Effects of Dry–Wet Cycles on Permeability and Shear Strength of Yuanmou Red Clay

Abstract

1. Introduction

2. Materials and Methods

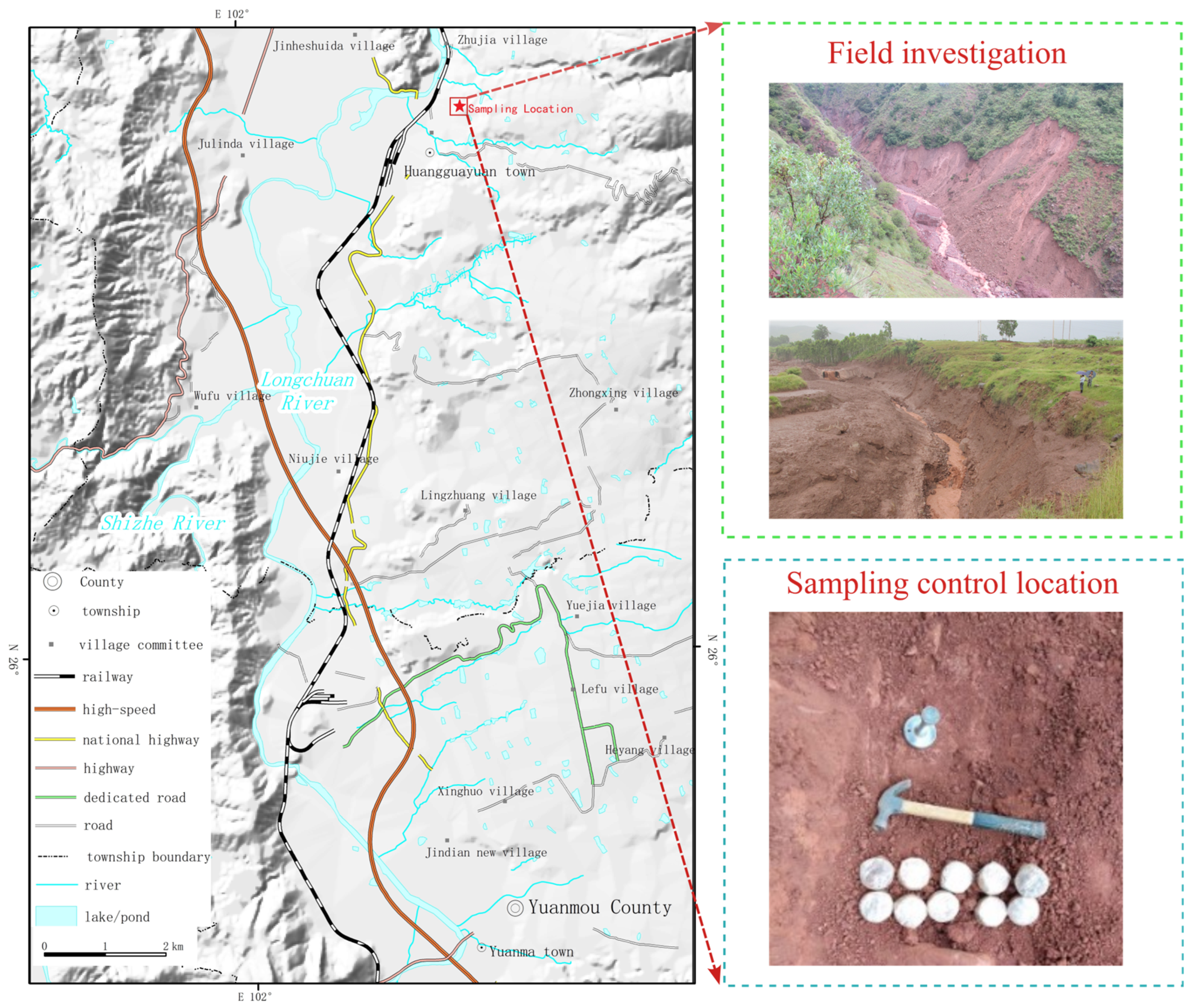

2.1. Test Material

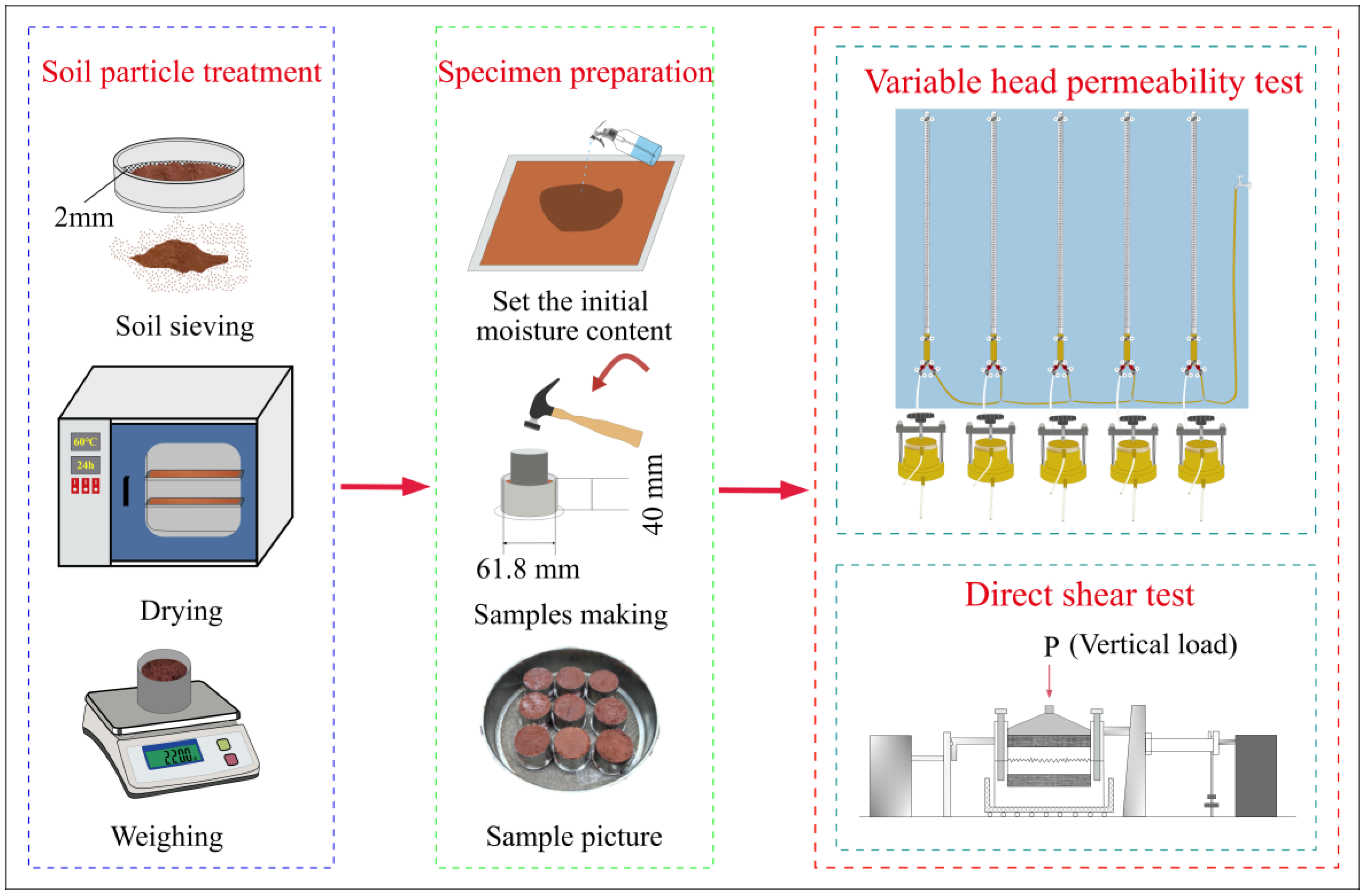

2.2. Testing Program

2.2.1. Test Procedure

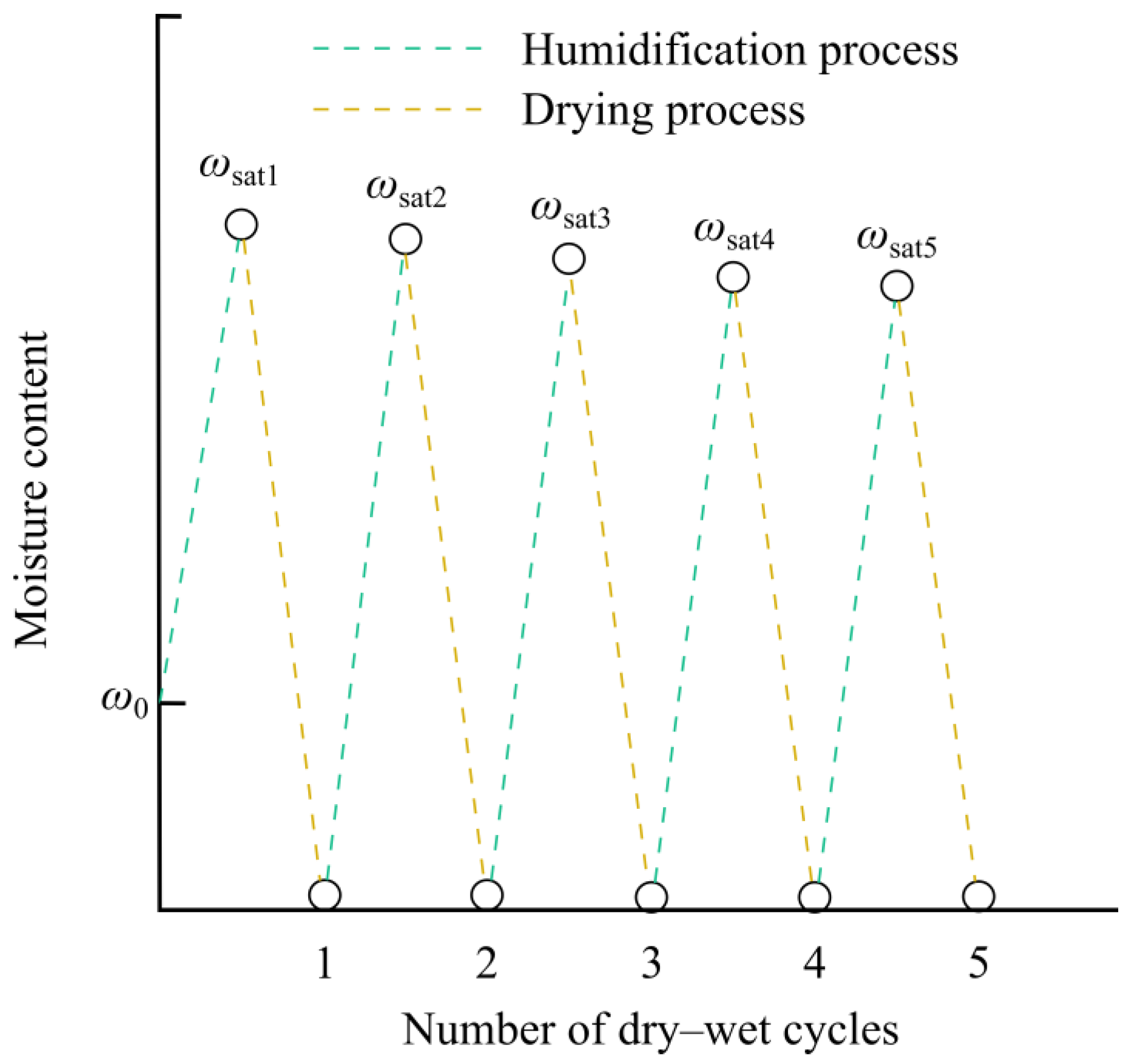

2.2.2. Dry–Wet Process

3. Results and Analysis

3.1. Variation Law of Saturated Moisture Content Under Dry–Wet Cycles

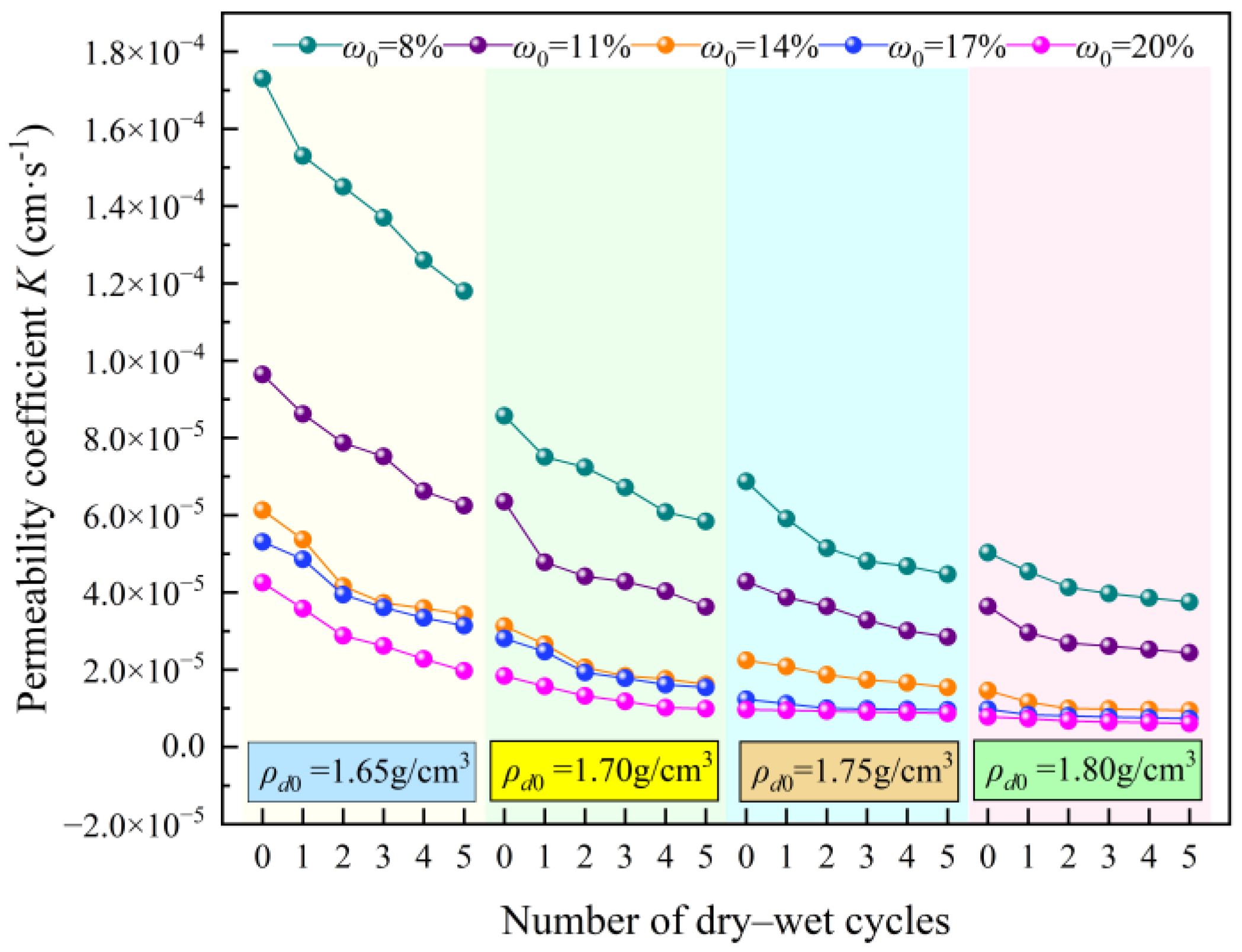

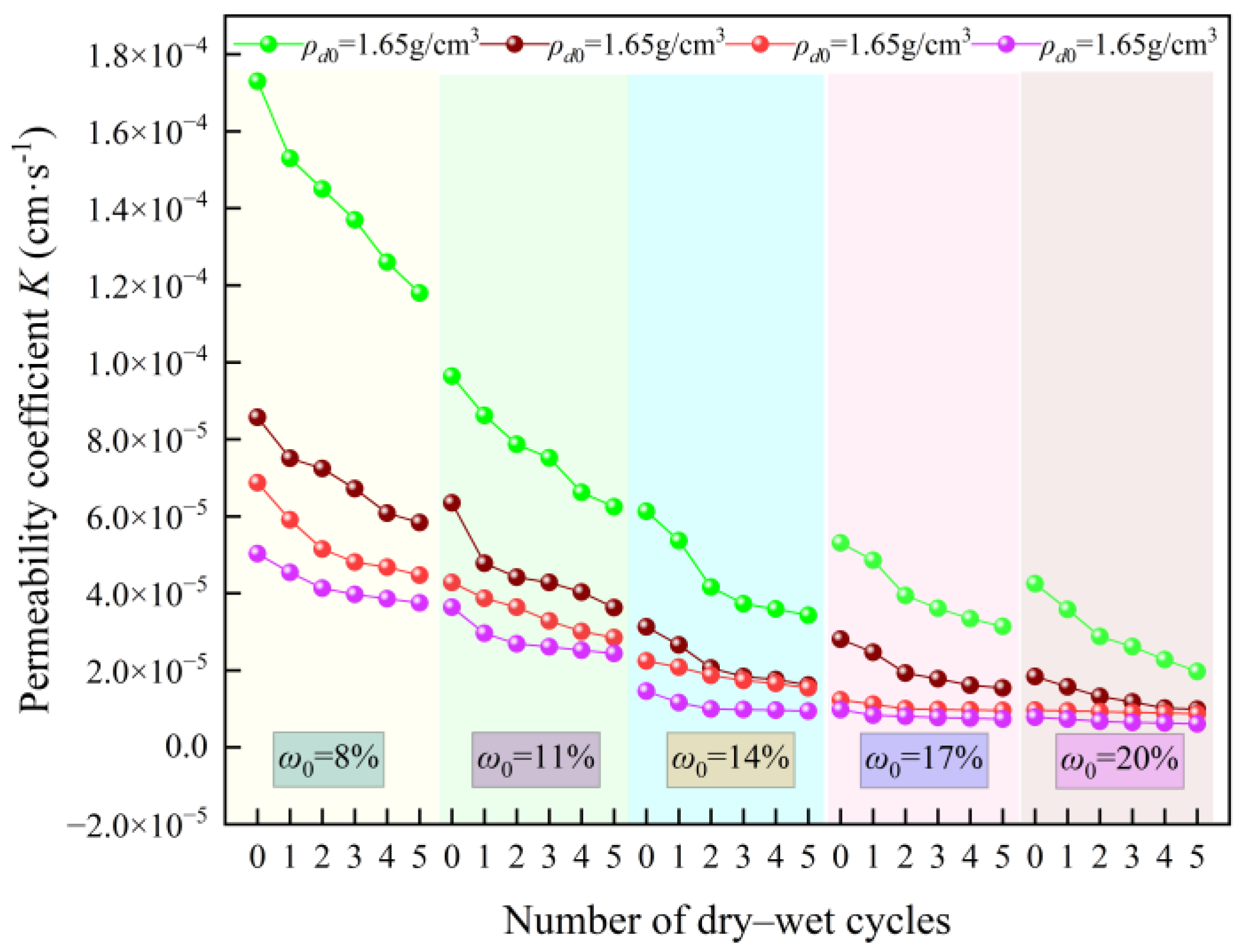

3.2. Variation Law of Permeability Coefficient Under Dry–Wet Cycling

3.3. The Law of Changes in Strength Characteristics Under the Action of Dry and Wet Cycles

