Determination of Nonylphenol in Crude Oils and Petroleum Products by Liquid Chromatography–Mass Spectrometry: Implications for Sustainable Petroleum Refining

Abstract

1. Introduction

2. Materials and Methods

2.1. Chemicals and Materials

2.2. Preparation of Calibration Standards

2.3. Sample Collection

2.4. Sample Pretreatment

2.4.1. Primary Purification by NPC

2.4.2. Further Enrichment by SPE

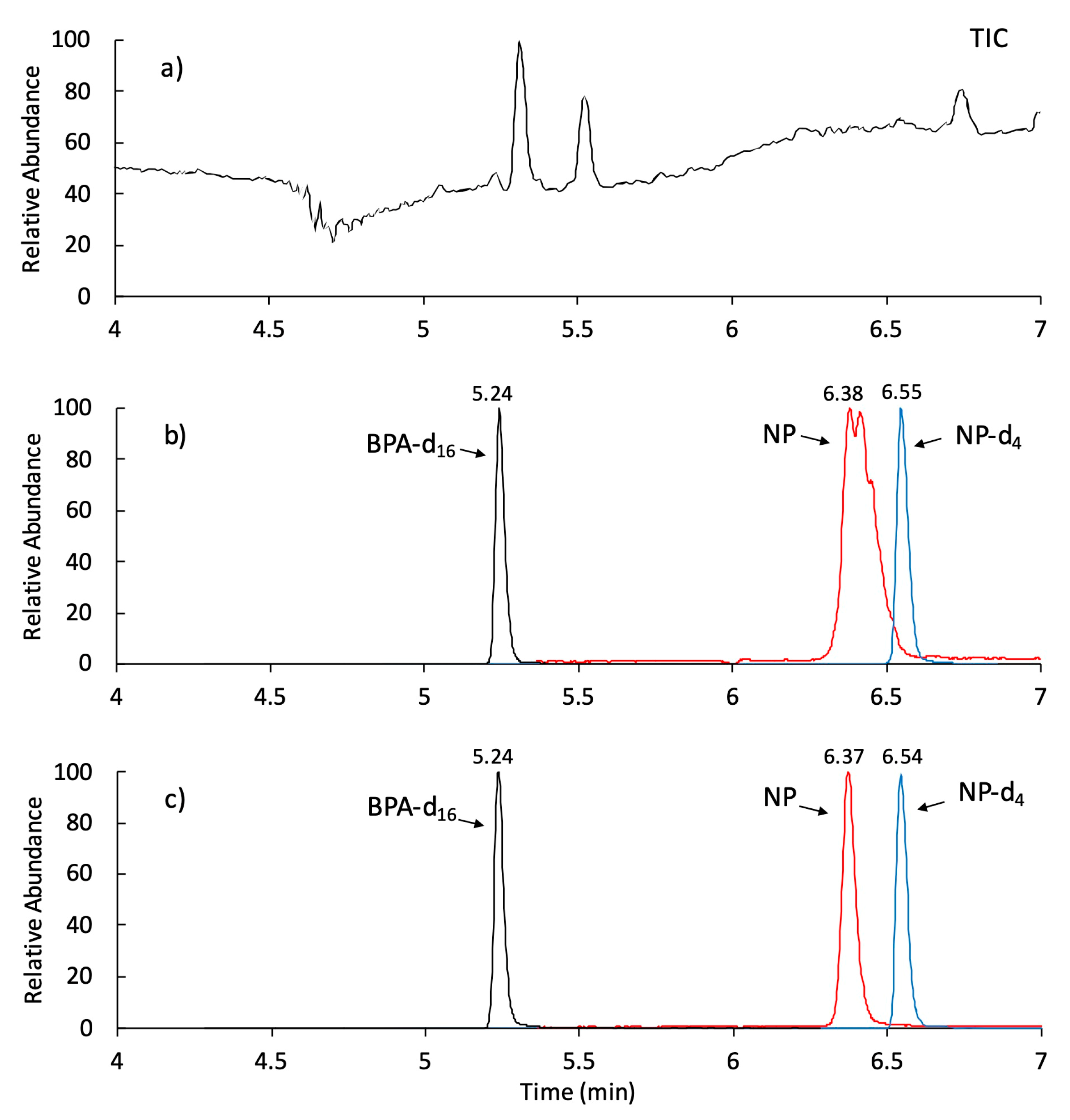

2.5. Instrumental Analysis

3. Results and Discussion

3.1. Optimization of Sample Pretreatment

3.1.1. Selection of NPC Packing Materials

3.1.2. Optimization of Alumina

3.1.3. Optimization of Elution Conditions

3.1.4. Selection of SPE Operations

3.2. Method Validation

3.3. Method Application

3.4. Potential Source of NPs in Crude Oil and Petrolium Products

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kapustin, N.O.; Grushevenko, D.A. Analysis of the “Circular Plastics Economy” Phenomena and Its Long-Term Implications for Demand for Petroleum Market. Environ. Sci. Pollut. Res. 2023, 30, 85889–85902. [Google Scholar] [CrossRef]

- Wang, H.; Liu, D.; Lv, Y.; Wang, W.; Wu, Q.; Huang, L.; Zhu, L. Ecological and Health Risk Assessments of Polycyclic Aromatic Hydrocarbons (PAHs) in Soils around a Petroleum Refining Plant in China: A Quantitative Method Based on the Improved Hybrid Model. J. Hazard. Mater. 2024, 461, 132476. [Google Scholar] [CrossRef] [PubMed]

- Energy Institute. Statistical Review of World Energy 2025; Energy Institute: London, UK, 2025. [Google Scholar]

- Chen, J.; Di, Z.; Shi, J.; Shu, Y.; Wan, Z.; Song, L.; Zhang, W. Marine Oil Spill Pollution Causes and Governance: A Case Study of Sanchi Tanker Collision and Explosion. J. Clean. Prod. 2020, 273, 122978. [Google Scholar] [CrossRef]

