Economic Value-Added Innovative Management of Leaf Waste in Green Areas of Government Agencies, Bangkok, Thailand

Abstract

1. Introduction

2. Materials and Methods

2.1. Study Site

2.2. Creating Planting Blocks from Leftover Waste

2.2.1. Conceptual Overview

2.2.2. Materials and Equipment

2.2.3. Preprocessing and Feedstock Preparation

2.2.4. Block Forming and Curing

2.3. Plant Experiments

2.4. The Comparative Study on the Growth of Mitragyna speciosa (Korth.) Havil. Using a Completely Randomized Design (CRD)

2.5. Economic Cost Analysis

2.5.1. Cost

2.5.2. Net Present Value (NPV) [13]

2.5.3. Payback Period (PBP)

3. Results

3.1. Study of Leaf Waste Data in the Study Area

3.2. Creating Leaf Waste Planting Blocks

3.2.1. Consideration of the Idea of Creating Pre-Made Plantation Cubes from Natural Elements

3.2.2. PL from Dry Leaf Waste to Replace Soil

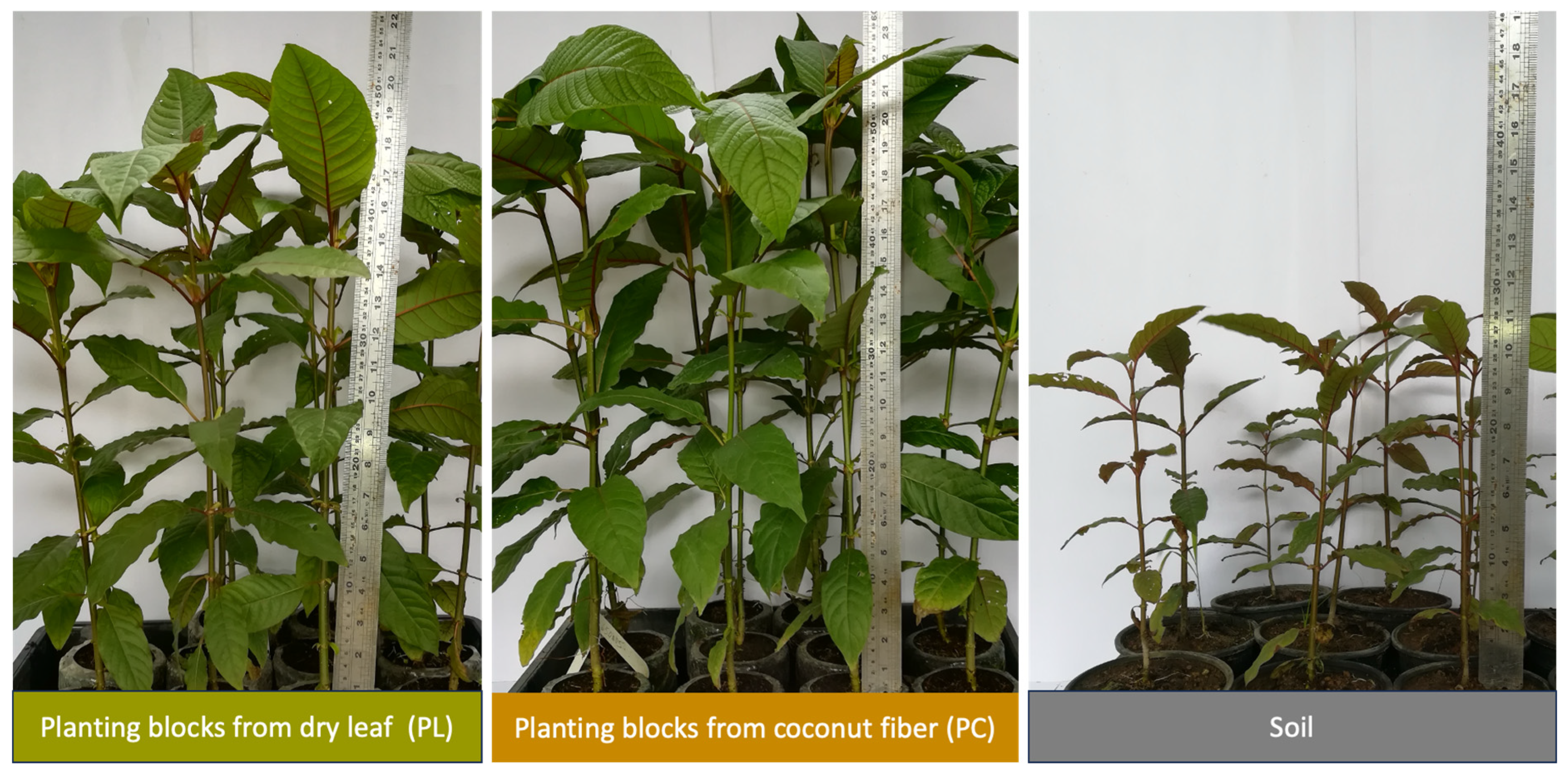

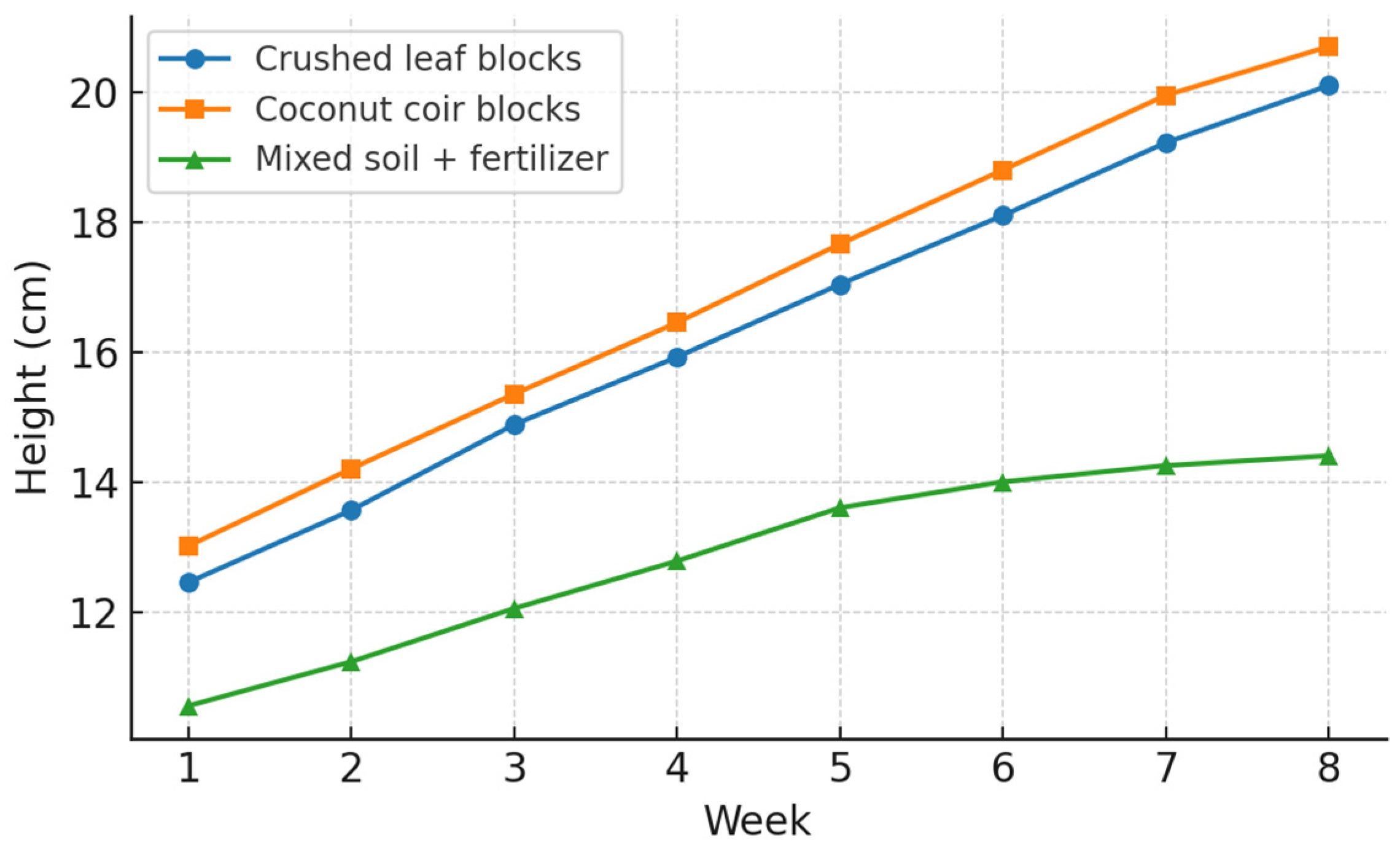

3.2.3. Comparative Growth of Mitragyna speciosa (Korth.) Havil. Using a Completely Randomized Design (CRD)

3.3. Economic Feasibility Analysis

- (1)

- A leaf mill engine power of 5.5 hp, THB 55,000.

