Determination of the Pyrolytic Characteristics of Various Biomass Pellets

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Pellet Fuel Properties

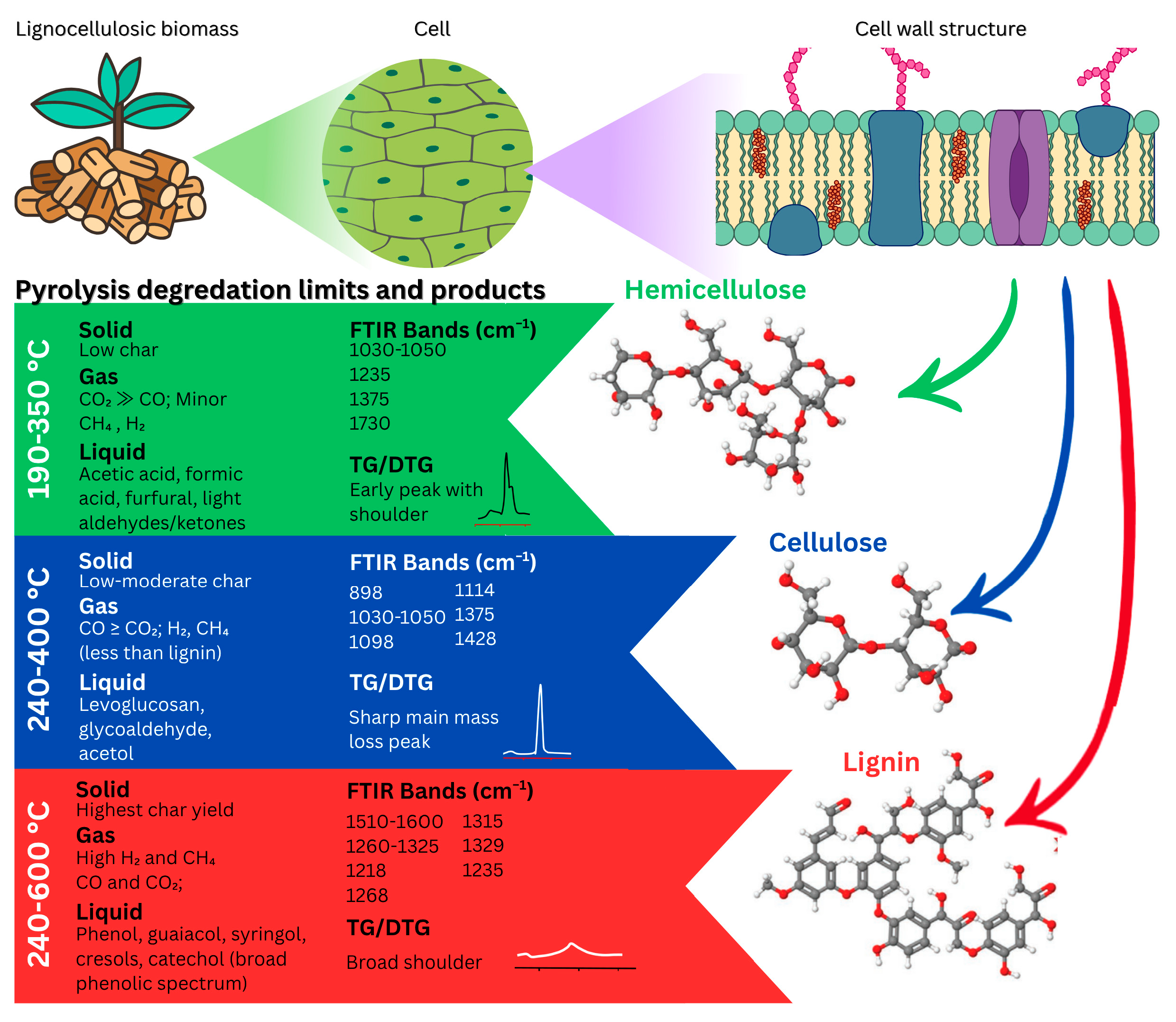

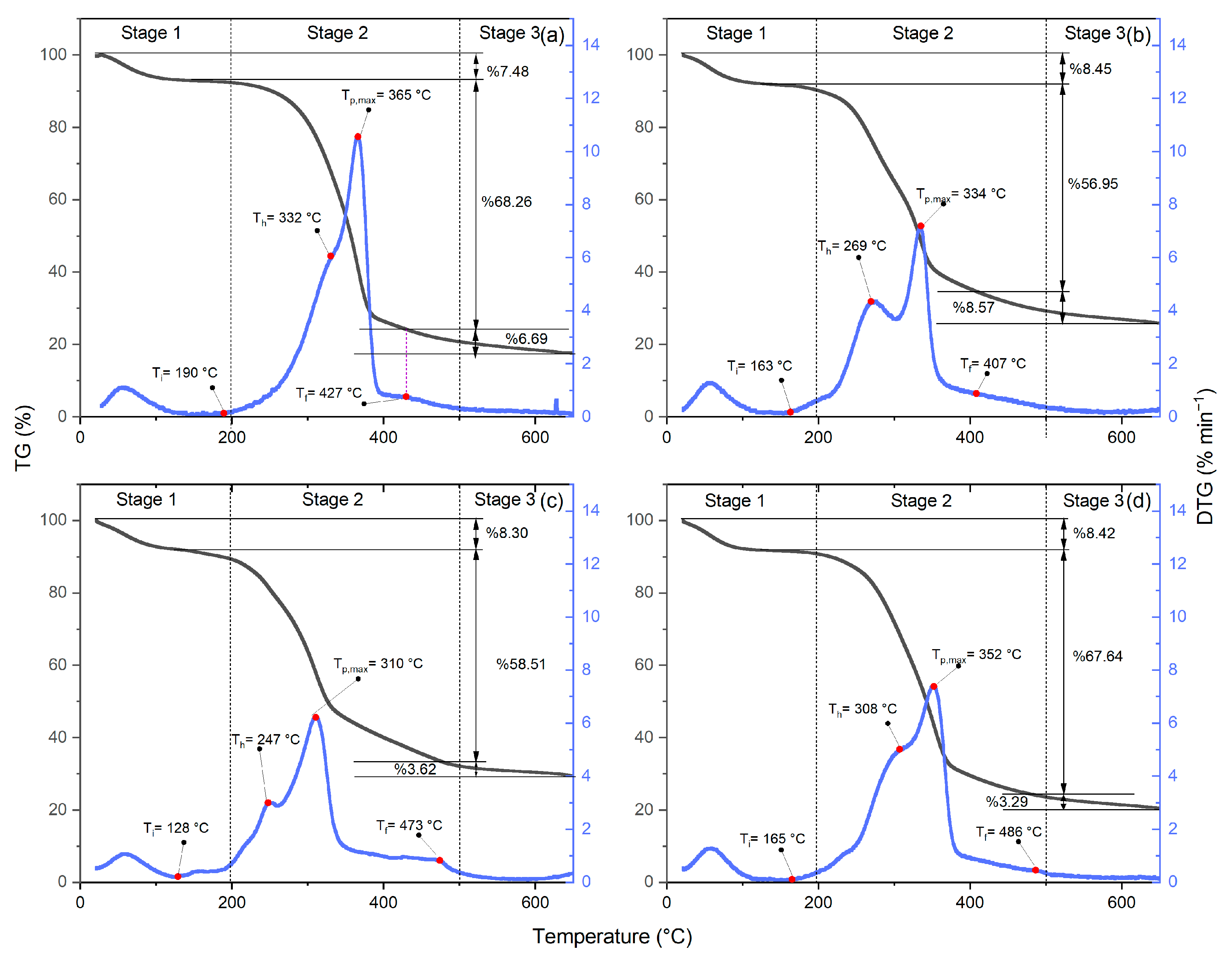

3.2. Pyrolytic Characterization of Pellets

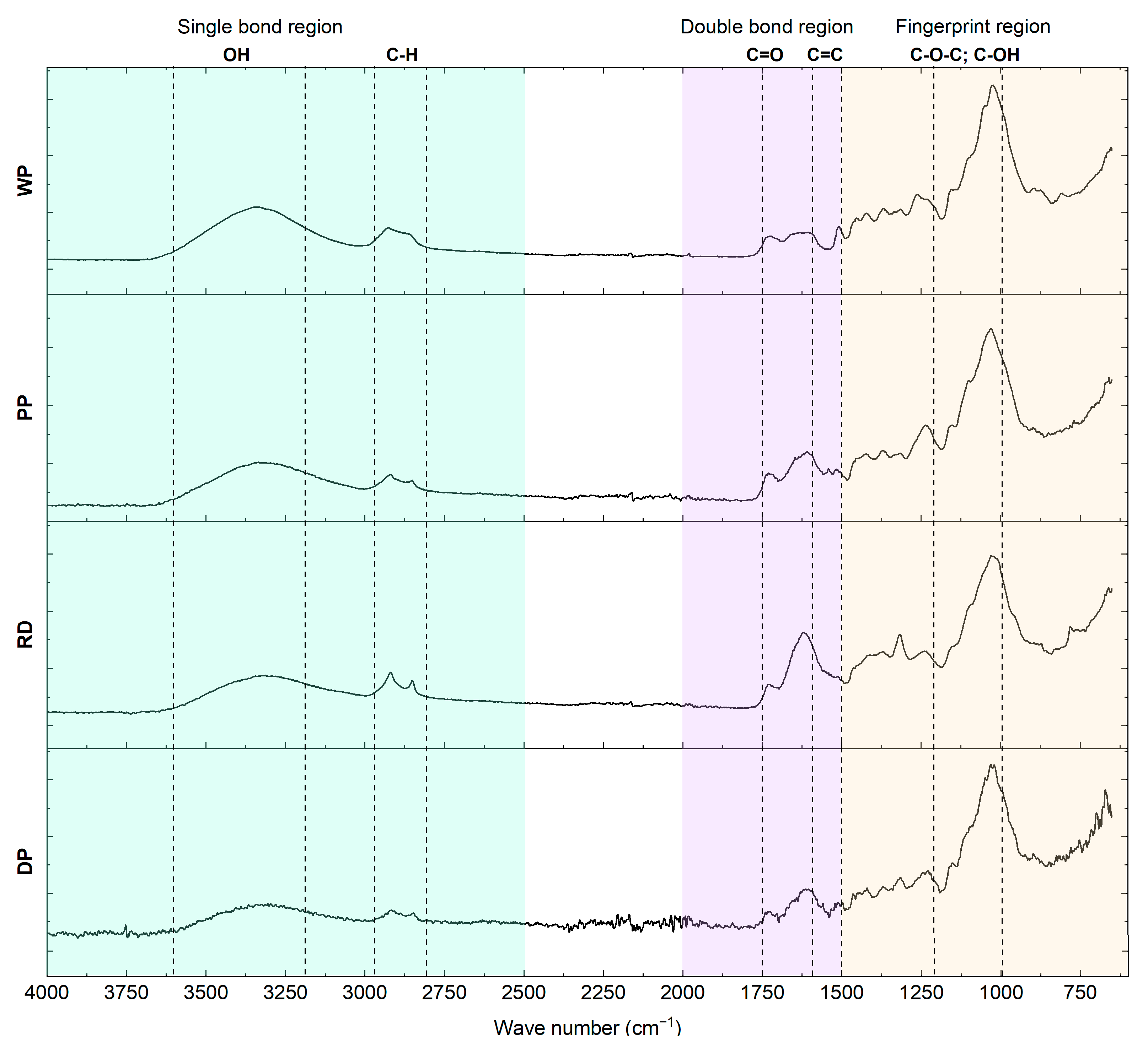

3.3. Evaluation of the FTIR Spectral Bands of the Pellets

3.4. Integrated Product Distribution from Composition, TG/DTG and FTIR

3.5. Contribution of This Research to Sustainability

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Carpenter, D.; Westover, T.L.; Czernik, S.; Jablonski, W. Biomass Feedstocks for Renewable Fuel Production: A Review of the Impacts of Feedstock and Pretreatment on the Yield and Product Distribution of Fast Pyrolysis Bio-Oils and Vapors. Green Chem. 2014, 16, 384–406. [Google Scholar] [CrossRef]

- Liu, Q.; Chmely, S.C.; Abdoulmoumine, N. Biomass Treatment Strategies for Thermochemical Conversion. Energy Fuels 2017, 31, 3525–3536. [Google Scholar] [CrossRef]

- Zhao, M.; Han, Z.; Sheng, C.; Wu, H. Characterization of Residual Carbon in Fly Ashes from Power Plants Firing Biomass. Energy Fuels 2013, 27, 898–907. [Google Scholar] [CrossRef]

