1. Introduction

Carbon dioxide (CO

2) is the most prevalent greenhouse gas responsible for human-induced climate change, and cement production alone contributes approximately 7–8 percent of global CO

2 emissions [

1,

2]. Most of this impact (approximately 60%) is attributable to the 14 billion tonnes of concrete produced annually [

3]. Approximately 400 million tonnes of steel rebars are produced annually for use in reinforced concrete contributing a further 1.5% share of the global carbon emissions [

4]. As operational energy consumption in buildings has significantly declined due to improvements in insulation, energy-efficient technologies, and the integration of renewable energy, embodied carbon has become a leading concern in the development of sustainable buildings [

5]. This transition has positioned structural engineers as key contributors in reducing environmental impacts, particularly in reinforced concrete (RC) structures, which account for the largest share of building mass and embodied emissions [

6,

7].

Given that reinforced concrete is not expected to be widely replaced in the near future, improving the efficiency of its design is essential for addressing climate targets. The Global Cement and Concrete Association (GCCA) identifies design and construction efficiency as one of the most impactful strategies, with the potential to achieve 22 percent of the required emissions reductions to reach net-zero carbon in the concrete sector by 2050 [

8,

9]. Within typical multistorey buildings, floor systems account for approximately 60 percent of the total concrete volume, representing a major opportunity for carbon reduction [

10,

11,

12]. As a result, a growing number of studies focus on reducing the embodied carbon of RC floors through structural optimisation methods [

13,

14,

15].

A recent study examining 769 buildings across Europe identified the lowest, average, and highest carbon footprints for concrete frame structures as 400, 650, and 1200 kg CO

2e/m

2 of built-up area, respectively [

16]. Similar values (420, 750, and 1350 kg CO

2e/m

2) were reported in another study based on a global survey of 95 reinforced concrete residential case studies [

17]. The considerable variation in these carbon benchmarks is largely attributed to the influence of irregular floor plan geometries, particularly in office buildings [

18]. For modular mid-rise buildings, a survey of over 600 examples in Europe found that current best practices result in carbon footprints ranging between 270 and 367 kg CO

2e/m

2 [

19]. Notably lower target values of 160 and 137 kg CO

2e/m

2 have been proposed for mid-rise reinforced concrete buildings in Canada and the United States, respectively [

20].

Many of these investigations apply parametric or algorithmic techniques to explore how various design parameters affect environmental impacts. Parameters such as column spacing [

9,

14], concrete strength [

13,

21], and reinforcement ratio [

22] have been analysed. However, most studies concentrate on a single floor typology, usually flat slabs, due to their practical advantages including simple geometry, ease of construction, minimal interference with mechanical systems, and flexibility in architectural layouts [

9,

23,

24]. Recent studies have emphasized the potential of structural design to improve sustainability outcomes. One investigation showed that omitting shear walls in low-to-medium-rise reinforced concrete (RC) buildings in the UK can reduce concrete use by 12% and CO

2 emissions by 4.6%, without compromising performance under wind loads [

25]. Complementing this, another comprehensive analysis evaluated the embodied carbon associated with various RC floor systems. The results indicated that two-way joist slabs and voided systems offer considerably lower embodied carbon compared to traditional solid or beam and slab systems. The study emphasized the need for adopting low-carbon design strategies and innovative flooring technologies to meet future decarbonization targets [

26].

Design practices for reinforced concrete buildings vary significantly across countries, with both regulatory frameworks and cultural engineering norms contributing to these differences, as reported in [

27]. Compared to steel or timber alternatives, concrete building design typically requires a greater mass of material for the structural frame [

28], underscoring the need to identify the key design parameters that influence embodied carbon. Critical factors such as design loads, column spacing, floor-to-ceiling height, and slab strength directly impact the embodied carbon associated with concrete structures. These elements fall within the domain of structural design, which has increasingly become the focus of optimization strategies aimed at minimizing environmental impact. Previous research has explored the optimization of concrete frames [

29], beams [

30], and floor systems [

31] as effective means of reducing embodied carbon. Notably, material-efficient design of conventional floor systems has shown considerable potential in enhancing sustainability outcomes, alongside innovations in non-conventional geometries [

32,

33].

Three primary strategies have been identified in the literature for reducing the volume of concrete and steel in reinforced concrete buildings. The first strategy involves the selection of slab systems and span widths, as slabs typically account for over 50% of the total concrete volume in a building [

34]. A case study demonstrated that precast hollow core slabs can optimise material usage for spans greater than 10 m [

35]. For more commonly used cast in situ systems, an extensive study found that, for a 7.5 m span, the use of a waffle slab could reduce concrete volume by approximately 50% and 75% compared to two-way slab and beam and flat slab systems, respectively, although this comparison did not include shorter spans [

36]. The second strategy is the application of the yield line method (YLM), a limit state design approach that enables more efficient reinforcement layouts. Previous research has shown that using YLM can lead to significant reductions in the required steel reinforcement for slabs [

37]. The third strategy focuses on reducing the dimensions of structural concrete elements by specifying higher concrete strength classes. While this approach has proven effective in bridge piers [

38] and high-rise buildings [

39].

Few studies have conducted a truly holistic comparison of multiple slab types across a full range of spans and concrete grades using nonlinear FE modelling, while simultaneously evaluating both cost and embodied carbon. Most research to date has focused on a single slab typology, often flat slabs, under specific design scenarios, which limits the generalisability of the findings [

40]. A notable exception was identified, in which parametric design was combined with nonlinear finite element (FE) models to assess long-term deflection and identify flat slab configurations optimised for embodied carbon across various thicknesses, reinforcement layouts, and concrete grades [

41,

42]. In a separate study, textile-reinforced concrete shells spanning 6–18 m were investigated, and up to approximately 58% reductions in embodied carbon were demonstrated compared to flat slabs, although the associated cost implications were not considered [

43].

It has been demonstrated in several comparative studies that two-way joist (waffle) slabs and beam and slab systems can lead to substantial reductions in embodied carbon and, flat slabs have not been considered the most environmentally efficient option. For instance, a reduction of approximately 25 percent in embodied emissions compared to flat slabs has been reported for waffle slabs [

11]. Similarly, it has been found that flat slabs may result in up to 50 percent more embodied carbon than beam-supported or waffle slabs [

14]. A reduction of up to 40 percent in emissions has also been reported when beams are introduced into the slab system [

44].

In addition to environmental performance, construction time and cost are also influenced by the choice of slab type. However, embodied carbon and cost have rarely been addressed together in existing studies. Many comparative assessments have been limited by a narrow focus on flat slabs [

9], by emphasising optimisation methods without evaluating the performance of multiple typologies [

45], or by omitting key cost components such as labour [

35].

In addition to conventional slab systems, some researchers have explored innovative floor configurations such as textile-reinforced concrete shells and post-tensioned slabs. These systems have been analysed using nonlinear FE methods to capture both geometric and material efficiency under service loads. Structural shell floors have been shown to reduce embodied carbon through their efficient load paths and reduced material consumption, although their cost implications are still not comprehensively studied [

46]. Meanwhile, post-tensioned slabs have demonstrated notable reductions in both cost and emissions when compared to reinforced flat slabs, especially at mid to long spans [

47]. Additionally, post-tensioned slabs were studied using nonlinear FE and Firefly-ANN modelling techniques, by which both cost and embodied CO

2 were estimated; the results indicated approximately 39% cost savings and 12% emission reduction at 12 m spans when compared to conventional flat slabs, with slab thickness and concrete strength identified as critical sensitivity parameters [

48].

This research addresses a significant gap in the literature by systematically comparing three commonly used reinforced concrete (RC) slab systems in the United Kingdom: flat slab, beam and slab, and two-way joist slab. Most existing studies tend to focus on idealised or simplified conditions, often limited to square plan configurations and fixed material choices. In contrast, this study adopts a more realistic and comprehensive approach. A structural model consisting of a 3 × 3 bay layout is developed, covering a full range of square and rectangular spans varying from 4 m to 14 m in each direction. Multiple concrete grades, including C25/30, C32/40, and C40/50, are considered to reflect practical design scenarios. As shown in

Figure 1, a total of 324 distinct design alternatives are generated within the scope of this case study.

Each slab system is evaluated based on Eurocode-compliant structural design, embodied carbon estimates derived from ICE (Inventory of Carbon and Energy) data, and construction cost analysis. Nonlinear finite element (FE) modelling is employed to simulate the mechanical behaviour of each configuration under realistic loading conditions. This integrated methodology allows for a detailed assessment of how span geometry and material selection influence performance outcomes.

The novelty of this study lies in performing a span-sensitive comparative analysis of three widely used reinforced concrete slab systems, integrating Eurocode-based nonlinear finite element design with embodied carbon and cost assessment. While previous studies have mainly examined individual typologies, cross-system comparisons of this scope remain scarce, particularly in a Eurocode context. The present work addresses this gap by comprehensively covering the full range of practical spans.

