Abstract

Manure-based anaerobic digestion (AD) systems serve multiple functions, including waste treatment, energy recovery, and nutrient cycling. However, they also entail additional energy consumption and pollutant emissions. Life cycle assessment (LCA) methodology is typically used to holistically quantify the actual environmental impacts of these systems. Nevertheless, comprehensive reviews synthesizing LCA studies in this field remain limited. Following PRISMA guidelines, this study conducted a systematic literature review of LCA studies on manure-based AD systems, focusing on advancements, inconsistencies, and limitations in LCA methodologies and environmental impact results. The findings indicate considerable variability in functional units, allocation methods, system boundaries, and inventory analysis methods across the literature. These methodological discrepancies and the lack of standardized protocols result in remarkable variability in environmental impact potentials. Additionally, there is lack of consensus on the environmental benefits of AD systems compared to traditional manure management, and co-digestion with energy crops or food waste compared to mono-digestion of manure. Consequently, the environmental impacts of manure-based AD systems remain inconclusive due to methodological heterogeneity and data inconsistencies. Future research should develop scientific and standardized approaches and focus on the completeness of system boundaries, selection of key environmental impact categories, environmental load allocation, inventory data quality, and the transparency of the analysis.

1. Introduction

Livestock manure contributes to environmental issues such as water eutrophication, acidification, and global warming [1]. The pathogens and parasite eggs in manure can cause zoonotic diseases; antibiotics and heavy metals can accumulate in soil, threatening food security and human health through the food chain [2]. Manure also contains nitrogen, phosphorus, and potassium, which are essential nutrients for crop growth [3]. Therefore, the proper treatment and utilization of livestock manure have always been a key concern for sustainable agricultural development [4]. Current types of manure management mainly include anaerobic digestion (AD), composting, direct combustion, and using dried manure as bedding [5]. Among them, manure-based AD produces organic fertilizers and bioenergy, which can replace fossil fuels. Owing to its multiple functions, especially fossil energy substitution, manure-based AD is widely recognized as an effective measurement to mitigate greenhouse gas emissions [6]. It has attracted considerable attention and is being promoted globally [3,7].

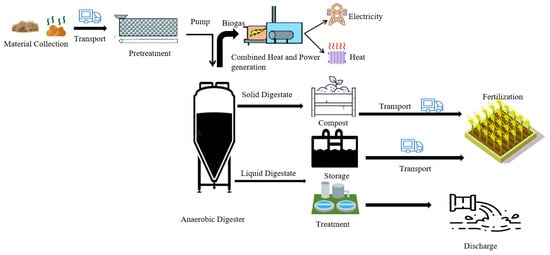

Compared to other manure-management options, AD systems require a more complex infrastructure and stricter process control. These include maintaining temperature and pH, sustaining microbial communities, and implementing safety and emergency protocols. It involves several stages and activities (Figure 1), such as collection, storage, pretreatment of manure and co-digestion substrate [8], biogas utilization (e.g., combined heat and power generation), treatment and utilization of digestate [9], transportation of feedstock and digestate [10], and building construction and producing facilities for the above stages [11]. Each stage consumes extra energy and emits pollutants. Hence, the overall benefits of manure AD to save fossil energy resources and mitigate greenhouse gas emissions could not be judged solely by the stage of anaerobic fermentation and biogas utilization. For a comprehensive and objective understanding of the actual effects of manure AD on natural environment, a systematic analysis method that includes all relevant stages should be employed.

Figure 1.

Flow chart of anaerobic digestion system.

Life cycle assessment (LCA) is a comprehensive methodology used to evaluate the potential environmental impacts associated with resource consumption and pollutant emissions throughout a product’s entire life cycle—from raw material extraction (‘cradle’) to final disposal (‘grave’) [12]. It helps prevent the shifting of environmental burden between stages, while providing essential data for technical, managerial, and policy-related decision-making [13]. Although numerous studies have evaluated the environmental impacts of manure-based AD systems using LCA, comprehensive reviews that synthesize methodologies, findings, and gaps in this field remain limited. Esteves et al. [14] conducted a review on LCA in manure-based biogas production; however, their analysis primarily focused on comparing different process stages (e.g., raw material, transportation, AD plant, and digestate), without quantitatively evaluating the methodology used in life cycle inventory (LCI) analysis, which significantly influences LCA results. In addition, the potential environmental impacts of manure-based AD systems, which would be important for policy makers, were not reviewed in Esteves et al. [14]. The present study aims to quantitatively review LCA methods, results, and conclusions and identify limitations of previous LCA studies on manure-based AD systems, aiming to hold a comprehensive understanding on the environmental impact potentials in previous studies and provide a theoretical and methodological support for future scientific, objective, and in-depth research in this field.

2. Data Sources and Analysis Methods

2.1. Information Sources and Search Strategy

A comprehensive literature search was conducted across four databases: China National Knowledge Infrastructure, Web of Science, Elsevier Science Direct, and Engineering Village databases. Search items included “life cycle assessment of anaerobic digestion of manure”, “life cycle assessment of manure biogas”, “environmental impacts of anaerobic digestion of manure”, “life cycle environmental impacts of manure biogas”, “environmental impacts of manure biogas”, “life cycle environmental impacts of manure anaerobic digestion”, “environmental impacts of manure anaerobic digestion”, “LCA of combined heat and power production from manure biogas”, and “LCA of anaerobic digestion manure biogas production”. The search focused on peer-reviewed articles published between 1 January 2010 and 1 January 2022.

2.2. Selection Criteria and Process

Studies included in this analysis had to meet the following criteria: (1) They must be case studies that apply LCA to evaluate the environmental impacts of manure-based AD; review papers were excluded; (2) The studies must use livestock manure as the main feedstock, defined as manure making up at least 40% of the fresh weight of the feedstock. Studies or scenarios where co-digestion substrates account for more than 60% were excluded; (3) The studies must provide environmental impact potentials that are either directly available or can be extracted using data tools such as Get Data Graph Digitizer. Studies for which environmental impact results could not be obtained were excluded.

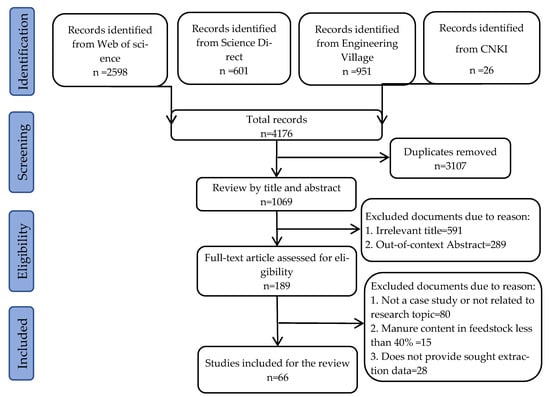

The selection process was divided into four stages:

Firstly, a total of 4176 potentially relevant studies were identified and imported into EndNote 21. These studies were sourced from the Web of Science, Elsevier ScienceDirect, Engineering Village, and China National Knowledge Infrastructure databases using predefined keywords in the titles and abstracts.

Secondly, duplicate articles appearing across multiple databases were removed, resulting in 1069 unique articles.

In the third stage, titles and abstracts were screened to determine their relevance to the research objective. After manual screening, 189 articles were selected for further assessment.

Finally, full-text articles were reviewed, and those not meeting the eligibility criteria were excluded. As a result, 66 studies using LCA methods to evaluate the environmental impacts of manure AD systems were included in the analysis.

The search process and results are presented in a flow diagram based on the “Preferred Reporting Items for Systematic Reviews and Meta-Analyses for Scoping Reviews” (PRISMA-ScR) guidelines (PRISMA 2020 flow diagram) (Figure 2). A summary of 66 studies was conducted in Table A1.

Figure 2.

PRISMA-ScR flow diagram of the literature selection process.

2.3. Data Collection and Processing

For the studies included in this review, the extracted information primarily falls into two categories:

- (1)

- Methodological information: This includes the specific processes covered within the system boundaries, the functional unit, allocation methods, and inventory analysis methods. Focus is placed on key processes and pollutants, such as the calculation methods and coefficients for CH4 emissions, N2O emissions, NH3 emissions, and NO3− and phosphorus (P) losses. Life cycle impact assessment methods used in each study were also recorded.

- (2)

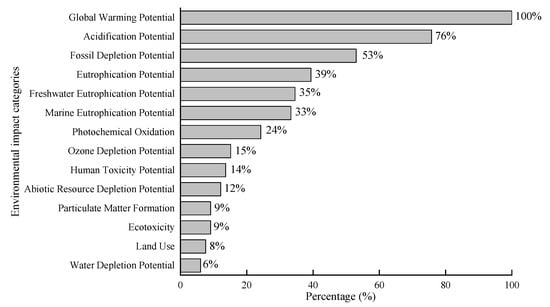

- Environmental impact indicators: This refers to the environmental impact indicators evaluated in each study along with their corresponding values. Indicators assessed in more than 5% of the studies are presented in Figure 3.

Figure 3. Environmental impact categories involved in the reviewed studies.

Figure 3. Environmental impact categories involved in the reviewed studies.

The software GetData Graph Digitizer Version 2.25 was used to extract data from plots where necessary. All data collection and extraction were carried out manually using Microsoft Excel 2021, while data analysis and plotting were performed with Origin 2021.

