1. Introduction

The construction industry, a cornerstone of global development, faces the challenge of minimizing its environmental footprint. Traditionally reliant on natural resources such as clay and cement, and a significant generator of waste, the sector is under increasing pressure to adopt more sustainable materials and processes. In this context, waste valorization emerges as a key strategy to mitigate environmental impact and advance toward a circular economy [

1,

2]. One of the most abundant and problematic types of waste is plastic, whose accumulation in landfills and ecosystems poses a critical environmental threat [

3,

4]. The development of innovative construction materials incorporating plastic waste not only offers a solution to the waste management problem [

5] but can also lead to the creation of products with improved or comparable properties to conventional ones—often at a reduced cost [

6,

7]. Bricks, as essential components in building construction [

8], are of particular interest for this type of integration [

9]. Several studies have explored the incorporation of recycled plastics in brick manufacturing [

10], with varying results in terms of their physico-mechanical properties, such as compressive strength, water absorption, density, and thermal conductivity [

11]. However, the optimization of plastic types and proportions, as well as their impact on long-term durability, remains an area that requires further research and standardization [

12]. For instance, while some studies report improvements in lightness and thermal insulation with the addition of certain plastics [

13], others highlight a potential reduction in mechanical strength if the proportions are not adequate or if the interface between the plastic and the clay matrix is suboptimal [

14].

The current global landscape, intensified by the climate crisis and pervasive plastic pollution, demands a paradigm shift in the construction industry toward more sustainable practices. In regions such as Chimbote, Áncash, Peru, this urgency is particularly evident, where El Ferrol Bay faces a recurring ecological crisis due to plastic accumulation, severely impacting marine biodiversity [

15,

16] and the urban landscape [

17]. In parallel, the growing need for affordable housing and the pursuit of innovative materials are driving research into alternatives that not only are technically and economically viable but also minimize environmental impact [

18]. In this context, the valorization of plastic waste in brick manufacturing emerges as a promising strategy, perfectly aligned with the Sustainable Development Goals (SDG 13: Climate Action) [

19]. This approach not only promotes a circular economy by reintegrating discarded materials into the value chain but also contributes to mitigating the exploitation of natural resources [

20]. Numerous studies, both internationally and domestically, support this trend, showing that the integration of recycled plastics into clay or cement matrices can lead to significant improvements in key properties such as mechanical strength, lightness, and thermal insulation—all while reducing the environmental footprint of construction materials [

21].

Worldwide research has explored various pathways for integrating plastics into brick production, yielding promising results. In terms of strength and lightness, bricks incorporating recycled polypropylene (PP) and polyethylene (PE) have been evaluated, revealing impressive compressive strengths of 789 N/cm

2 for PP bricks and 655 N/cm

2 for PE bricks, along with a 20% reduction in weight compared to conventional bricks [

21]. Similarly, in India, the use of polyethylene terephthalate (PET) at inclusion rates between 20% and 40% yielded an impressive compressive strength of 36.18 MPa—substantially higher than the 13.41 MPa recorded for conventional bricks. Additionally, PET-based bricks showed reduced water absorption, highlighting their potential for improved durability and performance in construction applications [

22]. Innovation in processes and materials has also been a key driver in Germany, where bricks have been developed using shredded high-density polyethylene (HDPE) and bitumen, achieving a compressive strength of 37.5 MPa and minimal water absorption (<1%) [

23]. In Malaysia, discarded polypropylene (PP) bumpers were repurposed to create blocks with a water absorption rate of just 0.04%. Structural performance was further enhanced by incorporating 5% bitumen, demonstrating the versatility of plastic waste in construction applications [

24]. In Lima, Peru, blocks incorporating 10% PET and glass demonstrated superior performance, exceeding a compressive strength of 77.99 kg/cm

2 [

25], thus complying with Peru’s rigorous E.070 building standard [

26]. The focus on the circular economy has also been a cornerstone of national research in Lima, where blocks combining rubber and PET (in proportions ranging from 12% to 36%) were evaluated. These blocks were classified between Type III and Type V based on their load-bearing capacity, with compressive strengths reaching up to 174.71 kg/cm

2 [

27]. This integration of PET with metal shavings resulted in compressive strengths of up to 194 kg/cm

2, making the blocks suitable for load-bearing constructions [

28].

Sustainable construction promotes the reduction in environmental impact through the reuse of waste and the use of locally sourced materials [

29]. In this context, the incorporation of recycled polyethylene terephthalate (PET) into construction materials [

30] has been shown to enhance the thermal and mechanical properties of bricks and mortars [

31], with studies reporting compressive strengths of up to 76.85 MPa, low water absorption, and a significant reduction in CO

2 emissions [

32]. In parallel, kaolin—an abundant clay material found in small-scale informal mining—shows great potential for brick manufacturing, although its sustainable use requires innovations to mitigate the associated environmental degradation [

33].

