Abstract

Sustainability is gaining relevance across organizations, yet significant challenges remain in how it is implemented and translated into daily operations. This paper examines how Lean Six Sigma can be used to address operational challenges while also supporting the integration of sustainability objectives in industrial contexts. The study is based on a project conducted in a fish processing plant, aiming to increase production capacity and reduce delays. Using the DMAIC framework, the team addressed key bottlenecks through demand-based workload leveling, earlier production planning, and targeted maintenance to improve equipment performance. These actions led to measurable gains in throughput, resource use, and schedule reliability. In parallel, they contributed to sustainability outcomes, including reduced rework, lower waste, and improved working conditions. The results suggest that Lean Six Sigma, typically focused on performance, can also act as a platform for embedding sustainability into existing routines. The findings offer insight into how performance-driven approaches can support sustainability transitions in process-intensive industries.

1. Introduction

Sustainability presents a multidisciplinary challenge that requires the involvement of varied technical domains and professional profiles. It spans areas such as operations management, engineering, environmental science, and organizational strategy. However, it is not solely a technical matter—it also demands a shift in organizational priorities and an adaptation of everyday practices, making it equally a cultural and structural challenge. To support this transition, we argue that sustainability goals and language must be integrated into the existing routines and practices that already shape how work is organized and decisions are made. Within this scope, continuous improvement initiatives—and in particular, Lean Six Sigma projects—may serve as effective vehicles for initiating this change [1]. Given their established presence in many industrial settings and their focus on measurable performance gains, these initiatives provide a context in which sustainability practices can be introduced pragmatically, aligned with existing operational logic, and gradually normalized as part of the organization’s way of working.

Lean Six Sigma has proven to be key in providing organizations, regardless of their business activity, with structured principles, methodologies, and tools to enhance their organizational results, especially regarding quality and productivity [2,3]. The use of these approaches has been noted in organizations from the most varied sectors of activity, in different parts of the world. Lean Six Sigma has thus become the most popular strategy for deploying continuous and quality improvement programs in the manufacturing, service, and process sectors. Likewise, it has been suggested that Lean Six Sigma offers a pragmatic way to align operational improvement with broader sustainability goals [1]. However, the number of existing studies regarding the inclusion of a sustainability perspective in Lean Six Sigma application remains scarce.

In this paper, we describe an application of a Lean Six Sigma project in a fish processing plant in order to improve operational and sustainability performance. The food industry, given its resource intensity, supply chain complexity, and waste generation, represents a prime context for initiatives that link operational improvement with sustainability objectives. We outline these efforts by presenting the activities that were carried out during each phase of the DMAIC roadmap. This plant is responsible for supplying more than 60 stores belonging to a multinational retail chain operating in Portugal. The need for the project was raised since the demand was growing in most of the existing stores and by the opening of new stores foreseen in the expansion plan in progress at the time. This increase in demand caused a supply constraint on the part of the fish processing plant, which on some days could not process all the orders for packaged fish from the stores on time. The project increased production capacity by more than 20%, corresponding to a gain equivalent to one month’s work.

The project’s design and results reflect the company’s priorities, which were centered on operational performance. However, and by framing sustainability within the operational improvements that the company was already committed to, the research team was able to introduce sustainability as a complementary dimension. This pragmatic alignment created the conditions for sustainability considerations to enter the organizational agenda. As such, the results of this work are important for both science and practice, as they reinforce the idea that Lean Six Sigma projects may be used to go beyond the productivity perspective and be used to promote a sustainability mindset in an organization.

The paper is organized into four main sections. Section 2 is a literature review on Lean, Six Sigma, and Lean Six Sigma, including the research conducted in Portugal on the subject. This literature review will focus on the application of Lean and/or Six Sigma to the food industry. The case study is presented and described throughout Section 3 and Section 4, as well as the discussion of its results and its practical implications. Finally, the conclusions of this paper are summarized in Section 5.

2. Literature Review

2.1. Lean Management, Six Sigma and Lean Six Sigma

Both Lean and Six Sigma were developed from the Japanese-style Total Quality Management (TQM), known as Company-Wide Quality Control (CWQC) [4,5]. Despite their unique histories and development cycles, they have become more and more integrated since the late 1990s and early 2000s [3,6,7].

While Six Sigma focuses on reducing process variability and enhancing process control, Lean drives out waste and promotes work standardization and greater efficiency in the process flows [3]; however, it is often considered that there is drawback in applying Lean or Six Sigma alone, therefore inhibiting the reach of the improvement rates that the combined use of both approaches can achieve [4,8]. Adding Lean tools to the well-structured DMAIC methodology strengthens and streamlines the toolbox available to develop improvement initiatives [9]. In addition to this, Six Sigma projects can be identified and selected from the value stream management activities [7]. Different works have studied the similarities and differences between Lean and Six Sigma attending to a set of dimensions, having proposed specific integrated models [10,11,12]. Across several studies, it was concluded that the adoption of Lean Six Sigma has grown significantly not only in the manufacturing environment, but also in some service sectors, such as finance and healthcare, while the number of published research papers on the topic is still growing [13,14,15]. One particular study, focused on the evolution of Lean Six Sigma over the years and its implementation in organizations, has also explored emerging future trends on the topic, namely its view as a holistic improvement strategy and methodology and how big data can be adopted to solve problems [7].

Big data analytics is crucial in Industry 4.0; hence, many authors have explored existing linkages, synergies, and challenges among Lean Six Sigma and Industry 4.0 [16,17,18,19,20,21]. Recent systematic literature review articles authored by provide state-of-the-art knowledge on the subject [22,23,24,25]. The concept of “Quality 4.0” (Q4.0) is related to the application of technologies and tools originating from Industry 4.0 to the areas of engineering and quality management [26], where recent technologies, such as Big Data, Blockchain and Machine Learning, are being integrated with traditional quality practices [27], including Lean and Six Sigma [28,29]. It has also been examined how Q4.0 can enhance the effectiveness of the DMAIC roadmap used in Lean Six Sigma projects [30], and critical success factors for Lean Six Sigma using Q4.0 were identified and discussed [31].

For quite some time, the application of Lean and Six Sigma has been confined to industrial environments [32,33], but over the last two decades, case studies illustrating practical applications of Lean and/or Six Sigma initiatives in various business sectors have been reported in academic journals [14,34,35], including implementations in non-manufacturing companies [3,36]. Despite this, researchers tend to focus on conceptual frameworks for the implementation of Lean Six Sigma, whereas validation through case studies seems to be lacking [15].

Still, a published literature review reveals that case study-related publications have increased over the last few years [35]. Similar works conclude that the majority of Lean Six Sigma published case studies are mainly limited to finance, healthcare, and manufacturing environments [13,15,35].

2.2. Lean, Six Sigma and Green Management

One emergent issue that has arisen over the last few years concerns the relationship between Lean, Six Sigma and Green management [37,38,39], and even more recently between Green, Lean, and Six Sigma [40,41,42]. Green Lean Six Sigma has emerged in the Industry 4.0 era as a business strategy contributing to the circular economy [43], and a model has been proposed to integrate Green Lean Six Sigma and Industry 4.0 to enhance organizational sustainability [41].

Sustainability has become a central priority for organizations seeking to reduce their environmental impact while maintaining economic and social value creation. Within this context, the integration of Lean, Six Sigma, and Green practices offers a powerful approach to simultaneously improve efficiency, quality, and environmental outcomes. Lean focuses on the systematic elimination of waste [1]. Six Sigma complements this by targeting process variability and improving consistency through data-driven problem-solving [44]. Combined, Lean Six Sigma (LSS) enables organizations to optimize processes while achieving high levels of performance and customer satisfaction.