2.4. Limitations and Risk of Bias

This review focused on the LCA methodology and did not explore the process characteristics of manure-based AD systems, as these have been addressed in previous studies. Given the multiple factors that influence the values of environmental impact indicators and the limited number of samples, we present the range and coefficient of variation for these values but did not analyze how each factor individually affects the results. Nevertheless, this review offers valuable insights into the accurate assessment of manure-based AD systems and highlights gaps within the current research field. To ensure the reliability of the extracted information and data, all entries were cross-checked by the reviewers more than four times to minimize errors.

3. Results and Discussion

The results are structured according to the four phases outlined in the ISO 14040 life cycle assessment framework [12]: (1) goal and scope definition, (2) life cycle inventory analysis, (3) life cycle impact assessment, and (4) interpretation of results.

3.1. Goal and Scope Definition

Defining the goal and scope is the first phase of an LCA study. This involves setting the research objectives, determining the functional unit and allocation methods, and establishing the system boundaries.

3.1.1. Research Objective

The objectives of the studies assessing manure-based AD systems can generally be grouped into two main categories: ① descriptive: these studies solely focus on the quantitative assessment of the environmental impacts associated with manure AD [15,16,17,18,19,20,21,22]; and ② comparative: These studies compare the environmental impacts of manure AD with other manure management methods or compare the environmental impacts of different digestion methods and co-digestion substrates. Approximately 88% of the reviewed studies fall into the comparative category. Among these the majority compares AD to alternative manure management systems, accounting for 35% of the reviewed studies, while 22% investigate the differences between mono-digestion and co-digestion of manure, and the types and proportions of co-digestion substrates used. Other comparative studies examine factors, such as plant scale, digestate treatment strategies, and comparisons with traditional fossil energy sources—each account for no more than 6% of the total literature.

3.1.2. Functional Unit

The functional unit provides a quantitative reference for the primary function of a system, serving as a standardized measurement scale for comparing across different studies [23,24]. In the context of LCA studies on manure AD systems, the functional units can be broadly classified into four main categories, encompassing over 14 distinct unit types (Table 1). Among these, manure and animal farm effluents is the most frequently used functional unit, suggesting that the majority of the studies regard the primary function of manure AD systems as manure treatment.

Table 1.

Functional units of the examined literature.

Table 1.

Functional units of the examined literature.

| Type of Functional Units | Unit | Percentage of Literature (%) | |

|---|---|---|---|

| Manure and animal farm effluents * | Manure, slurry, feces | t | 30.30, 6.06, 6.06 |

| Feedstock ** | Feedstock | t | 15.15 |

| Bioenergy *** | Generated bioelectricity, net bioelectricity generation, generated bioelectricity and heat, net generation of bioelectricity and heat, generated bio-methane, generated biogas | kwh/MJ/ MJ LHV/m3 | 12.12, 7.58, 4.55, 1.52, 1.52, 6.06 |

| Others **** | Digestate, a slaughter pig, pig carcass, milk, livestock units | t, kg, LU | 1.52, 1.52, 1.52, 3.03, 1.52 |

* References: [1,3,6,8,9,15,25,26,27,28,29,30,31,32,33,34,35,36,37,38,39,40,41,42,43,44,45,46]; ** References: [10,20,47,48,49,50,51,52,53,54]; *** References: [11,16,17,21,22,55,56,57,58,59,60,61,62,63,64,65,66,67,68,69,70,71]; **** References: [18,19,72,73,74,75].

3.1.3. Allocation Method

Manure-based AD systems are multi-product and multi-functional systems, simultaneously providing waste treatment, bioenergy, organic fertilizers, and other co-products. To assess the environmental impact attributable to a specific product or function, it is necessary to allocate the total environmental burden of the AD system across its multiple outputs. According to ISO 14044 [12], system expansion or subdivision are the preferred methods for impact allocation in multi-output systems. If these options are not applicable, allocation based on physical properties or economic value can be considered. Among the reviewed studies, 74% have adopted the system expansion (or substitution) method. However, a few studies—such as those by Timonen et al. [69] and Rehl et al. [66]—employed allocation based on physical mass and economic value. Other studies, including [6,16,18,31,36,46], did not allocate environmental burdens at all. The system expansion method, also referred to as the substitution method. When the system expansion method is employed, environmental impact of primary product (A) is separated from the total impacts by subtracting the environmental burden of by-products (B), and impacts of byproducts (B) is substituted with that of another product (C) that performs the same function with byproducts (B). The product C represents the substituted material, and the environmental impacts associated with its production and use are referred to as avoided environmental impacts or environmental credit [60,66]. In practice, this is implemented by expanding the system boundaries to include the upstream processes of product C within the inventory analysis [12].

When the system expansion method is applied, the type of avoided environmental impact (or environmental credit) is determined by the primary function of the AD system. For instance, if the main function is manure treatment, the secondary functions may include the generation of bioenergy and organic fertilizers. In this case, environmental credits stem from bioenergy and organic fertilizers and are calculated based on the substitution of conventional energy sources and chemical fertilizers. Accordingly, the functional unit is typically defined in terms of manure or feedstock input [29]. Table 2 presents the alignment between system functions, functional units, and environmental credits in the literature, in accordance with the established standards. Approximately 59% of the studies that adopted the system expansion allocation method adhered to the definitions of functional units and allocation methods outlined in ISO 14044 [12], matching functional units with avoided environmental impacts. In contrast, the remaining studies failed to consistently align functional units with environmental credits [17,71], resulting in a lack of comparability in the results, even when the same functional units and system boundaries are applied.

Table 2.

Relationship between function, function unit, and environmental credit.

Table 2.

Relationship between function, function unit, and environmental credit.

| Main Functions | Co-Functions | Type of Functional Units | Environmental Credits | References |

|---|---|---|---|---|

| Treating livestock and poultry manure | Producing bioenergy and organic matter | per unit of livestock manure | Substituting traditional energy and fertilizers | [1,8,9,25,27,28,29,30,32,33,34,35,37,40,41,42,45] |

| Treating livestock and poultry manure | Producing bioenergy and organic matter | per unit of digestion feedstock | Substituting traditional energy and chemical fertilizers | [10,47,48,50,52,53] |

| Producing bioenergy | Treating manure and producing organic matter | per unit of bioenergy | Substituting traditional manure management methods and chemical fertilizers | [22,59,60,62,66,67] |

Note: The organic matter produced by the manure-based AD system refers to the digestate or products processed from it, which can replace chemical fertilizers or other similar products.

3.1.4. System Boundary

The system boundary defines which production processes and life cycle stages are included in a given system. Defining it entails identifying the specific processes and stages to be included in this study. Its definition is influenced not only by data availability and research objectives but also by the chosen allocation methods [24,66]. Table A2 presents the processes included in the system boundaries of each reviewed literature. The main processes involved in manure-based AD systems include biogas plant construction; co-digestion substrate production; collection, storage, pretreatment of digestion materials; anaerobic digestion; biogas utilization; transportation of digestion feedstock and digestate; digestate treatment; and utilization or final disposal of digestate [49]. Studies that apply system expansion for allocation extend the boundary to include the production systems of product substituted by by-product, whereas some studies involving co-digestion of manure expand the system boundary to encompass the original treatment and utilization systems of co-digestion substrates [15,72]. In general, studies employing system expansion for allocation feature more comprehensive system boundaries compared to those employing no allocation or physical/economic allocation methods.

Table A2 demonstrates variations in system boundary definitions among the reviewed articles, totaling 41 distinct system boundaries. In most cases, the system boundaries start from the anaerobic digestion stage, with less than 35% of the studies considering processes before anaerobic digestion, such as biogas plant construction, collection, storage, and feedstock pretreatment. Although the environmental impact of biogas plant construction is often overlooked, Fuchsz et al. (2015) reported that this phase contributes 7.75% to global warming potential (GWP) and 8.87% to acidification [58].

Approximately 77% of the reviewed studies include four key processes: anaerobic digestion, biogas utilization, digestate treatment, utilization and its final disposal. About 23% of the studies either exclude the digestate treatment, omit the utilization and final disposal of digestate, or both are not considered.

It is noteworthy that 59% of the reviewed studies examined the co-digestion of livestock manure with energy crops, food waste, and other materials. However, only about 40% considered the production of co-digestion substrates, and none accounted for the upstream emissions of livestock manure. This is primarily because livestock manure, food waste, and similar materials are often classified as waste, leading researchers to overlook their upstream environmental emissions [49]. However, Esteves et al. [14], based on the EU regulations distinguishing between byproducts and waste, argued that livestock manure and food waste used as feedstocks in subsequent processes of AD should be regarded as by-products from farms or food processing stages. Therefore, their upstream emissions should be included within the system boundary using appropriate allocation methods.

3.2. Life Cycle Inventory Analysis

Life cycle inventory (LCI) analysis is a data-driven and objective process that quantifies the resources, energy inputs, environmental emissions, and product outputs of each unit process within the system boundaries [12]. Considering that majority of the reviewed studies adopted system expansion approach, this review analyzes the LCI methodologies from two key perspectives: the environmental emissions of AD systems and the environmental credits and lost opportunity associated with co-digestion substrates.

3.2.1. Environmental Emissions from Manure AD Systems

The environmental emissions associated with manure-based AD systems arise from both energy consumption and biochemical reactions occurring through various system processes. Energy consumption is primarily linked to heating and mixing of the feedstock, operation of AD facilities and digestate treatment units, transportation of feedstock and digestate, and the use of agricultural machinery-particularly when crops are used as co-digestion substrates [10,25,30,41,65,70]. Pollutant emissions resulting from energy use are commonly estimated using the emission factor method, with factors primarily obtained from databases like Ecoinvent [76].