2. Significance of Research

Reinforced concrete (RC) slabs are among the most material-intensive components in modern building frames, accounting for a large proportion of a building’s embodied carbon and construction cost. While the provision of structural safety and serviceability remains the top priority, there is growing recognition that sustainability metrics, particularly embodied carbon, must also inform structural design decisions. Although previous research has examined low-carbon materials or individual slab arrangements, there are few in-depth studies comparing different slab systems across a variety of spans and concrete grades with consideration of practical design requirements such as deflection limits, punching shear, and reinforcement needs. Furthermore, to the authors’ knowledge, there is a scarcity of nonlinear finite element parametric studies examining different floor systems with respect to various span lengths, concrete grades, and long-term deflection utilising the actual frame.

This research fills this gap with a span-sensitive, comparative analysis of three common slab systems: flat slab, beam and slab, and two-way joist slab. Unlike previous studies that focused on a single slab typology or ignored long-span performance, this research provides a unified framework for comparing multiple systems under consistent structural and environmental conditions. It combines parametric modelling, Eurocode-based design, and validated embodied carbon and cost data to provide a holistic view of performance. By integrating nonlinear finite element analysis, long-term deflection calculation, and life cycle carbon calculation, the study offers practical guidance on the selection of floor systems that achieve an optimum combination of structural efficiency, economy, and environmental sustainability. The findings offer better-informed design practice that supports the decarbonisation goals of the construction industry.

3. Methodology

This research employs a structured parametric modelling and optimisation framework to assess and compare the embodied carbon and cost efficiency of RC slab systems in multispan office floor scenarios. The methodology consists of six stages: structural modelling, Eurocode-based design, Nonlinear finite element simulation, material quantification, embodied carbon and cost calculation, and multi-objective optimisation.

For all alternatives, to calculate the building concrete and steel material intensities, structural analysis and design have been performed using CSI ETABS 22 and CSI SAFE 22 [

49]. CSI ETABS and SAFE were selected for their capacity to perform integrated RC slab design, deflection checks, and reinforcement detailing in compliance with Eurocode standards. Their use is widespread in UK structural engineering practice, supporting replicability. All structural elements have been designed to use the least possible volume of materials, while still satisfying the requirement of both ultimate and serviceability limit states (ULS and SLS, respectively).

The material intensity of concrete and steel is determined based on the sizing of various structural elements, such as slabs, beams, columns, and walls, to meet the structural and serviceability requirements defined by design standards. This study focuses exclusively on the structural components, namely concrete and steel, of reinforced concrete buildings, as these materials account for approximately 80% of the total material intensity and 90% of the overall embodied carbon in typical multi-storey buildings [

50]. Focusing on these dominant contributors allows for a more targeted and meaningful assessment of potential carbon reduction strategies. The exclusion of non-structural components, such as finishes, partitions, and services, is further justified by the objective of this study to offer globally relevant insights. These non-structural elements vary considerably across climate zones and building typologies due to differences in thermal insulation, façade systems, and regulatory requirements [

51].

For office buildings, both deflection and crack width checks were rigorously carried out to ensure serviceability performance under operational loads. The structural analysis and design of the reinforced concrete superstructure were performed in full compliance with the provisions of EN 1992-1-1:2004 (Eurocode 2) [

52], covering aspects such as ultimate and serviceability limit states, concrete material properties, and reinforcement detailing requirements.

3.1. Structural Configuration

In this study, a 3 × 3 bay reinforced concrete frame structure was developed to represent a typical office floor layout commonly adopted in multistorey buildings. As illustrated in

Figure 2 and

Figure 3, the analysis focused on three slab typologies: (i) flat slabs directly supported on columns, (ii) beam and slab systems with two-way slabs supported on beams, and (iii) two-way joist (waffle) slabs consisting of a thin topping slab supported on orthogonal ribs. These systems, designed with three concrete grades (C25/30, C32/40, and C40/50), reflect the most widely adopted solutions in the UK construction industry and provide a controlled baseline for parametric comparison. Future work will extend the scope to additional systems such as hollow-core and post-tensioned slabs, as well as a broader range of concrete and reinforcement grades.

The bay spans range from 4 m to 14 m in both directions, increasing in 2 m increments, with a constant floor-to-floor height of 3.0 m. For all floor systems, column dimensions vary from 400 × 400 mm to 600 × 600 mm. In flat slab systems, the slab thickness ranges from 180 mm to 530 mm. For beam and slab floors, the slab thickness ranges from 100 mm to 560 mm, supported by beams between 200 × 400 mm and 600 × 800 mm. In two-way joist slabs, the topping thickness varies from 50 mm to 100 mm, with ribs 100–500 mm deep and 100–160 mm wide.

Across the 324 alternatives, slab thicknesses varied within practical design ranges depending on span and typology. To avoid an exhaustive table of all cases,

Table 1 reports illustrative values for three representative spans (short, mid, and long span) under a typical office loading scenario, with Eurocode-compliant design checks (ULS/SLS) performed in ETABS/SAFE. The complete set of 324 configurations was designed parametrically; the values below are indicative of the trends discussed in

Section 4.1,

Section 4.2 and

Section 4.3Non-structural elements such as partitions, infill walls, glazing and finishes were excluded from the analysis, since the study focuses on the primary contributors to embodied carbon, namely concrete and reinforcement steel.

The choice between flat slabs and beam-supported systems typically depends on the available floor-to-floor height relative to the required clear ceiling height, as well as contractor preferences. Other factors influencing the selection include material cost, labour availability and site-specific construction constraints. For instance, the limited availability of skilled formwork carpenters may encourage the use of flat slabs due to their simpler formwork, whereas two-way joist slabs are often preferred for longer spans and heavier loads because their ribbed configuration provides higher flexural stiffness and more efficient load distribution with reduced overall material consumption.

3.2. Structural Design and Eurocode Compliance

All slab systems were designed in accordance with Eurocode 2 (EN 1992-1-1) [

52], using linear elastic analysis. The structural frame was modelled and analysed in ETABS, while the slab systems were designed and evaluated in SAFE to ensure compliance with design standards and to accurately capture structural performance. Both ultimate limit states (ULS) and serviceability limit states (SLS) were verified, including flexural and shear strength, deflection, cracking, and punching shear around columns. Long-term deflection was determined in line with Eurocode provisions for creep and shrinkage, with the maximum permissible deflection limited to L/250. Crack control was achieved by following maximum bar spacing and minimum reinforcement requirements, and punching shear was checked using critical perimeters around column faces, with shear reinforcement provided when necessary.

The feasibility of long-span slabs (8–14 m) was ensured by progressively increasing the dimensions of structural members in accordance with Eurocode requirements. For instance, column cross-sections increased from 400 × 400 mm at 4–6 m spans to 600 × 600 mm at 14 m spans, while beam depths were raised from 200 × 400 mm in short spans to 600 × 800 mm at longer spans. Slab thicknesses were also adjusted to maintain stiffness and control long-term deflections. In two-way joist slabs, rib depth and spacing were modified to provide sufficient flexural capacity and serviceability performance.

Through these adjustments, all structural configurations up to 14 m spans were shown to be structurally feasible. Although longer spans required higher reinforcement ratios and larger cross-sections, leading to greater embodied carbon and cost, the parametric workflow guaranteed that every design met Eurocode strength and serviceability requirements. As a result, the comparative assessment presented in

Section 4 is based on practical and code-compliant design solutions, rather than theoretical extrapolations.

3.3. Finite Element Modeling

Finite Element Modeling was employed to simulate the structural behaviour of various reinforced concrete slab systems under realistic loading and boundary conditions. This section outlines the modelling process, material definitions, meshing strategies, nonlinearity considerations, and loading scenarios applied in accordance with Eurocode standards.

3.3.1. Modeling

A hybrid modelling workflow using ETABS and SAFE was employed to capture both the global behaviour of the structure and the detailed performance of the slab systems. All structural alternatives were designed as reinforced concrete frame structures consisting of columns, beams and slabs. No shear walls or bracing systems were introduced, as the study focuses on the comparative performance of slab systems within a standard RC frame.

The modelling was conducted in two stages. First, the entire three-dimensional RC frame structure (columns, beams and slabs) was analysed in ETABS using linear elastic analysis to capture global stiffness, load transfer and internal force distribution. In the second stage, each slab system (flat slab, beam and slab, two-way joist slab) was isolated and analysed in SAFE. This enabled a more refined assessment of slab-specific flexural response, cracking behaviour and long-term deflection, using nonlinear cracked-section properties to reflect realistic structural performance.