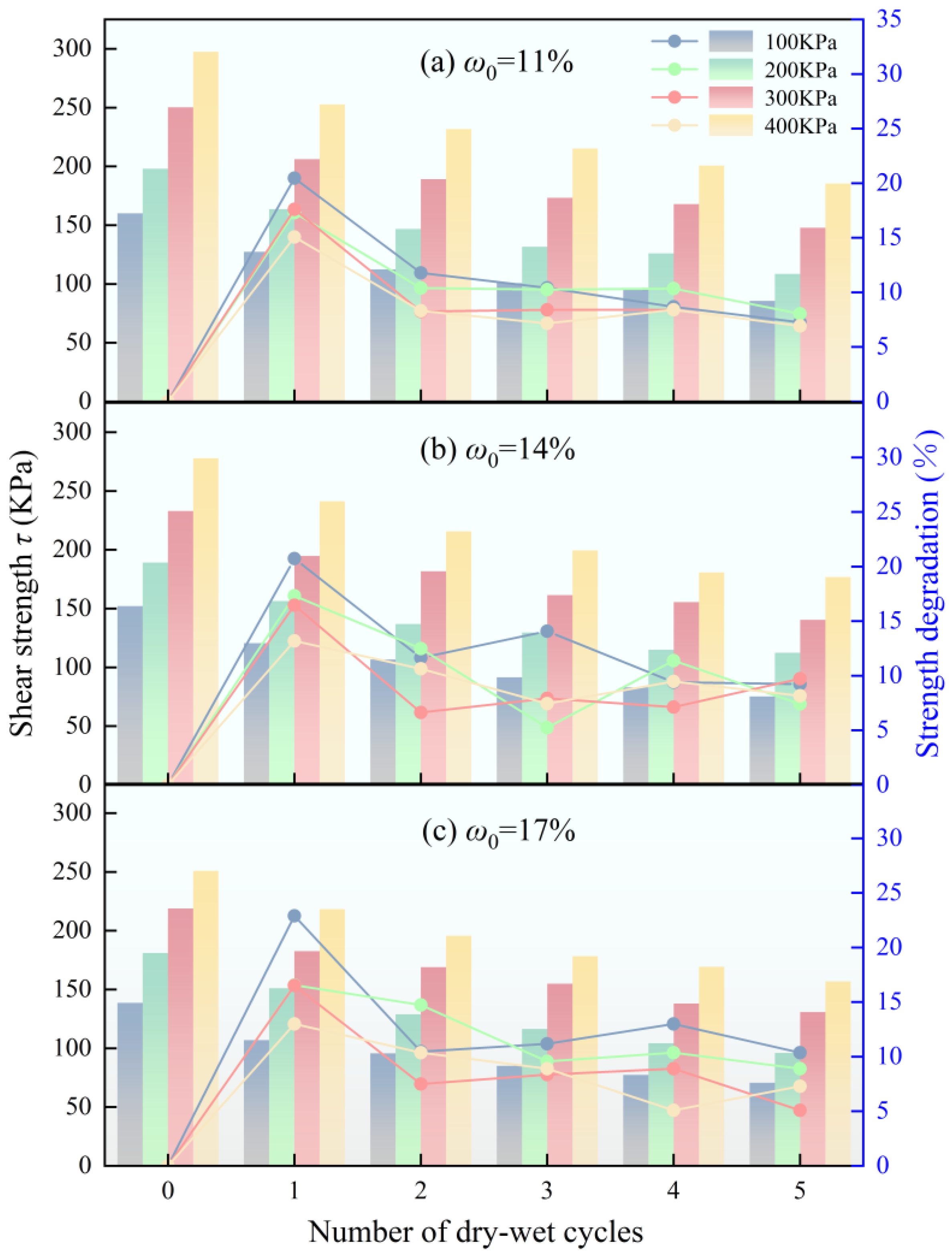

3.3.1. Characteristic Law of Shear Strength

3.3.2. Characteristic Law of Cohesion

3.3.3. Characteristic Law of Internal Friction Angle

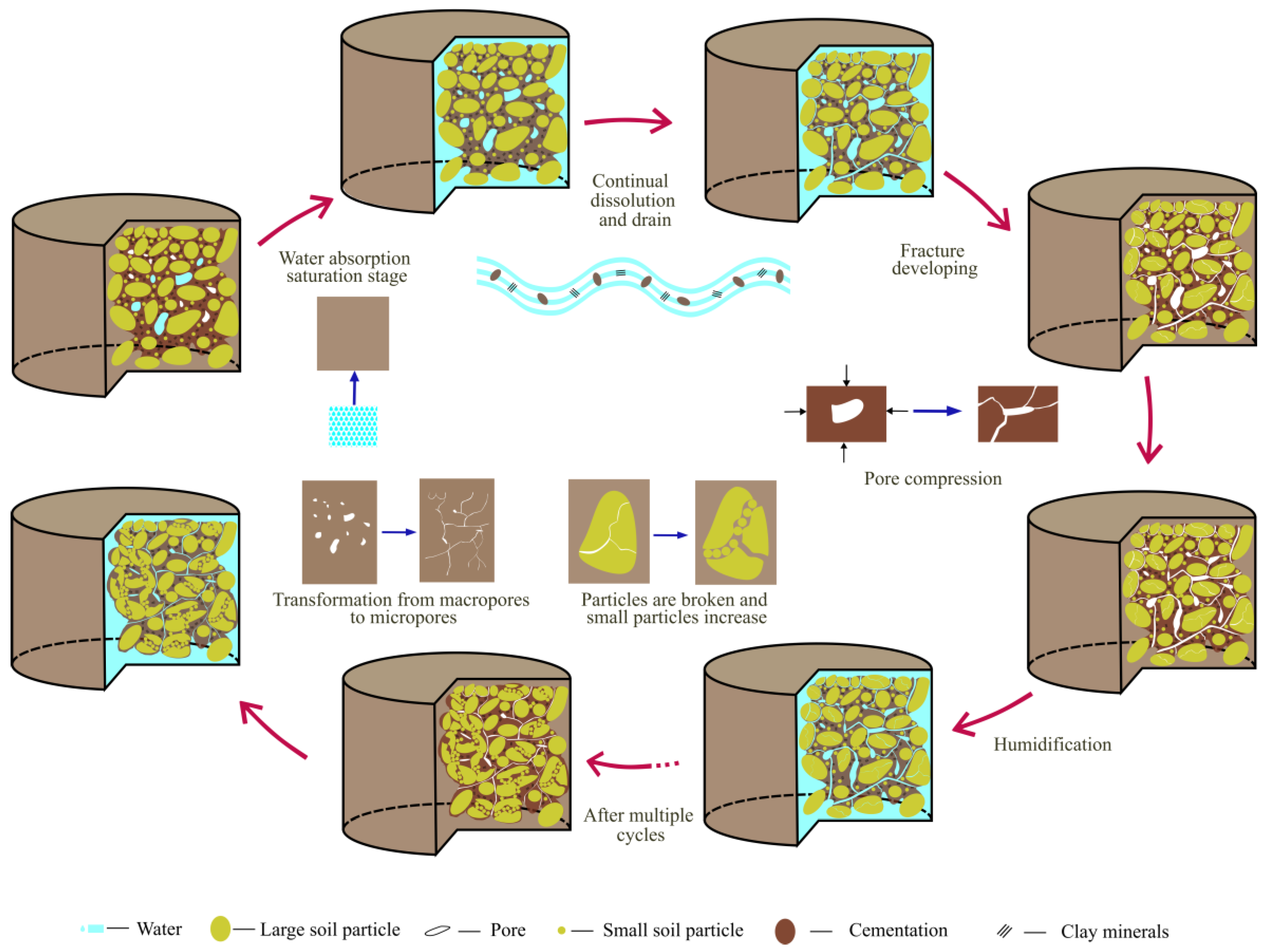

3.4. Analysis of Red Clay Degradation Mechanism Under Dry–Wet Cycles

3.5. Comparative Analysis with Previous Studies and Limitations

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Guo, J.; Xi, W.; Huang, G.; He, G.; Shi, L.; Yang, Z.; Ding, Z.; Wang, L.; Cao, R. Study on erosion deformation of dry-red soil in Yuanmou dry-hot valley with different elevation gradients based on SBAS-InSAR technology. Front. Earth Sci. 2024, 12, 1394439. [Google Scholar] [CrossRef]

