1. Introduction

Prefabrication in a controlled factory setting may improve the energy performance of modular buildings compared to traditional site-built facilities. However, few studies report empirical evidence to support this premise in full-scale operational buildings. Given the potential for modular to consume less energy than site-built buildings during operation, the objective of this study was to gain an understanding of how modular and site-built projects meet or exceed energy standards through plan review and in-field verification visits. The results of the study provided researchers with a nuanced understanding of energy consumption metrics given field-verified System Efficiency Characteristics (SECs) among a sample of 25 modular and 30 site-built multifamily structures. All such buildings were built and/or assembled in four climate zones defined by the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE).

Exploring SEC metrics among 25 modular and 30 site-built projects allowed the researchers to observe, compare and report trends in building characteristics, material and equipment selection in multifamily projects utilizing modular versus traditional construction methods. Factory and field confirmation visits alleviated the potential for changes in material and SECs due to design changes as well as the materials and equipment substitutions inherent to the shop drawing and submittal process implemented in the U.S. construction industry. From this perspective, the defined similarities and differences between modular and site-built multifamily projects allow researchers to isolate important externalities, such as installation quality and human consumption behavior. This is particularly true when evaluating a multifamily building’s overall energy consumption during building operation.

2. Literature Review

Off-Site Construction (OSC) when broadly defined comprises the design and assembly of components to create building elements or modules at a location other than the construction site [

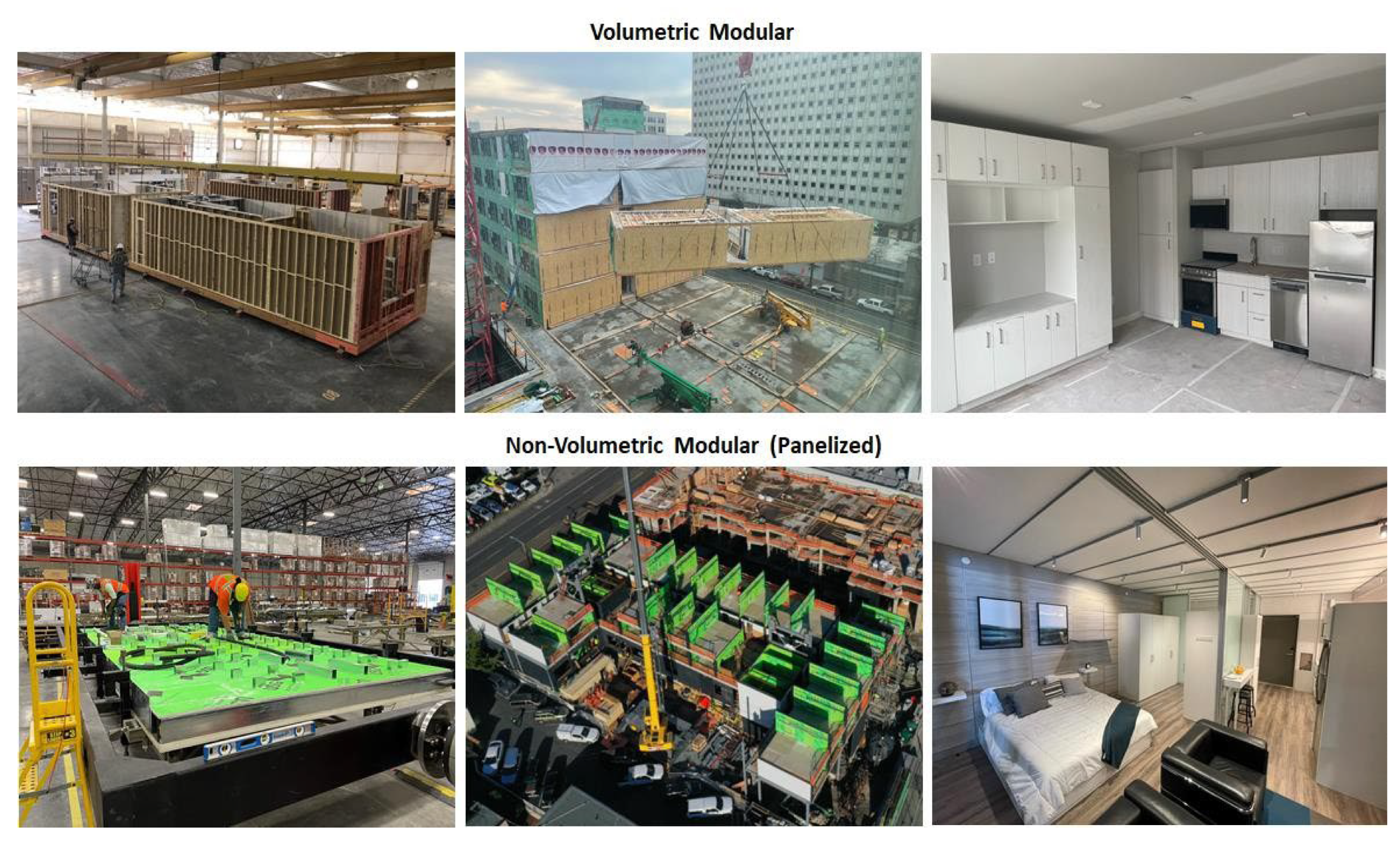

1]. These prefabricated elements and components are then assembled at the building’s location to create a full and complete structure. OSC can be divided into two general categories: prefabricated elements and volumetric building modules. Prefabricated elements can consist of single- and multi-trade assemblies such as panelized wall systems, pipe racks, medical headwalls, bathroom pods and so on. On the other hand, volumetric modules comprise a section of a building, such as a hotel room or apartment, that is finished to 95% completion in a factory setting before being transported and set in erected on site [

2,

3]

According to the Modular Building Institute (MBI) [

4], modular construction falls into one of the following categories: semi-permanent, relocatable or permanent modular construction. Semi-permanent modular buildings are designed to allow for removal and reinstallation on a permanent stem wall style foundation with applied additional exterior architectural elements to provide a sense of permanence. Relocatable modular buildings comply with applicable codes or state regulations but are constructed with the intent of being relocated, reused or repurposed multiple times at different sites. Finally, permanent modular construction (hereafter, modular) is a construction delivery method utilizing prefabricated single- or multi-story permanent whole building solutions delivered in module sections. Modules can be integrated into site-built projects such as a mixed used building or can stand-alone as a turnkey solution.

Figure 1 provides an example of permanent multifamily projects constructed utilizing volumetric and panelized construction methodologies.

