Energy and Surface Performance of Light-Coloured Surface Treatments

Abstract

1. Introduction

- Initial non-destructive measurements of geometric, volumetric, mass, photometric, texture, and friction properties on the black surface.

- Application of the mixture on the sample surface using tape to prevent lateral spillage.

- Two-day curing period.

- Post-treatment non-destructive measurements of the same properties.

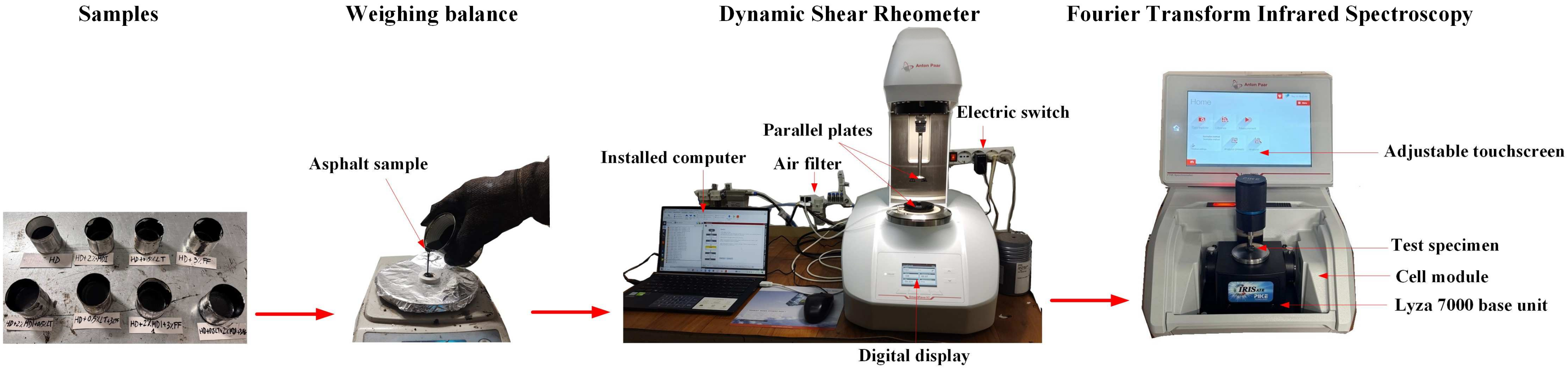

2. Materials and Methods

- (1)

- The materials produced. Basically, hot-mix asphalts (HMA) were prepared, and, on each sample, a given light-coloured surface treatment was applied.

- (2)

- The methods used for testing them.

