Comparative Study on the Combustion Characteristics of Korean Wood with Changes in the Radiant Heat

Abstract

1. Introduction

2. Materials and Methods

2.1. Selection of the Target Species

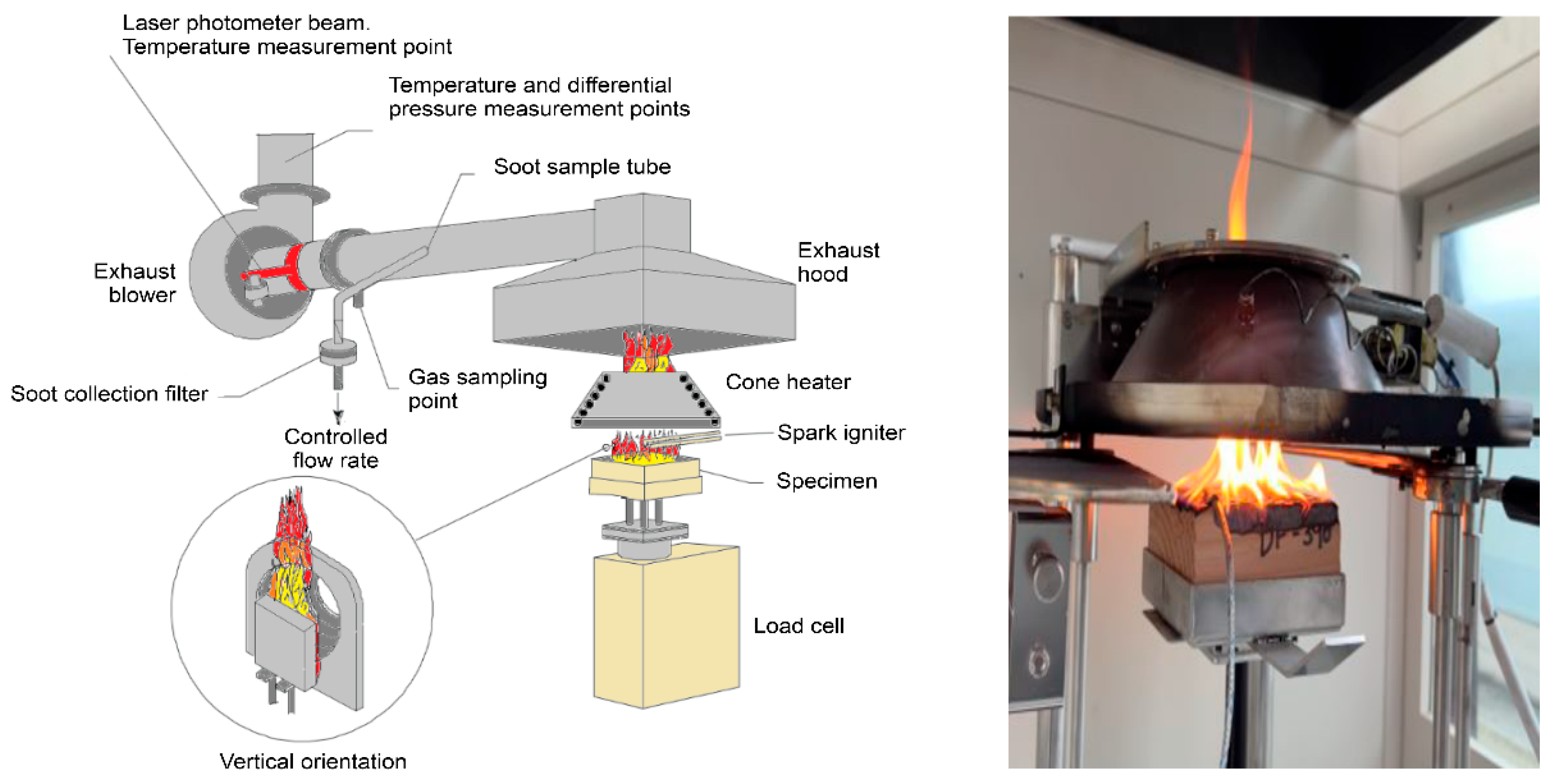

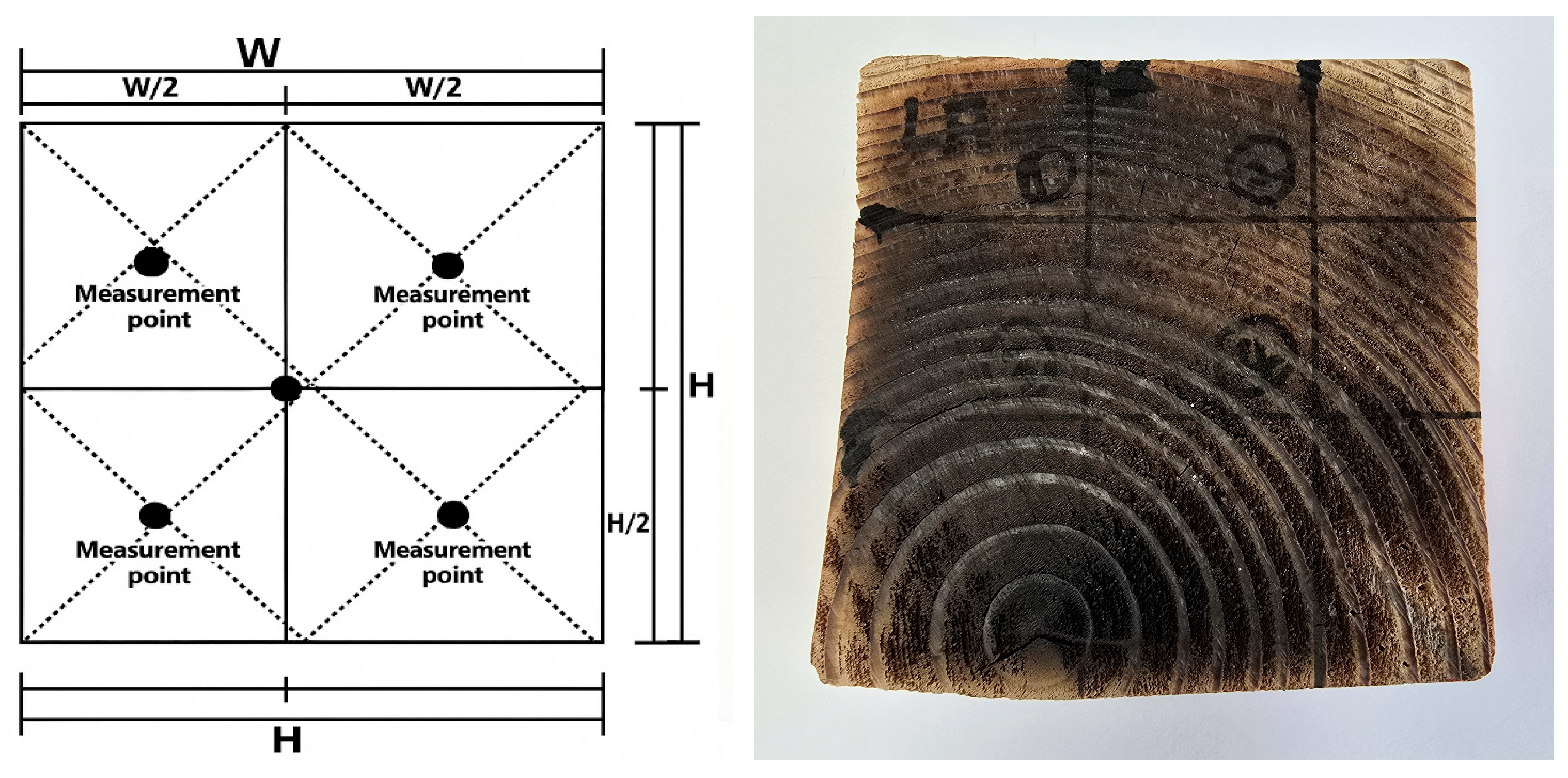

2.2. Experimental Setup

2.3. Experimental Method

3. Results

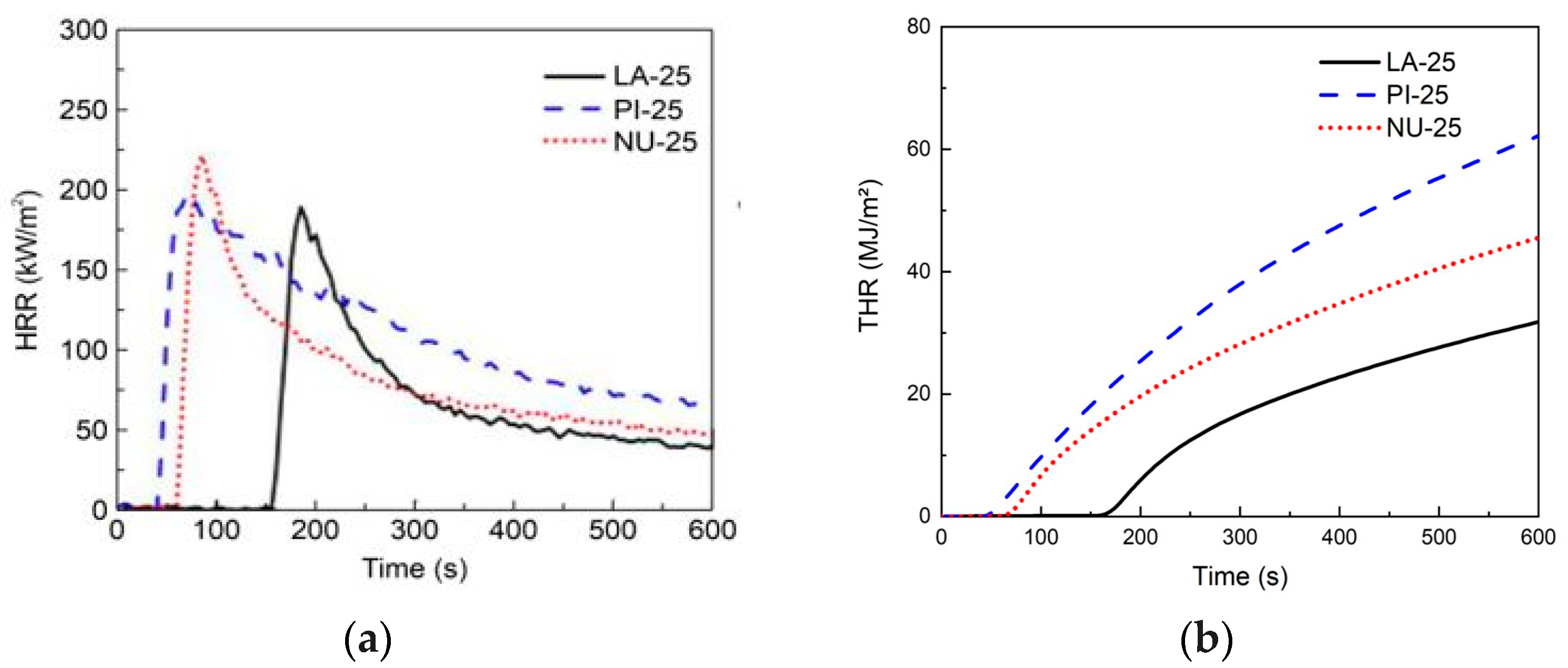

3.1. Determination of the HRR

3.2. Determination of the THR

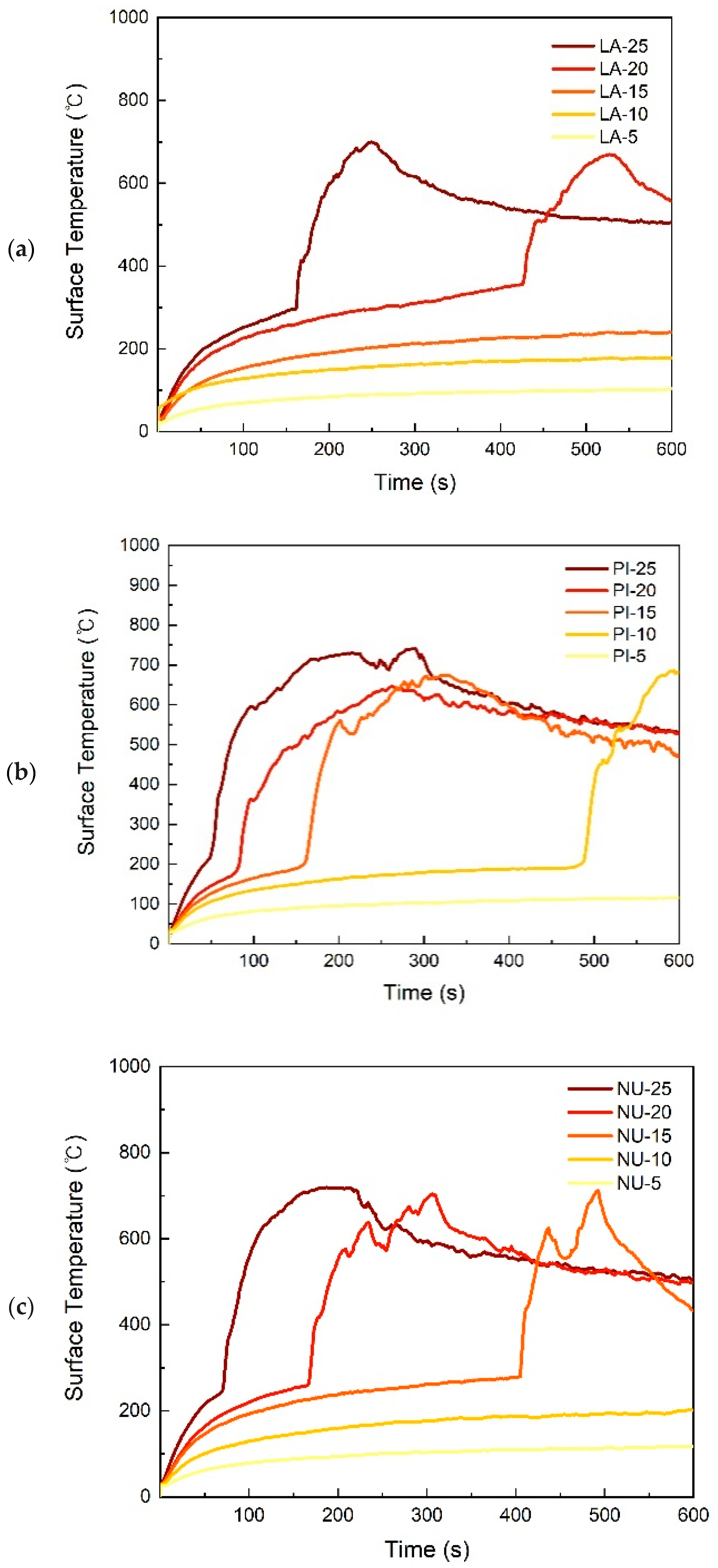

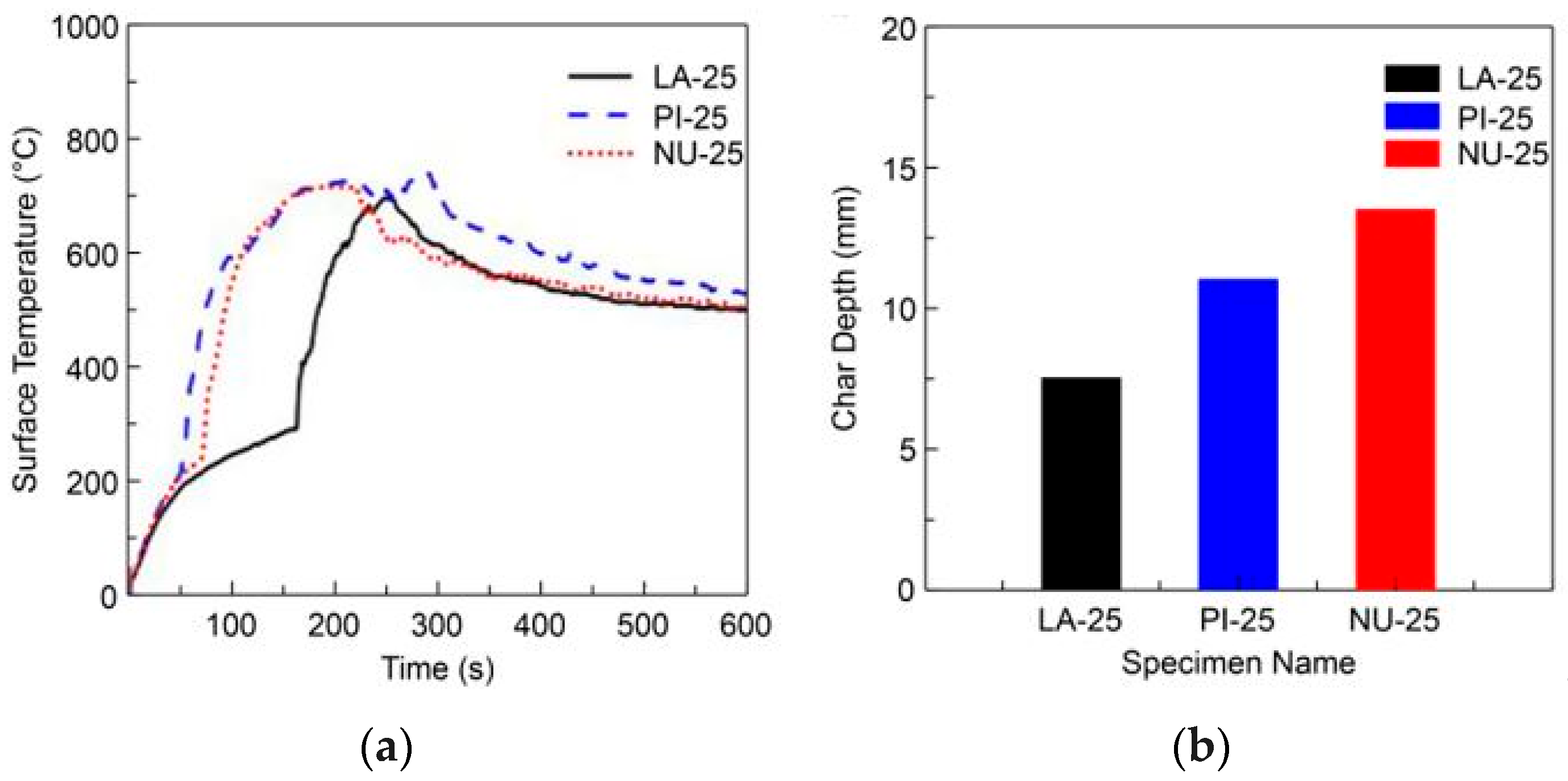