Emissions not related to energy consumption, such as biochemical reactions in various processes, represent a significant source of pollutants in manure-based AD systems. These include:

- CH4, N2O, and NH3 from manure and digestate storage.

- CH4 leakage during anaerobic digestion and biogas utilization.

- N2O, NH3, NO3−, and P runoff and leaching loss during digestate field application and the cultivation of co-digested energy crops [17,27,30,34,49].

A small number of studies have also investigated changes in soil organic carbon due to digestate application [29,33,38,43,48]. These emissions are primarily estimated using the emission factor method, while only a limited number of studies used model simulations or empirical formulas [26,28,53]. The accuracy of the emission factor method is influenced by the baseline substance and the source of the emission factors. Emission factors based on the carbon or nitrogen contents of manure or digestate generally yield more accurate results than those based on the mass or volume of manure or digestate. The most reliable source of emission factors is derived from direct measurement, followed by meta-analysis, regional or national emission inventories [77,78], and default values from the IPCC National Greenhouse Gas Inventory Guidelines [5,79,80]. The literature reveals significant variability in the sources and baseline substances used for emission factor. Although IPCC guidelines and manure C or N contents are the most common sources are reference bases, their adoption rates are low—7.58–39.39% and 6.06–59.09%, respectively.

Table 3 summarizes the emission factors of key pollutants across the main processes in manure-based AD systems, based on the carbon and nitrogen contents of manure or digestate. It is evident that substantial discrepancies exist across studies. On the one hand, these variations are influenced by factors such as digestate storage methods [30,32], local climate conditions [8,74], land-use types for digestate application [27], and fertilization practices [9]. For instance, open digestate storage at 20 °C yields a Methane Conversion Factor (MCF) of 42% [74], whereas covered storage below 14 °C reduces the MCF to 1% [8]. Ammonia emissions during land application also depend on both land-use type and application technique: injection into cropland results in 0.02 kg NH3-N per kg total ammoniacal nitrogen (TAN), compared with 0.19 kg NH3-N kg−1 TAN for surface application to grassland [27]. Similarly, drip irrigation produces 0.05 kg NH3-N per kg N applied, whereas surface broadcasting yields 0.19 kg NH3-N per kg N applied [9]. On the other hand, these discrepancies also depend on the sources of the emission factors [9,20,30,47] and the quality of the data [1,73].

These variations in emission factors can markedly influence the environmental impact potentials of AD systems. As shown by sensitivity analyses in the reviewed literature, even a modest 2.5–6% increase in the CH4 leakage coefficient can result in a 16–90% increase in global warming potential (GWP) [6,10,43,49,51]. However, current studies typically derive CH4 leakage coefficients from secondary data rather than from direct measurements. This practice introduces systematic bias, potentially skewing estimates of AD systems’ contributions to global warming. Therefore, incorporating site-specific emission factors for N- and C-containing pollutants, together with real-world operational data, is critical for accurate environmental impact assessments.

Table 3.

Emission factors of main pollutants from the main processes of manure-based anaerobic digestion.

Table 3.

Emission factors of main pollutants from the main processes of manure-based anaerobic digestion.

| CH4 Leakage Coefficient * (% of CH4 Produced) | Storage Process of Digestate | Land Application of Digestate | ||||||

|---|---|---|---|---|---|---|---|---|

| CH4 (MCF, %) | N2O (kg N2O/kg N) | NH3 (kg NH3/kg N) | N2O (kg N2O/kg N) | NH3 (kg NH3/kg N) | NO3− (kg NO3−-N/kg N) | P (kg P/kg P) | ||

| Min | 0.50 | 1 | 0.002 | 0.004 | 0.001 | 0.001 | 0.021 | 0.006 |

| Max | 15.00 | 42 | 0.075 | 0.491 | 0.031 | 0.510 | 0.510 | 0.300 |

* The methane leakage coefficient during anaerobic digestion; MCF: Methane conversion factor, which is used to calculate the methane emissions during digestate storage.

Quantitatively assessing the changes in soil organic carbon (SOC) resulting from digestate application in cropland is crucial for comprehensive evaluation of the climate change impact of AD systems. However, the existing literature presents conflicting views regarding the carbon sequestration effects of digestate application, with sequestration coefficients ranging from −14.1% to 51% [15,48,49,54]. Consequently, incorporating the carbon-sequestration potential of digestate application into the inventory analysis would introduce significant uncertainty in the results.

3.2.2. Environmental Credits and Lost Opportunity of Manure Based AD Systems

Environmental Credits of Traditional Energy Substitution

Bioenergy (e.g., bioelectricity, bio-heat, biomethane) generated from manure-based AD systems can replace conventional energy sources, such as coal and natural gas. This substitution avoids pollutant emissions from traditional energy production and use, with environmental credit is typically calculated based on the quantity of bioenergy produced and the emission coefficients of the displaced conventional energy sources [6,11,56,62,63]. Key factors influencing this credit include the bioenergy yield, the types of traditional energy replaced, and the associated pollutant emission coefficients. Most studies calculate bioenergy yield based on methane or biogas production and their conversion efficiencies into bioelectricity, heat, or biomethane. In general, biogas or methane production is estimated using yield coefficient methods [11,32,33,57,59]. Only 3% of the studies reported bioelectricity yields derived from on-site operational data [29,63], and fewer than 10% used actual measurements for biogas or methane production [6,28,58,64,71]. Manure-based anaerobic digestion is a complex biochemical process comprising four sequential stages: hydrolysis, acidogenesis, hydrogen-producing acetogenesis, and methanogenesis. Enzymes and microorganisms participating in these stages exhibit optimal activity at ~37 °C [81]. Owing to technical and operational challenges—maintaining optimal reactor temperatures, sustaining microbial activity, and ensuring high efficiency of biogas utilization systems (e.g., in combined heat and power systems), biogas plants often experience low operational efficiency and stability [82], resulting in actual operational data that typically fall short of theoretical values [83]. Consequently, widespread reliance on yield coefficient leads to LCA results that fail to accurately reflect the environmental credits of manure-based AD systems when substituting conventional energy sources. From a technical standpoint, full-scale biogas facilities should implement integrated test strategies to ensure operational stability and optimize biogas production [84].

Environmental Credits Substituting Chemical Fertilizer

Digestate produced from manure-based AD can partially replace chemical fertilizers, thereby reducing the energy consumption and pollutant emissions associated with the production and application of synthetic fertilizer. The environmental credit associated with this substitution is typically calculated based on the quantity of chemical fertilizers replaced and the corresponding pollutant emission factors [15,20,34]. However, the nitrogen in chemical fertilizers exists in a readily available inorganic form that can be directly utilized by crops, whereas much of the nitrogen in digestate is organic and must first be mineralized by soil microorganisms before it becomes plant available. Owing to the relatively slow mineralization rate, the nitrogen-use efficiency (NUE) of digestate during the growing season is generally lower than that of chemical fertilizers [85,86]. To address this, studies commonly use the fertilizer equivalent value (FEV)—the nutrient utilization efficiency of digestate relative to chemical fertilizers—to estimate replaceable fertilizer quantities [74]. The two main methods for calculating FEV of nitrogen in digestate are as follows: (i) the ratio of inorganic N to total N in digestate [17,38,48,50], and (ii) the combined ratio of inorganic N plus mineralizable organic N during the growing season to total N [20,44,50,51,52,54]. Some studies simplify this process by assuming that the nitrogen in digestate is equivalent to that in chemical fertilizers, considering it an equivalent substitution for chemical fertilizers [19,22,33,39]. Two methods are also employed for phosphorus (P) and potassium (K). The first assumes that P and K in digestate are fully equivalent to those in chemical fertilizers (FEV = 100%) [27,28,49,50,73]. A more refined method recognizes that when crop N demand is fully met through digestate, the levels of phosphorus and potassium provided may exceed the crop’s nutrient requirements. If the fertilizer replacement is calculated using the equivalence method, it may overestimate its environmental credit. Therefore, the FEVs for phosphorus and potassium in digestate are calculated based on the nitrogen fertilizer equivalent value; the nitrogen, phosphorus, and potassium contents in the digestate; and the crop’s nutrient requirements, the estimated FEVs of digestate range from 31% to 70% for phosphorus and from 32% to 87% for potassium [6,56].

According to the study by De Vries et al., a 10% increase in the FEV of digestate substituting for calcium ammonium nitrate (CAN) results in approximately a 68% reduction in GWP for the mono-digestion scenario, while for the co-digestion scenario, the reduction ranges from 6% to 19% [27]. Although the methods for calculating the substitution amount and types of fertilizers replaced by digestate are critical for determining the environmental credit of fertilizer replacement, approximately 43% of the studies calculating credits from synthetic fertilizer substitution did not specify the FEVs or the calculation methods. Meanwhile, 23% fail to indicate the types of synthetic fertilizers substituted. Given that organic nitrogen in digestate must be mineralized before plant uptake, and that nutrient surpluses can occur, substituting chemical fertilizers with equivalent amounts of total N, P, and K from digestate overestimate the environmental credit. Calculating FEVs based on plant-available nutrients and crop demand provides a more accurate estimate.