- Dula, M.; Kraszkiewicz, A.; Parafiniuk, S. Combustion Efficiency of Various Forms of Solid Biofuels in Terms of Changes in the Method of Fuel Feeding into the Combustion Chamber. Energies 2024, 17, 2853. [Google Scholar] [CrossRef]

- Palma, A.; Gallucci, F.; Papandrea, S.; Carnevale, M.; Paris, E.; Vincenti, B.; Salerno, M.; Di Stefano, V.; Proto, A.R. Experimental Study of the Combustion of and Emissions from Olive and Citrus Pellets in a Small Boiler. Fire 2023, 6, 288. [Google Scholar] [CrossRef]

- Islamova, S.; Tartygasheva, A.; Karaeva, J.; Panchenko, V.; Litti, Y. A Comprehensive Study on the Combustion of Sunflower Husk Pellets by Thermogravimetric and Kinetic Analysis, Kriging Method. Agriculture 2023, 13, 840. [Google Scholar] [CrossRef]

- Aktaş, T. Çeltik Saplarının Gazlaştırılması Amacıyla Laboratuvar Tipi Bir Gazlaştırıcının Geliştirilmesi ve Denenmesi. J. Tekirdag Agric. Fac. 2017, 14, 119–128. [Google Scholar]

- Lee, S.Y.; Sankaran, R.; Chew, K.W.; Tan, C.H.; Krishnamoorthy, R.; Chu, D.; Show, P.L. Waste to Bioenergy: A Review on the Recent Conversion Technologies. BMC Energy 2019, 1, 1–22. [Google Scholar] [CrossRef]

