How Does Digital Transformation Drive Green Innovation? The Key Roles of Green Dynamic Capabilities and Environmental Munificence

Abstract

1. Introduction

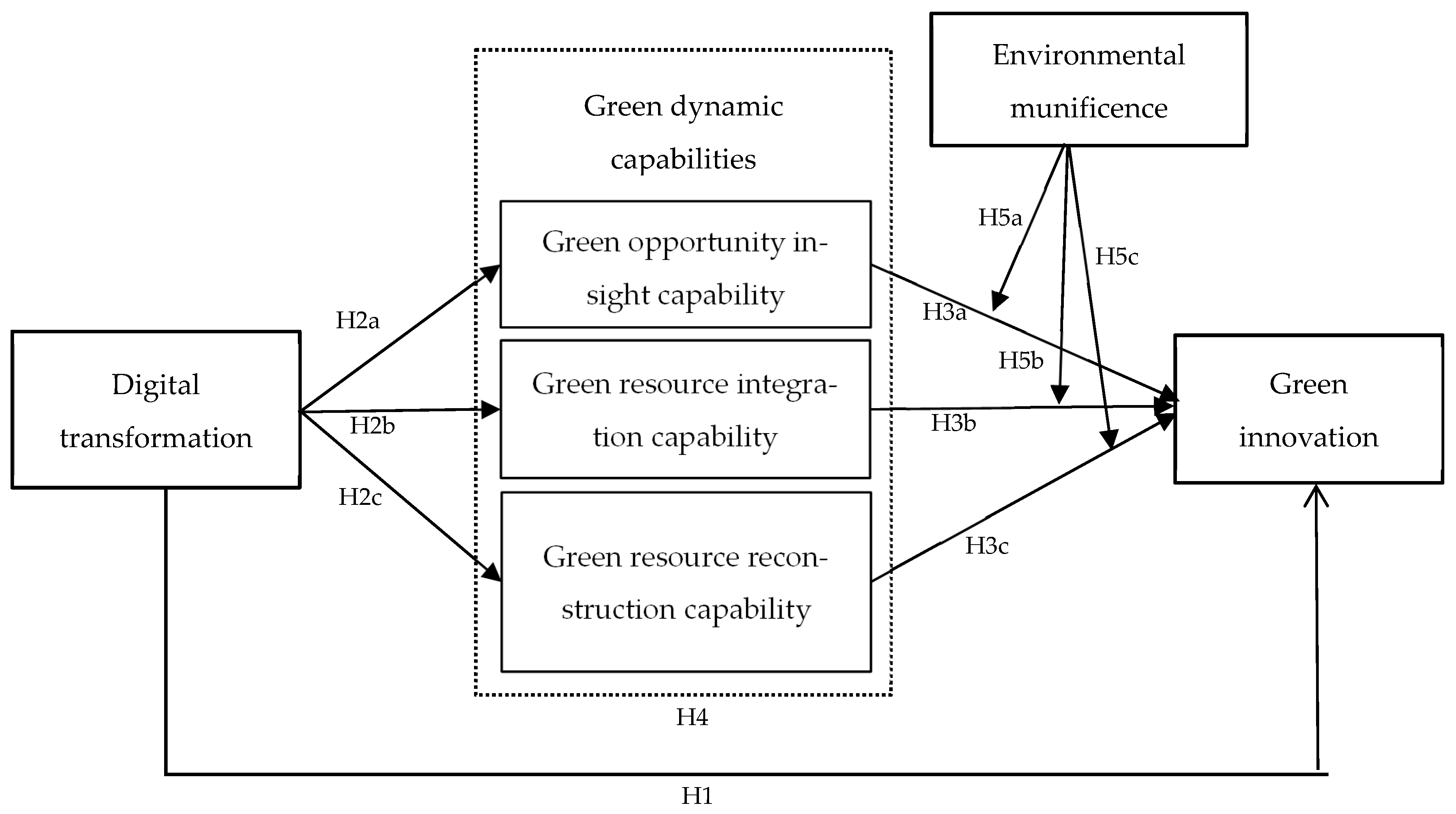

2. Theoretical Analysis and Research Hypotheses

2.1. Theoretical Framework Based on RBV and DCT

2.2. Digital Transformation and Green Innovation

2.3. Digital Transformation and Green Dynamic Capabilities

2.4. Green Dynamic Capabilities and Green Innovation

2.5. The Mediating Role of Green Dynamic Capabilities

2.6. The Moderating Role of Environmental Munificence

3. Research Design

3.1. Sample Selection and Data Sources

3.2. Variable Measurement

4. Empirical Analyses

4.1. Reliability and Validity Tests of the Questionnaire

4.2. Common Method Bias

4.3. Descriptive Statistics and Correlation Analysis

4.4. Test of the Mediating Effect of the Direct Effect of Digital Transformation and Green Dynamic Capabilities

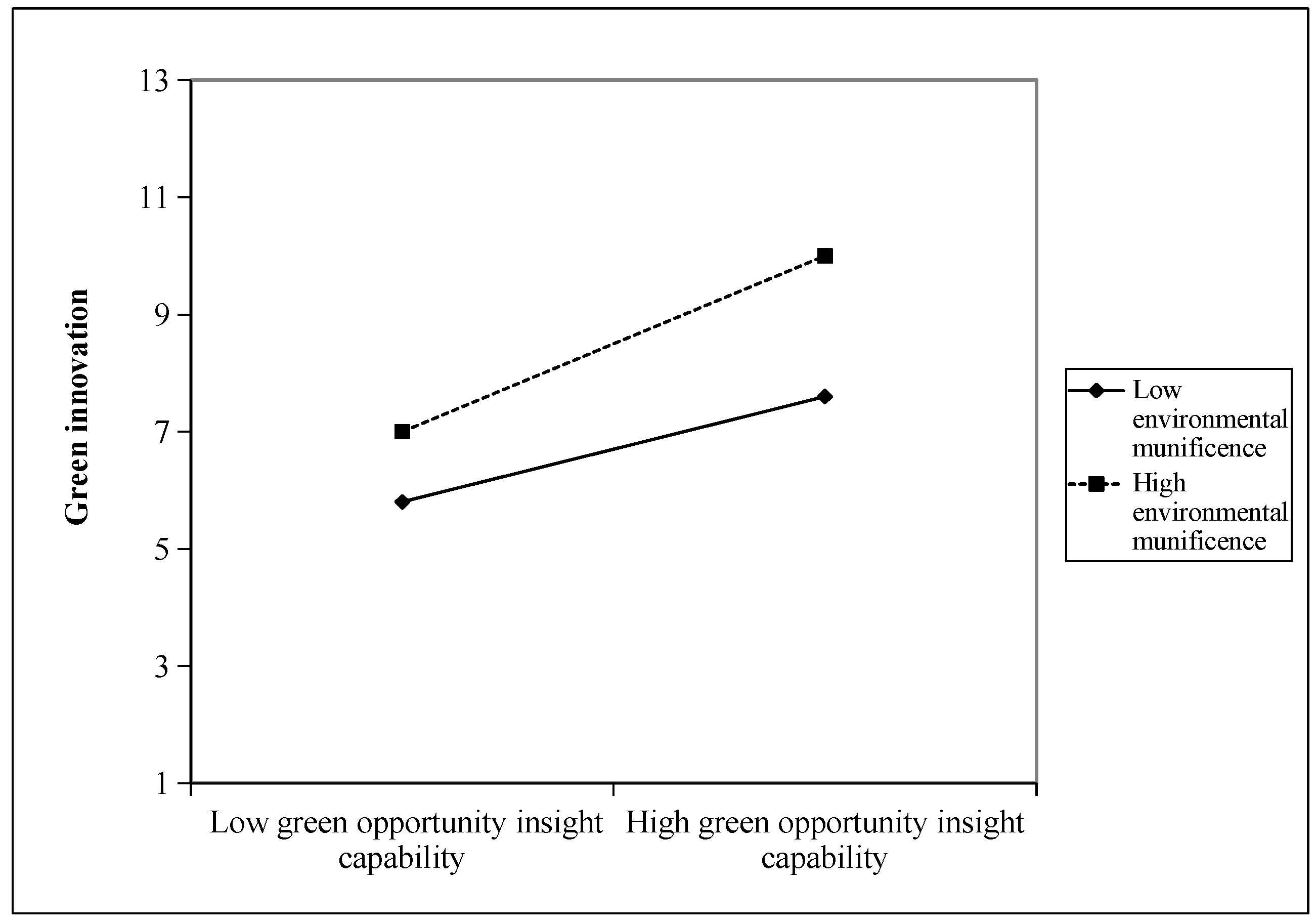

4.5. Tests of the Moderating Effect of Environmental Munificence

4.6. Tests for Moderated Mediation Effects

4.7. Case Analysis from Other Countries

4.8. Discussion

5. Conclusions

5.1. Conclusions of the Research

5.2. Theoretical and Managerial Implications

- (1)

- Theoretical implications

- (2)

- Managerial Implications

5.3. Limitations and Future Research

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Variable | Dimension | Item | Sources |

|---|---|---|---|

| Digital transformation | DT1: Are business processes based on digital technology | Based on Chi et al. [66] | |

| DT2: Is digital technology used to integrate and change business processes | |||

| DT3: Business operations are shifting to using digital technology | |||

| Green innovation | GI1: Use of environmentally friendly product materials in the product development, design, improvement, and production process | Based on Li [67] | |

| GI2: Use of biodegradable packaging for existing products or new products | |||

| GI3: The ease of recycling, reuse, and decomposition is evaluated during the product improvement and design processes | |||

| GI4: Less resources are used in the product development, design, improvement, and production processes, and green product labels are used | |||

| GI5: Reduce the use of water, electricity, coal, oil and other energy sources in the production process | |||

| GI6: Use clean production technology to save energy and prevent pollutants | |||

