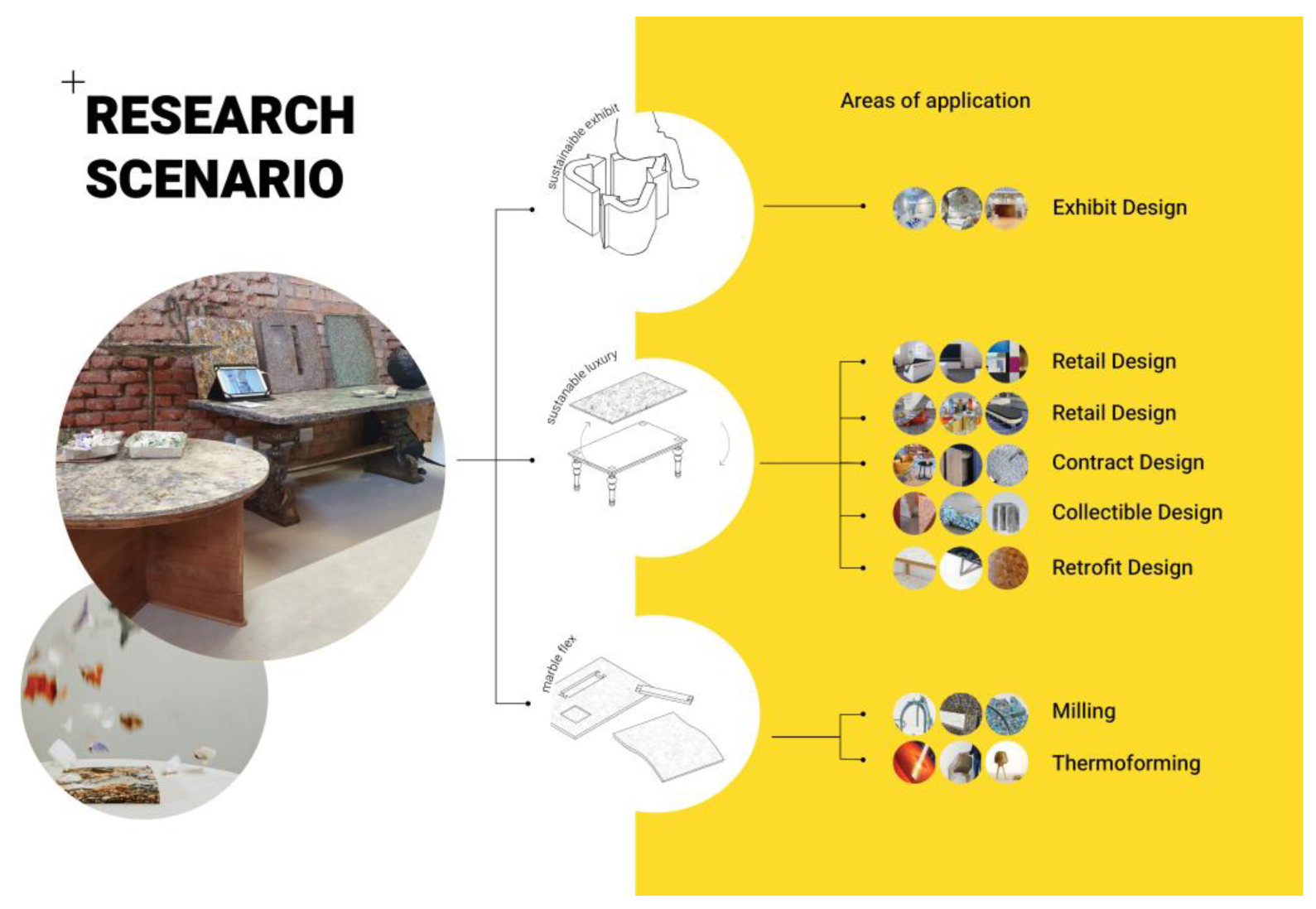

The research concluded with the development of usage scenarios and the validation of their application through market testing (

Figure 19).

In summary, the following are the results obtained:

Creation of a demonstration collection of prototypes for display, consisting of designer furniture that showcases the die-cast slabs and tests their possible applications through CNC cutting and milling processes.

In particular, creation of two prototypes revisiting a coffee table with a round top (diameter 80 cm) and a square top (side 80 cm) for Cappellini, a well-known Italian design company. In this case, the traditional marble top is replaced with a top made from the new material, which simulates its appearance but brings high symbolic and ecological added value. The table tops were milled to ensure the best surface finish.

The research produced a product analysis that led to the definition of meta-design application scenarios and dialogue with a number of internationally renowned companies and commercial entities. In particular, fruitful discussions were initiated with three renowned players in the field of art and design (Cappellini, Rossana Orlandi, Listone Giordano), who are interested in possibly continuing the research and potentially introducing the material to the market.

Obviously, expectations regarding the use of the material will have to be assessed taking into account a wide range of critical issues and potentialities including the following: future possibilities for supplying the material, potential annual supply quantities, artisanal or mass production capacity, possible applications, possible sales and distribution, certification requirements, performance constraints.

5. Conclusions

The conclusions are organised into two parts, one more specific to the proposed case study, and a second that builds on this to offer broader reflections.

Firstly, we wish to emphasise how the example of CAPitoli urbani represents not only a process innovation, but also a best practice in terms of public–private relations; the challenge faced by the team of designers, beyond the primary one of testing a new material, was to codify a virtuous partnership between the public and private sectors, starting from a supply chain that had to be structured from scratch.

