2.1. Digitalization in Manufacturing and Supply Chain

In this section, we handled digital transformation tool applications in supply chain and operation management. This entailed a bibliometric analysis of AI and IoT integration on supply chain and operation management to benefit the analysis of the general picture of technology preferences in digital supply chain management and smart manufacturing [

9]. According to this study, in the analysis results of the clustering topic analysis, seven different topics are AI and machine learning, the agri-food supply chain, cold chain logistics, smart grid and energy management systems, supply chain performance, water distribution systems, and smart manufacturing. Supply chain performance and smart production are very related with this study’s focus. This topic highlights the essential role of IoT, cloud computing, and advanced technologies in transforming supply chain management and risk assessment, ultimately driving improvements in efficiency, security, and competitiveness across these vital areas. Moreover, bibliometric and topic modeling analyses identify key technologies—such as the industrial Internet of Things, digital twins, cloud manufacturing, and big data analytics—as central themes in smart manufacturing research [

10,

11]. Supervised learning remains the primary approach for addressing a wide array of supply chain problems. Nonetheless, unsupervised, reinforcement, and hybrid algorithms are also successfully utilized to solve other significant supply chain issues, providing alternative pathways for process optimization. Similarly, key technologies utilized in the digitalization of supply chains include artificial intelligence, blockchain technology, supply chain management systems, Industry 4.0 solutions, and logistics platforms [

12,

13,

14,

15,

16]. Therefore, clustering algorithms like k-means and dimensionality reduction techniques such as principal component analysis (PCA) are commonly employed when there are no labeled data, particularly for grouping observations or simplifying complex data sets. These approaches are especially advantageous in applications like customer segmentation [

17,

18]. Artificial Neural Networks (ANNs) and grading boosting are very useful analytics methods for predicting demand forecasting in business organizations, which helps inventory management and supply chain planning. Thus, organizations can make informed planning decisions, pricing dynamically, and maintain optimal inventory level management [

17] Unforeseen disruptions in supply chain risk prediction are able to be predicted by using supervised machine learning techniques, which are convolutional neural networks, (CNNs) and reinforcement learning (RL). These models ensure billions of data points can be processed in the steps of receiving IoT sensors, enabling real-time decision-making and proactive risk mitigation [

19]. Additionally, the combination of fuzzy logic and ML enables dynamic supply chain configuration, which may be more flexible and lead to more accurate decisions in organizations [

20].

Finally, it is understood that firms’ adoption of AI algorithms in their supply chain and operation management is very critical for those that struggle with huge amounts of data in their business processes and managing, because it gives strategical advances to gain operation excellence, which provides capabilities for dynamic demand forecasting, dynamic pricing, cyber-attack defending, and streamlined tasks. In other words, AI algorithms help business process operational excellence in organizations. Because they enable easy solutions and usability, supervised and unsupervised algorithmic analytic models with small budgets can, on day one, facilitate agility in SMEs for being an effective player in the marketplace due to excellence in inventory and supply chain management.

From a lean management perspective, digital transformation acts as a strategic enabler that enhances both operational efficiency and sustainability in manufacturing and supply chain contexts. Theoretically, digital technologies such as the IoT, AI, and cloud-based analytics extend lean principles by enabling real-time visibility, predictive control, and adaptive resource allocation—thus transforming static process optimization into dynamic, data-driven continuous improvement. Practically, these technologies support the reduction of waste, energy consumption, and material inefficiencies, while improving responsiveness and traceability across supply networks. This integration allows organizations to embed sustainability not only through efficiency gains but also via circular resource flows, proactive risk mitigation, and resilient supply chain design, aligning lean operational excellence with long-term environmental and strategic goals.

