1. Introduction

The global environment in which the Healthcare Supply Chain (HSC) operates is increasingly unstable. This instability is driven in part by repeated public health crises, rapid technological advancements, and shifting policy landscapes. Factors such as pandemics, AI-enabled healthcare services, and geopolitical conflicts have contributed to an unprecedented level of complexity, intensifying task uncertainty and operational challenges across the HSC [

1,

2,

3]. In such a dynamic and high-risk external environment, organizations are required not only to maintain operational efficiency but also to make timely and optimal decisions under uncertainty [

4]. The HSC typically involves highly sensitive, strictly regulated, and time-critical products and services [

5]. It integrates multiple stakeholders across the value chain, including manufacturers, distributors, logistics providers, storage facilities, hospitals, and patients [

6]. As a result, HSCs are distinguished by a high level of intricacy, multi-actor involvement, and low tolerance for risk [

5]. In the context of China, the sector faces a range of structural challenges, such as lengthy management chains, information overload, fragmented coordination mechanisms, and poor system interoperability. These limitations severely constrain response agility and hinder the fulfillment of modern healthcare’s demands for flexibility [

7,

8].

To achieve their intended performance goals, firms must have the capacity to effectively respond to uncertainty. According to Organizational Information Processing Theory (OIPT), the core function of a firm is to coordinate the acquisition, transmission, and utilization of information in order to cope with task-related uncertainty [

9]. As uncertainty limits the organization’s capacity to make decisions through pre-established plans, enhancing information processing capability becomes critical for enabling high-quality decision-making. OIPT posits two strategic pathways for managing uncertainty: the first involves reducing information processing requirements, such as creating slack resources or decoupling tasks to minimize coordination costs; the second focuses on enhancing information processing capacity, through investments in vertical information systems and the development of lateral coordination mechanisms to improve sensing, communication, and response capabilities [

10]. In today’s highly interconnected and fast-paced supply chain environments, the former strategy often proves insufficient to keep pace with rapid change, whereas the latter is increasingly viewed as a more strategically viable option.

In the digital era, organizations are increasingly leveraging advanced technologies to build high-performance information systems tailored for dynamic environments [

11]. For instance, Internet of Things (IoT) technologies have enhanced supply chain visibility by enabling cross-level and cross-organizational information transparency [

12]. Blockchain technologies, through smart contracts and immutable ledgers, have improved the security and reliability of information systems [

13,

14]. Furthermore, enterprise platforms such as Enterprise Resource Planning (ERP), Health Information Exchange (HIE), and Manufacturing Execution Systems (MES) have significantly enhanced system compatibility and cross-organizational data integration [

15,

16,

17]. These digital characteristics serve as essential enablers of information processing capability and form the technical foundation for developing agile information system competencies [

18]. Agility, considered an adaptive capability, provides entities with the means to swiftly perceive environmental variations, process information, and respond effectively, ultimately supporting the optimization of operational decisions [

19]. In highly uncertain and time-sensitive domains such as the pharmaceutical supply chain, establishing an agile information infrastructure powered by digital technologies is critical to strengthening risk responsiveness and decision-making efficiency.

While prior research has largely examined the direct benefits of IT investment and system deployment, such as Vishwakarma et al. [

20], who examined the impact of blockchain technology on HSC performance, most of this literature tends to analyze the effect of specific drivers on firm on performance outcomes. For instance, Kumar [