- Yao, Y.; Meng, Y.; Chen, H.; Zhu, L.; Sun, H. Non-Target Discovery of Emerging PFAS Homologues in Dagang Oilfield: Multimedia Distribution and Profiles in Crude Oil. J. Hazard. Mater. 2022, 437, 129300. [Google Scholar] [CrossRef] [PubMed]

- Zhao, M.; Yao, Y.; Dong, X.; Baqar, M.; Fang, B.; Chen, H.; Sun, H. Nontarget Identification of Novel Per- and Polyfluoroalkyl Substances (PFAS) in Soils from an Oil Refinery in Southwestern China: A Combined Approach with TOP Assay. Environ. Sci. Technol. 2023, 57, 20194–20205. [Google Scholar] [CrossRef]

- Cattelaens, F.; Myrdek, T. Study of the Efficiency of Technical Grade Nonionic Surfactants. J. Surfactants Deterg. 2023, 26, 53–60. [Google Scholar] [CrossRef]

- Nassar, A.M.; Ahmed, N.S.; Abdel-Hameed, H.S.; El-Kafrawy, A.F. Synthesis and Utilization of Non-Metallic Detergent/Dispersant and Antioxidant Additives for Lubricating Engine Oil. Tribol. Int. 2016, 93, 297–305. [Google Scholar] [CrossRef]

- Zhao, Y.; Ji, J.; Wu, Y.; Chen, S.; Xu, M.; Cao, X.; Liu, H.; Wang, Z.; Bi, H.; Guan, G.; et al. Nonylphenol and Its Derivatives: Environmental Distribution, Treatment Strategy, Management and Future Perspectives. Chemosphere 2024, 352, 141377. [Google Scholar] [CrossRef]

- Diehl, J.; Johnson, S.E.; Xia, K.; West, A.; Tomanek, L. The Distribution of 4-Nonylphenol in Marine Organisms of North American Pacific Coast Estuaries. Chemosphere 2012, 87, 490–497. [Google Scholar] [CrossRef]

- Deng, Z.-H.; Li, N.; Jiang, H.-L.; Lin, J.-M.; Zhao, R.-S. Pretreatment Techniques and Analytical Methods for Phenolic Endocrine Disrupting Chemicals in Food and Environmental Samples. TrAC Trends Anal. Chem. 2019, 119, 115592. [Google Scholar] [CrossRef]

- Hermabessiere, L.; Dehaut, A.; Paul-Pont, I.; Lacroix, C.; Jezequel, R.; Soudant, P.; Duflos, G. Occurrence and Effects of Plastic Additives on Marine Environments and Organisms: A Review. Chemosphere 2017, 182, 781–793. [Google Scholar] [CrossRef]