2.1. Materials and Mix Design

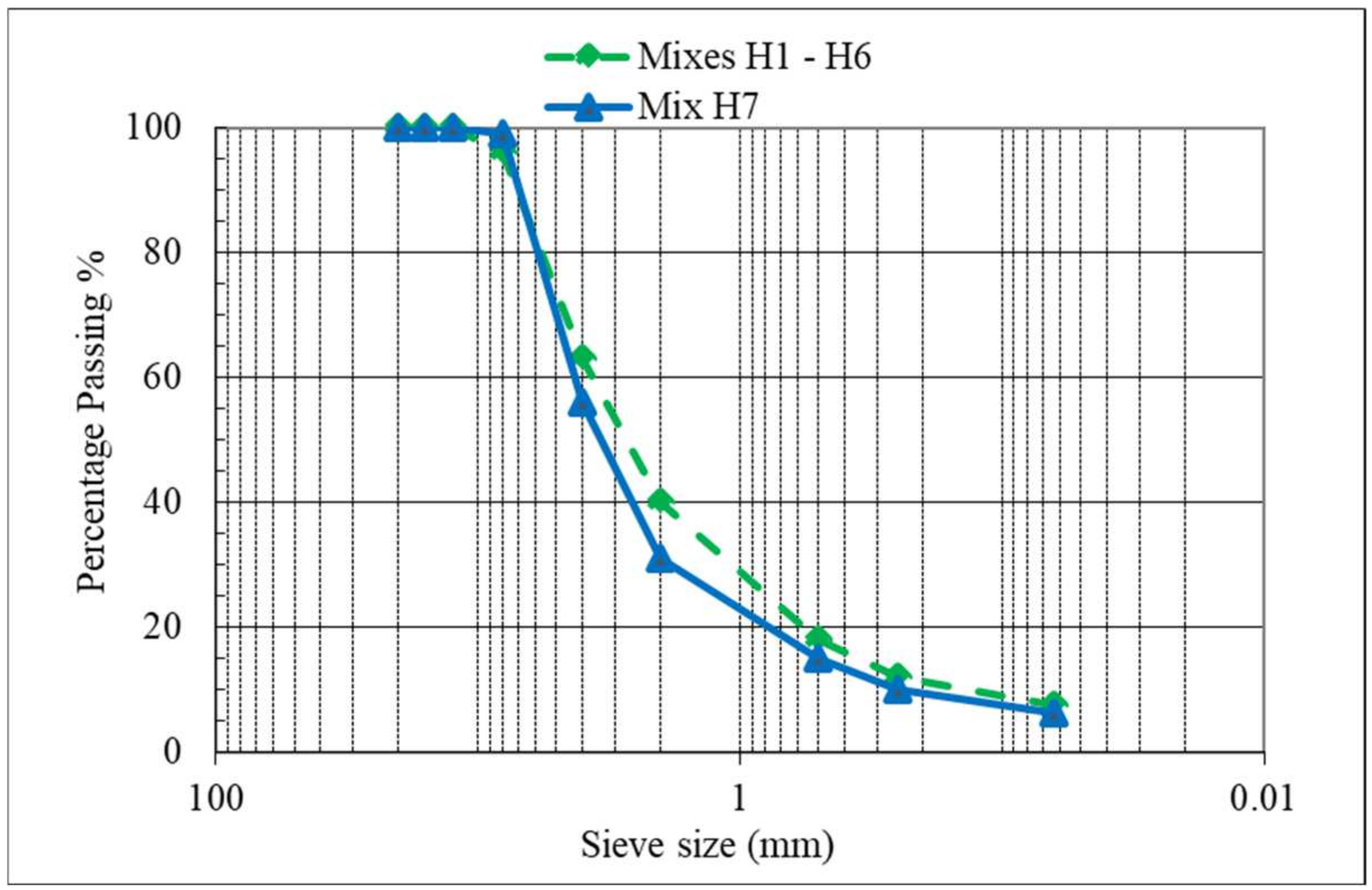

HMA Samples Production

2.2. Surface Treatment

2.3. Macrotexture and Friction Properties

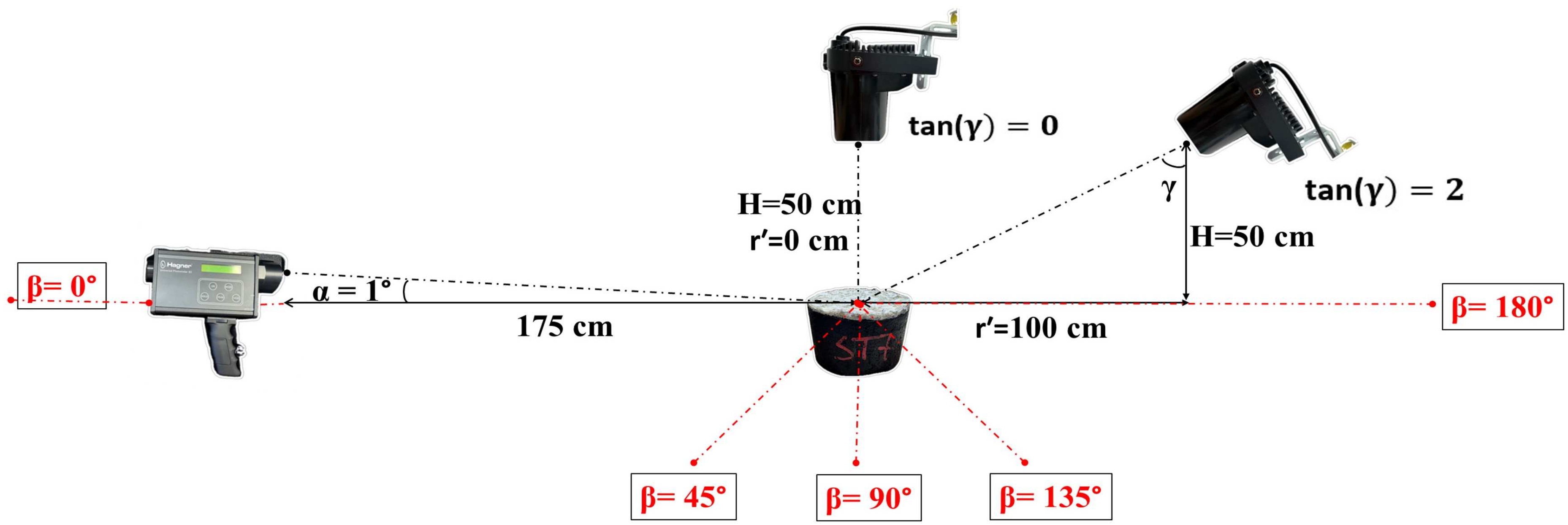

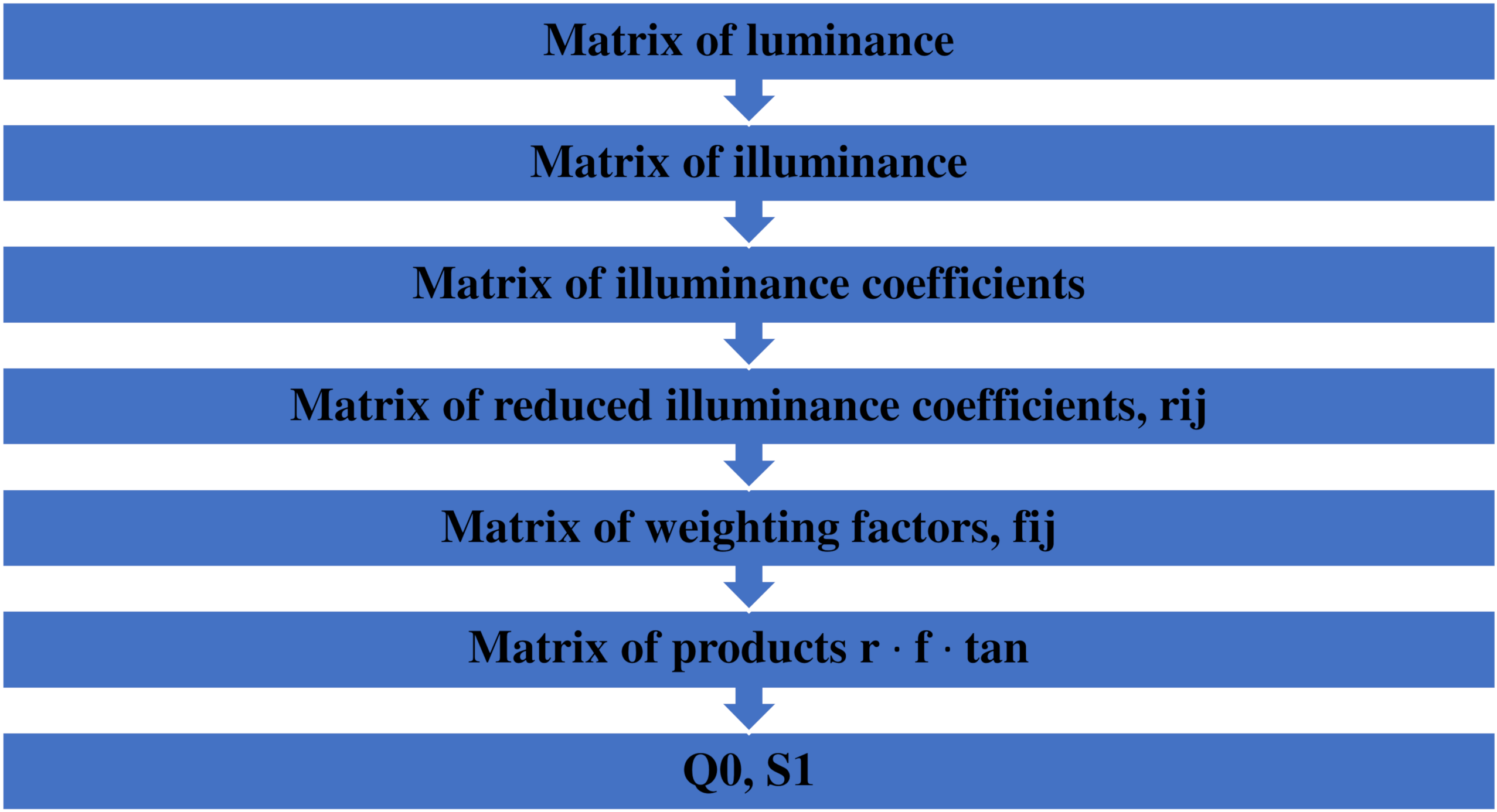

2.4. Photometric Measurements

- CIE 144:2001 [64]: Road surface and road marking reflection characteristics (The report also offers recommendations for measuring road surface and marking reflectivity on site).

- CIE 88:2004 [65]: Lighting of tunnels and underpasses (where recommendations concerning the daytime and night time lighting are given).

- CIE 194:2011 [66]: On Site Measurement of the Photometric Properties of Road and Tunnel Lighting (where essential photometric quantities and types and characteristics of instruments, the conditions and methodologies of measurements, the evaluation of uncertainty in measurement results and data elaboration are discussed).

- CEN 14380:2004 [67]: Tunnel lighting (where the design is considered, based on photometric considerations).

- EN 13201-1:2015 [68]: Road lighting—Part 1: Guidelines on selection of lighting classes (where geometry of the road, markings, visual environment, difficulty of the navigation task, lack of visibility, risks of glares due to existing elements, local weather, specific users such as high rate of elderly or visually impaired people are considered to choose the appropriate lighting class).

- EN 13201-2:2015 [69]: Road lighting—Part 2: Performance requirements (where lighting classes for road lighting, aiming at the visual needs of road users, are considered).

- EN 13201-3:2015 [70]: Road lighting—Part 3: Calculation of performance (where the photometric performance of road lighting installations is considered).

- EN 13201-4:2015 [71]: Road lighting—Part 4: Methods of measuring lighting performance (where procedures for measuring various photometric parameters like luminance and illuminance are considered).

- EN 13201-5:2015 [72]: Road lighting—Part 5: Energy performance indicators (where energy efficiency in different road lighting installations is considered).

- UNI 10439:2001 [73]: Illuminotecnica—Requisiti illuminotecnici delle strade con traffico motorizzato (where important details about measurements and specifications are provided).

