Minimizing the Damage of Underground Coal Mining to a Village Through Integrating Room-and-Pillar Method with Backfilling: A Case Study in Weibei Coalfield, China

Abstract

1. Introduction

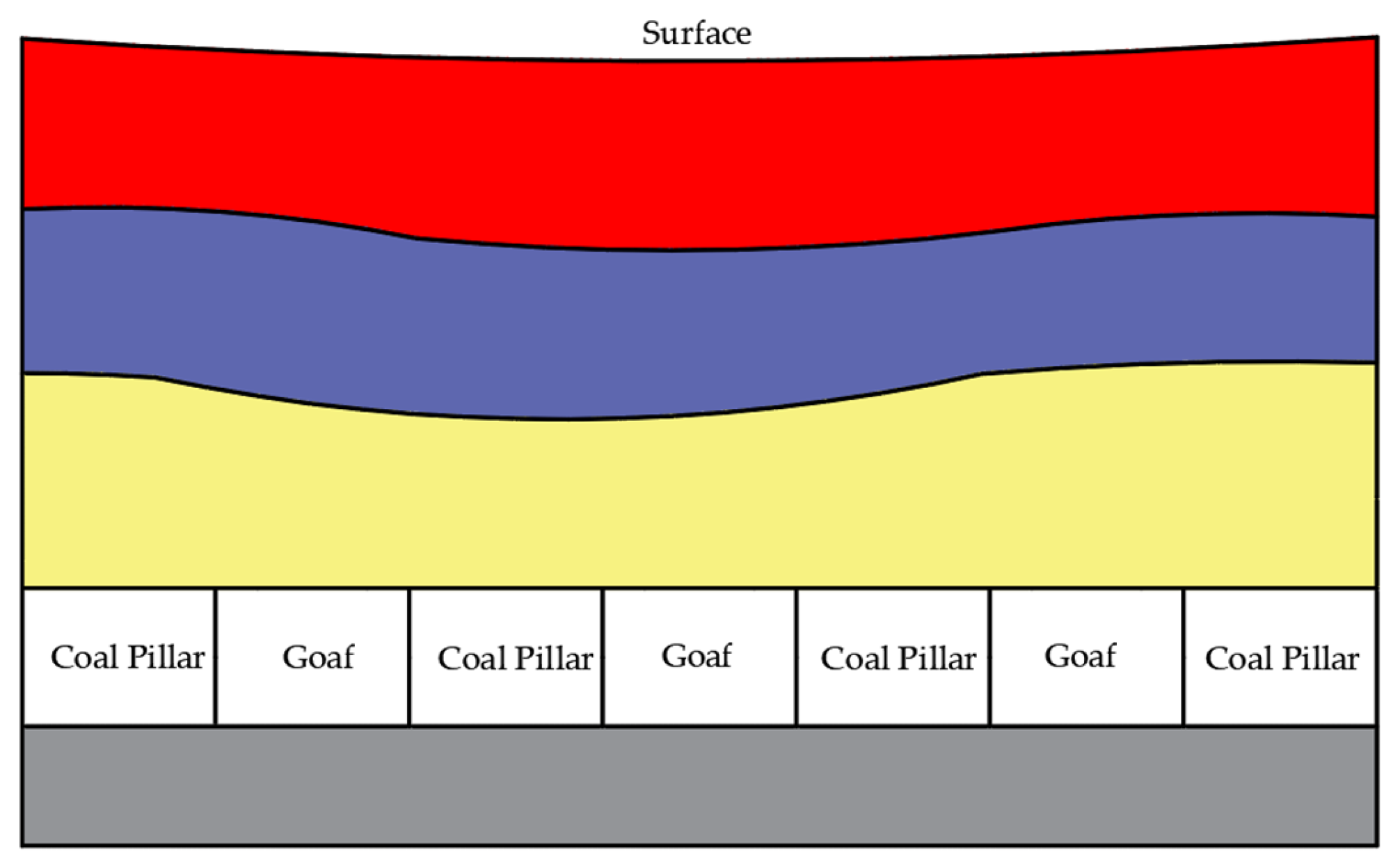

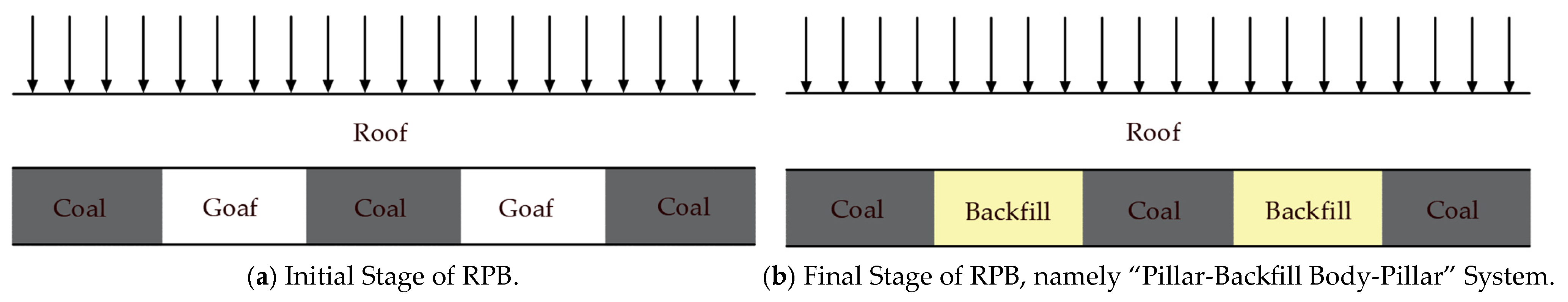

2. Ground Control Mechanism of RPB

3. Factors of Surface Deformation Control