The combination of global ETABS modelling with detailed SAFE slab analysis ensured that both frame behaviour and slab performance were captured accurately in compliance with Eurocode provisions. The scope of the study is limited to the reinforced concrete superstructure consisting of columns, beams and slabs. The ground floor slab was excluded, as it would be identical across all alternatives. Foundation design was also not considered, as it depends primarily on site-specific geotechnical conditions rather than the chosen slab typology.

3.3.2. Material Properties

The mechanical properties of the materials used in this study comply with the specifications of Eurocode 2 (EC2) [

39]. Accordingly, a characteristic yield strength of 500 MPa is assumed for reinforcing steel in tension (

), and reinforcement detailing follows typical UK practice with high-yield steel (B500C) [

52]. The characteristic cylinder compressive strength of concrete (

) is treated as a variable parameter, with concrete strength classes C25/30, C32/40 and C40/50 consideredIn addition, in each model, the same concrete strength class is applied to all structural components, including slabs, beams, and columns. For instance, if C25/30 is selected, it is used consistently across the entire structure. This approach facilitates a clearer comparison between slab systems and avoids introducing variability due to differing material strengths. The full set of assumed material properties is summarised in

Table 2.

3.3.3. Mesh

Mesh discretisation is a fundamental aspect of finite element analysis, as it significantly influences the accuracy, numerical stability, and computational efficiency of the results. An adequately refined mesh enables accurate representation of stress gradients, deflection profiles, and localised phenomena, particularly in regions near supports, openings, and areas of high moment. In contrast, an overly coarse mesh may result in inaccurate predictions, while an excessively fine mesh can increase computational time without offering substantial improvements in accuracy.

To ensure an appropriate balance between accuracy and computational cost, a mesh sensitivity analysis was performed on a representative span for all three slab types. Mesh sizes ranging from 2.0 m to 0.05 m were evaluated to examine the influence of mesh refinement on key structural responses, and as shown in

Figure 4, the results stabilised at a mesh size of 0.5 m × 0.5 m. This mesh resolution was therefore adopted for all slab configurations, as it provided sufficient accuracy in capturing flexural behaviour and serviceability performance while maintaining computational efficiency across all models.

3.3.4. Nonlinearity

To accurately simulate the time-dependent behaviour of the slab systems under service loads, nonlinear analysis was performed using SAFE’s long-term deflection module. This approach accounts for the gradual degradation in stiffness due to material nonlinearity and time-dependent effects such as creep and shrinkage, which are critical for serviceability assessment in reinforced concrete structures.

The analysis employed cracked section properties, which provide a more realistic representation of slab behaviour following flexural cracking. This adjustment reflects the redistribution of internal forces and the reduction in effective stiffness that occur under sustained loading. The Age-Adjusted Effective Modulus (AAEM) method, recommended by Eurocode 2 (EN 1992-1-1) [

52], was used to simulate creep, incorporating both the duration of loading and the age of the concrete at the time of load application.

Shrinkage strains were also included based on the environmental exposure class and the maturity of the concrete at various stages of the structure’s life cycle. These parameters were applied in accordance with the time-dependent models defined in Eurocode 2, ensuring consistency with design code provisions.

In combination, the incorporation of creep, shrinkage, and cracking effects allowed for the reliable estimation of long-term deflections, which are particularly relevant in slab systems with longer spans or reduced structural depth. This level of modelling detail is essential not only for serviceability verification but also for enabling meaningful comparisons between different slab typologies in terms of long-term performance.

3.3.5. Loading

The load specifications provided in EN 1991-1-1 (EC1) for office buildings [

54] were used as a reference to determine the load combinations for both ultimate limit state (ULS) and serviceability limit state (SLS) analyses. The self-weight of the structure (q

sw) was calculated using CSI ETABS and CSI SAFE [

49], based on the assumed unit weight of reinforced concrete. Each structural configuration is subjected to identical vertical loading conditions, including a superimposed dead load of 2.0 kN/m

2 and a live load of 2.5 kN/m

2 respectively, were adopted to act as distributed loads on slabs. These loads were applied as uniformly distributed surface loads on the slab elements, representing typical office occupancy and finishes. No lateral or seismic loads were considered, as the study focuses on vertical loading and flexural behaviour.

3.3.6. Load Combinations

Design (EN 1992-1-1)

Design load combinations were developed in accordance with EN 1990 [

55] and EN 1991 [

54], considering both the Ultimate Limit State (ULS) and Serviceability Limit State (SLS) criteria. As shown in Equation (1) [

55], load partial factors of

for permanent loads and

for variable loads were adopted to estimate the design load. The ULS combination employed is:

For SLS evaluation under short-term loading:

where

is the total dead load (self-weight + superimposed) and

is the live load. These combinations ensured safety and performance under both extreme and routine conditions.

Long Term Deflection

To evaluate long-term deflection in accordance with EN 1992-1-1 [

52], a nonlinear finite element approach was employed using four distinct load cases (

Table 3). These cases were defined to isolate and quantify both immediate and time-dependent deflections under service conditions. The load cases are as follows:

The final long-term deflection is calculated by combining these cases, as shown in Equation (3).

This formulation captures the net long-term deflection by summing the time-dependent deflection from sustained loads (Case 4), the short-term contribution of the transient portion of live load (Case 2–Case 3), and subtracting the initial elastic deformation due to dead load alone (Case 1). The resulting deflection is then checked against the Eurocode serviceability limit, typically L/250, to ensure compliance with long-term deflection criteria for floors and slabs. This method offers a refined and physically representative approach, particularly suited for cracked-section nonlinear FE models where creep and cracking interact nonlinearly.

3.4. Material Quantity and Embodied Carbon Calculation

The embodied carbon intensity of the structures was estimated using a simplified Life Cycle Assessment (LCA) approach [

56]. The assessment is limited to modules A1–A3 (raw material supply, transport, and manufacturing), as defined in EN 15804 [

57], in order to ensure comparability across alternatives. These stages were considered for concrete and steel, while subsequent processes such as material transport to site and on-site waste were excluded. Transportation distances vary with supplier selection and site location, introducing additional uncertainty, and site waste is highly dependent on construction management practices. As the study focuses on structural design decisions, these factors were not included in the analysis.

Only the structural concrete and reinforcement steel quantities were included in the embodied carbon and cost calculations, as these materials dominate the environmental impact of RC frames. Formwork, finishes, partitions, and services were excluded, since they vary significantly between projects and regions and were beyond the scope of this comparative study. Material quantities, including concrete volumes and reinforcement steel masses, were obtained directly from the structural design outputs generated in SAFE for each slab configuration. These values represent the actual material demand required to satisfy Eurocode strength and serviceability requirements, ensuring that the embodied carbon assessment reflects realistic design practice. The extracted quantities were then converted into embodied carbon emissions per square metre of slab area using verified cradle-to-gate emission factors from established databases.

The embodied carbon of in situ reinforced concrete was calculated using the upper bound values provided by the Institution of Structural Engineers [

58], derived from the Inventory of Carbon and Energy (ICE) Database v5.0 [

59]. These conservative estimates reflect UK concrete mixes containing 0% supplementary cementitious materials (SCMs). This approach ensures consistency across all slab types and enables fair comparison of design alternatives. The values used for each concrete grade are shown in

Table 4.

The embodied carbon intensity (EC) was calculated using Equation (4), where Q

i represents the quantity of each material, ECC

i denotes the embodied carbon coefficient of material, and A is the total floor area.

3.5. Construction Cost Estimation

Material costs are calculated using unit rates derived from the CONCEPT cost guidance tool provided by the Concrete Centre [

59]. The material rates used in this study are shown in

Table 5. These rates include average UK supply and placement costs based on recent market data. The total construction cost of each slab system is calculated by combining the volume of concrete and the mass of reinforcement per square metre.

All calculated costs are expressed in GBP/m

2 of slab area and are standardised for comparison across slab types and span configurations. Regional adjustments, such as London indices, are not applied separately, as the base data is considered reflective of national averages within the UK. The cost of production is obtained by applying Equation 5, Where C

i represent the amount of materials used and

indicate the unit costs of the materials.

4. Results and Discussions

This section presents the results of the embodied carbon and construction cost analysis for the three slab systems: flat slab, beam and slab, and two-way joist slab. The analysis covers a range of span lengths from 4 m to 14 m and concrete grades C25/30, C32/40, and C40/50. The performance of each system is evaluated in terms of its environmental impact, represented by embodied carbon (kgCO2e/m2), and its economic cost (GBP/m2). The following subsections provide a detailed comparison of the results for each slab system, highlighting the influence of span length and concrete grade on their structural, environmental, and economic efficiency.

The governing design criteria across span lengths varied between serviceability and ultimate limit states, primarily involving deflection limits, punching shear, and crack width control. At shorter spans, ultimate conditions such as punching shear were more likely to govern the design, particularly in flat slab systems. In contrast, longer spans were predominantly controlled by serviceability requirements, including deflection limits and crack width restrictions, due to increased flexural demand and long-term deformation. Ensuring compliance with crack width limits was especially important for durability considerations, as excessive cracking can compromise both structural performance and long-term service life.