3. Results and Analyses

3.1. Effect of Surface Treatments on Friction and Macrotexture

3.2. Results of Photometric Measurements

3.2.1. Pilot Tests

3.2.2. R-Classification Characteristics

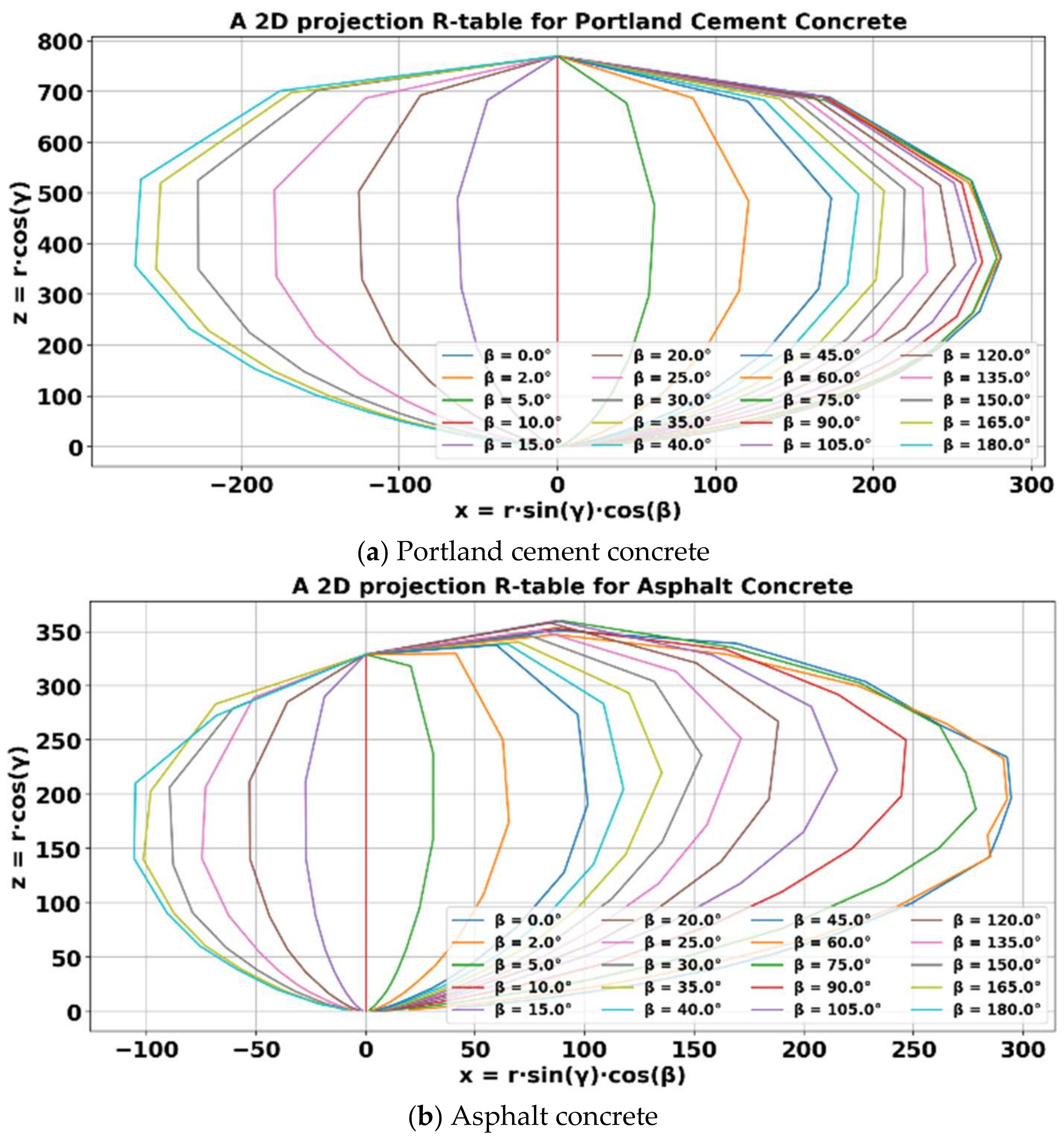

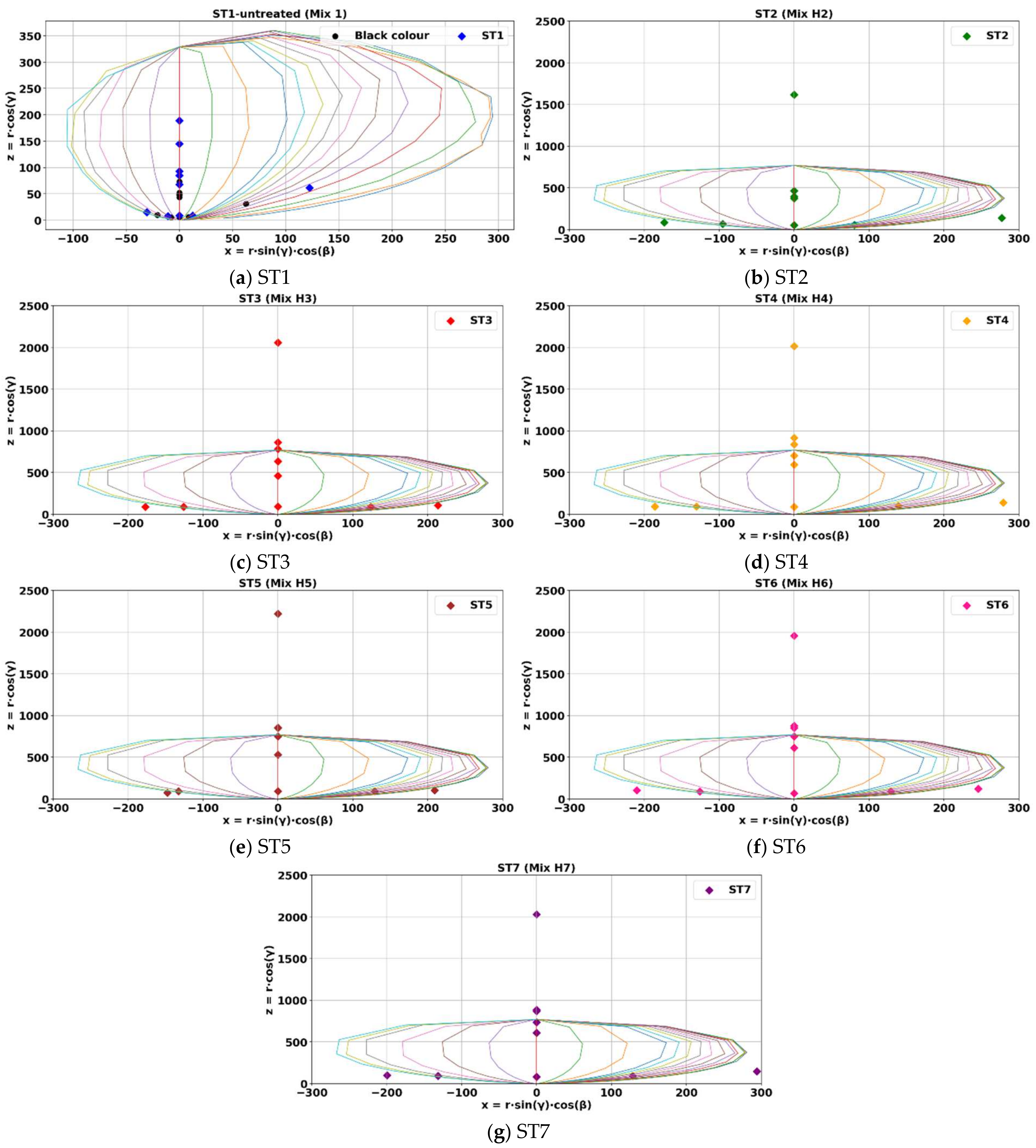

3.2.3. Reflection Characteristics of Light-Coloured Asphalt Mixtures Under the Different Surface Treatments

3.3. Evaluation and Ranking of Light-Coloured Pavement Mixtures

- Step 1. The indicators 1/S1, Q0, MTD, and PTV were selected as the most important in terms of energy and safety, with a “direction” towards benefits (the higher the indicator, the better). Indeed, a high specularity of pavement, especially when wet, can be dangerous due to reduced visibility and increased glare for drivers and pedestrians, potentially leading to accidents. This phenomenon is a significant safety concern, as it can create hazardous conditions on roads and pathways. Consequently, 1/S1 was selected as the indicator of concern.

- Step 2. For each indicator, Ii, a lower specification limit (LSLi) was selected, based on contract specifications and on the literature (2.38; 0.10; 0.4 mm; and 58, respectively).

- Step 3. For the given treatment STj, the differences Ii-LSLi were derived, assigning zero when Ii-LSLi < 0 (algorithm: if (Ii-LSLi > 0,Ii−LSLi,0))

- Step 4. For the given treatment STj, the feature scaling was applied to the differences Ii-LSLi (considered as a new feature, Ni). The normalisation of Ni = Ii-LSLi was carried out so that each feature contributes approximately proportionately to the final ranking. In more detail, rescaling was carried out using min-max normalisation to scale the range to [0, 1]. The algorithm used is: Ni’ = (Ni−MIN(Ni))/(MAX(Ni)−MIN(Ni))

- Step 5. For each treatment STj, the cumulative product, CPj, of the four new indicators above, Ni’ = (Ii−LSLi)’ was derived. The product of the sequence (CPj) enabled the clear separation of the solutions STj into two sets: unsatisfactory solutions (those with zero for one or more characteristics) and more or less satisfactory solutions (those with characteristics that comply with the specification limits set up in contract specifications or literature).

- Step 6. The ranking (for the second set of STj above) was derived based on the cumulative product CPj > 0, arranged from highest to lowest (cf. Table 12).

- Step 7. A robustness check was carried out (cf. Table 13), leaving one indicator out at a time. The robustness check was very satisfactory, resulting in ST5 always being the best, ST1 and ST2 always being excluded, and the remaining surface treatments having an intermediate ranking. This implies that conclusions remain consistent and there is a substantial stability of results, ensuring that findings are valid and reliable.

- (1)

- The conditions considered in the study by Moretti Moretti, Cantisani, Di Mascio and Caro [11], which also incorporate Italian standards, were considered. In their studies, tunnel lighting is divided into two main components: permanent lighting and reinforcement lighting. Permanent lighting is applied along the entire tunnel length (0–750 m), whereas reinforcement lighting provides high-level illumination during daytime in the tunnel’s entrance section (0–577 m) and is organised into seven different reinforcement sections (zones). These zones correspond to functional areas, including the access zone, threshold zone, transition zone, interior zone, and exit zone. The zone distances and the design luminance values are presented in Table 15.