3.1. Factors Influencing Surface Deformation

3.2. Selection of Filling Materials

4. Numerical Analysis of Overlying Strata in RPB

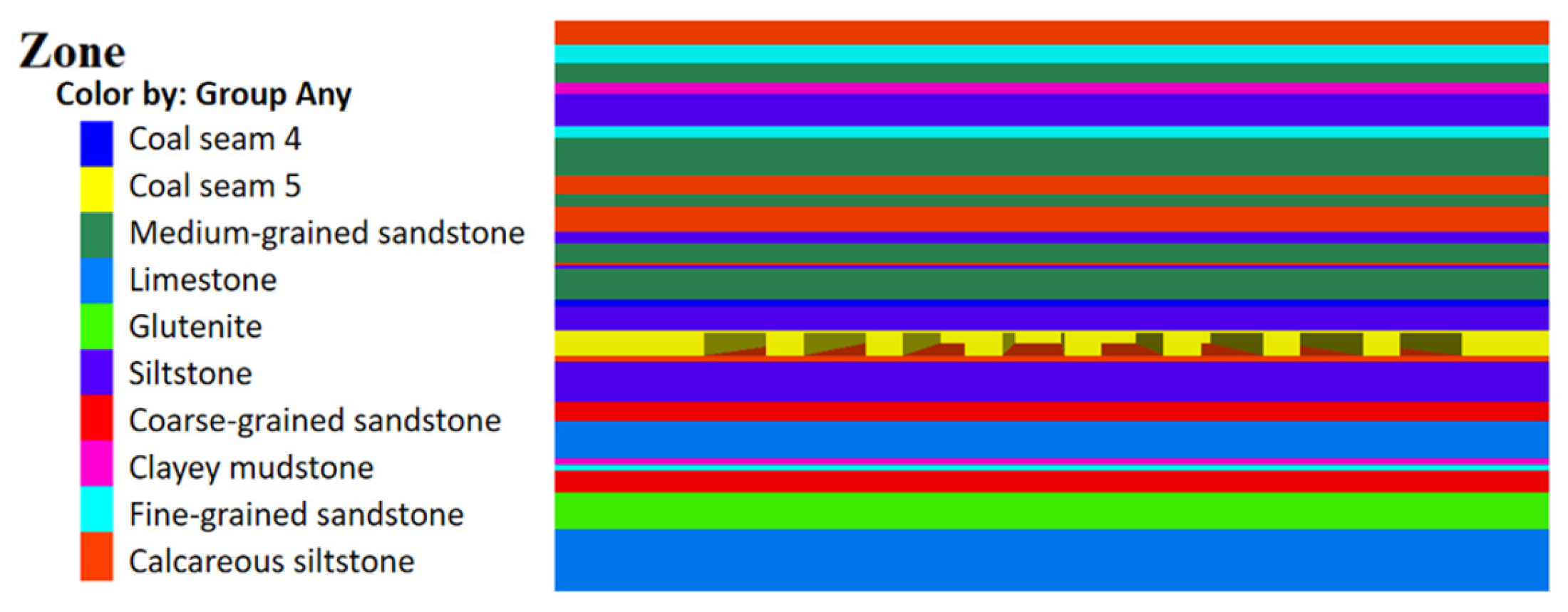

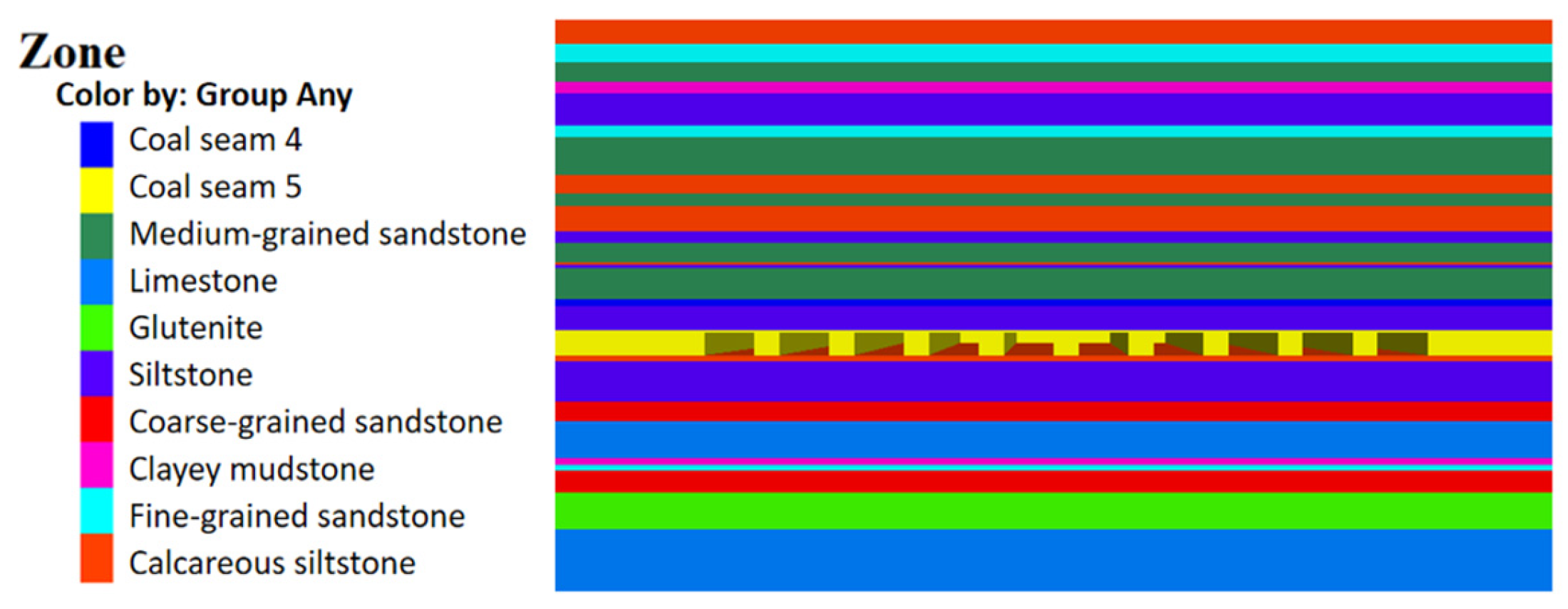

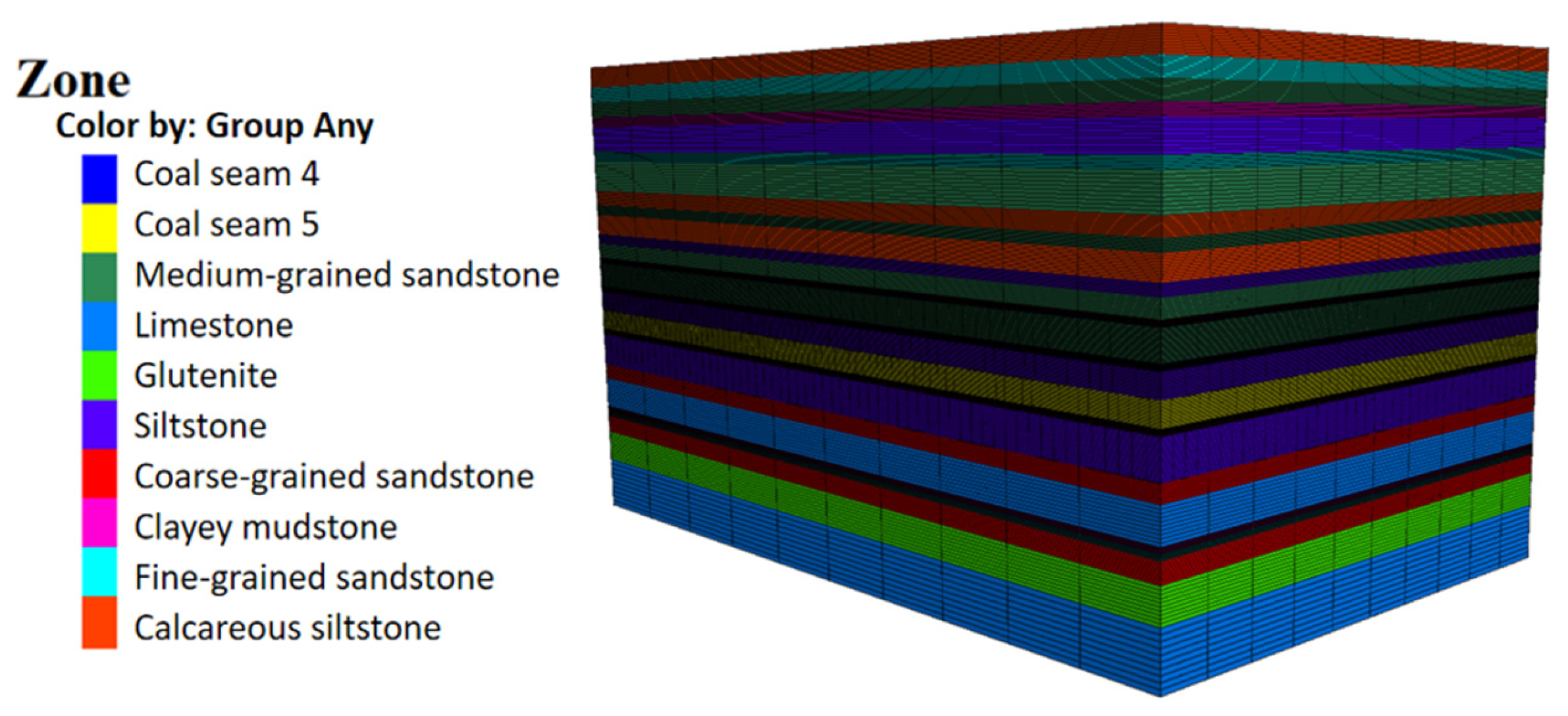

4.1. The Settings of Geology

4.2. Model Establishment