4.1. Flat Slab

4.1.1. The Effect of Span Length

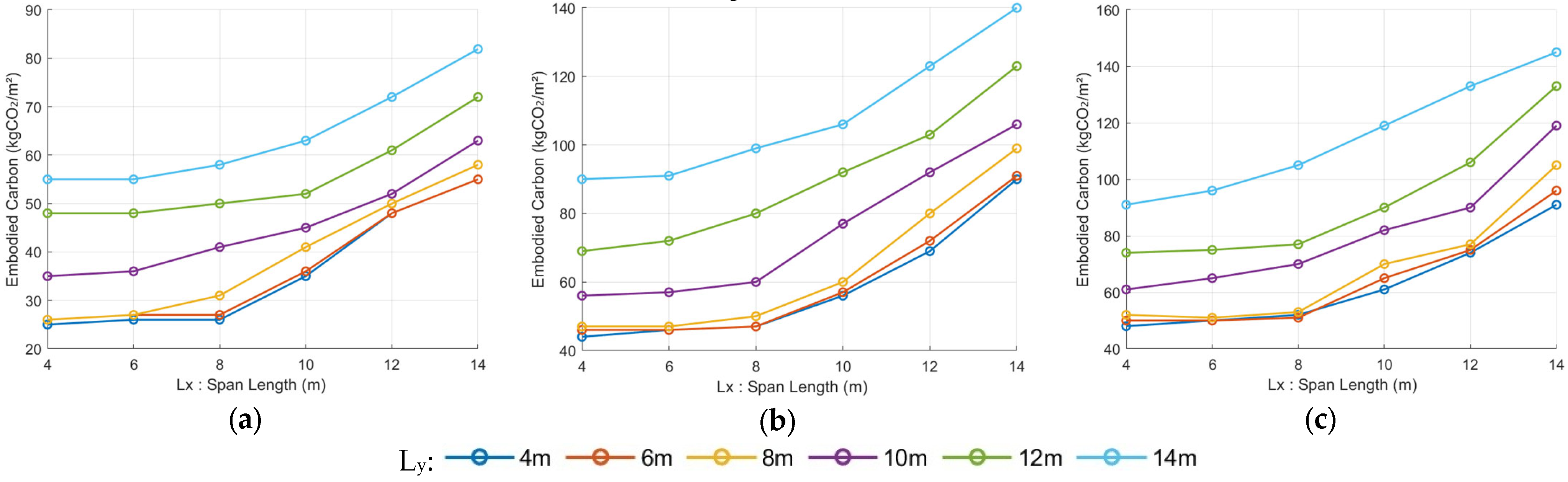

The embodied carbon and construction cost of flat slabs with C32/40 concrete were assessed for spans ranging from 4 m to 14 m in both directions, considering both square and rectangular layouts. Either the X-span (Lx) or Y-span (Ly) was held constant while the other was varied, enabling the influence of span geometry on material efficiency to be evaluated, as shown in

Figure 5.

When Ly = 4 m and Lx increases, both embodied carbon and cost rise steadily. At 4 × 4 m, the slab recorded 44 kgCO2e/m2 with a cost of GBP 26/m2. These values increased to 56 kgCO2e/m2 and GBP 34/m2 at 10 × 4 m, and further to 90 kgCO2e/m2 and GBP 55/m2 at 14 × 4 m. The progression becomes approximately linear beyond 8 m, reflecting the higher slab thicknesses and reinforcement required to control deflection and punching shear at longer spans.

A similar trend is observed when Lx is fixed. For example, at Lx = 6 m, embodied carbon grows from 46 to 91 kgCO2e/m2 and cost from GBP 27 to GBP 54/m2 as Ly increases from 4 m to 14 m. Square configurations generally perform better than rectangular ones, as balanced load distribution reduces reinforcement demand. For instance, a 12 × 12 m flat slab records 103 kgCO2e/m2 and GBP 57/m2, while a rectangular 6 × 12 m slab reaches 72 kgCO2e/m2 and GBP 44/m2—around 10–15% higher in carbon and cost compared to a square 6 × 6 m slab (46 kgCO2e/m2, GBP 27/m2).

4.1.2. The Effect of Concrete Grade

The flat slab system was evaluated using three concrete grades (C25/30, C32/40, and C40/50) across spans from 4 m to 14 m in both directions. For each configuration, slab thickness and reinforcement were adjusted to satisfy serviceability and strength requirements.

The results show that embodied carbon and cost generally increase with higher concrete grades, even when span dimensions are held constant. This trend is primarily due to the higher cement content of stronger concrete mixes, which increases emissions per cubic metre.

At shorter spans (4–8 m), the differences between grades remain relatively modest. For example, at a 6 × 6 m slab, embodied carbon values were 27 kgCO2e/m2 for C25/30, 46 kgCO2e/m2 for C32/40, and 50 kgCO2e/m2 for C40/50, with corresponding costs of GBP 25/m2, GBP 27/m2, and GBP 29/m2. However, beyond 10 m, both embodied carbon and cost increase more sharply as higher slab thickness and reinforcement are required. At a 12 × 12 m span, C25/30 recorded 61 kgCO2e/m2 and GBP 53/m2, compared with 103 kgCO2e/m2 and GBP 57/m2 for C32/40, and 106 kgCO2e/m2 and GBP 57/m2 for C40/50. At the maximum span of 14 × 14 m, C25/30 reached 81.9 kgCO2e/m2 and GBP 71/m2, while C32/40 and C40/50 escalated to 140 kgCO2e/m2 and GBP 78/m2, and 145 kgCO2e/m2 and GBP 78/m2, respectively.

Overall, while higher-strength grades (C32/40 and C40/50) provide structural advantages and allow for thinner slabs at equivalent spans, their increased cement intensity offsets material savings, resulting in higher embodied carbon. C25/30 consistently achieves the lowest embodied carbon and cost at long spans, whereas differences between grades remain minor at short spans. Despite the variation among grades, the flat slab system as a whole shows steep increases in both embodied carbon and cost beyond 8 m, reaffirming its limited efficiency for long-span applications.

4.2. Beam and Slab

4.2.1. The Effect of Span Length

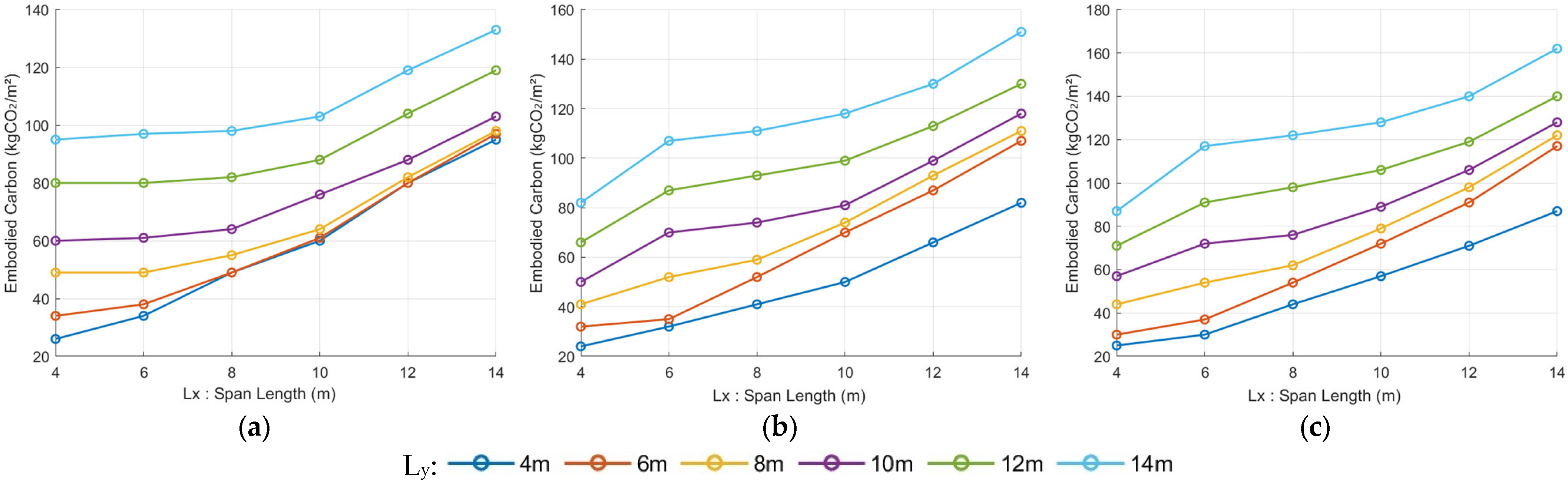

The embodied carbon and construction cost of the beam and slab system with C25/30 concrete were evaluated for span lengths between 4 m and 14 m in both directions. The combined action of the slab and beams provides effective stiffness at short and medium spans, but material demand increases rapidly at longer spans.