- (2)

- The basis of this study is the lumen method, which shows the relationship between the number of lamps needed in the tunnel and the Q0 values obtained with ST applications. In this context, the number of lamps required for each zone is calculated using Equations (6) and (7).

- (3)

- Consequently, in this study, design luminance values for each zone, the reinforcement zone distances and road width, light loss factor, coefficient of utilisation, power of lamp type, annual usage period and average used power factor for Equations (6)–(9) to be used to calculate the potential energy savings of all ST applications are fixed. However, the required number of lamps for each zone varies according to the Q0 values determined according to ST applications, and the potential energy savings are calculated using Equation (10) with respect to ST1 (reference). Table 16 shows the calculated potential energy savings (%) of ST applications.

4. Conclusions and Recommendations

- (1)

- The average luminance coefficient (Q0) of the pavement was increased through surface treatment applications by improving its reflectance capability.

- (2)

- The specular reflection coefficients of LCPMs containing varying types and amounts of white materials were found to decrease significantly compared to traditional black asphalt.

- (3)

- Surface treatments containing only white polymer were observed to reduce surface macrotexture and to lower microtexture performance.

- (4)

- Surface treatments incorporating white powder, glass fibre, and glass aggregate were shown to be more effective than white polymer in enhancing surface macrotexture relative to the reference mixture. Notably, the addition of glass materials was found to improve surface texture, friction, and Q0 value.

- (5)

- The reflectance factor of untreated asphalt surfaces was increased from 0.11 to 0.97 through surface treatments, indicating a significant improvement in light reflection. Surface treatments containing glass materials were particularly effective in enhancing the reflection factor. Conversely, the use of glass fibres in amounts exceeding 2.5% was observed to reduce reflection performance.

- (6)

- Based on the new method established and implemented to compare different surface treatments considering multiple characteristics, ST5, which exhibited the highest Q0 value (0.2406) and the lowest S1 value (0.1052), was selected as the optimal surface treatment design. ST5 represented the most favourable combination of energy efficiency and safety, alongside enhanced visual comfort. Among the remaining six surface treatments, three (ST4, ST6, and ST7) were determined to achieve a satisfactory balance of surface properties, while the other three (ST1, ST2, and ST3) failed to meet the selected specification thresholds.

- (7)

- Treated surfaces improved brightness with Q0 up to 0.24 cd·m−2·lx−1 (ST5) (vs. 0.04 for the untreated samples), and reduced glare with S1 as low as 0.10, enabling 83% tunnel lighting energy savings.

- (8)

- Glass-enhanced treatments (ST4–ST7) achieved PTV 70–75 (vs. safety threshold ≥55) and MTD 0.9–1.1 mm (vs. minimum 0.4 mm).

- (9)

- ST5 (Q0 = 0.24, S1 = 0.10, PTV = 75, MTD = 1.1 mm) was the best performer, combining the highest brightness, the lowest glare, and excellent skid resistance/texture.

- (10)

- ST1 (Q0 = 0.04, PTV = 70, MTD = 0.4) and ST2 (Q0 = 0.08, PTV = 36, MTD = 0.3) failed to meet one or more safety/lighting requirements and are not recommended.

- (11)

- Fibre/mineral-reinforced coatings (e.g., ST5) are expected to be more durable, with literature showing 21–43% lower abrasion loss, but require tunnel field validation.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rahman, T.; Tajudin, A.N.; Suwarto, F.; Sudigdo, P.; Thom, N. Durability evaluation of heat-reflective coatings for road surfaces: A systematic review. Sustain. Cities Soc. 2024, 112, 105625. [Google Scholar] [CrossRef]

- Zhu, S.; Li, Z.; Long, K.; Zhou, S.; Zhou, Z. Study of illumination and reflection performances on light-colored pavement materials. Constr. Build. Mater. 2024, 456, 139239. [Google Scholar] [CrossRef]

- Diao, H.; Peng, B.; Ling, T. Enhancing tunnel lighting quality and energy efficiency with color aggregate semi-flexible pavement. Constr. Build. Mater. 2024, 411, 134361. [Google Scholar] [CrossRef]

- Ling, T.Q.; Zhang, S.G.; Li, X.L. Study on light–colored technology of highway tunnel pavement. Adv. Mater. Res. 2011, 168, 211–216. [Google Scholar] [CrossRef]

- Xin, Z.G. Research application of colored asphalt mixture pavement. Adv. Mater. Res. 2014, 900, 459–462. [Google Scholar] [CrossRef]

- Pratico, F.G.; Vaiana, R.; Noto, S. Photoluminescent road coatings for open-graded and dense-graded asphalts: Theoretical and experimental investigation. J. Mater. Civ. Eng. 2018, 30, 04018173. [Google Scholar] [CrossRef]

- Kim, K.K.; Choi, Y.-S.; Lee, H.J.; Rodrigazo, S.A.; Yeon, J. Enhanced Thermal Resistance and Mechanical Performance of Methyl Methacrylate-Based Pavement Coatings for Urban Heat Mitigation. Polymers 2025, 17, 586. [Google Scholar] [CrossRef]

- Praticò, F.; Noto, S.; Moro, A. Optimisation of photoluminescent painting treatments on different surface layers. In Functional Pavement Design; CRC Press: Boca Raton, FL, USA, 2016; pp. 1533–1542. [Google Scholar]

- Cheela, V.S.; John, M.; Biswas, W.; Sarker, P. Combating urban heat island effect—A review of reflective pavements and tree shading strategies. Buildings 2021, 11, 93. [Google Scholar] [CrossRef]

- Ferrari, A.; Kubilay, A.; Derome, D.; Carmeliet, J. The use of permeable and reflective pavements as a potential strategy for urban heat island mitigation. Urban Clim. 2020, 31, 100534. [Google Scholar] [CrossRef]

- Moretti, L.; Cantisani, G.; Di Mascio, P.; Caro, S. Technical and economic evaluation of lighting and pavement in Italian road tunnels. Tunn. Undergr. Space Technol. 2017, 65, 42–52. [Google Scholar] [CrossRef]

- Praticò, F.; Briante, P. Prediction of surface texture for better performance of friction courses. Constr. Build. Mater. 2020, 230, 116991. [Google Scholar] [CrossRef]

- Sha, A.; Liu, Z.; Tang, K.; Li, P. Solar heating reflective coating layer (SHRCL) to cool the asphalt pavement surface. Constr. Build. Mater. 2017, 139, 355–364. [Google Scholar] [CrossRef]

- Chen, Q.; Wang, C.; Fu, H.; Zhang, L. Durability evaluation of road cooling coating. Constr. Build. Mater. 2018, 190, 13–23. [Google Scholar] [CrossRef]

- Yi, X.; Chen, H.; Wang, H.; Shi, C.; Yang, J. The feasibility of using epoxy asphalt to recycle a mixture containing 100% reclaimed asphalt pavement (RAP). Constr. Build. Mater. 2022, 319, 126122. [Google Scholar] [CrossRef]

- Zheng, M.; Han, L.; Wang, F.; Mi, H.; Li, Y.; He, L. Comparison and analysis on heat reflective coating for asphalt pavement based on cooling effect and anti-skid performance. Constr. Build. Mater. 2015, 93, 1197–1205. [Google Scholar] [CrossRef]

- Xu, X.; Swei, O.; Xu, L.; Schlosser, C.A.; Gregory, J.; Kirchain, R. Quantifying location-specific impacts of pavement albedo on radiative forcing using an analytical approach. Environ. Sci. Technol. 2020, 54, 2411–2421. [Google Scholar] [CrossRef]

- Guo, R.; Liu, S. Design and experiment of self-luminescent asphalt-based pavement materials. Constr. Build. Mater. 2022, 342, 127991. [Google Scholar] [CrossRef]

- U.S. Environmental Protection Agency. Available online: https://www.epa.gov/heatislands/using-cool-pavements-reduce-heat-islands (accessed on 29 July 2025).

