Utilization of Low-Viscosity Sustainable Quaternary Microemulsification Fuels Containing Waste Frying Oil–Diesel Fuel–Bio-Alcohols in a Turbocharged-CRDI Diesel Engine

Abstract

1. Introduction

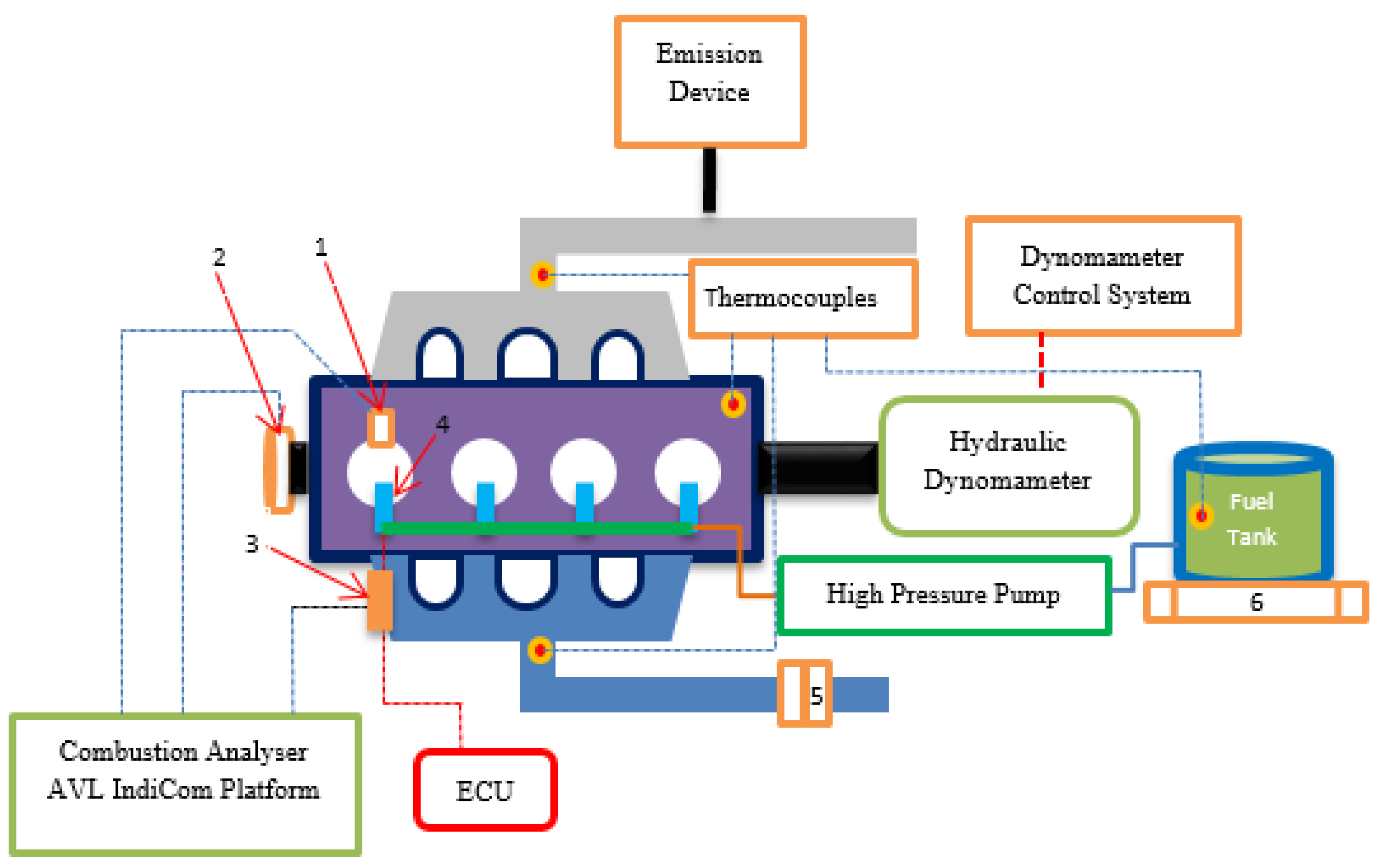

2. Materials and Methodology

3. Results and Discussion

3.1. Performance Characteristics

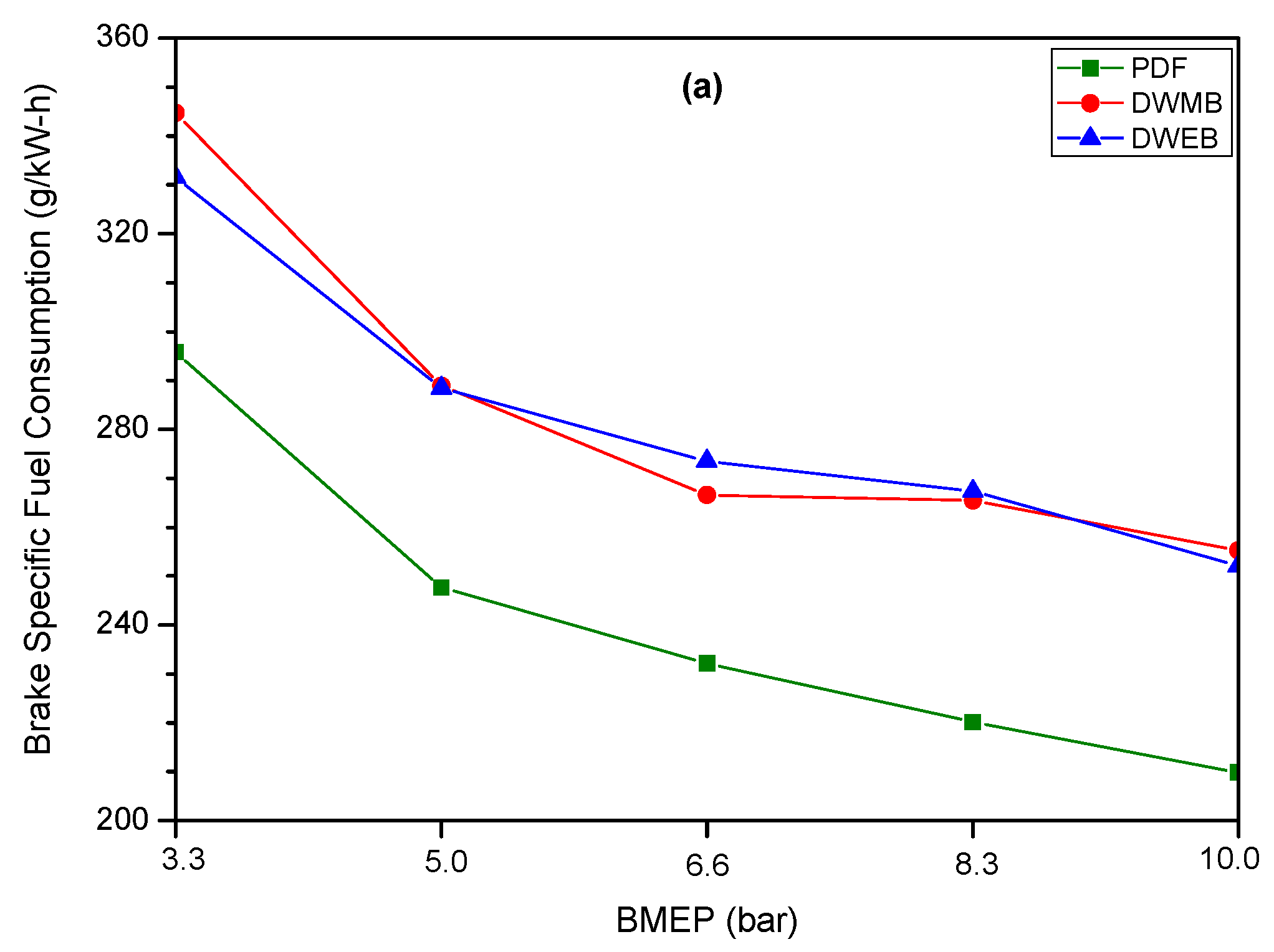

3.1.1. Brake Specific Fuel Consumption

3.1.2. Brake Specific Energy Consumption

3.1.3. Brake Thermal Efficiency

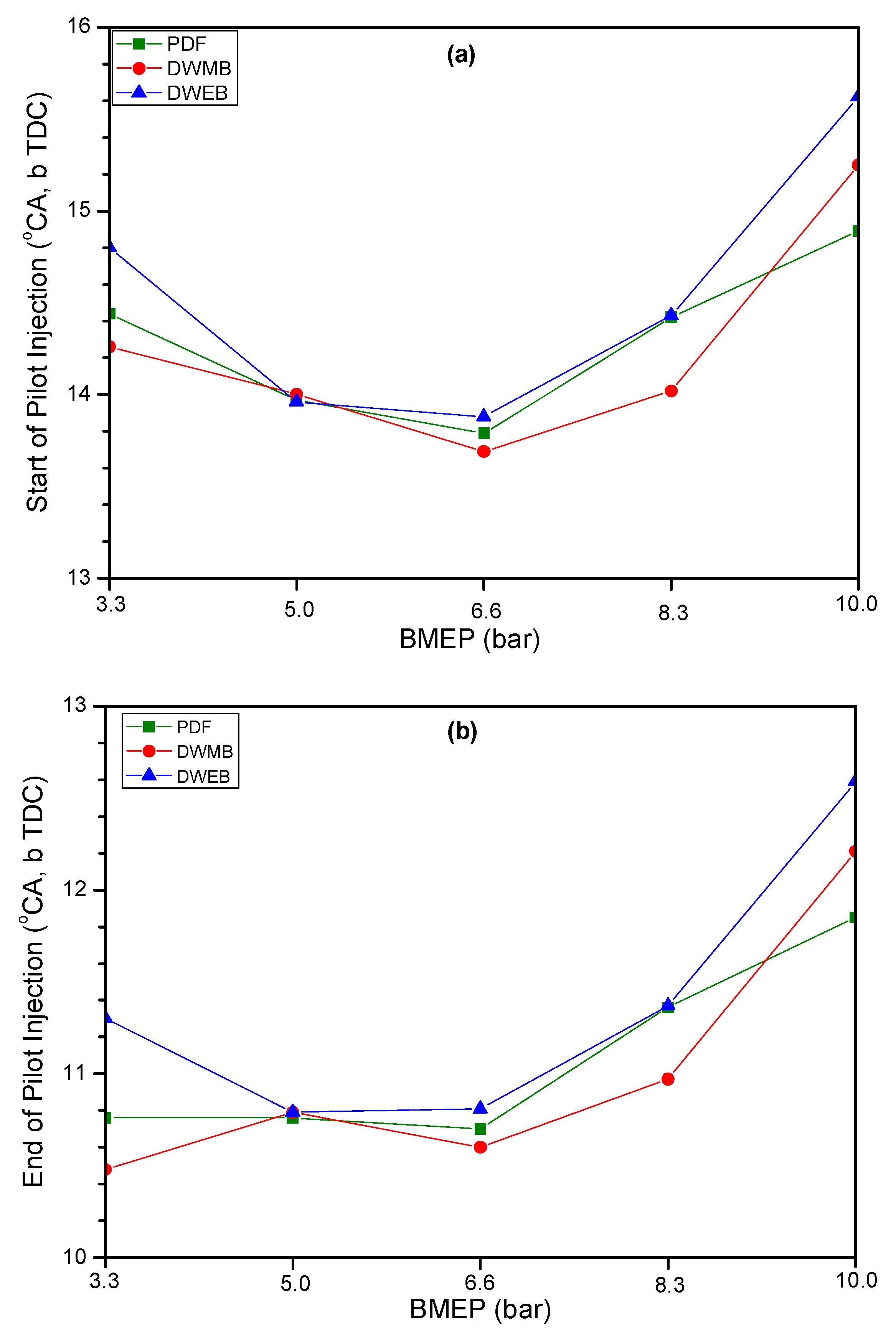