The modular construction industry in North America has nearly tripled in volume since 2015, generating 12B USD in revenue in 2022, or approximately 5% of all new commercial construction starts. MBI [

4] estimates that there are 255 modular manufacturing companies in North America generating some portion of revenue from commercial construction. Twenty-four of these manufacturers surveyed reported a total production of 8.1M square feet (sf) or approximately 338,480 sf each. Projects averaged 24,060 sf and 37 modules. The average total cost of these projects was 6.7M USD or 278.84 USD/sf. The project completion timeline, from approval to occupancy, averaged 309 days. The multifamily sector was the largest market for the modular industry, accounting for more than one-third of all factory output.

Significant growth is being realized in the U.S. multifamily sector where energy costs and housing affordability are incentivizing many residents to transition from single- to multifamily housing. A similar trend was observed as developers look to modular construction to offset the high cost of construction [

6]. According to the Department of Housing and Urban Development [

7] and U.S. Census Bureau [

8] in 2021, 31.1% of the U.S. population lived in over 39.9 million multifamily residences. As a result, the use of modular construction methods in the multifamily sector is expected to increase from 16% of projects in 2017 to over 50% of projects by 2025 [

9].

2.1. Energy Code Compliance in Volumetric Modular

Manufactured housing codes and standards are regulated by the United States Department of Housing and Urban Development [

10] and published in the title 24 of the U.S. Code of Federal Regulations part 3280 [

11]. Additionally, code compliance for volumetric modular building units is regulated and certified to meet the state and local requirements where the building will be placed. The onsite portion of a modular project (utilities, foundations, etc.) is permitted and inspected by local code authorities such as the locally mandated International Building Code (IBC), Title 24 (California) and International Energy Conservation Code (IECC). The off-site, factory-constructed modules are third-party inspected in the factory to meet the applicable codes, with state amendments determined by where they will be permanently installed.

2.2. Barriers to and Drivers of Modular Methods

Off-site construction practices, including manufactured single-family homes, are not a new concept. In the U.S. residential construction industry, mobile and manufactured homes have been in production for decades. However, the proliferation of manufactured homes has left a negative perception among some project stakeholders that modular construction is of low quality, is not aesthetically pleasing and provides an owner with limited design options [

12,

13]. Some progress has been made to reduce the stigma associated with modular construction methods due to greater adoption, yet the lack of awareness and misunderstandings of modular construction continue. More recent studies [

14,

15] indicated that perceived barriers preventing wide-spread adoption of modular construction still include a lack of awareness of the benefits of modular construction among owners. However, barriers have shifted toward lack of modularization provisions in typical project design, perception of modular design rigidity, limited availability of prefabrication facilities within the project vicinity, restricted staging areas and limited equipment for setting modular units. Researchers report the following drivers that promote a shift to more modular construction solutions [

16,

17]:

A lack of on-site, skilled labor in the U.S. construction industry;

Efficient and sustainable use of materials and labor [

18];

Achieving higher quality through a controlled factory environment;

The lack of capacity to meet housing shortages using conventional construction methods.

2.3. Advantages of Modular Methods

Numerous agencies and associations report potential advantages of modular construction, and academic publications highlight potential benefits of off-site construction methods. The notable construction-phase advantages of modular methodologies include reduction in project schedule duration, cost and material waste [

18,

19,

20,

21] as well as improved building quality, labor productivity and safety. For benefits of modular methods realized during the building operation phase, the potential for reduced energy consumption and associated costs received the most attention [

22,

23,

24,

25,

26,

27,

28]. However, few studies exist that empirically measure and validate the increased energy performance of modular as compared to traditional site-built buildings.

2.4. Energy Consumption in Modular Construction

Researchers have explored the topic of energy consumption in modular construction through the lens of Life Cycle Assessment, embodied energy and energy modeling simulations [

29,

30,

31]. It was noted that different construction materials and building types were compared in some studies and field-based data collection on full-scale operational buildings were nonexistent. Exemplary LCA studies [

29] compared one single-family conventional home to two modular single-family homes through the application of cradle-to-gate LCA methods. The cradle-to-gate LCA method only accounts for the first two stages of the building life cycle which includes raw material extraction and the manufacturing and processing of materials. However, cradle-to-gate LCA neglects the inclusion of transportation, usage and waste disposal stages of LCA which appear critically important given the differences between modular and conventional methods in single-family residential construction. Another LCA study [

30] compared one modular and one conventional single-family residential project, reporting that the average impacts of building the home are less for modular construction with the caveat that averages may hide significant variation between contractors and builders as well as individual project characteristics. For energy modeling simulations, one study [

13] focused on energy efficiency during the manufacturing process, but not on energy consumption during the operation phase of the building life cycle.

The National Renewable Energy Laboratory (NREL) has completed notable work exploring energy consumption in a modular building unit (i.e., iUnit) in controlled and field-based tests as well as through their Energy in Modular (EMOD) design guide [

3,

4]. Through these investigations, NREL has identified that modular construction represents an important and scalable pathway to meet national energy efficiency goals. Further, they posit that utilizing modular techniques specifically in multifamily construction is an essential step for developing a transformational pathway for our clean energy future.

3. Study Purpose and Objective

In the U.S. Construction industry, the metrics that contribute to energy efficiency and performance such as material selection, thermal insulation, air barriers, envelope tightness, etc., are governed by various building codes and verified through field-based inspection by the authorities having jurisdiction at the building’s location. Given the critical influence of building codes and standards, building certification paths (performance, trade-off, etc.) and field verification inspections on building energy performance, one might expect to find existing studies exploring these topics in modular construction. However, a review of the literature revealed no existing studies that explored energy code compliance between modular and site-built multifamily projects that included a comprehensive review of construction documents, drawings and specifications in conjunction with field-collected verification data.

Given the potential for modular to consume less energy than site-built buildings during operation, the objective of this study was to gain an understanding of how modular and site-built projects meet or exceed energy standards through in-field verification. The results of the study provided researchers with a more defined understanding of potential energy consumption metrics given field-verified building characteristics from a relatively large sample of both modular and site-built multifamily structures in four American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) climate zones. Normalizing building characteristics and the confirmation that modular and site-built multifamily buildings are similar, or different, allowed researchers to identify other important variables distinctive to both construction methods.