3.3. Evaluation of the Surface Temperature

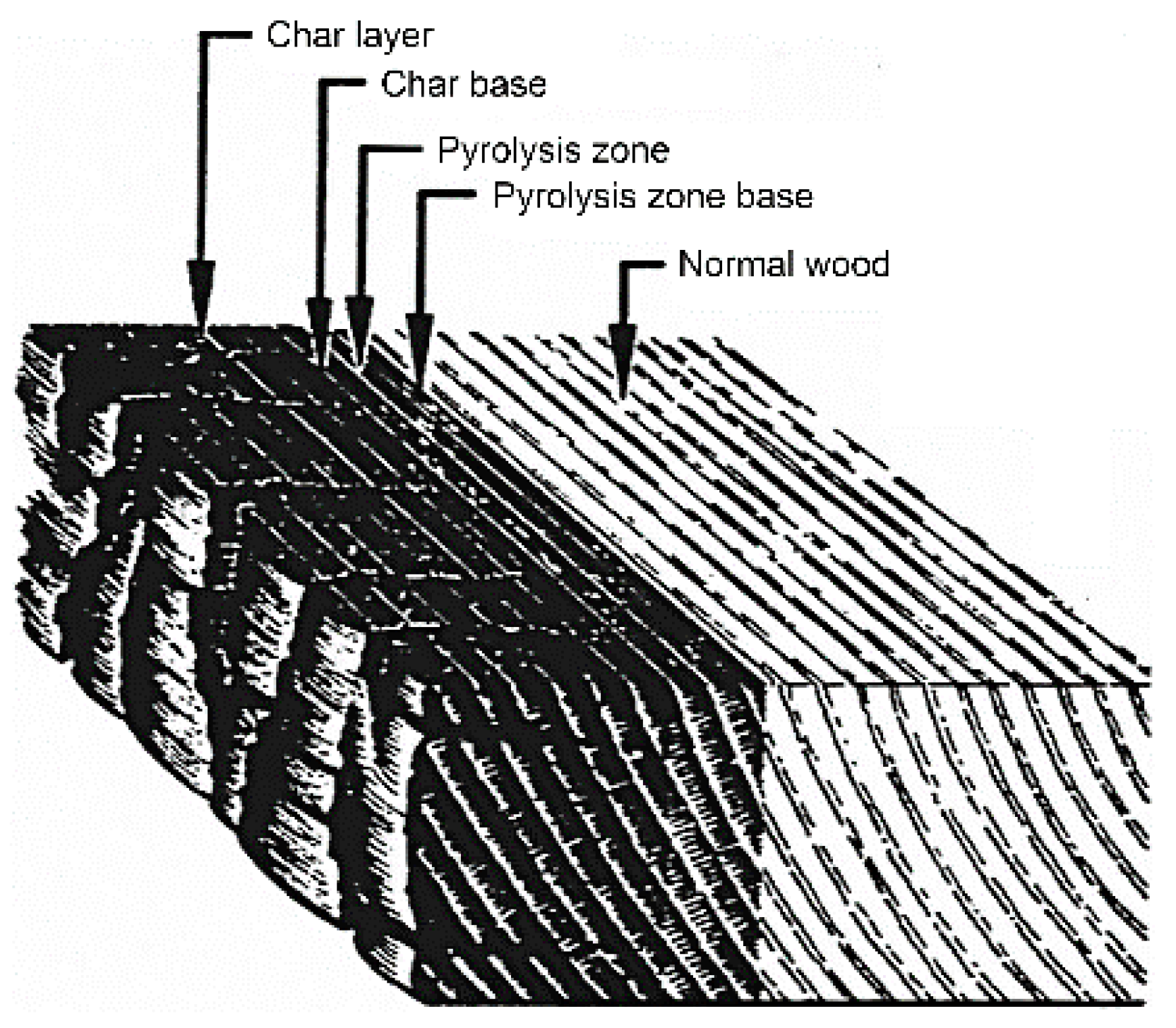

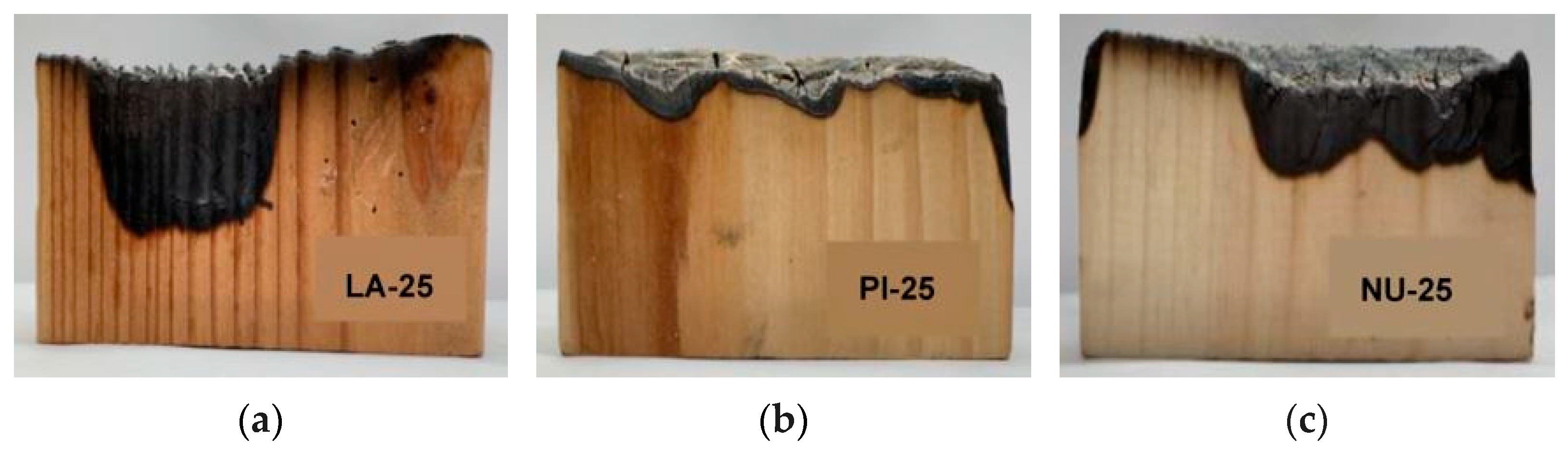

3.4. Evaluation of the Char Depth

3.5. Discussion of the Combustion Characteristics

3.6. Evaluation of the Charring Characteristics

4. Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| CLT | Cross-laminated timber |

| GLT | Glued laminated timber |

| HRR | Heat release rate |

| THR | Total heat release |

References