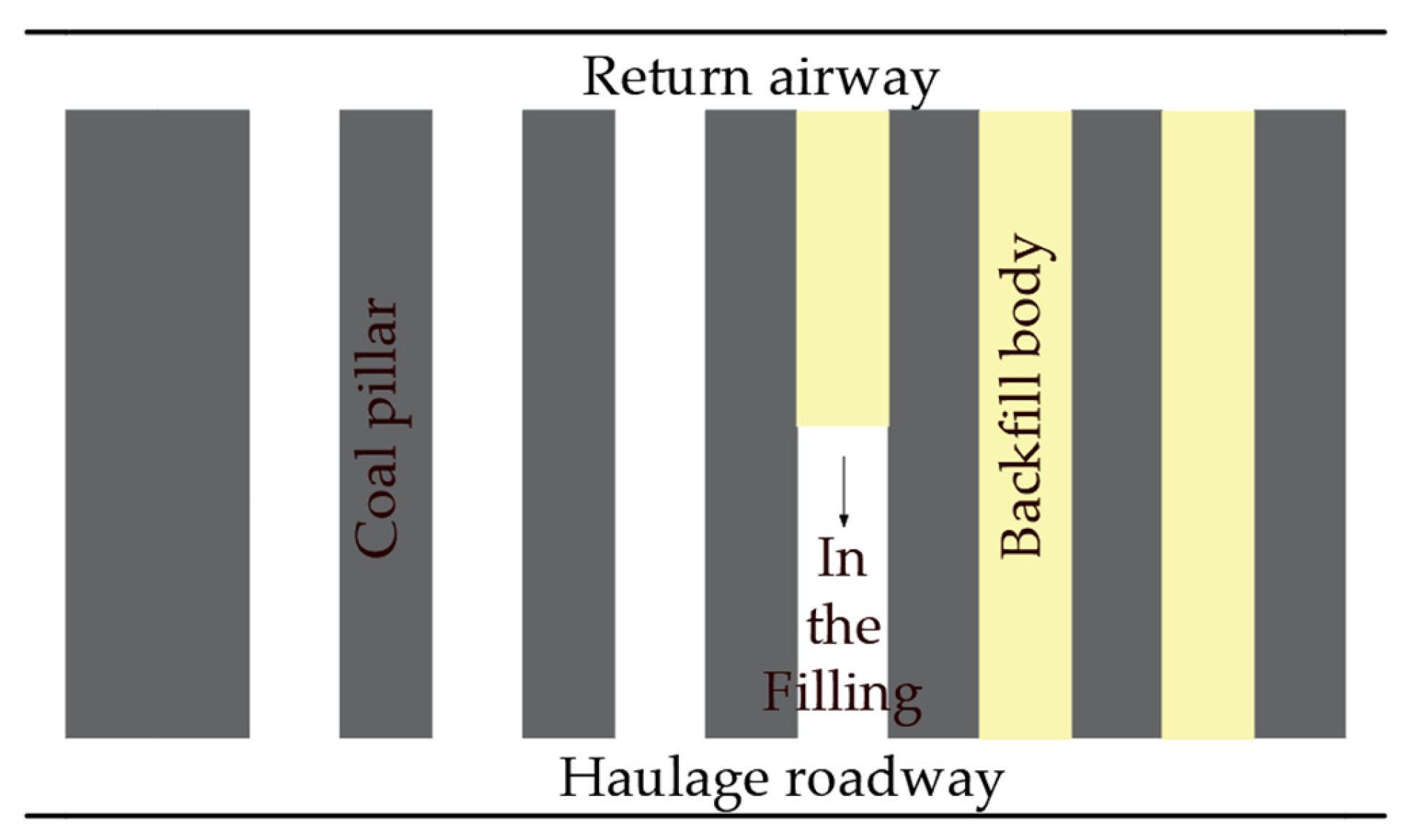

4.3. Experimental Plan

- (1)

- The strata structure shaped by the 8-room-8-pillar scheme is shown in Figure 7;

- (2)

- The strata structure shaped by the 8-room-6-pillar scheme is shown in Figure 8;

- (3)

- The strata structure shaped by the 6-room-6-pillar scheme is shown in Figure 9.