The “Green” dimension introduces sustainability goals into this operational improvement framework. When aligned with Lean and Six Sigma, Green initiatives enhance environmental stewardship by minimizing emissions, resource use, and waste generation. Yet, the integration is not always seamless. For instance, JIT practices in Lean may lead to increased transportation and carbon emissions, and upgrading to more sustainable technologies may generate short-term costs [45]. Despite these trade-offs, the potential for synergy is significant. Research has shown that organizations applying LSS with a sustainability lens can realize substantial benefits—such as reductions in energy use, waste, and environmental impact—without compromising productivity [46,47]. Moreover, the use of digital tools and green technologies further amplifies these gains, particularly in manufacturing and logistics [48,49]. However, a gap remains in empirical studies that evaluate the Lean–Six Sigma–Green triad across service and manufacturing environments, where complexities and stakeholder dynamics differ from traditional industrial settings [50,51]. The integration of Lean, Six Sigma, and Green practices holds particular relevance for the food industry, where operational efficiency, quality control, and sustainability are critical. Studies have shown that Lean Six Sigma can significantly reduce resource and food waste in production [44]. To that end, this study looks in to this industry in particular and advances a practical case illustrating how Lean and Six Sigma methods, when informed by sustainability principles, can support systemic improvements that are both operationally effective and environmentally responsible.

2.3. Lean Six Sigma, Sustainability, and the Food Industry

The food production industry is a sector that deals with high demand uncertainty, perishable products, and quality assurance requirements to deliver safe and competitive products to powerful retailers and demanding customers [52]. It is characterized as being highly competitive, forcing companies to reduce their waste, cost, and increase their efficiency [53,54]. Improvement methodologies such as Lean, and Six Sigma, or their combined utilization in this sector can be useful for such purposes [55].

The food industry has not been excluded from implementing Lean Six Sigma initiatives [56], albeit the number of published articles and case studies remains low [35,57]. The specific characteristics of the food industry may be a constraining factor that affects the implementation of some Lean Six Sigma practices [58]. The predominance of SMEs in the sector could also be a constraining factor for the implementation of Lean and/or Six Sigma [59]. In a contrary opinion it has been argued that manufacturing concepts like Lean principles, production systems, and mass customization principles can easily be applied to the food industry as well [60].

The spread of Lean and/or Six Sigma in food industries is much less when compared to other sectors because of the lack of awareness and business benefits that Lean Six Sigma could offer to these industries, especially in terms of sustainability [13]. Lean Six Sigma (LSS) offers a valuable framework for addressing sustainability challenges by systematically eliminating waste and improving process efficiency. Traditionally applied to enhance operational performance, LSS aligns particularly well with the pressing issue of food waste, especially in the retail sector. Lean focuses on the removal of non-value-adding activities [61], making it inherently compatible with sustainability efforts.

In recent years, the environmental and social impact of food loss has driven stakeholders—including retailers, governments, and NGOs—to adopt various strategies such as regulatory measures, innovative business models, and consumer education [62,63,64]. Initiatives range from redesigning packaging to legislation that prevents the disposal of edible goods [65]. LSS, when integrated with sustainability objectives, may support these efforts by providing structured tools to identify root causes, reduce inefficiencies, and foster continuous improvement in environmentally responsible ways.

We conducted a careful literature review about the adoption or application of Lean and/or Sigma in the food processing industry, the results being summarized in Table 1. Based on this review, we can conclude the following:

Table 1.

Evolution of papers on Lean and/or Six Sigma in the food industry.

- The first published academic article regarding the use of Six Sigma in the food industry can only be traced back to 2004, while the first one focusing on the application of Lean to this sector occurred one year later in 2005. Until 2013, academic publications only referred to isolated applications of Lean or Six Sigma to the food processing industry [52].

- Of the papers published in academic journals between 2004 and 2023, about half of them refer to the simultaneous use of Lean and Six Sigma.

- The number of papers published on Lean Six Sigma applied to the food industry has significantly increased in the last few years.

- Just over half of the published papers fall into the “case study” category, so the number of reports of new empirical evidence remains limited.

- Regarding the food industry typology, the category that is related to fish processing is only represented by two articles.

- Only 3 of the works present projects where a clear alignment is made between sustainability and operational performance goals.

This review of prior research confirms that the application of Six Sigma in the fish processing industry remains scarce; while also highlighting how there with very few contributions addressing the joint use of Six Sigma (or Lean six Sigma) and sustainability in the food industry at large. Most existing studies concentrate either on general manufacturing contexts or on operational efficiency, without systematically incorporating sustainability dimensions. The combined integration of Six Sigma, Lean Six Sigma, and sustainability—particularly with reference to food and fish processing—has received almost no attention in the literature. This gap underscores the relevance of the present study, which explores how Lean Six Sigma can be applied in this specific sector while also aligning improvements with sustainability goals.

3. Case Study

The case study was organized around the five stages of the DMAIC roadmap. Each one of them is described after the problem that led to the project selection is stated.

The project took place in a fish processing plant, which is on the central coast of Portugal next to a fishing auction. The plant infrastructure is part of a logistics platform used to prepare and supply the stores of a large food retail chain in the country. Production activities take place only on working days, from Monday to Friday.

The operations of fresh fish reception, processing, and packaging are ensured by the retailer’s personnel; however, all the activities taking place downstream, namely the separation of the processes product already packed according to the store to be sent for, palletization of the packages, and place these pallets in the containers attached to the lorries that will distribute the products to the stores.

3.1. Problem Statement

For the past few years, with the implementation of a new strategic plan that envisaged the opening of a set of new stores, overall customer demand for products in the fishmonger’s section increased significantly, with growth levels of around 10% being observed. This growth brought along new challenges:

- The late arrival of trucks with the supplied product to the stores causes a delay in the restocking process with a potential negative impact on stockouts in the supermarket shelves. These delays also compromise efforts to maintain cold chain integrity, which is vital not only for food safety but also for reducing spoilage and food waste.

- Complaints by a local partner (due to overtime) that is responsible for sorting the packaged product units by the various stores, palletizing them, and putting them onto lorries that will make the delivery. In light of these challenges, the project also began to assess the social sustainability of work practices, considering how scheduling and workloads affect external partners.

As part of the broader strategic shift, the opportunity to progressively integrate sustainability goals into operational improvement projects was identified. Rather than imposing top-down directives, the approach has been to embed sustainability incrementally, aligning specific project objectives with selected Sustainable Development Goals (SDGs). This method allows teams to maintain a focus on tangible process outcomes—such as efficiency, quality, and reliability—while gradually building awareness of their environmental and social impacts. Over time, this strategy is expected to foster a culture of sustainability, where considerations such as resource efficiency, fair working conditions, and responsible production practices become integral to decision-making at all levels.

3.2. Define Phase

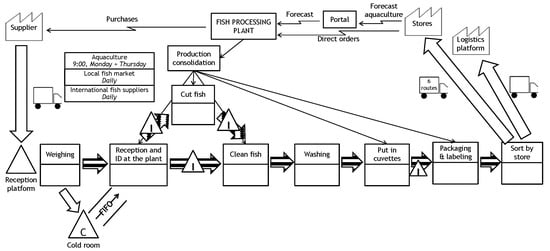

To understand the end-to-end process and its inherent flows, the project team drew the current state map using a Value Stream Mapping (VSM), which is depicted in Figure 1. The use of VSM can comprise the whole DMAIC roadmap. The bottleneck of product flow was in the packaging and labeling operations since the accumulation of work-in-progress inventory occurred in this location. Beyond identifying process inefficiencies, the VSM analysis also enabled the team to surface potential risks to economic and social sustainability, such as increased overtime costs, uneven workload distribution, and operational strain on personnel. Addressing these elements early on was seen as essential not only for improving productivity but also for fostering more resilient and equitable working conditions throughout the process chain.

Figure 1.

VSM of the current state of the fish processing operations.