- (2)

- Heat compression molding, 600 pounds per square inch hydraulic compression force, production capacity of 1.5 pieces per minute, THB 130,000.

- (1)

- The monthly labor cost for three individuals is THB 12,000 for each person.

- (2)

- Each piece of plastic PL covering costs THB 1.

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Pollution Control Department. Thailand’s POPs Inventory Assessment Report. 2023. Available online: https://www.pcd.go.th/wp-content/uploads/2023/05/pcdnew-2023-05-26_03-27-36_620650.pdf (accessed on 19 September 2025).

- Office of the National Economic and Social Development Council (NESDC). National Strategy 2018–2037. 2018. Available online: https://www.nesdc.go.th/en/ (accessed on 19 September 2025).

- Wiangnon, J.; Sreesathith, S.; Sangaroon, P.; Popradit, A. Environmental impact of solid wastes generated from land use change in highland tourism: A case study of Pai District, Mae Hong Son Province. Thai Environ. Eng. J. 2020, 34, 67–77. [Google Scholar]

- Hartley, K.R.; van Santen, R.; Kirchherr, J. Policies for transitioning towards a circular economy: Expectations from the European Union (EU). Resour. Conserv. Recycl. 2020, 155, 104634. [Google Scholar] [CrossRef]

- Popradit, A.; Wiangnon, J.; Jitrabiab, P.; Pakvilai, N. Organic fertilizer application using leaf waste according to Maejo engineering method 1. Thai Environ. Eng. J. 2022, 36, 47–54. [Google Scholar]

- Tscharntke, T.; Clough, Y.; Bhagwat, S.A.; Buchori, D.; Faust, H.; Hertel, D.; Hölscher, D.; Juhrbandt, J.; Kessler, M.; Perfecto, I.; et al. Multifunctional shade-tree management in tropical agroforestry landscapes—A review. J. Appl. Ecol. 2011, 48, 619–629. [Google Scholar] [CrossRef]

- Nagendra, H.; Gopal, D. Street trees in Bangalore: Density, diversity, composition and distribution. Urban For. Urban Green. 2010, 9, 129–137. [Google Scholar] [CrossRef]

- Alam, T.; Ikram, M.; Chaudhry, A.N.; Subhan, C.M.; Alotaibi, K.D.; Haq, Z.U.; Yousaf, M.S.; Ahmed, H.P.; Fatima, N.; Jilani, G.; et al. Utilization of Organic-Residues as Potting Media: Physico-Chemical Characteristics and Their Influence on Vegetable Production. PLoS ONE 2024, 19, e0302135. [Google Scholar] [CrossRef]

- Pot, S.; De Tender, C.; Ommeslag, S.; Delcour, I.; Ceusters, J.; Gorrens, E.; Debode, J.; Vandecasteele, B.; Vancampenhout, K. Understanding the Shift in the Microbiome of Composts That Are Optimized for a Better Fit-for-Purpose in Growing Media. Front. Microbiol. 2021, 12, 643679. [Google Scholar] [CrossRef]

- Aguilar-Paredes, A.; Valdés, G.; Araneda, N.; Valdebenito, E.; Hansen, F.; Nuti, M. Microbial Community in the Composting Process and Its Positive Impact on the Soil Biota in Sustainable Agriculture. Agronomy 2023, 13, 542. [Google Scholar] [CrossRef]

- Eisenman, S.W. The botany of Mitragyna speciosa (Korth.) Havil. and related species. Krat. Other Mitragynines Chem. Pharmacol. Opioids Non-Opium Source 2014, 57, 57–76. [Google Scholar]

- Horngren, C.T.; Datar, S.M.; Rajan, M.V. Cost Accounting: A Managerial Emphasis, 16th ed.; Pearson: Boston, MA, USA, 2015. [Google Scholar]