Advances in hybrid materials highlight the viability of bricks made with recycled plastic, with research demonstrating high compressive strengths (38–76 MPa) and a reduced carbon footprint when using PET-sand mixtures [

34]. Likewise, geopolymers incorporating mining waste are being explored [

35], although the specific integration of kaolin from informal mining remains unaddressed. Despite these advancements, significant challenges persist. The direct compatibility between PET and artisanal kaolin has not been widely examined in the literature, particularly regarding adhesion and thermal stability of such combinations. Moreover, although laboratory results show promising strengths (>30 MPa), the scalability of artisanal production and regulatory standardization still require optimization [

31]. It is at this intersection that a clear research gap emerges: no studies have specifically combined recycled PET with kaolin from informal mining for the production of artisanal bricks. While previous works have addressed similar components, none have done so within this particular context of mining by-products and artisanal manufacturing [

32].

This study aims to evaluate the physical and mechanical properties of bricks manufactured using a combination of clay and recycled plastic. The underlying hypothesis is that the controlled incorporation of recycled plastic into the clay matrix will yield bricks with competitive physical and mechanical characteristics compared to conventional bricks while simultaneously offering a sustainable solution for plastic waste valorization. Specifically, the study will investigate the effect of varying percentages of recycled plastic (5%, 10%, and 15%) on compressive strength, water absorption, bulk density, and thermal conductivity, seeking to identify the optimal formulation that balances performance and sustainability. This research directly addresses existing gaps by evaluating the physical and mechanical properties of bricks made with clay and recycled PET. The goal is to actively contribute to reducing plastic pollution in the region; validate a sustainable alternative to traditional bricks that complies with Peru’s E.070 standard [

26], as well as international standards such as ASTM C67 [

36] and ASTM C62 [

37]; and generate robust technical data to support the scalability of production in areas similar to the study site [

38].

The main contribution of this research lies in its dual approach, combining the use of PET and mining waste to produce bricks [

17]. Unlike previous studies that focus on a single type of waste, our work evaluates the technical feasibility of an integrated dual-waste solution [

39]. Furthermore, the study addresses a critical gap in the literature by applying this methodology within an artisanal production context in Peru. In doing so, we not only assess the physical and mechanical properties of the material but also demonstrate how the addition of PET can improve the consistency of the base bricks—an inherent challenge in local manufacturing practices [

40].

Therefore, this research is positioned to fill a critical gap by integrating environmental sustainability (through the use of recycled PET and locally sourced kaolin to reduce waste and mining-related degradation), technical innovation (by optimizing mechanical and thermal properties in artisanal bricks) [

41], and a significant social impact by supporting mining communities through accessible, value-added technologies. This synergistic approach elevates the research beyond a simple material analysis, positioning it as a comprehensive solution that addresses multiple facets of the sustainability challenge.

4. Discussion

This study aimed to evaluate the physical and mechanical properties of bricks incorporating varying proportions of recycled PET plastic (0%, 5%, 10%, and 15%). The findings were contextualized through comparison with prior research, focusing on key parameters such as void ratio, dimensional variability, water absorption, warping, capillary suction, and both unit compressive strength () and prism compressive strength ().

