Innovation in Vertical Farming: A Model-Based Energy Assessment and Performance Comparison of Adaptive Versus Standard Systems

Abstract

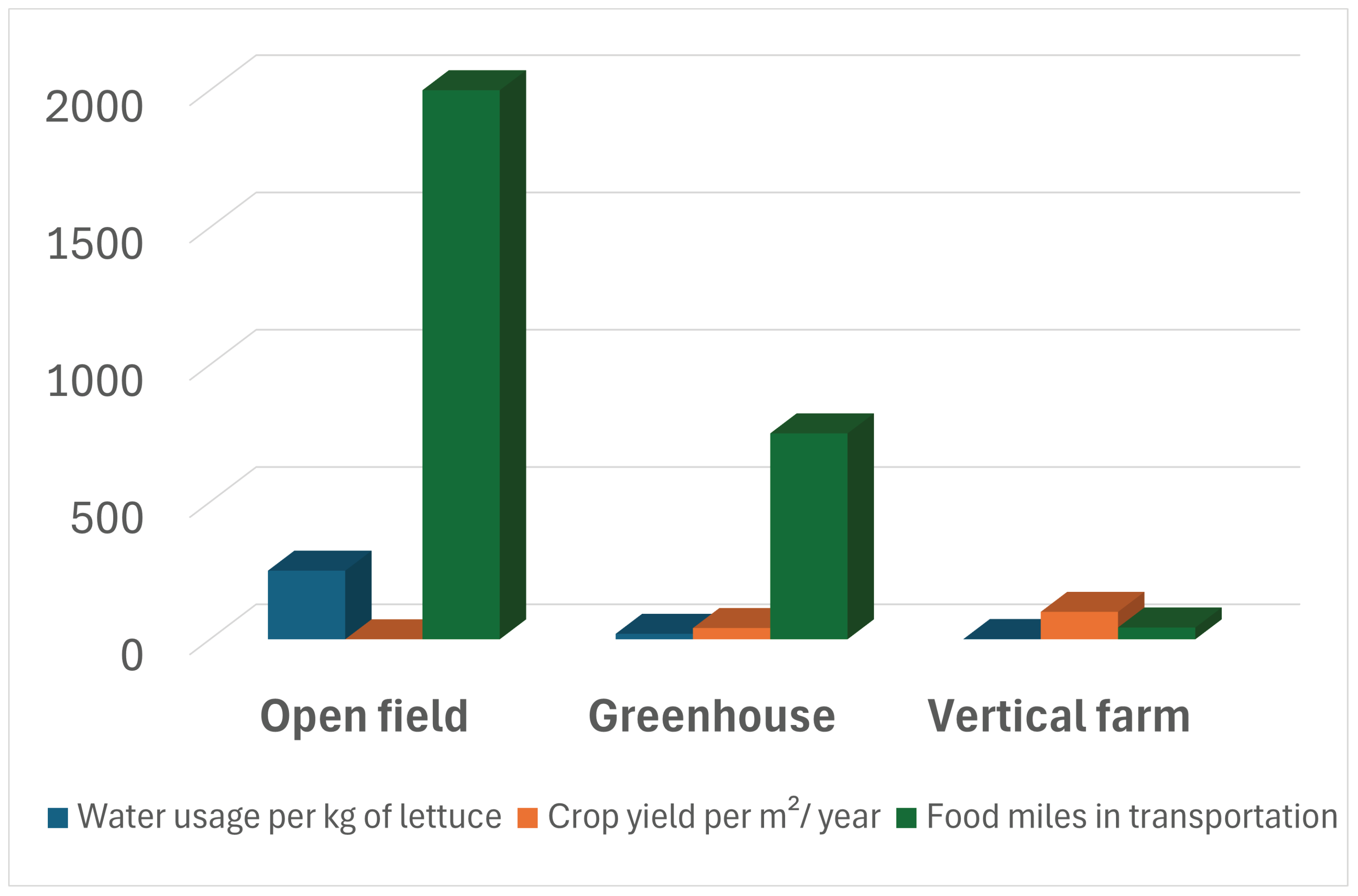

1. Introduction

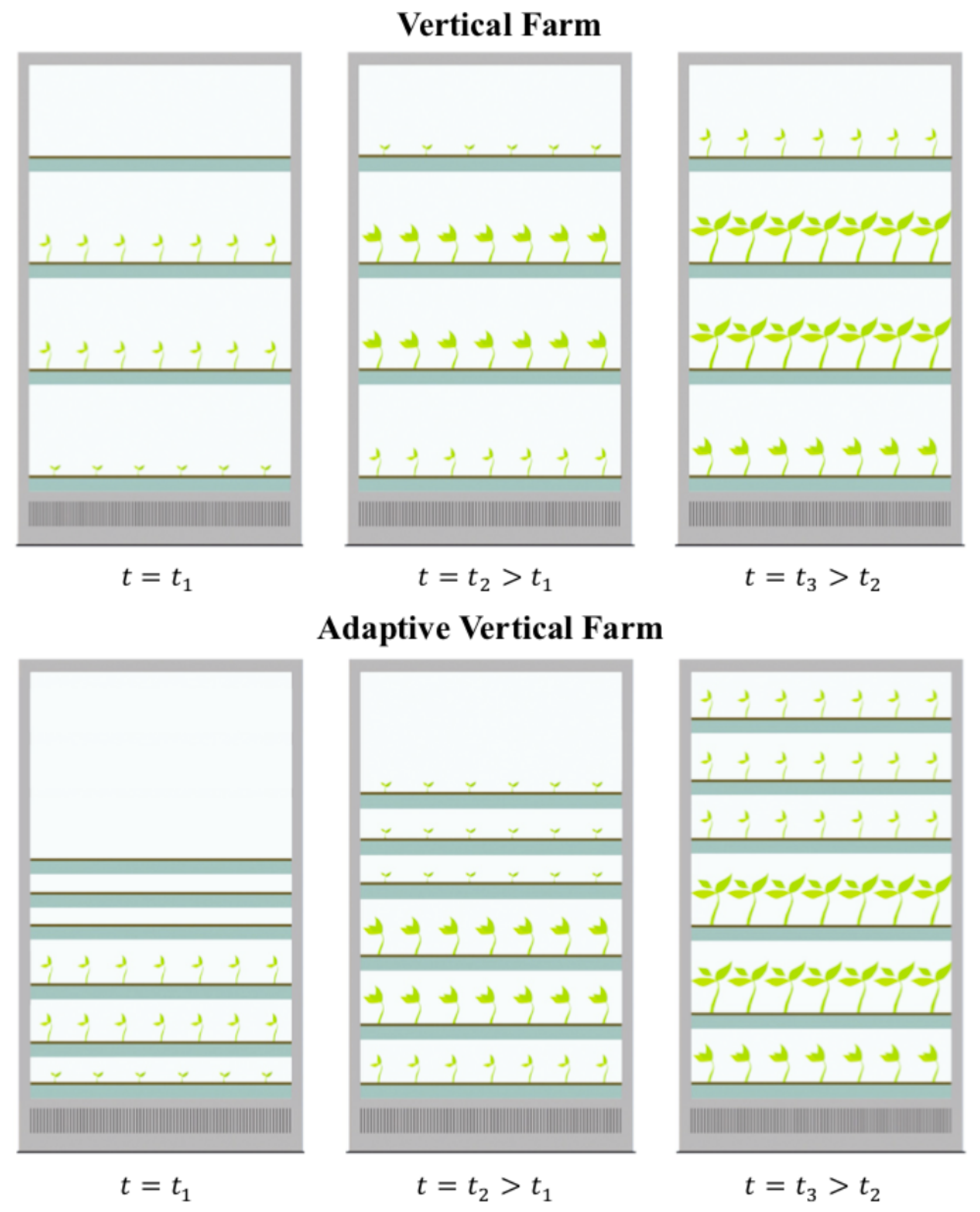

Adaptive Vertical Farm, a New Perspective

2. Description of Adaptive Vertical Farm Technology

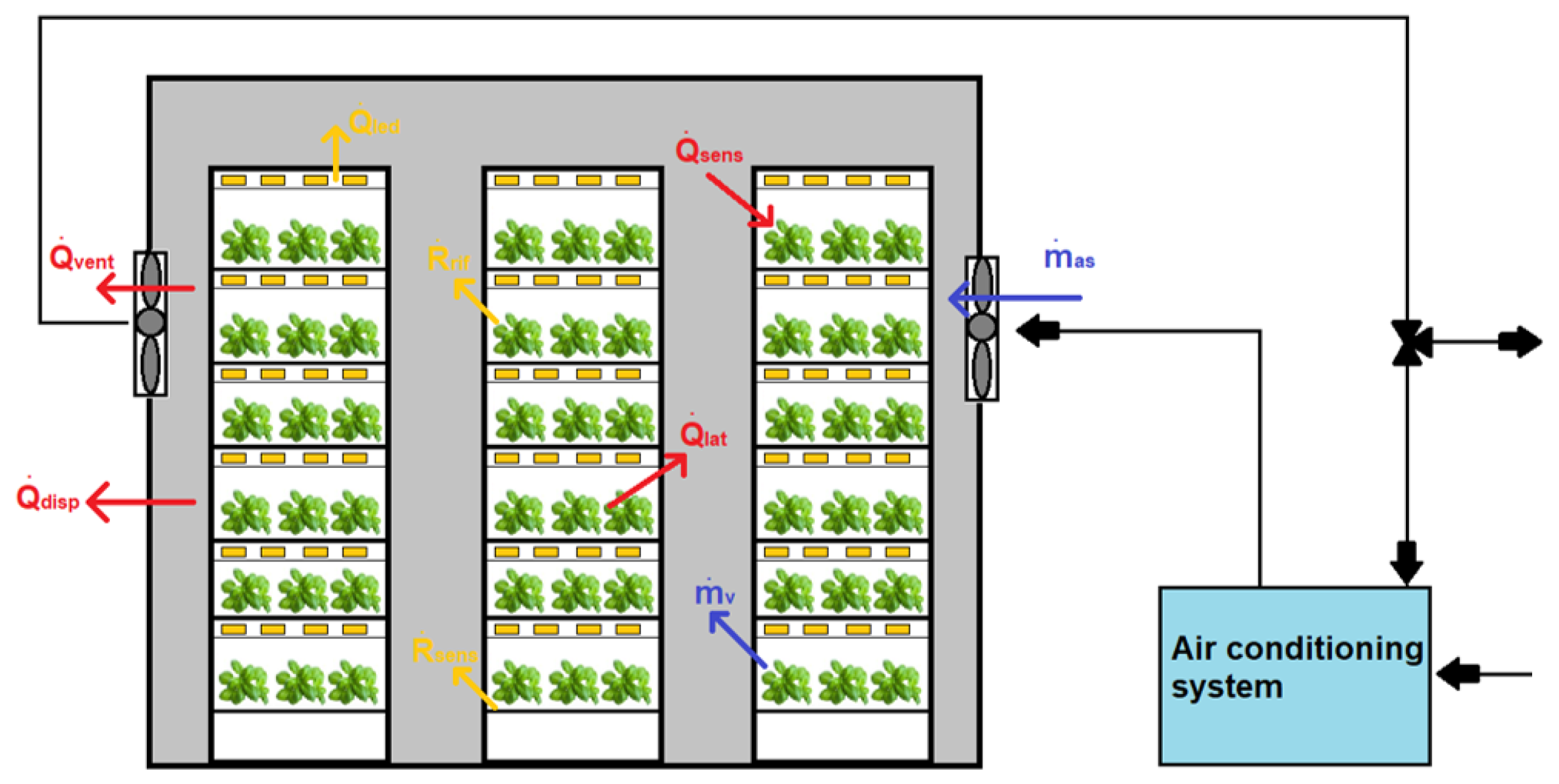

Air Conditioning System

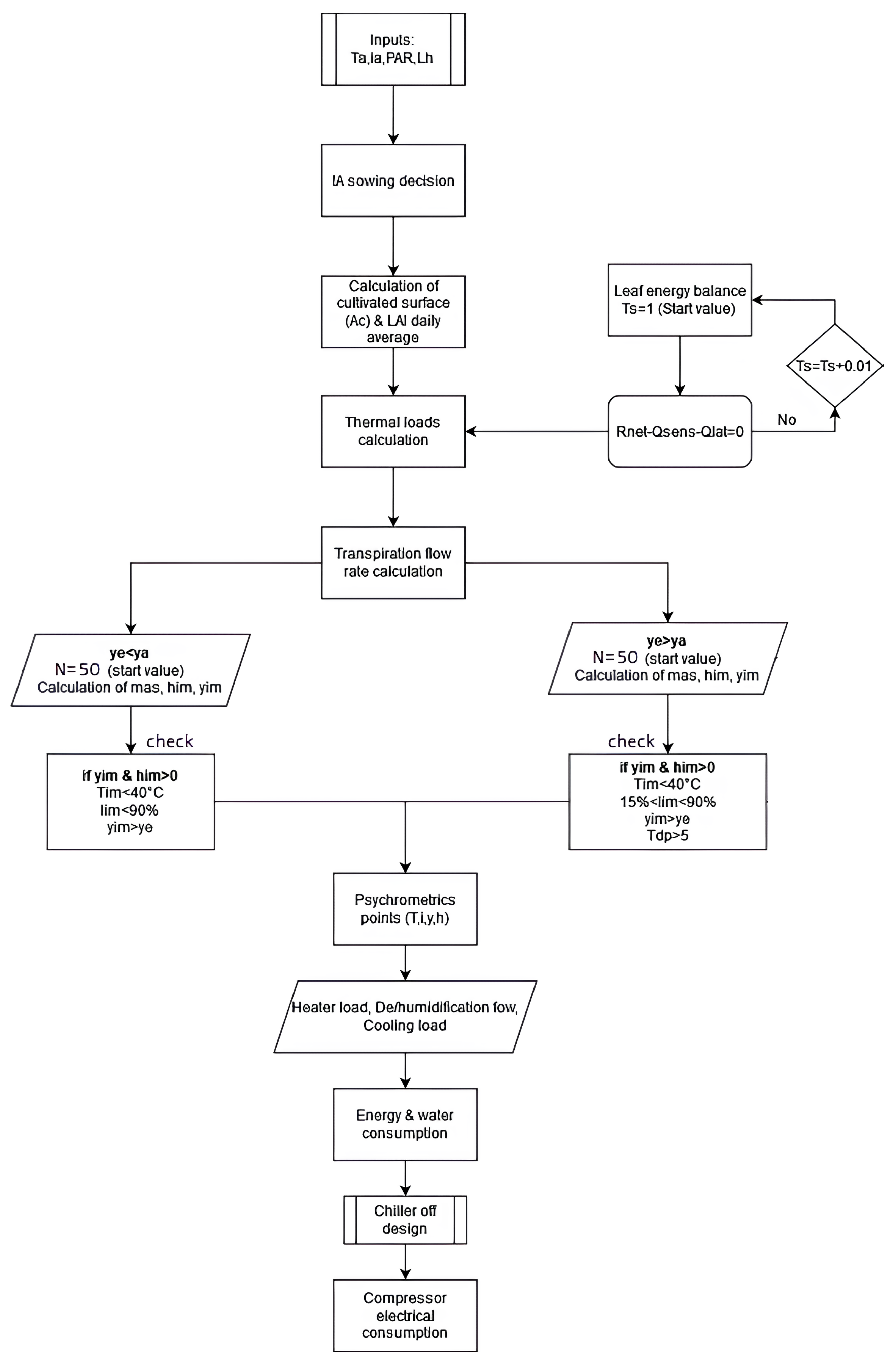

3. Description of the Calculation Model

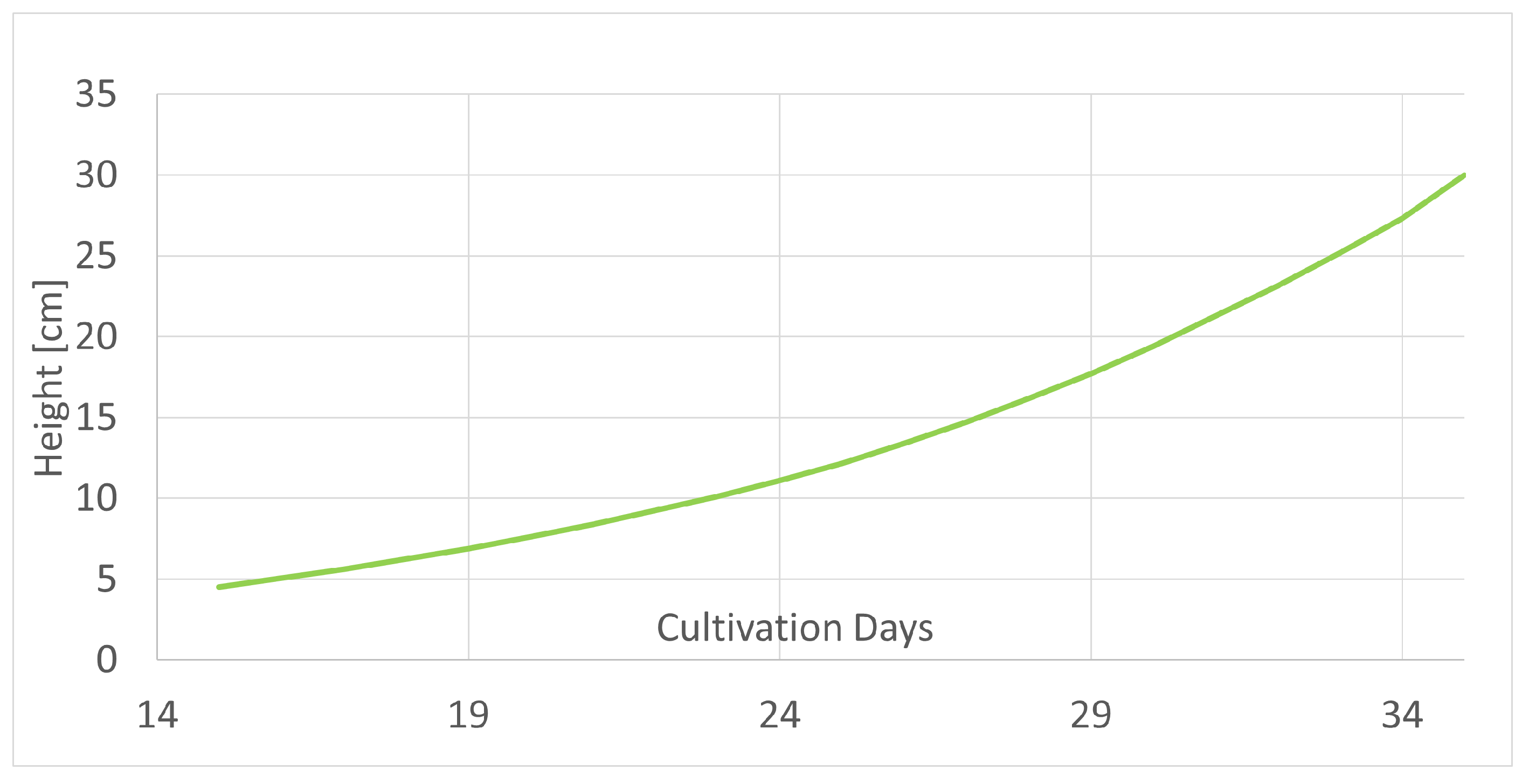

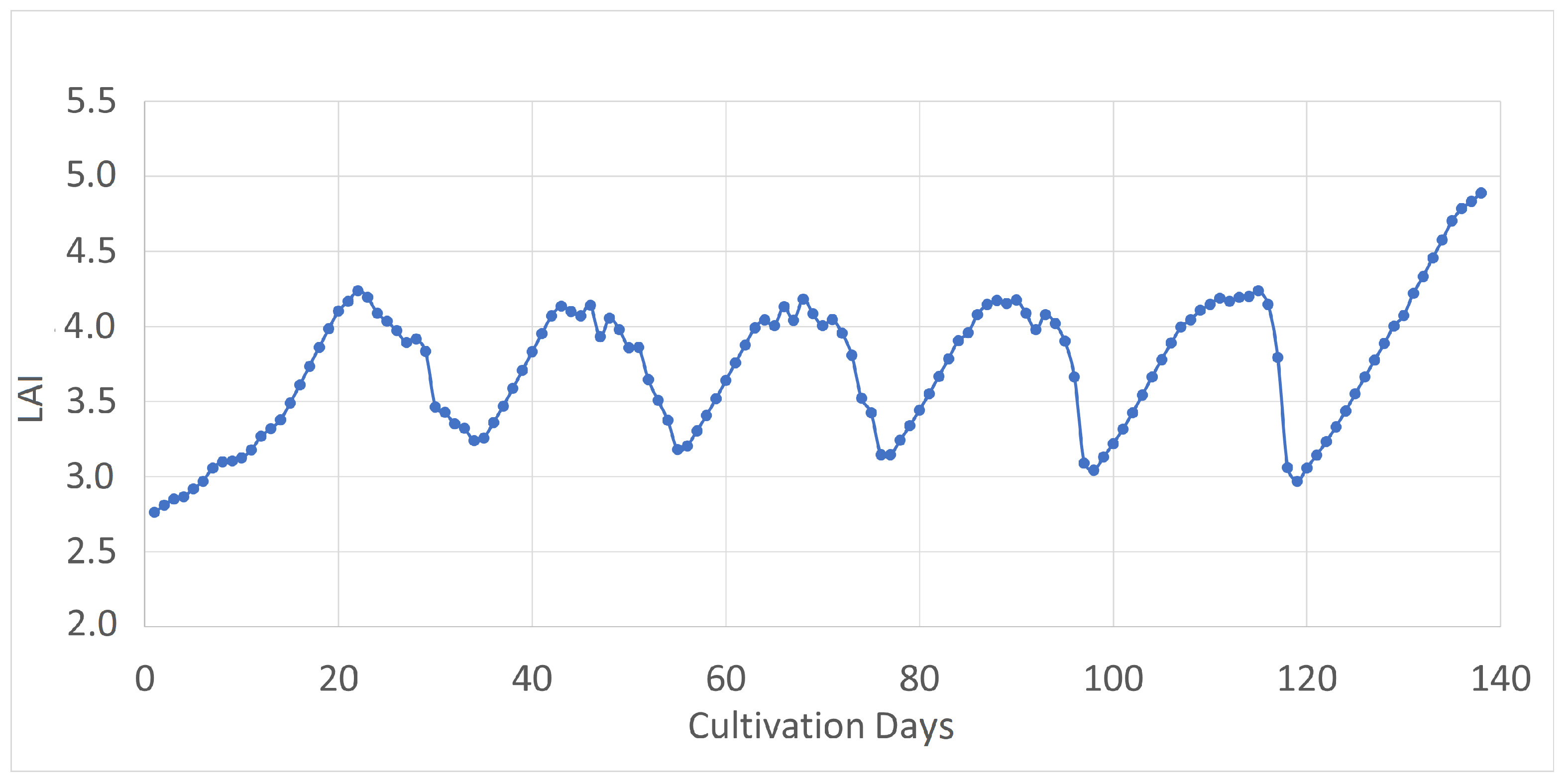

3.1. Transpiration Model