Environmental Credits from Avoiding Original Manure Treatment

When the primary function of manure-based AD systems is bioenergy production, and the functional unit is based on the quantity of bioenergy, the system expansion method for environmental burden allocation requires subtracting the environmental emissions of the original manure treatment from the system’s total emissions. This subtraction represents the environmental credit gained by avoiding the emissions that would have occurred under traditional manure management practices [56,57,59,62,64]. The key factors influencing this environmental credit are the type of traditional manure treatment and the emission coefficients associated with manure storage and field application. Given that different manure treatment methods exhibit varying pollutant emission coefficients (e.g., the values of CH4 conversion factor for covered storage and uncovered anaerobic lagoon storage are 10% and 68%, respectively), discrepancies in the choice of original treatment method can lead to significant differences in environmental credits [15,72]. Moreover, there are opposite views in the literature on whether the emission coefficients for N2O, NH3, and NO3− during the storage and field application of manure are same with that of digestate [52]. Some studies report higher coefficients for manure than digestate [30,38,60,62], while others report the opposite [29,48,55,56] or treat them as identical [26,27,43,52]. This discrepancy further contributes to uncertainty in LCA results.

Lost Opportunity and Environmental Credits of Co-Digested Substrates

Due to the low carbon-to-nitrogen (C/N) ratio of manure relative to the optimal ratio required for AD, other organic materials with a high C/N ratio are often added as co-digested substrates to enhance the methane production efficiency of the manure AD system. Common co-digested substrates include energy crops (e.g., silage maize), crop residues, and food waste [6,50,57,58,60]. When these substrates are diverted from their original roles—as animal feed, energy sources, or fertilizers—alternative materials must be produced to maintain those functions. Consequently, alternative materials are required to provide these services. The environmental credit of the original purpose or the environmental impact caused by the production of substitutes is referred to as the lost opportunity of the co-digested substrates [6,49]. If the co-digested material is originally a waste product, the pollutant emissions associated with its previous disposal method would be avoided, which is referred to as the environmental credit of the co-digested material [6,48]. Although 59% of the reviewed studies involved co-digestion models, only 7.58% and 10.61% accounted for the lost opportunity of co-digested substrates and the environmental credits from avoiding the original disposal of co-digested materials, respectively [6,42,49,52,54].

The primary factors influencing the lost opportunity or environmental credit of co-digested materials are the type of co-digested substrates, their proportion in feedstock, and original use or disposal method. According to Hameli et al. [6], when straw and household waste are used as co-substrates, the exclusion of opportunity cost reduces GWP of the AD system by 31% and 81%, respectively. In this study, both straw and household waste were originally intended for electricity generation through incineration, yet their energy generation efficiencies differ, resulting in varying magnitudes of opportunity cost impact on GWP [6]. Notably, the same co-digested material may have diverse original uses or disposal methods in various studies, especially food waste (Table 4). For example, Hameli et al. [6] and Vaneeckhaute et al. [54] assume that food waste was originally incinerated to generate power, Ebner et al. [52] regard it as animal feed, while Styles et al. [72] treat it as waste requiring composting. These varying choices lead to significant differences in lost opportunity/environmental credits, ultimately affecting the final environmental impact. When food waste was originally composted and landfilled, and environmental credit was accounted for, the GWP of AD systems decreased by 156% and 140%, respectively [20,52]. However, when food waste was originally used to produce bioenergy substituting for fossil fuels and natural gas, accounting for lost opportunity increases GWP by 15.88% [6] and 81.21% [54], respectively. Where the original use was for animal feed, the GWP of AD systems increased by 32.42% [52]. Consequently, to enable objective and consistent evaluation of manure-based AD systems, standardized guidelines for environmental credit and opportunity cost accounting in manure-based AD systems are urgently needed.

Table 4.

Original uses/disposal methods of food waste and their alternatives in the literature.

Table 4.

Original uses/disposal methods of food waste and their alternatives in the literature.

| Original Uses/Original Treatment Methods | Alternatives | Lost Opportunity/Environmental Credit | References |

|---|---|---|---|

| Compost | - | Environmental credit | [72] |

| Landfilling | - | Environmental credit | [52] |

| Incineration for power generation | Fossil fuels | Lost opportunity | [6] |

| Incineration for power generation | Natural gas | Lost opportunity | [54] |

| Animal feed | Corn | Lost opportunity | [52] |

3.3. Life Cycle Impact Assessment

Life cycle impact assessment (LCIA) is intended to quantitatively evaluate the potential environmental impacts of a system based on the results of LCI analysis. This is typically achieved using characterization models, which represent environmental change mechanisms and are used to classify and convert emission data into impact potential for specific impact categories [12].

Different characterization models give rise to various impact assessment methods. In the LCA studies of manure-based AD system, CML [87] and ReCiPe [88] are the most frequently used methods, accounting for approximately 38% and 28% of the studies, respectively.

The most assessed environmental impact categories include GWP, acidification potential (AP), eutrophication potential (EP)—which is further divided into freshwater and marine eutrophication potentials (FEP and MEP) based on affected water bodies—and fossil depletion potential (FDP) (Figure 3). Notably, the environmental issues receiving the most attention in the reviewed studies are primarily related to greenhouse gases, nitrogen and phosphorus pollution, and energy consumption. By contrast, impact categories associated with heavy metal pollution, such as human toxicity and ecotoxicity, are less studied and account for only 14% and 9%, respectively [10,16,28,48,50,60,61]. However, the addition of trace elements to animal feed elevates environmental pollution risks from heavy metals in livestock manure and digestate [89]. These heavy metals can enter soil and water bodies through field application of manure or digestate. Furthermore, they are resistant to microbial degradation, posing threats to human health and ecosystems [90]. Consequently, omitting human toxicity and ecotoxicity impacts may lead to an underestimation of the environmental risks associated with manure-based AD systems.

3.4. Interpretation of Results

Table 5 presents the range and coefficient of variation (CV) for six most commonly assessed environmental indicators in the literature, using three frequently applied functional units. The selected indicators include GWP, EP, FEP, MEP, AP, and FD.

Table 5.

Environmental impact potential range and coefficient of variation of livestock manure anaerobic digestion system.

As shown in Table 5, the environmental impact potentials exhibit considerable variability across studies, regardless of the functional unit used. This variation highlights the significant heterogeneity in LCA of manure-based AD systems and underscores the challenges in comparing results across different studies.

Over half of the reviewed literature aimed to compare the environmental impacts of manure-based AD systems with traditional manure management methods, as well as the environmental impacts of mono-digestion versus co-digestion. Despite some variability in scope and methodology, the literature generally reaches consensus on two key conclusions: ① AD systems for livestock manure have a lower GWP compared to conventional manure management methods [1,3,27,28,29,30,31,32,33,36,37,38,44,45,46,73,74,75], and ② co-digestion has a lower impact on fossil energy depletion compared to mono-digestion [30,49,72]. However, there remains considerable debate regarding other environmental indicators. The main controversies are as follows: ① compared with traditional livestock manure management, whether AD systems increase AP, FEP, and MEP is controversial, with 44% [3,27,32,74], 25% [33], and 50% [33,74] of the literature indicating agreement, respectively. ② Compared with the mono-digestion of manure, whether co-digestion with energy crops increases GWP, AP, and FEP is debated, with approximately 64% [6,40,49,51,60,67,72], 91% [6,30,40,43,49,50,58,60,67,72], and 71% [6,40,51,60,67] of the studies indicating agreement, respectively. Finally, ③ the issue of whether the co-digestion of manure with food waste increases GWP, with around 40% of the literature stating agreement [6,42].

In addition to differences in AD technology and specific site, the observed variation in environmental impact potentials and the inconsistent conclusions in literature are primarily attributed to differences in system boundaries, inventory analysis methods, and approaches for calculating environmental credits and lost opportunity [29,47]. Furthermore, some studies have further increased result uncertainties due to irregularly match functional units and allocation methods [1,6,11,20,25,32,46,49,75].

4. Conclusions and Prospects

AD of livestock manure is an integrated engineering technology that combines manure treatment, resource recovery, and bioenergy generation. As a tool for sustainable management and analysis, LCA is widely applied in evaluating the energy and environmental benefits of manure-based AD systems. Although numerous LCA studies have been conducted to evaluate the environmental impacts of AD systems for livestock manure, significant discrepancies exist across the literature in terms of functional units, allocation methods, system boundaries, inventory analysis approaches, and treatment of lost opportunity and environmental credits for co-digested materials. The absence of standardized methodological frameworks and a lack of consensus have resulted in considerable variability in reported outcomes, hindering the ability to draw definitive conclusions about the true environmental impacts of manure-based AD systems.