- Vladimir, R.A.; Olga, A.L. Forest Products Annual Market Review 2020–2021; United Nations: Geneva, Switzerland, 2021. [Google Scholar]

- Priyadarshi, R.S.; Jim, S.K. Agriculture, forestry and other land uses. In Climate Change 2022 Mitigation of Climate Change; United Nations: Geneva, Switzerland, 2022. [Google Scholar]

- Green, M.I. The Case for Tall Wood Buildings: How Mass Timber Offers a Safe, Economical, and Environmentally Friendly Alternative for Tall Building Structures, 2nd ed.; Blurb: San Francisco, CA, USA, 2020. [Google Scholar]

- Ramage, M.H.; Burridge, H.; Busse-Wicher, M.; Fereday, G.; Reynolds, T.; Shah, D.U.; Wu, G.; Yu, L.; Fleming, P.; Densley-Tingley, D.; et al. The wood from the trees: The use of timber in construction. Renew. Sustain. Energy Rev. 2017, 68, 333–359. [Google Scholar] [CrossRef]

- Park, J.Y.; Hong, S.I.; Choi, Y.J.; An, J.H. Comparative study on combustion characteristics of domestic larch and pine. J. Korea Inst. Build. Constr. 2024, 24, 685–696. [Google Scholar] [CrossRef]