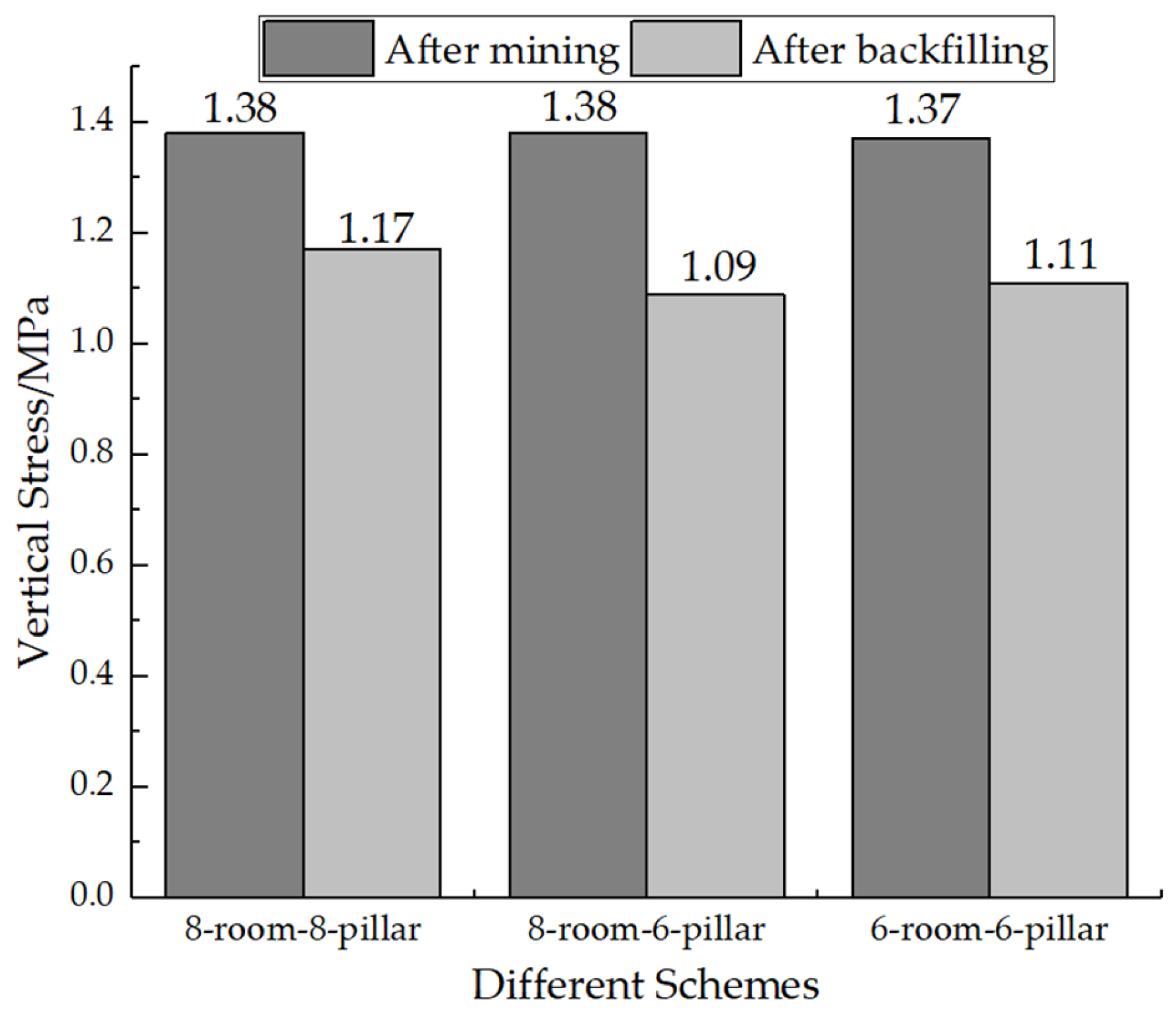

4.4. Analysis of Calculation Results

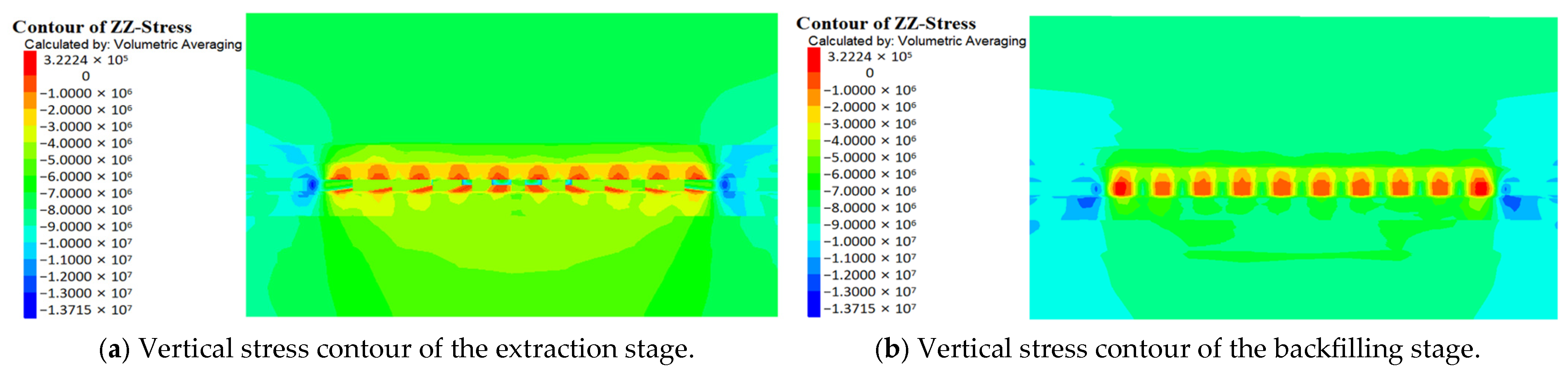

4.4.1. Stress Characteristics

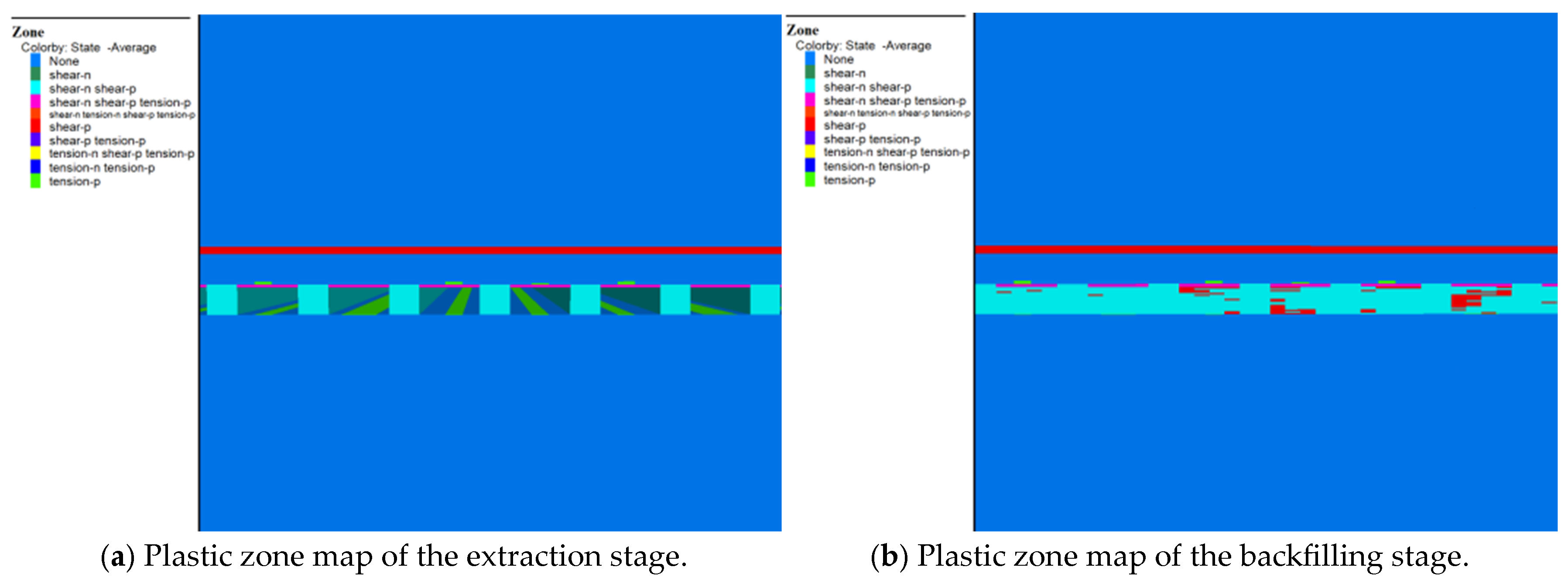

4.4.2. Plastic Zone Distribution

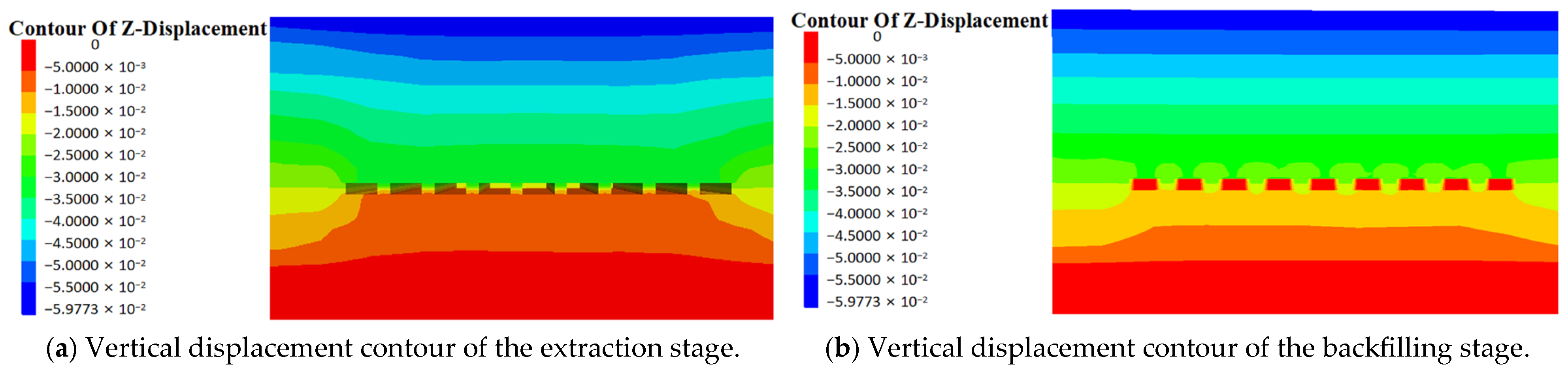

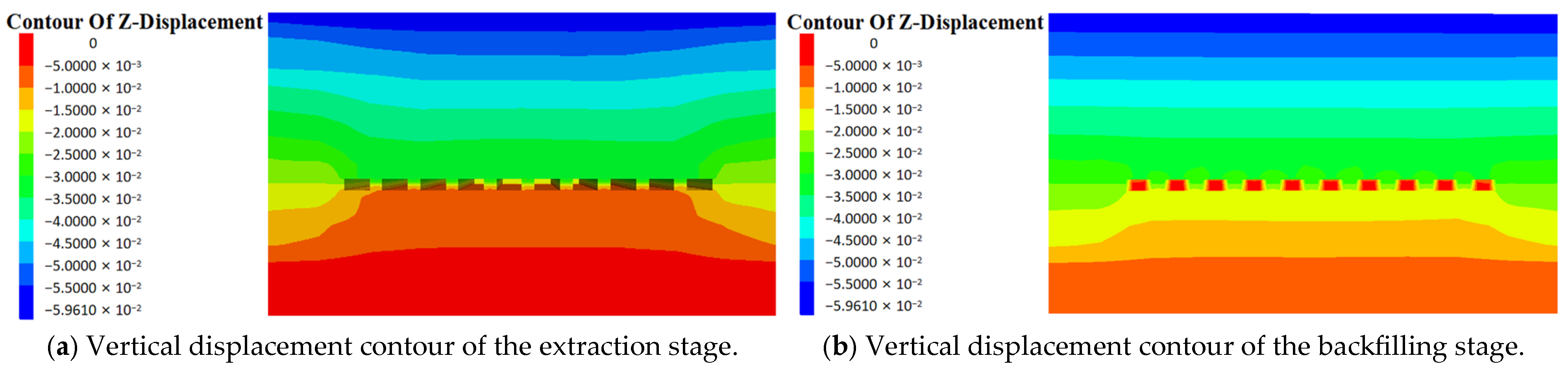

4.4.3. Displacement and Deformation of Roof Strata

5. Field Verification

6. Discussion and Conclusions

6.1. Discussion

- (1)

- The study presented in this manuscript is primarily based on the geological conditions of Weibei Coalfield, and further study is needed to determine whether the laws governing the movement and deformation of the overlying strata and surface remain applicable in other regions and under special geological conditions.