| GI7: Can be recycled, reused, and remanufactured materials | |||

| GI8: Effectively reduce the discharge of harmful substances and waste in the production process | |||

| GI9: Has the production process effectively reduced the use of raw materials | |||

| Green dynamic capabilities | Green opportunity insight capability | GOIC1: Timely understanding and grasping of the support policies related to green development | Refer to Qiu et al. [44] |

| GOIC2: Timely grasping and responding to the green technology changes in the industry | |||

| GOIC3: Timely understanding and grasping of the industry development trend | |||

| GOIC4: Timely understanding of the green needs of customers to adapt to the market changes | |||

| Green resource integration capability | GRIC1: Environmental protection department, product design, manufacturing, marketing and other departments to cooperate with each other | ||

| GRIC2: Customer requirements for environmental performance will be considered | |||

| GRIC3: Supplier knowledge and capabilities will be incorporated into the environmental impact of raw materials and components | |||

| GRIC4: Supplier knowledge and capabilities will be incorporated into the environmental impact of the production process | |||

| GRIC5: Will work with wholesalers, retailers and other channel members to minimise environmental hazards to the product | |||

| Green resource reconstruction capability | GRRC1: Recruiting environmental experts in product lifecycle assessment and environmental design | ||

| GRRC2: Training product development team members or developers by attending meetings, holding symposiums or other means to improve their environmental knowledge and competence | |||

| GRRC3: Increase research and development efforts in product environmental protection (such as increasing investment) | |||

| GRRC4: Restructuring by creating new divisions, adjusting product lines, or otherwise focusing on environmental sustainability | |||

| GRRC5: Adjust the relationship with suppliers by conducting environmental audit or replacing suppliers to reduce the environmental pollution caused by their products | |||

| GRRC6: Adjust the relationship with customers to mitigate the environmental impact of their products (such as lending products rather than selling them) | |||

| Environmental munificence | EM: There is almost no possible threat to the survival and development of enterprises | Adapted from Li et al. [69] |