2.2. Lean Management in Textile Sector

The textile industry operates within a highly competitive landscape, compelling firms to consistently integrate innovative strategies to refine their operations. Among these, lean manufacturing has garnered substantial attention for its capacity to boost both productivity and operational efficiency across diverse sectors, including textiles. In empirical research, which applied lean manufacturing principles, there was reported a 44% surge in productivity by utilizing tools such as 5S and Poka-Yoke. Furthermore, this approach led to a 75% decline in idle time within the organization [

21]. In a similar vein, other research introduced a suite of lean instruments—including 5S, Kaizen, Poka-Yoke, Kanban, and Andon—across various divisions of an Indian apparel enterprise [

22]. Their implementation yielded an 8% rise in productivity, attributed to shortened process cycles, minimized material waste, and enhanced product quality. Comparable outcomes were observed in a Slovakian study focusing exclusively on the Poka-Yoke technique [

23], which demonstrated improvements in operational efficiency, market competitiveness, customer satisfaction, and workforce morale. Collectively, these investigations underscore the effectiveness of deploying either a comprehensive set of lean tools or the targeted use of Poka-Yoke in fostering systematic organization and mitigating errors throughout all organizational units.

The academic literature presents a range of investigations into the application of lean management techniques to enhance productivity and operational efficiency within textile enterprises. These studies often concentrate on distinct operational challenges. For instance, one study examined delays in the delivery of protective clothing orders, which adversely affect the company’s productivity levels [

24]. Their research employs a comprehensive set of lean manufacturing tools, utilizing Value Stream Mapping (VSM) for diagnostic purposes and integrating 5S, SMED, Poka-Yoke, and Kanban to streamline operations. The study centers on reconfiguring the company’s business process model, ultimately achieving a 10% reduction in delivery time and a 50.37% improvement in the sewing department’s production efficiency. These outcomes suggest that re-engineering business processes through lean practices can significantly enhance customer satisfaction.

A parallel study also targeted delivery time optimization. They apply VSM to identify inefficiencies and time-related losses within assembly operations and broader business workflows [

25]. The primary objective is to detect and eliminate Non-Value-Added Activities (NVAs) that hinder time efficiency. As a result of this intervention, setup time was reduced by approximately 180 min, and process time by around 98 min, leading to a notable decrease in total production time and a corresponding rise in efficiency [

25]. These findings reinforce the premise that lean manufacturing seeks to minimize costs and maximize throughput by removing wasteful practices. Moreover, the study highlights that lean management not only contributes to improved time efficiency and customer satisfaction but also supports firms in achieving financial objectives related to revenue growth and profitability.

Complementing these findings, a series of empirical studies conducted in Peru provide further evidence of lean manufacturing’s effectiveness in micro and small enterprises (MSEs) and other industrial sectors. For example, Tejada et al., implemented a data-driven lean framework in a Peruvian textile MSE, integrating 5S, TPM, and digital analytics to address a significant productivity gap [