The delaying problem is felt in the “sort by store” operation that is performed by the local partner company. To avoid such delay, all upstream processing tasks that occur in the plant, from “weighing” to “packaging and labeling”, should already be finalized by 9:30 p.m. Having a formal and visual depiction of the process was important to align all team members and to comprehend where to focus: the operation corresponding to the bottleneck. At this point of the methodology, it is also relevant to determine measurable critical-to-quality (CTQ), critical-to-cost (CTC), or critical-to-delivery (CTD) characteristics, by which it can be determined whether the performance of the process has improved. Since time and capacity are the parameters of interest that will determine the success or failure of the project, the measurable characteristic to be optimized falls into the “delivery” case. The CTDs that were defined are the following:

- CTD1: Average amount of daily processed fish until 6:00 p.m. [kg].

- CTD2: Average daily time for production closure [clock time].

- CTD3: Proportion of times when production closes no later than 9.30 p.m. [%].

The company has an internal objective of completing at least 70% of the day’s planned production by 6:00 p.m. Meeting this target supports timely completion by 9:30 p.m., while also helping reduce overtime costs and promote more balanced working hours for both in-house and partner teams.

Besides the CTDs, two sets of goals were defined based on Sustainability and Operational. One was to improve operations in general, with a focus on Overall Equipment Effectiveness (OEE). The second was the framing of the project within a broader sustainability perspective, and the alignment between the project objectives and the UN’s Sustainable Development Goals.

OEE is a metric from Total Productive Maintenance (TPM) that is a function of equipment availability, process performance, and quality yield. Improvements in OEE contribute to both economic and environmental sustainability by maximizing resource utilization and reducing process-related waste. It helps identify losses and improvement opportunities by evaluating three core dimensions:

- Availability: accounts for downtime losses, such as breakdowns or setup time.

- Performance: captures speed losses, like reduced operating speed or brief stops.

- Quality: covers quality losses, including scrap, defects, or reprocessing.

Finally, and from the sustainability perspective, defining Sustainable Development Goals (SDG) in an industrial improvement project provides a structured way to align operational performance with broader sustainability commitments. In the context of a fish processing plant, where resource flows, labor conditions, and supply chain dynamics intersect. In this project, contributions to the following SDG were identified:

- SDG 8—Decent Work and Economic Growth: promotion of stable and balanced workloads across teams and partners to support fair working conditions and reduce overtime pressures.

- SDG 9—Industry, Innovation and Infrastructure: strengthening of operational resilience through process optimization and data-driven decision-making.

- SDG 12—Responsible Consumption and Production: minimization of inefficiencies and reduce process-related waste to support more sustainable production practices.

- SDG 14—Life Below Water: contribution to the sustainable use of marine resources by improving efficiency along the fish supply chain and avoiding avoidable product loss.

3.3. Measure Phase

In this stage of the DMAIC roadmap, the current situation was assessed in greater detail, and the baseline performance was estimated. Table 2 provides the baseline values that were estimated for each CTD that was established in the Define stage. It also contains the values that are targeted at each of them. It is possible to see that the target values were far from being met. The following analyses were performed:

Table 2.

Baseline and target values for each CTD.

- Baseline calculation of the CTD values and segmented characterization of the problem per weekday.

- Determination of the Overall Equipment Effectiveness (OEE) in the bottleneck.

- Review of the implication of the current conditions on the sustainability goals.

Regarding CTD2 and CTD3, the values must be based on the average of all weekly working days. It was likely that the delaying problem tends to occur on specific days of the week. To investigate this hypothesis, a segmented analysis based on recent historical data was carried out to evaluate each working day independently (Table 3).

Table 3.

Baseline performance and relevant data for each working day.

From the results summarized in Table 3, the following conclusions can be derived:

- On Fridays, the production plan can never be fulfilled within the normal 8 h working period.

- The average daily time for production closure on Mondays and Fridays exceeds the 9:30 p.m. threshold, while this is not the case on the remaining weekdays.

- Monday shows the highest variability and uncertainty regarding the volume of fish to be processed.

Friday presents a structural challenge, as production must accommodate the weekend’s demand—requiring higher output than any other day. Meanwhile, some Mondays experience volumes comparable to Fridays, given the convergence of supply sources: aquaculture, local fish market, and international deliveries. These patterns highlight the need to adjust resource allocation dynamically, ensuring workforce planning and equipment capacity are aligned with daily demand. This contributes to both economic efficiency and social sustainability, by avoiding overburdening personnel on high-volume days and minimizing downstream logistical pressure.

The second category of analysis regards the calculation of Overall Equipment Effectiveness (OEE), adopted to assess the baseline performance of the packaging and labeling operations, where the process bottleneck is located. The Maintenance Department was involved in supporting the diagnosis of equipment behavior. OEE is the metric that enables calculation of current equipment efficiency and, importantly, its improvement potential. Framed within the DMAIC roadmap, the use of OEE in the Measure phase allows to quantify the contribution of equipment performance to systemic inefficiencies. The resultant OEE value was calculated as shown in the equation below.

OEE = availability × performance × quality = 0.90 × 0.66 × 0.80 = 47.5%

Not only was possible to conclude that the current OEE value is quite low, but also that the element “performance” was the one contributing most to the bottleneck. Minor but frequent equipment stoppages (left-side and centered pictures in Figure 2) were causing speed losses, hence penalizing the potential cycle time. The contribution of the “quality” element, which is related to the conformity of the resulting packages (right-side picture in Figure 2), was also significant. The need for rework was common due to poor packaging conditions.

Figure 2.

Pictures representative of “performance” and output “quality” problems in the packaging machine.

OEE and CTDs were calculated using daily production records from the plant’s system of record, covering the baseline period and the post-improvement phase. Planned downtime such as breaks and cleaning was excluded, while unplanned stoppages and rework were included. The results section report mean values obtained directly from these daily records.

Finally, these results were analyzed against the suggested Sustainability context, validating the proposed SDGs in relation to the implication of the current conditions on their pursuit. Waste and inefficiencies have a direct implication of the pursuit of SDG 12 (Responsible Consumption and Production) and, by virtue of the food being processed—fish—also on SDG 14 (Life Below Water). However, these losses not only reduce productivity and increase operational costs but also place additional pressure on production teams, reinforcing the need for targeted interventions that support both economic performance and fair workload distribution across the workday, thus impacting SGD 8 (Decent Work and Economic Growth). The OEE diagnostic step further supports these implications, while also impacting SDG 9 (Industry, Innovation and Infrastructure) by reinforcing the need for data-driven maintenance strategies and identifying actionable improvements to core operations (Table 4).

Table 4.

Sustainability alignment. Validation of proposed Sustainable Development Goals against current state.

3.4. Analyze Phase

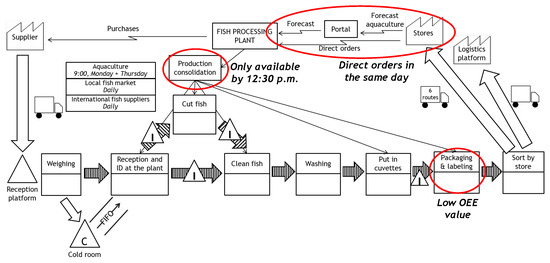

This stage focused on studying and understanding the root causes which prevented the planned daily production from being completed by 9:30 p.m. These causes are related to a set of wastes, such as excess of inventory, and were identified with the help of the previously drawn VSM, as depicted in Figure 3 by the red circles, and may be described as follows:

Figure 3.

Identification in the VSM of the causes for the lack of capacity to meet the production plan on time.

- The production plan could only be consolidated by 12:30 p.m., since the stores could issue direct orders on the same day until 11:30 a.m. This late consolidation prevented the packaging and labeling operations from taking place virtually throughout the morning, causing too much work in progress (WIP) inventory to accumulate upstream in the process and preventing a continuous flow that would have allowed the finished product to be available much earlier. This interruption of flow leads to time and material inefficiencies that increase operational pressure and can compromise product freshness, reinforcing the importance of leaner, more sustainable planning cycles.