To address the limitations identified in the literature, it is necessary to establish scientifically standardized LCA methods for manure-based AD and other manure management practices. This will guide researchers conducting objective and accurate evaluations and thereby enable sound decision-making. To facilitate comparison of results across different studies and enhance their applicability for comprehensive analysis, future research should focus on improving the following aspects: (1) The functional unit should be defined based on system functions or services. If system expansion is used for environmental load allocation, only the environmental credits associated with byproducts or secondary functions must be considered. To avoid logical confusion, the environmental credits of the primary function or service, which have already been considered as the functional unit, should not be counted again. (2) For a comprehensive assessment of manure AD systems, system boundaries should encompass the environmental impacts of main facilities, such as the construction of AD systems. The endpoint should cover the treatment, utilization, and final disposal of digestate. An appropriate allocation method should be selected to calculate the upstream emissions of manure, or a sensitivity analysis should be conducted to determine the inclusion of these upstream emissions within the system boundaries. (3) Using actual operational data for the production performance of AD or conducting uncertainty analysis on the theoretical and empirical values used is preferable to reflect the true environmental credits of the AD system in replacing traditional energy sources. The data, methods, and their sources and justifications for inventory analysis should be public and transparent, enabling readers to assess the quality and reliability of the results. (4) Given the heavy metal contamination risks in manure and digestate, extensive field application may pose a threat to human health and the ecological environment. Therefore, the environmental impact categories should include human toxicity and ecotoxicity, providing a comprehensive understanding of the environmental impacts of manure-based AD systems. (5) The lost opportunity and environmental credits of co-digestion substrates depend on their original uses or treatment methods, which may vary across different scenarios. Therefore, sensitivity analyses should be performed for different uses or treatment options. When environmental credits are assigned for avoided traditional manure management, uncertainty analyses must quantify the range of these credits across all relevant traditional practices. (6) Given the ongoing debate regarding pollutant emission factors from manure and digestate during storage/field application, as well as their impact on SOC sequestration, further research—particularly experimental studies—is essential to clarify these emission factors, and the SOC effects.

Due to the multitude of factors influencing LCA findings and the limited sample size, this study does not quantify their individual effects on manure-based AD system LCA results. Future research with sufficient data should quantify how system boundaries, allocation methods, co-substrate opportunity costs, environmental-credit accounting, and data quality shape LCA outcomes for manure-based AD. Regional analyses, especially across climate zones, are also crucial for planning these systems. More work is needed to clarify how operating parameters, co-substrate types, and reactor technologies interact to shape LCA outcomes. These analyses are essential for advancing the sustainable development of livestock manure AD systems.

For policymakers, standardizing LCA methodologies for livestock manure AD systems and localizing emission factors for digestate and raw manure should be prioritized. Equally important is implementing operational monitoring of existing systems to collect real-world data—including bioenergy production rates and methane leakage coefficients. Such data are critical for accurately assessing environmental impacts and guiding technological improvements.

Author Contributions

Conceptualization, X.W. (Xiaoqin Wang); methodology, X.W. (Xiaoqin Wang); formal analysis, J.W.; data extraction, J.W., C.D. and X.W. (Xinjing Wang); writing—original draft preparation, X.W. (Xiaoqin Wang); writing—review and editing, C.D. and D.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by National Natural Science Foundation of China, grant number 42277489, Natural Science Foundation in Shaanxi Province of China, grant number 2018JM4034, and Yangling Animal Husbandry Industry Innovation Center in Shaanxi Province of China, grant number 2022GD-TSLD-46-0502.

Data Availability Statement

The data presented in this study are available on right request from the corresponding author.

Acknowledgments

All authors thank Isaac Dennis Amoach from The University of Arizona for reviewing and editing the manuscript.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| LCA | Life Cycle Assessment |

| AD | Anaerobic Digestion |

| LCI | Life Cycle Inventory |

| ISO | International Organization for Standardization |

| IPCC | Intergovernmental Panel on Climate Change |

Appendix A

Table A1.

A literature review of 66 included studies.

Table A1.

A literature review of 66 included studies.

| No. | Publication Title | Region | Year | Functional Unit | Environmental Impact Category | Reference |

|---|---|---|---|---|---|---|

| 1 | A Life Cycle Assessment of integrated dairy farm greenhouse systems in British Columbia | Canada | 2013 | 1100 t feedstock | GWP, EP, AP, FDP, HTP, PMF | [48] |

| 2 | Life cycle assessment of anaerobic digestion of pig manure coupled with different digestate treatment technologies | China | 2020 | 1 t manure | GWP, FDP | [8] |

| 3 | Assuring the sustainable production of biogas from anaerobic mono-digestion | Italy | 2014 | 1t slurry | GWP, FEP, MEP, AP, FDP, PO, ODP | [26] |

| 4 | Co-digestion of rice straw and cow dung to supply cooking fuel and fertilizers in rural India: Impact on human health, resource flows and climate change | Indian | 2017 | 1.4 × 1010 MJ generated biogas | GWP, FDP | [55] |

| 5 | GHG emission factors for bioelectricity, biomethane, and bioethanol quantified for 24 biomass substrates with consequential life-cycle assessment | Denmark | 2016 | 1 kWh generated bioelectricity | GWP | [56] |

| 6 | Comparing environmental consequences of anaerobic mono- and co-digestion of pig manure to produce bio-energy-A life cycle perspective | Netherlands | 2012 | 1 t feedstock | GWP, FEP, MEP, AP, FDP, PMF, LU | [49] |

| 7 | Cattle feed or bioenergy? Consequential life cycle assessment of biogas feedstock options on dairy farms | British | 2015 | Large/medium dairy farm: 4,149,102/1,013,548 L milk and 9242/2446 kg live weight | GWP, EP, AP, FDP | [72] |

| 8 | Eco-efficiency assessment of farm-scaled biogas plants | Italy | 2017 | 1 MWh generated bioelectricity | FEP, MEP, AP | [57] |

| 9 | Environmental consequences of processing manure to produce mineral fertilizer and bio-energy | Netherlands | 2012 | 1 t manure | GWP, MEP, AP, FDP, PMF | [27] |

| 10 | Evaluating environmental benefits of low-cost biogas digesters in small-scale farms in Colombia: A life cycle assessment | Colombia | 2019 | 1 m3 generated biogas | GWP, FEP, MEP, AP, FDP, PO, ODP | [11] |

| 11 | Effects of swine manure storage time on solid-liquid separation and biogas production: A life-cycle assessment approach | Brazil | 2021 | 1 t manure | GWP, FEP, MEP, AP, HTP, PO | [28] |

| 12 | The BioValueChain model: a Norwegian model for calculating environmental impacts of biogas value chains | Norway | 2015 | 12.5 t manure | GWP, AP, FDP | [29] |

| 13 | Green-house gas mitigation capacity of a small-scale rural biogas plant calculations for Bangladesh through a general life cycle assessment | Bangladesh | 2017 | 1 kg feces | GWP | [15] |

| 14 | Improved environmental sustainability and bioenergy recovery through pig manure and food waste on-farm co-digestion in Ireland | Ireland | 2021 | 26,000 t feedstock | GWP, EP, AP, FDP, HTP, PO, ODP, E, ADP | [10] |

| 15 | Life cycle assessment of household biogas production in Egypt: Influence of digester volume, biogas leakages, and digestate valorization as biofertilizer | Egypt | 2021 | 1 m3 generated biogas | GWP, FEP, MEP, AP, FDP, HTP, PMF, PO, ODP, E, WDP, ADP | [16] |

| 16 | Comparison of the environmental effects of manure-and crop-based agricultural biogas plants using life cycle analysis | Germany | 2015 | the net bioelectricity | GWP, EP, AP | [58] |

| 17 | Environmental consequences of different carbon alternatives for increased manure-based biogas | Denmark | 2014 | 1 t manure | GWP, FEP, MEP, AP | [6] |

| 18 | Environmental sustainability assessment of pig manure mono- and co-digestion and dynamic land application of the digestate | Ireland | 2021 | 15,070 t manure | GWP, FDP | [30] |

| 19 | Manure management coupled with bioenergy production: An environmental and economic assessment of large dairies in New Mexico | USA | 2018 | 59,851.386 t manure | GWP, EP | [31] |

| 20 | Environmentally Sustainable Biogas? The Key Role of Manure Co-Digestion with Energy Crops | Italy | 2015 | 1 MJ generated bioelectricity | GWP, FEP, MEP, AP, FDP, PMF, PO, WDP | [59] |

| 21 | Environmental and sustainability evaluation of livestock waste management practices in Cyprus | Cyprus | 2018 | 1 t manure | GWP, FEP, MEP, AP, FDP, PO, WDP | [1] |

| 22 | Influence of different practices on biogas sustainability | European | 2013 | 1 MJ generated bioelectricity | GWP, FEP, MEP, AP, HTP, PMF, PO, ODP, ADP | [60] |

| 23 | Environmental assessment of energy production from anaerobic digestion of pig manure at medium-scale using life cycle assessment | Mexico | 2020 | 1 t manure | GWP, EP, AP, FDP, PO, ADP | [32] |

| 24 | Life Cycle Assessment of Biogas Production in Small-scale Household Digesters in Vietnam | Vietnam | 2015 | 1.1 t manure | GWP, FEP, MEP, FDP | [33] |

| 25 | Life cycle assessment of biogas production through anaerobic codigestion of nopal cladodes and dairy cow manure | USA | 2018 | 1 MJ generated biogas | GWP, EP, AP, HTP, PO, ODP, TE, ADP | [61] |

| 26 | Life Cycle Assessment of electricity production in Italy from anaerobic co-digestion of pig slurry and energy crops | Italy | 2014 | 100 kWh generated bioelectricity | GWP, EP, AP, FDP, PO, ODP, ADP | [17] |

| 27 | Environmental impacts of manure management based on life cycle assessment approach | Finland | 2020 | 1 t feces | GWP, EP, AP | [34] |

| 28 | Life cycle assessment of integrated solid state anaerobic digestion and composting for on-farm organic residues treatment | China | 2018 | 1 t manure | GWP, MEP, AP, FDP, TEP | [25] |