This study was unique in that it included not only an in-depth review of construction documents but also field verification visits to modular construction manufacturing facilities and project sites to confirm how in-field conditions met or exceeded the data in the construction documents. Factory and field confirmation visits alleviated the potential for changes in material and system efficiency characteristics (SECs) due to design changes as well as the materials and equipment substitutions inherent to the shop drawing and submittal process implemented in the U.S. construction industry.

Exploring these metrics across 25 modular and 30 site-built projects allowed the researchers to observe, compare and report trends in building characteristics, material and equipment selection in multifamily projects utilizing modular methods versus traditional construction methods. The comparatively large project sample (considering previous studies) alleviated a portion of the influence of latent variables related to individual company performance and project quality variations across the project sample.

Therefore, this study represents a foundational step in the exploration of energy consumption through the investigation and comparison of the metrics utilized to express material and SECs such as Seasonal Energy Efficiency Ratio (SEER), Heating Performance Factor (HSPF), U-value, Solar Heat Gain Coefficient (SHGC), Window to Wall Ratio (WWR), etc., among 55 commercial multifamily buildings (25 modular and 30 site-built) in four climate zones.

4. Methodology

4.1. Case Study Delimitation to Four Climate Zones

The climate of a given region is an important factor when considering building design standards for energy efficiency. In the U.S., the International Energy Conservation Code (2021) requirements are based upon zones established through longitudinal climate data collected by ASHRAE (see ‘Standard 90.1-2022 Energy Standard for Sites and Buildings Except Low-Rise Residential Buildings’ [

31]). For this study, data collection was limited to ASHRAE climate zones 3B, 3C, 4A and 4C (see 2021 IECC-2018 Climate Zones by County [

32]) based on the funding agency requirements. These climate zones were prioritized by the sponsor due to the prevalence of volumetric modular multifamily structures in design or under construction in these areas, as well as the enforcement of various energy codes and standards such as California’s Title 24 [

33,

34] and various years of the IECC code [

35,

36].

4.2. Case Study Methodology

A multi-project case study with a multifaceted data collection approach was developed to validate the ECC of modular and site-built commercial multifamily buildings. Data were collected through the review of construction documents and confirmed during the fabrication and construction phases via on-site verification inspections. The full methodology included the identification of priority SECs, case project recruitment, development of data collection protocols, data collection and analysis as described below.

4.3. Case Projects and System Efficiency Characteristics (SECs)

In this study, multifamily buildings were defined using the 2021 International Building Code [

37] which includes structures with more than 2 dwelling units (apartments and condominiums). The case projects were delimited to buildings of at least four stories above grade based on the project sponsor’s requirements. For mixed-use multifamily projects, data collection was limited to residential units and spaces directly associated with residential units (i.e., corridors, stairwells, lobbies, leasing offices and other common spaces). Applicable commercial energy codes included the California Title 24 Energy Code (2016 [

33]; 2019 [

34]) and the IECC (2015 [

35]; 2018 [

36]) with state amendments. Only spaces associated with residential occupancies were included in the data collection and analysis of SECs.

Modular and site-built case projects that met the requirement for study inclusion were recruited in ASHRAE climate zones (3B, 3C, 4A and 4C). Modular buildings were identified with the assistance of known multifamily modular manufacturers prior to construction. Internet searches were conducted for initial identification of site-built multifamily projects within the four climate zones. The research team conducted in-person visits to the identified site-built projects for recruitment, inclusion in the study and data collection. For each building included in the study, approval was obtained from the project developer or general contractor to provide construction documents and access the construction site for data collection.

A total of 38 System Efficiency Characteristics were selected for this study based on their energy savings potential in commercial multifamily settings (

Table 1). This process began with a Pacific Northwest National Laboratory (PNNL)-developed inventory of energy code requirements applicable to various building types and climate zones of interest from the provisions of the IECC and ASHRAE 90.1 standards [

31,

38].

4.4. Data Collection Protocol

A complete SEC data collection protocol comprised an in-depth review of construction documents followed by two field inspections to verify that installed materials and equipment were the same or equivalent to those specified in the construction documents. For modular multifamily projects, one inspection was conducted at the manufacturing site to verify envelope compliance and a second inspection was conducted at the construction site. For site-built projects, both inspections were conducted at the construction site: the first prior to the installation of finishes and the second near the end of construction prior to occupancy.

Table 2 illustrates when data were collected throughout the study. As noted, some data were collected in part during modular factory visits if components were installed in the factory (e.g., in-unit HVAC and domestic hot water (DHW) equipment, etc.); these data were also verified during subsequent site visits. It should be noted that field data collection comprised visual observation and confirmation of the material and equipment labels on site. Direct measurements of heat energy transfer across construction assemblies were not conducted due to the cost associated with the number of projects and their geographic dispersion across the United States.

On Center

® Software, Inc.’s (Cincinnati, OH, USA) On-Screen Takeoff (OST) application, version 3.98.8.52, was used for construction document review data collection. As a scalable PDF plan reader, OST was an effective tool for quantifying gross floor area and conditioned floor area as well as the area and orientation of roof insulation, wall insulation and fenestration. OST was utilized for the accounting of HVAC and DHW equipment systems as well as lighting fixtures by type and location. The software application was used to calculate both interior and exterior lighting power density (LPD). Plan review data collection was verified through factory and site visits. The values generated through plan review using OST were compared to those used in the project energy reports for energy code compliance and permitting. HVAC and DHW equipment performance data collected from construction documents, energy reports and field inspections were also verified using the Air-Conditioning, Heating, and Refrigeration Institute [

39] Directory of Certified Product Performance.

A common data collection form and protocols for factory and site verification inspections were established to ensure data collection consistency for comparison. Minimum data sample thresholds for project study inclusion were established as follows: inspection of 10% of living units or a minimum of 3 (whichever was greater) in buildings up to 50 units was required. For buildings with more than 50 living units, 2% of additional units over 50 units required inspection. For buildings with more than 200 units, 1% of additional units over 200 required inspection. Minimum data collection thresholds of 10% or a minimum of 2 (whichever was greater) were established for common spaces, corridor and stairwell inspections. Electronic data collection forms were developed to record code compliance information for each measure during document review, factory inspection and site inspection as well as to archive this information in a secure database. A photographic journal of products, labels and observed conditions for each measure was prepared following each factory and site inspection to verify the code compliance information provided in the construction documents and compiled data in collection forms. Information identifying projects, participants and stakeholders was redacted from the dataset.