When Ly = 4 m and Lx increases, both embodied carbon and cost rise steadily. At 4 × 4 m, the slab recorded 26 kgCO2e/m2 with a cost of GBP 19/m2. These values rose to 60 kgCO2e/m2 and GBP 36/m2 at 10 × 4 m, and further to 95 kgCO2e/m2 and GBP 57/m2 at 14 × 4 m. The increase is almost linear beyond 8 m, reflecting the demand for deeper beams and higher reinforcement to control deflection.

When Lx is fixed, a similar pattern is observed. For instance, at Lx = 6 m, embodied carbon increases from 34 to 97 kgCO2e/m2 and cost from GBP 23 to GBP 58/m2 as Ly extends from 4 m to 14 m. Square layouts generally perform better than rectangular ones of the same maximum span due to balanced load distribution. For example, a 12 × 12 m beam and slab system recorded 104 kgCO2e/m2 and GBP 62/m2, compared with 80 kgCO2e/m2 and GBP 48/m2 for a rectangular 6 × 12 m slab, representing a 30% increase in carbon and cost.

Beyond spans of 8 m, the performance trend of the beam and slab system reverses. Embodied carbon and construction cost rise steeply with increasing span and eventually surpass those of the flat slab system. This behaviour stems from the growing structural demand on beams, which require deeper sections and heavier reinforcement to maintain stiffness and serviceability. The combined effect of thicker slabs and more substantial beam elements at larger spans leads to higher concrete volumes and reinforcement consumption, rendering the system increasingly inefficient beyond 10 m. These patterns are clearly depicted in

Figure 6.

Overall, the beam and slab system exhibits a strong sensitivity to both span length and aspect ratio. While rectangular layouts consistently demand more material than square ones of equivalent span, the system performs competitively within the intermediate range of 6–10 m. In this zone, beam and slab floors achieve lower embodied carbon and construction costs compared with flat slabs, highlighting their potential as a more sustainable and economical option for moderate spans.

4.2.2. The Effect of Concrete Grade

Similar to the flat slab system, the beam and slab configuration was assessed using three concrete grades across spans from 4 m to 14 m in both directions. While higher-strength concrete can enhance load-carrying capacity and allow modest reductions in section depth, it also increases embodied carbon due to the higher cement content per cubic metre.

The results confirm that both embodied carbon and construction cost rise with increasing concrete grade, particularly at larger spans. For example, at a 14 × 14 m layout, C25/30 recorded 133 kgCO2e/m2 with a cost of GBP 80/m2, whereas C32/40 increased to 140 kgCO2e/m2 and GBP 78/m2, and C40/50 rose further to 162 kgCO2e/m2 and GBP 88/m2. The effect of grade is less pronounced at shorter spans: at 6 × 6 m, embodied carbon values were 27 kgCO2e/m2, 46 kgCO2e/m2, and 50 kgCO2e/m2 for C25/30, C32/40, and C40/50, respectively, with costs ranging narrowly between GBP 24–29/m2.

At intermediate spans (8–10 m), the influence of grade begins to amplify. For instance, at 10 × 10 m, C25/30 achieved 76 kgCO2e/m2 and GBP 46/m2, while C40/50 required 89 kgCO2e/m2 and GBP 49/m2. These increases reflect the combined demand of slab and beam elements, where thicker sections and additional reinforcement offset any material savings from stronger concrete.

In summary, while higher-strength concrete offers some efficiency benefits at shorter spans, the beam and slab system becomes increasingly carbon- and cost-intensive at longer spans, regardless of grade. The dual material demand of both beams and slabs makes this configuration the least efficient of the three slab systems beyond 10 m, highlighting the need to consider alternative solutions for sustainable long-span applications.

4.3. Two-Way Joist Slab

4.3.1. The Effect of Span Length

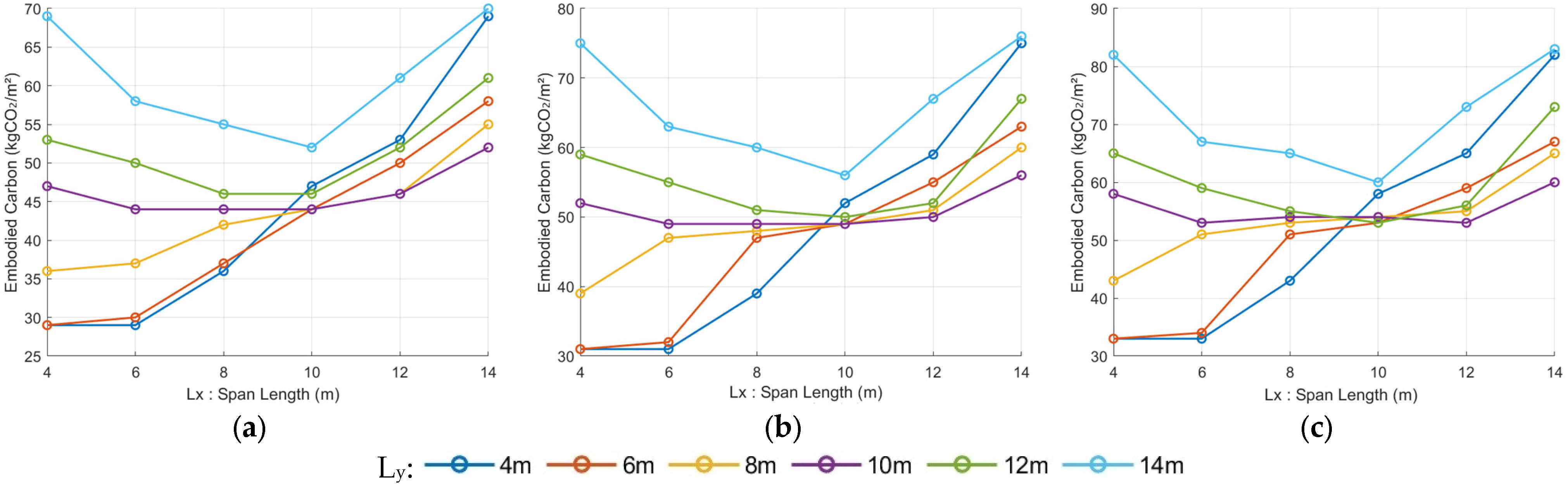

The two-way joist slab system consistently outperformed both the flat slab and the beam and slab systems across medium and long spans, offering the lowest embodied carbon and construction cost in almost all configurations. This superior performance is largely attributable to its ribbed geometry, which achieves highly efficient material distribution by reducing concrete volume and reinforcement demand, while still providing sufficient stiffness and load-carrying capacity.

As illustrated in

Figure 7, the advantages of the joist system become increasingly evident beyond 8 m, where it exhibits only a gradual rise in embodied carbon and cost compared with the steep increases observed in flat and beam and slab systems. For example, at a 12 × 12 m span, the joist slab designed with C40/45 concrete recorded 56 kgCO

2e/m

2 and GBP 42/m

2, whereas the flat slab and beam and slab systems reached approximately 103–104 kgCO

2e/m

2 and GBP 103/m

2. At the largest span of 14 × 14 m, the joist slab achieved 83 kgCO

2e/m

2 and GBP 58/m

2, a substantial improvement over the flat slab (140 kgCO

2e/m

2, GBP 140/m

2) and beam and slab (133 kgCO

2e/m

2, GBP 140/m

2). These results confirm the exceptional efficiency of the two-way joist system for long-span applications where both environmental and economic performance are critical.

However, this performance advantage does not extend to short spans (4–6 m). In this range, the joist system becomes less efficient than flat slabs, as the minimum rib dimensions and added formwork complexity are not offset by structural demand. For instance, at 4 × 4 m, the joist slab records 33 kgCO2e/m2 and GBP 26/m2 compared with only 26 kgCO2e/m2 and GBP 44/m2 for the beam and slab. Consequently, for compact floor layouts, the flat or beam and slab systems remain more viable, while the two-way joist slab is best suited to medium and long spans where its ribbed geometry delivers significant sustainability and cost benefits.

4.3.2. The Effect of Concrete Grade

The performance of the two-way joist slab system was assessed using three concrete grades across spans from 4 m to 14 m. Unlike flat slabs and beam and slab systems, where higher-strength concrete generally results in a sharp increase in embodied carbon, the joist system exhibited a more balanced trend. Its ribbed geometry improves strength-to-weight efficiency, enabling reductions in rib dimensions and reinforcement demand when stronger concrete grades are used, particularly at longer spans.