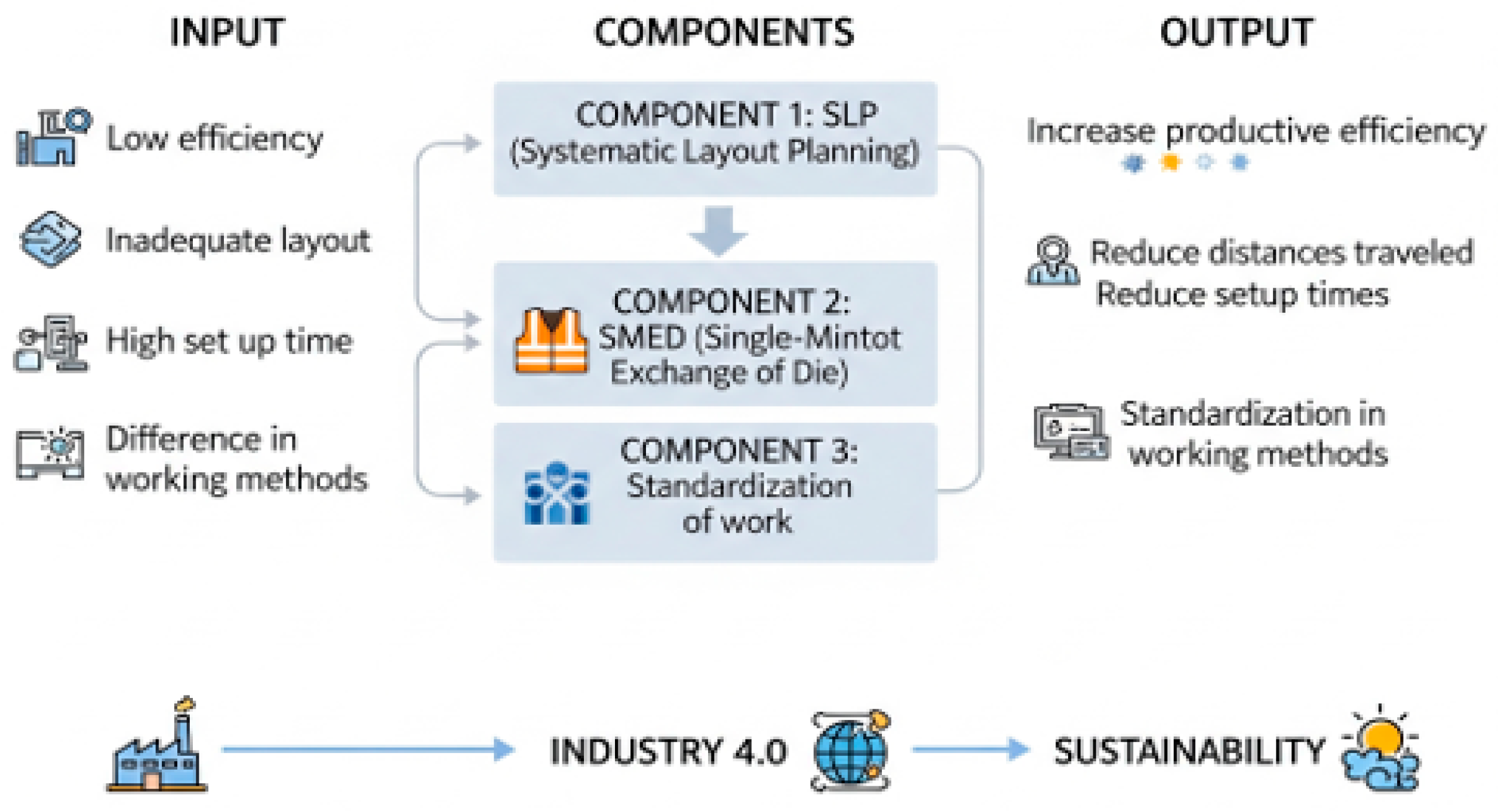

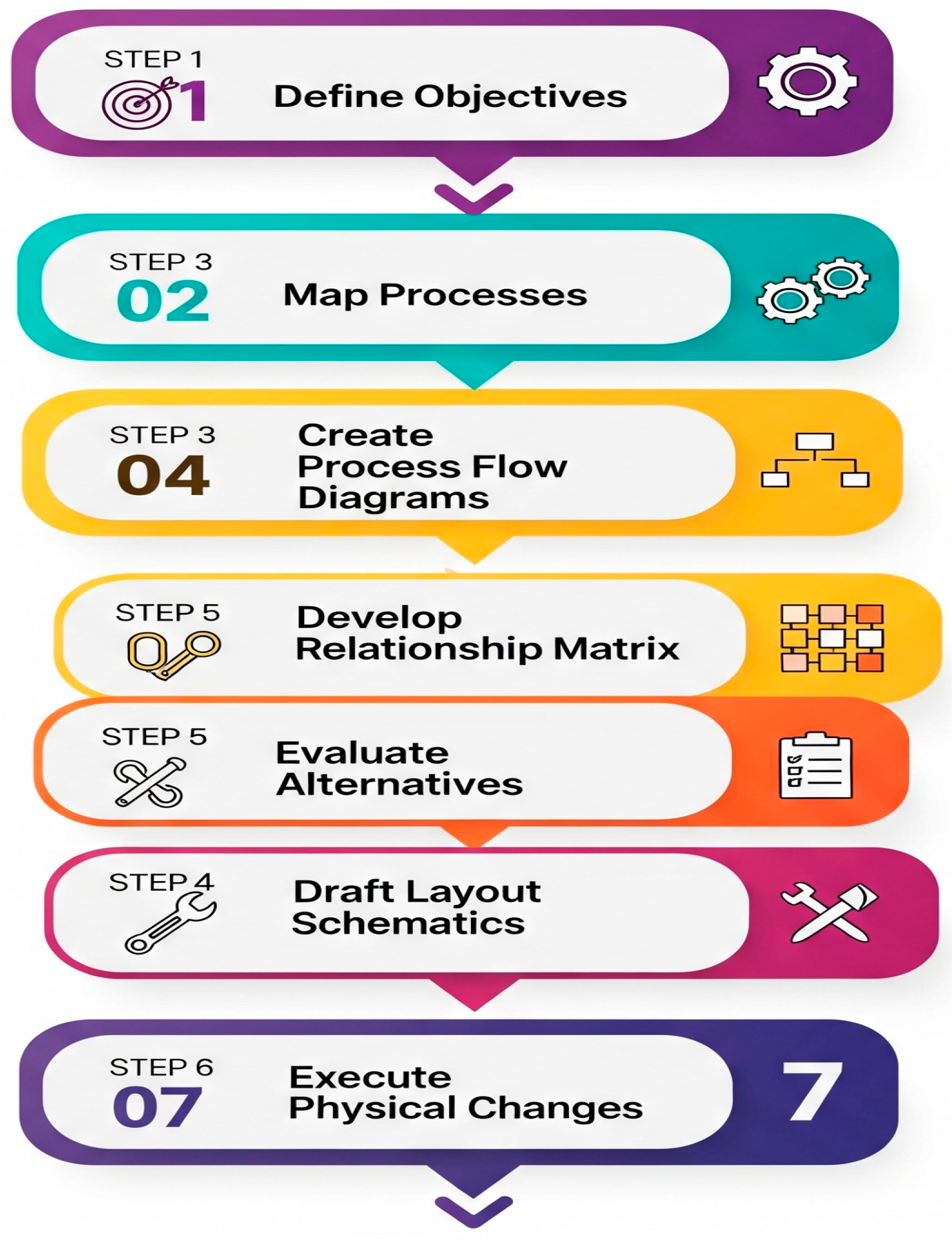

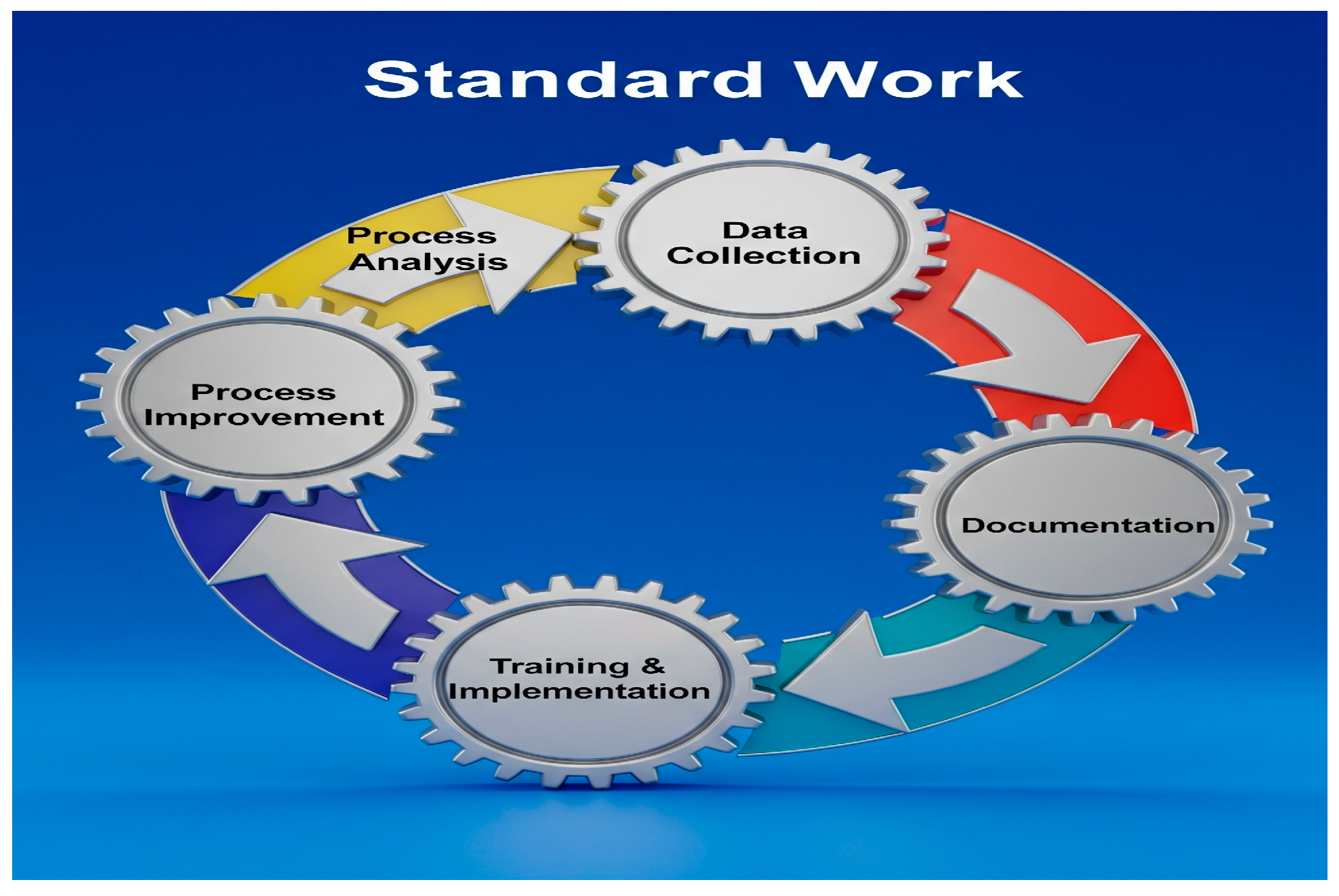

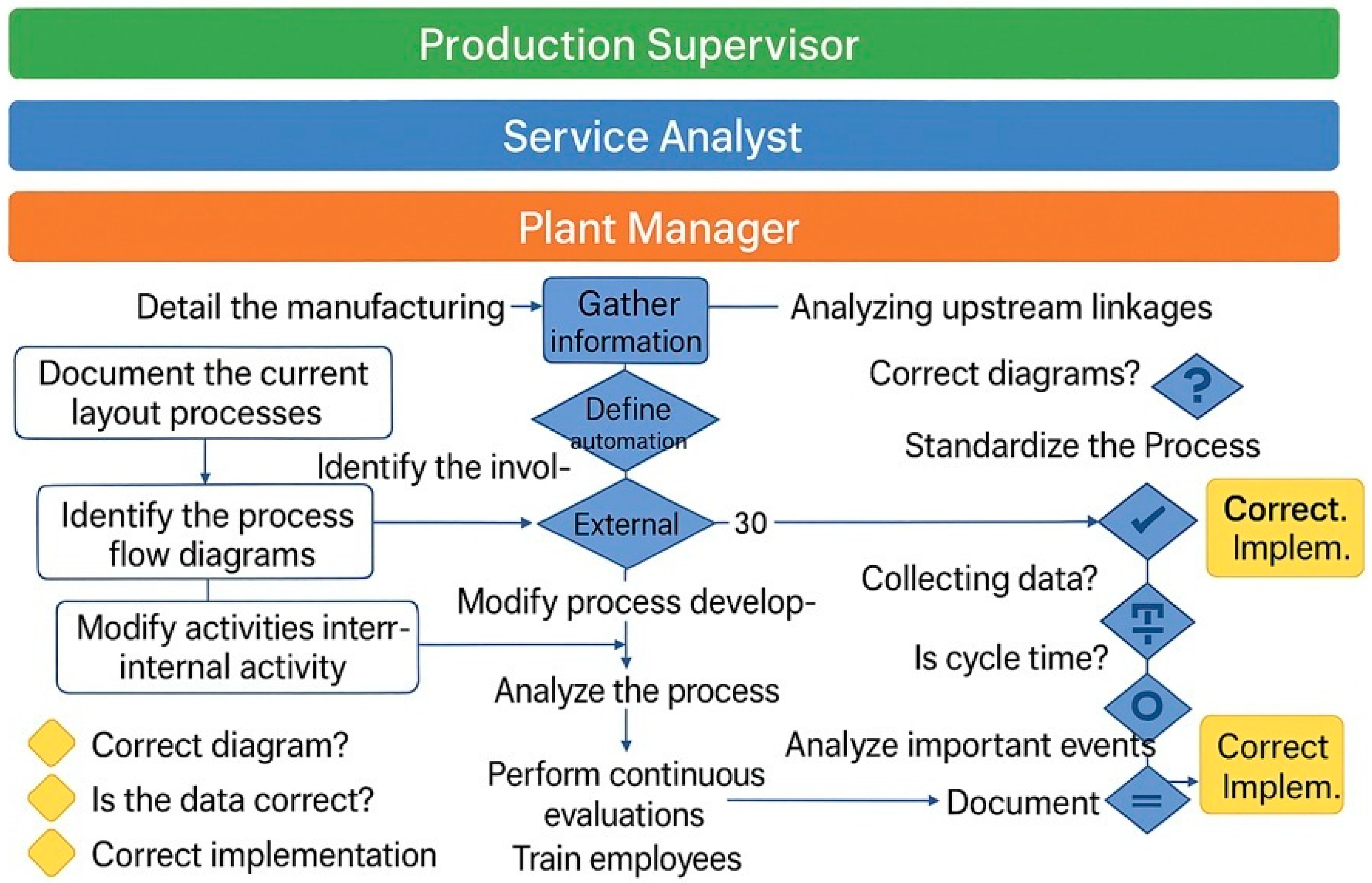

26]. Their pilot project led to a measurable increase in productivity and demonstrated the value of combining lean tools with digital transformation to optimize operations. Similarly, Matias et al., applied SMED, SLP, and work standardization in the production of industrial safety vests, achieving reductions in setup time and defective output while promoting sustainability and Industry 4.0 principles [

8].

Beyond the textile sector, Guerra et al., explored lean and circular economy practices in spinach production, showing how TPM, FIFO, and process standardization—enhanced by digital tools—can improve sustainability and operational efficiency in agro-industrial supply chains [

27]. Then, Calderon et al. examined the use of OEEM within a green–lean framework in plastic manufacturing, identifying barriers to adoption and demonstrating how strategic implementation of lean tools can enhance machine performance and reduce setup times [

28]. In the food industry, Castañeda et al. applied TPM, SMED, and Reliability-Centered Maintenance (RCM) methodologies to address inefficiencies caused by frequent equipment failures. The proposed model improved MTBF, MTTR, and OEE indicators, resulting in increased productivity and reduced operational costs [

29].

These cross-sectoral insights reinforce the versatility of lean methodologies and their adaptability to diverse industrial contexts. They also highlight the growing importance of integrating digital technologies and sustainability principles into lean frameworks to meet contemporary operational and environmental challenges.