- Careghini, A.; Mastorgio, A.F.; Saponaro, S.; Sezenna, E. Bisphenol A, Nonylphenols, Benzophenones, and Benzotriazoles in Soils, Groundwater, Surface Water, Sediments, and Food: A Review. Environ. Sci. Pollut. Res. 2015, 22, 5711–5741. [Google Scholar] [CrossRef]

- Castellani, F.; Vitali, M.; Antonucci, A.; Del Morrone, G.; Cofone, L.; D’Ancona, G.; Pindinello, I.; Mattiucci, S.; Protano, C. Optimization of a Fast and Sensitive Method Based on Matrix Solid-Phase Dispersion-LC-Ms/Ms for Simultaneous Determination of Phthalates and Bisphenols in Mussel Samples. Food Addit. Contam. Part A Chem. Anal. Control Expo. Risk Assess. 2024, 41, 537–549. [Google Scholar] [CrossRef]

- Mottier, P.; Frank, N.; Dubois, M.; Tarres, A.; Bessaire, T.; Romero, R.; Delatour, T. LC-MS/MS Analytical Procedure to Quantify Tris(Nonylphenyl)Phosphite, as a Source of the Endocrine Disruptors 4-Nonylphenols, in Food Packaging Materials. Food Addit. Contam. Part A Chem. Anal. Control Expo. Risk Assess. 2014, 31, 962–972. [Google Scholar] [CrossRef] [PubMed]

- Gao, H.; Ge, Y.; Tong, L.; Yin, L.; Ma, Q. Quantitative Analysis of Nonylphenol Ethoxylates in Textiles Using Ultrasonic/Microwave-Assisted Extraction Coupled with Ultra-High-Performance Supercritical Fluid Chromatography-Photodiode Array-Tandem Mass Spectrometry. J. Chromatogr. A 2025, 1753, 465985. [Google Scholar] [CrossRef] [PubMed]

- Luo, X.; Hong, J.; Zheng, H.; Qin, J.; Wang, M.; Yang, B. A Rapid Synergistic Cloud Point Extraction for Nine Alkylphenols in Water Using High Performance Liquid Chromatography and Fluorescence Detection. J. Chromatogr. A 2020, 1611, 460606. [Google Scholar] [CrossRef] [PubMed]

- Andreu, V.; Ferrer, E.; Rubio, J.L.; Font, G.; Picó, Y. Quantitative Determination of Octylphenol, Nonylphenol, Alkylphenol Ethoxylates and Alcohol Ethoxylates by Pressurized Liquid Extraction and Liquid Chromatography–Mass Spectrometry in Soils Treated with Sewage Sludges. Sci. Total Environ. 2007, 378, 124–129. [Google Scholar] [CrossRef]

- Yang, Y.; Lu, L.; Zhang, J.; Yang, Y.; Wu, Y.; Shao, B. Simultaneous Determination of Seven Bisphenols in Environmental Water and Solid Samples by Liquid Chromatography–Electrospray Tandem Mass Spectrometry. J. Chromatogr. A 2014, 1328, 26–34. [Google Scholar] [CrossRef]

- Salthammer, T.; Uhde, E.; Omelan, A.; Morrison, G.C. Sorption of Semi-Volatile Organic Compounds to Clothing Textiles. Sci. Total Environ. 2025, 981, 179578. [Google Scholar] [CrossRef]

- Omar, T.F.T.; Aris, A.Z.; Yusoff, F.M.; Mustafa, S. An Improved SPE-LC-MS/MS Method for Multiclass Endocrine Disrupting Compound Determination in Tropical Estuarine Sediments. Talanta 2017, 173, 51–59. [Google Scholar] [CrossRef]

- Erarpat, S.; Bodur, S.; Chormey, D.S.; Öz, E.; Bakirdere, S. Sensitive Determination of 4-n-Nonylphenol in Domestic Wastewater and Liquid Detergent by Binary Solvent Microextraction (BSME) and Gas Chromatography-Mass Spectrometry (GC-MS) with Matrix Matching Calibration. Anal. Lett. 2022, 55, 1080–1092. [Google Scholar] [CrossRef]