5. Results

5.1. Dataset

The dataset comprised energy code compliance and verification data for 55 multifamily projects (25 modular and 30 site-built) in ASHRAE climate zones 3B, 3C, 4A and 4C. Buildings included in the sample averaged 140,390 gross square feet (GSF) of floor space. Modular building floor areas were between 36,147 to 535,778 GSF, with an average of 127,882 GSF. Site-built building floor areas ranged from 21,035 to 688,165 GSF with an average of 157,066 GSF. Modular buildings were between four to fourteen stories and site-built buildings between four to nine stories with an average of six stories for all projects in the sample. Modular buildings comprised an average of 161 dwelling units with a range of 36 to 410 total. Site-built buildings comprised an average of 122 dwelling units per building (14 to 363) with an average of 144 dwelling units for all projects in the sample. Modular dwelling units averaged 556 sf per dwelling unit. Site-built dwelling units averaged 826 sf per dwelling unit.

Table 3 demonstrates that the average building floor area, story height and number of residential units between samples were similar. Notably, residential units in modular multifamily buildings were smaller on average with a greater composition of studio and one-bedroom units compared to site-built buildings with a greater composition of two- and three-bedroom units. Modular multifamily buildings were found to have a greater composition of affordable residential units (65%) compared to site-built buildings with a greater composition of market-rate units (62%).

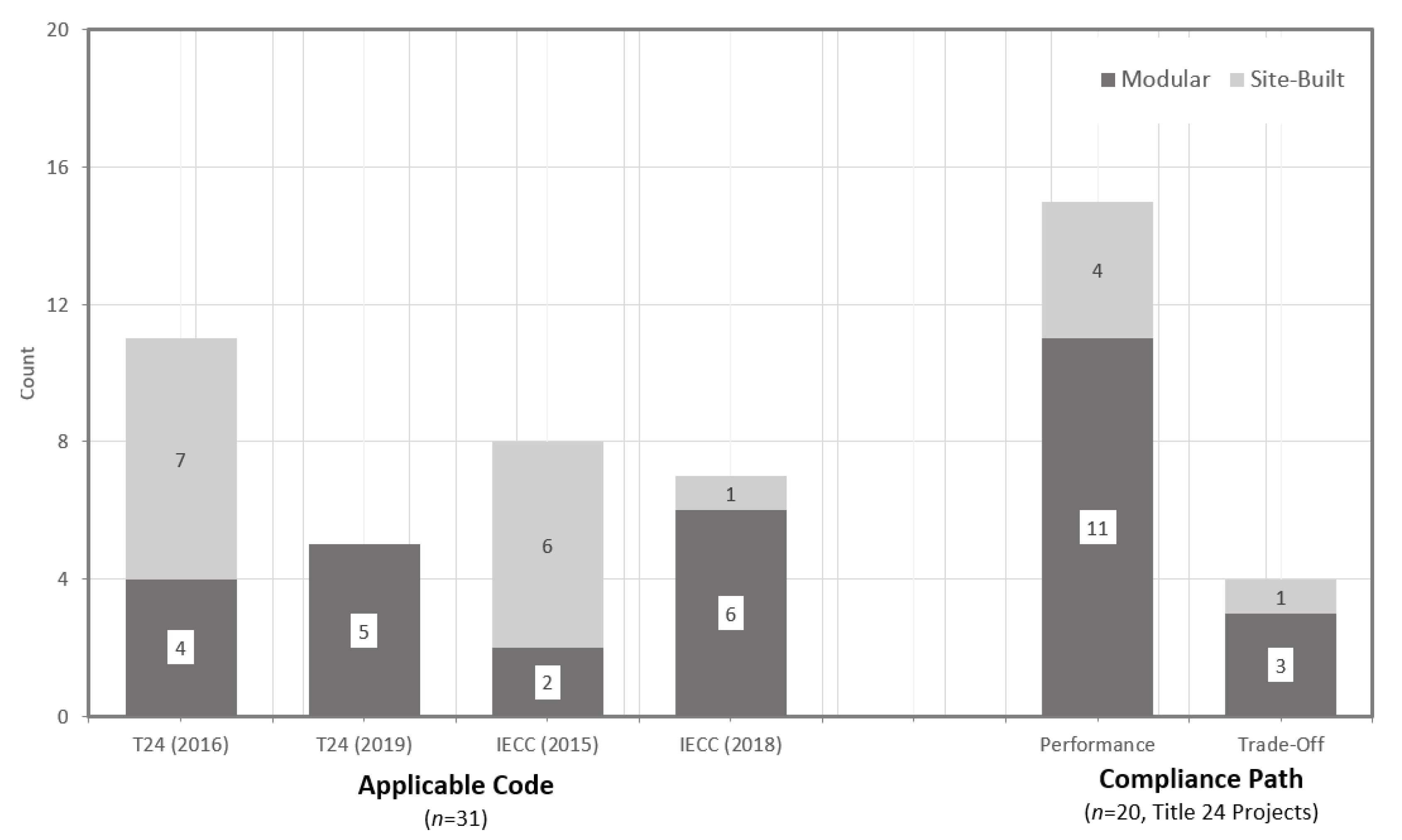

Of the 55 total code compliance projects, 28 were located in California. Of these, sixteen projects (seven modular and nine site-built) were located in the greater metro area of Los Angeles and twelve projects (five modular and seven site-built) were located in the San Francisco Bay area. All California projects were permitted under the 2016 or 2019 version of the Title 24 Energy Code. Of the remaining projects, eighteen (eight modular and ten site-built) were located in the metro area of Philadelphia, PA, and nine projects (five modular and four site-built) were located in the metro area of Seattle, WA. Projects in Philadelphia were approved under the 2015 or 2018 version of the IECC. Projects located in the greater Seattle metro area were approved under the 2018 IECC with Washington State or Seattle Energy Code [

30] amendments (WSEC and SEC, respectively). Applicable energy codes and code compliance paths by modular and site-built buildings are illustrated in

Figure 2.

All projects for which code compliance path information was available (n =20) were in California and subject to the Title 24 code. These projects were approved through the performance path with four of the twenty electing trade-off approaches. It is unlikely that compliance with the Title 24 prescriptive code requirement could be achieved with R-19/R-21 insulation in a 2 by 6 wall cavity without the added use of continuous exterior insulation. For these projects, performance path or envelope trade-off was likely a more cost-effective option. Therefore, the prescriptive code compliance rates of individual measures were not used to compare the energy code compliance rates of these modular and site-built multifamily buildings. For these projects, prototype energy use simulations were performed to verify compliance. Key SECs found in both modular and site-built multifamily buildings with respect to prescriptive requirements of the Title 24 energy code in climate zone 3 and the IECC (with Seattle Energy Code and WSEC amendments) in climate zone 4 are discussed below.