References

- Hammami, S.; Bachegour, H.; Samour, A.; Dimnwobi, S.K.; Mati, S. Technological innovation, industrialization, natural resources and ecological quality: Evidence from the load capacity factor. Discov. Sustain. 2025, 6, 355. [Google Scholar] [CrossRef]

- Lu, Q.; Deng, J.; Chen, S.; Hussain, Y. Managerial myopia and its barrier to green innovation in high-pollution enterprises: A machine learning approach. J. Environ. Manag. 2025, 376, 124477. [Google Scholar] [CrossRef]

- Algieri, B.; Aquino, A.; Succurro, M. Green-go: A green innovation competitiveness index. Sustain. Futures 2025, 10, 101062. [Google Scholar] [CrossRef]

- Schupfer, H.; Soppe, B. Greening from within: The role of organisational purpose shift in building internal legitimacy for fossil fuel incumbents’ green innovation. Ind. Innov. 2025, 32, 84–107. [Google Scholar] [CrossRef]

- Gao, J.; Feng, Q.; Guan, T.; Zhang, W. Unlocking paths for transforming green technological innovation in manufacturing industries. J. Innov. Knowl. 2023, 8, 100394. [Google Scholar] [CrossRef]

- Amani, A.M.; Tayebi, L.; Vafa, E.; Abbasi, M.; Vaez, A.; Kamyab, H.; Bazargan-Lari, R. On the horizon of greener pathways to travel into a greener future portal: Green MXenes, environment-friendly synthesis, and their innovative applications. J. Clean. Prod. 2024, 436, 140606. [Google Scholar] [CrossRef]

- Maulidi, A. Cost efficiency and green product innovation in SMEs for emerging economies: The roles of green brand knowledge and green innovation capability. J. Clean. Prod. 2025, 498, 145130. [Google Scholar] [CrossRef]

- Li, L.; Das, G.; Tunio, R.A.; Gopang, A.A.; Memon, S. Green innovation dynamics in SMEs: Unraveling the interplay of approach, expenditure, and performance. Sustain. Futures 2025, 10, 100888. [Google Scholar] [CrossRef]

- Abilakimova, A.; Bauters, M.; Afolayan Ogunyemi, A. Systematic literature review of digital and green transformation of manufacturing SMEs in Europe. Prod. Manuf. Res. 2025, 13, 2443166. [Google Scholar] [CrossRef]

- Costa, F.; Alemsan, N.; Bilancia, A.; Tortorella, G.L.; Staudacher, A.P. Integrating industry 4.0 and lean manufacturing for a sustainable green transition: A comprehensive model. J. Clean. Prod. 2024, 465, 142728. [Google Scholar] [CrossRef]

- El-Kassar, A.N.; Singh, S.K. Green innovation and organizational performance: The influence of big data and the moderating role of management commitment and HR practices. Technol. Forecast. Soc. Change 2019, 144, 483–498. [Google Scholar] [CrossRef]

- Mubarak, M.F.; Tiwari, S.; Petraite, M. How Industry 4.0 technologies and open innovation can improve green innovation performance? Manag. Environ. Qual. 2021, 32, 1007–1022. [Google Scholar] [CrossRef]

- Singh, R.; Joshi, A.; Dissanayake, H.; Iddagoda, A.; Khan, S.; Félix, M.J.; Santos, G. Integrating Industry 4.0, Circular Economy, and Green HRM: A Framework for Sustainable Transformation. Sustainability 2025, 17, 3082. [Google Scholar] [CrossRef]

- Liu, M.; Huang, X.; Wang, P.; Liao, Y. Enterprise digitalization, organizational slack, and green innovation. Int. Rev. Econ. Financ. 2025, 103, 104443. [Google Scholar] [CrossRef]

- Liu, Q.; Chen, R.; Gao, Q.; Yue, W. Improving sustainable development performance of new energy industry through green innovation network evolution empowered by digitalization: Based on temporal exponential random graph model. Energy Convers. Manag. 2025, 324, 119253. [Google Scholar] [CrossRef]

- Raoufi, K.; Sutherland, J.W.; Zhao, F.; Clarens, A.F.; Rickli, J.L.; Fan, Z.; Haapala, K.R. Current state and emerging trends in advanced manufacturing: Smart systems. Int. J. Adv. Manuf. Technol. 2024, 134, 3031–3050. [Google Scholar] [CrossRef]

- Tran, N.K.H. Customer pressure and creating green innovation: The role of green thinking and green creativity. Sustain. Futures 2024, 7, 100177. [Google Scholar] [CrossRef]

- Shahzad, M.A.; Chen, S.; Iqbal, T.; Li, Z. Sustainable futures: Leveraging green intellectual capital, HRM, innovation and leadership. J. Intellect. Cap. 2025, 26, 807–838. [Google Scholar] [CrossRef]

- Fu, X.; Pietrobelli, C.; Soete, L. The role of foreign technology and indigenous innovation in the emerging economies: Technological change and catching-up. World Dev. 2011, 39, 1204–1212. [Google Scholar] [CrossRef]