- The low OEE value in the packaging equipment reduces the product flow speed at this point of the process, reducing the ability to meet the target times. A maintenance company was asked to perform an expert appraisal on the two existing packaging machines in the plant to determine measures that would make them perform better, therefore preventing the occurrence of so many micro-stops and problems in the quality of the packaging of the final product. While mostly an equipment-focused intervention, this effort allows to support operational and sustainability goals, namely reducing rework, minimizing resource consumption, and extending machine life through preventive actions.

In addition to the two causes mentioned above, a third reason needs to be addressed, as described in the Measurement stage: the daily allocation of resources is not adequate for the expected production volume that varies significantly according to the working day. Aligning workforce capacity with demand contributes not only to operational efficiency but also to social sustainability by promoting fairer workloads and reducing the risk of excessive overtime or underutilization.

3.5. Improve Phase

At this stage of the project, the team focused on three areas of action targeting the main causes for the existing bottleneck in the packaging operation, which were identified in the previous stage:

- Area of action 1—Leveling of resources considering daily workload differences. Leveling of resources considering daily workload differences. This adjustment supports more sustainable workforce management, helping reduce overtime on high-volume days and promoting fairer workload distribution in line with social sustainability objectives.

- Area of action 2—Timely consolidation of the production plan. Earlier planning enables smoother process flow, minimizing work-in-progress accumulation and associated material and time waste—contributing to leaner, more sustainable production practices.

- Area of action 3—Increase the OEE value. By improving equipment availability, performance, and quality output, this action reduces rework, lowers downtime, and limits resource waste—supporting both economic and environmental sustainability.

Area of action 1—Leveling of resources considering daily workload differences.

The distribution of the 40 h per week over the different working days of the week was rethought, to adapt it to the expected production volume. Instead of considering an equal distribution of 8 h for all the working days, it was allocated a greater number of working hours on the days when a greater workload was expected (i.e., to match the number of working hours to the production volume’s historical data). The result of this weekly work reschedule is summarized in Table 5.

Table 5.

New distribution of the 40 h week over working days.

With the weekly work schedule now better leveled out, the promotion towards the implementation of a pulled and continuous flow was initiated. Efforts were now needed to improve the production flow, which was addressed in the other two action areas.

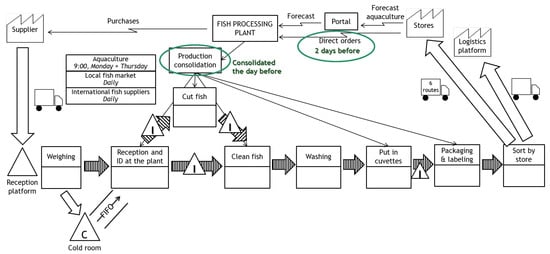

Area of action 2—Timely consolidation of the production plan.

This axel for improvement stream focused on further promoting the implementation of a pull system to have a timely production plan early in the working day, as soon as the fish processing tasks begin. The conduction of the packaging and labeling operations depends on whether or not the production plan is consolidated. In the current situation, the fish market managers of the different stores could send the orders directly to the fish processing plant on the same day (practically until the end of the morning), as described previously. This prevents the product from being packaged and labeled normally before 12.30 p.m., which leads to a build-up of WIP inventory around the fish cutting and cleaning operations. In the future state situation, displayed in Figure 4, the stores would place direct orders two days in advance, so that the production plan would be consolidated the day before.

Figure 4.

Future state VSM considering the consolidation of the production plan the day before so that it is possible to start packaging and labeling at the beginning of the working day.

Flow and pull value are at the heart of the Toyota Production System. By knowing the production plan in advance, the packaging and labeling operations could be carried out without any constraints, as all the references to be produced were already in the computer system at the beginning of the day. This situation immediately provided two major advantages:

- The promotion of a continuous flow that prevents the accumulation of stockpiles in the fish cleaning and cutting areas.

- Much earlier arrival of product for packaging and labeling.

Based on the diagnosis made to the packaging equipment, which by the time was more than 10 years old since they were acquired, a set of critical spare parts was replaced and several fine-tunings and some reconfigurations were made. It was not an expensive investment, less than 10 k€. After the maintenance interventions, the OEE was recalculated:

OEE = availability × performance × quality = 0.90 × 0.85 × 0.96 = 73.4%

If this action had not been sufficient to increase the OEE to a value of at least 70%, the team would also carry out a design of experiments (DOE) study to optimize the quality of the packaging output. As this was not the case, the project team considered that the maintenance measures implemented were effective.

Impact of the areas of action on the performance levels.

After the implementation of the actions previously described, the new levels of performance levels were determined. As is observable in Table 6, all CTDs have significantly improved, with CTD1 and CTD2 exceeding targets; CTD3 improved substantially (37% → 15%) but fell slightly short of <10%.

Table 6.

New performance values for each CTD after improvements’ implementation.

3.6. Control Phase

In this stage, some measures were implemented to sustain the gains accomplished by the implemented improvement measures. Some of the control actions that were established in this stage include the following:

- An internal maintenance plan was defined, while the supervisor and operators of the area received basic preventive maintenance training.

- A plan to monitor on an hourly basis the percentage of accomplishment of the production plan has been established and implemented.

- Basic stability instruments were implemented in the room where the product is distributed by the stores, namely a 5S program and visual management, as depicted in Figure 5, to ensure good housekeeping and speed of this operation.

Figure 5. Implementation of a 5S and visual management in the room where the product is sorted by store according to their format and name.

Figure 5. Implementation of a 5S and visual management in the room where the product is sorted by store according to their format and name.

As the company’s main focus was on operational results, sustainability emerged as essentially as a complementary objective introduced by the research team. While contributions were identified through alignment with the SDGs, no dedicated quantitative measures (e.g., overtime hours, rework rates, or waste quantities) were collected during the project. The assessment therefore remains qualitative, based on operational results directly linked to social and environmental implications.

4. Discussion of the Case Study Results

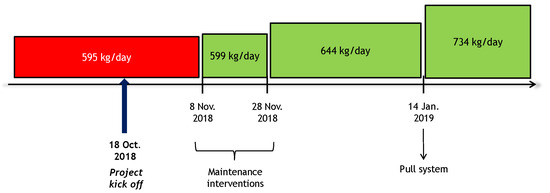

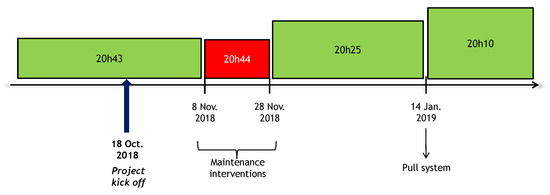

The project took 6 months, in which it was possible to complete the whole 5-stage DMAIC roadmap. As was already presented in Table 6, the results achieved were very positive. The graphics displayed in Figure 6 and Figure 7 provide a greater insight into the evolution in performance, showing the evolution of performance as the areas of action were being implemented. The evolution shown in these Figures also reflects the stepwise nature of the interventions. The first noticeable improvement occurred after the maintenance actions, which raised equipment performance and throughput. The most substantial gain, however, took place after the advance-ordering system was introduced, which enabled earlier starts and smoother flows. Together with resource leveling, these sequential interventions explain the progressive capacity gains observed.

Figure 6.

Evolution of the average daily processing capacity.

Figure 7.

Evolution of the average time for the closing of production.

The maintenance interventions that impacted the OEE value lasted about three weeks, after which it was verified that there was a relevant impact on the number of kilograms produced daily, as well as on the time at which production was closed; however, the greatest impact on the increase in the daily production capacity had just occurred after the stores began placing direct orders two days in advance.

In addition, regarding the fact that the fish processing plant no longer could process all the orders on time on several of the working days (namely on Fridays and often on Mondays), these improvements translated into the following monetary and time savings:

- The increase in production capacity, which led to an increase of around 140 kg/day, is equivalent to a potential gain in gross sales of around 250 k€/year.