At shorter spans (4–6 m), C25/30 typically recorded the lowest embodied carbon values due to its reduced cement content. For instance, at a 6 × 6 m configuration, embodied carbon was 29 kgCO2e/m2 for C25/30 compared with 31 kgCO2e/m2 for C40/50, while costs remained similar at GBP 24–25/m2. However, as span length increased, the advantages of higher-strength grades became more evident. At 12 × 12 m, C25/30 reached 65 kgCO2e/m2 with a cost of GBP 42/m2, whereas C32/40 improved slightly to 59 kgCO2e/m2 and GBP 41/m2. The best performance was observed with C40/50, achieving 55 kgCO2e/m2 and GBP 39/m2.

At the maximum span of 14 × 14 m, C25/30 recorded 82 kgCO2e/m2 with a cost of GBP 52/m2. By contrast, C32/40 reduced values to 76 kgCO2e/m2 and GBP 46/m2, while C40/50 achieved the lowest figures at 73 kgCO2e/m2 and GBP 44/m2. These results demonstrate that although higher-strength concrete carries greater embodied carbon per unit volume, the two-way joist system offsets this through reduced material quantities, leading to lower overall emissions and cost at medium-to-long spans.

In summary, while C25/30 performs well at short spans, C32/40 and particularly C40/50 become more efficient at spans above 10 m. The balance between strength and material optimisation makes high-strength concrete a practical and economical choice for two-way joist slabs, confirming their suitability as the most sustainable option for large-span applications.

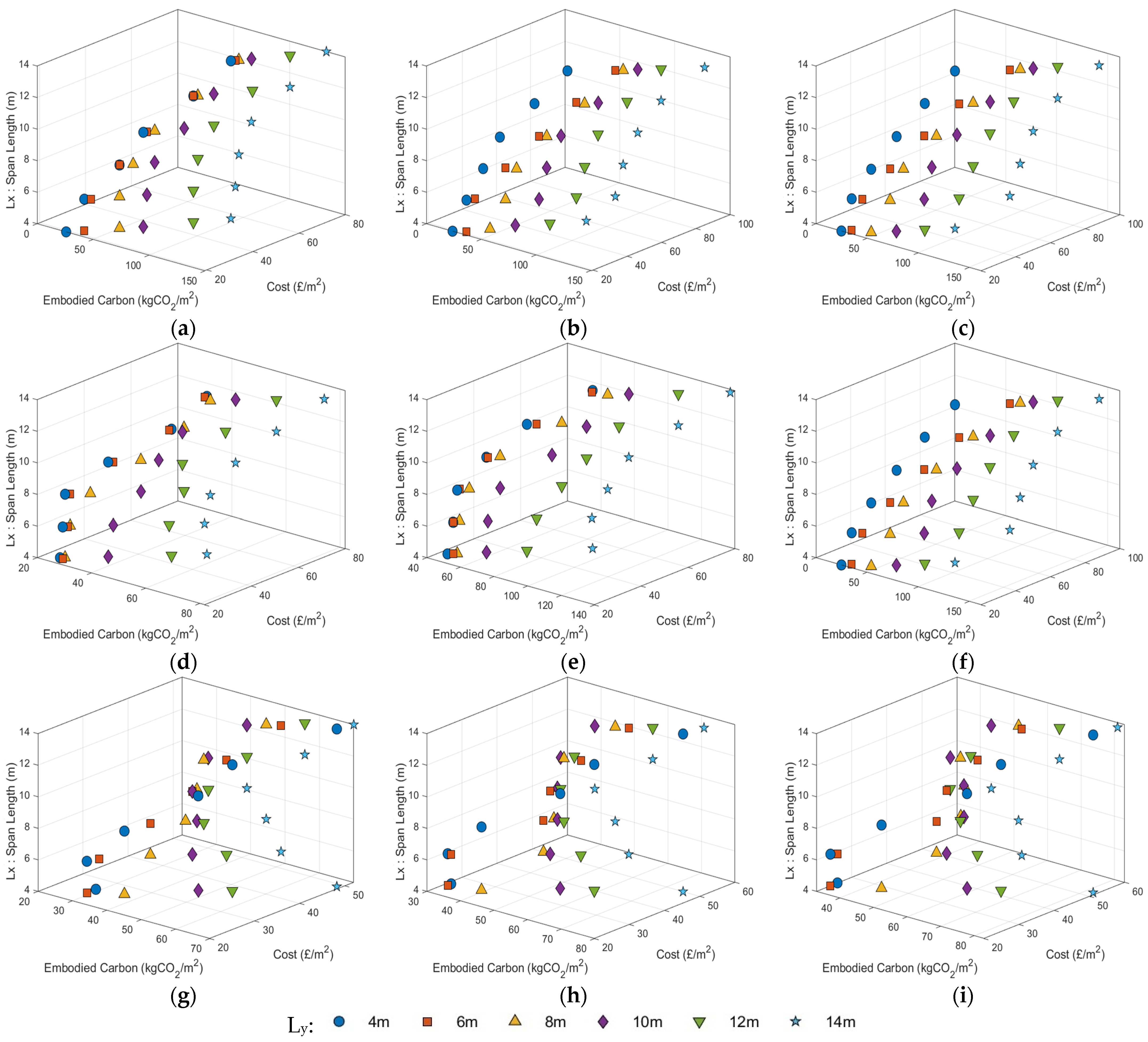

4.4. Comparative Analysis

Figure 8 and

Figure 9 summarise the comparison across all slab systems and show variation in cost and embodied carbon with column spacing. Two-way joist slabs outperform both flat and beam and slab systems across all concrete grades and span lengths, achieving reductions of ~25–35% in embodied carbon and ~30–40% in cost at spans above 10 m. Flat slabs, despite their simplicity and architectural appeal, exhibited higher material use and embodied emissions, particularly for spans beyond 8 m. The beam and slab configuration is economically viable primarily in scenarios where deflection limits or architectural constraints rule out alternative systems, as its material and labour costs remain significantly higher beyond spans of 8 m.

Figure 8,

Figure 9,

Figure 10,

Figure 11 and

Figure 12 collectively present both detailed span-by-span outcomes (

Figure 8 and

Figure 9) and broader system-level trends (

Figure 10,

Figure 11 and

Figure 12), ensuring that both specific and holistic patterns are captured. These additional plots highlight how geometry, slab typology, and concrete grade interact at a holistic level, offering broader insights beyond the individual case studies. Together,

Figure 8,

Figure 9,

Figure 10,

Figure 11 and

Figure 12 provide both detailed and holistic perspectives, ensuring the analysis captures span-by-span variations as well as overall system-level trends.

Consistent with previous research, this study demonstrates that the integration of beams or ribbed voids within slab systems provides both structural and environmental benefits, particularly at longer spans. These configurations enhance load distribution and stiffness, allowing for more efficient use of materials and leading to reductions in embodied carbon and overall cost.

In terms of concrete grade, higher-strength concrete allows for reduced material quantities due to its enhanced mechanical properties. However, the embodied carbon per unit volume of higher-grade concrete tends to increase at a faster rate than the corresponding reduction in volume. As a result, while higher grades can modestly reduce cost at long spans, their impact on embodied carbon is marginal compared to the dominant role of slab typology and geometry. This indicates that relying solely on higher concrete strength is not an effective approach for reducing embodied carbon. Instead, structural efficiency should be sought through geometric optimisation and system selection rather than material intensification.

However, adopting a two-way joist slab system significantly reduces the required concrete volume and consequently the total embodied carbon, achieving reductions of approximately 25 to 35% compared to flat slab and beam and slab systems at equivalent spans. While flat slab and beam and slab systems demonstrate marginally better performance in terms of embodied carbon at shorter spans (4–6 m), this advantage diminishes as the span increases. At longer spans (above 8 m), the two-way joist slab becomes the most efficient option, both structurally and environmentally, due to its superior ability to minimise concrete usage through ribbed geometry and improved load distribution. Moreover, the flat slab and beam and slab systems result in similar total concrete volumes overall. This is because the reduced slab thickness in the beam and slab configuration is effectively counterbalanced by the additional concrete required for the beams, limiting its potential for embodied carbon savings when compared to the more efficient two-way joist system.

While

Figure 8 and

Figure 9 present detailed results for specific span and column spacing scenarios,

Figure 10,

Figure 11 and

Figure 12 provide system-level visualisations that consolidate trends across all alternatives. These additional plots highlight how geometry, slab typology, and concrete grade interact at a holistic level, offering broader insights beyond the individual case studies.