- Li, W.; Wu, W.; Liu, Y.; Yu, B. How China’s manufacturers achieve technological catch-up: The periphery-core mode of R&D cooperation. Chin. Manag. Stud. 2017, 11, 139–162. [Google Scholar] [CrossRef]

- Liu, J.; Yu, J.; Chen, F.; Zhang, Y.; Li, B. How latecomers strategically respond to global-local resources and leverage local ecosystems: Evidence from China’s integrated circuit design firms. Technol. Forecast. Soc. Change 2022, 183, 121872. [Google Scholar] [CrossRef]

- Liu, J.; Jiang, Y.; Gan, S.; He, L.; Zhang, Q. Can digital finance promote corporate green innovation? Environ. Sci. Pollut. Res. 2022, 29, 35828–35840. [Google Scholar] [CrossRef]

- Padilla-Lozano, C.P.; Collazzo, P. Corporate social responsibility, green innovation and competitiveness-causality in manufacturing. Compet. Rev. 2022, 32, 21–39. [Google Scholar] [CrossRef]

- Li, Q.; Gao, Q.; Zhang, Y.; Gou, C. How can small and medium-sized manufacturing enterprises improve green innovation performance through innovation ecosystems? Sustainability 2024, 16, 2519. [Google Scholar] [CrossRef]

- Singh, S.K.; Del Giudice, M.; Jabbour, C.J.C.; Latan, H.; Sohal, A.S. Stakeholder pressure, green innovation, and performance in small and medium-sized enterprises: The role of green dynamic capabilities. Bus. Strategy Environ. 2022, 31, 500–514. [Google Scholar] [CrossRef]

- Zhou, H.; Zhao, S. Green supply chain integration on firm’s green innovation: The moderating role of resource orchestration capability. Oper. Manag. Res. 2024, 17, 1380–1396. [Google Scholar] [CrossRef]

- Dangelico, R.M.; Pujari, D.; Pontrandolfo, P. Green product innovation in manufacturing firms: A sustainability-oriented dynamic capability perspective. Bus. Strategy Environ. 2017, 26, 490–506. [Google Scholar] [CrossRef]

- Sun, Y.; Sun, H. Green innovation strategy and ambidextrous green innovation: The mediating effects of green supply chain integration. Sustainability 2021, 13, 4876. [Google Scholar] [CrossRef]

- Song, Y.; Gao, W.; Lee, C.C. Does China’s green credit interest subsidies policy promote enterprises’ green technology innovation quality? Based on the perspective of financial and fiscal coordination. J. Environ. Manag. 2025, 390, 126366. [Google Scholar] [CrossRef]

- Hu, C.; Yang, H.; Yin, S. Insight into the balancing effect of a digital green innovation (DGI) network to improve the performance of DGI for industry 5.0: Roles of digital empowerment and green organization flexibility. Systems 2022, 10, 97. [Google Scholar] [CrossRef]

- Alcalde-Calonge, A.; Ruiz-Palomino, P.; Sáez-Martínez, F.J. Fostering circular economy in small and medium-sized enterprises: The role of social capital, adaptive capacity, entrepreneurial orientation and a pro-sustainable environment. Bus. Strategy Environ. 2024, 33, 8882–8899. [Google Scholar] [CrossRef]

- Niesten, E.; Jolink, A. Motivations for environmental alliances: Generating and internalizing environmental and knowledge value. Int. J. Manag. Rev. 2020, 22, 356–377. [Google Scholar] [CrossRef]

- Chen, R.; Cao, L. How do enterprises achieve sustainable success in green manufacturing era? The impact of organizational environmental identity on green competitive advantage in China. Kybernetes 2025, 54, 71–89. [Google Scholar] [CrossRef]

- Chowdhury, S.K.; Endres, M.L. The influence of regional economy-and industry-level environmental munificence on young firm growth. J. Bus. Res. 2021, 134, 29–36. [Google Scholar] [CrossRef]

- Barney, J. Firm resources and sustained competitive advantage. J. Manag. 1991, 17, 99–120. [Google Scholar] [CrossRef]

- Abiodun, T.S.; Rampersad, G.; Brinkworth, R. Driving smartness for organizational performance through Industry 4.0: A systems perspective. J. Manuf. Technol. Manag. 2023, 34, 40–63. [Google Scholar] [CrossRef]

- Ritter, T.; Pedersen, C.L. Digitization capability and the digitalization of business models in business-to-business firms: Past, present, and future. Ind. Mark. Manag. 2020, 86, 180–190. [Google Scholar] [CrossRef]

- Wang, Z.; Lin, S.; Chen, Y.; Lyulyov, O.; Pimonenko, T. Digitalization effect on business performance: Role of business model innovation. Sustainability 2023, 15, 9020. [Google Scholar] [CrossRef]

- Lin, Y.; Wang, Q.J.; Zheng, M.Q. Nexus among digital economy, green innovation, and green development: Evidence from China. Emerg. Mark. Financ. Trade 2024, 60, 704–723. [Google Scholar] [CrossRef]

- Yin, X.; Wang, Z.; Chen, J.; Li, J. Digital Transformation and Green Technology Innovation in Manufacturing Enterprises: A Study Based on Big Data Text Mining. Front. Bus. Res. China 2024, 18, 298–317. [Google Scholar] [CrossRef]

- Sui, X.; Jiao, S.; Wang, Y.; Wang, H. Digital transformation and manufacturing company competitiveness. Financ. Res. Lett. 2024, 59, 104683. [Google Scholar] [CrossRef]

- Teece, D.J.; Pisano, G.; Shuen, A. Dynamic capabilities and strategic management. Strateg. Manag. J. 1997, 18, 509–533. [Google Scholar] [CrossRef]