- The time saving that was obtained is equivalent to about 20 working days, which translates into practically a gain of 1 month of work.

In parallel with performance improvements, the project also marked a first step toward embedding sustainability into the company’s continuous improvement culture. Several of the actions implemented—such as adjusting working schedules to real production needs, reducing equipment inefficiencies, and minimizing work-in-progress—reflect broader commitments to responsible resource use, fair labor practices, and reduced operational waste. While sustainability was not the initial driver of the project, the outcomes clearly illustrate how targeted efficiency measures can generate positive social and environmental impacts when viewed through a sustainability lens. These results provide a basis for progressively integrating sustainability goals into future projects, supporting long-term cultural change across the organization.

5. Summary, Conclusions, and Suggestions for Future Research

The paper started by providing a systematic review of the published literature focusing on the use of Lean, Six Sigma, and Lean Six Sigma in the food processing industry as well as on the adoption of these approaches in Portugal. The literature review allowed us to identify existing research gaps and better understand the contributions of this paper, based on the integrated application of Lean Six Sigma in a fish processing context with a focus on sustainable operational improvement. By doing so, this paper aims to

- Contribute to the growing but yet limited description of Lean Six Sigma implementation in the food industry, even more particularly in the fish processing industry;

- Demonstrate how Lean Six Sigma methodologies can be applied to improve production performance in a fish processing plant, while progressively integrating sustainability objectives—namely operational efficiency, social responsibility, and resource-conscious practices—into day-to-day industrial operations.

Sustainability transitions in industrial settings are challenging, as they require both multidisciplinary technical knowledge and gradual organizational change. Integrating sustainability into core operations is often difficult when it is introduced as a separate or external priority. However, when sustainability objectives are embedded within structured improvement initiatives—such as Lean Six Sigma—there is an opportunity to approach them through established operational logics. By aligning sustainability with efficiency, reliability, and cost-effectiveness, these initiatives can function as a practical entry point for change. Rather than being perceived as a parallel agenda, sustainability becomes part of the problem-solving process. Over time, this integration supports internal capability-building and can contribute to a broader cultural shift, where sustainability is progressively incorporated into decision-making and daily practices.

To operationalize this project, the methodology that was adopted was fully based on the DMAIC roadmap, thus following a typical Lean Six Sigma project structure. As discussed in the literature review, the DMAIC roadmap provides a proven approach to problem-solving according to a well-defined sequence of stages as well but it guides the application of improvement tools in a highly structured way. As such, the selection of this methodology provides a familiar approach through which we not only aimed to deliver operational and financial gains, but also those related to broader sustainability perspective—social, economic, and environmental. Throughout each of the five phases comprising the DMAIC project, both Lean and Six Sigma tools were applied to support these objectives. In the Define phase, the relevant material and information flows were mapped using the VSM approach, the process bottleneck located in the packaging and labeling operations was identified, and the critical-to-delivery (CTD) characteristics to be improved were established. Graphical aids such as value stream maps were revealed to be useful at this stage by facilitating an understanding of what needs to be changed or improved in the process. The baseline performance was estimated for each CTD in the Measure stage. It was possible to quantify and confirm that there was a problem in terms of processing capacity leading to delivery delays on Fridays and often also on Mondays. The baseline performance at the bottleneck was also estimated and the OEE metric from TPM was used for this purpose. The resulting OEE of 47.5% is considered poor but common for most manufacturing companies that are just starting to improve their manufacturing performance. The determination of the main causes for the stated problem was conducted in the Analyze stage. The value stream analysis also allowed the team to better understand the reasons why WIP inventory was being accumulated in the operations upstream of the bottleneck (packaging operation). Altogether, it enabled the definition of the following areas of action in the Improve phase:

- Leveling of resources attending to the different workloads over the weekly working days, which was actually a first step to promoting a pull system by ensuring that the number of resources was being planned according to the expected demand. This value stream design solution relies on the concept of a Heijunka (Leveling) schedule. Leveling of resources considering daily workload differences. This adjustment supports more sustainable workforce management, reducing overtime on high-volume days and promoting fairer workload distribution in line with social sustainability objectives.

- Timely consolidation of the production plan, as stores would start placing direct orders two days in advance. This demand-pull system would then eliminate the need to maintain a buffer of WIP inventory around the fish cutting and cleaning operations, hence promoting a continuous flow throughout the entire fish processing value stream, which also means that packaging and labeling can start around 3 h earlier. This reduction in the lead time due to the implementation of a demand-pull system is corroborated by the literature, as it helps to stabilize and reduce the WIP and enhances operational performance by building customer response capability. These efforts helped to minimize work-in-progress accumulation and associated material and time waste, this leads to leaner, more sustainable production practices.

- Increase in the OEE value in the packaging process where the process capacity bottleneck is located, by carrying out some relevant maintenance work that replaced a set of critical spare parts and performed several fine-tunings and some reconfigurations. It led to a significant increase in the OEE value from 47.5% to 73.4%, which corresponds to a good performance level. Improving the OEE directly translate in reducing rework, lowering downtime, and curbing resource waste, thus supporting both economic and environmental sustainability.

The reported results of the project showed a measurable improvement in the processing capacity of the plant, releasing the equivalent of 20 working days per year—approximately one month’s workload—to handle an additional 140 kg of fish per day, corresponding to an estimated annual gain of €250,000 in gross sales, assuming around 290 operating days a year. By increasing production capacity, the plant was able to complete the consolidated production plan before 9:30 p.m., thus avoiding delivery delays to stores and ensuring compliance with agreed service level agreements (SLAs). These gains also contributed to minimizing overtime, reducing stress on partner operations, and reinforcing process stability. The contributions of each improvement area can be directly associated with specific sustainability gains and specific Sustainable Development Goals (SDGs) and targets (Table 7). This alignment illustrates how targeted operational changes support broader social, economic, and environmental objectives in a structured and measurable way.

Table 7.

Alignment between operational gains and sustainability in different improvement areas. Results confirm that performance improvements achieved through Lean Six Sigma can also generate meaningful sustainability outcomes.

From a scientific review perspective, this study also contributes to filling an identified gap in the literature: the limited application of Six Sigma and Lean Six Sigma in food industries, especially in fish processing, and the near absence of research that explicitly integrates these approaches with sustainability. By documenting operational gains alongside sustainability implications, the case demonstrates the potential of Lean Six Sigma to act as a platform for advancing both efficiency and sustainability in contexts where such integration has rarely been explored.

The project was primarily driven by the company’s goal of improving operational results. Sustainability, while not an initial focus, emerged as a complementary dimension introduced by the research team and aligned with the operational improvements achieved. As a result, a limitation is that the sustainability impacts were assessed qualitatively, as the project did not capture dedicated environmental or social indicators. Nevertheless, this study thus shows how Lean Six Sigma can serve as a structured and pragmatic approach for introducing and integrating sustainability objectives into existing operational practices. Although the company did not initially set sustainability as a goal, the integration of sustainability concerns through operational improvement efforts proved effective. By linking sustainability to measurable efficiency gains, the project created an entry point for broader sustainability thinking within the organization. While the short-term impacts on performance and resource efficiency were measurable, the long-term cultural effects, however, can only be assessed over time and thus remained outside the scope of this project. Nevertheless, this project illustrates the potential of structured improvement initiatives to contribute not only to performance and financial outcomes but also to incremental sustainability gains. By aligning operational goals with improved resource use and workload balancing, Lean Six Sigma served as a platform for embedding sustainability into day-to-day routines. A relevant managerial contribution is the demonstrated link between process efficiency, service reliability, and sustainability-related outcomes—namely reduced waste, improved working conditions, and increased responsiveness.