- Sutejo, G.; Dewayanto, N.; Suyono, E.A.; Budiman, A. Technology Selection of Microalgae Thermochemical Conversion to Bio-Crude Oil. IOP Conf. Ser. Earth Environ. Sci. 2022, 1105, 1–7. [Google Scholar] [CrossRef]

- Wang, K.; Tong, R.; Zhai, Q.; Lyu, G.; Li, Y. A Critical Review of Life Cycle Assessments on Bioenergy Technologies: Methodological Choices, Limitations, and Suggestions for Future Studies. Sustainability 2025, 17, 3415. [Google Scholar] [CrossRef]

- Pilon, G.; Lavoie, J. Pyrolysis of Switchgrass (Panicum virgatum L.) at Low Temperatures Within N2 and CO2 Environments: Product Yield Study. ACS Sustain. Chem. Eng. 2012, 1, 198–204. [Google Scholar] [CrossRef]

- Álvarez, J.; Kumagai, S.; Wu, C.; Bilbao, J.; Olazar, M. Hydrogen Production from Biomass and Plastic Mixtures by Pyrolysis-Gasification. Int. J. Hydrog. Energy 2014, 39, 10883–10891. [Google Scholar] [CrossRef]

- Diken, B.; Kayişoğlu, B. A Research on the Determination of the Gasification Performance of Grass Pellets. J. Tekirdag Agric. Fac. 2020, 17, 24–36. [Google Scholar] [CrossRef]

- Gaudutis, A.; Jotautienė, E.; Mieldažys, R.; Bivainis, V.; Jasinskas, A. Sustainable Use of Biochar, Poultry and Cattle Manure for the Production of Organic Granular Fertilizers. Agronomy 2023, 13, 1426. [Google Scholar] [CrossRef]