- Teece, D.J. Dynamic capabilities as (workable) management systems theory. J. Manag. Organ. 2018, 24, 359–368. [Google Scholar] [CrossRef]

- Qiu, L.; Jie, X.; Wang, Y.; Zhao, M. Green product innovation, green dynamic capability, and competitive advantage: Evidence from Chinese manufacturing enterprises. Corp. Soc. Responsib. Environ. Manag. 2020, 27, 146–165. [Google Scholar] [CrossRef]

- Ben Amara, D.; Chen, H.; Hafeez, M. Role of entrepreneurial opportunity identification factors in the eco-innovation of agribusiness. Bus. Strategy Dev. 2020, 3, 435–448. [Google Scholar] [CrossRef]

- Tang, X.; Zhao, C.; Shen, Z. The green innovation effect of intelligent manufacturing: Substantive innovation or strategic innovation? Technol. Anal. Strateg. Manag. 2025, 1–17. [Google Scholar] [CrossRef]

- Cui, R.; Wang, J.; Xue, Y.; Liang, H. Interorganizational learning, green knowledge integration capability and green innovation. Eur. J. Innov. Manag. 2021, 24, 1292–1314. [Google Scholar] [CrossRef]

- Idrees, H.; Xu, J.; Andrianarivo Andriandafiarisoa Ralison, N.A. Green entrepreneurial orientation and knowledge creation process as enablers of green innovation performance: The moderating role of resource orchestration capability. Eur. J. Innov. Manag. 2025, 28, 754–782. [Google Scholar] [CrossRef]

- Liu, Y.; Mao, M.; Zhang, Y.; Xie, X. Leveraging digital empowerment for green product innovation: Unraveling the mediating role of resource integration and reconfiguration in Chinese manufacturing enterprises. Systems 2023, 11, 489. [Google Scholar] [CrossRef]

- Silva, S.E.; Correa, S.F.; Monnerat, C.S. Economic performance assessment of green innovation: A systematic literature review. Environ. Sustain. Indic. 2025, 27, 100804. [Google Scholar] [CrossRef]

- Wei, S.; Liu, H.; Xu, W.; Chen, X. The impact of supply chain digitalization on supply chain performance: A moderated mediation model. Inf. Technol. Manag. 2024, 1–15. [Google Scholar] [CrossRef]

- Bai, X.; Zhang, Z. Does the digital innovation ecosystem promote green technology innovation? Evidence from 264 cities in China. Technol. Soc. 2025, 83, 102977. [Google Scholar] [CrossRef]

- Li, H.; Yang, Z.; Wang, H.; Li, Y. Digitalization of business models, knowledge management and green technology innovation of Chinese manufacturing enterprises: A mixed analysis based on the Haier COSMOPlat ecosystem. Asia Pac. Bus. Rev. 2023, 1–29. [Google Scholar] [CrossRef]

- Mehmood, K.; Kautish, P.; Rashid, M.; Joshi, Y.; Iftikhar, Y. Digitalization in the circular economy: Synergistic impact of big data analytics, green internet of things, and ambidextrous green innovation. J. Clean. Prod. 2025, 509, 145610. [Google Scholar] [CrossRef]

- Xie, X.; Wang, M. Firms’ digital capabilities and green collaborative innovation: The role of green relationship learning. J. Innov. Knowl. 2025, 10, 100663. [Google Scholar] [CrossRef]

- Warner, K.S.; Wäger, M. Building dynamic capabilities for digital transformation: An ongoing process of strategic renewal. Long Range Plan. 2019, 52, 326–349. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, J.Z.; Jasimuddin, S.; Babai, M.Z. Exploring servitization and digital transformation of manufacturing enterprises: Evidence from an industrial internet platform in China. Int. J. Prod. Res. 2024, 62, 2812–2831. [Google Scholar] [CrossRef]

- Gregori, P.; Holzmann, P. Digital sustainable entrepreneurship: A business model perspective on embedding digital technologies for social and environmental value creation. J. Clean. Prod. 2020, 272, 122817. [Google Scholar] [CrossRef]

- Salamah, E.; Alzubi, A.; Yinal, A. Unveiling the impact of digitalization on supply chain performance in the post-COVID-19 era: The mediating role of supply chain integration and efficiency. Sustainability 2023, 16, 304. [Google Scholar] [CrossRef]

- Ning, J.; Jiang, X.; Luo, J. Relationship between enterprise digitalization and green innovation: A mediated moderation model. J. Innov. Knowl. 2023, 8, 100326. [Google Scholar] [CrossRef]

- Shimabukuro, N.M.; Paletta, F.C. Information anxiety and organizational performance: Challenges and solutions in the digital age. RDBCI-Rev. Digit. Bibliotecon. Cienc. Inf. 2025, 23, e025027. [Google Scholar] [CrossRef]

- Hartmann, J.; Vachon, S. Linking environmental management to environmental performance: The Interactive Role of Industry Context. Bus. Strategy Environ. 2018, 27, 359–374. [Google Scholar] [CrossRef]

- Xu, G.; Zhang, J.; Wang, S. How digitalization and sustainability promote digital green innovation for industry 5.0 through capability reconfiguration: Strategically oriented insights. Systems 2024, 12, 341. [Google Scholar] [CrossRef]

- Chen, Z.; Shentu, Q.N.; Cai, B.Q. Selection strategies for blockchain platforms to reduce carbon emissions in SMEs: A collaborative approach involving government, enterprises, and blockchain technology. J. Saf. Environ. 2025, 25, 3413–3424. [Google Scholar] [CrossRef]