Another potential limitation deals with the fact that the project is focused only on the internal operations of the fish processing plant (such as packaging and labeling phases), without addressing upstream (such as fishery supply) or downstream (such as retail distribution) aspects. The scope of this case study was deliberately centered on internal operations, consistent with most first-time Lean Six Sigma applications. The metrics selected for improvement were therefore inherently focused on the internal processes of the plant. While this focus was effective in delivering measurable results, extending the analysis to upstream supply and downstream retail operations would be necessary to capture the full sustainability impacts across the value chain.

Finally, it also important to address the issue of seasonality effects. The project was implemented between October and January, a period subject to seasonal variations in demand and product mix. While no other major initiatives overlapped, these seasonal effects may influence operational results. Nevertheless, the main focus of this paper is ensuring the inclusion of sustainability goals—even if as an initial and as qualitative indicators—in operational improvement project. As such, we believe that our theoretical results would expand beyond this plant or industry. While operational replication would require similar conditions, the use of Lean Six Sigma to align operational and sustainability improvement efforts—suggested recently in the literature [1], but until now poorly observed in industrial contexts—comes out reinforced.

Future work should explore how similar Lean Six Sigma initiatives can be applied in other fresh food processing contexts. Further research could also examine how explicitly sustainability-oriented approaches, such as Lean & Green, support industry-wide transitions by reducing food waste and resource consumption. The research was also developed under a constrained timeframe and limited to the processing stage. While operational and financial impacts were successfully validated within the plant, a broader optimization of the fishmonger’s department would require an extension of the analysis to retail operations.

Author Contributions

Conceptualization, P.M. and A.M.C.; methodology, P.M., L.C., A.M.C. and J.R.; validation, P.M., L.C., A.M.C. and J.R. formal analysis, P.M., L.C., A.M.C. and J.R.; investigation, P.M. and J.R.; writing—original draft preparation, P.M. and A.M.C.; writing—review and editing, P.M., L.C., A.M.C. and J.R. All authors have read and agreed to the published version of the manuscript.

Funding

Author A.M.C. acknowledges Fundação para a Ciência e a Tecnologia I.P. for its financial support via the project UID/00667: Unidade de Investigação e Desenvolvimento em Engenharia Mecânica e Industrial.

Institutional Review Board Statement

No applicable.

Informed Consent Statement

No applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| SDG | Sustainable Development Goals |

| LSS | Lean Six Sigma |

| DMAIC | Define, Measure, Analyze, Improve, Control |

| OEE | Overall Equipment Effectiveness |

| WIP | Work-in-progress |

| VSM | Value Stream Mapping |

| CTQ | Critical-to-quality |

| CTC | Critical-to-cost |

| CTD | Critical-to-delivery |

References

- Carneiro, F.; Nóvoa, H.; Carvalho, A.M.; Lamilla, F.; Optimising, E.S. G-enhanced performance: A literature review of lean, six sigma, and other continuous improvement methodologies. Total Qual. Manag. Bus. Excell. 2025, 36, 146–178. [Google Scholar] [CrossRef]

- Ikumapayi, O.M.; Akinlabi, E.T.; Mwema, F.M.; Ogbonna, O.S. Six sigma versus lean manufacturing—An overview. Mater. Today Proc. 2020, 26, 3275–3281. [Google Scholar] [CrossRef]

- Antony, J.; Snee, R.; Hoerl, R. Lean Six Sigma: Yesterday, today and tomorrow. Int. J. Qual. Reliab. Manag. 2017, 34, 1073–1093. [Google Scholar] [CrossRef]

- Drohomeretski, E.; Gouvea da Costa, S.E.; De Lima, E.P.; Da Rosa Garbuio, P.A. Lean, Six Sigma and Lean Six Sigma: An analysis based on operations strategy. Int. J. Prod. Res. 2014, 52, 804–824. [Google Scholar] [CrossRef]

- Chiarini, A. Japanese total quality control, TQM, Deming’s system of profound knowledge, BPR, Lean and Six Sigma: Comparison and discussion. Int. J. Lean Six Sigma 2011, 2, 332–355. [Google Scholar] [CrossRef]

- Laureani, A.; Antony, J. Leadership and Lean Six Sigma: A systematic literature review. Total Qual. Manag. Bus. Excell. 2017, 30, 53–81. [Google Scholar] [CrossRef]

- Snee, R.D. Lean Six Sigma—Getting better all the time. Int. J. Lean Six Sigma 2010, 1, 9–29. [Google Scholar] [CrossRef]

- Rodgers, B.A.; Antony, J.; He, Z.; Cudney, E.A.; Laux, C. A directed content analysis of view-points on the changing patterns of Lean Six Sigma research. TQM J. 2019, 31, 641–654. [Google Scholar] [CrossRef]

- Estrada-Orantes, F.J.; Alba-Baena, N.G. Creating the lean-sigma synergy. In Lean Manufacturing in the Developing World; Garcia-Alcaraz, J.L., Maldonado-Macías, A.A., Cortes-Robles, G., Eds.; Springer: Cham, Switzerland, 2014; pp. 117–134. [Google Scholar]

- Salah, S.; Rahim, A.; Carretero, J.A. The integration of Six Sigma and lean management. Int. J. Lean Six Sigma 2010, 1, 249–274. [Google Scholar] [CrossRef]

- Pepper, M.P.; Spedding, T.A. The Evolution of Lean Six Sigma. Int. J. Six Sigma Reliab. Manag. 2010, 27, 138–155. [Google Scholar] [CrossRef]

- Su, C.; Chiang, T.; Chang, C. Improving Service Quality by Capitalising on an Integrated Lean Six Sigma Methodology. Int. J. Six Sigma Compet. Advant. 2006, 2, 1–22. [Google Scholar] [CrossRef]

- Sreedharan, V.R.; Raju, R. A systematic literature review of Lean Six Sigma in different industries. Int. J. Lean Six Sigma 2016, 7, 430–466. [Google Scholar] [CrossRef]

- Singh, M.; Rathi, R. A structured review of Lean Six Sigma in various industrial sectors. Int. J. Lean Six Sigma 2019, 10, 622–664. [Google Scholar] [CrossRef]

- Patel, A.S.; Patel, K.M. Critical review of literature on Lean Six Sigma methodology. Int. J. Lean Six Sigma 2021, 12, 627–674. [Google Scholar] [CrossRef]

- Dogan, O.; Gurcan, O.F. Data perspective of Lean Six Sigma in Industry 4.0 Era: A guide to improve quality. In Proceedings of the International Conference on Industrial Engineering and Operations Management, Paris, France, 23–26 July 2019; pp. 943–953. [Google Scholar]

- Sony, M. Design of cyber physical system architecture for industry 4.0 through Lean Six Sigma: Conceptual foundations and research issues. Prod. Manuf. Res. 2020, 8, 158–181. [Google Scholar] [CrossRef]

- Titmarsh, R.; Assad, F.; Harrison, R. Contributions of Lean Six Sigma to sustainable manufacturing requirements: An Industry 4.0 perspective. Procedia CIRP 2020, 90, 589–593. [Google Scholar] [CrossRef]

- Kumar, P.; Bhadu, J.; Singh, D.; Bhamu, J. Integration between Lean, Six Sigma and Industry 4.0 technologies. Int. J. Six Sigma Compet. Advant. 2021, 13, 19–37. [Google Scholar] [CrossRef]

- Chiarini, A.; Kumar, M. Lean Six Sigma and Industry 4.0 integration for Operational Excellence: Evidence from Italian manufacturing companies. Prod. Plan. Control 2021, 32, 1084–1101. [Google Scholar] [CrossRef]

- Wang, F.-K.; Rahardjo, B.; Rovira, P.R. Lean Six Sigma with value stream mapping in Industry 4.0 for human-centered workstation design. Sustainability 2022, 14, 11020. [Google Scholar] [CrossRef]

- Antony, J.; McDermott, O.; Powell, D.; Sony, M. The evolution and future of lean Six Sigma 4.0. TQM J. 2023, 35, 1030–1047. [Google Scholar] [CrossRef]