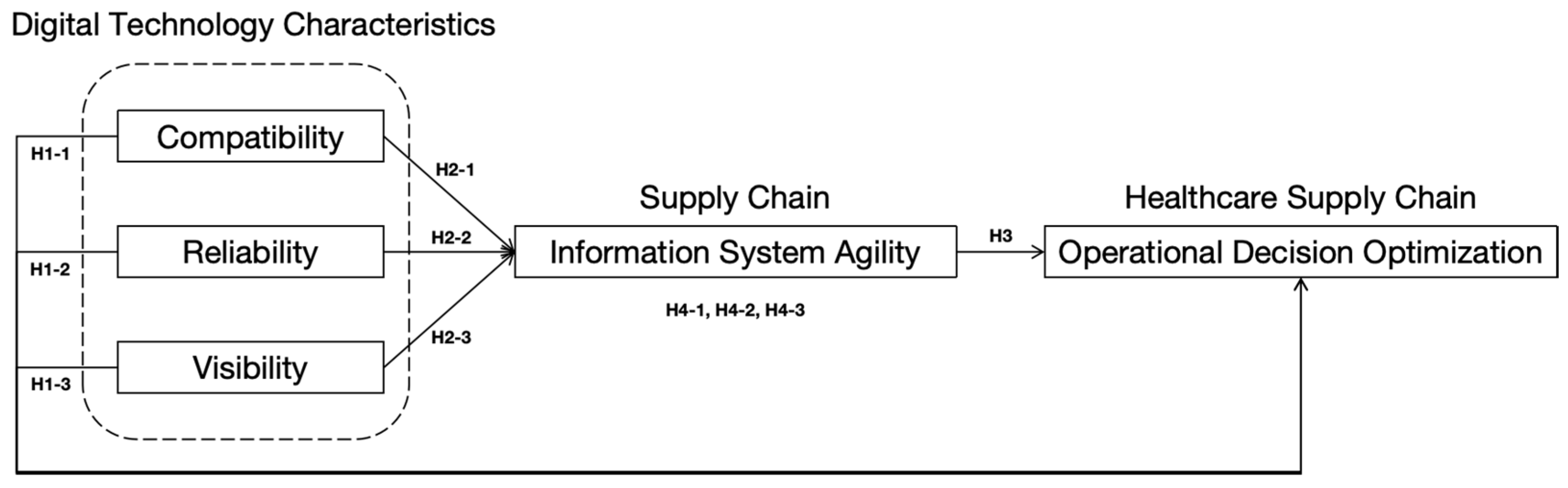

21] investigated how flexibility affects the sustainable development of healthcare organizations. However, in the HSC, an area characterized by high dynamism and risk, technologically enabled information decision systems play an especially critical role, yet empirical studies exploring this mechanism remain limited. To address this research gap, the current study builds on OIPT to develop an integrated framework. It posits that three key Digital Technology Characteristic (DTC)s, including compatibility, reliability, and visibility, can enhance supply chain Information System Agility (ISA), thereby improving Operational Decision Optimization (ODO).

This study focuses on the HSC, which is characterized by high complexity, information intensity, and time sensitivity. Grounded in OIPT, it investigates how DTCs influence the optimization of operational decisions through the mediating role of supply chain ISA. The primary aim is to extend the theoretical and empirical applicability of OIPT within the HSC context. By developing an integrated conceptual framework and validating it through empirical analysis, this research offers a novel perspective that reframes digital transformation not merely as an upgrade of technological infrastructure but as a strategic pathway for building agile decision-making systems tailored to high-risk and highly dynamic healthcare environments.

The rest of this article is organized as follows.

Section 2 provides a review of the relevant literature on DTCs (i.e., compatibility, reliability, and visibility), ISA, and ODO in the context of HSCs, while identifying key research gaps.

Section 3 presents the proposed research model and hypotheses, and outlines the research design and data collection procedures.

Section 4 reports the empirical results, including the validation of the structural model, path analysis, and mediation effect testing.

Section 5 examines the results with respect to their theoretical and practical significance and underscores the contributions of the study, and acknowledges its limitations along with suggestions for future research.

The objective of this study is to analyze the mediating role of ISA between DTCs and the optimization of operational decisions in HSCs in China. Although prior studies have examined digitalization in supply chains, little is known about how specific technological features are transformed into decision-making advantages through enhanced information processing capabilities. By adopting a Structural Equation Modeling (SEM) approach, this study not only addresses this gap but also provides a robust theoretical model that extends OIPT to the HSC while offering practical insights into digital transformation and decision optimization.