Research has underscored the comparatively low productivity levels of textile-sector SMEs in Latin America compared to other industries. In response, they carried out a study aimed at enhancing operational consistency and minimizing inefficiencies by implementing 5S and Standard Work methodologies within Peruvian textile SMEs [

30]. The proposed framework seeks to formalize existing procedures and design an optimized workflow, thereby enabling productivity gains through the structured deployment of lean tools. In a similar context, Barrientos-Ramos et al. explored productivity enhancement in a Peruvian textile SME through the application of lean management techniques [

31]. Their research emphasized the integration of workforce coordination, work methods, and production cycles to reduce waste and elevate efficiency. The study simulated three distinct scenarios involving various lean tools, ultimately demonstrating improvements such as increased sales, a 4% decline in defective output, and a 2% reduction in equipment malfunctions. These findings suggest that the company can pursue sustainable, growth-oriented operations aligned with continuous improvement principles, while also boosting customer satisfaction and ensuring timely delivery of high-quality products through enhanced team performance. Moreover, this case study offers a practical reference for textile SMEs seeking to align their internal culture with agile manufacturing standards. Thus, the research not only highlights the positive influence of lean tools on production efficiency, standardization, and delivery reliability, but also emphasizes their role in shaping organizational culture. These insights are particularly valuable as they illustrate how the systematic application of lean methodologies can address operational shortcomings while contributing to the strategic redesign of workflows—ultimately fostering sustainable productivity improvements and reinforcing long-term competitiveness. Based on the empirical outcomes of these studies, lean manufacturing practices have proven effective in reducing defect rates, underscoring cost reduction and waste elimination as key advantages of lean implementation.

A critical factor in advancing both productivity and sustainability within textile manufacturing lies in the ergonomic configuration of machinery across production environments. It can be argued that a layout prioritizing human-centered design and operational efficiency is essential for manufacturing success. Ergonomically refined production systems not only mitigate operational errors and time-related inefficiencies but also contribute to higher output levels. In this regard, it offered valuable contributions. By applying the SiSMED technique, the authors achieved an ergonomic restructuring of machinery within a production setting. They further employed the Interval-Valued Pythagorean Fuzzy Analytic Hierarchy Process (IVPF-AHP) alongside the Fuzzy Technique for Order Preference by Similarity to Ideal Solution (TOPSIS) to assess the outcomes. Their results revealed a 58% reduction in machine setup time and a 19% enhancement in ergonomic conditions [

32].

A related study utilized the Spaghetti Diagram within a lean management framework to optimize business processes through ergonomic improvements in the Hybrid Manufacturing and Machine Building Industry (HMMBI) [

33]. By identifying and resolving bottlenecks, the study achieved reductions in both operational and idle times, culminating in an 8.6% increase in process cycle efficiency. Similarly, it also focused on boosting productivity by redesigning business models through the elimination of non-value-adding activities using lean methodologies. Employing tools such as Value Stream Mapping and the Spaghetti Diagram, the researchers identified inefficiencies and losses in various workflow stages. Their intervention led to measurable improvements in production time, process duration, and the handling of raw, semi-finished, and finished materials, resulting in a 25.59% increase in overall process cycle efficiency [

34].

These findings collectively demonstrate that lean-based reconfiguration of business processes positively influences productivity and waste reduction, thereby supporting sustainable operations. Within the textile manufacturing domain, numerous recent studies have adopted lean strategies to restructure business models with the dual aim of enhancing efficiency and minimizing waste [

35,

36,

37,

38,

39,

40,

41]. For instance, it showed the effectiveness of Value Stream Mapping (VSM), SMED, and standardized work practices in optimizing fabric-cutting operations, leading to reduced rework, fewer delays, and notable productivity gains [

35]. It also emphasized the benefits of integrating Overall Equipment Effectiveness (OEE) with Total Productive Maintenance (TPM) and Six Sigma, which significantly improved production efficiency by addressing material and accessory availability issues [

36]. Moreover, Afum et al. (2024) examined the combined application of lean practices (LPs) and Quick Response Manufacturing (QRM) in Ghana’s textile sector during the COVID-19 pandemic, revealing that QRM played a mediating role in enhancing both internal operations and customer satisfaction [

37]. In the context of yarn production, it adopted a system dynamics model to implement 5S strategies, resulting in increased throughput and reductions in work-in-progress, processing time, and waste [

38]. Additionally, it applied VSM to identify non-value-adding steps in the preparatory phase of textile production, achieving improvements in cycle time, lead time, and process transparency [

23]. Finally, Tejada et al. (2025) proposed a data-driven lean manufacturing framework incorporating 5S, Total Productive Maintenance (TPM), digitalization, and advanced analytics, which—when piloted in a Peruvian textile micro-enterprise—led to a measurable productivity increase and demonstrated the effectiveness of integrating lean tools with data intelligence to address operational inefficiencies [

39].