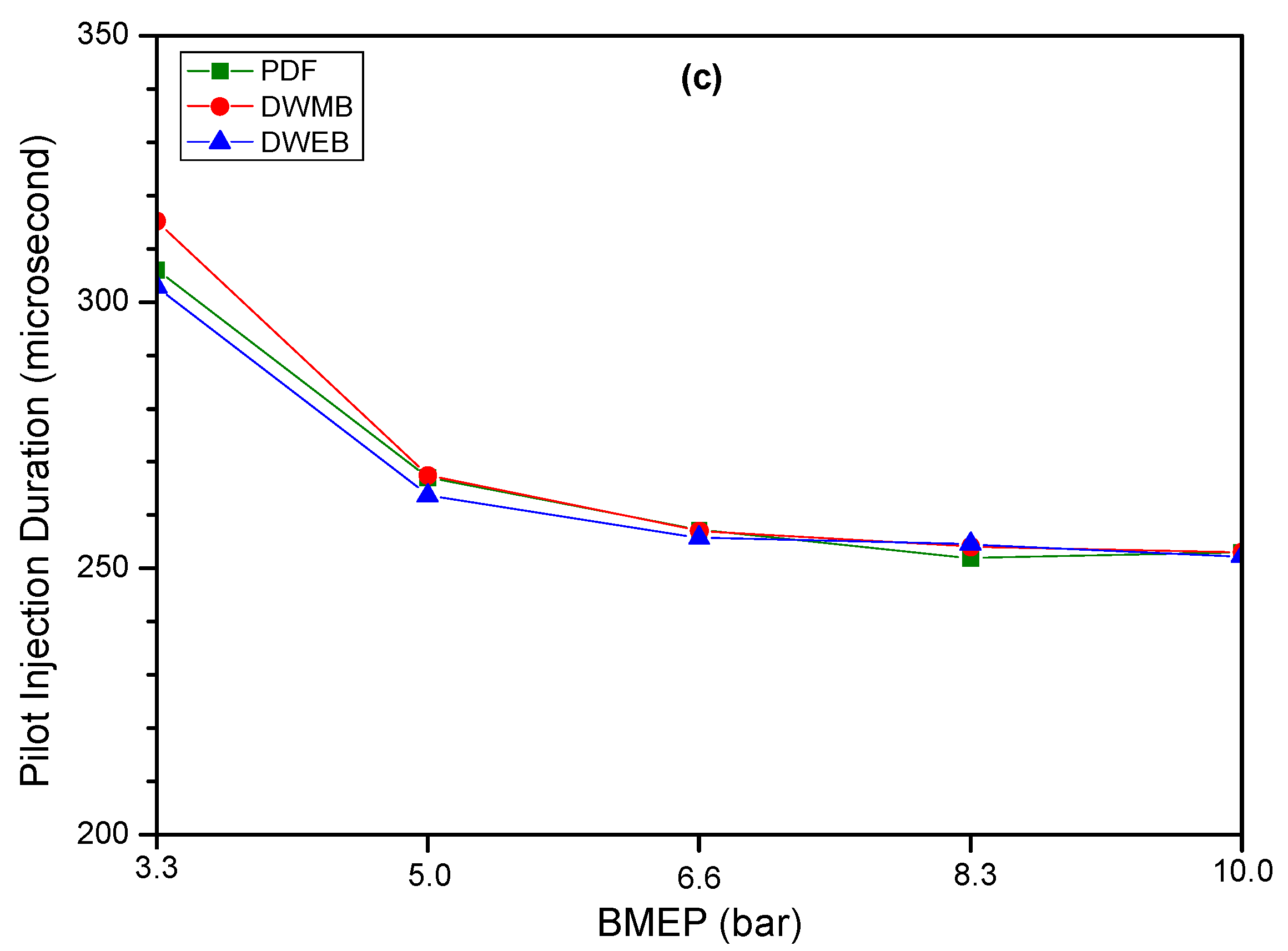

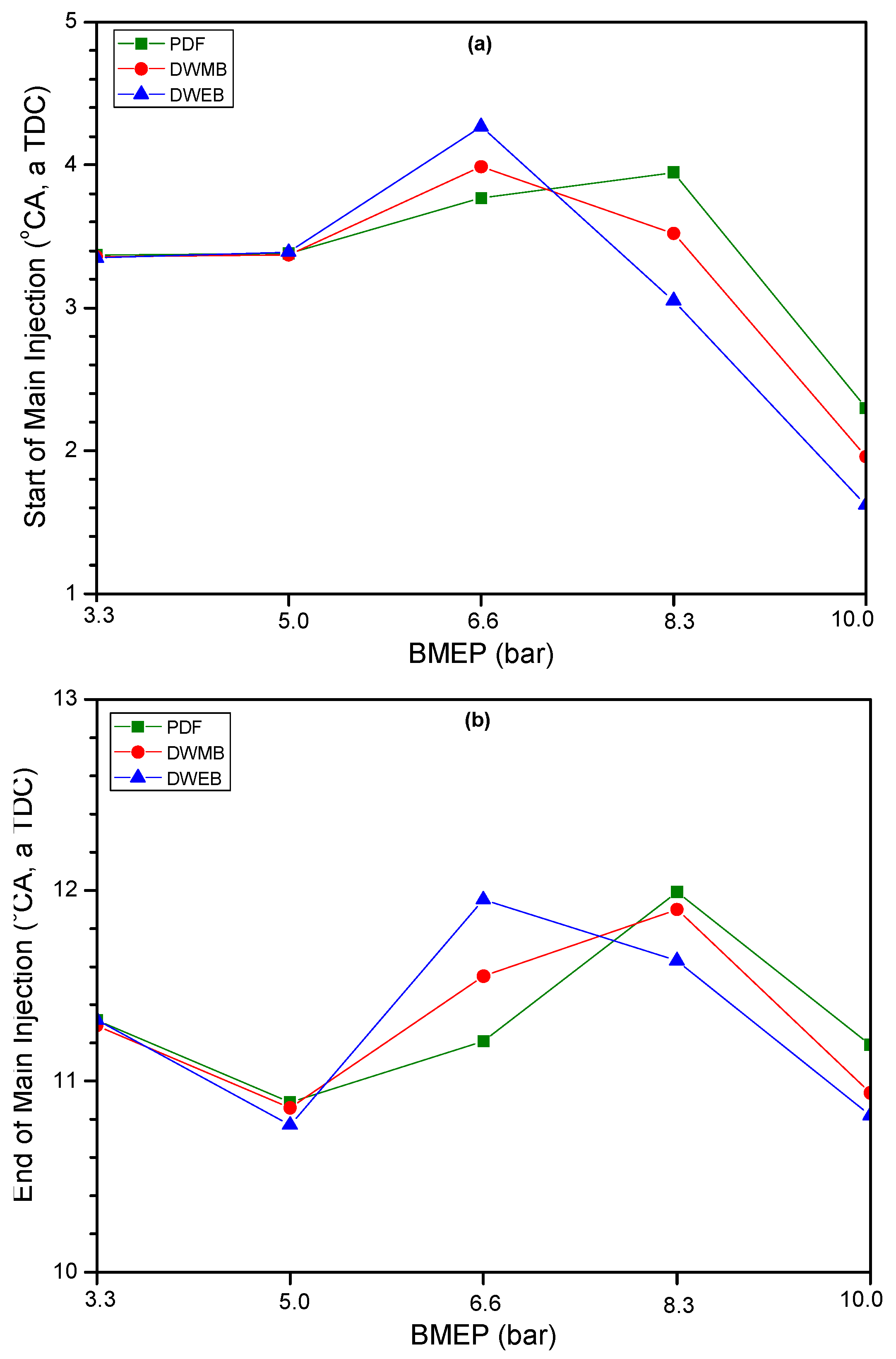

3.2. Injection Characteristics

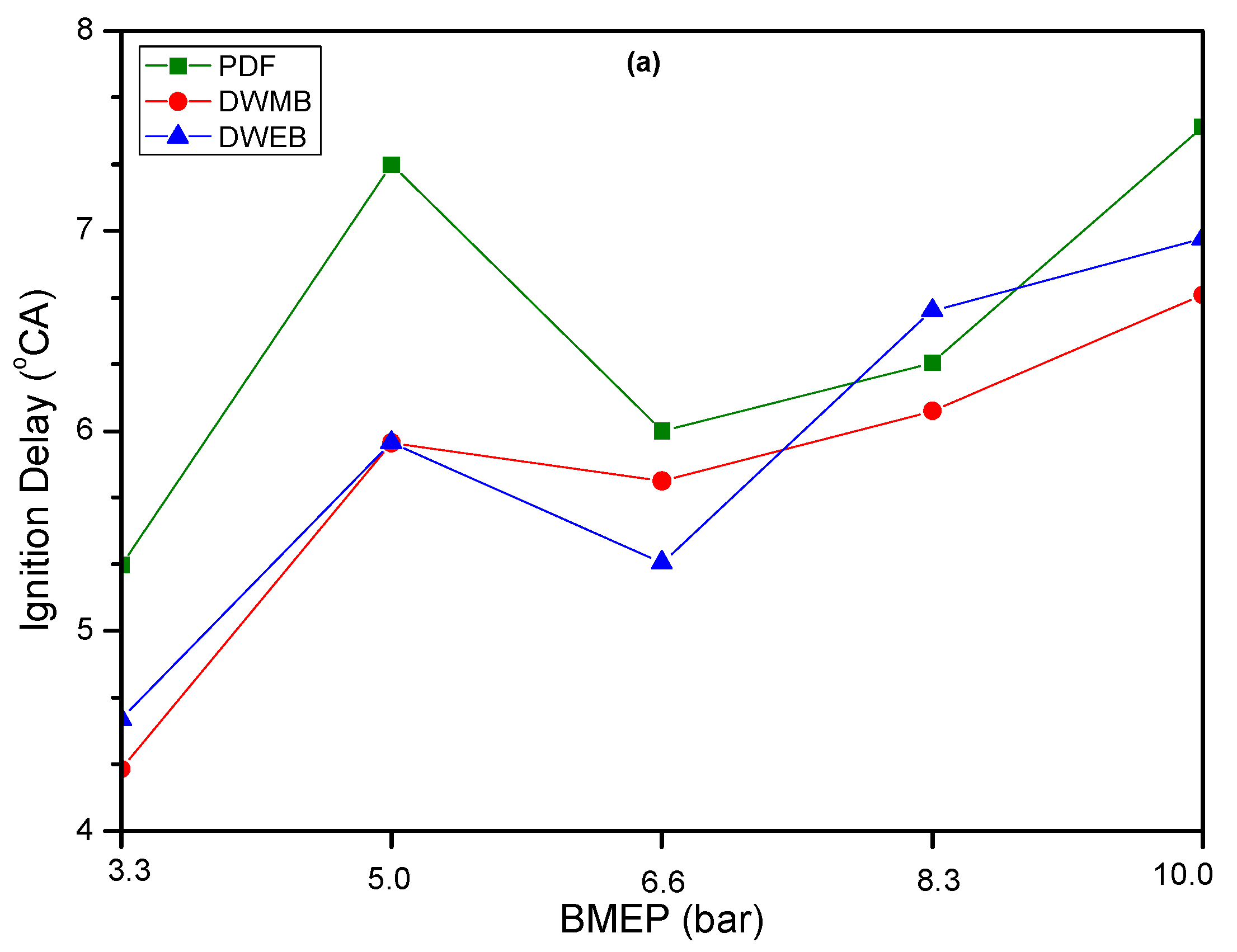

3.3. Combustion Characteristics

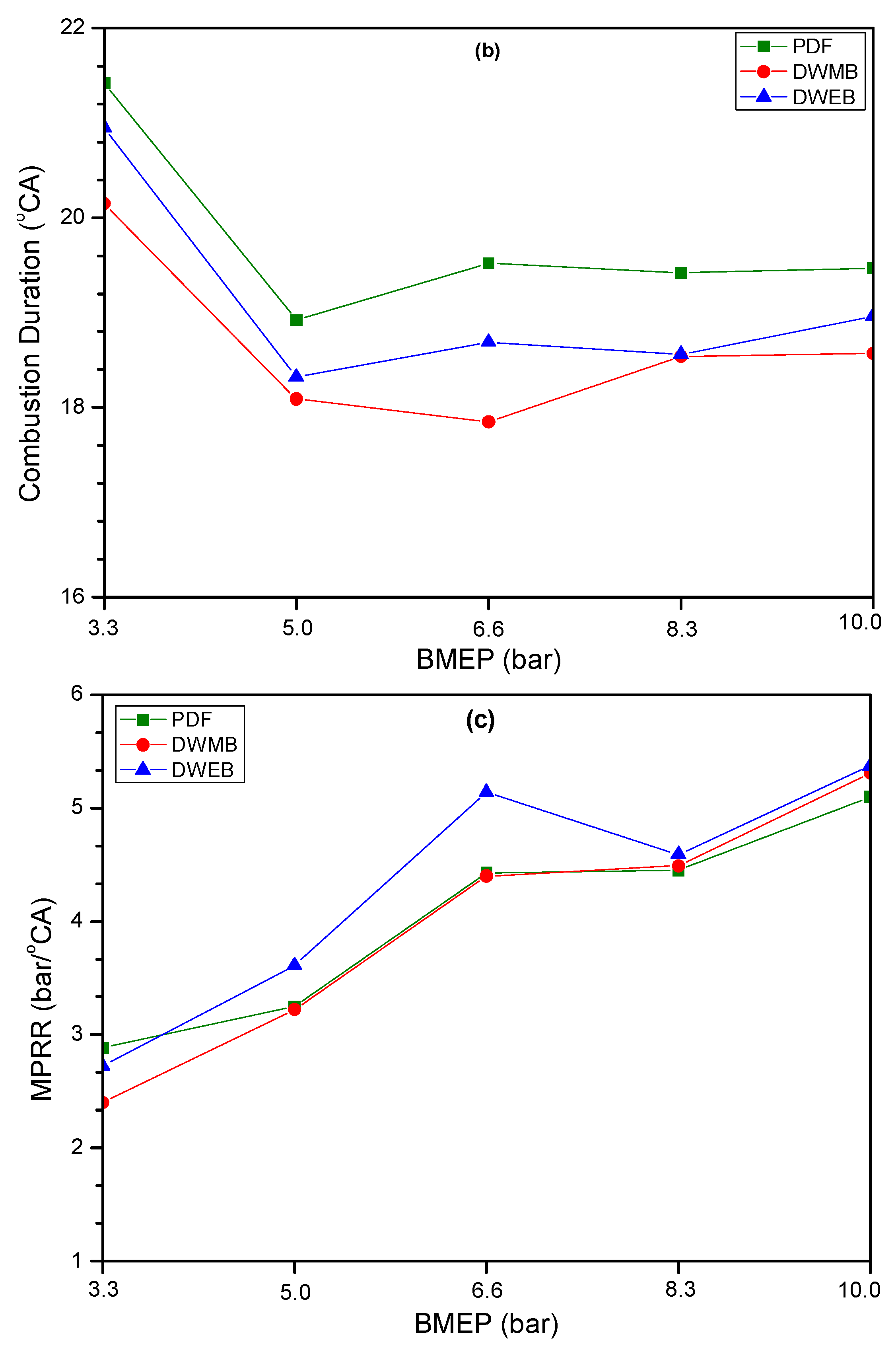

3.4. Exhaust Emission Characteristics

3.4.1. CO Emissions

3.4.2. THC Emissions

3.4.3. CO2 Emissions

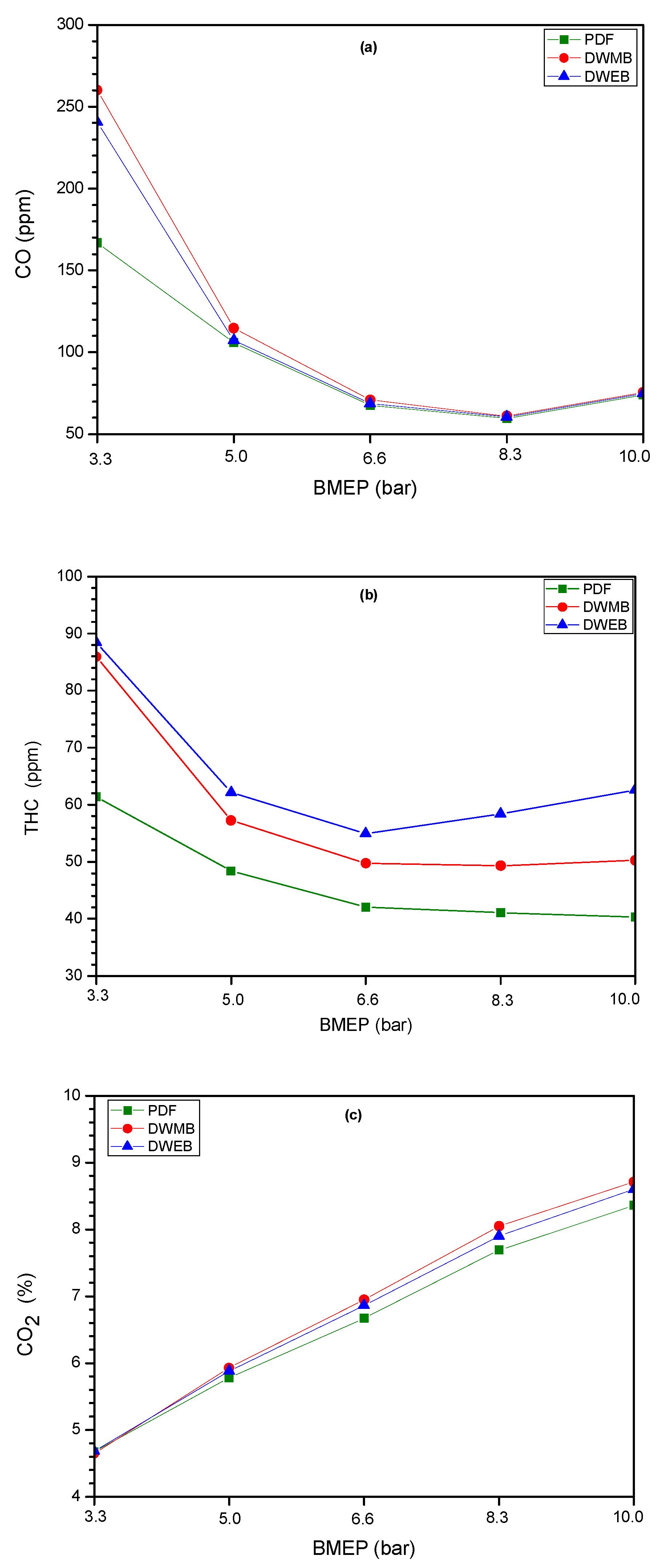

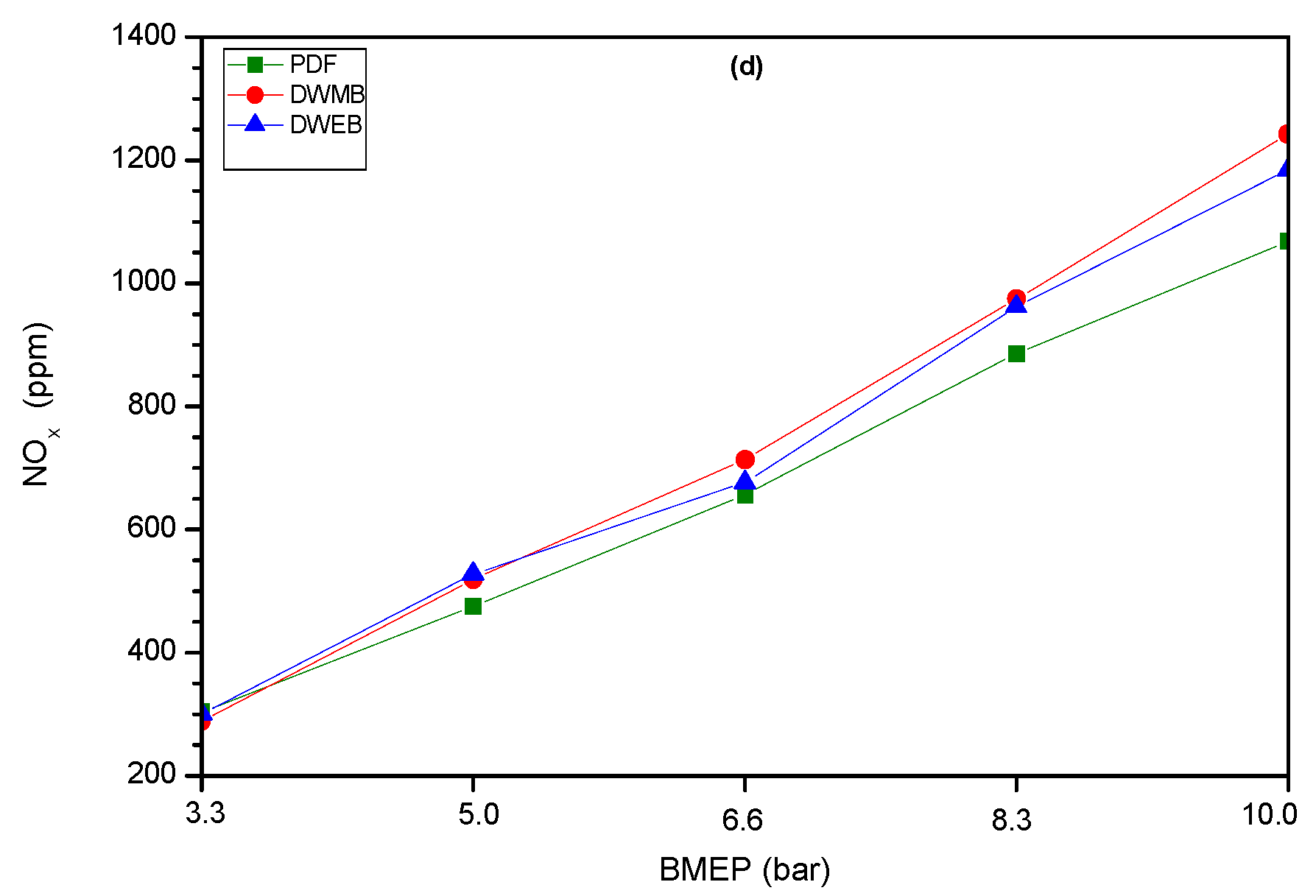

3.4.4. NOx Emissions

4. Conclusions