4. Methodology

SEM provides a robust analytical approach for simultaneously estimating measurement models and the structural relationships among latent constructs, while offering clear visualization for model validation. SEM typically evaluates two interrelated components: the measurement model and the structural path model [

85]. Two dominant approaches exist in the SEM domain: covariance-based SEM (CB-SEM) and variance-based partial least squares SEM (PLS-SEM). CB-SEM is generally more appropriate when the research objective is theory testing and validation using factor-based models, whereas PLS-SEM is recommended for prediction and theory development with composite-based models [

86]. Given that this study aims to validate an established theoretical framework and is supported by a sufficiently large sample size (n > 200), we employed CB-SEM implemented through SPSS 26.0 and AMOS 24.0, rather than PLS-SEM via SmartPLS 3.0 [

87]. This methodological choice allows for a more rigorous evaluation of model fit indices and enhances the robustness of the hypothesized causal inferences. It is particularly suitable for HSC research, where stringent methodological standards are required to ensure reliability and validity of the findings [

88].

To ensure the rigor of the research methodology, this study adopted a two-step analytical strategy using SPSS 26.0 and AMOS 24.0 [

89]. In the first stage, Exploratory Factor Analysis (EFA) was conducted to identify the underlying factor structure and minimize model specification bias [

90]. This was followed by Confirmatory Factor Analysis (CFA) to assess the reliability and validity of the measurement model, thereby ensuring the robustness of construct development [

91]. Pearson correlation analysis was performed to examine the associations and distinctions among variables. Construct reliability was evaluated using Cronbach’s α and Composite Reliability (CR), while model fit was assessed through indices such as CFI, TLI, RMSEA, and SRMR to confirm the robustness of the measurement model [

92,

93]. Furthermore, discriminant validity and multicollinearity tests were conducted to ensure variable independence and model stability [

94,

95,

96]. Building upon these validated foundations, the second stage tested the hypothesized causal relationships through CB-SEM. Path analysis was employed to examine the direct effects among variables, while the mediating effects were assessed using bootstrapping procedures with 5000 resamples [

97]. Compared with other statistical approaches, SEM offers the advantage of simultaneously testing both measurement and structural models, thereby reducing estimation bias and providing a holistic view of the interrelationships among constructs. This analytical strategy not only ensures the robustness of the empirical results but also strengthens the theoretical persuasiveness of the proposed model.

4.1. Measurement

Based on the theoretical framework and validated hypotheses of this study, a structured questionnaire was designed using measurement items adapted from well-established and empirically validated scales in prior literature. Each latent construct in the proposed model, including DTCs (compatibility, reliability, visibility), supply chain ISA, and ODO, was measured using five items. The selected items were refined to align with the HSC context while ensuring construct validity and conceptual consistency. This study employed a five-point Likert scale to measure all constructs. Under this approach, respondents were asked to indicate their level of agreement with each item on a five-level continuum: 1 = strongly disagree, 2 = disagree, 3 = neutral, 4 = agree, and 5 = strongly agree. This scaling method allows for the systematic quantification of respondents’ attitudes, ensuring comparability across constructs and enhancing the reliability of the measurement model [

98]. A detailed list of the measurement items and their sources is provided in

Table 1.

4.2. Demographics

This study targeted managers from organizations that constitute the Chinese HSC, including pharmaceutical companies, medical device manufacturers, pharmaceutical logistics enterprises, and online pharmaceutical retail platforms. These organizations are directly associated with the core links of the HSC, namely production, distribution, and end-user service. According to statistics from the National Medical Products Administration (NMPA), there are 10,239 registered pharmaceutical enterprises in China, encompassing state-owned, private, and multinational companies [

100]. This study targeted managers from these organizations. A non-probability random sampling method, specifically convenience sampling with random distribution, was employed, which is widely applied in quantitative research [

101]. Data were collected through an online questionnaire (

www.wjx.cn), which was distributed and retrieved via email and social networking services.

Prior to the formal survey, a pre-testing was conducted to assess the adequacy of the questionnaire design. The pilot respondents were also managers involved in the Chinese HSC, and the same random sampling method was applied. The pre-testing lasted one week, during which 20 questionnaires were distributed and retrieved. Reliability and validity of the scale were examined through the KMO test and Cronbach’s α coefficients, which yielded a KMO value greater than 0.6 and α values above 0.8, indicating satisfactory internal consistency.