| 29 | Assessing anaerobic co-digestion of pig manure with agroindustrial wastes: The link between environmental impacts and operational parameters | Spain | 2014 | 110,000 t manure | GWP, EP, AP, PO, ODP, ADP | [35] |

| 30 | Life cycle environmental impacts of compressed biogas production through anaerobic digestion of manure and municipal organic waste | European | 2021 | 1 MJ generated biomethane | GWP, FEP, MEP, AP | [62] |

| 31 | Life cycle environmental impacts of generating electricity and heat from biogas produced by anaerobic digestion | British | 2014 | 1 MWh generated bioelectricity and heat | GWP, EP, AP, FDP, PO, ODP, TEP, ADP | [63] |

| 32 | Environmental assessment of alternative treatment schemes for energy and nutrient recovery from livestock manure | Spain | 2018 | 274 t feedstock | GWP, FEP, MEP, AP, FDP, WDP | [47] |

| 33 | Life Cycle Assessment of Large-scale Piggery for Environmental Assessment | China | 2012 | a slaughter pig | GWP, EP, AP, FDP | [18] |

| 34 | Life Cycle Assessment of Two Manure Treatment Modes in Intensive Dairy Farms | China | 2021 | 1 t manure | GWP, EP, AP | [36] |

| 35 | Life Cycle Assessment of Different Treatment Modes of Pig Manure Based on Integrated Planting and Raising System in Intensive Agricultural Region | China | 2015 | 90 t slurry | GWP, EP, AP | [37] |

| 36 | Environmental impact analysis on the production and utilization of digestate based on LCA method | China | 2015 | 1 t digestate | GWP, EP, AP, FDP, HTP, PO, TEP | [19] |

| 37 | Environmental impacts of biogas deployment Part I: life cycle inventory for evaluation of production process emissions to air | Germany | 2012 | 1 t feedstock | GWP, MEP, AP, FDP, HTP, PO, ODP | [50] |

| 38 | Assessing the environmental sustainability of grass silage and cattle slurry for biogas production | Ireland | 2021 | Feedstock | GWP, FEP, AP | [51] |

| 39 | Anaerobic digestion of different feedstocks: Impact on energetic and environmental balances of biogas process | Italy | 2013 | 1 kWh generated bioelectricity | GWP, FDP | [64] |

| 40 | Environmental and economic assessment of integrated systems for dairy manure treatment coupled with algae bioenergy production | USA | 2013 | 2069.55 t manure | GWP, EP, FDP | [38] |

| 41 | Life cycle assessment of large-scale and household biogas plants in northwest China | China | 2018 | 2136 t feces | GWP, EP, AP, FDP, HTP, PO | [39] |

| 42 | Lifecycle Greenhouse Gas Analysis of an Anaerobic Codigestion Facility Processing Dairy Manure and Industrial Food Waste | USA | 2015 | 1 t feedstock | GWP | [52] |

| 43 | Life cycle assessment of manure management and nutrient recycling from a Chinese pig farm | China | 2014 | 1956 livestock units (LU) (1 LU = 500 kg life weight) | GWP, EP, AP | [73] |

| 44 | Life cycle assessment of swine production in Brazil: a comparison of four manure management systems | Brazil | 2015 | 1000 kg pig carcass | GWP, FEP, MEP, AP, FDP | [74] |

| 45 | Environmental Sustainability and Economic Benefits of Dairy Farm Biogas Energy Production: A Case Study in Umbria | Italy | 2014 | Generated bioelectricity and heat | GWP | [65] |

| 46 | Life cycle assessment of energy generation from biogas-Attributional vs. consequential approach | British | 2012 | 1 MJ net bioelectricity | GWP, EP, AP, FDP | [66] |

| 47 | Life cycle assessment of a medium commercial scale biogas plant and nutritional assessment of effluent slurry | Pakistan | 2017 | 20,000 kg slurry | GWP, FEP, AP | [40] |

| 48 | Environmental balance of the UK biogas sector: An evaluation by consequential life cycle assessment | British | 2016 | 1 t dry matter of feedstock | GWP, EP, AP, FDP | [20] |

| 49 | A case study on integrating anaerobic digestion into agricultural activities in British Columbia: Environmental, economic and policy analysis | Canada | 2021 | 1 t dry matter of feedstock | GWP | [53] |

| 50 | A life cycle assessment of an enterprise’s low-carbon emissions model: The Xinjiang Shihezi pig farm fecal treatment biogas project as a case study | China | 2022 | 7.4 t manure | GWP, EP, AP, FDP | [9] |

| 51 | Agricultural small anaerobic digestion plants: Combining economic and environmental assessment | Italy | 2019 | 1kWh net bioelectricity | GWP, FEP, MEP, AP | [67] |

| 52 | Anaerobic digestion of agricultural wastes from liquid to solid state: Performance and environ-economic comparison | China | 2021 | 38,200 t manure | GWP, EP, AP | [41] |

| 53 | Anaerobic digestion of poultry litter–A consequential life cycle assessment | Ireland | 2020 | 20,000 t feces | GWP, FEP, AP | [3] |

| 54 | Choosing co-substrates to supplement biogas production from animal slurry—A life cycle assessment of the environmental consequences | Denmark | 2014 | 1000 kg slurry | GWP, FEP, MEP, AP, FDP | [42] |

| 55 | Environmental impacts concerning the addition of trace metals in the process of biogas production from anaerobic digestion of slurry | Europe | 2020 | 1 MJ generated bioelectrity | GWP, EP, AP | [68] |

| 56 | Environmental implications of anaerobic digestion for manure management in dairy farms in Mexico: a life cycle perspective | Mexico | 2015 | 1 L milk | GWP, FEP, MEP, AP, FDP | [75] |

| 57 | Environmental performance of manure co-digestion with natural and cultivated grass—A consequential life cycle assessment | Estonia | 2017 | 1 t manure | GWP, FEP, MEP, AP | [43] |

| 58 | From waste-to-worth: energy, emissions, and nutrient implications of manure processing pathways | USA | 2014 | 1 t manure | GWP | [44] |

| 59 | Greenhouse gas mitigation and rural electricity generation by a novel two-stroke biogas engine | Indonesia | 2021 | 1 kWh generated bioelectricity | GWP, FEP, MEP, AP, FDP | [21] |

| 60 | LCA of anaerobic digestion: Emission allocation for energy and digestate | Europe | 2019 | 1 MJ generated bioelectricity and heat | GWP | [69] |

| 61 | LCA of bioenergy chains in Piedmont (Italy): A case study to support public decision makers towards sustainability | Italy | 2011 | 1 MJ net generated bioelectricity and heat | GWP, EP, AP | [70] |

| 62 | Greenhouse gas emissions from broiler manure treatment options are lowest in well-managed biogas production | Germany | 2021 | 1 t manure | GWP | [45] |

| 63 | Environmental and economic analysis of power generation in a thermophilic biogas plant | Spain | 2018 | 1 kWh net generated bioelectricity | GWP, FEP, AP | [22] |

| 64 | Use of agricultural by-products in the development of an agro-energy chain: A case study from the Umbria region | Italy | 2018 | 1 kWh net generated bioelectricity | GWP | [71] |

| 65 | Comparative life cycle assessment of anaerobic co-digestion for dairy waste management in large-scale farms | UAE | 2020 | 1 t manure | GWP, EP, AP, FDP | [46] |

| 66 | Closing nutrient loops through decentralized anaerobic digestion of organic residues in agricultural regions: A multi-dimensional sustainability assessment | Sweden | 2018 | 1 t dry matter of feedstock | GWP, EP, AP, FDP | [54] |

Note: GWP: Global Warming Potential; EP: Eutrophication Potential; AP: Acidification Potential; FEP: Freshwater Eutrophication Potential; MEP: Marine Eutrophication Potential; FDP: Fossil Depletion Potential; HTP: Human Toxicity Potential; PMF: Particulate Matter Formation; PO: Photochemical Oxidation; ODP: Ozone Depletion Potential; E: Ecotoxicity; LU: Land Use; WDP: Water Depletion Potential; ADP: Abiotic Resource Depletion Potential.

Table A2.

System boundary and allocation methods.

Table A2.