- Both emulsification fuels had higher BSFCs, and this difference increased with BMEP. At 10.0 bar, BSFC of DWMB and DWEB was 21.64% and 20.16% higher than PDF, respectively.

- DWMB and DWEB had higher BSEC and lower thermal efficiency. For both emulsification fuels, BSECs increased by 8% on average while thermal efficiency decreased by almost the same amount. The similarity in the percentages was remarkable.

- All fuels’ pilot and main injection timings were very close at low BMEPs. However, with increasing load, quaternary fuels’ injection timings were relatively earlier than PDF.

- PIDs of all fuels were almost the same, but MIDs of microemulsification fuels were longer, especially at high BMEPs.

- Quaternary fuels’ IA and IR values were higher than PDF, and this difference increased with BMEP.

- DWMB and DWEB exhibited shorter CDs and slightly higher Pmax at elevated loads. However, °CAPmax values were similar.

- Despite quaternary fuels’ lower cetane number, poor volatility, and high latent heat of vaporization, their IDs were shorter than PDF.

- Microemulsification fuels’ MPRRs remained close to PDF, indicating acceptable combustion stability.

- Although test fuels’ CO2 and NOx emissions were very close at low loads, quaternary fuels caused more emissions with increasing load. The opposite trend was observed for CO emissions.

- Among measured emissions, the biggest difference was observed for THC. For example, at 10.0 bar, THC emission of DWEB was 55.30% higher than PDF.

- DWMB had slightly better results than DWEB in terms of engine characteristics examined.