- Macias-Aguayo, J.; Garcia-Castro, L.; Barcia, K.F.; McFarlane, D.; Abad-Moran, J. Industry 4.0 and Lean Six Sigma integration: A systematic review of barriers and enablers. Appl. Sci. 2022, 12, 11321. [Google Scholar] [CrossRef]

- Pongboonchai-Empl, T.; Antony, J.; Garza-Reyes, J.A.; Komkowski, T.; Tortorella, G.L. Integration of Industry 4.0 technologies into Lean Six Sigma DMAIC: A systematic review. Prod. Plan. Control 2024, 35, 1403–1428. [Google Scholar] [CrossRef]

- Skalli, D.; Charkaoui, A.; Cherrafi, A.; Garza-Reyes, J.A.; Antony, J.; Shokri, A. Industry 4.0 and Lean Six Sigma integration in manufacturing: A literature review, an integrated framework and proposed research perspectives. Qual. Manag. J. 2023, 30, 16–40. [Google Scholar] [CrossRef]

- Saihi, A.; Awad, M.; Ben-Daya, M. Quality 4.0: Leveraging Industry 4.0 technologies to improve quality management practices—A systematic review. Int. J. Qual. Reliab. Manag. 2023, 40, 628–650. [Google Scholar] [CrossRef]

- Sader, S.; Husti, I.; Daroczi, M. A review of quality 4.0: Definitions, features, technologies, applications, and challenges. Total Qual. Manag. Bus. Excell. 2022, 33, 1164–1182. [Google Scholar] [CrossRef]

- Carvalho, A.M.; Sampaio, P.; Rebentisch, E.; Carvalho, J.Á.; Saraiva, P. The influence of operational excellence on the culture and agility of organizations: Evidence from industry. Int. J. Qual. Reliab. Manag. 2021, 38, 1520–1549. [Google Scholar] [CrossRef]

- Dias, A.M.; Carvalho, A.M.; Sampaio, P. Quality 4.0: Literature review analysis, definition and impacts of the digital transformation process on quality. Int. J. Qual. Reliab. Manag. 2022, 39, 1312–1335. [Google Scholar] [CrossRef]

- Escobar, C.A.; Macias, D.; McGovern, M.; Hernandez-de-Menendez, M.; Morales-Menendez, R. Quality 4.0—An evolution of Six Sigma, DMAIC. Int. J. Lean Six Sigma 2022, 13, 1200–1238. [Google Scholar] [CrossRef]

- Yadav, N.; Shankar, R.; Singh, S.P. Critical success factors for Lean Six Sigma in Quality 4.0. Int. J. Qual. Serv. Sci. 2021, 13, 123–156. [Google Scholar] [CrossRef]

- Null, G.; Cross, J.A.; Brandon, C. Effects of Lean Six Sigma in program management. J. Manuf. Technol. Manag. 2020, 31, 572–598. [Google Scholar] [CrossRef]

- Pacheco, D.; Pergher, I.; Vaccaro, G.L.R.; Jung, C.F.; Ten Caten, C. 18 comparative aspects between Lean and Six Sigma: Complementarity and implications. Int. J. Lean Six Sigma 2015, 6, 161–175. [Google Scholar] [CrossRef]

- Francescatto, M.; Neuenfeldt Júnior, A.; Kubota, F.I.; Guimarães, G.; de Oliveira, B. Lean Six Sigma case studies literature overview: Critical success factors and difficulties. Int. J. Product. Perform. Manag. 2023, 72, 1–23. [Google Scholar] [CrossRef]

- Shokri, A. Quantitative analysis of Six Sigma, Lean and Lean Six Sigma research publications in last two decades. Int. J. Qual. Reliab. Manag. 2017, 34, 598–625. [Google Scholar] [CrossRef]

- Sunder, M.V.; Ganesh, L.S.; Marathe, R.R. A morphological analysis of research literature on Lean Six Sigma for services. Int. J. Oper. Prod. Manag. 2018, 38, 149–182. [Google Scholar] [CrossRef]

- Pinto, C.M.A.; Mendonça, J.; Babo, L.; Silva, F.J.G.; Fernandes, J.L.R. Analyzing the implementation of Lean methodologies and practices in the Portuguese industry: A survey. Sustainability 2022, 14, 1929. [Google Scholar] [CrossRef]

- Hallam, C.; Contreras, C. Integrating Lean and Green Management. Manag. Decis. 2016, 54, 2157–2187. [Google Scholar] [CrossRef]

- Garza-Reyes, J.A. Lean and Green—A systematic review of the state of the art literature. J. Clean. Prod. 2015, 102, 18–29. [Google Scholar] [CrossRef]

- Gholami, H.; Jamil, N.; Saman, M.Z.M.; Streimikiene, D.; Sharif, S.; Zakuan, N. The application of Green Lean Six Sigma. Bus. Strategy Environ. 2020, 30, 1913–1931. [Google Scholar] [CrossRef]

- Kaswan, M.S.; Rathi, R. Green Lean Six Sigma for sustainable development: Integration and framework. Environ. Impact Assess. Rev. 2020, 83, 106396. [Google Scholar] [CrossRef]

- Kumar, S.; Kumar, N.; Haleem, A. Conceptualisation of sustainable Green Lean Six Sigma: An empirical analysis. Int. J. Bus. Excell. 2015, 8, 210–250. [Google Scholar] [CrossRef]

- Letchumanan, L.T.; Gholami, H.; Yusof, N.M.; Ngadiman, N.H.A.B.; Salameh, A.A.; Štreimikiene, D.; Cavallaro, F. Analyzing the factors enabling Green Lean Six Sigma implementation in the Industry 4.0 Era. Sustainability 2002, 14, 3450. [Google Scholar] [CrossRef]

- Amani, P.; Lindbom, I.; Sundström, B.; Östergren, K. Green-lean synergy-root-cause analysis in food waste prevention. Int. J. Food Syst. Dyn. 2015, 6, 99–109. [Google Scholar] [CrossRef]

- Sanchez Rodrigues, V.; Kumar, M. Synergies and misalignments in lean and green practices: A logistics industry perspective. Prod. Plan. Control 2019, 30, 369–384. [Google Scholar] [CrossRef]

- Pejić, V.; Lerher, T.; Jereb, B.; Lisec, A. Lean and green paradigms in logistics: Review of published research. Promet-Traffic Transp. 2016, 28, 593–603. [Google Scholar] [CrossRef]

- Azevedo, S.G.; Carvalho, H.; Duarte, S.; Cruz-Machado, V. Influence of green and lean upstream supply chain management practices on business sustainability. IEEE Trans. Eng. Manag. 2012, 59, 753–765. [Google Scholar] [CrossRef]

- Jagtap, S.; Garcia-Garcia, G.; Rahimifard, S. Optimisation of the resource efficiency of food manufacturing via the Internet of Things. Comput. Ind. 2021, 127, 103397. [Google Scholar] [CrossRef]

- Van der Goot, A.J.; Pelgrom, P.J.; Berghout, J.A.; Geerts, M.E.; Jankowiak, L.; Hardt, N.A.; Keijer, J.; Schutyser, M.A.; Nikiforidis, C.V.; Boom, R.M. Concepts for further sustainable production of foods. J. Food Eng. 2016, 168, 42–51. [Google Scholar] [CrossRef]

- Jónsdóttir, S. Innovation Processes in Retailing: A Way to Green Food Retail? Master’s Thesis, Lund University, Lund, Sweden, 2012. [Google Scholar]

- Petljak, K.; Zulauf, K.; Štulec, I.; Seuring, S.; Wagner, R. Green supply chain management in food retailing: Survey-based evidence in Croatia. Supply Chain Manag. Int. J. 2018, 23, 1–5. [Google Scholar] [CrossRef]