Secondly, it is important to remember that—although the exact production specifications have been omitted for reasons of confidentiality (as the process is in the process of being patented)—the results of sample panels and the codified production process have been presented and, above all, an attempt has been made to convey material heterogeneity not as a problem but as an asset. From this point of view, it should be noted that the flashes of light caused by the concentrated presence of aluminium, the unexpected veins created by uneven material residues, and the colours associated with the type of Big Bag of origin, are factors that give life to unique pieces, in which unpredictability becomes a valuable element characterising the final object. This scenario thus proposes a new paradigm that is potentially industrial in perspective, but capable of incorporating the imperfection typical of craftsmanship.

At present, given the stage reached by the research, it can be concluded that the result obtained—insofar as it cannot be controlled in aesthetic terms and is not yet certified in terms of performance—cannot be strictly replicated, but it is precisely these material “imperfections”, which make each slab unique, that are considered an added value in the new sustainable luxury market.

A further value to be conveyed concerns the absence of chemical additives or adhesives, which would improve the technical performance of the material but at the same time make it similar to many others already on the market. Conversely, design-oriented companies and art galleries interested in the material produced imagine that they can emphasise its “purity” with an innovative blockchain applied to waste traceability, which would increase its perceived value and, consequently, its possible price.

At the end of the process described here, reference parameters were identified that made it possible to achieve satisfactory results in terms of visual appearance, material performance, and process replicability (despite the desired uniqueness of the result), albeit still in limited numbers and defined sizes. This is, of course, the first pre-series phase of research that would require further engineering, chemical studies, and mechanical testing before the material could be brought to market for mass production (a scenario that would require testing for thermal resistance, structural integrity, and analysis of the material’s behaviour under critical conditions such as exposure to fire).

In summary, it is believed that the mechanical characteristics tested so far (still to be implemented), together with the aesthetic characteristics (extremely recognisable and unique), currently make the material produced suitable for use in small series, in niche markets, where artistic and conceptual value prevails over purely functional value, and make it compatible only with certain applications (typically not those at risk of wear and tear and overload, such as floor coverings).

With regard to its market positioning, it should be noted that the material fits into a niche in which similar panels already exist but are made of plastic, mainly HDPE. The product is therefore positioned in the same price range, but with the added value of “closing” a local circle, promoting ecological values, and featuring a particularly recognisable texture that is appreciated in product and furniture design. Due to these values, this new type of material is in demand on the market despite being positioned in the medium-high price range.

This is followed by a second part of less specific conclusions which, starting from the CAP case, draw broader conclusions.

Within the framework of

Waste-Driven Design (WDD), the material becomes the true focus of the design process—not as a mere object to be manipulated, but as an activator of possibilities, narratives, and transformations. In this sense, the design project functions as an accelerator: it does not simply respond to a need, but generates meaning around the material itself, opening up new trajectories of value. In the case of the

Marble CAP research, for instance, the material is not defined solely by its mechanical, aesthetic, or functional performance, but also by a series of secondary factors that contribute to its meaning and quality. The various batches of food waste transformed into panels offer not only chromatic and tactile variations, but also act as “X-rays” of consumption patterns within a specific territory. Each shade and texture is far from accidental; instead, it reflects local dietary habits, types of waste produced, and seasonal cycles. This layering of material and immaterial information grants the new material a renewed dignity, elevating it well beyond the conventional category of “waste.” Experimenting with this approach enables material designers to explore opportunities arising from unconventional resources, tools, and processes—often overlooked, and at times borrowed from other disciplines. This approach adopts a parallel perspective to the traditional technical one, radically reformulating the relationship between designer, technology, and material. Today, in fact, the most desirable forms of innovation are those that introduce

ontological, rather than merely chronological, novelty [

49]—that is, innovations that reorganise actors, rules, relationships, and strategies, ultimately redefining the very value of materials.

It is not simply a matter of generating “new solutions” (

solution innovation) or “new meanings” (

meaning innovation) [

50], but of activating processes that give rise to alternative forms of value—values that are not always quantifiable and are often rooted in narrative, context, and supply chain configurations [

51]. In this light, the use of waste as a design resource and the focus on transformation processes are paving the way for new production systems based on alternative technologies and emerging materials [

52]. The field of experimentation thus becomes a site for

learning-by-doing, where knowledge is acquired through hands-on practice and becomes part of a new language of making. Within this scenario, the materials designer assumes a hybrid role [

53], integrating manual, technical, and scientific knowledge into a single figure capable of reading, interpreting, and directing material processes. To support such processes, it is essential to engage individuals with cross-disciplinary expertise in both design and production [

54]—professionals capable not only of creating materials, but also of envisioning application scenarios and meaningful processes. As described by its author, the

Waste-Driven Design (WDD) method does not merely guide the reinterpretation of waste from a design perspective [

55]; rather, it builds operational processes rooted in the intrinsic characteristics of the material, activating an iterative cycle that integrates observation, experimentation, and application. In this process, the designer is not positioned at the end of the chain but is present from the very beginning in the following ways: in the interpretation of the resource waste, in the definition of recycling strategies, in the selection of appropriate technologies, and through to the production and validation of material samples. This approach clearly demonstrates how design can foster situated, operational, and cross-cutting forms of knowledge that enable the placement of new materials within real, scalable, and culturally relevant contexts.