- Yoon, I.S.; Yoon, C.H.; Jun, J.K.; Bae, G.I.; Jang, W.G.; Gang, M.S. Study on Legislation to Promote the Use of Wood in Buildings; Korea Legislation Research Institute: Sejong-Si, Republic of Korea, 2021. [Google Scholar]

- Shin, D.S.; Ahn, S.H. Wood Preservation; Seoul National University Press: Seoul, Republic of Korea, 2003. [Google Scholar]

- Chdong, Y.J.; Jin, E. Combustion properties of the Quercus variabilis and Zelkova serrata dried at room temperature (II). Appl. Chem. Eng. 2010, 21, 469–474. [Google Scholar]

- Seo, H.J.; Kang, M.R.; Son, D.W. Combustion properties of woods for indoor use (II). J. Korean Wood Sci. Technol. 2015, 43, 478–485. [Google Scholar] [CrossRef]

- Si, N. Combustion Characteristics of Wood Treated with Chemicals. Master’s Thesis, Kang-Won University, Kangwon-do, Republic of Korea, 2011. [Google Scholar]

- Dietenberger, M.A.; Hasburgh, L.E.; Yedinak, K.M. Fire safety of wood construction. In Wood Handbook—Wood as an Engineering Material; Ross, R., Ed.; Forest Products Laboratory: Madison, WI, USA, 2021; pp. 1–26. [Google Scholar]