- Cai, C.; Ying, Y.; Wu, P.; Tang, J.; Wang, L.; Ying, T. Survey of Octylphenol, Nonylphenol, and Bisphenol A in Infant Milk Powders by Solid-Phase Extraction Combined GC/MS Method. J. Food Qual. 2018, 2018, 2848627. [Google Scholar] [CrossRef]

- Cserbik, D.; Redondo-Hasselerharm, P.E.; Farre, M.J.J.; Sanchis, J.; Bartolome, A.; Paraian, A.; Herrera, E.M.; Caixach, J.; Villanueva, C.M.M.; Flores, C. Human Exposure to Per- and Polyfluoroalkyl Substances and Other Emerging Contaminants in Drinking Water. npj Clean Water 2023, 6, 16. [Google Scholar] [CrossRef]

- Lee, K.; Alava, J.J.; Cottrell, P.; Cottrell, L.; Grace, R.; Zysk, I.; Raverty, S. Emerging Contaminants and New POPs (PFAS and HBCDD) in Endangered Southern Resident and Bigg’s (Transient) Killer Whales (Orcinus Orca): In Utero Maternal Transfer and Pollution Management Implications. Environ. Sci. Technol. 2023, 57, 360–374. [Google Scholar] [CrossRef]

- Boti, V.; Kobothekra, V.; Albanis, T.; Konstantinou, I. QuEChERS-Based Methodology for the Screening of Alkylphenols and Bisphenol A in Dairy Products Using LC-LTQ/Orbitrap MS. Appl. Sci. 2021, 11, 9358. [Google Scholar] [CrossRef]

- Luo, X.; Zhang, L.; Niu, Z.; Ye, X.; Tang, Z.; Xia, S. Liquid Chromatography Coupled to Quadrupole-Orbitrap High Resolution Mass Spectrometry Based Method for Target Analysis and Suspect Screening of Non-Ionic Surfactants in Textiles. J. Chromatogr. A 2017, 1530, 80–89. [Google Scholar] [CrossRef]

- Xie, W.; Zhao, J.; Zhang, Q.; Ye, C.; Zheng, G.; Shan, Q.; Li, L.; Shao, X. Occurrence, Distribution and Bioaccumulation of Alkylphenols in the Pearl River Networks, South China. Ecol. Indic. 2020, 110, 105847. [Google Scholar] [CrossRef]

- Faramawy, S.; El-Naggar, A.Y.; El-Fadly, A.M.; El-Sabagh, S.M.; Ibrahim, A.A. Silica, Alumina and Aluminosilicates as Solid Stationary Phases in Gas Chromatography. Arab. J. Chem. 2016, 9, S765–S775. [Google Scholar] [CrossRef]

- Neugebauer, F.; Dreyer, A.; Lohmann, N.; Koschorreck, J. Determination of Halogenated Flame Retardants by GC-API-MS/MS and GC-EI-MS: A Multi-Compound Multi-Matrix Method. Anal. Bioanal. Chem. 2018, 410, 1375–1387. [Google Scholar] [CrossRef]

- Seok, J.; Phan, N.T.Y.; Kim, J.-C.; Shin, H.; Choi, M. Catalytic Synergy between Lewis Acidic Alumina and Pt in Hydrodechlorination for Plastic Chemical Recycling. J. Am. Chem. Soc. 2024, 146, 23881–23890. [Google Scholar] [CrossRef]

- Hu, Y.; Xi, C.; Cao, S.; Wang, G.; Li, X.; Zhang, L.; Zhang, Y. Simultaneous determination of 16 organophosphorous pesticides in vegetables, fruits and tea by gas chromatography coupled with clean-up by mesoporous alumina as solid-phase extraction adsorbent. Se Pu Chin. J. Chromatogr. 2014, 32, 784–788. [Google Scholar] [CrossRef] [PubMed]

- Xin, L.; Chen, Y.; Li, M.; Liang, F.; Xia, N.; Wang, L. Determination of Sedative and Anesthetic Drug Residues in Aquatic Food Products Using Solid Phase Extraction (SPE) and Liquid Chromatography-Tandem Mass Spectrometry (LC-MS/MS). Anal. Lett. 2025, 58, 1182–1203. [Google Scholar] [CrossRef]