- Chen, C.; Chandra, S.; Han, Y.; Seo, H. Deep learning-based thermal image analysis for pavement defect detection and classification considering complex pavement conditions. Remote Sens. 2021, 14, 106. [Google Scholar] [CrossRef]

- Xing, Z.; Meng, Z.; Zheng, G.; Ma, G.; Yang, L.; Guo, X.; Tan, L.; Jiang, Y.; Wu, H. Intelligent rehabilitation in an aging population: Empowering human-machine interaction for hand function rehabilitation through 3D deep learning and point cloud. Front. Comput. Neurosci. 2025, 19, 1543643. [Google Scholar] [CrossRef]

- Xing, Z.; Ma, G.; Wang, L.; Yang, L.; Guo, X.; Chen, S. Towards visual interaction: Hand segmentation by combining 3D graph deep learning and laser point cloud for intelligent rehabilitation. IEEE Internet Things J. 2025, 12, 21328–21338. [Google Scholar] [CrossRef]

- Blouch, N.; Kazmi, S.N.H.; Metwaly, M.; Akram, N.; Mi, J.; Hanif, M.F. Towards Sustainable Construction: Experimental and Machine Learning-Based Analysis of Wastewater-Integrated Concrete Pavers. Sustainability 2025, 17, 6811. [Google Scholar] [CrossRef]

- Nabipour, N.; Karballaeezadeh, N.; Dineva, A.; Mosavi, A.; Mohammadzadeh, S.D.; Shamshirband, S. Comparative analysis of machine learning models for prediction of remaining service life of flexible pavement. Mathematics 2019, 7, 1198. [Google Scholar] [CrossRef]

- Tsoka, S.; Theodosiou, T.; Tsikaloudaki, K.; Flourentzou, F. Modeling the performance of cool pavements and the effect of their aging on outdoor surface and air temperatures. Sustain. Cities Soc. 2018, 42, 276–288. [Google Scholar] [CrossRef]

- Zhu, S.; Mai, X. A review of using reflective pavement materials as mitigation tactics to counter the effects of urban heat island. Adv. Compos. Hybrid Mater. 2019, 2, 381–388. [Google Scholar] [CrossRef]

- Tran, N.; Powell, B.; Marks, H.; West, R.; Kvasnak, A. Strategies for design and construction of high-reflectance asphalt pavements. Transp. Res. Rec. 2009, 2098, 124–130. [Google Scholar] [CrossRef]

- Riaz, A.; Yasir, N.; Badin, G.; Mahmood, Y. Innovative Pavement Solutions: A Comprehensive Review from Conventional Asphalt to Sustainable Colored Alternatives. Infrastructures 2024, 9, 186. [Google Scholar] [CrossRef]

- Li, H.; Xie, N. Reflective coatings for high albedo pavement. In Eco-Efficient Pavement Construction Materials; Elsevier: Amsterdam, The Netherlands, 2020; pp. 127–146. [Google Scholar]

- Zhang, C.; Lei, C.; Ye, L.; Kang, C.; Wang, M.; Huang, Z.; Wu, K. Reflective Properties and Lighting Quality of Urban Asphalt Roads in a Full-Service Cycle: A Longitudinal Study in Zhejiang Province, China. Sustainability 2023, 15, 16784. [Google Scholar] [CrossRef]

- Yi, Y.; Jiang, Y.; Fan, J.; Zhang, Y.; Deng, C.; Tian, T.; Ji, X. Durability of a heat-reflective coating on an asphalt pavement. Road Mater. Pavement Des. 2022, 23, 2651–2668. [Google Scholar] [CrossRef]

- EN 1426; Bitumen and Bituminous Binders—Determination of Needle Penetration. European Committee for Standardization (CEN): Brussels, Belgium, 2017.

- EN 1427; Bitumen and Bituminous Binders—Determination of the Softening Point—Ring and Ball Method. European Committee for Standardization (CEN): Brussels, Belgium, 2017.

- EN 13589; Bitumen and Bituminous Binders—Determination of the Tensile Properties of Modified Bitumen by the Force Ductility Method. European Committee for Standardization (CEN): Brussels, Belgium, 2018.

- EN 13398; Bitumen and Bituminous Binders—Determination of the Elastic Recovery of Modified Bitumen. European Committee for Standardization (CEN): Brussels, Belgium, 2017.

- EN 13702-2; Bitumen and Bituminous Binders—Determination of Dynamic Viscosity of Modified Bitumen—Part 2: Coaxial Cylinders Method. European Committee for Standardization (CEN): Brussels, Belgium, 2003.

- EN 1097-2; Tests for Mechanical and Physical Properties of Aggregates—Part 2: Methods for the Determination of Resistance to Fragmentation. European Committee for Standardization (CEN): Brussels, Belgium, 2020.

- EN 933-3; Tests for Geometrical Properties of Aggregates—Part 3: Determination of Particle Shape—Flakiness Index. European Committee for Standardization (CEN): Brussels, Belgium, 2013.

- EN 1097-8; Tests for Mechanical and Physical Properties of Aggregates—Part 8: Determination of the Polished Stone Value. European Committee for Standardization (CEN): Brussels, Belgium, 2020.

- EN 933-8; Tests for Geometrical Properties of Aggregates—Part 8: Assessment of Fines—Sand Equivalent Test. European Committee for Standardization (CEN): Brussels, Belgium, 2016.

- EN 12697-3; Bituminous Mixtures—Test Methods—Part 3: Bitumen Recovery: Rotary Evaporator. European Committee for Standardization (CEN): Brussels, Belgium, 2013.

- Alhassan, H.; Yunusa, G.; Sanusi, D. Potential of glass cullet as aggregate in hot mix asphalt. Niger. J. Technol. 2018, 37, 338–345. [Google Scholar] [CrossRef]

- Afkhamy Meybodi, P.; Khani Sanij, H.; Hosseini, S.; Olazar, M. Effect of crushed glass on skid resistance, moisture sensitivity and resilient modulus of hot mix asphalt. Arab. J. Sci. Eng. 2019, 44, 4575–4585. [Google Scholar] [CrossRef]

- Shafabakhsh, G.; Sajed, Y. Investigation of dynamic behavior of hot mix asphalt containing waste materials; case study: Glass cullet. Case Stud. Constr. Mater. 2014, 1, 96–103. [Google Scholar] [CrossRef]

- Airey, G.D.; Collop, A.C.; Thom, N.H. Mechanical performance of asphalt mixtures incorporating slag and glass secondary aggregates. In Proceedings of the 8th Conference on Asphalt Pavements for Southern Africa (CAPSA’04), Sun City, South Africa, 12–16 September 2004; p. 16. [Google Scholar]

- Almuhmdi, A.D.; Muhmood, A.A.; Salih, A.O. Effects of crushed glass waste as a fine aggregate on properties of hot asphalt mixture. Tikrit J. Eng. Sci. 2021, 28, 129–145. [Google Scholar] [CrossRef]

- Lachance-Tremblay, É.; Vaillancourt, M.; Perraton, D. Evaluation of the impact of recycled glass on asphalt mixture performances. Road Mater. Pavement Des. 2016, 17, 600–618. [Google Scholar] [CrossRef]

- Salem, Z.T.A.; Khedawi, T.S.; Baker, M.B.; Abendeh, R. Effect of waste glass on properties of asphalt concrete mixtures. Jordan J. Civ. Eng. 2017, 11, 117–131. [Google Scholar]

- Tobi, G.A.; Abidemi, O.R.; Felix, O.M. The use of crushed waste glass as a partial replacement of fine aggregates in asphalt concrete mixtures (glassphalt). J. Eng. Res. Rep. 2021, 21, 1–10. [Google Scholar] [CrossRef]

- Aashish, A.; Tamrakar, G.B.S. Effect of adding waste crushed glass to asphalt mix. Int. J. Adv. Eng. Manag. 2019, 4, 10–18. [Google Scholar]

- EN 13036-4; Road and Airfield Surface Characteristics—Test Methods—Part 4: Measurement of Slip/Skid Resistance Using the Pendulum Test. European Committee for Standardization (CEN): Brussels, Belgium, 2004.

- EN 13036-1; Road and Airfield Surface Characteristics—Test Methods—Part 1: Measurement of Pavement Surface Macrotexture Depth Using a Volumetric Patch Technique. European Committee for Standardization (CEN): Brussels, Belgium, 2010.

- Praticò, F.G.; Astolfi, A. A new and simplified approach to assess the pavement surface micro-and macrotexture. Constr. Build. Mater. 2017, 148, 476–483. [Google Scholar] [CrossRef]

- Wrekin. Available online: https://www.wrekinproducts.com/ (accessed on 20 July 2025).

- BS 7976-2:2002+A1:2013; Pendulum Test Value (PTV)—Part 2: Method of Operation. British Standards Institution (BSI): London, UK, 2013.

- ASTM E303-93(2013); Standard Test Method for Measuring Surface Frictional Properties Using the British Pendulum Tester. ASTM International: West Conshohocken, PA, USA, 2013.