The formal data collection was conducted over a five-month period (7 October 2024–7 March 2025). A total of 381 responses were obtained. To mitigate potential bias introduced by convenience sampling and to ensure that the data met the assumptions of normal distribution for subsequent statistical analyses, this study performed an outlier elimination procedure on the formal survey data. The specific steps were as follows: first, all item responses from each participant were summed and averaged; the mean scores were then transformed into standardized Z-scores [

102,

103]. Using the standard normal distribution as a reference, observations with Z-values greater than +2 or less than –2 were identified as outliers, resulting in the exclusion of 21 extreme cases from the dataset. After excluding 21 invalid responses due to inconsistent data, 360 valid responses were retained for analysis, yielding a valid response rate of 94.48%. To ensure the adequacy of the sample size for CB-SEM, a post hoc power analysis was conducted using G*Power 3.1. With a sample size of 360, three predictors, a significance level of 0.05, and a medium effect size (f

2 = 0.15), the achieved power was 0.99, exceeding the recommended threshold of 0.80 [

104]. This confirms that the sample size was sufficient for the application of CB-SEM.

As shown in

Table 2, the respondents were predominantly female (55.6%) and relatively young, with 69.2% under the age of 35 and 29.4% between 35 and 50 years old. Most participants held a bachelor’s degree (62.2%) or above, indicating a well-educated sample. Regarding professional experience, 54.4% had less than five years of work experience, while 37.8% had five to fifteen years, aligning with the relatively young age distribution. In terms of organizational background, the majority of respondents worked in firms with annual revenue under 40 million CNY (54.7%), followed by 31.4% in medium-sized firms (40–400 million CNY), and 13.9% in large-scale enterprises (above 400 million CNY). Most organizations were domestic enterprises (61.9%), with the remainder comprising joint ventures (31.1%) and wholly foreign-owned firms (6.9%).

6. Discussion

This study applied structural equation modeling to empirically assess the causal relationships among DTCs (compatibility, reliability, and visibility), ISA, and ODO in the HSC context.

First, the path analysis results indicate that compatibility exerts a significant and positive effect on ODO, supporting Hypothesis H1-1. This finding is consistent with Rong and Liu [

65] and confirms the critical role of compatibility in enhancing information processing capability and resource integration efficiency, while also underscoring its strategic value as a foundational technology for achieving high-quality operational decisions in HSCs. The positive impact of reliability on ODO, however, was not significant, and thus Hypothesis H1-2 was not supported. This result contrasts with the results of Skowron-Grabowska et al. [

37] and suggests that reliability primarily ensures stability and accuracy in information processing. Such stability does not necessarily translate directly into decision optimization outcomes. Rather, it may require the involvement of mediating mechanisms, such as supply chain agility, integration capability, or collaborative information sharing to translate its potential benefits into improved decision-making and performance [

70,

115,

116]. The mediation analysis in this study further corroborates that the influence of reliability on decision optimization is largely dependent on such transformation mechanisms. Visibility has a significant and positive impact on ODO, supporting Hypothesis H1-3. This finding is consistent with Baah et al. [

67], confirming the pivotal role of visibility in strengthening HSC transparency and environmental sensing capability. It also demonstrates that by facilitating the rapid identification of operational bottlenecks and risk nodes, visibility provides an essential safeguard for enabling more precise and efficient operational decisions within HSCs.

Compatibility has a significant and positive effect on ISA, supporting Hypothesis H2-1. This finding is consistent with Rajaguru and Matanda [

64] and indicates that compatibility, by facilitating seamless integration between systems and processes, effectively enhances the efficiency and speed of data flows across multiple supply chain stages. Reliability also has a significant and positive impact on ISA, supporting Hypothesis H2-2. In line with the findings of Joo and Han [

66], reliability ensures the stability and accuracy of data transmission, thereby providing a solid foundation for rapid response and efficient system operation during critical periods. Visibility exerts a significant and positive influence on ISA, supporting Hypothesis H2-3. Consistent with Srinivasan and Swink [

69], visibility enhances the timely perception of supply chain operational status and potential risk points, enabling the information system to adjust strategies more flexibly and coordinate resources effectively, thus improving overall agility.

Furthermore, ISA has a significant and positive effect on ODO, supporting Hypothesis H3. This result aligns with Shashikumar [

72] and demonstrates that higher levels of agility can accelerate information processing and response speed, thereby improving both the accuracy and execution efficiency of operational decisions.