- Mehdi, R.; Khoja, A.H.; Naqvi, S.R.; Gao, N.; Amin, N.A.S. A Review on Production and Surface Modifications of Biochar Materials via Biomass Pyrolysis Process for Supercapacitor Applications. Catalysts 2022, 12, 798. [Google Scholar] [CrossRef]

- Damian, C.S.; Devarajan, Y.; Raja, T.; Jayabal, R. A Comprehensive Review of Biomass Pyrolysis for Hydrogen Production in India. Process Saf. Environ. Prot. 2024, 190, 646–662. [Google Scholar] [CrossRef]

- Akubo, K.; Nahil, M.A.; Williams, P.T. Pyrolysis-Catalytic Steam Reforming of Agricultural Biomass Wastes and Biomass Components for Production of Hydrogen/Syngas. J. Energy Inst. 2019, 92, 1987–1996. [Google Scholar] [CrossRef]

- Chen, J.; Zhou, X.; Mei, C.; Xu, J.; Zhou, S.; Wong, C.-P. Evaluating Biomass-Derived Hierarchically Porous Carbon as the Positive Electrode Material for Hybrid Na-Ion Capacitors. J. Power Sources 2017, 342, 48–55. [Google Scholar] [CrossRef]

- Wang, P.; Zhang, G.; Li, M.-Y.; Yin, Y.-X.; Li, J.-Y.; Li, G.; Wang, W.-P.; Peng, W.; Cao, F.-F.; Guo, Y.-G. Porous Carbon for High-Energy Density Symmetrical Supercapacitor and Lithium-Ion Hybrid Electrochemical Capacitors. Chem. Eng. J. 2019, 375, 122020. [Google Scholar] [CrossRef]

- Escalante, J.; Chen, W.-H.; Tabatabaei, M.; Hoang, A.T.; Kwon, E.E.; Andrew Lin, K.-Y.; Saravanakumar, A. Pyrolysis of Lignocellulosic, Algal, Plastic, and Other Biomass Wastes for Biofuel Production and Circular Bioeconomy: A Review of Thermogravimetric Analysis (TGA) Approach. Renew. Sustain. Energy Rev. 2022, 169, 112914. [Google Scholar] [CrossRef]

- Tumuluru, J.S.; Sokhansanj, S.; Hess, J.R.; Wright, C.T.; Boardman, R.D. A Review on Biomass Torrefaction Process and Product Properties for Energy Applications. Ind. Biotechnol. 2011, 7, 384–401. [Google Scholar] [CrossRef]

- Hagner, M.; Tiilikkala, K.; Lindqvist, I.; Niemelä, K.; Wikberg, H.; Källi, A.; Rasa, K. Performance of Liquids from Slow Pyrolysis and Hydrothermal Carbonization in Plant Protection. Waste Biomass Valor. 2020, 11, 1005–1016. [Google Scholar] [CrossRef]

- Huang, J.; Khan, M.T.; Perecin, D.; Coelho, S.T.; Zhang, M. Sugarcane for Bioethanol Production: Potential of Bagasse in Chinese Perspective. Renew. Sustain. Energy Rev. 2020, 133, 110296. [Google Scholar] [CrossRef]

- Kumar, J.A.; Sathish, S.; Prabu, D.; Renita, A.A.; Saravanan, A.; Deivayanai, V.C.; Anish, M.; Jayaprabakar, J.; Baigenzhenov, O.; Hosseini-Bandegharaei, A. Agricultural Waste Biomass for Sustainable Bioenergy Production: Feedstock, Characterization and Pre-Treatment Methodologies. Chemosphere 2023, 331, 138680. [Google Scholar] [CrossRef]

- Cai, J.; Xu, D.; Dong, Z.; Yu, X.; Yang, Y.; Banks, S.W.; Bridgwater, A.V. Processing Thermogravimetric Analysis Data for Isoconversional Kinetic Analysis of Lignocellulosic Biomass Pyrolysis: Case Study of Corn Stalk. Renew. Sustain. Energy Rev. 2018, 82, 2705–2715. [Google Scholar] [CrossRef]

- Martí, B.V. Evaluation of the Intermediate Values of the TGA Curves as Indicators of the Proximal Analysis of Biomass. Agronomy 2023, 13, 2552. [Google Scholar] [CrossRef]

- Butler, E.; Devlin, G.; Meier, D.; McDonnell, K. A Review of Recent Laboratory Research and Commercial Developments in Fast Pyrolysis and Upgrading. Renew. Sustain. Energy Rev. 2011, 15, 4171–4186. [Google Scholar] [CrossRef]

- Zhai, M.; Guo, L.; Dong, P.; Qi, G.; Huang, Y. Kinetic Parameters of Biomass Pyrolysis by TGA. Bioresources 2016, 11, 8548–8557. [Google Scholar] [CrossRef]

- Ahmed, A.; Hidayat, S.; Abu Bakar, M.S.; Azad, A.K.; Sukri, R.S.; Phusunti, N. Thermochemical Characterisation of Acacia Auriculiformis Tree Parts via Proximate, Ultimate, TGA, DTG, Calorific Value and FTIR Spectroscopy Analyses to Evaluate Their Potential as a Biofuel Resource. Biofuels 2021, 12, 9–20. [Google Scholar] [CrossRef]

- Sanchez-Silva, L.; López-González, D.; Villaseñor, J.; Sánchez, P.; Valverde, J.L. Thermogravimetric–Mass Spectrometric Analysis of Lignocellulosic and Marine Biomass Pyrolysis. Bioresour. Technol. 2012, 109, 163–172. [Google Scholar] [CrossRef] [PubMed]