- (2)

- The characteristics of various mining areas in China differ significantly. Due to geological structures, climatic conditions, and resource distributions, each mining area exhibits unique geological formations, coal seam distributions, and mining environments. These differences necessitate the adoption of targeted mining strategies and technological approaches based on the specific conditions of each mining area to ensure the efficiency and safety of resource extraction.

6.2. Conclusions

- (1)

- Stress transfer can be observed during the operation of RPB. The backfill body becomes a concentration area of stress, which is induced by the transmission of the weight of the overlying strata from the goaf area. The backfill body plays a stabilizing role in the movement of strata and inhibits the subsidence of the roofs. The 8-room-8-pillar scheme exhibits the highest degree of stress concentration on both sides of the backfill body, while the 6-room-6-pillar scheme has the lowest.

- (2)

- The backfilling of RPB restrains the development of plastic deformation within overlying strata. The caving and fracture zones of strata which are naturally developed in longwall mining are not present in the RPB mining. The plastic failure is confined around the upper part of the backfill body and presents a shear feature, while the immediate roof experiences less damage, primarily in the form of tensile failure. As the width of the backfill body decreases, the tensile and shear failures in the immediate roof gradually diminish, weakening the impact of overburden.

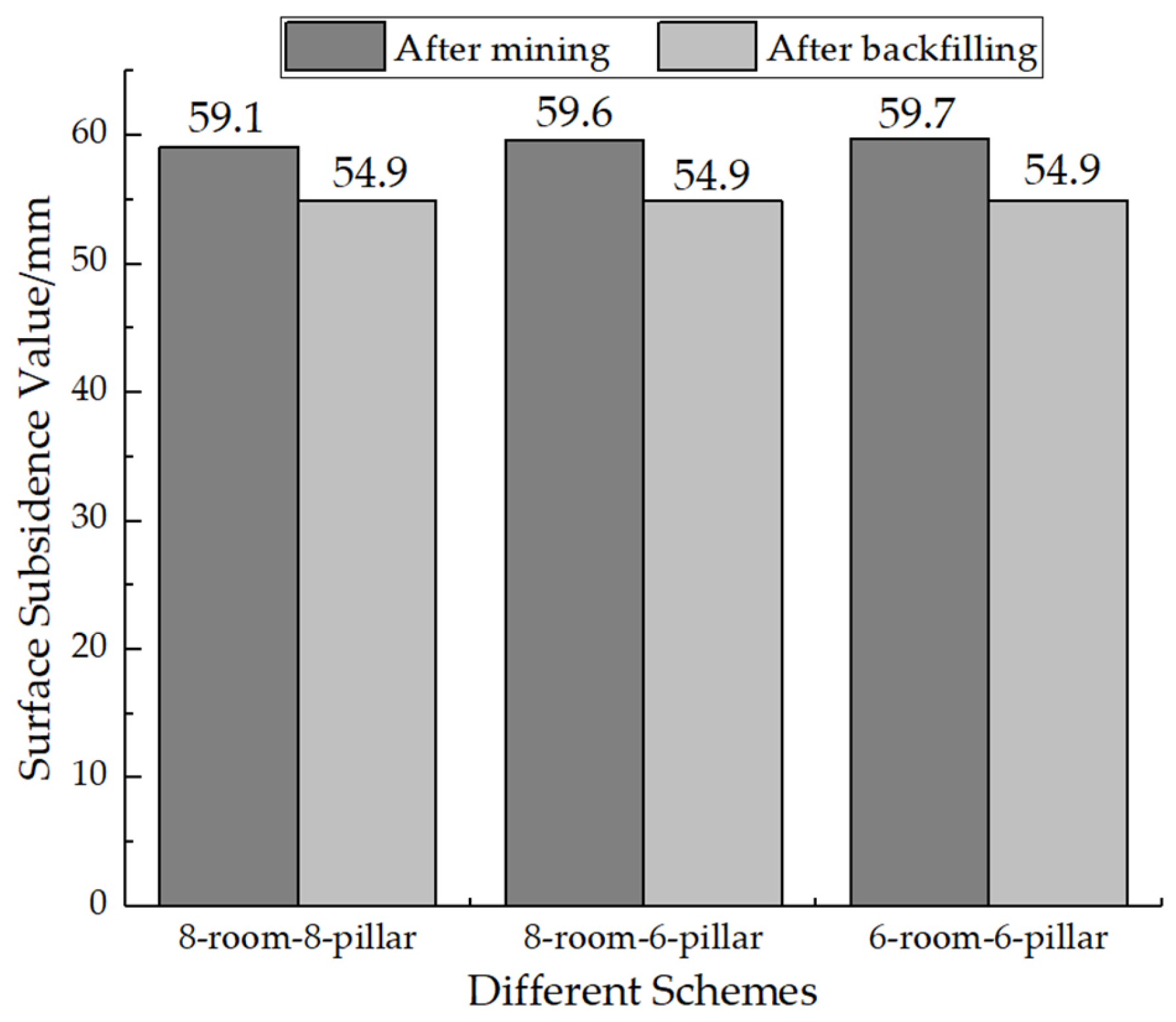

- (3)

- The comparisons of the three mining schemes indicate that the widths of both pillar and backfill body have an influence on the surface subsidence, but the subsidence is controlled to be within a low extent by RPB. Among the three mining schemes, the 6-room-6-pillar scheme exhibits the best inhibition effect on subsidence and can therefore protect the village buildings to a large extent.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Guo, W.B.; Hu, Y.H.; Hu, C.Q. China’s “Three-Under” Coal Mining Technology System and Engineering Practice. Coal Sci. Technol. 2024, 52, 1–21. [Google Scholar]

- Sarfarazi, V.; Fattahi, S.; Asgari, K.; Bahrami, R.; Wang, X. Failure Behavior of Room and Pillar with Different Room Configuration Under Uniaxial Loading Using Experimental Test and Numerical Simulation. Geotech. Geol. Eng. 2022, 40, 2881–2896. [Google Scholar] [CrossRef]

- Zhou, Y.J.; Li, M.; Xu, X.D.; Li, X.T.; Ma, Y.D.; Ma, Z.G. Research on Catastrophic Instability in Room and Pillar Gypsum Mining. Sustainability 2018, 10, 3773. [Google Scholar] [CrossRef]

- Yu, Y.; Chen, S.E.; Deng, K.Z.; Wang, P.; Fan, H.D. Subsidence Mechanism and Stability Assessment Methods for Partial Extraction Mines for Sustainable Development of Mining Cities—A Review. Sustainability 2018, 10, 113. [Google Scholar] [CrossRef]