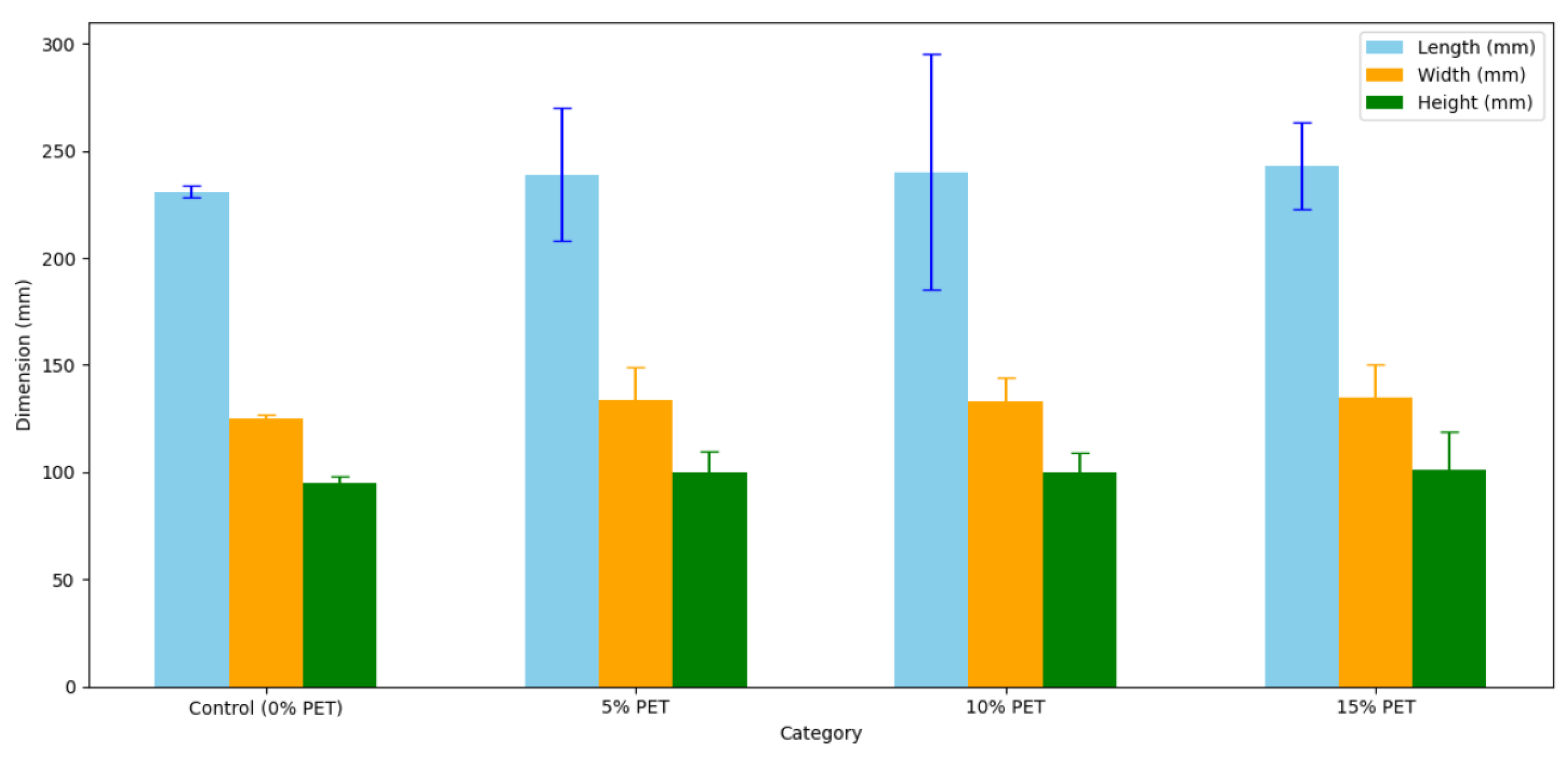

A key finding of this study was the improved dimensional stability (less warping) with increased PET content. The 15% PET mixture exhibited the lowest deformation (concavity: 0.5–0.8 mm; convexity: 0.8–0.9 mm), outperforming even the control brick in some metrics. This suggests that PET particles could act as a filler that more uniformly redistributes thermal stresses during firing, mitigating the typical shrinkage of high-plasticity clays. This result stands in direct contrast to the findings reported by Limami et al. [

21], who observed significant volumetric expansion and dimensional variation with increased additions of PET. This discrepancy highlights the critical influence of both the matrix composition and the type of additive; while glass may contribute to sintering issues in certain systems, PET appears to enhance thermal stability within our clay-based matrix.