- Podsakoff, P.M.; Mackenzie, S.B.; Lee, J.Y.; Podsakoff, N.P. Common method biases in behavioral research: A critical review of the literature and recommended remedies. J. Appl. Psychol. 2003, 88, 879–903. [Google Scholar] [CrossRef] [PubMed]

- Chi, M.; Ye, D.; Wang, J.; Zhai, S. How to improve the performance of new product development in Chinese small and medium-sized manufacturing enterprises: Based on the perspective of digital empowerment. Nankai Manag. Rev. 2020, 23, 63–75. [Google Scholar]

- Li, H.Y. Green innovation, green dynamic capability, and enterprise performance: Evidence from heavy polluting manufacturing enterprises in China. Complexity 2022, 2022, 7755964. [Google Scholar] [CrossRef]

- Chen, Y.S.; Lai, S.B.; Wen, C.T. The influence of green innovation performance on corporate advantage in Taiwan. J. Bus. Ethics. 2006, 67, 331–339. [Google Scholar] [CrossRef]

- Li, Y.; Wei, Z.; Zhao, J.; Zhang, C.; Liu, Y. Ambidextrous organizational learning, environmental munificence and new product performance: Moderating effect of managerialties in China. Int. J. Prod. Econ. 2013, 146, 95–105. [Google Scholar] [CrossRef]

- Dehghanimadvar, M.; Egan, R.; Chang, N.L. Quantifying the costs of diversifying silicon PV module assembly with local economic policies. Joule 2024, 8, 1322–1349. [Google Scholar] [CrossRef]

- Borah, P.S.; Dogbe, C.S.K.; Marwa, N. Green dynamic capability and green product innovation for sustainable development: Role of green operations, green transaction, and green technology development capabilities. Corp. Soc. Responsib. Environ. Manag. 2024, 32, 911–926. [Google Scholar] [CrossRef]

- Horn, M. The European green deal, retail investors and sustainable investments: A perspective article covering economic, behavioral, and regulatory insights. Curr. Res. Environ. Sustain. 2024, 7, 100241. [Google Scholar] [CrossRef]

- Bistline, J.; Blanford, G.; Brown, M.; Burtraw, D.; Domeshek, M.; Farbes, J.; Fawcett, A.; Hamilton, A.; Jenkins, J.; Jones, R.; et al. Emissions and energy impacts of the Inflation Reduction Act. Science 2023, 380, 1324–1327. [Google Scholar] [CrossRef] [PubMed]

- Sun, Z.; Zhao, L.; Mehrotra, A.; Salam, M.A.; Yaqub, M.Z. Digital transformation and corporate green innovation: An affordance theory perspective. Bus. Strategy Environ. 2025, 34, 433–449. [Google Scholar] [CrossRef]

- Hao, X.; Miao, E.; Wen, S.; Xue, Y.; Wu, H. Digital tsunami and the green wave: How R&D steers enterprise innovation towards sustainability. Environ. Dev. Sustain. 2025, 1–26. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, Q.; Pan, X.; Mata, M.N. Green entrepreneurial intention, knowledge management process, and green entrepreneurial behaviour through a lens of transformative innovation. J. Innov. Knowl. 2024, 9, 100567. [Google Scholar] [CrossRef]

- Yi, Y.; Zeng, S.; Chen, H.; Shi, J.J. When does it pay to be good? A meta-analysis of the relationship between green innovation and financial performance. IEEE Trans. Eng. Manag. 2021, 70, 3260–3327. [Google Scholar] [CrossRef]

- Nguyen, N.T.T.; Van Nguyen, P.; Vrontis, D.; Vo, N.T.T. Enhancing organizational sustainable performance through green innovation: The roles of knowledge application, government policy, and green market orientation. J. Knowl. Manag. 2025, 29, 870–890. [Google Scholar] [CrossRef]

- Farooq, U.; Wen, J.; Tabash, M.I.; Fadoul, M. Environmental regulations and capital investment: Does green innovation allow to grow? Int. Rev. Econ. Financ. 2024, 89, 878–893. [Google Scholar] [CrossRef]

- Langinier, C.; Martínez-Zarzoso, I.; RayChaudhuri, A. Environmental regulations and green innovation: The role of trade and technology transfer. Energy Econ. 2025, 150, 108755. [Google Scholar] [CrossRef]

| Feature | Type | Quantity | Proportion | Feature | Type | Quantity | Proportion |

|---|---|---|---|---|---|---|---|

| Company nature | Belong to the state | 65 | 20.83% | Scale | Less than 20 people | 10 | 3.21% |

| Privately operated | 194 | 62.18% | From 20–299 persons | 63 | 20.19% | ||

| Joint venture | 39 | 12.50% | From 300–999 persons | 136 | 43.59% | ||

| Foreign capital | 6 | 1.92% | More than 1000 persons | 103 | 33.01% | ||

| Other | 8 | 2.564% | Average per year Sales volume | Less than $3 million yuan | 18 | 5.7% | |

| Company years | Under 3 years | 37 | 11.86% | 3–20 million yuan | 104 | 33.3% | |

| 3–5 Years | 83 | 26.60% | 20 million–400 million yuan | 133 | 42.5% | ||

| 6–8 Years | 79 | 25.32% | Over 400,000 million yuan | 57 | 18.4% | ||

| More than 8 years | 113 | 36.22% |

| Variable | Measure the Item | α Price | CR | AVE | Load | Overall α Values |

|---|---|---|---|---|---|---|

| Digital transformation | Are business processes based on digital technology | 0.817 | 0.885 | 0.720 | 0.864 | ------ |

| Is digital technology used to integrate and change business processes | 0.816 | |||||