- Yu, Y.; Deng, K.Z.; Chen, S.E. Mine Size Effects on Coal Pillar Stress and Their Application for Partial Extraction. Sustainability 2018, 10, 792. [Google Scholar] [CrossRef]

- Yu, Y.; Chen, S.E.; Deng, K.Z.; Fan, H.D. Long-Term Stability Evaluation and Pillar Design Criterion for Room-and-Pillar Mines. Energies 2017, 10, 1644. [Google Scholar] [CrossRef]

- Rankine, R.; Pacheco, M.; Sivakugan, N. Underground mining with backfills. Soils Rocks 2007, 30, 93–101. [Google Scholar] [CrossRef]

- Luo, Y. Room-and-pillar panel design method to avoid surface subsidence. Min. Eng. 2015, 67, 105–110. [Google Scholar]

- Feng, X.W.; Zhang, N.; Gong, L.Y.; Xue, F.; Zheng, X.G. Application of a Backfilling Method in Coal Mining to Realise an Ecologically Sensitive “Black Gold” Industry. Energies 2015, 8, 3628–3639. [Google Scholar] [CrossRef]

- Shao, X.P.; Li, X.; Wang, L.; Fang, Z.Y.; Zhao, B.C.; Liu, E.S.; Tao, Y.Q.; Liu, L. Study on the Pressure-Bearing Law of Backfilling Material Based on Three-Stage Strip Backfilling Mining. Energies 2020, 13, 211. [Google Scholar] [CrossRef]

- Zubov, V.P.; Phuc, L.Q. Development of resource-saving technology for excavation of flat-lying coal seams with tight roof rocks (on the example of the Quang Ninh coal basin mines). J. Min. Inst. 2022, 257, 795–806. [Google Scholar] [CrossRef]

- Zubov, V.P.; Li, Y.P. Slicing mining of thick gently dipping coal in China: Problems and improvement. Min. Inf. Anal. Bull. 2023, 7, 37–51. [Google Scholar]

- Chen, Y.F. Study on the Law of Strata Movement and Prediction Method of Surface Subsidence in Strip Filling Mining. Master’s Thesis, China University of Mining and Technology, Xuzhou, China, 2018. [Google Scholar]

- Schreiber, J.; Konicek, P.; Stonis, M. Seismological Activity During Room and Pillar Hard Coal Extraction at Great Depth. Procedia Eng. 2017, 191, 67–73. [Google Scholar] [CrossRef]

- Chang, Q.L.; Zhou, H.Q.; Bai, J.B.; Duan, C.R.; Li, Y.W. Stability Study and Practice of Overlying Strata with Paste Backfilling. J. Min. Saf. Eng. 2011, 28, 279–282. [Google Scholar]

- Ham, H.S.; Kim, Y.K.; Park, C.M.; Lee, C.H.; Kim, Y.S. A study on the effect of ground conditions of room and pillar method on pillar and room strain. J. Korean Tunn. Undergr. Space Assoc. 2021, 23, 577–587. [Google Scholar]

- Vlachogiannis, I.; Benardos, A. Proposed formulas for pillar stress estimation in a regular room-and-pillar pattern. Int. J. Rock Mech. Min. Sci. 2024, 180, 105826. [Google Scholar] [CrossRef]

- Zhu, W.B.; Xu, J.L.; Chen, L.; Li, Z.; Liu, W.T. Mechanism of disaster induced by dynamic instability of coal pillar group in room-and-pillar mining of shallow and close coal seams. J. China Coal Soc. 2019, 44, 358–366. [Google Scholar]

- Zhu, W.B.; Xu, J.M.; Xu, J.L.; Chen, D.Y.; Shi, J.X. Pier-column backfill mining technology for controlling surface subsidence. Int. J. Rock Mech. Min. Sci. 2017, 96, 58–65. [Google Scholar] [CrossRef]

- Guan, Y.W.; Wei, Y.Q.; Yang, Z.J.; Li, Z.J.; Wu, J. Failure mechanism of the key strata-pillar system in room and pillar goaf based on a numerical simulation. Chin. J. Geol. Hazard Control 2017, 28, 59–63. [Google Scholar]

- Waclawik, P.; Ptacek, J.; Konicek, P.; Kukutsch, R.; Nemcik, J. Stress-state monitoring of coal pillars during room and pillar extraction. J. Sustain. Min. 2016, 15, 49–56. [Google Scholar] [CrossRef]

- Qian, M.G.; Xu, J.L. Coal Mining and Stratum Movement. J. China Coal Soc. 2019, 44, 973–984. [Google Scholar]

- Zhang, Y.J.; Zhang, Z.W. Research Progress on the Failure Law and Control Technology of Overlying Rocks in Coal Mining. Coal Sci. Technol. 2020, 48, 85–97. [Google Scholar]

- Guo, W.B.; Bai, E.H.; Zhao, G.B. Status and Progress of Surface Failure of Overlying Rocks and Prevention and Control Technologies in High-Intensity Mining. J. China Coal Soc. 2020, 45, 509–523. [Google Scholar]

- Xu, J.L.; Xuan, D.Y.; Zhu, W.B. Partial Backfill Mining Technology Based on Key Stratum Control. J. Min. Strat. Control Eng. 2019, 1, 69–76. [Google Scholar]

- Liu, J.G.; Li, X.W.; He, T. Current Application Status and Development of Backfill Mining in China’s Coal Mines. J. China Coal Soc. 2020, 45, 141–150. [Google Scholar]

- Guo, Y.M.; Liu, H.F.; Yin, W. Study on the Law of Slip Failure Between Overlying Rock Strata in Coordinated Mining with Backfill and Caving. Coal Sci. Technol. 2022, 50, 92–103. [Google Scholar]

- Sun, X.K. Current Status and Prospects of Green Backfill Mining in Mines. Coal Sci. Technol. 2020, 48, 48–55. [Google Scholar]

- Yan, B.X.; Zhu, W.C.; Hou, C. Comparative Study on Theoretical Analysis and Numerical Simulation of Stress Distribution in Backfill. J. Northeast. Univ. Nat. Sci. 2019, 40, 1773–1778. [Google Scholar]

- Zhang, J.X.; Li, J.; An, T.L. Study on the Deformation Characteristics of Key Strata in Overlying Rocks during Gangue Backfill Fully Mechanized Mining. J. China Coal Soc. 2010, 35, 357–362. [Google Scholar]