- Cardona, Y.; Korili, S.A.; Gil, A. Use of Response Surface Methodology to Optimize Triclosan Adsorption on Alumina Pillared Clays in a Fixed-Bed Column for Applications in Solid-Phase Extraction. Appl. Clay Sci. 2023, 235, 106879. [Google Scholar] [CrossRef]

- Pesek, J.J.; Matyska, M.T. Modified Aluminas as Chromatographic Supports for High-Performance Liquid Chromatography. J. Chromatogr. A 2002, 952, 1–11. [Google Scholar] [CrossRef]

- Cui, K.; Wen, J.; Zeng, F.; Zhou, X.; Li, S.; Zeng, Z. Determination of Organophosphate Ester Flame Retardants and Plasticizers in Soil Samples by Microwave-Assisted Extraction Coupled with Silica Gel/Alumina Multilayer Solid-Phase Extraction and Gas Chromatography-Mass Spectrometry. Anal. Methods 2017, 9, 986–993. [Google Scholar] [CrossRef]

- Coker, A.K. Characterization of Petroleum and Petroleum Fractions. In Petroleum Refining Design and Applications Handbook; John Wiley & Sons, Ltd.: Hoboken, NJ, USA; Scrivener Publishing LLC.: Beverly, MA, USA, 2018; pp. 31–62. ISBN 978-1-119-25711-0. [Google Scholar]

- Wu, M.; Wang, L.; Xu, G.; Liu, N.; Tang, L.; Zheng, J.; Bu, T.; Lei, B. Seasonal and Spatial Distribution of 4-Tert-Octylphenol, 4-Nonylphenol and Bisphenol A in the Huangpu River and Its Tributaries, Shanghai, China. Environ. Monit. Assess. 2013, 185, 3149–3161. [Google Scholar] [CrossRef] [PubMed]

- Rashidian, A.; Dušek, J.; Drastik, M.; Smutná, L.; Fritsche, K.; Braeuning, A.; Pijnenburg, D.; van Beuningen, R.; Honkakoski, P.; Poso, A.; et al. Filling the Blank Space: Branched 4-Nonylphenol Isomers Are Responsible for Robust Constitutive Androstane Receptor (CAR) Activation by Nonylphenol. Environ. Sci. Technol. 2024, 58, 6913–6923. [Google Scholar] [CrossRef]

- Bhandari, G.; Bagheri, A.R.; Bhatt, P.; Bilal, M. Occurrence, Potential Ecological Risks, and Degradation of Endocrine Disrupter, Nonylphenol, from the Aqueous Environment. Chemosphere 2021, 275, 130013. [Google Scholar] [CrossRef]

- Guenther, K.; Kleist, E.; Thiele, B. Estrogen-Active Nonylphenols from an Isomer-Specific Viewpoint: A Systematic Numbering System and Future Trends. Anal. Bioanal. Chem. 2006, 384, 542–546. [Google Scholar] [CrossRef]

- Pawar, R.; Vidic, R.D. Impact of Surfactants Used in Oil and Gas Extraction on Produced Water Treatment by Membrane Distillation. Desalination 2024, 586, 117906. [Google Scholar] [CrossRef]

- Ratnakar, R.K.; Pandian, S.; Mary, H.; Choksi, H. Flow Assurance Methods for Transporting Heavy and Waxy Crude Oils via Pipelines without Chemical Additive Intervention. Pet. Res. 2025, 10, 204–215. [Google Scholar] [CrossRef]

- Ying, G.-G.; Kookana, R.S. Degradation of Five Selected Endocrine-Disrupting Chemicals in Seawater and Marine Sediment. Environ. Sci. Technol. 2003, 37, 1256–1260. [Google Scholar] [CrossRef]

- Micić, V.; Kruge, M.A.; Hofmann, T. Variations of Common Riverine Contaminants in Reservoir Sediments. Sci. Total Environ. 2013, 458–460, 90–100. [Google Scholar] [CrossRef]