- is the radiation absorbed by a leaf and it is a function of the number of leaves and their arrangement. It can be expressed aswhere is the reflection coefficient of the leaves, typically in the range [0.05–0.08], cf. [32]; (photosynthetically active radiation [33] [W/m2] is the radiation available for the photosynthesis process to work; and is the leaf area index, a parameter indicating leaf area in relation to cultivated area.

- is the sensible heat flux exchanged between the leaves and the environment, determined by the fact that the temperature of the leaves is different from the temperature of the air around them . It can be expressed aswhere [kg/m3] is the density of air evaluated at , [kJ/kgK] is the specific heat of the air evaluated at , and [s/m] is the aerodynamic resistance to the passage of heat and diffusion of water. For , Fuchs, ref. [34] proposed a method that integrates the mean leaf diameter (l), the uninhibited air speed () and :with l [m] being the average leaf size and [m/s] being the air velocity lapping the leaf. The aerodynamic boundary layer resistance influences the transfer of sensible heat and water vapor from the leaf surface into the surrounding air. It is made with the resistance to momentum transfer [35,36]. It has been shown, e.g., Stanghellini [26], that the transpiration of crops is only minimally dependent on the aerodynamic resistance of the boundary layer (as a consequence of thermal feedback). It is practical, however, to formulate standardized values for preliminary calculations for simplicity. An of 3 [37,38] and a mean leaf size of 0.11 m [39] can be used for predictive, static calculations. Near the leaf surface, it is better to have low air speeds to avoid excessive mechanical stress. Considering an air velocity between the leaves of 0.15 m/s, we obtain a value of ra equal to 100 s/m.

- is the latent heat flux due to the mass exchange of water between the leaves and the air. It can be expressed aswhere [kJ/kg] is the latent heat of vaporization of water, [gv/m3] is the concentration of vapor in moist air under saturation conditions at temperature , is the vapor concentration in the humid air under conditions of temperature and humidity , and is the resistance of the stoma to vapor diffusion, which can be expressed as [25]where [/m2s] is the density of the photosynthetic photon flux on the surface, i.e., photons with wavelengths in the 400–700 nm spectrum. Wang et al. [40] found that different R/B ratios (red light to blue light) in particular influence the of lettuce and illustrate the response of stomatal conductance to irradiance.Given the latent heat flux , the flow rate of water evaporated by the leaves is computed by