5.2. Primary Energy Conservation Measures

Of the 38 SECs selected for code compliance verification in this study, those related to the building envelope (roof wall and window U-value, window SHGC, Window-to-Wall Ratio), HVAC equipment and efficiency, domestic hot water (DHW) equipment and efficiency and lighting power density (LPD) were identified to have the greatest impact on overall building energy performance. These Primary SECs are presented below.

5.3. Building Envelope

The U-values for roof assemblies are based on insulation location (e.g., cavity, above deck or both), insulation type (e.g., loose fill, batt, rigid or spray foam) and insulation thickness and include layers of the roof assembly as per ASHRAE 90.1-2022 [

32]. For modular buildings, cavity insulation was observed in the factory. Above-deck insulation was observed in the field. In some cases, insulation was unobservable in the field due to the timing of site visits and project construction schedules as described below. Roofing assemblies consisted mainly of conventional or pre-engineered wood framing and both cavity and above-deck (continuous rigid) insulation. Of 22 modular and site-built buildings in ASHRAE climate zone 3, 22 (100%) of projects were found to have met the Title 24 prescriptive code requirement. Of 16 modular and site-built buildings in ASHRAE climate zone 4, 14 (88%) were found to have met the IECC/SEC/WSEC prescriptive code. The two site-built projects below code minimums followed the trade-off compliance path.

When interpreting the wall and roof U-values reported in this study, it should be noted that U-values were gathered from third-party energy compliance reports or calculated based on roof and wall details when reports were not provided. For Title 24 projects, the drawings include T-24 compliance certification reports which provide the U-value used in the study. For projects in the State of Washington, wall and roof assembly U-values were taken from C407 energy compliance reports when available. When compliance certification reports were not provided, building sections and details in the construction documents were analyzed to identify all layers comprising wall and roof assemblies. Since only two site visits were conducted, in the case of some assemblies, all layers of the assembly and some insulated assemblies were not visible. Therefore, the U-values presented did not include any adjustment given the installation quality of insulation materials. The lack of an installation quality rating by an Energy Services Network (RESNET)-certified professional represents a limitation in the study findings, as well as an area of further research.

Table 4 illustrates the effective U-values of primary R2 occupancy above-grade wall assemblies for each building in the sample. These values are based on insulation location (e.g., cavity, continuous or both), insulation type (e.g., batt, rigid or spray foam) and insulation thickness and include the effective U-value for all layers of the wall assembly as per Appendix A of ASHRAE 90.1-2022 [

32]. For modular buildings, wall insulation was observed in the factory. Wall assemblies consisted mainly of 2 by 6 wood framing and cavity (fiberglass batt) insulation. Of 25 modular and site-built buildings in ASHRAE climate zone 3, none were found to have met the Title 24 prescriptive code requirement. Of 17 modular and site-built buildings in ASHRAE climate zone 4, 17 (100%) were found to have met the IECC/SEC/WSEC prescriptive code requirement. As noted previously, it is unlikely that compliance with the Title 24 prescriptive code requirement could be achieved with R-19/R-21 insulation in a 2 by 6 wall cavity without the added use of continuous exterior insulation. For these projects, performance path or envelope trade-off was likely a more cost-effective option.

The average weighted U-factor and Window Solar Heat Gain Coefficient (SHGC) of primary R2 occupancy windows for each building sampled are presented in

Table 4. These values are based on U-factor and SHGC values found in window schedules and verified on National Fenestration Rating Council labels during field inspection. For modular buildings, window U-factor was observed in the factory. Windows consisted of both fixed and operable glazing and both vinyl and aluminum framing (with and without thermal break). Windows consisted mainly of insulated glass (with and without argon gas) and low emissivity coatings. Since several different window types were observed for each building sampled, average weighted U-factor and SHGC values were calculated for each building based on the area of each window type relative to the total window area of the building. Of 24 modular and site-built buildings in ASHRAE climate zone 3, 24 (100%) were found to have met the Title 24 U-factor and SHGC prescriptive code requirement. Of 23 modular and site-built buildings in ASHRAE climate zone 4, 23 (100%) were found to have met the IECC/SEC/WSEC U-factor and SHGC prescriptive code requirement.

The WWR for buildings in the sample are provided in

Table 4. WWR is the amount of exterior fenestration area (windows, storefronts, non-opaque doors), divided by the exterior gross wall area, expressed as a percentage. WWR accounts for all building fenestration including both dwelling units and common areas. Maximum allowed WWR is 40% under Title 24 and 30–35% under IECC/SEC/WSEC depending on code year. Of 16 modular and site-built buildings in ASHRAE climate zone 3, 16 (100%) were found to have met the Title 24 prescriptive code requirement. Of 14 modular and site-built buildings in ASHRAE climate zone 4, 13 (93%) were found to have met the IECC/SEC/WSEC prescriptive code requirement.

5.4. Space Conditioning, Water Heating and Lighting Equipment

Primary residential space heating and cooling equipment type, fuel source and efficiency for the building sample are presented in

Table 5 and

Table 6, respectively. Data were collected on all HVAC systems, except for equipment serving commercial spaces on mixed-used buildings. Residential equipment included equipment serving dwelling units, corridors and residential common spaces. Data included a count of each type, description and spaces served by each piece of equipment from mechanical schedules. Additionally, the model number, fuel source, efficiency and rated heating and/or cooling capacity of each type of equipment was recorded from the equipment name or data plate in the field. Using the model number, performance data were verified using the manufacturer’s website or the Air-Conditioning, Heating, and Refrigeration Institute [

29] product directory.

For both modular and site-built buildings, space heating and cooling equipment was most often observed in the field although modular indoor Air Handling Units (AHU) and packaged units were often observed in the factory. In ASHRAE climate zone 3, the most common HVAC systems observed in both modular and site-built multifamily buildings were split heat-pump systems followed by ductless mini-split and variable refrigerant flow (VRF) multi-split systems (≤30 MBTUH). In ASHRAE climate zone 4, the most common HVAC systems observed were Dedicated Outside Air Systems (DOAS) followed by split air-conditioning and heat-pump systems. Of note, packaged thru-wall systems were only observed in modular multifamily buildings. Split AC systems with gas heating were only observed in site-built multifamily buildings in ASHRAE climate zone 4a. Of 15 modular and site-built buildings in ASHRAE climate zone 3, 15 (100%) were found to have met the Title 24 prescriptive code requirement for HVAC system efficiency. Of 11 modular and site- built buildings in ASHRAE climate zone 4, 11 (100%) were found to have met the IECC/SEC/WSEC prescriptive code requirement.