| Business operations are shifting to using digital technology | 0.864 | |||||

| Green opportunity insight capability | Timely understanding and grasping of the support policies related to green development | 0.886 | 0.889 | 0.667 | 0.831 | 0.945 |

| Timely grasping and responding to the green technology changes in the industry | 0.831 | |||||

| Timely understanding and grasping of the industry development trend | 0.803 | |||||

| Timely understanding of the green needs of customers to adapt to the market changes | 0.800 | |||||

| Green resource integration capability | Environmental protection department, product design, manufacturing, marketing and other departments to cooperate with each other | 0.890 | 0.890 | 0.618 | 0.774 | |

| Customer requirements for environmental performance will be considered | 0.792 | |||||

| Supplier knowledge and capabilities will be incorporated into the environmental impact of raw materials and components | 0.752 | |||||

| Supplier knowledge and capabilities will be incorporated into the environmental impact of the production process | 0.789 | |||||

| Will work with wholesalers, retailers and other channel members to minimise environmental hazards to the product | 0.823 | |||||

| Green resource reconstruction capability | Recruiting environmental experts in product lifecycle assessment and environmental design | 0.903 | 0.904 | 0.611 | 0.761 | |

| Training product development team members or developers by attending meetings, holding symposiums or other means to improve their environmental knowledge and competence | 0.837 | |||||

| Increase research and development efforts in product environmental protection (such as increasing investment) | 0.814 | |||||

| Restructuring by creating new divisions, adjusting product lines, or otherwise focusing on environmental sustainability | 0.771 | |||||

| Adjust the relationship with suppliers by conducting environmental audit or replacing suppliers to reduce the environmental pollution caused by their products | 0.709 | |||||

| Adjust the relationship with customers to mitigate the environmental impact of their products (such as lending products rather than selling them) | 0.790 | |||||

| Green innovation | Use of environmentally friendly product materials in the product development, design, improvement, and production process | 0.924 | 0.920 | 0.562 | 0.675 | ------ |

| Use of biodegradable packaging for existing products or new products | 0.701 | |||||

| The ease of recycling, reuse, and decomposition is evaluated during the product improvement and design processes | 0.714 | |||||

| Less resources are used in the product development, design, improvement, and production processes, and green product labels are used | 0.744 | |||||

| Reduce the use of water, electricity, coal, oil and other energy sources in the production process | 0.804 | |||||

| Use clean production technology to save energy and prevent pollutants | 0.760 | |||||

| Can be recycled, reused, and remanufactured materials | 0.762 | |||||

| Effectively reduce the discharge of harmful substances and waste in the production process | 0.792 | |||||

| Has the production process effectively reduced the use of raw materials | 0.786 | |||||

| Environmental munificence | There is almost no possible threat to the survival and development of enterprises | 0.864 | 0.901 | 0.694 | 0.842 | ------ |

| Variable | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

|---|---|---|---|---|---|---|---|---|---|---|

| Nature | / | |||||||||

| Years | 0.102 * | / | ||||||||

| Scale | 0.061 | 0.4370 *** | / | |||||||

| annual sales volume | 0.063 | 0.3710 *** | 0.4150 *** | / | ||||||

| Digital transformation | 0.041 | 0.2460 *** | 0.1890 *** | 0.018 | 0.848 | |||||

| Green opportunity insight capability | 0.132 ** | 0.269 *** | 0.064 | 0.081 | 0.2360 *** | 0.816 | ||||

| Green resource integration capability | 0.107 | 0.283 *** | 0.198 *** | 0.090 | 0.1730 *** | 0.5240 *** | 0.786 | |||

| Green resource reconstruction capability | 0.064 | 0.308 *** | 0.173 *** | 0.142 ** | 0.1630 *** | 0.4770 *** | 0.5920 *** | 0.781 | ||

| Green innovation | 0.106 * | 0.370 *** | 0.293 *** | 0.151 *** | 0.220 *** | 0.5380 *** | 0.7310 *** | 0.7310 *** | 0.749 | |

| Environmental munificence | 0.079 | 0.130 ** | 0.007 | 0.141 ** | 0.3120 *** | 0.231 *** | 0.1590 *** | 0.1650 *** | 0.1670 *** | 0.833 |

| Mean | 2.030 | 2.860 | 3.060 | 3.070 | 4.970 | 4.761 | 4.915 | 4.678 | 4.759 | 4.321 |

| Standard deviation | 0.801 | 1.042 | 0.811 | 0.855 | 1.379 | 1.308 | 1.185 | 1.181 | 1.156 | 1.283 |

| Model | Factor | χ2/df | CFI | TLI | IFI | RMSEA |

|---|---|---|---|---|---|---|

| Model 1 | 6 Factors: DT; GEIC; GRIC; GRRC; EM; GI | 2.086 | 0.929 | 0.922 | 0.930 | 0.059 |

| Model 2 | 4 Factor: DT; GEIC + GRIC + GRRC; EM; GI | 3.873 | 0.809 | 0.792 | 0.810 | 0.096 |

| Model 3 | 1 Factor: DT + GEIC + GRIC + GRRC + EM + GI | 7.004 | 0.595 | 0.566 | 0.597 | 0.139 |

| Variable | GI | GEIC | GRIC | GRRC | GI | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| M1 | M2 | M3 | M4 | M5 | M6 | M7 | M8 | M9 | M10 | M11 | M12 | M13 | M14 | M15 | M16 | M17 | M18 | M19 | M20 | |

| constant term | 3.006 *** | 2.606 *** | 1.837 *** | 0.636 * | 0.7500 ** | 1.583 *** | 0.387 | 0.503 * | 3.551 *** | 2.408 *** | 0.6183 *** | 2.979 *** | 0.4123 *** | 0.7652 *** | 3.405 *** | 3.425 *** | 3.878 *** | 3.938 *** | 3.866 *** | 3.935 *** |