- Zainal, N.A.; Zulkifli, N.W.M.; Gulzar, M.; Masjuki, H.H. A Review on the Chemistry, Production, and Technological Potential of Bio-Based Lubricants. Renew. Sustain. Energy Rev. 2018, 82, 80–102. [Google Scholar] [CrossRef]

| Refinery Plants | Collection Date | Location | Sample Type | Sample Name | Source |

|---|---|---|---|---|---|

| A | 17 January 2025 | Northwestern China | crude oil | crude oil A1 | Imported and Domestic |

| crude oil A2 | Domestic | ||||

| petroleum products | gasoline A | / | |||

| diesel oil A | / | ||||

| aviation kerosene A | / | ||||

| B | 22 May 2025 | North China | crude oil | crude oil B1 | Domestic |

| crude oil B2 | Domestic | ||||

| petroleum products | Gasoline B | / | |||

| diesel oil B | / | ||||

| aviation kerosene B | / | ||||

| C | 25 October 2023 | Northeastern China | crude oil | crude oil C | Domestic |

| Time | A (0.35% Ammonia in Water, %) | B (Methanol, %) |

|---|---|---|

| 0.00 | 95.0 | 5.0 |

| 1.00 | 95.0 | 5.0 |

| 5.00 | 1.0 | 99.0 |

| 7.00 | 1.0 | 99.0 |

| 7.10 | 95.0 | 5.0 |

| 9.00 | 95.0 | 5.0 |

| Number | Substance | Retention Time (min) | Precursor Ion (m/z) | Product Ion (m/z) | Collision Energy (%) | Remarks |

|---|---|---|---|---|---|---|

| 1 | NP | 6.37 | 219.1754 | 133.0658 | 50 | Target |

| 2 | NP-d4 | 6.54 | 223.2005 | 110.0675 | 50 | Surrogate |

| 3 | BPA-d16 | 5.24 | 231.1329 | 216.1091 | 45 | Internal standard |

| Fractionation Number | Elution Solvent | Relative Fraction | ||

|---|---|---|---|---|

| Florisil | Silica | Alumina | ||

| F1 | n-hexane | ND | ND * | ND * |

| F2 | n-hexane/dichloromethane (4:1, v/v) | ND | ND | ND |

| F3 | n-hexane/dichloromethane (1:1, v/v) | 20.8% | ND | ND |

| F4 | dichloromethane | 79.2% | 98.8% | ND |

| F5 | dichloromethane/methanol (3:1, v/v) | ND | 1.2% | 71.6% |

| F6 | dichloromethane/methanol (1:1, v/v) | ND | ND | 23.7% |

| F7 | methanol | ND | ND | 4.7% |

| Fractionation Number | Solvents | Relative Fraction | |

|---|---|---|---|

| Alumina | 5% Deactivated Alumina | ||

| F1 | n-hexane | ND | ND * |

| F2 | n-hexane/dichloromethane (4:1, v/v) | ND | ND |

| F3 | n-hexane/dichloromethane (1:1, v/v) | ND | ND |

| F4 | dichloromethane | 2% | 85% |

| F5 | dichloromethane/methanol (2:1, v/v) | 90% | 15% |

| F6 | methanol | 8% | ND |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, L.; Zhang, S.; Long, Z.; Ju, F.; Zhen, H.; Luan, H.; Xiu, G.; Tang, Z. Determination of Nonylphenol in Crude Oils and Petroleum Products by Liquid Chromatography–Mass Spectrometry: Implications for Sustainable Petroleum Refining. Sustainability 2025, 17, 8485. https://doi.org/10.3390/su17188485

Wang L, Zhang S, Long Z, Ju F, Zhen H, Luan H, Xiu G, Tang Z. Determination of Nonylphenol in Crude Oils and Petroleum Products by Liquid Chromatography–Mass Spectrometry: Implications for Sustainable Petroleum Refining. Sustainability. 2025; 17(18):8485. https://doi.org/10.3390/su17188485

Chicago/Turabian StyleWang, Limin, Shijie Zhang, Zi Long, Feng Ju, Huajun Zhen, Hui Luan, Guangli Xiu, and Zhihe Tang. 2025. "Determination of Nonylphenol in Crude Oils and Petroleum Products by Liquid Chromatography–Mass Spectrometry: Implications for Sustainable Petroleum Refining" Sustainability 17, no. 18: 8485. https://doi.org/10.3390/su17188485

APA StyleWang, L., Zhang, S., Long, Z., Ju, F., Zhen, H., Luan, H., Xiu, G., & Tang, Z. (2025). Determination of Nonylphenol in Crude Oils and Petroleum Products by Liquid Chromatography–Mass Spectrometry: Implications for Sustainable Petroleum Refining. Sustainability, 17(18), 8485. https://doi.org/10.3390/su17188485