- Rhoda, A.M.; Lin, J.; Julianna, S.R.; Qiang, X. Characterisation of the behavior of wood: From pyrolysis to fire retardant mechanisms. J. Therm. Anal. Calorim. 2022, 148, 1407–1422. [Google Scholar] [CrossRef]

- Wang, Z. Pyrolysis and combustion behaviors of densified wood. Proc. Combust. Inst. 2022, 39, 4175–4184. [Google Scholar] [CrossRef]

- Kim, A.K.; Onno, R. A System to Evaluate Fire Hazards of Materials Using Small Scale and Full-Scale Fire Test Methods Internal Report No. 649; NRCC: Washington, DC, USA, 1993; pp. 6–7. [Google Scholar]

- KS F 3020:2023 (Softwood Structural Lumber). Available online: https://www.standard.go.kr/KSCI/standardIntro/getStandardSearchList.do (accessed on 30 June 2025).

- KS F 3021:2022 (Structural Glued Laminated Timber). Available online: https://www.standard.go.kr/KSCI/standardIntro/getStandardSearchList.do (accessed on 30 June 2025).

- Babrauskas, V. The cone calorimeter. In SFPE Handbook of Fire Protection Engineering, 3rd ed.; Di Nenno, P.J., Ed.; National Fire Protection Association: Quincy, MA, USA, 2002; Volume 3, pp. 63–81. [Google Scholar]

- ISO 5660-1; Reaction-to-Fire Tests—Heat Release, Smoke Production and Mass Loss Rate—Part 1: Heat Release Rate (Cone Calorimeter Method) and Smoke Production Rate (Dynamic Measurement). International Organization for Standardization: Geneva, Switzerland, 2015.

- Hong, S.I. Experimental Study on the Charring Characteristics of Domestic Timber. Master’s Thesis, National University of Science and Technology, Seoul, Republic of Korea, 2024. [Google Scholar]

- Vytenis, B.; Richard, D.P.; Paul, A.R. Defining flashover for fire hazard calculation: Part II. Fire Saf. J. 2003, 38, 613–622. [Google Scholar] [CrossRef]

- Tamer, M.I.; Khaled, R. Experimental study on char production from the pyrolysis of biomass. Biomass Convers. Biorefinery 2023, 13, 6145–6161. [Google Scholar] [CrossRef]

- Kwon, H.; Lee, J.H. A Study on the Combustion Characteristics of the Crown of Pine Trees in the Drying season. J. Korean Soc. Saf. 2023, 38, 39–46. [Google Scholar] [CrossRef]

- Choi, J.M. A Study on Combustion Characteristics of Fire Retardant Treated Pinus densiflora and Pinus koraiensis. J. Korean Wood Sci. Technol. 2011, 39, 244–251. [Google Scholar] [CrossRef]

- Elza, M.F. Charring rate determination of wood pine profiles submitted to high temperatures. WIT Trans. Built Environ. 2009, 108, 449–457. [Google Scholar] [CrossRef]

- Zhimin, L.; Xin, L.; Jie, J.; Yao, S.C. Flame combustion of single wet-torrefied wood particle: Effects of pretreatment temperature and residence time. Fuel 2019, 250, 160–167. [Google Scholar] [CrossRef]

- Martinka, J.; Rantuch, P.; Liner, M. Calculation of charring rate and char depth of spruce and pine wood from mass loss. J. Therm. Anal. Calorim. 2018, 132, 1105–1113. [Google Scholar] [CrossRef]

- Hao, H.; Chow, C.L.; Lau, D. Effect of Heat Flux on combustion of different wood species. Fuel 2020, 278, 118325. [Google Scholar] [CrossRef]

- Birgit, O.; Lazaros, T. Durability of the reaction to fire performance for fire retardant treated (FRT) wood products in exterior applications-a ten years report. In Proceedings of the MATEC Web of Conferences, 2nd International Seminar for Safety of Facades, Stockholm, Sweden, 4 May 2016. [Google Scholar] [CrossRef]

- Albert, C.M.; Liew, K.C. A review on the role of thermogravimetric analysis in assessing thermal stability and degradation of wood. Wood Sci. Technol. 2025, 59, 55. [Google Scholar] [CrossRef]

| Group | Group A | Group B | Group C |

|---|---|---|---|

| Representative species | Larix kaempferi | Pinus densiflora | Pinus koraiensis |

| Cross-sectional image |  |  |  |

| Species | Species ID | Sample Specifications (Length × Width × Height) (mm) | Water Content (%) | Mass (g) | Density (g/cm3) |