- Luo, J.; Ma, X.; Wang, L.; Zhang, B.; Yang, X.; Yue, T. The influence of short-term heavy rainfall on hydraulic characteristics and rill formation in the Yuanmou dry-hot valley. Int. J. Environ. Res. Public Health 2022, 19, 15232. [Google Scholar] [CrossRef]

- Tan, P.; Wang, F.; Guo, C.; Liu, J.; Lei, Q.; Liu, Z. Performance evaluation and stabilization mechanism of red clay treated with polyurethane. Chemosphere 2023, 340, 139864. [Google Scholar] [CrossRef]

- Yang, L.; Chen, K.; Lyu, M.; Wang, Y. Study on failure of red clay slopes with different gradients under dry and wet cycles. Bull. Eng. Geol. Environ. 2020, 79, 4609–4624. [Google Scholar] [CrossRef]

- Chen, K.; Zhu, R. Study of the Deformation Characteristics for Red Clay Under Drying-Wetting Cycles; Atlantis Press: Paris, France, 2015; pp. 511–516. [Google Scholar]

- Song, Y.; Chen, X.; Wang, J.; Huang, X. Shear strength characteristics of cadmium-contaminated red clay following the analysis of dry-wet cycles and water content. Desalin Water Treat. 2021, 241, 29–34. [Google Scholar] [CrossRef]

- D’Angelo, B.; Bruand, A.; Qin, J.; Peng, X.; Hartmann, C.; Sun, B.; Hao, H.; Rozenbaum, O.; Muller, F. Origin of the high sensitivity of Chinese red clay soils to drought: Significance of the clay characteristics. Geoderma 2014, 223, 46–53. [Google Scholar] [CrossRef]