- Saengsawang, S.; Suksri, S. Economic Evaluation of Renewable Energy Projects Using Net Present Value Method: Case Study of Biogas Plant in Thailand. Sustainability 2022, 14, 5246. [Google Scholar] [CrossRef]

- Huang, X.; Qu, Y.; Zhu, Z.; Wu, Q. Techno-Economic Analysis of Photovoltaic Hydrogen Production Considering Technological Progress Uncertainty. Sustainability 2023, 15, 3580. [Google Scholar] [CrossRef]

- McCabe, K.G.; Schrader, J.A.; Madbouly, S.; Grewell, D.; Graves, W.R. Evaluation of biopolymer-coated fiber containers for container-grown plants. HortTechnology 2014, 24, 439–448. [Google Scholar] [CrossRef]

- Li, X.; Li, J.; Zhao, Z.; Zhou, K.; Zhan, X.; Wang, Y.; Liu, N.; Han, X.; Li, X. Soil Organic Carbon and Humus Characteristics: Response and Evolution to Long-Term Direct/Carbonized Straw Return to Field. Agronomy 2024, 14, 2400. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, J.; Zhang, X. The Addition of Exogenous Compost Humus Shortens the Composting Period and Improves Corn Growth. Sustainability 2025, 17, 7177. [Google Scholar] [CrossRef]

- Fesenko, A.N.; Provorov, N.A.; Orlova, I.F.; Orlov, V.P.; Simarov, B.V. Selection of Rhizobium leguminosarum bv. viceae strains for inoculation of Pisum sativum L. cultivars: Analysis of symbiotic efficiency and nodulation competitiveness. Plant Soil 1995, 172, 189–198. [Google Scholar] [CrossRef]

- Nguyen, V.-T.; Le, T.-H.; Bui, X.-T.; Nguyen, T.-N.; Vo, T.-D.; Lin, C.; Vu, T.-M.; Nguyen, H.-H.; Nguyen, D.-D.; Senoro, D.B.; et al. Effects of C/N ratios and turning frequencies on the composting process of food waste and dry leaves. Bioresour. Technol. Rep. 2020, 11, 100527. [Google Scholar] [CrossRef]

- Davison, J.; Moora, M.; Jairus, T.; Vasar, M.; Öpik, M.; Zobel, M. Hierarchical assembly rules in arbuscular mycorrhizal (AM) fungal communities. Soil Biol. Biochem. 2016, 97, 63–70. [Google Scholar] [CrossRef]

- Kadir, A.A.; Zulkifly, S.N.M.; Al Bakri, A.M.; Sarani, N.A. The utilization of coconut fibre into fired clay brick. Key Eng. Mater. 2016, 673, 213–222. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation. Towards the Circular Economy: Economic and Business Rationale for an Accelerated Transition; Ellen MacArthur Foundation: Cowes, UK, 2013. [Google Scholar]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The circular economy—A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- Pandey, A.; Soccol, C.R.; Nigam, P.; Soccol, V.T.; Vandenberghe, L.P.S.; Mohan, R. Biotechnological potential of agro-industrial residues. II: Cassava bagasse. Bioresour. Technol. 2000, 74, 81–87. [Google Scholar] [CrossRef]

- Abad, M.; Fornes, F.; Carrión, C.; Noguera, P.; Noguera, V.; Maquieira, Á.; Puchades, R. Physical properties of various coconut coir dusts compared to peat. HortScience 2005, 40, 2138–2144. [Google Scholar] [CrossRef]

- Liu, X.; Shi, Y.; Kong, L.; Tong, L.; Cao, H.; Zhou, H.; Lv, Y. Long-Term Application of Bio-Compost Increased Soil Microbial Community Diversity and Altered Its Composition and Network. Microorganisms 2022, 10, 462. [Google Scholar] [CrossRef]

- Ahmed, T.; Noman, M.; Qi, Y.; Shahid, M.; Hussain, S.; Masood, H.A.; Xu, L.; Ali, H.M.; Negm, S.; El-Kott, A.F.; et al. Fertilization of Microbial Composts: A Technology for Improving Stress Resilience in Plants. Plants 2023, 12, 3550. [Google Scholar] [CrossRef] [PubMed] [PubMed Central]