5.5. Water Heating Equipment

Primary residential space water heating equipment type and fuel source and efficiency for the buildings sampled are shown in

Table 5 and

Table 6, respectively. Data were collected on all DHW systems except for equipment serving commercial spaces. This includes equipment serving dwelling units and residential common spaces. Data included the type, description and spaces served by that equipment from mechanical schedules. Additionally, the model number, fuel source, efficiency and rated water heating capacity (or storage tank size) of each type of equipment were recorded from the equipment name or data plate in the field. Using the model number, performance data were verified using the manufacturer’s website or the Air-Conditioning, Heating, and Refrigeration Institute [

40] product directory.

For both modular and site-built buildings, water heating equipment was most often observed in the field, although unitary systems were often observed in the factory. In ASHRAE climate zone 3, the most common DHW systems observed in both modular and site-built multifamily buildings were central gas boiler systems (≥300 MBtuh). Nearly half (45%) of these systems were supplemented by solar water heating. In ASHRAE climate zone 4, the most common DHW systems observed were in-unit electric tank storage water heaters (<50 gal) followed by central air–water heat-pump (AWHP) systems. Of 18 modular and site-built buildings in ASHRAE climate zone 3, 18 (100%) were found to have met the Title 24 prescriptive code requirement for DHW system efficiency. Of 13 modular and site-built buildings in ASHRAE climate zone 4, 13 (100%) were found to have met the IECC/SEC/WSEC prescriptive code requirement.

5.6. Lighting Power Density (LPD)

The LPD values for all dwelling units and residential commons interior lighting equipment are provided in

Table 6. LPD was calculated as the sum of lighting fixture wattage for the space divided by the floor square footage of the space (W/sf). Lighting fixtures serving corridors and residential common spaces were included in the LDP. Fixtures serving commercial spaces and lighting for public safety were excluded. Data included residential lighting fixture quantities, description, lamp type, number of lamps and wattages per fixture for each type recorded from the lighting schedules. Light fixtures were verified in the field for each sample space. Data were also collected on lighting systems within dwelling units, although dwelling units are generally exempt from power allowance code requirements. In ASHRAE climate zone 3, the LPD of dwelling units averaged 0.29 W/sf for modular buildings and 0.23 W/sf for site-built buildings. The LPD of residential commons averaged 0.31 W/sf for modular buildings and 0.36 W/sf for site-built buildings. Of eleven modular and site-built buildings in ASHRAE climate zone 3, nine (82%) were found to have met the Title 24 prescriptive code requirement for residential corridor and common area LPD. In ASHRAE climate zone 4, the LPD of dwelling units averaged 0.33 W/sf for modular buildings and 0.32 W/sf for site-built buildings. The LPD of residential commons averaged 0.32 W/sf for modular buildings and 0.31 W/sf for site-built buildings. Of eight modular and site-built buildings in ASHRAE climate zone 4, eight (100%) were found to have met the IECC/SEC/WSEC prescriptive code requirement for residential corridor and common area LPD.

5.7. Secondary Energy Conservation Measures

Of the 38 ECMs selected for code compliance verification in this study, roughly 30% were not required by code in one or more study regions or were not applicable to all buildings, space uses and equipment systems. Examples include high reflectance roofs, entrance vestibules, night fan controls, duct leakage, DHW heat traps, temperature maintenance systems, demand recirculation controls, exterior lighting controls and interior daylighting controls. Therefore, data collection for these secondary measures was limited.