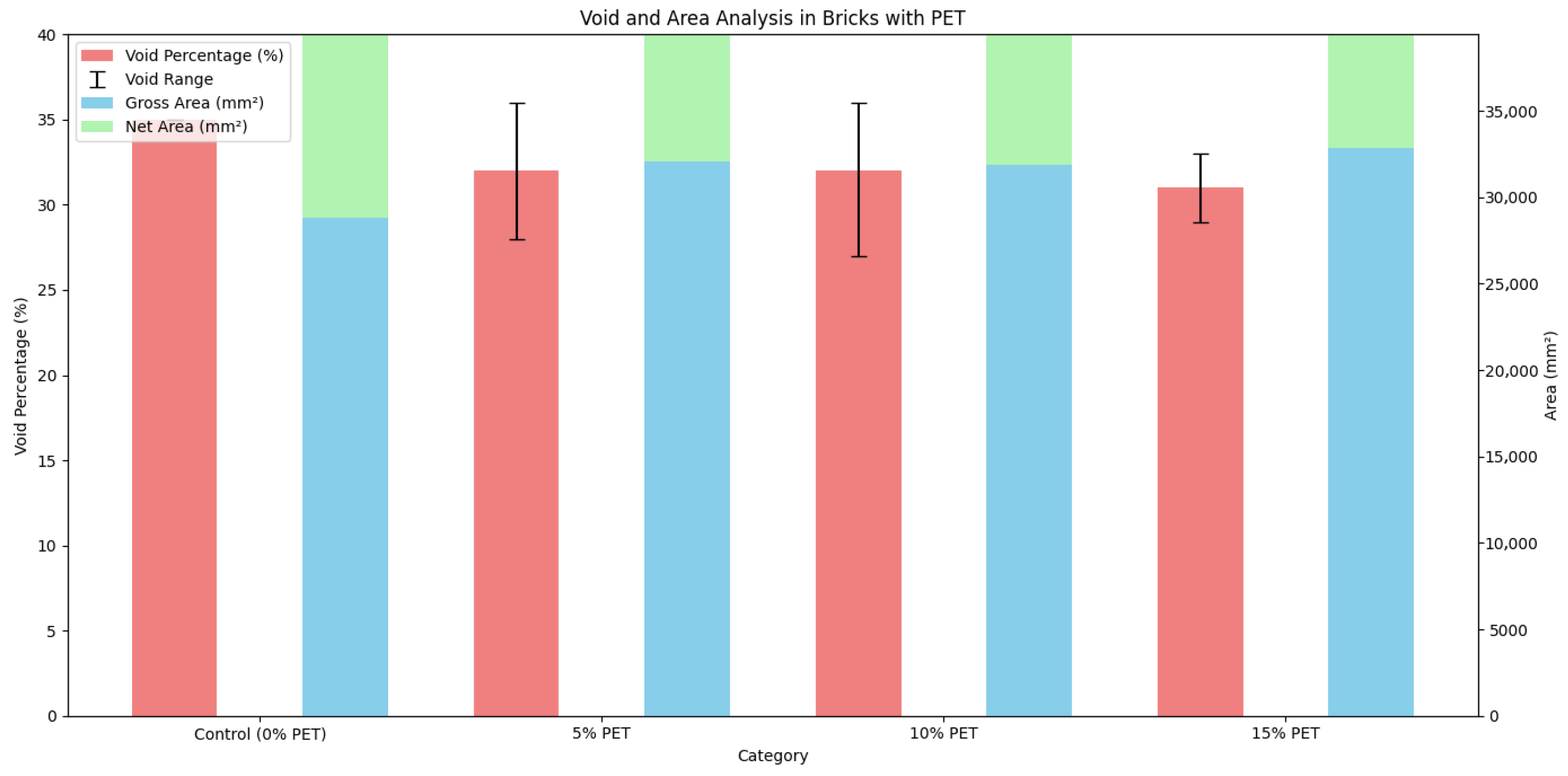

Furthermore, the incorporation of PET led to a reduction in the percentage of voids (from 35% in the control to 31–32%) and a significant decrease in water absorption and capillary suction. This indicates a densification of the clay matrix, a phenomenon also observed with polyolefins and PET, respectively [

39,

40]. They attributed this effect to the non-absorbent nature of plastics, which fill the pores between particles. Our results confirm this general trend, reinforcing the potential of plastic waste to improve the hydraulic resistance of clay bricks, a vital factor for their durability in construction applications.