- Xie, Y.; Zhang, B.; Liu, B.; Zeng, Z.; Zhang, Y.; Zheng, Y. Shrinkage cracking and strength deterioration of red clay under cyclic drying and wetting. Alex. Eng. J. 2022, 61, 2574–2588. [Google Scholar] [CrossRef]

- Ma, H.; Pei, C.; Huang, R.; Xu, S. Crack evolution and strength attenuation of red clay under dry–wet cycles. J. Mater. Civ. Eng. 2024, 36, 04024045. [Google Scholar] [CrossRef]

- Chen, D.; Hou, X.; Wu, C. Investigation of red clay internal stress anisotropy and influence factors. Appl. Sci. 2024, 14, 5592. [Google Scholar] [CrossRef]

- Tang, H.; Yang, Z.; Zhu, H.; Dong, H. Experimental study on the mechanical properties of Xinyang red clay improved by lime and fly ash. Appl. Sci. 2023, 13, 6271. [Google Scholar] [CrossRef]

- Yuan, K.; Ni, W.; Lü, X.; Wang, X. Permeability characteristics and structural evolution of compacted loess under different dry densities and wetting-drying cycles. PLoS ONE 2021, 16, e0253508. [Google Scholar] [CrossRef] [PubMed]

- Jing, J.; Hou, J.; Sun, W.; Chen, G.; Ma, Y.; Ji, G. Study on influencing factors of unsaturated loess slope stability under dry-wet cycle conditions. J. Hydrol. 2022, 612, 128187. [Google Scholar] [CrossRef]

- Zhou, B.; Wu, Y.; Chan, J.; Wang, S.; Qiao, Z.; Hu, S. Wetting–drying cycles enhance the release and transport of autochthonous colloidal particles in Chinese loess. Hum. Ecol. Risk Assess. Int. J. 2019, 25, 335–353. [Google Scholar] [CrossRef]