- Apaydın Varol, E.; Mutlu, Ü. TGA-FTIR Analysis of Biomass Samples Based on the Thermal Decomposition Behavior of Hemicellulose, Cellulose, and Lignin. Energies 2023, 16, 3674. [Google Scholar] [CrossRef]

- Boundzanga, H.M.; Cagnon, B.; Roulet, M.; de Persis, S.; Vautrin-Ul, C.; Bonnamy, S. Contributions of Hemicellulose, Cellulose, and Lignin to the Mass and the Porous Characteristics of Activated Carbons Produced from Biomass Residues by Phosphoric Acid Activation. Biomass Conv. Bioref. 2022, 12, 3081–3096. [Google Scholar] [CrossRef]

- Collard, F.-X.; Blin, J. A Review on Pyrolysis of Biomass Constituents: Mechanisms and Composition of the Products Obtained from the Conversion of Cellulose, Hemicelluloses and Lignin. Renew. Sustain. Energy Rev. 2014, 38, 594–608. [Google Scholar] [CrossRef]

- Kurian, J.K.; Gariepy, Y.; Orsat, V.; Raghavan, G.S.V. Microwave-Assisted Lime Treatment and Recovery of Lignin from Hydrothermally Treated Sweet Sorghum Bagasse. Biofuels 2015, 6, 341–355. [Google Scholar] [CrossRef]

- Patwardhan, P.R.; Dalluge, D.L.; Shanks, B.H.; Brown, R.C. Distinguishing Primary and Secondary Reactions of Cellulose Pyrolysis. Bioresour. Technol. 2011, 102, 5265–5269. [Google Scholar] [CrossRef]

- Wang, W.; Lemaire, R.; Bensakhria, A.; Luart, D. Review on the Catalytic Effects of Alkali and Alkaline Earth Metals (AAEMs) Including Sodium, Potassium, Calcium and Magnesium on the Pyrolysis of Lignocellulosic Biomass and on the Co-Pyrolysis of Coal with Biomass. J. Anal. Appl. Pyrolysis 2022, 163, 105479. [Google Scholar] [CrossRef]

- Ungureanu, N.; Vlăduț, N.-V.; Biriș, S.-Ș.; Gheorghiță, N.-E.; Ionescu, M. Biomass Pyrolysis Pathways for Renewable Energy and Sustainable Resource Recovery: A Critical Review of Processes, Parameters, and Product Valorization. Sustainability 2025, 17, 7806. [Google Scholar] [CrossRef]

- Mack, R.; Schön, C.; Kuptz, D.; Hartmann, H.; Brunner, T.; Obernberger, I.; Behr, H.M. Quality Range of ENplus A1 Certified Wood Pellets and Their Combustion Behavior in Residential Pellet Stoves and Pellet Boilers. Biomass Conv. Bioref. 2025, 15, 17155–17171. [Google Scholar] [CrossRef]

- Ordoudi, S.A.; Papapostolou, M.; Nenadis, N.; Mantzouridou, F.T.; Tsimidou, M.Z. Bay Laurel (Laurus nobilis L.) Essential Oil as a Food Preservative Source: Chemistry, Quality Control, Activity Assessment, and Applications to Olive Industry Products. Foods 2022, 11, 752. [Google Scholar] [CrossRef]

- Altın, S.; Işık, M.; Alp, C.; Dikici, E.; Köksal, E.; Kırboğa, K.K.; Rudrapal, M.; Rakshit, G.; Beydemir, Ş.; Khan, J. Therapeutic Potential of Laurus Nobilis Extract by Experimental and Computational Approaches: Phenolic Content and Bioactivities for Antioxidant, Antidiabetic, and Anticholinergic Properties. Front. Chem. 2025, 13, 1541250. [Google Scholar] [CrossRef]

- Gündüz, G.; Saraçoğlu, N.; Aydemir, D. Characterization and Elemental Analysis of Wood Pellets Obtained from Low-Valued Types of Wood. Energy Sources Part A Recovery Util. Environ. Eff. 2016, 38, 2211–2216. [Google Scholar] [CrossRef]

- Yılmaz, H.; Çanakcı, M.; Topakcı, M.; Karayel, D.; Yiğit, M.; Ortaçeşme, D. In-Situ Pelletization of Campus Biomass Residues: Case Study for Akdeniz University. Renew. Energy 2023, 212, 972–983. [Google Scholar] [CrossRef]

- Alexiou Ivanova, T.; Paramonova, K.; Talipov, O.; Tanyrbergenov, N.; Zhakupov, T.; Akayev, A. Assessment of Common Reed (Phragmites australis (Cav.) Trin. Ex Steud.) Biomass Suitability for Solid Biofuels Production. Sustainability 2024, 16, 7378. [Google Scholar] [CrossRef]

- ASTM E871-82; Standard Test Method for Moisture Analysis of Particulate Wood Fuels. ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM D1102-84; Standard Test Method for Ash in Wood. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM E872-82; Standard Test Method for Volatile Matter in the Analysis of Particulate Wood Fuels. ASTM International: West Conshohocken, PA, USA, 2019.