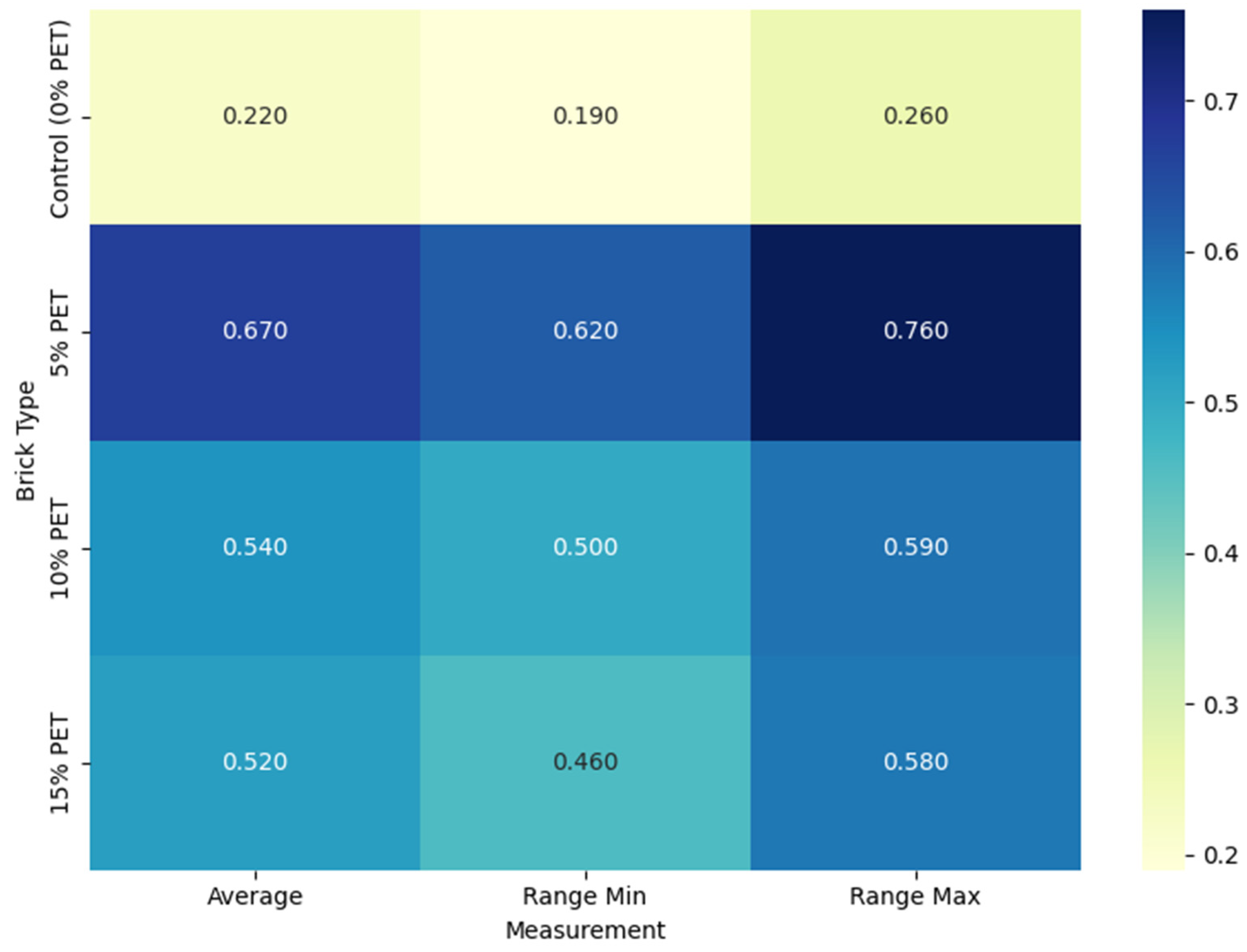

The marked reduction in compressive strength (

and

) observed across all PET-containing bricks aligns with previous studies attributing this phenomenon to the incorporation of a non-sinterable plastic phase, which results in a weak interface with the clay matrix [

21,

22]. The particle size of the PET used may have exacerbated this issue, reinforcing the argument that optimizing both the proportion and morphology of the plastic is critical [

12].

This outcome contrasts sharply with research reporting high compressive strengths in plastic-based composites, such as the 36.18 MPa achieved with PET [

22], the 37.5 MPa with HDPE and bitumen [

23], and the values meeting Peruvian standards [

25,

27]. The discrepancy may be attributed to several key factors: the use of cementitious or bitumen-based matrices that bond more effectively with plastic [

23,

24], optimized compression molding processes instead of traditional firing, and the use of finely ground or melted plastic to enhance homogeneity and interfacial bonding [

34], in contrast to the coarse PET flakes employed in this study.