Secondly, the mediation analysis results indicate that ISA exerts a significant total mediation effect between compatibility and ODO, with both the direct and indirect effects being significant. Therefore, ISA plays a partial mediating role in this relationship, supporting Hypothesis H4-1. Consistent with Ma and Chang [

79], compatibility not only directly promotes ODO but also enhances the timeliness and effectiveness of decision-making through improved system agility. The mediation results also show that ISA has a significant total mediation effect between reliability and ODO, with a significant direct effect but a non-significant indirect effect. Thus, ISA fully mediates the relationship, supporting Hypothesis H4-2. In line with Akhtar et al. [

81], the influence of reliability on ODO primarily depends on its transformation through enhanced system agility, whereby its potential advantages are converted into tangible decision-making performance only when agility is improved. Moreover, ISA demonstrates a significant total mediation effect between visibility and ODO, with both direct and indirect effects being significant. Therefore, ISA serves as a partial mediator in this relationship, supporting Hypothesis H4-3. Consistent with Roy et al. [

82], in the context of HSCs, the visibility afforded by digital technologies can, through enhanced system agility, translate rapid environmental perception into efficient strategy adjustments and resource allocation.

7. Conclusions

This study examined how DTCs (compatibility, reliability, and visibility) shape ODO in HSCs, with ISA serving as a key mediating mechanism. The empirical findings demonstrate that compatibility and visibility directly and indirectly enhance decision optimization, while reliability exerts its influence primarily through the full mediation of agility. These results not only validate the applicability of OIPT in the HSC but also highlight the critical role of agility in transforming technological potential into actionable decision-making advantages.

7.1. Theoretical Contribution

This study addresses the theoretical gap in applying OIPT to the digitalization of HSCs and contributes academic value to research in this domain.

First, this study substantially extends the applicability of the OIPT to the HSC domain and demonstrates its theoretical value in high-uncertainty, high-risk environments. OIPT posits that organizations should improve their data processing competence to bridge the divide between information needs and capacity [

10]. This theoretical logic is particularly salient in the dynamic and complex context of HSCs, which not only face demand fluctuations, public health emergencies, and stringent regulatory requirements but also carry exceptionally high demands for timeliness and accuracy in operations. These characteristics render the sector heavily dependent on the efficiency of information processing and the speed of decision-making responses. Existing OIPT research has largely focused on manufacturing and general commercial supply chains, with limited attention to the highly dynamic HSC context. By incorporating DTCs (compatibility, reliability, and visibility) alongside ISA into the OIPT framework, this study systematically examines the mechanisms through which these technological features enhance ODO via information processing capabilities. The findings not only validate the explanatory power of OIPT in this domain but also enrich its theoretical connotation in the emerging research directions of digitalization and information systems.

Second, this study develops a novel structured path analysis framework, the chain of DTC → ISA → ODO. Specifically, it disaggregates the DTC of the HSC into three dimensions including compatibility, reliability, and visibility, revealing the differentiated pathways through which each characteristic enhances information processing efficiency and optimizes operational decision-making. The analysis further verifies how these characteristics, through technological integration and functional complementarity, drive the agility of supply chain information systems, thereby supporting decision optimization. This framework underscores the bridging role of ISA in transforming technological advantages into decision-making advantages and provides new theoretical and empirical support for the digital management mechanisms of HSCs.

7.2. Practical Implications

China’s pharmaceutical-centered HSC is currently at a critical stage of accelerated digitalization; however, challenges such as system fragmentation, insufficient collaboration, and uneven levels of technological maturity continue to constrain its high-quality development [

117]. According to the empirical analysis, our study introduces concrete recommendations for practice.