Taking together, these studies highlight the transformative capacity of lean methodologies in re-engineering business models to foster productivity, sustainability, and long-term competitiveness in textile manufacturing.

Recent scholarly work has increasingly focused on advancing sustainability within the textile industry by harnessing data-driven insights made possible through digital transformation and Industry 4.0 technologies. These studies adopt lean management principles to enhance productivity and minimize inefficiencies, thereby promoting more sustainable manufacturing systems [

42,

43,

44]. In this context, an empirical study was conducted, identifying key enablers for successful Industry 4.0 implementation in Indian manufacturing sectors, including textiles, highlighting the pivotal roles of organizational commitment, employee preparedness, technological readiness, and effective data utilization [

42]. Complementarily, another study also explored the dual transition—digital and sustainable—among textile firms in Italy’s Prato region, demonstrating that the integration of Industry 4.0 tools with lean methodologies significantly supports both environmental sustainability and innovation in business models [

43]. Additionally, Azzolini Junior et al. (2025) introduced a simulation-based decision-support system that merges lean practices with optimization techniques, yielding tangible improvements in operational performance and throughput within a textile packaging environment [

44].

To contextualize the innovative contribution of this study, a comparative analysis of recent scholarly work on lean manufacturing and digital transformation in textile production is presented in

Table 1. The table synthesizes key studies that address similar thematic areas, methodological approaches, and toolsets, enabling a clearer understanding of how this research advances the field.

The reviewed literature demonstrates a consistent emphasis on productivity enhancement through lean tools such as 5S, Poka-Yoke, SMED, and Value Stream Mapping. While these interventions have yielded measurable improvements in operational efficiency, waste reduction, and delivery reliability, most studies remain limited in their integration of digital technologies. For instance, several works focus solely on physical process optimization without embedding real-time data systems or digital process modelling frameworks.

Moreover, sustainability is often addressed narrowly—primarily through ergonomic improvements or reductions in idle time and material waste. In contrast, the present study adopts a broader sustainability perspective, encompassing environmental, economic, and operational dimensions. It also distinguishes itself by embedding lean tools within a digitally enabled Business Process Management (BPM) structure supported by IoT technologies, thereby facilitating data-driven decision-making and continuous improvement.

Table 1 below provides a structured comparison of key studies in the field of lean manufacturing and digital transformation within textile production. It synthesizes the thematic focus, methodological approaches, toolsets, sustainability dimensions, and digital integration levels of each study. This comparative overview serves to highlight the distinctive contribution of the present research, which integrates lean methodologies with Industry 4.0 technologies through a digitally enabled Business Process Management (BPM) framework tailored to the operational realities of textile SMEs.

In conclusion, despite the growing body of research integrating lean manufacturing and digital transformation, most existing studies tend to examine these domains in isolation—either focusing on the application of lean tools or on the adoption of Industry 4.0 technologies without a unified operational framework. This fragmentation leaves a critical gap in the literature regarding how data-driven lean practices can be systematically embedded within digitalized business process models to achieve both operational efficiency and long-term sustainability. Addressing this gap, the present study proposes a holistic, data-centric framework that integrates SMED, work standardization, and ergonomic layout redesign within a digitally enabled BPM structure, supported by real-time data analytics. By doing so, it not only enhances production efficiency and process agility but also empowers operators through digital control mechanisms. Accordingly, this research seeks to answer the following questions:

- (1)

How can lean manufacturing tools be effectively integrated into a digital BPM framework to improve production efficiency in textile manufacturing?

- (2)

What role does real-time data tracking play in enhancing transparency, decision-making, and sustainability outcomes in re-engineered production systems?

- (3)

To what extent can such an integrated approach contribute to long-term operational resilience and competitiveness in the textile sector?