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| Abbreviation | Description |

| aTDC | After Top Dead Center |

| BMEP | Brake Mean Effective Pressure |

| BSFC | Brake Specific Fuel Consumption |

| BSEC | Brake Specific Energy Consumption |

| BTE | Brake Thermal Efficiency |

| °CA | Crank Angle |

| °CAPmax | Crank Angle Position of Maximum Pressure |

| CD | Combustion Duration |

| CI | Compression Ignition |

| CO | Carbon Monoxide |

| CO2 | Carbon Dioxide |

| CRDI | Common Rail Direct Injection |

| DWEB | Diesel–Waste Frying Oil–Ethanol–n-Butanol Fuel Blend |

| DWMB | Diesel–Waste Frying Oil–Methanol–n-Butanol Fuel Blend |

| ECU | Electronic Control Unit |

| EJ | Exajoule (1018 joules) |

| eMI | End of Main Injection |

| ePI | End of Pilot Injection |

| HC | Hydrocarbons |

| HRR | Heat Release Rate |

| IA | Injection Amount |

| ID | Ignition Delay |

| IR | Injection Rate |

| λ (Lambda) | Excess Air Ratio |

| MID | Main Injection Duration |

| MPRR | Maximum Pressure Rise Rate |

| NOx | Nitrogen Oxides |

| Petroleum-Diesel | |

| PID | Pilot Injection Duration |

| Pmax | Maximum In-Cylinder Pressure |

| rpm | Revolutions Per Minute |

| sMI | Start of Main Injection |

| sPI | Start of Pilot Injection |

| THC | Total Hydrocarbons |

| TDC | Top Dead Center |

| WFO | Waste Frying Oil |

References

- International Energy Agency (IEA)-Global Energy Reviews 2025-Global Trends. Available online: https://iea.org/reports/global-energy-review-2025/global-trends (accessed on 20 August 2025).

- International Energy Agency (IEA)-World Energy Outlook 2024. Available online: https://www.iea.org/reports/world-energy-outlook-2024 (accessed on 20 August 2025).

- Statista. Share of Renewable Energy in Electricity Generation Globally from 2010 to 2024. Available online: https://www.statista.com/statistics/489131/share-of-renewables-in-power-generation-globally/ (accessed on 20 August 2025).

- Energy Institute. Statistical Review of World Energy 2025 (74th Edition). Available online: https://www.energyinst.org/statistical-review (accessed on 20 August 2025).

- Sanli, H. Characterizing three generation biodiesel feedstocks: A statistical approach and emprical modeling of fuel properties. Waste Manag. 2025, 200, 114755. [Google Scholar] [CrossRef]

- Ali, M.; Shakaib, M.; Zaidi, A.A.; Javed, M.A.; Khan, S.Z.; Hassan, A.A. Performance and environmental sustainability of fish waste biodiesel on diesel engines. Sustainability 2025, 17, 5385. [Google Scholar] [CrossRef]

- Syed, J. Significant research on sustainable oxygenated fuel for compression ignition engines with controlled emissions and optimum performance prediction using artifical neural network. Sustainability 2025, 17, 788. [Google Scholar] [CrossRef]

- Gotovusa, M.; Huzjak, P.; Zadravec, I.; Zadravec, M.; Vukovic, J.P. Biodiesel from higher alcohols for removal of crude oil spills from coastal sediments. Sustainability 2024, 16, 8574. [Google Scholar] [CrossRef]

- Raju, V.D.; Veza, I.; Venu, H.; Soudagar, M.E.M.; Kalam, M.A.; Ahamad, T.; Appavu, P.; Nair, J.N.; Ashrafur Rahman, S.M. Comprehensive analysis of compression ratio, exhaust gas recirculation, and pilot injection in a diesel engine fuelled with tamarind biodiesel. Sustainability 2023, 15, 15222. [Google Scholar] [CrossRef]

- Sanli, H. An experimental investigation on the usage of waste frying oil-diesel fuel blends with low viscosity in a Common Rail DI-diesel engine. Fuel 2018, 222, 434–443. [Google Scholar] [CrossRef]

- Abrar, I.; Bahaskarwar, A.N. Microemulsion fuels for compression ignition engines: A review on engine performance and emission characteristics. Fuel 2019, 257, 115944. [Google Scholar] [CrossRef]

- Mitchell, B.J.; Zare, A.; Bodisco, T.A.; Nabi, M.N.; Hossain, F.M.; Ristovski, Z.D.; Brown, R.J. Engine blow-by with oxygenated fuels: A comparative study into cold and hot start operation. Energy 2017, 140, 612–624. [Google Scholar] [CrossRef]

- Kumar, H.; Kumar, H. Microemulsification-based hybrid oxygenated biofuel for CI engine locomotives: With special reference to “preparation” techniques and “performance” analysis. Environ. Sci. Pollut. Res. 2025. [Google Scholar] [CrossRef]

- Jin, C.; Ding, C.; Hu, J.; Geng, Z.; Li, X.; Dong, J.; Xu, T.; Liu, H. Study on the stability and properties of carbon neutral methanol in blends with diesel fuel. Fuel 2024, 374, 132453. [Google Scholar] [CrossRef]

- El Nagy, H.A.; Abdel-Aziz Mohamed, M. Formulation of a stable diesel microemulsion using eco-friendly ionic liquids and investigation of particle size and fuel properties as an alternative fuel. Sci. Rep. 2024, 14, 19819. [Google Scholar] [CrossRef]

- Abrar, I.; Arora, T.; Khandelwal, R. Bioalcohols as an alternative fuel for transportation: Cradle to grave analysis. Fuel Process. Technol. 2023, 242, 107646. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhu, X.; Zhang, L.; Zhu, X. Preparation and characterization of microemulsion fuels from diesel and model compound of walnut shell pyrolysis oil. Fuel 2019, 243, 478–484. [Google Scholar] [CrossRef]

- Zheng, S.; Lv, Z.; Yang, Y.; Liu, H.; Lu, Q. Effects of n-butanol blending on soot and NO formation in biodiesel/air co-flow diffusion flame. Energy 2025, 323, 135842. [Google Scholar] [CrossRef]

- Zhao, D.; Wang, Y.; Liu, J. Preparation and application of diesel microemulsion. Pet. Sci. Technol. 2006, 24, 1017–1025. [Google Scholar] [CrossRef]

- Li, X.; Guan, C.; Yang, K.; Cheung, C.S.; Huang, Z. Impact of lower and higher alcohol additions to diesel on the combustion and emissions of a direct-injection diesel engine. Environ. Sci. Pollut. Res. 2019, 26, 21001–21012. [Google Scholar] [CrossRef]

- Zhang, Y.; Gao, S.; Zhang, Z.; Li, W.; Yuan, T.; Tan, D.; Duan, L.; Yang, G. A comprehensive review on combution, performance and emission aspects of higher alcohols and its additive effect on the diesel engine. Fuel 2023, 335, 127011. [Google Scholar] [CrossRef]

- Karabektas, M.; Yilancilar, M.S. Investigation of the effects of high-carbon alcohol addition to camelina oil methyl ester on the performance parameters and soot emission of a diesel engine. Int. J. Low Carbon Technol. 2022, 17, 206–213. [Google Scholar] [CrossRef]

- Appavu, P.; Ramanan, V.; Venu, H. Quaternary blends of diesel/biodiesel/vegetable oil/pentanol as a potential alternative feedstock for existing unmodified diesel engine: Performance, combustion and emission characteristics. Energy 2019, 186, 115856. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, Y.; Chen, Y.; Chen, D.; Li, Y.; Qin, J. Microemulsion phase behavior based on biodiesel and its performance in treating oil-contaminated soil. J. Environ. Chem. Eng. 2024, 12, 112552. [Google Scholar] [CrossRef]

- Feng, H.; Chen, X.; Sun, L.; Ma, R.; Zhang, X.; Zhu, L.; Yang, C. The effect of methanol/diesel fuel blends with co-solvent on diesel engine combustion based on experiment ana exergy analysis. Energy 2023, 282, 128792. [Google Scholar] [CrossRef]

- Khan, M.M.; Hasnain, S.M.M.; Kadian, A.K.; Sharma, R.P.; Abbas, M.; Pandey, S. Reduction of fossil fuel usage and emissions of diesel engines by the application of quaternary blends and varied fuel injection pressures. ACS Omega 2024, 9, 26388–26399. [Google Scholar] [CrossRef]