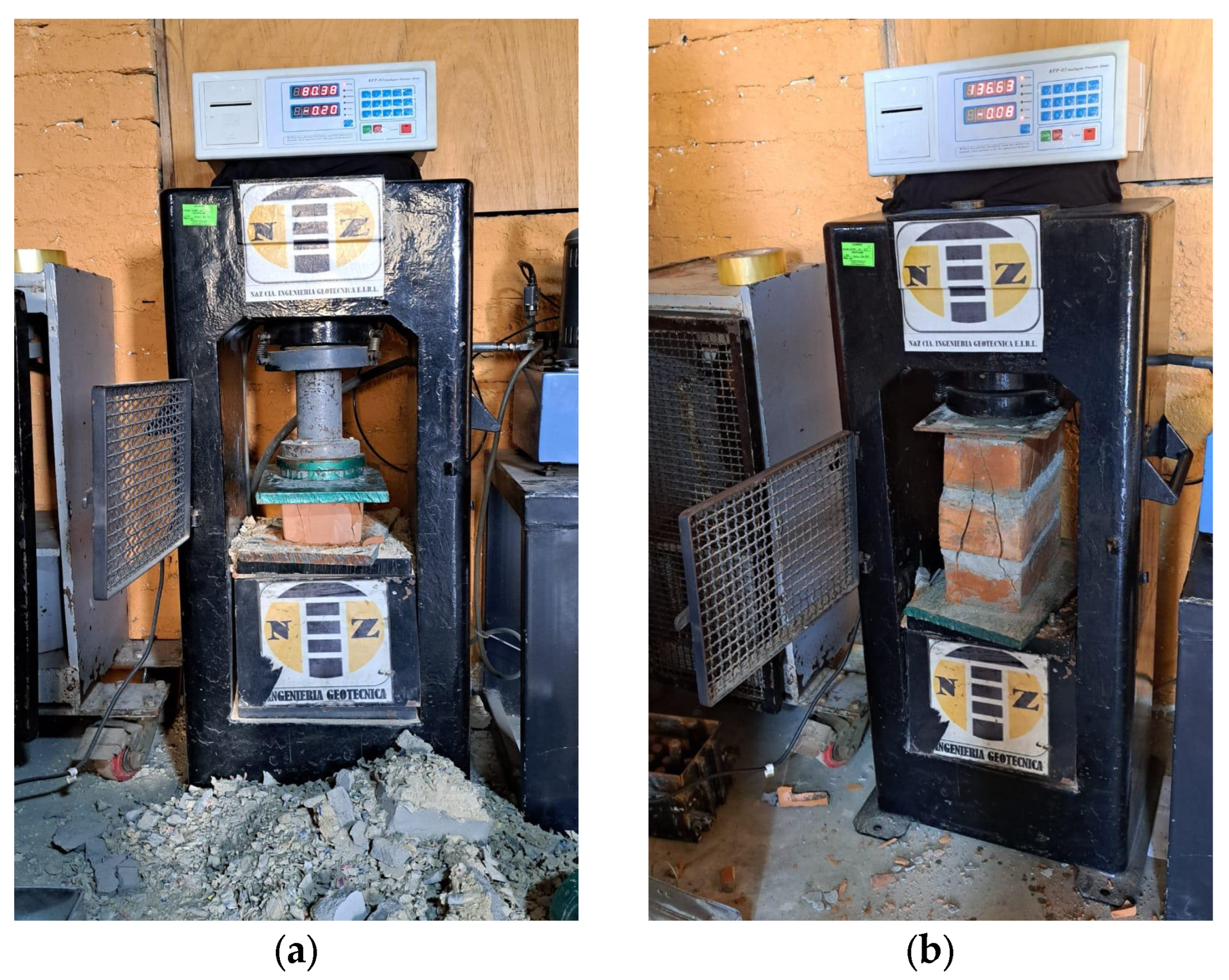

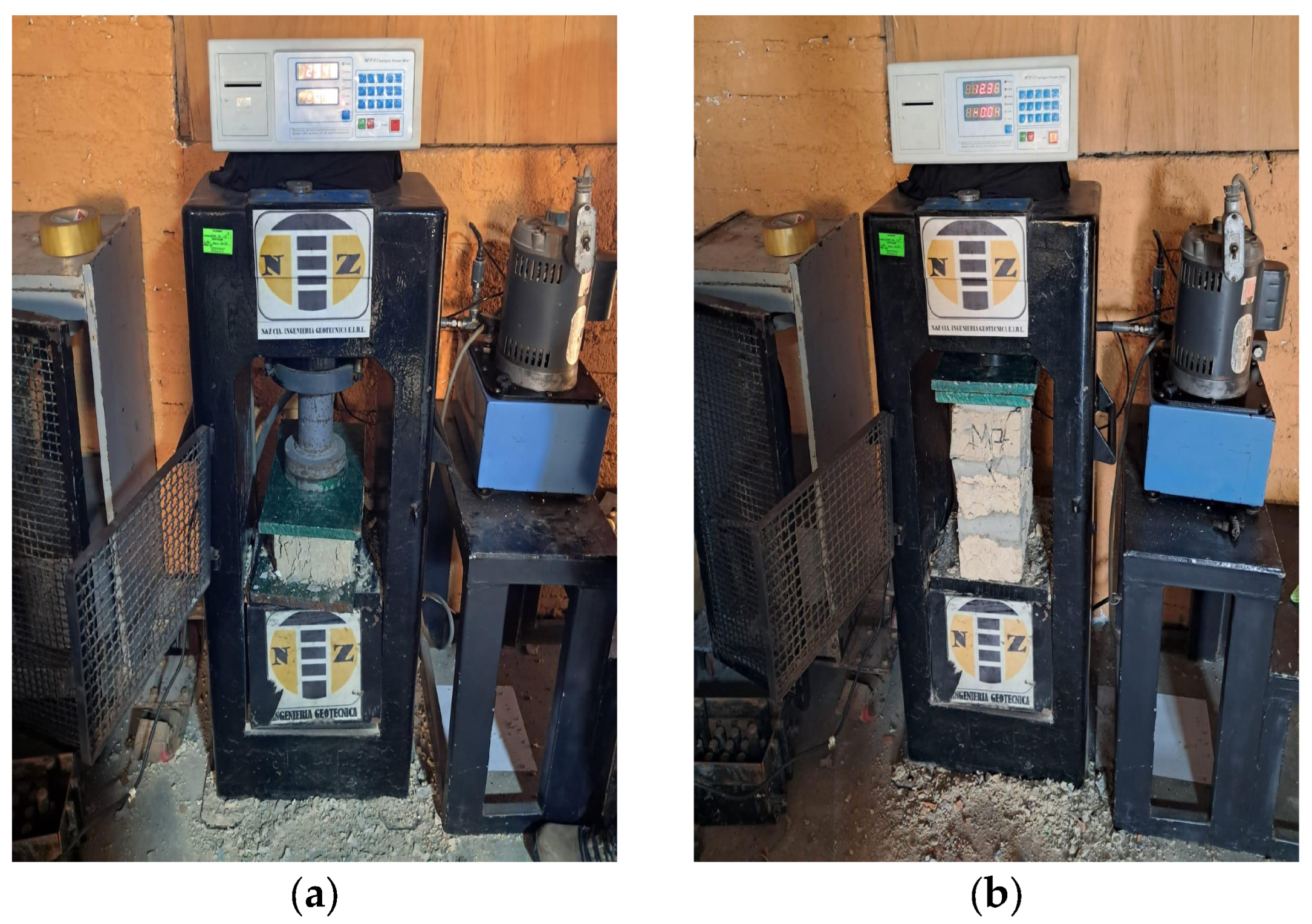

A statistical analysis was conducted to assess the impact of recycled PET content (5%, 10%, 15%) on the physical and mechanical properties of the bricks. Normality tests (Shapiro–Wilk) were applied to determine the appropriate statistical approach (parametric or non-parametric), using a significance level of p < 0.05.