- An, R.; Kong, L.; Zhang, X.; Li, C. Effects of dry-wet cycles on three-dimensional pore structure and permeability characteristics of granite residual soil using X-ray micro computed tomography. J. Rock Mech. Geotech. Eng. 2022, 14, 851–860. [Google Scholar] [CrossRef]

- Albrecht, B.A.; Benson, C.H. Effect of desiccation on compacted natural clays. J. Geotech. Geoenviron. Eng. 2001, 127, 67–75. [Google Scholar] [CrossRef]

- Yang, H.; Huang, Y.; Zhou, D.; Li, J.; Tang, S. The effect of drying-wetting cycle on the permeability of yunnan laterite. Sci. Technol. Eng. 2019, 19, 289–297. (In Chinese) [Google Scholar]

- Chen, C.; Zhang, C.; Liu, X.; Pan, Y.; Jia, P. Effects of freeze-thaw cycles on permeability behavior and desiccation cracking of Dalian red clay in China considering saline intrusion. Sustainability 2023, 15, 3858. [Google Scholar] [CrossRef]

- Wan, Y.; Xue, Q.; Zhao, L.; Du, Y.; Liu, L. Effects of wetting-drying cycles on permeability of compacted clay cover at landfill site. Rock Soil Mech. 2015, 36, 679–686. (In Chinese) [Google Scholar]

- Ivoke, J.; Khan, M.S.; Nobahar, M. Unsaturated hydraulic conductivity variation of expansive Yazoo clay with wet-dry cycles. Transp. Res. Rec. 2021, 2675, 629–641. [Google Scholar] [CrossRef]

- Wang, J.; Ma, R.; Zhang, X. Effect of Fissure Development of Collapsed Soils on Their Permeability Under Dry-wet Cycle. J. Soil Water Conserv. 2021, 35, 90–95. [Google Scholar]

- Louati, F.; Trabelsi, H.; Jamei, M.; Taibi, S. Impact of wetting-drying cycles and cracks on the permeability of compacted clayey soil. Eur. J. Environ. Civ. Eng. 2021, 25, 696–721. [Google Scholar] [CrossRef]

- Qi, Y.; Bai, M.; Zhou, H.; Shi, H.; Li, P.; He, B. Study on the Mechanical Properties of Red Clay under Drying-Wetting Cycles. Adv. Mater. Sci. Eng. 2021, 2021, 8665167. [Google Scholar] [CrossRef]

- Chang, J.; Ma, J.; Tang, X. Study on Strength Attenuation Characteristics of Residual Expansive Soil under Wetting-Drying Cycles and Low Stress and Its Relationship with Shallow Landslide. Geofluids 2022, 2022, 6277553. [Google Scholar] [CrossRef]

- Ding, J.; Wang, S.; Huang, H.; Pan, F.; Wu, Y.; Gu, Y.; Zhang, Y. Prediction model of residual soil shear strength under dry–wet cycles and its uncertainty. Water 2023, 15, 3931. [Google Scholar] [CrossRef]

- Jimoh, Y.A. Shear Strength/Moisture Content Models for a Laterite Soil in Ilorin, Kwara State, Nigeria; IOS Press: Osaka, Japan, 2005; pp. 521–525. [Google Scholar]

- Chen, R.; Xu, T.; Lei, W.; Zhao, Y.; Qiao, J. Impact of multiple drying–wetting cycles on shear behaviour of an unsaturated compacted clay. Environ. Earth Sci. 2018, 77, 683. [Google Scholar] [CrossRef]

- Liu, W.; Tang, X.; Yang, Q.; Li, W. Influence of drying/wetting cycles on the mechanical cyclic behaviours of silty clay. Eur. J. Environ. Civ. Eng. 2015, 19, 867–883. [Google Scholar] [CrossRef]

- Luo, S.; Huang, D.; Peng, J.; Liu, F.; Gao, X.; Tomás, R. Influencing of drying-wetting cycles on mechanical behaviors of silty clay with different initial moisture content. Geomech. Eng. 2024, 38, 307–317. [Google Scholar]

- Hao, R.; Zhang, Z.; Guo, Z.; Huang, X.; Lv, Q.; Wang, J.; Liu, T. Investigation of changes to triaxial shear strength parameters and microstructure of yili loess with drying–wetting cycles. Materials 2021, 15, 255. [Google Scholar] [CrossRef] [PubMed]

- Wang, M.; Liu, Q.; Zhang, L.; Li, Y.; Xu, X. Experimental investigation on strength behavior and microstructure of unsaturated net-like red soil. Arab. J. Geosci. 2021, 14, 2722. [Google Scholar] [CrossRef]