First, from the perspective of technological deployment, the findings provide clear guidance on the prioritization and integration strategies for digital technology implementation in HSC enterprises. In China’s HSC, it is essential to formulate a phased and tiered roadmap for digital transformation, specifying the implementation pace for different types of enterprises in process reengineering, system deployment, and capability building, thereby enhancing overall structural decision-making efficiency [

118]. Given the foundational role of technological compatibility in system deployment, it is critical to establish unified data standards and interface protocols to enable rapid cross-organizational and cross-regional data exchange and collaborative decision-making [

119,

120]. This approach can not only strengthen the overall resilience and responsiveness of the industry but also provide real-time and accurate decision support for resource allocation and policy formulation during public health emergencies [

121]. Moreover, the deployment of digital technologies should consider their contribution to system visibility. For instance, priority should be given to platforms integrating 5G, IoT, and real-time visual analytics to achieve end-to-end, full-chain transparency, thereby enhancing risk perception and rapid response capabilities [

122]. Such initiatives can significantly optimize operational decision-making efficiency and offer a viable pathway for developing standardized and replicable digital transparency management models in the healthcare sector [

123,

124]. Finally, embedding emerging technologies such as IoT, AI, and blockchain into scenarios including pharmaceutical traceability, anti-counterfeiting verification, and collaborative decision-making can substantially improve the security and stability of the supply chain [

125]. Through coordinated advancement along these multiple pathways, China’s HSC is poised to achieve systematic enhancement and sustained optimization of operational decision-making within the broader context of digital transformation.

Second, from the perspective of capability enhancement, the study highlights the pivotal role of ISA in transforming technological advantages into decision-making advantages. Operationally, drawing on case studies of organizational resource interconnection and omnichannel integration in Ghana’s HSC, China should strengthen resource coordination and data sharing among hospitals, pharmaceutical companies, insurance providers, and logistics platforms to establish a diversified service linkage mechanism anchored in data [

126]. Promoting cross-platform technological integration across industries is essential; for example, enterprises can integrate healthcare platforms (HIE, Hospital Information Systems, Personal Health Records), business management platforms (ERP, MES), supply chain collaboration platforms (Transportation Management Systems, Warehouse Management Systems), and data analytics platforms (big data and AI-based decision support systems) to improve information processing speed and system flexibility [

18,

127,

128]. For instance, deeply integrating electronic Health Record Systems (EHR), pharmaceutical traceability systems, and logistics scheduling platforms can enhance cross-functional coordination capabilities, enabling the optimized allocation of healthcare resources and rapid linkage in emergency responses [

129,

130]. Such agility can help enterprises swiftly devise and efficiently execute viable response plans in the face of sudden changes in drug demand, supply disruptions, or strategic adjustments [

131]. Strategically, it is recommended that industry regulatory bodies establish a digital maturity assessment and certification system for the HSC, enabling the quantification of enterprise capabilities in areas such as digital technology adoption, system integration, data collaboration, and agile responsiveness [

132]. Moreover, this digital capability building should be closely aligned with supply chain sustainability objectives, ensuring the long-term stability and balance of resource utilization, economic efficiency, and public health goals by optimizing resource allocation, reducing operational waste, and mitigating risk exposure, thereby securing the sustained effectiveness of decision optimization [

133,

134].

Third, from a micro-operational perspective, this study demonstrates how DTC, particularly compatibility, reliability, and visibility, integrated through ISA, enable healthcare organizations to streamline decision-making processes and improve operational efficiency. From a resource utilization perspective, the model highlights how compatibility-driven system integration reduces duplication of effort, reliability ensures the stable use of scarce medical resources, and visibility minimizes mismatches in inventory and logistics, thereby conserving resources and reducing waste [

135]. At the macro level, by strengthening responsiveness and coordination across hospitals, pharmaceutical firms, and logistics platforms, this supports long-term system resilience, improves equitable access to medical resources, and reduces the environmental footprint of healthcare operations [

136]. These improvements contribute to building a sustainable healthcare system that supports long-term stability, environmental responsibility, and social value.

7.3. Limitations and Future Research

Although this study offers valuable theoretical and practical insights for the continuous optimization of HSCs, this study is subject to certain limitations that call for additional inquiry. First, the empirical evidence relies on cross-sectional data, which limits the ability to capture the dynamic evolution of relationships among variables over time and under changing environmental conditions. Future studies could adopt a longitudinal research design to more comprehensively validate and strengthen the robustness of the proposed theoretical model. Second, the scope of this research is confined to the HSC sector; applying the proposed framework to other types of supply chains would allow for further examination of its generalizability and explanatory power. Finally, the data sample is primarily drawn from organizations in China, and contextual factors may influence the external validity of the findings. Future research could extend the investigation to other countries and regions to enhance the applicability and international relevance of the results.