6. Discussion

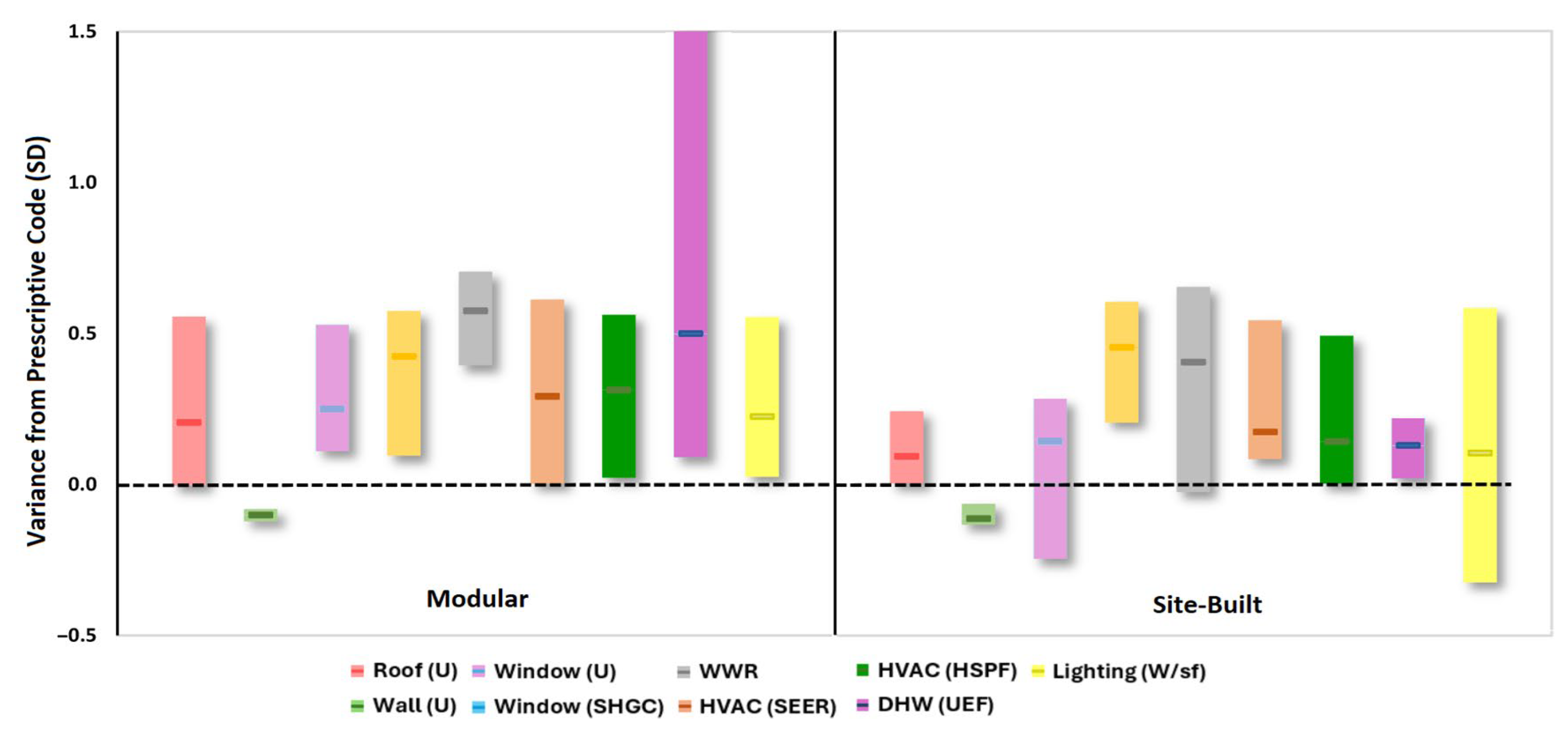

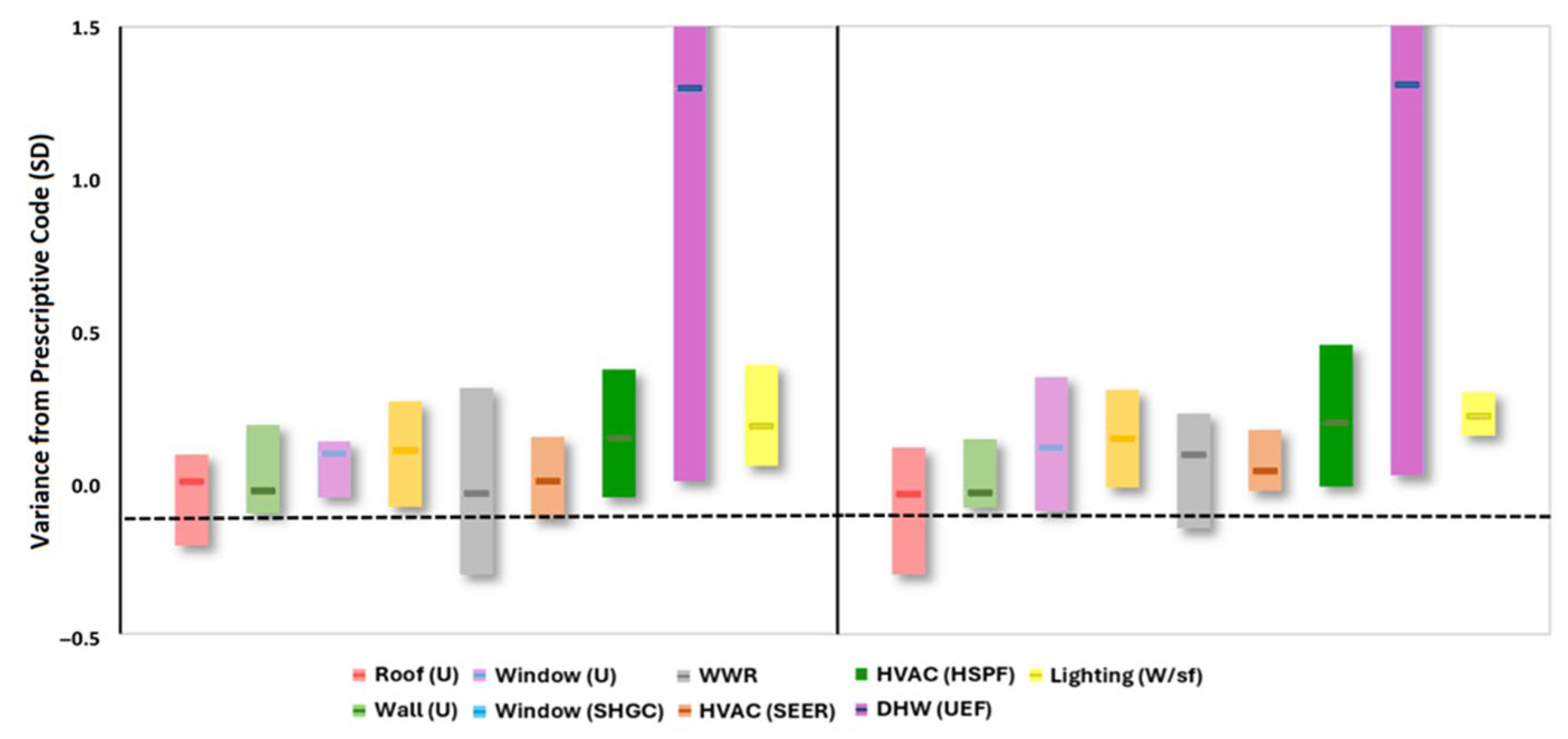

The overall results suggest that the average efficiency of primary SECs (envelope, HVAC, DHW and lighting) in modular construction slightly exceeded the average efficiency of primary energy measures in site-built construction for multifamily buildings in ASHRAE climate zone 3. For multifamily buildings in ASHRAE climate zone 4, the average efficiency of SECs in site-built construction slightly exceeded the average efficiency of primary energy measures in modular construction (

Table 7). While the prescriptive code compliance rates of individual measures were not used to compare the energy code compliance rate of modular to site-built buildings, the vast majority of buildings met or exceeded the prescriptive energy code requirements for each climate zone. Exceptions include wall U-factor in ASHRAE climate zone 3 and window-to-wall-ratio (WWR) for one modular building which used the envelope trade-off compliance path in climate zone 4. One site-built building’s HVAC SEER values were below prescriptive code in ASHRAE climate zone 3; however, this building used the performance compliance path. Lighting-specific exceptions include the LPD for two modular projects in ASHRAE climate zone 3 due to residential dwelling exclusions and/or space type evaluation methods. Improvements (standard deviation) from prescriptive code requirements by ASHRAE climate zone are presented in

Figure 3 and

Figure 4, respectively.

Overall, the results of this study indicate that, by and large, similar methods of achieving code compliance are used in modular and site-built multifamily projects in ASHRAE climate zones 3B, 3C, 4A and 4C. Some variations in SECs existed between the modular and site-built projects on domestic hot water UEF values in climate zone 3. These slightly larger differences can be attributed to the specification of in-unit heat pump water heaters which typically have UEF ratings 2.5 to 3 times higher than standard electrical or gas water heaters. Site-built multifamily projects in climate zone 3 utilized other water heating equipment with traditionally lower UEF ratings which impacted the max and average statistics.