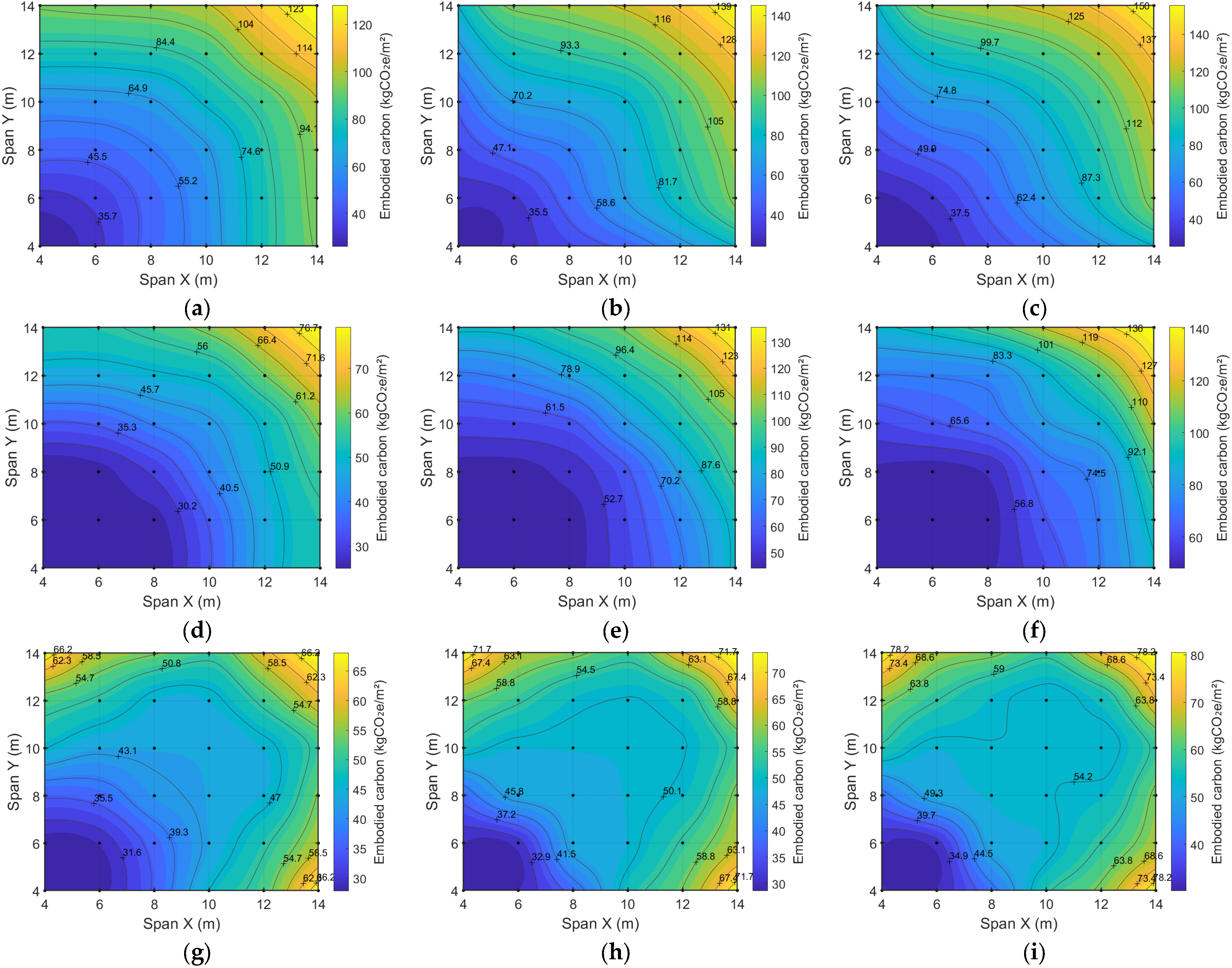

As shown in

Figure 10, the contour plot provides a holistic view of how span geometry governs the embodied carbon intensity of reinforced concrete floor systems. Results demonstrate a clear escalation of embodied carbon with increasing span length, particularly beyond 10 m where serviceability constraints such as long-term deflection (L/250) and crack width control require thicker slabs and additional reinforcement. Square layouts, represented along the diagonal axis, consistently exhibit lower embodied carbon compared to rectangular layouts of equivalent area. This outcome reflects the more balanced distribution of bending moments in orthogonal directions, which reduces peak reinforcement demand and limits slab depth growth. In contrast, elongated rectangular spans concentrate structural demand in one direction, driving up both slab depth and reinforcement quantities, thus elevating carbon intensity. The sharp gradients observed in the top-right region (>120 kgCO

2e/m

2 at 14 × 14 m) emphasise the inefficiency of large spans without structural optimisation measures. These findings are consistent with prior studies that identified column spacing as a critical parameter in early-stage design, with inefficient layouts potentially doubling embodied carbon relative to optimised square geometries. Overall,

Figure 10 demonstrates that beyond slab typology and concrete grade, span configuration itself represents a major lever for carbon mitigation, underscoring the importance of geometric optimisation in early architectural and structural coordination.

As illustrated in

Figure 11, the dual-axis comparison of embodied carbon and cost against span length provides a more nuanced understanding of trade-offs between environmental and economic performance. A strong correlation is observed between the two metrics, yet the relative slope of each curve differs across slab systems. Flat slabs show cost competitiveness up to 8 m, largely due to their simple formwork and reduced labour demand. However, this advantage rapidly diminishes beyond 10 m, where punching shear reinforcement and increased slab depth cause a disproportionate escalation in both carbon and cost. Beam and slab systems initially perform moderately well, benefiting from beams that control deflections and allow reduced slab thickness at short spans. At 12–14 m spans, beam and slab floors record up to 60% higher embodied carbon and cost than two-way joist slabs, confirming their limited suitability for long-span applications. Nevertheless, as spans lengthen, the compounded concrete volume in beams and slabs together leads to steep increases in embodied carbon and cost, making this configuration the least sustainable option at 12–14 m. Conversely, two-way joist slabs show a more gradual increase, reflecting the efficiency of ribbed geometry in distributing loads and limiting slab depth. The closer alignment of cost and carbon trends in this system suggests that environmental and economic objectives can be met simultaneously, rather than requiring trade-offs. Additionally, the influence of concrete grade is apparent in

Figure 11: higher grades (C40/50) tend to elevate embodied carbon due to cement intensity, but this is partially offset by reductions in slab depth and reinforcement, which can lead to cost savings at longer spans.

As depicted in

Figure 12, the scatter plot consolidates 324 design alternatives, revealing systemic patterns in cost–carbon interactions across slab types and concrete grades. A clear separation of clusters is evident, with flat slabs populating the upper-right quadrant, indicating higher embodied carbon and cost. This reflects their inefficiency at longer spans, where thickness and reinforcement requirements escalate disproportionately. Beam and slab systems form a mid-to-upper cluster, overlapping with flat slabs in cost and carbon at longer spans, suggesting that their structural stiffness does not translate into sustainability gains. By contrast, two-way joist slabs dominate the lower-left frontier, forming a near Pareto-optimal envelope of solutions that simultaneously minimise cost and embodied carbon. This confirms their superior structural efficiency and supports their prioritisation in sustainable design for medium to long spans. The scatter also illustrates the effect of concrete grade: higher-grade concretes shift points towards lower cost but higher carbon, highlighting a tension between economy and environment. For example, C40/50 joist slabs achieve some of the lowest costs but incur higher embodied carbon than their C25/30 counterparts, particularly at shorter spans. Importantly,

Figure 12 reinforces that slab typology has a far greater impact than concrete grade alone, as system-level geometry dictates overall material volume.

Table 6 summarises the comparative performance of the three slab systems. Overall, slab typology and span geometry dominate both cost and carbon outcomes, far outweighing the effect of concrete grade. Flat slabs are most economical at short spans (≤8 m), beam and slab systems are justified only where stiffness is essential, and two-way joist slabs deliver the best performance at spans ≥10 m, reducing embodied carbon by up to 35% and cost by ~40%. This study therefore extends prior research by quantifying 324 design cases and demonstrating that system-level optimisation is the most effective strategy for sustainable structural design.

4.5. Comparison with Previous Studies

The findings of this research are broadly consistent with, and in several cases extend beyond, values reported in the recent literature. Previous studies have shown that beam and slab floors can exhibit very high embodied carbon intensities, in some cases exceeding 200–300 kgCO

2e/m

2 for long spans [

26]. By contrast, the present study shows that beam and slab floors achieve only 133 kgCO

2e/m

2 with a cost of GBP 80/m

2 at a 14 × 14 m span.

Other research demonstrated that adopting more efficient slab systems, such as waffle or ribbed floors, together with reducing spans from 7.5 m to 5 m, can cut building-level embodied carbon by up to 20% [

11]. This aligns closely with the present results, where two- way joist slabs deliver 25–35% lower embodied carbon and ~30–40% lower cost than flat and beam and slab systems for spans beyond 10 m.