- Cedik, J.; Pexa, M.; Holubek, M.; Mrazek, J.; Valera, H.; Agarwal, A.K. Operational parameters of a diesel engine running on diesel-rapeseed oil-methanol-iso-butanol blends. Energies 2021, 14, 6173. [Google Scholar] [CrossRef]

- Dimitriadis, A.; Chrysikou, L.P.; Kokkalis, A.I.; Doufas, L.I.; Bezergianni, S. Animal fats valorization to green transportations fuels: From concept to industrially relevant scale validation. Waste Manag. 2022, 143, 242–252. [Google Scholar] [CrossRef]

- Abrar, I.; Bhaskarwar, A.N. Mitigating exhaust emissions in CI engines using butanol-diesel-water microemulsions. Environ. Sci. Pollut. Res. 2023, 30, 30632–30643. [Google Scholar] [CrossRef]

- Alptekin, E.; Sanli, H.; Canakci, M. Combustion and performance evaluation of a common rail DI diesel engine fueled with ethyl and methyl esters. Appl. Therm. Eng. 2019, 149, 180–191. [Google Scholar] [CrossRef]

- Ooi, J.B.; Chan, X.L.; Jaliliantabar, F.; Tan, B.T.; Wang, X.; Song, C.P.; Chiong, M.C.; Hung, Y.M. Experimental study of quaternary blends with diesel/palm-oil biodiesel/ethanol/diethyl ether for optimum performance and emissions in a light-duty diesel engine using response surface methodology. Energy 2024, 301, 131782. [Google Scholar] [CrossRef]

- Bidir, M.G.; Narayanan, K.M.; Adaramola, M.S.; Hagos, F.Y.; Singh, R.C. Comparative study on the effects of nanoparticles in ternary fuel blends on combustion, performance, and emissions characteristics of diesel engine. Int. J. Engine Res. 2022, 24, 4509–4520. [Google Scholar] [CrossRef]

- Kolhe, A.V.; Malwe, P.D.; Chopkar, Y.; Panchal, H.; Ağbulut, Ü.; Mubarak, N.M.; Chowdhury, S.; Amesha, K.T.T. Performance analysis of biofuel-ethanol blends in diesel engine and its validation with computational fluid dynamics. Environ. Sci. Pollut. Res. 2023, 30, 125117–125137. [Google Scholar] [CrossRef] [PubMed]

- Patnaik, S.; Khatri, N.; Rene, E.R. Artificial neural networks-based performance and emission characteristics prediction of compression ignition engines powered by blends of biodiesel derived from waste cooking oil. Fuel 2024, 370, 131806. [Google Scholar] [CrossRef]

- Dhanasekaran, Y.; Sriramulu, J. An outcome of quaternary fuel blended Fe3O4- doped reduced graphene oxide nanocomposite on the diesel engine. Heat Transf. 2022, 51, 4741–4767. [Google Scholar] [CrossRef]

- Qi, D.H.; Bae, C.; Feng, Y.M.; Jia, C.C.; Bian, Y.Z. Combustion and emission characteristics of a direct injection compression ignition engine using rapeseed oil based micro-emulsions. Fuel 2013, 107, 570–577. [Google Scholar] [CrossRef]

- Vellaiyan, S.; Kandasamy, M.; Devarajan, Y. Optimization of bauhinia parviflora biodiesel production for higher yield and its compatibility assessment with water and di-tert-butyl peroxide emulsion. Waste Manag. 2023, 162, 63–71. [Google Scholar] [CrossRef] [PubMed]

- Waluyo, B.; Fatimah, Y.A.; Habibi, I.; Pertiwi, F.D.; Setiyo, M.; Marlina, E. Enhancing biodiesel-methanol blends with 1-butanol for stable and efficient fuels. Fuel 2024, 361, 130667. [Google Scholar] [CrossRef]

- El-Seesy, A.I.; Waly, M.S.; Nasser, A.; El-Zoheiry, R.M. Improvement of the combustion, emission, and stability features of diesel-methanol blends using n-decanol as cosolvent. Sci. Rep. 2022, 12, 18963. [Google Scholar] [CrossRef]

- Sanli, H.; Alptekin, E.; Canakci, M. Using low viscosity micro-emulsification fuels composed of waste frying oil-diesel fuel-higher bio-alcohols in a turbucharged-CRDI diesel engine. Fuel 2022, 308, 121966. [Google Scholar] [CrossRef]

- Teoh, Y.H.; How, H.G.; Peh, C.G.; Le, T.D.; Nguyen, H.T. Implementation of common rail direct injection system and optimization of fuel injector parameters in an experimental single-cylinder engine. Processes 2020, 8, 1122. [Google Scholar] [CrossRef]

- Agarwal, A.K.; Singh, A.P.; Maurya, R.K.; Shukla, P.C.; Dhar, A.; Srivastava, D.K. Combustion characteristics of a common rail direct injection engine using different fuel injection strategies. Int. J. Therm. Sci. 2018, 134, 475–484. [Google Scholar] [CrossRef]

- Wang, X.; Fan, W.; Chen, J.; Zhang, H. Experimental stduy of effect of a novel ammonia/coal co-firing mode on NOx emission under high temperature conditions. Renew. Energy 2024, 235, 121379. [Google Scholar] [CrossRef]

- Korkmaz, M.; Lakshmanan, R.; Falkenstein, T.; Beeckman, J.; Pitsch, H. Experimental and numerical investigation of the maximum pressure rise rate for an LTC concept in a single cylinder CI engine. In Proceedings of the 14th International Conference on Engines & Vehicles, Capri, Napoli, Italy, 15–19 September 2019; SAE Technical Paper. Volume 24, p. 0023. [Google Scholar] [CrossRef]

- Abed, K.A.; Gad, M.S.; El Morsi, A.K.; Sayed, M.M.; Abu Elyazeed, S. Effect of biodiesel fuels on diesel engine emissions. Egypt. J. Petroleum 2019, 28, 183–188. [Google Scholar] [CrossRef]

- Tarangan, D.; Sobati, M.A.; Shahnazari, S.; Ghobadian, B. Physical properties, engine performance, and exhaust emissions of waste fish oil biodiesel/bioethanol/diesel fuel blends. Sci. Rep. 2023, 13, 14024. [Google Scholar] [CrossRef] [PubMed]

- Alptekin, E. Evaluation of ethanol and isopropanol as additives with diesel fuel in a CRDI diesel engine. Fuel 2017, 205, 161–172. [Google Scholar] [CrossRef]

- Ramesh, T.; Sathiyagnanam, A.P.; De Poures, M.V.; Murugan, P. A comprehensive study on the effect of dimethyl carbonate oxygenate and EGR on emission reduction, combustion analysis, and performance enhancement of a CRDI diesel engine using a blend of diesel and Porsopis juliflora biodiesel. Int. J. Chem. Eng. 2022, 2022, 5717362. [Google Scholar] [CrossRef]

- Lv, J.; Yan, B.; Zhou, S.; Wu, Z.; Liu, X.; Lu, S.; Zhu, X.; Sun, Y.; Li, J.; Lin, F.; et al. Ignition, combustion and pollutant emissions characteristics of a excavated waste in low oxygen concentration and O2/CO2 atmosphere. Waste Manag. 2025, 200, 114770. [Google Scholar] [CrossRef]

- Jeong, J.W.; Baek, S.; Kim, Y.; Woo, S.; Lim, Y.; Lee, K. Investigation of CO2 and PN emission characteristics according to the propane content for a LPG engine. Fuel 2024, 357, 129877. [Google Scholar] [CrossRef]