System boundary and allocation methods.

| System Boundary | Allocation Method | Reference | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Processes Included in AD System | Processes Introduced Through System Expansion | |||||||||||||||

| No. | P1 | P2 | P3 | P4 | P5 | P6 | P7 | P8 | SEP1 | SEP2 | SEP3 | SEP4 | A1 | A2 | A3 | |

| 1 | √ | √ | √ | √ | √ | √ | √ | [48] | ||||||||

| 2 | √ | √ | √ | √ | √ | √ | √ | √ | [8] | |||||||

| 3 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | [26] | |||||

| 4 | √ | √ | √ | √ | √ | √ | √ | [55] | ||||||||

| 5 | √ | √ | √ | √ | √ | √ | √ | √ | √ | [56] | ||||||

| 6 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | [49] | |||||

| 7 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | [49] | |||

| 8 | √ | √ | √ | √ | √ | √ | √ | √ | √ | [72] | ||||||

| 9 | √ | √ | √ | √ | √ | √ | √ | √ | [57] | |||||||

| 10 | √ | √ | √ | √ | √ | √ | √ | √ | √ | [57] | ||||||

| 11 | √ | √ | √ | √ | √ | √ | √ | √ | √ | [27] | ||||||

| 12 | √ | √ | √ | √ | √ | √ | √ | √ | [11] | |||||||

| 13 | √ | √ | √ | √ | √ | √ | √ | √ | √ | [28] | ||||||

| 14 | √ | √ | √ | √ | √ | √ | √ | √ | √ | [29] | ||||||

| 15 | √ | √ | √ | √ | √ | √ | √ | √ | [29] | |||||||

| 16 | √ | √ | √ | √ | [15] | |||||||||||

| 17 | √ | √ | √ | √ | √ | √ | √ | √ | √ | [10] | ||||||

| 18 | √ | √ | √ | √ | √ | [16] | ||||||||||

| 19 | √ | √ | √ | √ | √ | √ | √ | √ | √ | [58] | ||||||

| 20 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | [58] | |||||

| 21 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | [6] | ||||

| 22 | √ | √ | √ | √ | √ | √ | √ | √ | [30] | |||||||

| 23 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | [30] | |||||

| 24 | √ | √ | √ | √ | √ | √ | [31] | |||||||||

| 25 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | [59] | |||||

| 26 | √ | √ | √ | √ | √ | √ | √ | √ | √ | [1] | ||||||

| 27 | √ | √ | √ | √ | √ | √ | √ | [60] | ||||||||

| 28 | √ | √ | √ | √ | √ | √ | √ | √ | [60] | |||||||

| 29 | √ | √ | √ | √ | √ | √ | √ | √ | √ | [32] | ||||||

| 30 | √ | √ | √ | √ | √ | √ | √ | [33] | ||||||||

| 31 | √ | √ | √ | √ | √ | √ | [61] | |||||||||

| 32 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | [17] | |||||

| 33 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | [34] | |||||

| 34 | √ | √ | √ | √ | √ | √ | √ | √ | √ | [25] | ||||||

| 35 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | [25] | |||||

| 36 | √ | √ | √ | √ | √ | √ | √ | √ | √ | [35] | ||||||

| 37 | √ | √ | √ | √ | √ | √ | √ | [62] | ||||||||

| 38 | √ | √ | √ | √ | √ | √ | √ | √ | [62] | |||||||

| 39 | √ | √ | √ | √ | √ | √ | √ | √ | [63] | |||||||

| 40 | √ | √ | √ | √ | √ | √ | √ | √ | [47] | |||||||

| 41 | √ | √ | √ | √ | √ | [18] | ||||||||||

| 42 | √ | √ | √ | √ | √ | √ | √ | [36] | ||||||||

| 43 | √ | √ | √ | √ | √ | √ | √ | √ | [37] | |||||||

| 44 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | [19] | |||||

| 45 | √ | √ | √ | √ | √ | √ | √ | √ | √ | [50] | ||||||

| 46 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | [50] | |||||

| 47 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | [51] | |||||

| 48 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | [51] | ||||

| 49 | √ | √ | √ | √ | √ | √ | √ | √ | [64] | |||||||

| 50 | √ | √ | √ | √ | √ | √ | √ | √ | √ | [64] | ||||||

| 51 | √ | √ | √ | √ | √ | √ | √ | [38] | ||||||||

| 52 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | [39] | |||||

| 53 | √ | √ | √ | √ | √ | √ | √ | √ | [52] | |||||||

| 54 | √ | √ | √ | √ | √ | √ | √ | √ | [73] | |||||||

| 55 | √ | √ | √ | √ | √ | √ | √ | √ | √ | [74] | ||||||

| 57 | √ | √ | √ | √ | √ | √ | √ | √ | √ | [66] | ||||||

| 58 | √ | √ | √ | √ | √ | √ | √ | √ | √ | [40] | ||||||

| 59 | √ | √ | √ | √ | √ | √ | √ | √ | [20] | |||||||

| 60 | √ | √ | √ | √ | √ | √ | √ | √ | √ | [53] | ||||||

| 61 | √ | √ | √ | √ | √ | √ | √ | √ | √ | [9] | ||||||

| 62 | √ | √ | √ | √ | √ | √ | √ | [67] | ||||||||

| 63 | √ | √ | √ | √ | √ | √ | √ | √ | [67] | |||||||

| 64 | √ | √ | √ | √ | √ | √ | √ | √ | [41] | |||||||

| 65 | √ | √ | √ | √ | √ | √ | √ | √ | √ | [3] | ||||||

| 66 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | [42] | |||||

| 67 | √ | √ | √ | √ | [68] | |||||||||||

| 68 | √ | √ | √ | √ | √ | √ | [75] | |||||||||

| 69 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | [43] | ||||

| 70 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | [43] | |||

| 71 | √ | √ | √ | √ | √ | √ | √ | [44] | ||||||||

| 72 | √ | √ | √ | √ | [21] | |||||||||||

| 73 | √ | √ | √ | √ | √ | √ | √ | [69] | ||||||||

| 74 | √ | √ | √ | √ | √ | √ | √ | √ | √ | [70] | ||||||

| 75 | √ | √ | √ | √ | √ | √ | √ | √ | √ | [45] | ||||||

| 76 | √ | √ | √ | √ | √ | √ | √ | [22] | ||||||||

| 77 | √ | √ | √ | √ | √ | √ | √ | √ | √ | [71] | ||||||

| 78 | √ | √ | √ | √ | √ | √ | [46] | |||||||||

| 79 | √ | √ | √ | √ | √ | √ | √ | √ | √ | [54] | ||||||

| 80 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | [54] | |||||

Note:P1: Biogas plant construction, P2: Co-digestion substrate production, P3: Collection, storage, pre-treatment of digestion materials, P4: Anaerobic digestion, P5: Biogas utilization, P6: Transportation, P7: Digestate treatment, P8: Digestate utilization or final disposal, SEP1 Chemical fertilizer production, SEP2: Traditional energy production, SEP3: Traditional manure management, SEP4: Original treatment and utilization of co-digestion substance, A1: System expansion, A2: Physical/economic allocation, A3: No allocation.

References

- Lijó, L.; Frison, N.; Fatone, F.; González-García, S.; Feijoo, G.; Moreira, M.T. Environmental and sustainability evaluation of livestock waste management practices in Cyprus. Sci. Total Environ. 2018, 634, 127–140. [Google Scholar] [CrossRef]

- Yuan, k.; Xiong, S.Y.; Liang, J.; Li, Y.M.; Qiao, Y.H.; Li, H.F.; Chen, Q. Status and risk analysis of copper and zinc pollution in livestock manure. J. Agro-Environ. Sci. 2020, 39, 1837–1842. [Google Scholar]

- Beausang, C.; McDonnell, K.; Murphy, F. Anaerobic digestion of poultry litter-A consequential life cycle assessment. Sci. Total Environ. 2020, 735, 139494. [Google Scholar] [CrossRef]

- Ferreira, J.; Santos, L.; Ferreira, M.; Ferreira, A.; Domingos, I. Environmental Assessment of Pig Manure Treatment Systems through Life Cycle Assessment: A Mini-Review. Sustainability 2024, 16, 3521. [Google Scholar] [CrossRef]

- Intergovernmental Panel on Climate Change (IPCC). Refinement to the 2006 IPCC Guidelines for National Greenhouse Gas Inventories. Agriculture, Forestry and Other Land Use. In Emissions from Livestock and Manure Management; Institute for Global Environmental Strategies: Hayama, Japan, 2019; Volume 4, Chapter 10; Available online: https://www.ipcc-nggip.iges.or.jp/public/2019rf/vol4.html (accessed on 28 May 2023).

- Hamelin, L.; Naroznova, I.; Wenzel, H. Environmental consequences of different carbon alternatives for increased manure-based biogas. Appl. Energy 2014, 114, 774–782. [Google Scholar] [CrossRef]

- Li, Y.L.; Bai, J.S.; Zhao, L.P.; Li, Z.Z. Spatiotemporal distribution of livestock and poultry waste and its resource utilization potential in China. Soil Fertil. Sci. China 2023, 5, 114–124. [Google Scholar]

- Duan, N.; Khoshnevisan, B.; Lin, C.; Liu, Z.D.; Liu, H.B. Life cycle assessment of anaerobic digestion of pig manure coupled with different digestate treatment technologies. Environ. Int. 2020, 137, 105522. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Dong, X.; Wang, X.C.; Zhang, P.; Liu, R.R.; Klemeš, J.J.; Zheng, J.H. A life cycle assessment of an enterprise’s low-carbon emissions model: The Xinjiang Shihezi pig farm faecal treatment biogas project as a case study. J. Environ. Manag. 2022, 304, 114251. [Google Scholar] [CrossRef]

- Jiang, Y.; Zhang, Y.; Wang, S.; Wang, Z.Z.; Liu, Y.C.; Hu, Z.H.; Zhan, X.M. Improved environmental sustainability and bioenergy recovery through pig manure and food waste on-farm co-digestion in Ireland. J. Clean. Prod. 2021, 280, 125034. [Google Scholar] [CrossRef]

- Garfí, M.; Castro, L.; Montero, N.; Escalante, H.; Ferrer, I. Evaluating environmental benefits of low-cost biogas digesters in small-scale farms in Colombia: A life cycle assessment. Bioresour. Technol. 2019, 274, 541–548. [Google Scholar] [CrossRef]

- ISO 14044:2006; International Organization for Standardization (ISO). Environmental Management-Life Cycle Assessment-Requirements and Guidelines. ISO: Geneva, Switzerland, 2006.