- ISO 13473-2; Characterization of Pavement Texture by Use of Surface Profiles—Part 2: Terminology and Basic Requirements Related to Pavement Texture Profile Analysis. International Organization for Standardization: Geneva, Switzerland, 2002.

- PIARC—World Road Association. Road Tunnels Manual; PIARC Technical Committee D.5.: Paris, France, 2019. [Google Scholar]

- FHWA. Available online: https://www.fhwa.dot.gov/about/webstate.cfm (accessed on 20 July 2025).

- ISO 13473-1:2019; Characterization of Pavement Texture by Use of Surface Profiles—Part 1: Determination of Mean Profile Depth. International Organization for Standardization: Geneva, Switzerland, 2019.

- ASTM E965-15; Standard Test Method for Measuring Pavement Macrotexture Depth Using a Volumetric Technique. ASTM International: West Conshohocken, PA, USA, 2006.

- AASHTO T279; Standard Method of Test for Accelerated Polishing of Aggregates Using the British Wheel. AASHTO: Washington, DC, USA, 2018.

- Federal Highway Administration (FHWA). T 5040.36 Surface Texture for Asphalt and Concrete Pavements; Federal Highway Administration (FHWA): Washington, DC, USA, 2010. [Google Scholar]

- CIE 144:2001; Road Surface and Road Marking Reflection Characteristics. International Commission on Illumination (CIE): Vienna, Austria, 2001.

- CIE 88:2004; Guide for the Lighting of Road Tunnels and Underpasses. International Commission on Illumination (CIE): Vienna, Austria, 2004.

- CIE 194:2011; On Site Measurement of the Photometric Properties of Road and Tunnel Lighting. International Commission on Illumination (CIE): Vienna, Austria, 2011.

- CEN 14380:2004; Lighting Applications—Tunnel Lighting. European Committee for Standardization (CEN): Brussels, Belgium, 2004.

- EN 13201-1:2015; Road Lighting—Part 1: Guidelines on Selection of Lighting Classes. European Committee for Standardization (CEN): Brussels, Belgium, 2015.

- EN 13201-2:2015; Road Lighting—Part 2: Performance Requirements. European Committee for Standardization (CEN): Brussels, Belgium, 2015.

- EN 13201-3:2015; Road Lighting—Part 3: Calculation of Performance. European Committee for Standardization (CEN): Brussels, Belgium, 2015.

- EN 13201-4:2015; Road Lighting—Part 4: Methods of Measuring Lighting Performance. European Committee for Standardization (CEN): Brussels, Belgium, 2015.

- EN 13201-5:2015; Road Lighting—Part 5: Energy Performance Indicators. European Committee for Standardization (CEN): Brussels, Belgium, 2015.

- UNI 10439:2001; Illuminotecnica—Requisiti Illuminotecnici delle Strade con Traffico Motorizzato. UNI: Milan, Italy, 2001.

- CIE 061:1984; Guide on the Limitation of the Effects of Obtrusive Light from Outdoor Lighting Installations. International Commission on Illumination (CIE): Vienna, Austria, 1984.

- ANSI/IES RP-22; Lighting for Roadway and Parking Facilities. American National Standards Institute: New York, NY, USA, 2020.

- Corell, D.D.; Sørensen, K. An Instrument for the Measurement of Road Surface Reflection Properties. Nordisk Møde for Forbedret Vejudstyr (NMF). 2017; pp. 443–452. Available online: https://nmfv.dk/wp-content/uploads/2012/03/An-instrument-for-the-measurement-of-road-surface-reflection-properties.pdf (accessed on 30 September 2025).

- AASHTO T-331; Standard Method of Test for Bulk Specific Gravity (Gmb) and Density of Compacted Asphalt Mixtures Using Automatic Vacuum Sealing Method. AASHTO: Washington, DC, USA, 2023.

- ASTM D6752-09; Standard Test Method for Bulk Specific Gravity and Density of Compacted Bituminous Mixtures Using Automatic Vacuum Sealing Method. ASTM International: West Conshohocken, PA, USA, 2011.

- Castorena, C.; Rawls, M.; Hyuk-Im, J. In-Situ Determination of Emulsion Application Rates for Tack Coats and Surface Treatments; Research Development, NCDOT Project 2014-03; Department of Civil, Construction, & Environmental Engineering North Carolina State University: Raleigh, NC, USA, 2016. [Google Scholar]

- Praticò, F.G.; Fedele, R. Road pavement macrotexture estimation at the design stage. Constr. Build. Mater. 2023, 364, 129911. [Google Scholar] [CrossRef]

- Ma, Z.; Wang, H.; Zhang, Y.; Jelagin, D.; Li, Y. Effects of aggregate shape on the macrotexture and performance of chip seal: A laboratory study. Road Mater. Pavement Des. 2025, 26, 181–202. [Google Scholar] [CrossRef]

- Mazurek, G.; Bąk-Patyna, P.; Ludwikowska-Kędzia, M. Modelling of the Luminance Coefficient in the Light Scattered by a Mineral Mixture Using Machine Learning Techniques. Appl. Sci. 2024, 14, 5458. [Google Scholar] [CrossRef]

- Gidlund, H.; Lindgren, M.; Muzet, V.; Rossi, G.; Iacomussi, P. Road surface photometric characterisation and its impact on energy savings. Coatings 2019, 9, 286. [Google Scholar] [CrossRef]

- Li, H.; Xie, N.; Zhang, X.; Sun, L.; Harvey, J.T.; Wang, L. Investigation on Mixed Reflection Behavior of Cool Pavement Coating and Its Impact on Safety of Road Light Environment. Engineering 2025. [Google Scholar] [CrossRef]

- CIE 66:1984; Road Surfaces and Lighting (Joint Technical Report CIE/PIARC). International Commission on Illumination (CIE): Vienna, Austria, 1984.

- CIE 47:1979; Road Lighting for Wet Conditions. International Commission on Illumination (CIE): Vienna, Austria, 1979.

- CIE 115:2010; Lighting of Roads for Motor and Pedestrian Traffic. International Commission on Illumination (CIE): Vienna, Austria, 2010.

- ASTM E2302-03a; Standard Test Method for Measurement of the Luminance Coefficient Under Diffuse Illumination of Pavement Marking Materials Using a Portable Reflectometer. ASTM International: West Conshohocken, PA, USA, 2022.

- Salata, F.; Golasi, I.; Bovenzi, S.; de Lieto Vollaro, E.; Pagliaro, F.; Cellucci, L.; Coppi, M.; Gugliermetti, F.; de Lieto Vollaro, A. Energy optimization of road tunnel lighting systems. Sustainability 2015, 7, 9664–9680. [Google Scholar] [CrossRef]

- Bocci, E.; Bocci, M. Clear asphalt concrete for energy saving in road tunnels. In Proceedings of the 12th International Conference on Asphalt Pavements (ISAP), Raleigh, NC, USA, 1–5 June 2014; pp. 1817–1825. [Google Scholar]

- UNI 11095:2011; Light and Lighting—Road Tunnel Lighting. UNI: Milan, Italy, 2011.

| Performance Metric | Conventional Asphalt (Untreated) | Light-Coloured Asphalt | Reference |

|---|---|---|---|

| Solar Reflectance (Albedo) | 0.05–0.10 new; 0.10–0.15 aged | 0.4–0.8 initial; 0.3–0.5 after weathering; up to 0.20 after ageing | [1,25] |

| Solar Reflectance Index | 4–6% | 45–65% | [26,27,28,29] |

| Average luminance coefficient (Q0) | 0.076 cd·m−2·lx−1 | 0.076–0.157 cd·m−2·lx−1 for white-coloured asphalt | [2,30] |

| Illuminance | 6.15 lx in tunnel (2 W LED power) | 7.8 lx for light-coloured asphalt in tunnel (2 W LED power) | |

| Lighting Efficiency | Baseline (100% lighting power required) | Up to 20–30% lower lighting power needed | [2,3] |

| Peak Surface Temperature | 65–70 °C in hot climates | Typically 5–10 °C cooler (e.g., 58 °C) | |

| Abrasion Loss | Higher material loss under wear | 21–70% lower abrasion loss in tests | [1,9,14,31] |

| Skid Resistance (BPN) | 50–70 (adequate when new) | Up to 90 with added aggregates (very high) | [7,17] |

| Service Lifespan | Not applicable (asphalt lasts 10–15 years before resurfacing) | 0.5–3 years on low-traffic roads; 1 year on high-traffic roads; up to 7 years for special applications | [9,15] |