- Ozyuguran, A.; Akturk, A.; Yaman, S. Optimal Use of Condensed Parameters of Ultimate Analysis to Predict the Calorific Value of Biomass. Fuel 2018, 214, 640–646. [Google Scholar] [CrossRef]

- Dołżyńska, M.; Obidziński, S.; Piekut, J.; Yildiz, G. The Utilization of Plum Stones for Pellet Production and Investigation of Post-Combustion Flue Gas Emissions. Energies 2020, 13, 5107. [Google Scholar] [CrossRef]

- Bongomin, O.; Nzila, C.; Igadwa Mwasiagi, J.; Maube, O. Comprehensive Thermal Properties, Kinetic, and Thermodynamic Analyses of Biomass Wastes Pyrolysis via TGA and Coats-Redfern Methodologies. Energy Convers. Manag. X 2024, 24, 100723. [Google Scholar] [CrossRef]

- El-Sayed, S.A.; Khass, T.M.; Mostafa, M.E. Thermal Degradation Behaviour and Chemical Kinetic Characteristics of Biomass Pyrolysis Using TG/DTG/DTA Techniques. Biomass Conv. Bioref. 2024, 14, 17779–17803. [Google Scholar] [CrossRef]

- Hopa, D.Y.; Alagöz, O.; Yılmaz, N.; Dilek, M.; Arabacı, G.; Mutlu, T. Biomass Co-Pyrolysis: Effects of Blending Three Different Biomasses on Oil Yield and Quality. Waste Manag. Res. 2019, 37, 925–933. [Google Scholar] [CrossRef]

- Mullen, C.A.; Boateng, A.A.; Dadson, R.B.; Hashem, F.M. Biological Mineral Range Effects on Biomass Conversion to Aromatic Hydrocarbons via Catalytic Fast Pyrolysis over HZSM-5. Energy Fuels 2014, 28, 7014–7024. [Google Scholar] [CrossRef]

- Al-Rahbi, A.S.; Williams, P.T. Waste Ashes as Catalysts for the Pyrolysis–Catalytic Steam Reforming of Biomass for Hydrogen-Rich Gas Production. J. Mater. Cycles Waste Manag. 2019, 21, 1224–1231. [Google Scholar] [CrossRef]

- Wei, J.; Guo, Q.; Ding, L.; Gong, Y.; Yu, J.; Yu, G. Understanding the Effect of Different Biomass Ash Additions on Pyrolysis Product Distribution, Char Physicochemical Characteristics, and Char Gasification Reactivity of Bituminous Coal. Energy Fuels 2019, 33, 3068–3076. [Google Scholar] [CrossRef]

- Garyntseva, N.V.; Levdansky, V.A.; Kondrasenko, A.A.; Skripnikov, A.M.; Kuznetsov, B.N. Isolation and Characterization of the Hemicelluloses Polysaccharides of Scots Pine (Pinus sylvestris) Wood. Russ. J. Bioorg. Chem. 2023, 49, 1596–1606. [Google Scholar] [CrossRef]

- Najahi, A.; Tarrés, Q.; Mutjé, P.; Delgado-Aguilar, M.; Putaux, J.-L.; Boufi, S. Lignin-Containing Cellulose Nanofibrils from TEMPO-Mediated Oxidation of Date Palm Waste: Preparation, Characterization, and Reinforcing Potential. Nanomaterials 2023, 13, 126. [Google Scholar] [CrossRef]

- Wöhler-Geske, A.; Moschner, C.R.; Gellerich, A. Provenances and Properties of Thatching Reed (Phragmites australis). Appl. Agric. For. Res. 2016, 66, 1–10. [Google Scholar]

- Rincón, E.; Espinosa, E.; García-Domínguez, M.T.; Balu, A.M.; Vilaplana, F.; Serrano, L.; Jiménez-Quero, A. Bioactive Pectic Polysaccharides from Bay Tree Pruning Waste: Sequential Subcritical Water Extraction and Application in Active Food Packaging. Carbohydr. Polym. 2021, 272, 118477. [Google Scholar] [CrossRef]

- Zhou, C.; Liu, Q.S.; Li, Y.; Teng, Y.Y.; Zhi, K.D.; Song, Y.; He, R.X. Influence of Pyrolysis Temperature on the Gaseous Products of Lignite. Adv. Mater. Res. 2012, 524–527, 883–886. [Google Scholar] [CrossRef]

- Li, X.; Yang, C.; Liu, M.; Bai, J.; Li, W. Influence of Different Biomass Ash Additive on Anthracite Pyrolysis Process and Char Gasification Reactivity. Int. J. Coal Sci. Technol. 2020, 7, 464–475. [Google Scholar] [CrossRef]

- Li, X.; Zhang, R.; Dong, R.; Meng, X.; Li, P.; Ni, C.; Zhang, B. Influence of Biomass Ashes on the Structural Evolution and Oxygen-Donating Capacity of Red Mud during Chemical Looping Gasification. Waste Manag. 2025, 205, 115022. [Google Scholar] [CrossRef]

- Hedayati, A.; Lindgren, R.; Skoglund, N.; Boman, C.; Kienzl, N.; Öhman, M. Ash Transformation during Single-Pellet Combustion of Agricultural Biomass with a Focus on Potassium and Phosphorus. Energy Fuels 2021, 35, 1449–1464. [Google Scholar] [CrossRef]

- Rizkiana, J.; Guan, G.; Widayatno, W.B.; Hao, X.; Li, X.; Huang, W.; Abudula, A. Promoting Effect of Various Biomass Ashes on the Steam Gasification of Low-Rank Coal. Appl. Energy 2014, 133, 282–288. [Google Scholar] [CrossRef]