- Jiang, R.; Wang, H.T.; Zhang, H.; Chen, X.X. Life cycle assessment of cement technologies in China and recommendations. Acta Sci. Circumstantiae 2010, 30, 2361–2368. [Google Scholar]

- Esteves, E.M.M.; Herrera, A.M.N.; Esteves, V.P.P.; Morgado, C.R.V. Life cycle assessment of manure biogas production: A review. J. Clean. Prod. 2019, 219, 411–423. [Google Scholar] [CrossRef]

- Rahman, K.M.; Melville, L.; Fulford, D.; Huq, S.I. Green-house gas mitigation capacity of a small scale rural biogas plant calculations for Bangladesh through a general life cycle assessment. Waste Manag. Res. J. A Sustain. Circ. Econ. 2017, 35, 1023–1033. [Google Scholar] [CrossRef] [PubMed]

- Ioannou-Ttofa, L.; Foteinis, S.; Moustafa, A.S.; Abdelsalam, E.; Samer, M.; Fatta-Kassinos, D. Life cycle assessment of household biogas production in Egypt: Influence of digester volume, biogas leakages, and digestate valorization as biofertilizer. J. Clean. Prod. 2021, 286, 125468. [Google Scholar] [CrossRef]

- Lijó, L.; González-García, S.; Bacenetti, J.; Fiala, M.; Feijoo, G.; Lema, J.M.; Moreira, M.T. Life Cycle Assessment of electricity production in Italy from anaerobic co-digestion of pig slurry and energy crops. Renew. Energy 2014, 68, 625–635. [Google Scholar] [CrossRef]

- Zhang, Y.; Xia, X.F.; Zhou, S.X.; He, Z.S.; Meng, R.; Xi, B.D. Life Cycle Assessment of Large-scale Piggery for Environmental Assessment. J. Environ. Eng. Technol. 2012, 2, 428–432. [Google Scholar]

- Yi, R.J.; Zhang, W.Q.; Zhou, J.; Li, W.; Wu, S.B.; Chen, L.; Dong, R.J. Environmental impact analysis on the production and utilization of digestate based on LCA method. Renew. Energy Resour. 2015, 33, 301–307. [Google Scholar]

- Styles, D.; Dominguez, E.M.; Chadwick, D. Environmental balance of the UK biogas sector: An evaluation by consequential life cycle assessment. Sci. Total Environ. 2016, 560–561, 241–253. [Google Scholar] [CrossRef]

- Nindhia, T.G.T.; McDonald, M.; Styles, D. Greenhouse gas mitigation and rural electricity generation by a novel two-stroke biogas engine. J. Clean. Prod. 2021, 280, 124473. [Google Scholar] [CrossRef]

- Ruiz, D.; San Miguel, G.; Corona, B.; Domínguez, A. Environmental and economic analysis of power generation in a thermophilic biogas plant. Sci. Total Environ. 2018, 633, 1418–1428. [Google Scholar] [CrossRef]

- Baidini, C.; Gardoni, D.; Guarino, M. A critical review of the recent evolution of Life Cycle Assessment applied to milk production. J. Clean. Prod. 2017, 140, 421–435. [Google Scholar] [CrossRef]

- Yang, J.X. Life Cycle Assessment Methods and Applications for Products; China Meteorological Press: Beijing, China, 2002. [Google Scholar]

- Li, Y.; Manandhar, A.; Li, G.; Shah, A. Life cycle assessment of integrated solid state anaerobic digestion and composting for on-farm organic residues treatment. Waste Manag. 2018, 76, 294–305. [Google Scholar] [CrossRef]

- Lijó, L.; González-García, S.; Bacenetti, J.; Fiala, M.; Feijoo, G.; Moreira, M.T. Assuring the sustainable production of biogas from anaerobic mono-digestion. J. Clean. Prod. 2014, 72, 23–34. [Google Scholar] [CrossRef]

- De Vries, J.W.; Groenestein, C.M.; De Boer, I.J.M. Environmental consequences of processing manure to produce mineral fertilizer and bio-energy. J. Environ. Manag. 2012, 102, 173–183. [Google Scholar] [CrossRef] [PubMed]

- Hollas, C.E.; Bolsan, A.C.; Chini, A.; Venturin, B.; Bonassa, G.; Cândido, D.; Antes, F.G.; Steinmetz, R.L.R.; Prado, N.V.; Kunz, A. Effects of swine manure storage time on solid-liquid separation and biogas production: A life-cycle assessment approach. Renew. Sustain. Energy Rev. 2021, 150, 111472. [Google Scholar] [CrossRef]

- Lyng, K.A.; Modahl, I.S.; Møller, H.; Morken, J.; Briseid, T.; Hanssen, O. The BioValueChain model: A Norwegian model for calculating environmental impacts of biogas value chains. Int. J. Life Cycle Assess. 2015, 20, 490–502. [Google Scholar] [CrossRef]

- Zhang, Y.; Jiang, Y.; Wang, S.; Wang, Z.Z.; Liu, Y.C.; Hu, Z.H.; Zhan, X.M. Environmental sustainability assessment of pig manure mono- and co-digestion and dynamic land application of the digestate. Renew. Sustain. Energy Rev. 2021, 137, 110476. [Google Scholar] [CrossRef]

- Joshi, J.; Wang, J.J. Manure management coupled with bioenergy production: An environmental and economic assessment of large dairies in New Mexico. Energy Econ. 2018, 74, 197–207. [Google Scholar] [CrossRef]

- Ramírez-Islas, M.E.; Güereca, L.P.; Sosa-Rodriguez, F.S.; Cobos-Peralta, M.A. Environmental assessment of energy production from anaerobic digestion of pig manure at medium-scale using life cycle assessment. Waste Manag. 2020, 102, 85–96. [Google Scholar] [CrossRef]

- Vu, T.K.V.; Vu, D.Q.; Jensen, L.S.; Sommer, S.G.; Bruun, S. Life Cycle Assessment of Biogas Production in Small-scale Household Digesters in Vietnam. Asian-Australas. J. Anim. Sci. 2015, 28, 716–729. [Google Scholar] [CrossRef]

- Havukainen, J.; Väisänen, S.; Rantala, T.; Saunila, M.; Ukko, J. Environmental impacts of manure management based on life cycle assessment approach. J. Clean. Prod. 2020, 264, 121576. [Google Scholar] [CrossRef]

- Rodriguez-Verde, I.; Regueiro, L.; Carballa, M.; Hospido, A.; Lema, J.M. Assessing anaerobic co-digestion of pig manure with agroindustrial wastes: The link between environmental impacts and operational parameters. Sci. Total Environ. 2014, 497–498, 475–483. [Google Scholar] [CrossRef] [PubMed]

- Li, D.Y.; Hu, J.; Dong, Y.W.; Jin, H.M. Life Cycle Assessment of Two Manure Treatment Modes in Intensive Dairy Farms. J. Ecol. Rural Environ. 2021, 37, 257–264. [Google Scholar]

- Jin, H.M.; Chang, Z.Z.; Ma, Y.; Yan, S.H.; Sheng, J.; Huang, H.Y.; Wu, H.S.; Sun, G.F. Life Cycle Assessment of Different Treatment Modes of Pig Manure Based on Integrated Planting and Raising System in Intensive Agricultural Region. J. Agro-Environ. Sci. 2015, 34, 1625–1632. [Google Scholar]

- Zhang, Y.; White, M.A.; Colosi, L.M. Environmental and economic assessment of integrated systems for dairy manure treatment coupled with algae bioenergy production. Bioresour. Technol. 2013, 130, 486–494. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, X.; Tong, X.; Li, T.T.; Wu, F.Q. Life cycle assessment of large-scale and household biogas plants in northwest China. J. Clean. Prod. 2018, 192, 221–235. [Google Scholar] [CrossRef]

- Yasar, A.; Rasheed, R.; Tabinda, A.B.; Tahir, A.; Sarwar, F. Life cycle assessment of a medium commercial scale biogas plant and nutritional assessment of effluent slurry. Renew. Sustain. Energy Rev. 2017, 67, 364–371. [Google Scholar] [CrossRef]

- Li, Y.Y.; Qi, C.; Zhang, Y.; Li, Y.M.; Wang, Y.Q.; Li, G.X.; Luo, W.H. Anaerobic digestion of agricultural wastes from liquid to solid state: Performance and environ-economic comparison. Bioresour. Technol. 2021, 332, 125080. [Google Scholar] [CrossRef]

- Croxatto Vega, G.C.; Hoeve, M.T.; Birkved, M.; Sommer, S.G.; Bruun, S.B. Choosing co-substrates to supplement biogas production from animal slurry-A life cycle assessment of the environmental consequences. Bioresour. Technol. 2014, 171, 410–420. [Google Scholar] [CrossRef]

- Pehme, S.; Veromann, E.; Hamelin, L. Environmental performance of manure co-digestion with natural and cultivated grass-A consequential life cycle assessment. J. Clean. Prod. 2017, 162, 1135–1143. [Google Scholar] [CrossRef]

- Aguirre-Villegas, H.A.; Larson, R.; Reinemann, D.J. From waste-to-worth: Energy, emissions, and nutrient implications of manure processing pathways. Biofuels Bioprod. Biorefining 2014, 8, 770–793. [Google Scholar] [CrossRef]

- Kreidenweis, U.; Breier, J.; Herrmann, C.; Libra, J.; Prochnow, A. Greenhouse gas emissions from broiler manure treatment options are lowest in well-managed biogas production. J. Clean. Prod. 2021, 280, 124969. [Google Scholar] [CrossRef]