| property | 0.096 | 0.094 | 0.024 | 0.021 | 0.065 | 0.040 | 0.028 | 0.070 | 0.219 * | 0.2290 ** | 0.115 | 0.121 | 0.047 | 0.053 | 0.023 | 0.030 | 0.018 | 0.012 | 0.061 | 0.036 |

| age limit | 0.3340 *** | 0.3030 *** | 0.2560 *** | 0.1490 ** | 0.124 * | 0.235 *** | 0.1300 ** | 0.107 * | 0.235 ** | 0.148 * | 0.282 *** | 0.2330 *** | 0.3170 *** | 0.2670 *** | 0.2540 *** | 0.2590 *** | 0.1450 ** | 0.1530 ** | 0.120 * | 0.1300 ** |

| scale | 0.2450 ** | 0.221 * | 0.2490 ** | 0.144 * | 0.2070 *** | 0.2270 ** | 0.132 * | 0.1910 ** | −0.011 | −0.066 | 0.155 * | 0.124 | 0.059 | 0.028 | 0.2530 ** | 0.2550 *** | 0.152 * | 0.151 * | 0.2140 *** | 0.1960 ** |

| Annual sales | −0.049 | −0.028 | −0.059 | −0.003 | −0.067 | −0.037 | 0.012 | −0.050 | 0.031 | 0.083 | −0.070 | −0.041 | 0.027 * | 0.057 | −0.064 | −0.102 | −0.011 | −0.042 | −0.075 | −0.083 |

| DT | 0.276 * | 0.117 ** | 0.095 *** | 0.0930 *** | 0.3000 *** | 0.167 *** | 0.170 *** | |||||||||||||

| GEIC | 0.3290 *** | 0.275 *** | 0.3220 *** | 0.277 *** | ||||||||||||||||

| GRIC | 0.6550 *** | 0.6240 *** | 0.6490 *** | 0.5930 *** | ||||||||||||||||

| GRRC | 0.6610 *** | 0.6300 *** | 0.6550 *** | 0.6160 *** | ||||||||||||||||

| EM | 0.025 | 0.062 | 0.039 | 0.050 | 0.041 | 0.035 | ||||||||||||||

| GEIC × EM | 0.1210 *** | |||||||||||||||||||

| GRIC × EM | 0.1140 *** | |||||||||||||||||||

| GRRC × EM | 0.1350 *** | |||||||||||||||||||

| R2 | 0.163 | 0.177 | 0.295 | 0.571 | 0.575 | 0.317 | 0.588 | 0.590 | 0.060 | 0.191 | 0.095 | 0.145 | 0.098 | 0.150 | 0.295 | 0.330 | 0.573 | 0.596 | 0.577 | 0.608 |

| ΔR2 | 0.163 | 0.014 | 0.131 | 0.408 | 0.412 | 0.154 | 0.424 | 0.427 | 0.060 | 0.131 | 0.095 | 0.050 | 0.098 | 0.052 | 0.132 | 0.035 | 0.410 | 0.023 | 0.414 | 0.031 |

| F | 14.970 *** | 13.142 *** | 25.553 *** | 81.601 *** | 82.805 *** | 23.571 *** | 72.412 *** | 73.241 *** | 4.907 *** | 14.487 *** | 8.034 *** | 10.374 *** | 8.326 *** | 10.772 *** | 21.291 *** | 21.373 *** | 68.263 *** | 64.146 *** | 69.326 *** | 67.346 *** |

| Group of Regulatory Variables | Intermediary Effect Value | Standard Error | Confidence Interval | Significance p-Values | |

|---|---|---|---|---|---|

| Lower Limit | Superior Limit | ||||

| Mediation effect 1: DTGEI GI | |||||

| Low EM (−1 SD) | 0.037 | 0.018 | 0.005 | 0.077 | 0.000 |

| High EM (+1 SD) | 0.114 | 0.028 | 0.064 | 0.173 | 0.000 |

| Mediation effect 2: DTGRIC GI | |||||

| Low EM (−1 SD) | 0.074 | 0.020 | 0.039 | 0.116 | 0.000 |

| High EM (+1 SD) | 0.119 | 0.027 | 0.066 | 0.174 | 0.000 |

| Mediation effect 3: DTGRRCEM | |||||

| Low EM (−1 SD) | 0.072 | 0.020 | 0.036 | 0.114 | 0.000 |

| High EM (+1 SD) | 0.129 | 0.032 | 0.068 | 0.193 | 0.000 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, R.; Xie, M.; Li, Y. How Does Digital Transformation Drive Green Innovation? The Key Roles of Green Dynamic Capabilities and Environmental Munificence. Sustainability 2025, 17, 8885. https://doi.org/10.3390/su17198885

Liu R, Xie M, Li Y. How Does Digital Transformation Drive Green Innovation? The Key Roles of Green Dynamic Capabilities and Environmental Munificence. Sustainability. 2025; 17(19):8885. https://doi.org/10.3390/su17198885

Chicago/Turabian StyleLiu, Renpu, Mengchen Xie, and Yu Li. 2025. "How Does Digital Transformation Drive Green Innovation? The Key Roles of Green Dynamic Capabilities and Environmental Munificence" Sustainability 17, no. 19: 8885. https://doi.org/10.3390/su17198885

APA StyleLiu, R., Xie, M., & Li, Y. (2025). How Does Digital Transformation Drive Green Innovation? The Key Roles of Green Dynamic Capabilities and Environmental Munificence. Sustainability, 17(19), 8885. https://doi.org/10.3390/su17198885