- Cannavo, P.; Recous, S.; Valé, M.; Bresch, S.; Paillat, L.; Benbrahim, M.; Guénon, R. Organic Fertilization of Growing Media: Response of N Mineralization to Temperature and Moisture. Horticulturae 2022, 8, 152. [Google Scholar] [CrossRef]

- Van Gerrewey, T.; Ameloot, N.; Navarrete, O.; Vandecruys, M.; Perneel, M.; Boon, N.; Geelen, D. Microbial activity in peat-reduced plant growing media: Identifying influential growing medium constituents and physicochemical properties using fractional factorial design of experiments. J. Clean. Prod. 2020, 256, 120323. [Google Scholar] [CrossRef]

- Brás, I.; Silva, E.; Raimondo, R.; Saetta, R.; Mignano, V.; Fabbricino, M.; Ferreira, J. Valorisation of Forest and Agriculture Residual Biomass—The Application of Life Cycle Assessment to Analyse Composting, Mulching, and Energetic Valorisation Strategies. Sustainability 2024, 16, 630. [Google Scholar] [CrossRef]

- Bottausci, S.; Magrini, C.; Tuci, G.A.; Bonoli, A. Plastic impurities in biowaste treatment: Environmental and economic life cycle assessment of a composting plant. Environ. Sci. Pollut. Res. 2024, 31, 9964–9980. [Google Scholar] [CrossRef]

- United Nations. Transforming Our World: The 2030 Agenda for Sustainable Development; United Nations: New York, NY, USA, 2015; Available online: https://sdgs.un.org/2030agenda (accessed on 11 August 2025).

- IPCC. Climate Change 2022: Mitigation of Climate Change. Contribution of Working Group III to the Sixth Assessment Report; Intergovernmental Panel on Climate Change: Geneva, Switzerland, 2022. [Google Scholar] [CrossRef]

- Wilson, D.C.; Velis, C.; Cheeseman, C. Role of informal sector recycling in waste management in developing countries. Habitat Int. 2006, 30, 797–808. [Google Scholar] [CrossRef]

- Zurbrugg, C.; Gfrerer, M.; Ashadi, H.; Brenner, W.; Kühr, R. Determinants of sustainability in solid waste management—The Gianyar Waste Recovery Project in Indonesia. Waste Manag. 2012, 32, 2126–2133. [Google Scholar] [CrossRef]

| Government Agencies | Amount (kg) | Leaf Waste Transportation Costs to Landfill Sites per Month (THB) |

|---|---|---|

| Faculty of Science, Chulalongkorn University, Pathumwan (SCU) | 2910.00 | 3000.00 |

| Ministry of Finance, Phaya-Thai (MF) | 4115.00 | 4500.00 |

| Bangkok Local Museum, Bang Rak (BLM) | 2840.00 | 3000.00 |

| Type | C/N Ratio | Total Potassium | Total Nitrogen | Total Organic Carbon |

|---|---|---|---|---|

| Dry leaf waste | 57 | 0.02 | 0.13 | 79.84 [19] |

| Coconut fibers | 271 | 0.07 [20] | 0.02 | 48.80 [21] |

| Planting Media | Week 1 | Week 2 | Week 3 | Week 4 | Week 5 | Week 6 | Week 7 | Week 8 |

|---|---|---|---|---|---|---|---|---|

| PL | 12.45 ± 1.21 a | 13.56 ± 1.34 a | 14.88 ± 1.45 a | 15.92 ± 1.56 a | 17.04 ± 1.67 a | 18.10 ± 1.78 a | 19.22 ± 1.89 a | 20.10 ± 2.01 a |

| PC | 13.01 ± 1.11 a | 14.20 ± 1.22 a | 15.35 ± 1.33 a | 16.45 ± 1.45 a | 17.66 ± 1.57 a | 18.80 ± 1.68 a | 19.95 ± 1.79 a | 20.70 ± 1.90 a |

| Soil | 10.55 ± 0.98 b | 11.23 ± 1.05 b | 12.05 ± 1.12 b | 12.78 ± 1.19 b | 13.60 ± 1.25 b | 14.00 ± 1.34 b | 14.25 ± 1.40 b | 14.40 ± 1.50 b |