|---|---|---|---|---|---|

| Larix kaempferi | LA-5 (5 kW/m2) | 100 × 100 × 50 | 8.9 | 252.9 | 0.51 |

| LA-10 (10 kW/m2) | 9.1 | 254.2 | 0.51 | ||

| LA-15 (15 kW/m2) | 8.8 | 250.8 | 0.50 | ||

| LA-20 (20 kW/m2) | 9.3 | 255.1 | 0.51 | ||

| LA-25 (25 kW/m2) | 9.0 | 250.0 | 0.50 | ||

|

Pinus

densiflora | PI-5 (5 kW/m2) | 7.8 | 264.8 | 0.53 | |

| PI-10 (10 kW/m2) | 9.0 | 256.0 | 0.51 | ||

| PI-15 (15 kW/m2) | 8.0 | 254.3 | 0.50 | ||

| PI-20 (20 kW/m2) | 8.1 | 253.7 | 0.51 | ||

| PI-25 (25 kW/m2) | 7.4 | 262.8 | 0.53 | ||

| Pinus koraiensis | NU-5 (5 kW/m2) | 8.8 | 192.2 | 0.38 | |

| NU-10 (10 kW/m2) | 8.5 | 187.6 | 0.38 | ||

| NU-15 (15 kW/m2) | 7.5 | 213.8 | 0.43 | ||

| NU-20 (20 kW/m2) | 7.9 | 187.1 | 0.37 | ||

| NU-25 (25 kW/m2) | 7.9 | 194.4 | 0.39 |

| Species | Specimen | HRRmean (kW/m2) | HRRpeak (kW/m2) | HRRpeak_time (s) |

|---|---|---|---|---|

|

Larix

kaempferi | LA-5 | 1.8 | 15.9 | 340 |

| LA-10 | −0.8 | 3.4 | 315 | |

| LA-15 | −0.1 | 2.0 | 425 | |

| LA-20 | 113.2 | 194.9 | 450 | |

| LA-25 | 72.1 | 189.3 | 185 | |

|

Pinus

densiflora | PI-5 | −0.0 | 11.1 | 65 |

| PI-10 | 115.8 | 147.3 | 550 | |

| PI-15 | 85.5 | 160.9 | 210 | |

| PI-20 | 93.9 | 180.9 | 115 | |

| PI-25 | 112.1 | 198.7 | 75 | |

|

Pinus

koraiensis | NU-5 | −0.4 | 9.1 | 145 |

| NU-10 | −0.6 | 9.3 | 70 | |

| NU-15 | 116.6 | 206.8 | 430 | |

| NU-20 | 87.2 | 241.6 | 180 | |

| NU-25 | 84.5 | 221.9 | 85 |

| Species | 5 kW/m2 | 10 kW/m2 | 15 kW/m2 | 20 kW/m2 | 25 kW/m2 |

|---|---|---|---|---|---|

| Larix kaempferi | 1.3 | 0.1 | 0.2 | 19.7 | 31.8 |

| Pinus densiflora | 0.3 | 15.6 | 40.7 | 49.4 | 62.2 |

| Pinus koraiensis | 0.4 | 0.2 | 22.8 | 39.0 | 45.5 |

| Species | 5 kW/m2 | 10 kW/m2 | 15 kW/m2 | 20 kW/m2 | 25 kW/m2 |

|---|---|---|---|---|---|

| Larix kaempferi |  |  |  |  |  |

| Pinus densiflora |  |  |  |  |  |

| Pinus koraiensis |  |  |  |  |  |

| Species | 5 kW/m2 | 10 kW/m2 | 15 kW/m2 | 20 kW/m2 | 25 kW/m2 |

|---|---|---|---|---|---|

| Larix kaempferi | - | - | - | 5.5 mm | 7.5 mm |

| Pinus densiflora | - | 3.5 mm | 5.0 mm | 8.0 mm | 11.0 mm |

| Pinus koraiensis | - | - | 7.5 mm | 11.5 mm | 13.5 mm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, J.-Y.; Hong, S.-I.; Chio, Y.-J.; An, J.-H. Comparative Study on the Combustion Characteristics of Korean Wood with Changes in the Radiant Heat. Sustainability 2025, 17, 8360. https://doi.org/10.3390/su17188360

Park J-Y, Hong S-I, Chio Y-J, An J-H. Comparative Study on the Combustion Characteristics of Korean Wood with Changes in the Radiant Heat. Sustainability. 2025; 17(18):8360. https://doi.org/10.3390/su17188360

Chicago/Turabian StylePark, Ji-Young, Seong-In Hong, Yun-Jeong Chio, and Jae-Hong An. 2025. "Comparative Study on the Combustion Characteristics of Korean Wood with Changes in the Radiant Heat" Sustainability 17, no. 18: 8360. https://doi.org/10.3390/su17188360

APA StylePark, J.-Y., Hong, S.-I., Chio, Y.-J., & An, J.-H. (2025). Comparative Study on the Combustion Characteristics of Korean Wood with Changes in the Radiant Heat. Sustainability, 17(18), 8360. https://doi.org/10.3390/su17188360