| Properties | Value | Standard |

|---|---|---|

| Penetration (0.1 mm) at 25 °C | 52–61 | EN 1426 [32] |

| Softening point (°C) | 49–51 | EN 1427 [33] |

| Ductility at 25 °C (cm) | >100 | EN 13589 [34] |

| Elastic recovery (%) | 9–11 | EN 13398 [35] |

| Dynamic viscosity at 100 °C (mPa.s) | 5000–6000 | EN 13702-2 [36] |

| Dynamic viscosity at 135 °C (mPa.s) | 300–800 | EN 13702-2 [36] |

| Properties | Value | Standard |

|---|---|---|

| Los Angeles abrasion (%) | 18 | EN 1097-2 [37] |

| Flakiness index (%) | 12 | EN 933-3 [38] |

| Polished stone value (PSV) | 44 | EN 1097-8 [39] |

| Sand equivalent (SE)(%) | 95.3 | EN 933-8 [40] |

| HMA Name | Density (Gmb) t/m3 | Air Void (Av)% | Bitumen Content (B)% | Sand (S)% | Filler (F)% |

|---|---|---|---|---|---|

| H1–H7 | 2.3–2.4 | 1–6 | 5.3–6.4 | 21–28 | 6.2–7.6 |

| Material | Parameter | Specification | Basis for Parameter Determination |

|---|---|---|---|

| White Polymer | Type | Acrylic and polymer-modified material. | Prior coating studies. Ensures adequate adhesion without excessive viscosity. |

| White Powder | Composition | 40% Portland cement + 60% quartz sand | Ratio selected from prior IASNAF/SILENT studies for binding and reflectance. |

| Glass Fibres | Length | 5 mm (short-cut fibres) | Literature suggests 5 mm is optimal for dispersion and surface reinforcement. |

| Diameter | ~12 µm | Industry standard for chopped E-glass fibres. | |

| Glass Aggregate | Particle size distribution | ≤4.75 mm, with 70% between 2.36 and 4.75 mm | This range balances stability, friction, and texture. |

| Water | Ratio | 5–7% of dry weight | To aid polymer activation, cement hydration, and uniform mixing. |

| S. Treatment ID | ST1 | ST2 | ST3 | ST4 | ST5 | ST6 | ST7 |

|---|---|---|---|---|---|---|---|

| HMA Past Name | H1 = 92-UCEBFF-3SSFF-MDI | H2 = 78-UCB-5.30 | H3 = 109-UCBFF-3SSFF-MDI; | H4 = 87-UCB-5.30 | H5 = 97-UCB-5.30 | H6 = 81-UCBFF-35SSFF- MDI | H7 = 1LOP |

| HMA Project | IASNAF | IASNAF | IASNAF | IASNAF | IASNAF | IASNAF | C.03-2023 |

| HMA mass, g | 1152.53 | 1133.07 | 1155.9 | 1150.83 | 1146.64 | 1150.99 | 1141.09 |

| White polymer, g | - | 52 | 9.45 | 9.45 | 9.45 | 9.45 | 9.45 |

| 0% | 100% | 18.17% | 18.17% | 18.17% | 18.17% | 18.17% | |

| White powder, g (40% cement + 60% quartz) | - | - | 39.11 | 37.92 | 36.72 | 30.75 | 31.94 |

| 0% | 0% | 75.21% | 72.92% | 70.62% | 59.13% | 61.42% | |

| Water, g | - | - | 3.44 | 3.33 | 3.23 | 2.70 | 2.81 |

| 0% | 0% | 6.62% | 6.40% | 6.21% | 5.19% | 5.40% | |

| Glass fibre, g | - | - | - | 1.3 | 2.6 | 1.3 | 2.6 |

| 0% | 0% | 0% | 2.5% | 5.00% | 2.50% | 5.00% | |

| Glass aggregate, g | - 0% | - | - | - | - | 7.8 | 5.2 |

| 0% | 0% | 0% | 0% | 15.00% | 10.00% | ||

| White material total, g | 0 | 52 | 52 | 52 | 52 | 52 | 52 |

| Test | Unit | Detail | Standards/References | Set Up/Literature |

|---|---|---|---|---|

| PTV* | - | Wet PTV typically 35–60 (higher = better). UK Highways minimum 36 (wet) for safety and design targets often ≥45 (low risk) or ≥60 (high risk) [54]. Note: values depend on aggregate polish and contamination. | BS 7976-2:2002/A1:2013 (pendulum test) [55]; EN 13036-4 (pendulum) [51]; ASTM E303 [56]; ISO 13473-2 (friction) [57]; PIARC Road Tunnels Manual [58]. | British Pendulum Skid Tester (e.g., Munro or James Heal “Sliptest”); GripTester (Kassel); Deighton pendulum; BPN/PSV testers (though PSV is material only); Dynamic Friction Tester (DFT). |

| MTD* | mm | 0.5–1.0 mm (new hot-mix asphalt, depends on mix); FHWA suggests 0.7 mm on high-speed roads (Lower texture 0.3–0.5 mm for old surfaces; >1.0 mm for open-graded friction courses.) [59]. | ISO 13473-1:2019 (macrotexture by sand patch) [60]; ASTM E965 [61] (AASHTO T279 [62], volumetric sand patch); EN 13036-1 (sand patch method) [52]; PIARC Road Tunnels Manual [58]; FHWA/MaST [63]. | Sand patch kit (volumetric method, e.g., ASTM sand cone); Circular Track Metre (CTM, e.g., Kj Law CTM-III or TRL CTM); laser profilers (e.g., Pavemetrics LCMS series; Dynatest/ViDiG LTS-1, Dynatest 365); high-speed texture profilers (Keyence LJ-X, LSL instruments). |

| Test | Unit | Detail | Standards/References | Device |

|---|---|---|---|---|

| Luminance | cd·m−2 | Threshold zone: 60–330 cd·m−2 (low to high speed/volume) Interior zone: 1–3 cd·m−2 in extra-urban low-speed tunnels; Exit zone often 5× interior. | CIE 088:2004 Guide for road tunnels [65]; CIE 061:1984 (tunnel entrance) [74]; ANSI/IES RP-8-22 [75]; PIARC Road Tunnels Manual [58]; EN 13201 (road lighting) [68]; | Luminance metres (e.g., Hagner S5 S/N 119; Konica Minolta LS-110/LS-100; Topcon BM-7A; Tektronix/Keysight J-17L; Dr. Lange LLG-450 “ProfiLux”); high-range lux metres; certified colorimeters. |

| Illuminance | Lux | Entrance/threshold: on the order of 500–1000 lx (daylight conditions); Interior zone: tens of lx (e.g., 30–50 lx) depending on design (lower at night); Exit zone: several times interior (often 150–250 lx) to counter daylight. | CIE 088:2004 Guide for road tunnels [65], CIE 061:1984 (tunnel entrance) [74]; ANSI/IES RP-8-22 [75]; PIARC Road Tunnels Manual [58]; EN 13201 (road lighting) [68]; | Illuminance metres/light metres (e.g., Hagner S5 S/N 119; Sekonic L-308, Extech HD450, Testo 540); many luminance metres (Konica Minolta, Topcon) can switch to lux mode; spectroradiometers. |

| Sample Condition | Illuminance (lux) | Luminance (cd·m−2) | Expected Luminance (cd·m−2) |

|---|---|---|---|

| Dark Room Conditions | |||

| White colour | 7.25 | 0.21 | 5 |

| White colour | 90.75 | 0.86 | 5 |

| Black colour | 90.14 | 0.60 | 5 |

| ST1 | 90.07 | 0.69 | 5 |

| Laboratory Conditions | |||

| ST1 | 92 | 3.28 | 5 |

| ST1 | 180 | 2.91 | 10 |

| ST1 | 270 | 3.85 | 15 |

| ST1 | 360 | 7.87 | 20 |

| White colour | 7.5 | 1.84 | 5 |

| White colour | 15 | 3.98 | 10 |

| White colour | 22.5 | 5.22 | 15 |

| White colour | 30 | 6.65 | 20 |

| White colour | 450 | 100 | - |

| Reference Checks | Reflectance (%) | ||

| Calibration reflectance—daylight | 502.2 | 117.8 | 73.69 |

| Calibration reflectance—daylight | 521.5 | 111.3 | 67.05 |

| Calibration reflectance—dark lab | 63.79 | 6.82 | 33.59 |

| General Conditions | |||

| Desk with light | 780 | 185.2 | - |

| Desk without light | 307 | 65.7 | - |

| Outdoors (sunlight) | 6680 | - | - |

| ST1—outdoors (sunlight) | - | 151.2 | - |

| ST1—with light | - | 21.5 | - |

| ST1—without light | - | 7.56 | - |

| Desk with light (repeated measure) | 819.6 | 176.2 | - |

| ST1—with light (repeated) | 853.3 | 20.85 | - |

| Different Lens (f = 500) | |||

| ST1—with light | 865.3 | 21.36 | - |

| White colour—with light | 860.4 | 200.7 | - |

| Desk with light | 821.5 | 156.7 | - |

| Calibration reflectance—with light | 843.5 | 190.5 | 70.95 |

| ID Sample | Sample Number | ) | Q0 (σ) | 95% CIs= | ) | S1 (σ) | 95% CIs= | Grade Standard (CIE) |