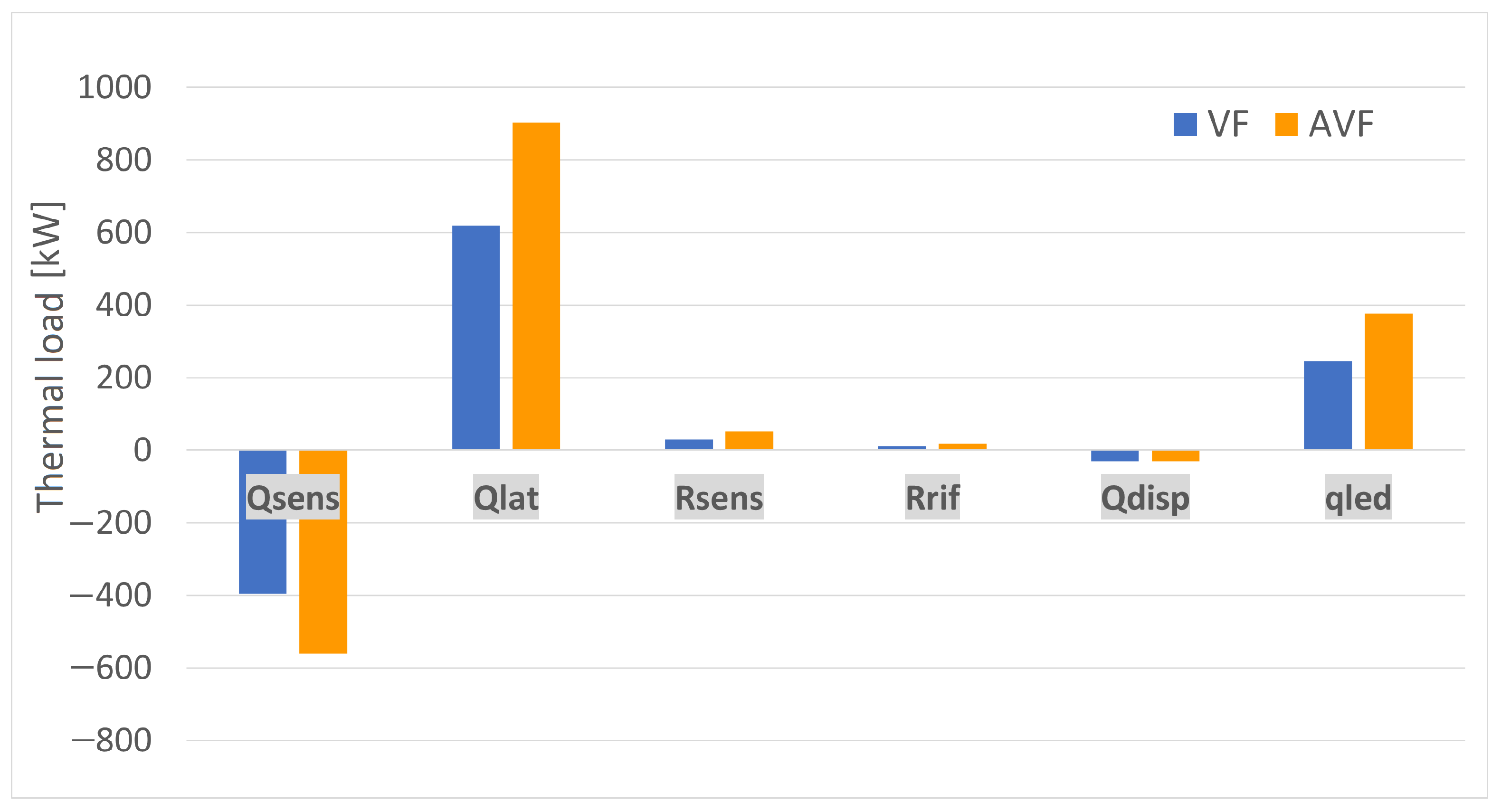

3.2. Energy and Mass Balances

- is the contribution related to heat exchange through the shell of the structure, and is given bywhere K is walls thermal transmittance, assumed to be 0.4 [W/m2K], the dispersing surface to the outside [m2], is the dispersing surface to the ground [m2], and n is the number of dispersing surfaces.

- is the contribution related to plant evapotranspiration and is defined as follows:where is the cultivated surface, expressed in m2.

- is a contribution related to artificial lighting, specifically the heat flux that reaches the ground through radiation. It is assumed that this heat flux becomes sensible flux:where is a portion of covered by the canopy, expressed in m2.

- is another contribution related to LED illumination; it refers to the heat flux that, arriving on the leaves through radiation, is reflected by the leaf surface, and is given by

- is the last contribution related to artificial lighting. The term is the heat dissipated by LEDs, due to their non-unitary efficiency:where is the led efficiency, assumed equal to 0.52 ([44]).

- is a contribution related to air exchange within the shellwhere N is the number of air changes per hour [h−1], is the conditioned volume [m3], and is the enthalpy variation [kJ/kgK].The conditioned volume is given by the base area of 1358 m2 multiplied by the height of the structure (6.5 m). It is assumed that the 272 racks occupy a portion of this volume equal to 35% in the traditional vertical farm and 40% in AVF. As the air handling system is an HVAC system, the term is included inwhere is the air flow rate processed by the system [kg/s], is the enthalpy content of indoor thermohygrometric conditions [kJ/kgK], and is the enthalpy content of inlet thermohygrometric conditions [kJ/kgK].

- is a contribution related to the sensible flux that the leaf exchanges with the environment:

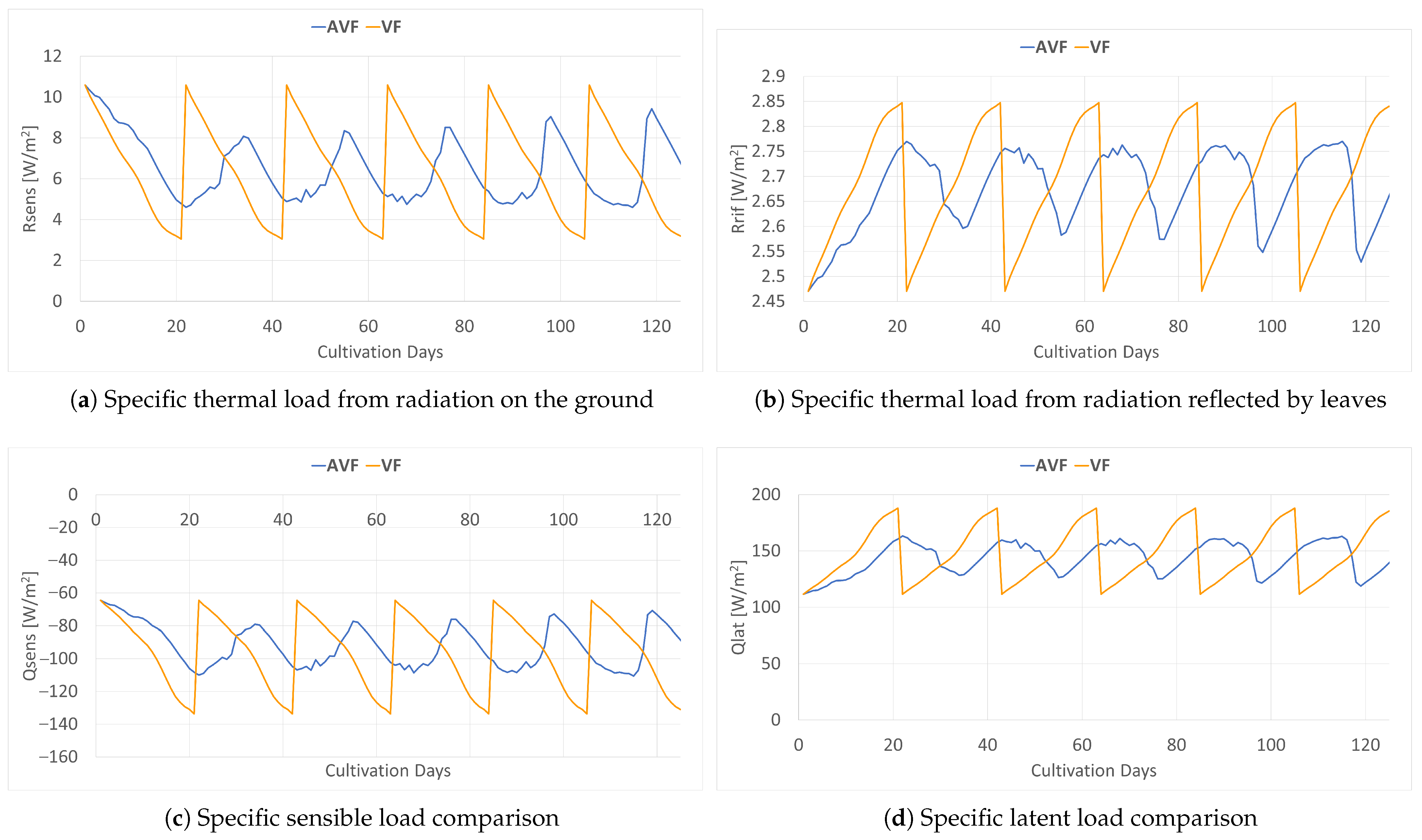

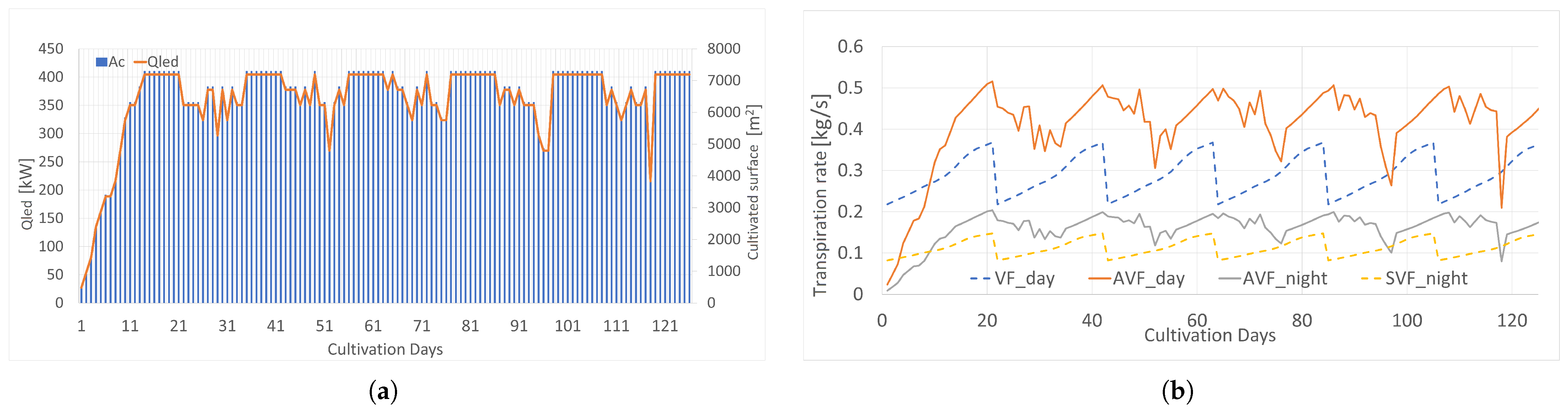

4. Thermal Loads and Humidity

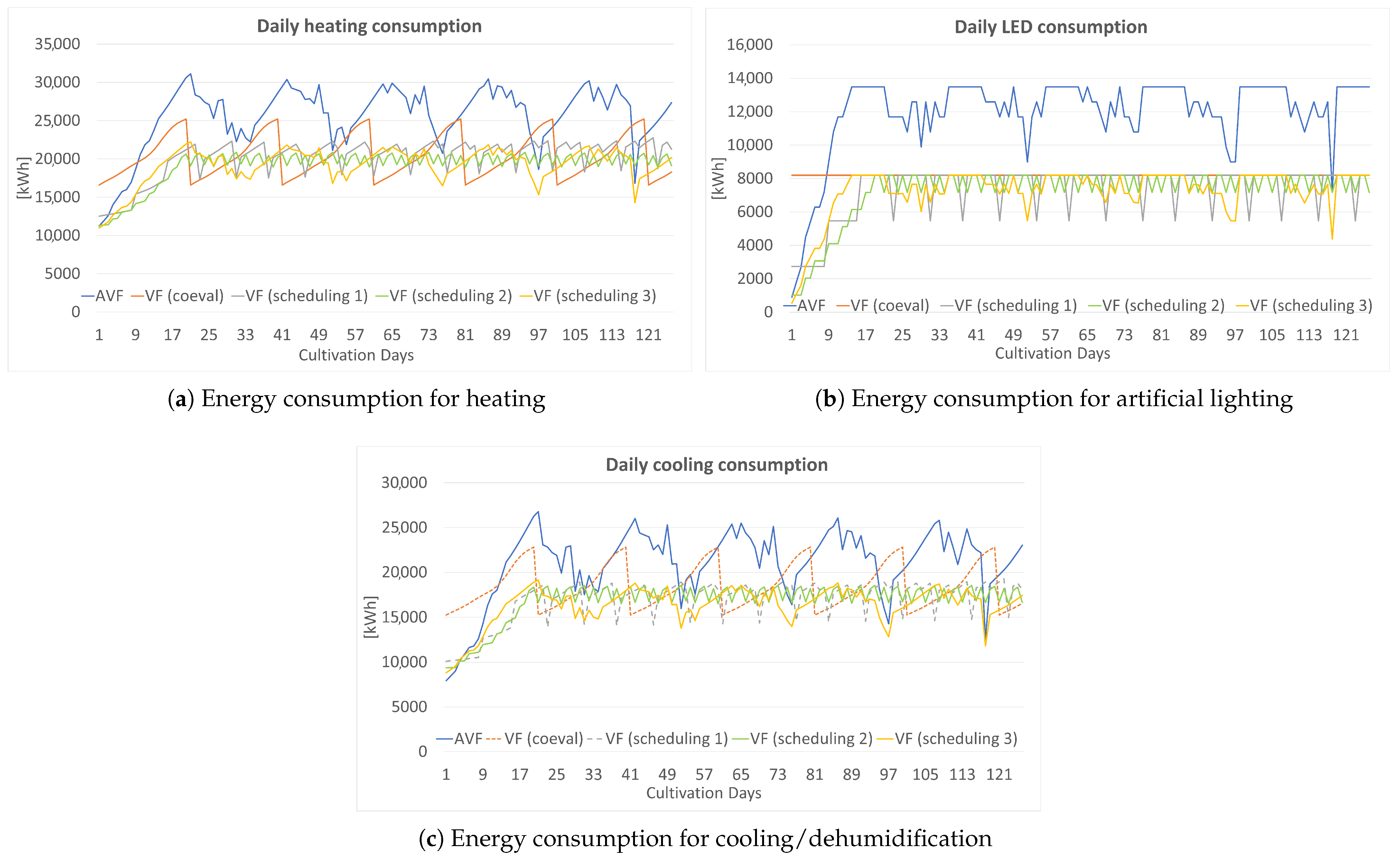

5. Results and Discussion

5.1. General Approach to Other Scenarios

- Coeval transplant: All transplantation takes place in one day.

- Scheduling 1: Transplantation takes place so that the VF is 1/3 filled every week.