This study provides evidence that modular and site-built projects utilize the same methods to achieve code compliance. This is an important distinction for researchers investigating energy consumption in buildings during operation. Specifically, the results show that, at the time of this study, across a large sample, the methods employed to achieve code compliance were nearly identical for modular (n = 25) and site-built (n = 30) multifamily construction, aside from the fact that large portions of the building are constructed in a factory for modular methods. For building owners and developers, this finding can dispel some of the prevailing stigma that modular projects are of lower quality than their site-built counterparts.

The findings are particularly important for researchers attempting to isolate specific variables associated with a building’s operational energy consumption. Evidence that building characteristics are nearly identical regardless of the metric provides justification for the normalization of the construction methods when completing energy modeling scenarios. Those metrics include the following:

Seasonal Energy Efficiency Ratio (SEER);

Heating Performance Factor (HSPF);

Water Heating Efficiency (UEF);

Light Power Density (LPD for both residential unis and residential common areas);

Wall and Roof U-value (without accounting for installation quality);

Window U-factor;

Solar Heat Gain Coefficient (SHGC);

Window to Wall Ratio (WWR).

With the establishment that modular and site-built multifamily buildings are essentially the same from a construction and equipment selection standpoint, researchers can isolate other important building variables, such as construction quality and human behavior when comparing modular and site-built multifamily projects on actual operational energy consumption.

While few differences were observed between the types of materials and equipment used in either modular or site-built multifamily construction, field observation indicated the installation quality of envelope measures (e.g., insulation, air barrier, etc.) in modular multifamily construction may be better when compared to site-built construction (

Figure 5). These observations suggest that prefabrication in a controlled factory setting has the potential to reduce energy loss and improve the energy performance of modular buildings compared to traditional site-built buildings. That said, a longitudinal comparison of modular and site-built multifamily building energy consumption and air-leakage testing would be needed to empirically confirm the study observations.

It should be noted that confirmation of material installation quality was not included in the grant scope of work, and drawing conclusions from qualitative observation should be made with caution. As previously stated, the field inspection process was based on visual observation and confirmation of the material and equipment labels on site. In the case of insulation, the presence of the correct material was confirmed when possible but direct measurements of field conditions, such as heat flux, were not completed. Several challenges related to the nature of site-built construction limited the researchers’ ability to visually observe insulation in every condition that existed on site. This limitation was due to the allowance of only two site visits per project at 55 geographically dispersed locations as well as challenges associated with the nature of construction schedules.

For modular projects, the nature of assembly line production made insulation quality observation less challenging. In the factory, there were typically modular units at various stages in the production line including the insulation stage, while others were simultaneously in the drywall and finished stage in the manufacturing process. This allowed researchers to obtain consistent and repetitive observations of insulation quality regardless of the factory visit date. For site-built projects, based on the schedule visit date, insulation was generally hidden in large areas due to finishes being installed on some floors. In these cases, insulation was typically installed and visible on other floors which is where observations were made. One important note of interest is that roof insulation scopes of work were often split between factory-built roof modules and site-built scopes of work, e.g., batts between framing members and additional rigid above-deck insulation being installed on site to achieve specified R-values. The same was true for some wall assemblies, where cavity insulation was installed in the factory, and continuous rigid insulation was installed as part of the exterior finish scope on site.

Another important consideration is that follow-on trades often disturb installed insulation on site when completing their work (wood blocking, making electrical changes, etc.) increasing the difficulty of accurate assessment of ‘final’ insulation quality without constant observation on site to verify insulation quality immediately prior to drywall, exterior finishes and roofing materials. Nonetheless, an empirical investigation that includes direct measurement and more frequent site visits to document insulation quality to account for in-field U-value calculation and insulation quality grading represents a promising area of further research.

7. Conclusions

This study provides a robust comparison of energy code compliance between modular and site-built multifamily buildings across four ASHRAE climate zones. By analyzing 55 projects through construction document review and field verification, the research offers a nuanced understanding of how modular and site-built methods perform relative to prescriptive energy standards. The findings reveal that both construction types largely meet or exceed code requirements, with modular buildings showing slightly higher efficiency in climate zone 3 and site-built buildings performing marginally better in climate zone 4.

Importantly, the study demonstrates that modular and site-built projects employ nearly identical strategies to achieve energy code compliance, dispelling misconceptions about the quality and performance of modular construction. This disparity in system efficiency characteristics—such as SEER, HSPF, UEF, LPD, U-values, SHGC and WWR—supports the normalization of construction methods in energy modeling and operational performance studies.

While installation quality of envelope measures appeared higher in modular buildings due to the controlled factory environment, further longitudinal research is needed to validate these observations through direct measurement and expanded site inspections. The study lays a critical foundation for future investigations into operational energy consumption, enabling researchers to isolate variables such as construction quality and occupant behavior with greater confidence.

Ultimately, this research contributes to the growing body of evidence supporting modular construction as a viable alternative to traditional building methods—particularly in the multifamily sector where energy efficiency and housing affordability are increasingly vital.

8. Limitations and Further Research

The data collection for this project was adversely affected by the COVID-19 pandemic and associated construction lending and supply chain disruptions. Several projects in design failed to start, limiting data collection to construction document reviews. Other projects that were under construction were delayed beyond the grant timeframe. In addition to COVID-19 pandemic-related challenges, Seattle-based projects in ASHRAE climate zone 4C were further delayed due to a 140-day concrete driver strike [

40] which extended several projects’ substantial completion beyond the data collection period.

Night fan controls, duct sealing, DHW heat traps, temperature maintenance systems and demand recirculation controls were often unobservable in the field due to the timing of site visits and/or components being enclosed in or behind other materials. While these measures may not substantially contribute to energy use in multifamily buildings, the majority of data were only collected through construction document review and could not be field-verified. Data were further limited for temperature maintenance systems because they were not required by code for several projects and did not apply to another third of projects having tankless or in-unit storage tank systems. Demand recirculation similarly does not apply to tankless or in-unit storage tank systems and was not allowed in some code jurisdictions.

As noted previously, field observations indicated the installation quality of envelope measures (e.g., insulation, air barrier, etc.) in modular multifamily construction may be better when compared to site-built construction. These observations suggest that prefabrication in a controlled factory setting has the potential to reduce energy loss and improve the energy performance of modular buildings compared to traditional site-built buildings. Therefore, a longitudinal comparison of modular and site-built multifamily building energy consumption and air-leakage testing to empirically confirm study observations represents a promising area of further research.