|---|---|---|---|---|---|---|---|---|

| ST1 | 2 | 0.0388 | 0.0065 | 0.0298–0.0478 | 0.7218 | 0.0280 | 0.6830–0.7606 | R2 |

| ST2 | 2 | 0.1884 | 0.0855 | 0.0699–0.3069 | 0.1916 | 0.1287 | 0.0132–0.3700 | R1 |

| ST3 | 2 | 0.2253 | 0.0651 | 0.1351–0.3155 | 0.1162 | 0.0192 | 0.0896–0.1428 | R1 |

| ST4 | 2 | 0.2265 | 0.0579 | 0.1463–0.3067 | 0.1548 | 0.0011 | 0.1533–0.1563 | R1 |

| ST5 | 2 | 0.2406 | 0.0778 | 0.1328–0.3484 | 0.1052 | 0.0433 | 0.0452–0.1652 | R1 |

| ST6 | 2 | 0.2182 | 0.0291 | 0.1779–0.2585 | 0.1407 | 0.0199 | 0.1131–0.1683 | R1 |

| ST7 | 2 | 0.2292 | 0.0144 | 0.2092–0.2492 | 0.1622 | 0.0442 | 0.1009–0.2235 | R1 |

| Sample Name | Luminance (cd·m−2) | Reflection Factor (RF) |

|---|---|---|

| Calibration reflectance—with light | 190.5 | 0.956 |

| Black colour—with light | 9.76 | 0.05 |

| ST1—with light | 21.36 | 0.11 |

| ST2—with light | 50.02 | 0.25 |

| ST3—with light | 144.2 | 0.73 |

| ST4—with light | 192.0 | 0.97 |

| ST5—with light | 162.8 | 0.82 |

| ST6—with light | 184.5 | 0.93 |

| ST7—with light | 166.5 | 0.84 |

| Surface Treatment | ST1 | ST2 | ST3 | ST4 | ST5 | ST6 | ST7 | |

|---|---|---|---|---|---|---|---|---|

| Indicators, Ii | LSLi | |||||||

| 1/S1 | 1.39 | 5.22 | 8.60 | 6.46 | 9.50 | 7.11 | 6.16 | 2.38 |

| Q0 | 0.04 | 0.19 | 0.23 | 0.23 | 0.24 | 0.22 | 0.23 | 0.10 |

| MTD | 0.39 | 0.34 | 1.02 | 0.93 | 1.08 | 1.02 | 0.90 | 0.40 |

| PTV | 69.95 | 35.76 | 46.45 | 74.22 | 74.93 | 69.95 | 74.93 | 58 |

| New Indicators, Ni = Ii−LSLi > 0, 0 | ||||||||

| Ref: 1/S1 | - | 2.84 | 6.22 | 4.08 | 7.12 | 4.72 | 3.78 | |

| Ref: Q0 | - | 0.09 | 0.13 | 0.13 | 0.14 | 0.12 | 0.13 | |

| Ref: MTD | - | - | 0.62 | 0.53 | 0.68 | 0.62 | 0.50 | |

| Ref: PTV | 11.95 | - | - | 16.22 | 16.93 | 11.95 | 16.93 | |

| Scaled Features (min–max normalisation), Ni’ | ||||||||

| Ref: 1/S1 | - | 0.40 | 0.87 | 0.57 | 1.00 | 0.66 | 0.53 | |

| Ref: Q0 | - | 0.63 | 0.89 | 0.90 | 1.00 | 0.84 | 0.92 | |

| Ref: MTD | - | - | 0.92 | 0.78 | 1.00 | 0.92 | 0.73 | |

| Ref: PTV | 0.71 | - | - | 0.96 | 1.00 | 0.71 | 1.00 | |

| CPj | - | - | - | 0.39 | 1.00 | 0.36 | 0.36 | |

| Ranking | Excluded | Excluded | Excluded | 2nd | 1st | 3rd | 4th | |

| Scenario | ST1 | ST2 | ST3 | ST4 | ST5 | ST6 | ST7 |

|---|---|---|---|---|---|---|---|

| All (see above) | Excluded | Excluded | Excluded | 2nd | 1st | 3rd | 4th |

| S1 out | Excluded | Excluded | Excluded | 2nd | 1st | 4th | 3rd |

| Q0 out | Excluded | Excluded | Excluded | 2nd | 1st | 3rd | 4th |

| MTD out | Excluded | Excluded | Excluded | 2nd | 1st | 4th | 3rd |

| PTV out | Excluded | Excluded | 2nd | 4th | 1st | 3rd | 5th |

| Parameter/Aspect | Relevant International Standard | Application to ST4–ST7 |

|---|---|---|

| Road surface reflection characteristics | CIE 144:2001 [64]—Road Surface and Road Marking Reflection Characteristics | ST4–ST7 can be benchmarked by measuring Q0 and S1, allowing classification relative to international reference surfaces. |

| Reference surface classes (dry conditions) | CIE 66:1984 [85]—Road Surfaces and Lighting (R1-R4 classes) | ST4–ST7 may correspond to higher-reflectance classes (closer to R1–R2) due to inclusion of reflective aggregates and fibres. |

| Reference surface classes (wet conditions) | CIE 47:1979 [86]—Road Lighting for Wet Conditions (W1–W4 classes) | Wet reflectance of ST4–ST7 can be evaluated against W-class standards to ensure no excessive specular glare in tunnels. |

| Roadway lighting performance requirements (luminance, uniformity, glare) | CIE 115:2010 [87] and EN 13201-2:2015 [69] | ST4–ST7 must enable compliance with required luminance and uniformity levels in road/tunnel lighting design. |

| Tunnel lighting design (zone-based luminance, uniformity, glare control) | CIE 88:2004 [65]—Guide for the Lighting of Road Tunnels and Underpasses | Light-coloured ST4–ST7 mixtures support energy-efficient tunnel lighting by increasing pavement luminance without excessive glare. |

| Measurement of diffuse luminance coefficient (Qd) | ASTM E2302-03a(2022) [88]—Test Method for Luminance Coefficient under Diffuse Illumination | Provides a standardised way to measure and verify the brightness of ST4–ST7 in line with international practice. |

| Design Parameters Per Zone | Permanent | Zone 1 | Zone 2 | Zone 3 | Zone 4 | Zone 5 | Zone 6 | Zone 7 |

|---|---|---|---|---|---|---|---|---|

| Reinforcement zone distance (m) | 0–750 | 0–80 | 80–115 | 115–155 | 155–200 | 200–250 | 250–350 | 350–577 |

| Design luminance (cd·m−2) | 2 | 130 | 110 | 80 | 40 | 20 | 10 | 5 |

| Surface Treatment | Potential Energy Savings (%) (Rounded to the Nearest Integer) |

|---|---|

| ST1 | - |

| ST2 | 79% |

| ST3 | 82% |

| ST4 | 82% |

| ST5 | 83% |

| ST6 | 82% |

| ST7 | 83% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Eren, E.; Mypati, V.N.K.; Praticò, F.G. Energy and Surface Performance of Light-Coloured Surface Treatments. Sustainability 2025, 17, 8902. https://doi.org/10.3390/su17198902

Eren E, Mypati VNK, Praticò FG. Energy and Surface Performance of Light-Coloured Surface Treatments. Sustainability. 2025; 17(19):8902. https://doi.org/10.3390/su17198902

Chicago/Turabian StyleEren, Ezgi, Vamsi Navya Krishna Mypati, and Filippo Giammaria Praticò. 2025. "Energy and Surface Performance of Light-Coloured Surface Treatments" Sustainability 17, no. 19: 8902. https://doi.org/10.3390/su17198902

APA StyleEren, E., Mypati, V. N. K., & Praticò, F. G. (2025). Energy and Surface Performance of Light-Coloured Surface Treatments. Sustainability, 17(19), 8902. https://doi.org/10.3390/su17198902