- Puri, L.; Hu, Y.; Naterer, G. Critical Review of the Role of Ash Content and Composition in Biomass Pyrolysis. Front. Fuels 2024, 2, 1378361. [Google Scholar] [CrossRef]

- Sen, S.; Singh, A.P.; Kailasam, K.; Bera, C.; Roy, S. Facile Synthesis of Cellulose and Fly-Ash Based Sustainable Nanohybrids for Thermal Insulation Applications. Cellulose 2023, 30, 9127–9145. [Google Scholar] [CrossRef]

- Li, S.; Wang, C.; Luo, Z.; Zhu, X. Investigation on the Catalytic Behavior of Alkali Metals and Alkaline Earth Metals on the Biomass Pyrolysis Assisted with Real-Time Monitoring. Energy Fuels 2020, 34, 12654–12664. [Google Scholar] [CrossRef]

- Zhang, X.; Luo, Q.; Zhan, H.; Evrendilek, F.; Yang, R.; Zeng, W.; Li, Y.; Dong, S.; Huang, W.; Liu, J. Pyrolytic Energy Performance and Byproducts of Ganoderma lucidum: Their Multi-Objective Optimization. J. Anal. Appl. Pyrolysis 2023, 176, 106225. [Google Scholar] [CrossRef]

- Xu, Y.; Zhai, M.; Guo, H.; Qi, H.; Zou, X.; Jin, S.; Dong, P. High-Temperature Pyrolysis Characteristics for a Single Biomass Particle. Energy Fuels 2019, 33, 11153–11162. [Google Scholar] [CrossRef]

- Lessa, M.d.O.; Calixto, G.Q.; das Chagas, B.M.E.; Aguiar, E.M.d.; Melo, M.A.d.F.; Braga, R.M. Energetic Characterization and Flash Pyrolysis of Different Elephant Grass Cultivars (Pennisetum purpureum Schum.). Can. J. Chem. Eng. 2021, 100, 2825–2834. [Google Scholar] [CrossRef]

- Yang, X.-W.; Xia, S.; Wang, C.; Zheng, A.; Zhao, Z. Selective Production of Platform Chemicals from Low-Temperature Pyrolysis of Biomass Mediated by Exogenous Acid–Intrinsic Base Balance. ACS Sustain. Chem. Eng. 2022, 10, 5895–5910. [Google Scholar] [CrossRef]

- Nan, H.; Yang, F.; Zhao, L.; Mašek, O.; Cao, X.; Xiao, Z. Interaction of Inherent Minerals with Carbon during Biomass Pyrolysis Weakens Biochar Carbon Sequestration Potential. ACS Sustain. Chem. Eng. 2018, 7, 1591–1599. [Google Scholar] [CrossRef]

- Ben, H.; Wu, F.; Wu, Z.; Han, G.; Jiang, W.; Ragauskas, A.J. A Comprehensive Characterization of Pyrolysis Oil from Softwood Barks. Polymers 2019, 11, 1387. [Google Scholar] [CrossRef]

- Hossain, M.M.; Subbiah, V.K.; Siddiquee, S. Augmented Retting Effect on Kenaf Fibers Using Alkalophilic Pectinase-Producing Bacteria in Combination with Water Solvents. Appl. Sci. 2022, 12, 7136. [Google Scholar] [CrossRef]

- Levdansky, A.V.; Vasilyeva, N.Y.; Malyar, Y.N.; Kondrasenko, A.A.; Fetisova, O.Y.; Kazachenko, A.S.; Levdansky, V.A.; Kuznetsov, B.N. An Efficient Method of Birch Ethanol Lignin Sulfation with a Sulfaic Acid-Urea Mixture. Molecules 2022, 27, 6356. [Google Scholar] [CrossRef]

- Acquah, G.E.; Via, B.K.; Fasina, O.O.; Eckhardt, L.G. Rapid Quantitative Analysis of Forest Biomass Using Fourier Transform Infrared Spectroscopy and Partial Least Squares Regression. J. Anal. Methods Chem. 2016, 2016, e1839598. [Google Scholar] [CrossRef]

- Zheng, A.; Jiang, L.; Zhao, Z.; Huang, Z.; Zhao, K.; Wei, G.; Wang, X.; He, F.; Li, H. Impact of Torrefaction on the Chemical Structure and Catalytic Fast Pyrolysis Behavior of Hemicellulose, Lignin, and Cellulose. Energy Fuels 2015, 29, 8027–8034. [Google Scholar] [CrossRef]

- Wang, L.; Riva, L.; Skreiberg, Ø.; Khalil, R.; Bartocci, P.; Yang, Q.; Yang, H.; Wang, X.; Chen, D.; Rudolfsson, M.; et al. Effect of Torrefaction on Properties of Pellets Produced from Woody Biomass. Energy Fuels 2020, 34, 15343–15354. [Google Scholar] [CrossRef]

- Chen, W.-H.; Peng, J.; Bi, X.T. A State-of-the-Art Review of Biomass Torrefaction, Densification and Applications. Renew. Sustain. Energy Rev. 2015, 44, 847–866. [Google Scholar] [CrossRef]

- Zadeh, Z.E.; Abdulkhani, A.; Aboelazayem, O.; Saha, B. Recent Insights into Lignocellulosic Biomass Pyrolysis: A Critical Review on Pretreatment, Characterization, and Products Upgrading. Processes 2020, 8, 799. [Google Scholar] [CrossRef]