In terms of physical properties, PET addition significantly reduced both water absorption and capillary suction across all proportions. Dimensional variability (length, width, height) increased, while void percentage decreased. Although warping on the top face showed a notable deviation at 5% PET, the bottom face remained consistent across other PET levels.

For mechanical properties—specifically unit and Prism Compressive Strength—the results indicated a significant reduction in strength with PET incorporation at all studied levels, compared to the control brick. Despite certain improvements in physical characteristics, PET did not enhance the structural capacity of the bricks, in

Table 7.

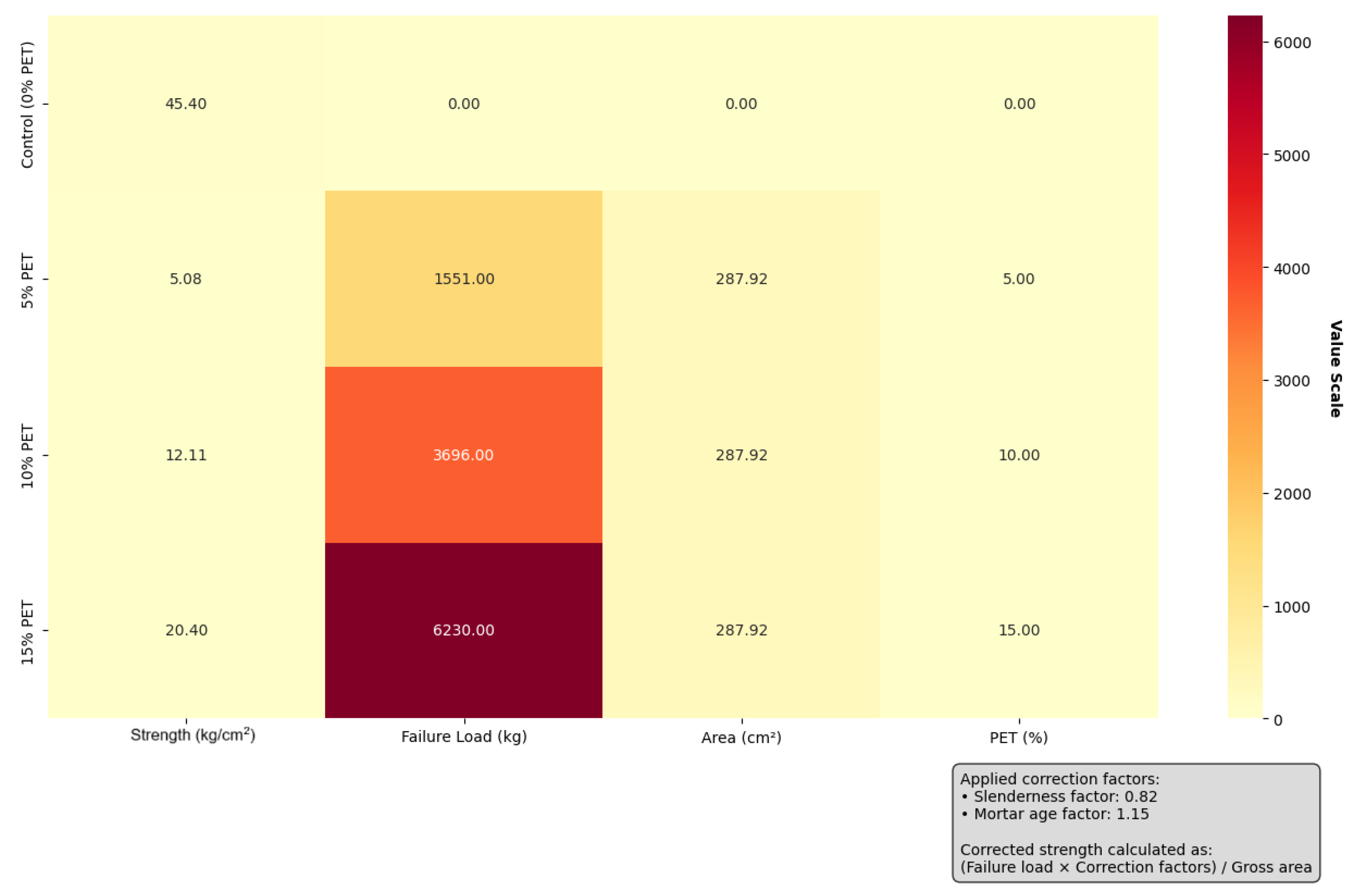

The compressive strength results (

and

) indicate that although increasing the PET content from 5% to 15% leads to a gradual improvement in the strength of PET-modified bricks, none of the tested proportions match or approach the strength of the control brick. In fact, the compressive strength of PET-containing bricks is markedly lower across all configurations, both for individual units and prism assemblies. Despite the reduction in mechanical strength, this study highlights the potential of PET-infused bricks for non-structural applications, such as partition walls or insulating façades. This shift in application is justified by improvements in physical properties: lower water absorption enhances durability and suggests improved thermal insulation potential [

13]. This approach aligns with circular economy principles by valorizing plastic waste [

1,

2], reducing the demand for virgin clay, and contributing to the mitigation of plastic pollution [

3].

The study also underscores the need for targeted research on locally sourced materials. While the combination of native clay and recycled PET from informal sources presents technical challenges, these findings establish a critical baseline. They demonstrate that replicating laboratory methodologies using purified materials is insufficient. Future work should focus on adapting production processes to accommodate suboptimal and locally available material flows, thereby achieving environmentally and socially responsible impact in support of regional communities. The relevance of this research is justified by its ability to connect the results of physical and mechanical properties (porosity, density) with environmental implications and potential insulation performance [

56]. Although the latter was not directly measured, the observed reduction in void percentage following the addition of PET suggests improved material densification. This finding is critical, as a denser matrix is directly associated with enhanced thermal and acoustic insulation properties [

57,

58], which are a key rationale for using this type of composite. Therefore, the study not only addresses waste reutilization, but also lays the groundwork for future research evaluating the energy and acoustic performance of these materials.

The limitations of this study—particularly the large particle size of the PET and the restricted firing temperature range—had a direct impact on the results. Nonetheless, these constraints offer a clearer pathway for future research:

Particle Size Optimization: As demonstrated by the success of previous studies, employing finer PET gradations is likely the most effective strategy to enhance both homogeneity and mechanical strength.