| Week | Source of Variation | df | SS | MS | F | p-Value | F Crit |

|---|---|---|---|---|---|---|---|

| 1 | Between groups | 2 | 39.82 | 19.91 | 14.30 | 4.28 × 10−6 | 3.10 |

| Within groups | 87 | 121.16 | 1.39 | ||||

| Total | 89 | 160.97 | |||||

| 2 | Between groups | 2 | 192.15 | 96.08 | 36.22 | 3.60 × 10−12 | 3.10 |

| Within groups | 87 | 230.78 | 2.65 | ||||

| Total | 89 | 422.93 | |||||

| 3 | Between groups | 2 | 625.51 | 312.76 | 78.65 | 3.13 × 10−20 | 3.10 |

| Within groups | 87 | 345.97 | 3.98 | ||||

| Total | 89 | 971.48 | |||||

| 4 | Between groups | 2 | 1528.87 | 764.44 | 140.34 | 5.90 × 10−28 | 3.10 |

| Within groups | 87 | 473.88 | 5.45 | ||||

| Total | 89 | 2002.76 | |||||

| 5 | Between groups | 2 | 4249.05 | 2124.53 | 132.43 | 4.00 × 10−27 | 3.10 |

| Within groups | 87 | 1395.71 | 16.04 | ||||

| Total | 89 | 5644.77 | |||||

| 6 | Between groups | 2 | 8830.57 | 4415.29 | 231.31 | 1.50 × 10−35 | 3.10 |

| Within groups | 87 | 1660.68 | 19.09 | ||||

| Total | 89 | 10,491.25 | |||||

| 7 | Between groups | 2 | 13,914.17 | 6957.09 | 114.59 | 4.19 × 10−25 | 3.10 |

| Within groups | 87 | 5282.24 | 60.72 | ||||

| Total | 89 | 19,196.41 | |||||

| 8 | Between groups | 2 | 16,647.80 | 8323.90 | 114.59 | 1.13 × 10−33 | 3.10 |

| Within groups | 87 | 3526.60 | 40.54 | ||||

| Total | 89 | 20,174.40 |

| Government Agency | Leaf Waste/yr (kg) | Number of PL/yr (Pieces) | Annual Revenue (Pieces × 30) | Annual Covering Cost (Pieces × 1) | Annual Labor (Year) | Annual Net Cashflow (Income/Covering/Labor) | PBP (Years) | PBP (Days) | NPV (5 Years, r = 8%) |

|---|---|---|---|---|---|---|---|---|---|

| SCU | 34,920 | 112,645 | 3,379,355 | 112,645 | 432,000 | 2,834,710 | 0.07 | 23.8 | 11,133,173 |

| MF | 49,380 | 159,290 | 4,778,710 | 159,290 | 432,000 | 4,187,419 | 0.04 | 16.1 | 16,534,151 |

| BLM | 34,080 | 109,935 | 3,298,065 | 109,935 | 432,000 | 2,756,129 | 0.07 | 24.5 | 10,819,424 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Akaravarothai, A.; Dansawad, N.; Jitrabiab, P.; Boruah, I.; Chetia, R.; Popradit, A. Economic Value-Added Innovative Management of Leaf Waste in Green Areas of Government Agencies, Bangkok, Thailand. Sustainability 2025, 17, 8511. https://doi.org/10.3390/su17188511

Akaravarothai A, Dansawad N, Jitrabiab P, Boruah I, Chetia R, Popradit A. Economic Value-Added Innovative Management of Leaf Waste in Green Areas of Government Agencies, Bangkok, Thailand. Sustainability. 2025; 17(18):8511. https://doi.org/10.3390/su17188511

Chicago/Turabian StyleAkaravarothai, Aroon, Napattchan Dansawad, Pattama Jitrabiab, Ichangdaw Boruah, Rashmi Chetia, and Ananya Popradit. 2025. "Economic Value-Added Innovative Management of Leaf Waste in Green Areas of Government Agencies, Bangkok, Thailand" Sustainability 17, no. 18: 8511. https://doi.org/10.3390/su17188511

APA StyleAkaravarothai, A., Dansawad, N., Jitrabiab, P., Boruah, I., Chetia, R., & Popradit, A. (2025). Economic Value-Added Innovative Management of Leaf Waste in Green Areas of Government Agencies, Bangkok, Thailand. Sustainability, 17(18), 8511. https://doi.org/10.3390/su17188511