- The Sustainable Development Goals Report 2024|DESA Publications. Available online: https://desapublications.un.org/publications/sustainable-development-goals-report-2024 (accessed on 29 September 2025).

| Parameter | WP | PP | RD | DP |

|---|---|---|---|---|

| Moisture (%, wb 1) | 8.32 | 6.34 | 6.40 | 6.90 |

| Ash (%, db 1) | 1.73 | 11.65 | 13.12 | 1.93 |

| Volatile matter (%, db) | 82.47 | 69.27 | 68.38 | 80.51 |

| Fixed carbon (%, db) | 15.80 | 19.08 | 18.50 | 17.56 |

| C (%, db) | 49.68 | 44.69 | 41.59 | 47.26 |

| H (%, db) | 6.14 | 5.59 | 5.49 | 5.88 |

| N (%, db) | 0.10 | 1.37 | 1.63 | 0.34 |

| S (%, db) | 0.00 | 0.35 | 0.12 | 0.01 |

| O (%, db) | 42.35 | 36.35 | 38.05 | 44.58 |

| O/C | 0.64 | 0.61 | 0.69 | 0.71 |

| H/C | 1.47 | 1.49 | 1.57 | 1.48 |

| HHV (MJ kg−1) | 20.19 | 18.15 | 16.82 | 19.15 |

| LHV (MJ mkg−1) | 18.65 | 16.77 | 15.47 | 17.70 |

| Hemicellulose (%) 2 | 17.50 | 22.00 | 26.85 | 17.58 |

| Cellulose (%) 2 | 46.90 | 44.00 | 51.53 | 30.84 |

| Lignin (%) 2 | 27.30 | 28.00 | 11.91 | 22.31 |

| Parameter 1 | Unit | WP | PP | RD | DP |

|---|---|---|---|---|---|

| (°C) | 190 | 163 | 128 | 165 | |

| (°C) | 427 | 407 | 473 | 486 | |

| (%) | 75.74 | 65.4 | 66.81 | 76.06 | |

| (°C) | 365 | 334 | 310 | 352 | |

| (% min−1) | 55.9 | 56.8 | 61.01 | 46.19 | |

| (°C) | 59 | 90 | 59 | 88 | |

| (10−3%3 °C−3 min−2) | 10.9 | 5.4 | 10.8 | 6.2 | |

| (103% °C min−3) | 1.2 | 1.4 | 0.9 | 1.4 | |

| (109% min−1 °C−2) | 1.7 | 1.3 | 1.3 | 1.4 |

| Pellet | Key Temperatures (°C) | 1 Liquid-max range (°C) | Char @600 °C (100–m∞, wt%) | 2 Expected Liquid Families (Bio-Oil) | 3 Gas Tendency (Qual.) | 4 Char Quality (Qual.) |

|---|---|---|---|---|---|---|

| WP | Ti: 190 | 335–395 | 24.3 | Oxygenates (strong anhydrosugar/levoglucosan path) + phenolics (G/S) | Low–mid | Clean, low ash, higher aromaticity with high temp. |

| Tpmax: 365 | ||||||

| Tf: 427 | ||||||

| ΔT1/2: 59 | ||||||

| PP | Ti: 163 | 289–379 | 34.6 | Phenolic rich (guaiacol/syringol); anhydrosugars suppressed; some light acids | Mid–high | Ash rich, aromatic; catalytically hardened |

| Tpmax: 334 | ||||||

| Tf: 407 | ||||||

| ΔT1/2: 90 | ||||||

| RD | Ti: 128 | 280–340 | 33.2 | Light oxygenates (acetic acid, furfural); anhydrosugars suppressed | Mid–high (CO2/CO, some H2) | Ash rich, moderate aromaticity |

| Tpmax: 310 | ||||||

| Tf: 473 | ||||||

| ΔT1/2: 59 | ||||||

| DP | Ti: 165 | 308–396 | 23.9 | Oxygenates (less anhydrosugar than WP) + some phenolics | Low–mid | Cleaner than PP and RD, moderate aromaticity |

| Tpmax: 352 | ||||||

| Tf: 486 | ||||||

| ΔT1/2: 88 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bilgin, S.; Yılmaz, H.; Topakcı, M.; Gürdil, G.A.K.; Çanakcı, M.; Karayel, D. Determination of the Pyrolytic Characteristics of Various Biomass Pellets. Sustainability 2025, 17, 9003. https://doi.org/10.3390/su17209003

Bilgin S, Yılmaz H, Topakcı M, Gürdil GAK, Çanakcı M, Karayel D. Determination of the Pyrolytic Characteristics of Various Biomass Pellets. Sustainability. 2025; 17(20):9003. https://doi.org/10.3390/su17209003

Chicago/Turabian StyleBilgin, Sefai, Hasan Yılmaz, Mehmet Topakcı, Gürkan Alp Kağan Gürdil, Murad Çanakcı, and Davut Karayel. 2025. "Determination of the Pyrolytic Characteristics of Various Biomass Pellets" Sustainability 17, no. 20: 9003. https://doi.org/10.3390/su17209003

APA StyleBilgin, S., Yılmaz, H., Topakcı, M., Gürdil, G. A. K., Çanakcı, M., & Karayel, D. (2025). Determination of the Pyrolytic Characteristics of Various Biomass Pellets. Sustainability, 17(20), 9003. https://doi.org/10.3390/su17209003