Studies comparing post-tensioned and conventional flat slabs have reported that at 12 m spans, PT slabs achieved ~12% lower embodied carbon and ~39% lower cost [

48]. In comparison, the two-way joist system in this study reduced embodied carbon by 45–55% and cost by 25–40% relative to flat slabs, demonstrating that typology selection provides more substantial sustainability gains than prestressing alone.

Flat slab benchmarks reported in the literature indicate embodied carbon values of ~90–140 kgCO

2e/m

2 for spans of 10–14 m, depending on grade [

23]. The flat slab results of the present study (103–140 kgCO

2e/m

2) fall within this range, confirming the validity of the modelling approach. Importantly, the joist slabs remain significantly below these benchmarks at equivalent spans.

Comparative studies of slab systems have shown that non-flat slab typologies can achieve up to ~37% reductions in embodied carbon at short to medium spans [

35]. The present study quantifies this advantage, showing that at 6–10 m spans, two-way joist slabs achieve 30–35% lower embodied carbon and cost than flat slabs, closely matching the trend reported in the literature.

Building-scale case studies have demonstrated that adopting flat slabs can reduce embodied carbon by ~6.6% and cost by ~19% compared to conventional slabs [

60]. While these savings are modest, they reinforce the present findings that efficiency gains are relatively small at short spans, but become much larger at 12–14 m where the joist system outperforms alternatives by up to 35–40%.

Whole-building comparisons report average embodied carbon intensities of 306 kgCO

2e/m

2 for traditional concrete-frame structures and 286 kgCO

2e/m

2 for MMC projects [

61]. Although these are building-level values, the much lower slab-only values reported here (typically 45–140 kgCO

2e/m

2) highlight how floor system optimisation can substantially influence whole-building performance.

Other analyses emphasise that design choices such as geometry and span have a greater influence on embodied carbon than material grade [

18]. This is directly confirmed by the present results, which demonstrate that system-level typology and span configuration dominate performance, whereas higher-strength concrete grades often increase embodied carbon despite modest cost benefits.

Finally, innovative slab geometries, such as thin-shell systems, have been reported to achieve embodied carbon as low as 45.8 kgCO

2e/m

2 [

43]. While these outperform the 56 kgCO

2e/m

2 achieved by two-way joist slabs at 12 × 12 m in this study, they require complex geometry and bespoke formwork. The joist system therefore represents a more practical balance between constructability, cost, and environmental performance.

Overall, these comparisons confirm that the embodied carbon and cost results obtained in this research are consistent with published benchmarks while also extending existing knowledge. The novelty of this work lies in systematically modelling 324 span–system–grade combinations, quantifying both carbon and cost impacts, and demonstrating that system-level optimisation and geometric efficiency are far more effective strategies for sustainable design than material-strength upgrades alone.

5. Conclusions

This study presented a comprehensive evaluation of the embodied carbon and construction cost of three common reinforced concrete floor systems: flat slab, beam and slab, and two-way joist slab. The analysis covered span lengths from 4 m to 14 m and three concrete grades (C25/30, C32/40, and C40/50).

The results show that slab typology is the dominant factor influencing both environmental and economic performance. The two-way joist slab consistently achieved the lowest embodied carbon and cost, as its ribbed geometry reduces material demand without compromising stiffness. By contrast, the beam and slab system, although structurally rigid, proved to be the least sustainable and most costly, particularly at longer spans. The flat slab occupied an intermediate position, offering competitive cost efficiency at shorter spans (≤ 8 m) but consistently higher embodied carbon than the two-way joist system.

A key finding relates to the trade-off introduced by concrete strength. Increasing the grade from C25/30 to C40/50 reduces material volumes and overall cost, yet raises embodied carbon intensity due to the higher cement content and energy demand of stronger mixes. As a result, embodied carbon does not necessarily decline with higher grades and may even increase slightly for certain span configurations.

The two-way joist slab demonstrated clear efficiency in reducing concrete consumption, delivering 25–35% lower embodied carbon than the other systems, particularly at spans greater than 8 m. Although flat slabs and beam and slab systems showed marginal advantages at shorter spans (4–6 m), their relative performance declined with increasing span, reinforcing the joist slab as the most sustainable option for medium to long spans.

These findings highlight a fundamental tension between cost and carbon. Designers must balance the lower embodied carbon associated with lower-strength, higher-volume concrete against the lower cost of higher-strength, reduced-volume mixes. The optimal solution depends on project-specific priorities, including budget constraints, sustainability targets, and structural performance requirements.

Overall, the study underscores the importance of early-stage design decisions in shaping the sustainability of reinforced concrete office buildings, which account for nearly 60% of the total concrete used in multi-storey structures. Incorporating cost and embodied carbon assessments at the conceptual design stage enables more informed and balanced decisions, supporting national and international decarbonisation targets. The findings are consistent with IStructE guidance and the GCCA net-zero concrete roadmap, reaffirming the value of early optimisation of slab typology.

The scope of this research is numerical, without experimental validation or case-study calibration. Nevertheless, the observed trends were cross-checked with published literature, showing strong agreement and lending confidence to the conclusions. Future work will extend the modelling framework to real projects and laboratory testing to verify both structural and environmental performance.

Finally, the study adopted a deterministic design approach, where reinforcement ratios, concrete properties, and embodied carbon coefficients were treated as fixed inputs. While this ensured internal consistency, it does not reflect the variability inherent in material properties and environmental datasets. Future extensions will incorporate sensitivity analyses (e.g., varying reinforcement ratios by ±10% and carbon coefficients by ±15%) together with probabilistic methods such as Monte Carlo simulation. These enhancements will help quantify uncertainty and provide more robust decision support for sustainable structural design.

6. Future Research and Limitations

This study is subject to several limitations, which also highlight important avenues for future research.

First, the analysis was based on numerical parametric modelling without experimental validation or case-study calibration. Although the framework was Eurocode-compliant and systematically applied across 324 scenarios, future work should extend the methodology to laboratory testing and real building projects to verify both structural behaviour and environmental performance.

Second, the scope was restricted to three slab typologies (flat slab, beam-and-slab, and two-way joist slab) and three concrete grades (C25/30, C32/40, C40/50). While this reflects common UK practice, it does not capture the full diversity of available solutions. Future studies should broaden the analysis to include additional systems such as hollow-core and post-tensioned slabs, a wider range of concrete strengths, and alternative reinforcement grades.

Third, the sustainability assessment considered only modules A1–A3 of the life cycle, excluding transportation (A4), construction (A5), and end-of-life (C) stages. Extending the boundary conditions to cover these modules would provide a more complete perspective and enable assessment of whole-life carbon performance.

Fourth, the analysis was deterministic, using fixed material coefficients and reinforcement ratios. Future research should incorporate sensitivity analysis and probabilistic methods to capture variability and quantify uncertainty, thereby improving the robustness of the findings.

Fifth, while the workflow was developed using ETABS and SAFE, it is inherently compatible with Building Information Modelling (BIM) and digital twin platforms. Linking embodied carbon and cost outputs with BIM environments, and extending the workflow to digital twin applications, offers a promising avenue for integration, collaboration, and continuous optimisation throughout design and operation.

Sixth, the present modelling focused on linear elastic design outputs. Although adequate for comparative embodied carbon and cost assessment, it does not capture nonlinear behaviour, cracking, or redistribution effects. Future work will extend the framework to finite element (FE) modelling in ABAQUS, allowing detailed simulation of nonlinear material behaviour, punching shear, deflection control, and ultimate limit state performance. Integrating these advanced FE results with carbon and cost assessments will provide a more rigorous validation of design efficiency.

Seventh, the influence of regional construction practices, labour availability, and supply chain variability was not explicitly considered. Incorporating these practical constraints into optimisation frameworks would improve the transferability of the results across different geographical contexts.

Eighth, the study focused on superstructure elements (columns, beams, and slabs), excluding foundations and non-structural components such as partitions, glazing, and finishes. Including these elements in future assessments would provide a more holistic representation of building-level embodied carbon and cost.

Ninth, only conventional concrete and reinforcement materials were examined. Exploring supplementary cementitious materials (SCMs), recycled aggregates, ultra-high-performance concretes, and hybrid concrete–timber or concrete–steel systems could open additional pathways for reducing embodied carbon and enhancing structural efficiency.

Tenth, the analysis considered single-storey floor layouts. Extending the modelling to multi-storey configurations would allow cumulative effects such as vertical load transfer, stiffness requirements, and long-term deflection to be captured more realistically.

Eleventh, the decision-making process in this study was manual and sequential. Developing automated decision-support tools that integrate structural, environmental, and economic criteria within multi-objective optimisation frameworks could provide real-time guidance to designers during the conceptual design stage.

By addressing these limitations, future research can strengthen methodological robustness, expand the scope of application, and align the study more closely with emerging digital workflows and practical design needs, ultimately contributing to more sustainable and efficient reinforced concrete structures.