- Berk, S.; Alptekin, E. Optimization of NOx emissions of a CRDI diesel engine using CMA-ES method. Int. J. Engine Res. 2024, 25, 2184–2203. [Google Scholar] [CrossRef]

- Jeong, J.W.; Kim, N.; Lee, K. Investigation of real-world NOx and NH3 emissions from various powertrain vehicles using trip analysis method. Fuel 2026, 403, 136087. [Google Scholar] [CrossRef]

- Moradi, J.; Banagar, I.; Mehranfar, S.; Andwari, A.M.; Könnö, J.; Gharehghani, A. Advancing combustion technologies and alternative fuels in hybrid electric vehicles: A pathway to high-efficiency, low-emission propulsion systems. Future Technol. 2023, 3, 42–54. [Google Scholar] [CrossRef]

- Qiu, Z.; Tian, J.; Liu, Y.; Sun, H.; Ni, Z.; Lin, Q. Expansion/micro-explosion of ethanol-biodiesel doplet doped with microparticles in oxygenated hot co-flow. Appl. Therm. Eng. 2023, 221, 119345. [Google Scholar] [CrossRef]

- Tipanluisa, L.; Thakkar, K.; Fonseca, N.; Lopez, J.M. Investigation of diese/n-butanol blends as drop-in fuel for heavy-duty diesel engines: Combustion, performance, and emissions. Energy Convers. Manag. 2022, 255, 115334. [Google Scholar] [CrossRef]

- Niknejad, M.; Hajinezhad, A.; Moosavian, S.Y. Effect of Norozak (Salvia ierrifolia) biodiesel fuel on diesel engine performance. Future Sustain. 2023, 1, 39–45. [Google Scholar] [CrossRef]

| Property | Unit | Test Method | Value | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Viscosity (40 °C) | mm2·s−1 | ASTM D445 | 40.28 | |||||||

| Density (15 °C) | kg·m−3 | ASTM D4052 | 925.7 | |||||||

| Acid Value | mg KOH·g−1 | AOCS Cd 3d-63 | 0.28 | |||||||

| Higher Heating Value | kJ·kg−1 | ASTM D240 | 39604 | |||||||

| C 14:0 | C 16:0 | C 16:1 | C 18:0 | C 18:1 | C 18:2 | C 18:3 | C 20:0 | C 22:0 | Total Saturation | |

| 0.18 | 9.60 | 0.17 | 3.46 | 35.18 | 50.00 | 0.08 | 0.16 | 0.58 | 13.99 | |

| Test Fuel | Chemical Formula | Viscosity (mm2·s−1, 40 °C) | Density (kg·m−3, 15 °C) | Heating Value (MJ·kg−1) |

|---|---|---|---|---|

| C12H23 | 2.96 | 832.6 | 45.95 | |

| DWMB | C11.9H22.8O0.8 | 4.20 | 851.2 | 40.52 |

| DWEB | C12H23O0.8 | 4.71 | 850.8 | 41.74 |

| Engine | 1.9 L, Fiat JTD |

|---|---|

| Type | Direct injection, turbocharged, intercooled, four-stroke, water-cooled, common rail. |

| Number of Cylinder | 4 |

| Bore-Stroke | 82 mm–90.4 mm |

| Compression Ratio | 18.45:1 |

| Maximum Power | 77 kW (at 4000 rpm) |

| Maximum Brake Torque | 205 Nm (at 1750 rpm) |

| Product | Intended Purpose |

|---|---|

| Hydraulic dynamometer (BT-190 FR) | For providing engine load Maximum Power = 100 kW Maximum Load = 750 Nm |

| Crank angle encoder (AVL 365C) | For detecting the crankshaft position |

| Air mass flow meter | AVL Flowsonix-Air product |

| Glow-plug sensor (AVL-GH13P) | For measuring the cylinder pressure |

| Cylinder pressure measurement system (AVL FlexIFEM) | For signal amplification and data acquisition |

| Current clamp (Fluke) | For receiving the injection signals |

| Combustion analysis program (AVL Indicom) | For obtaining and analyzing cylinder gas pressure, heat release rate, and injection timing data |

| Measurement | Unit | Accuracy |

|---|---|---|

| Engine Speed | rpm | ±1 |

| Engine Load | Nm | ±1 |

| Temperature | °C | ±1 |

| Time | s | ±0.5 |

| Air Mass Flow | kg/h | <±1.5% |

| Fuel Consumption | g | <±1% |

| HC, CO, NOx, CO2 | (ppm, ppm, ppm, %) | <±2% |

| Calculated Results | Uncertainty | |

| Brake Specific Fuel Consumption | g/kWh | ≤±2% |

| Brake Specific Energy Consumption | J/kWh | ≤±2% |

| Brake Thermal Efficiency | % | ≤±2% |

| 3.3 bar | 5.0 bar | 6.6 bar | 8.3 bar | 10.0 bar | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Fuel | Pmax (bar) | °CAPmax (a TDC) | Pmax (bar) | °CAPmax (a TDC) | Pmax (bar) | °CAPmax (a TDC) | Pmax (bar) | °CAPmax (a TDC) | Pmax (bar) | °CAPmax (a TDC) |

| 64.21 | 2.0 | 68.78 | 2.4 | 74.75 | 2.2 | 80.69 | 2.6 | 88.24 | 19.8 | |

| DWMB | 62.93 | 2.6 | 68.27 | 2.8 | 73.89 | 2.0 | 80.69 | 2.8 | 91.55 | 19.2 |

| DWEB | 63.90 | 2.8 | 68.89 | 2.8 | 75.43 | 2.0 | 79.68 | 2.4 | 91.95 | 19.2 |

| 3.3 bar | 5.0 bar | 6.6 bar | 8.3 bar | 10.0 bar | |

|---|---|---|---|---|---|

| 2.60 | 2.13 | 1.84 | 1.60 | 1.39 | |

| DWMB | 2.55 | 2.13 | 1.85 | 1.55 | 1.40 |

| DWEB | 2.67 | 2.15 | 1.84 | 1.54 | 1.43 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sanli, H. Utilization of Low-Viscosity Sustainable Quaternary Microemulsification Fuels Containing Waste Frying Oil–Diesel Fuel–Bio-Alcohols in a Turbocharged-CRDI Diesel Engine. Sustainability 2025, 17, 8835. https://doi.org/10.3390/su17198835

Sanli H. Utilization of Low-Viscosity Sustainable Quaternary Microemulsification Fuels Containing Waste Frying Oil–Diesel Fuel–Bio-Alcohols in a Turbocharged-CRDI Diesel Engine. Sustainability. 2025; 17(19):8835. https://doi.org/10.3390/su17198835

Chicago/Turabian StyleSanli, Huseyin. 2025. "Utilization of Low-Viscosity Sustainable Quaternary Microemulsification Fuels Containing Waste Frying Oil–Diesel Fuel–Bio-Alcohols in a Turbocharged-CRDI Diesel Engine" Sustainability 17, no. 19: 8835. https://doi.org/10.3390/su17198835

APA StyleSanli, H. (2025). Utilization of Low-Viscosity Sustainable Quaternary Microemulsification Fuels Containing Waste Frying Oil–Diesel Fuel–Bio-Alcohols in a Turbocharged-CRDI Diesel Engine. Sustainability, 17(19), 8835. https://doi.org/10.3390/su17198835