- Zhang, Q.; Zhang, J.X.; Wang, J.Q. Theoretical Research and Engineering Practice on Critical Packing Ratio in Backfill Mining. J. China Coal Soc. 2017, 42, 3081–3088. [Google Scholar]

- Ghasemi, E.; Shahriar, K. A new coal pillars design method in order to enhance safety of the retreat mining in room and pillar mines. Saf. Sci. 2012, 50, 579–585. [Google Scholar] [CrossRef]

- Sahu, P.; Lokhande, D.R. An investigation of sinkhole subsidence and its preventive measures in underground coal mining. Procedia Earth Planet. Sci. 2015, 11, 63–75. [Google Scholar] [CrossRef]

- Jaiswal, A.; Shrivastva, B.K. Numerical simulation of coal pillar strength. Int. J. Rock Mech. Min. Sci. 2009, 46, 779–788. [Google Scholar] [CrossRef]

- Mathey, M. Investigation into the Mechanism of Strength and Failure in Squat Coal Pillars in South Africa. Ph.D. Thesis, University of the Witwatersrand, Johannesburg, South Africa, 2015. [Google Scholar]

- Zhu, W.B.; Chen, L.; Zhou, Z.L.; Shen, B.T.; Xu, Y. Failure propagation of pillars and roof in a room and pillar mine induced by longwall mining in the lower seam. Rock Mech. Rock Eng. 2019, 52, 1193–1209. [Google Scholar] [CrossRef]

- Ghasemi, E.; Ataei, M.; Shahriar, K. An intelligent approach to predict pillar sizing in designing room and pillar coal mines. Int. J. Rock Mech. Min. Sci. 2014, 65, 86–95. [Google Scholar] [CrossRef]

- Trigueros, E.; Cánovas, M.; Arzúa, J.; Baraibar, J.M. Evaluating the influence of backfilling on the stability of an abandoned room-and-pillar mine: A case study in northern Spain. Geomech. Geophys. Geo-Energy Geo-Resour. 2024, 10, 116. [Google Scholar] [CrossRef]

- Toderas, M. Stability Analysis of the Exploitation System with Room and Pillar by Analytical Methods. Appl. Sci. 2024, 14, 1827. [Google Scholar] [CrossRef]

- Yang, C.Y.; Yin, H.; Guo, S. Application of Integrated BeiDou/GNSS and Precise Leveling Method in Surface Deformation Monitoring of Old Goaf Collapse Areas. Bull. Surv. Mapp. 2024, 5, 142–146. [Google Scholar]

- Li, R.F.; Chang, L.; Qin, H. Comparative Study on InSAR Monitoring Technology and Leveling Measurement Technology. Eng. Qual. 2021, 39, 72–76. [Google Scholar]

- Liu, L. Analysis of Measurement Accuracy and Discussion on Technical Methods for Tunnel Connection in Underground Coal Mines. Inn. Mong. Coal Econ. 2024, 13, 31–33. [Google Scholar]

| Strata | Elastic Modulus (GPa) | Shear Modulus (GPa) | Internal Friction Angle (°) | Cohesion (MPa) | Tensile Strength (MPa) | Density (kg/m3) | Poisson’s Ratio |

|---|---|---|---|---|---|---|---|

| Limestone | 23.50 | 2.34 | 42 | 5.22 | 3.80 | 2240 | 0.30 |

| Glutenite | 14.30 | 7.0 | 27.80 | 12.20 | 1.17 | 1500 | 0.25 |

| Coarse-grained sandstone | 6.57 | 2.90 | 34 | 3.50 | 1.50 | 2500 | 0.30 |

| Fine-grained sandstone | 3.51 | 1.60 | 35 | 0.50 | 1.00 | 2500 | 0.40 |

| Clay mudstone | 7.61 | 3.20 | 30 | 0.20 | 0.50 | 2800 | 0.40 |

| Siltstone | 14.50 | 4.80 | 38 | 2.25 | 1.20 | 2600 | 0.30 |

| Calcareous siltstone | 8.60 | 3.80 | 35 | 4.50 | 2.50 | 2400 | 0.30 |

| No. 5 coal seam | 4.00 | 5.70 | 36 | 0.085 | 0.20 | 1330 | - |

| Medium-grained sandstone | 5.49 | 5.40 | 37 | 2.50 | 1.20 | 2500 | 0.30 |

| Backfill body | 2.83 | 1.31 | 20 | 3.80 | 0.90 | 1370 | 0.30 |

| Measurement Date | Measurement Area | Meter Reading (m) | Instrument Height (m) | Measured Elevation (m) | Initial Elevation (m) | Subsidence (mm) |

|---|---|---|---|---|---|---|

| 1 May 2023 | Zhongyuantou Village | 1.250 | 1.500 | 2.750 | 2.752 | −2 |

| 15 May 2023 | 1.248 | 1.500 | 2.748 | 2.750 | −2 | |

| 1 June 2023 | 1.249 | 1.500 | 2.749 | 2.750 | −1 | |

| 1 May 2023 | Baoya Village | 1.250 | 1.500 | 2.750 | 2.752 | −2 |

| 15 May 2023 | 1.250 | 1.500 | 2.70 | 2.752 | −2 | |

| 1 June 2023 | 1.247 | 1.500 | 2.747 | 2.750 | −3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, S.; Guo, Y.; Liu, Q.; Guo, R.; Xu, Y. Minimizing the Damage of Underground Coal Mining to a Village Through Integrating Room-and-Pillar Method with Backfilling: A Case Study in Weibei Coalfield, China. Sustainability 2025, 17, 602. https://doi.org/10.3390/su17020602

Yang S, Guo Y, Liu Q, Guo R, Xu Y. Minimizing the Damage of Underground Coal Mining to a Village Through Integrating Room-and-Pillar Method with Backfilling: A Case Study in Weibei Coalfield, China. Sustainability. 2025; 17(2):602. https://doi.org/10.3390/su17020602

Chicago/Turabian StyleYang, Sen, Yubo Guo, Qingzhou Liu, Ruihang Guo, and Yang Xu. 2025. "Minimizing the Damage of Underground Coal Mining to a Village Through Integrating Room-and-Pillar Method with Backfilling: A Case Study in Weibei Coalfield, China" Sustainability 17, no. 2: 602. https://doi.org/10.3390/su17020602

APA StyleYang, S., Guo, Y., Liu, Q., Guo, R., & Xu, Y. (2025). Minimizing the Damage of Underground Coal Mining to a Village Through Integrating Room-and-Pillar Method with Backfilling: A Case Study in Weibei Coalfield, China. Sustainability, 17(2), 602. https://doi.org/10.3390/su17020602