Alternative Binders and Processing Routes: Investigating low-temperature binders or implementing PET pretreatment methods to improve its compatibility with clay could help bridge the performance gap.

Microstructural Analysis: A detailed examination of the clay–PET interface is essential to understand failure mechanisms and to inform the design of targeted solutions.

In summary, although this study did not demonstrate superior mechanical performance compared to the control brick, the results suggest that PET may be a viable component in the production of sustainable bricks. The observed variations, when compared to previous studies, underscore the complexity of optimizing these mixtures and highlight the need for more targeted and in-depth research to develop products that meet required structural standards.

5. Conclusions

This study systematically evaluated the physical and mechanical properties of clay bricks (red kaolin) incorporating recycled PET at 5%, 10%, and 15%, providing critical insights into the feasibility of valorizing plastic waste within a ceramic matrix derived from artisanal mining. The main conclusions, drawn from the analysis and contextualized through existing literature, are as follows:

The incorporation of recycled PET resulted in a clear trade-off, significantly enhancing physical properties such as dimensional stability (reducing warping by up to 44% with 15% PET), water resistance (lowering absorption by approximately 30%), and matrix densification (reducing void percentage from 35% to 31–32%). The 15% PET blend emerged as the optimal proportion within the evaluated range, achieving the best balance of properties—namely, the highest compressive strength ( = 24.00 kg/cm2; = 20.40 kg/cm2), the lowest water absorption (18.7%), and superior dimensional stability.

However, this optimal proportion does not meet the minimum structural requirements prescribed by Peruvian and international standards for load-bearing masonry. Therefore, we conclude that these bricks are not suitable for structural applications. Nonetheless, they show strong potential for future research in non-load-bearing uses such as partition walls, insulating façades, and decorative elements, where their lightweight nature, low water absorption, and potential improvements in thermal insulation—supported by existing literature—offer promising advantages.

This study concludes that these discrepancies are not anomalous but are primarily attributable to fundamental differences in matrix composition (cementitious vs. clay), production processes (compression molding vs. traditional firing), and plastic preparation methods (finely ground/melted vs. coarse flakes). The findings clearly demonstrate that simply adding coarse plastic waste to a conventional clay firing process is insufficient to achieve structural performance.

Moreover, the integration of materials from artisanal sources—such as locally sourced clay and post-consumer PET—underscores the complexity of working with informal supply chains. While this approach presents significant technical challenges, it establishes a critical baseline for developing truly sustainable and socially responsible solutions. It also highlights the need for future innovation to adapt to these often suboptimal, locally available material flows in order to support mining communities and informal recyclers. We are confident that such efforts can be aligned with the principles of the circular economy.