- Costa, L.B.M.; Filho, M.G.; Fredendall, L.D.; Paredes, F.J.G. Lean, six sigma and lean six sigma in the food industry: A systematic literature review. Trends Food Sci. Technol. 2018, 82, 122–133. [Google Scholar] [CrossRef]

- Sharma, J.; Tyagi, M.; Panchal, D.; Singh, R.P. Contemplation of food industry attributes confronted in smooth adoption of Lean Six Sigma practices. Int. J. Six Sigma Compet. Advant. 2022, 14, 32–69. [Google Scholar] [CrossRef]

- Noorwali, A. Apply Lean and Taguchi in different level of variability of food flow processing system. Procedia Eng. 2013, 63, 728–734. [Google Scholar] [CrossRef]

- Aytekin, A.; Okoth, B.O.; Korucuk, S.; Mishra, A.R.; Memiş, S.; Karamaşa, Ç.; Tirkolaee, E.B. Critical success factors of lean six sigma to select the most ideal critical business process using q-ROF CRITIC-ARAS technique: Case study of food business. Expert Syst. Appl. 2023, 224, 120057. [Google Scholar] [CrossRef]

- Azalanzazllay, N.N.; Lim, S.A.H.; Abidin, U.F.U.Z.; Anass, C. Uncovering readiness factors influencing the Lean Six Sigma pre-implementation phase in the food industry. Sustainability 2022, 14, 8941. [Google Scholar] [CrossRef]

- Costa, L.B.M.; Filho, M.G.; Fredendall, L.D.; Ganga, G.M.D. The effect of Lean Six Sigma practices on food industry performance: Implications of the sector’s experience and typical characteristics. Food Control 2020, 112, 107110. [Google Scholar] [CrossRef]

- Costa, L.B.M.; Filho, M.G.; Fredendall, L.D.; Ganga, G.M.D. Lean Six Sigma in the food industry: Construct development and measurement validation. Int. J. Prod. Econ. 2021, 231, 107843. [Google Scholar] [CrossRef]

- Trubetskaya, A.; McDermott, O.; Brophy, P. Implementing a customised Lean Six Sigma methodology at a compound animal feed manufacturer in Ireland. Int. J. Lean Six Sigma 2023, 14, 1075–1095. [Google Scholar] [CrossRef]

- Mahalik, N.P.; Nambiar, A.N. Trends in food packaging and manufacturing systems and technology. Trends Food Sci. Technol. 2010, 21, 117–128. [Google Scholar] [CrossRef]

- Bhasin, S. Clarification of the Lean concept. In Lean Management Beyond Manufacturing: A Holistic Approach; Bhasin, S., Ed.; Springer: Cham, Switzerland, 2015; pp. 11–26. [Google Scholar]

- Ribeiro, P.; Sá, J.C.; Ferreira, L.P.; Pereira, M.; Silva, F.J.G.; Pereira, M.T.; Santos, G. The impact of the application of Lean tools for improvement of process in a plastic company: A case study. Procedia Manuf. 2019, 38, 765–775. [Google Scholar] [CrossRef]

- Buisman, M.E.; Haijema, R.; Bloemhof-Ruwaard, J.M. Discounting and dynamic shelf life to reduce fresh food waste at retailers. Int. J. Prod. Econ. 2019, 209, 274–284. [Google Scholar] [CrossRef]

- Lohnes, J.D. Regulating surplus: Charity and the legal geographies of food waste enclosure. Agric. Hum. Values 2021, 38, 351–363. [Google Scholar] [CrossRef]

- Arcuri, S. Food poverty, food waste and the consensus frame on charitable food redistribution in Italy. Agric. Hum. Values 2019, 36, 263–275. [Google Scholar] [CrossRef]

- Knowles, G.; Johnson, M.; Warwood, S. Medicated sweet variability: A Six Sigma application at a UK food manufacturer. TQM Mag. 2004, 16, 284–292. [Google Scholar] [CrossRef]

- Simons, D.; Zokaei, K. Application of Lean paradigm in red meat processing. Br. Food J. 2005, 107, 192–211. [Google Scholar] [CrossRef]

- Simons, D.; Taylor, D. Lean thinking in the UK red meat industry: A systems and contingency approach. Int. J. Prod. Econ. 2007, 106, 70–81. [Google Scholar] [CrossRef]

- Scherrer-Rathje, M.; Boyle, T.A.; Deflorin, P. Lean, take two! Reflections from the second attempt at Lean implementation. Bus. Horiz. 2009, 52, 79–88. [Google Scholar] [CrossRef]

- Engelund, E.H.; Friis, A.; Breum, G. Optimisation of large-scale food production using Lean Manufacturing principles. J. Foodserv. 2009, 20, 4–14. [Google Scholar] [CrossRef]

- Hung, H.-C.; Sung, M.-H. Applying Six Sigma to manufacturing processes in the food industry to reduce quality cost. Sci. Res. Essays 2011, 6, 580–591. [Google Scholar]

- Besseris, G. Multi-factorial Lean Six Sigma product optimization for quality, leanness and safety: A case study in food product improvement. Int. J. Lean Six Sigma 2014, 5, 253–278. [Google Scholar] [CrossRef]

- Desai, D.A.; Kotadiya, P.; Makwana, N.; Patel, S. Curbing variations in packaging process through Six Sigma way in a large-scale food-processing industry. J. Ind. Eng. Int. 2015, 11, 119–129. [Google Scholar] [CrossRef]

- Dora, M.; Gellynck, X. Lean Six Sigma implementation in a food processing SME: A case study. Qual. Reliab. Eng. Int. 2015, 31, 1151–1159. [Google Scholar] [CrossRef]

- Lopes, R.B.; Freitas, F.; Sousa, I. Application of Lean Manufacturing tools in the food and beverage industries. J. Technol. Manag. Innov. 2015, 10, 120–130. [Google Scholar] [CrossRef]

- Idrissi, İ.; Mesfioui, A.; Aftais, İ.; Benazzouz, B. Implementation of Lean manufacturing in fish canning company: A case study of a canned sardines production company in Morocco. Int. J. Lean Think. 2015, 6, 17–28. [Google Scholar]

- Powell, D.; Lundeby, S.; Chabada, L.; Dreyer, H. Lean Six Sigma and environmental sustainability: The case of a Norwegian dairy producer. Int. J. Lean Six Sigma 2017, 8, 53–64. [Google Scholar] [CrossRef]

- Nandakumar, N.; Saleeshya, P.G.; Harikumar, P. Bottleneck identification and process improvement by Lean Six Sigma DMAIC methodology. Mater. Today Proc. 2020, 24, 1217–1224. [Google Scholar] [CrossRef]

- Vanany, I.; Hua Tan, K.; Siswanto, N.; Arvitrida, N.I.; Pahlawan, F.M. Halal Six Sigma framework for defects reduction. J. Islam. Mark. 2021, 12, 776–793. [Google Scholar] [CrossRef]

- Sodhi, H.S. Lean Six Sigma in food industry: A case study. Int. J. Product. Qual. Manag. 2021, 34, 336–349. [Google Scholar] [CrossRef]

- Marques, P.A.; Carvalho, A.M.; Santos, J.O. Improving operational and sustainability performance in a retail fresh food market using lean: A Portuguese case study. Sustainability 2021, 14, 403. [Google Scholar] [CrossRef]

- Carneiro, F.; Rodrigues, G.; Carvalho, A.M.; Moreira, B. Improving cheese production capacity in a dairy company: A Lean Six Sigma approach for enhanced efficiency and performance. Int. J. Lean Six Sigma, 2025; in press. [Google Scholar]

- Carneiro, F.; Serôdio, M.; Nóvoa, H.; Carvalho, A.; Antony, J.; Bhat, S.; Gijo, E.V. Spice Quality: A Six-Sigma Approach to Increasing SCAN Colour in a Paprika Production. Int. J. Product. Perform. Manag. 2025; in press. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).