- Xie, W.; Liu, Z.; Kong, Z.; Jing, L.; Xiao, R. A multi-scale investigation of sandy red clay degradation mechanisms during wet–dry cycles and their implications for slope stability. Appl. Sci. 2025, 15, 4085. [Google Scholar] [CrossRef]

| Natural Density (g·cm−3) | Liquid Limit (%) | Plastic Limit (%) | Soil Classification | Specific Gravity | Optimum Moisture Content (%) | Maximum Dry Density (g·cm−3) |

|---|---|---|---|---|---|---|

| 1.94 | 37 | 24 | CL | 2.707 | 14 | 1.85 |

| Test Type | Initial Dry Density (g/cm3) | Initial Moisture Content (%) | Number of Dry–Wet Cycles |

|---|---|---|---|

| Variable-Head Permeability Test | 1.65, 1.70, 1.75, 1.80 | 8, 11, 14, 17, 20 | 0, 1, 2, 3, 4, 5 |

| Direct Shear Test | 1.65, 1.70, 1.75, 1.80 | 11, 14, 17 | 0, 1, 2, 3, 4, 5 |

| Initial Dry Density (g/cm3) | Initial Moisture Content (%) | Void Ratio e | Degree of Saturation Sr (%) |

|---|---|---|---|

| 1.65 | 8 | 0.641 | 33.8 |

| 1.65 | 11 | 0.641 | 46.5 |

| 1.65 | 14 | 0.641 | 59.1 |

| 1.65 | 17 | 0.641 | 71.8 |

| 1.65 | 20 | 0.641 | 84.5 |

| 1.70 | 8 | 0.592 | 36.6 |

| 1.70 | 11 | 0.592 | 50.3 |

| 1.70 | 14 | 0.592 | 64.0 |

| 1.70 | 17 | 0.592 | 77.8 |

| 1.70 | 20 | 0.592 | 91.5 |

| 1.75 | 8 | 0.547 | 39.6 |

| 1.75 | 11 | 0.547 | 54.4 |

| 1.75 | 14 | 0.547 | 69.3 |

| 1.75 | 17 | 0.547 | 84.1 |

| 1.75 | 20 | 0.547 | 99.0 |

| 1.80 | 8 | 0.504 | 43.0 |

| 1.80 | 11 | 0.504 | 59.1 |

| 1.80 | 14 | 0.504 | 75.2 |

| 1.80 | 17 | 0.504 | 91.3 |

| 1.80 | 20 | 0.504 | 107.4 |

| Number of Dry–Wet Cycles | Cohesion (KPa) | Percentage of Attenuation Compared with No Dry–Wet Cycle | ||||

|---|---|---|---|---|---|---|

| ω0 = 11% | ω0 = 14% | ω0 = 17% | ω0 = 11% | ω0 = 14% | ω0 = 17% | |

| 0 | 114.55 | 108 | 100.71 | 0% | 0% | 0% |

| 1 | 82.84 | 77.5 | 71.27 | 27.68% | 28.24% | 29.23% |

| 2 | 69.85 | 66.89 | 60.88 | 39.02% | 38.06% | 39.55% |

| 3 | 58.95 | 56.59 | 52.64 | 48.54% | 47.60% | 47.73% |

| 4 | 54.64 | 48.56 | 44.93 | 54.92% | 55.96% | 55.39% |

| 5 | 47.12 | 43.52 | 40.52 | 58.87% | 59.70% | 59.77% |

| Number of Dry–Wet Cycles | Internal Friction Angle (°) | Percentage of Attenuation Compared with No Dry–Wet Cycle | ||||

|---|---|---|---|---|---|---|

| ω0 = 11% | ω0 = 14% | ω0 = 17% | ω0 = 11% | ω0 = 14% | ω0 = 17% | |

| 0 | 24.64 | 22.67 | 20.53 | 0% | 0% | 0% |

| 1 | 22.62 | 21.83 | 19.54 | 3.63% | 8.21% | 8.21% |

| 2 | 21.83 | 20.41 | 18.05 | 11.40% | 9.97% | 12.08% |

| 3 | 21.05 | 19.57 | 18.19 | 14.57% | 13.67% | 11.40% |

| 4 | 19.56 | 18.66 | 17.69 | 20.62% | 17.69% | 13.83% |

| 5 | 18.65 | 18.11 | 16.33 | 24.31% | 20.11% | 20.46% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, J.; Liu, F.; Yang, Y.; Yang, Z.; Zi, Z.; Ding, Q.; Wang, G.; Zhang, W.; Dai, X.; Liang, Y.; et al. Effects of Dry–Wet Cycles on Permeability and Shear Strength of Yuanmou Red Clay. Sustainability 2025, 17, 8900. https://doi.org/10.3390/su17198900

Zhang J, Liu F, Yang Y, Yang Z, Zi Z, Ding Q, Wang G, Zhang W, Dai X, Liang Y, et al. Effects of Dry–Wet Cycles on Permeability and Shear Strength of Yuanmou Red Clay. Sustainability. 2025; 17(19):8900. https://doi.org/10.3390/su17198900

Chicago/Turabian StyleZhang, Jie, Fucai Liu, Yi Yang, Zhiquan Yang, Zhong Zi, Qiuyue Ding, Guanqun Wang, Wenjun Zhang, Xusheng Dai, Yilin Liang, and et al. 2025. "Effects of Dry–Wet Cycles on Permeability and Shear Strength of Yuanmou Red Clay" Sustainability 17, no. 19: 8900. https://doi.org/10.3390/su17198900

APA StyleZhang, J., Liu, F., Yang, Y., Yang, Z., Zi, Z., Ding, Q., Wang, G., Zhang, W., Dai, X., Liang, Y., & Liu, G. (2025). Effects of Dry–Wet Cycles on Permeability and Shear Strength of Yuanmou Red Clay. Sustainability, 17(19), 8900. https://doi.org/10.3390/su17198900