- Scheduling 2: The algorithm used to decide the transplantation days is the same as in AVF but with only 8 shelves.

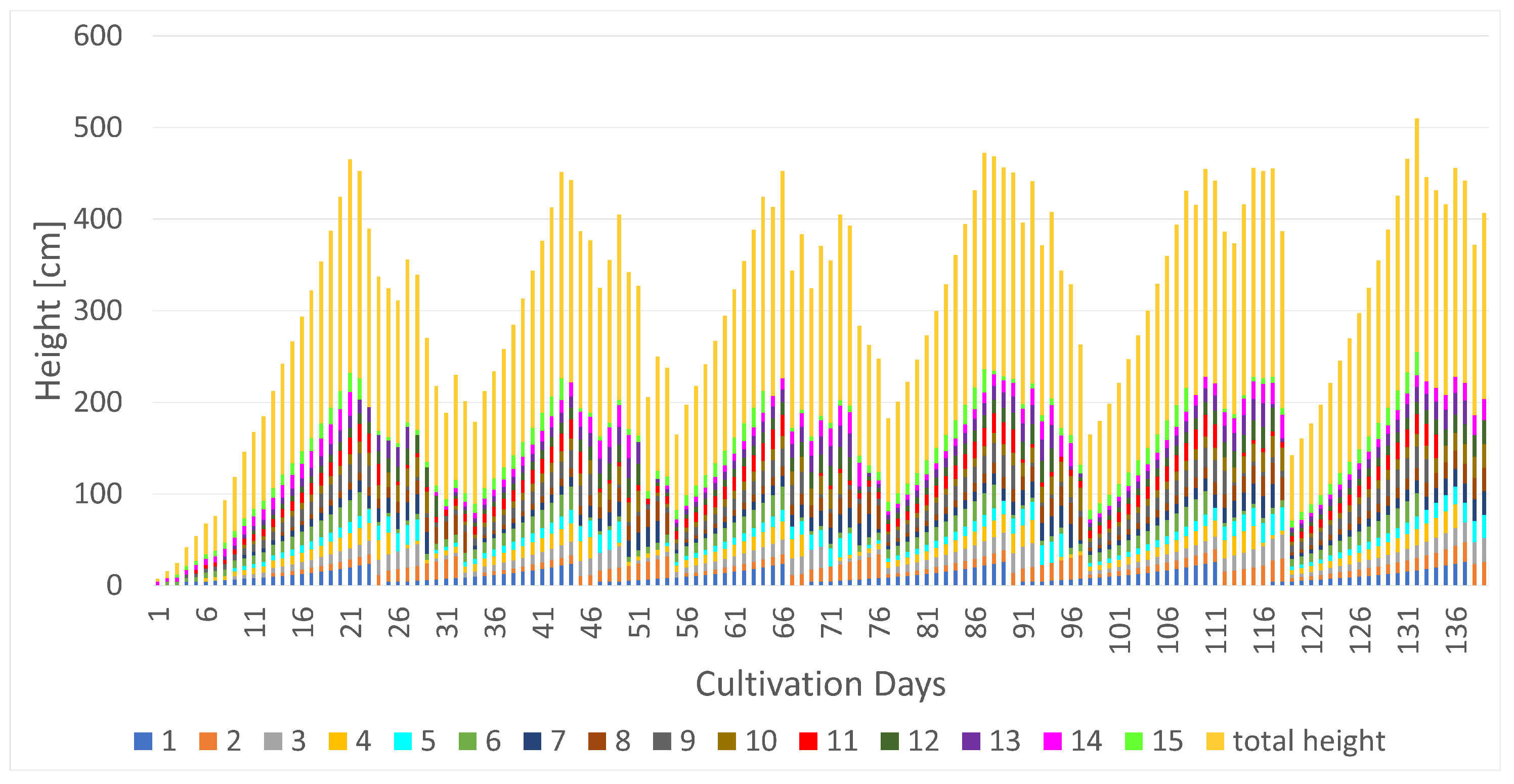

- Scheduling 3: The algorithm used to decide the transplantation days is the same as in AVF; in this case, the racks are divided into 15 groups: 13 groups of 18 racks and 2 groups of 19 racks. In this case, the algorithm decide by group and not by shelves.

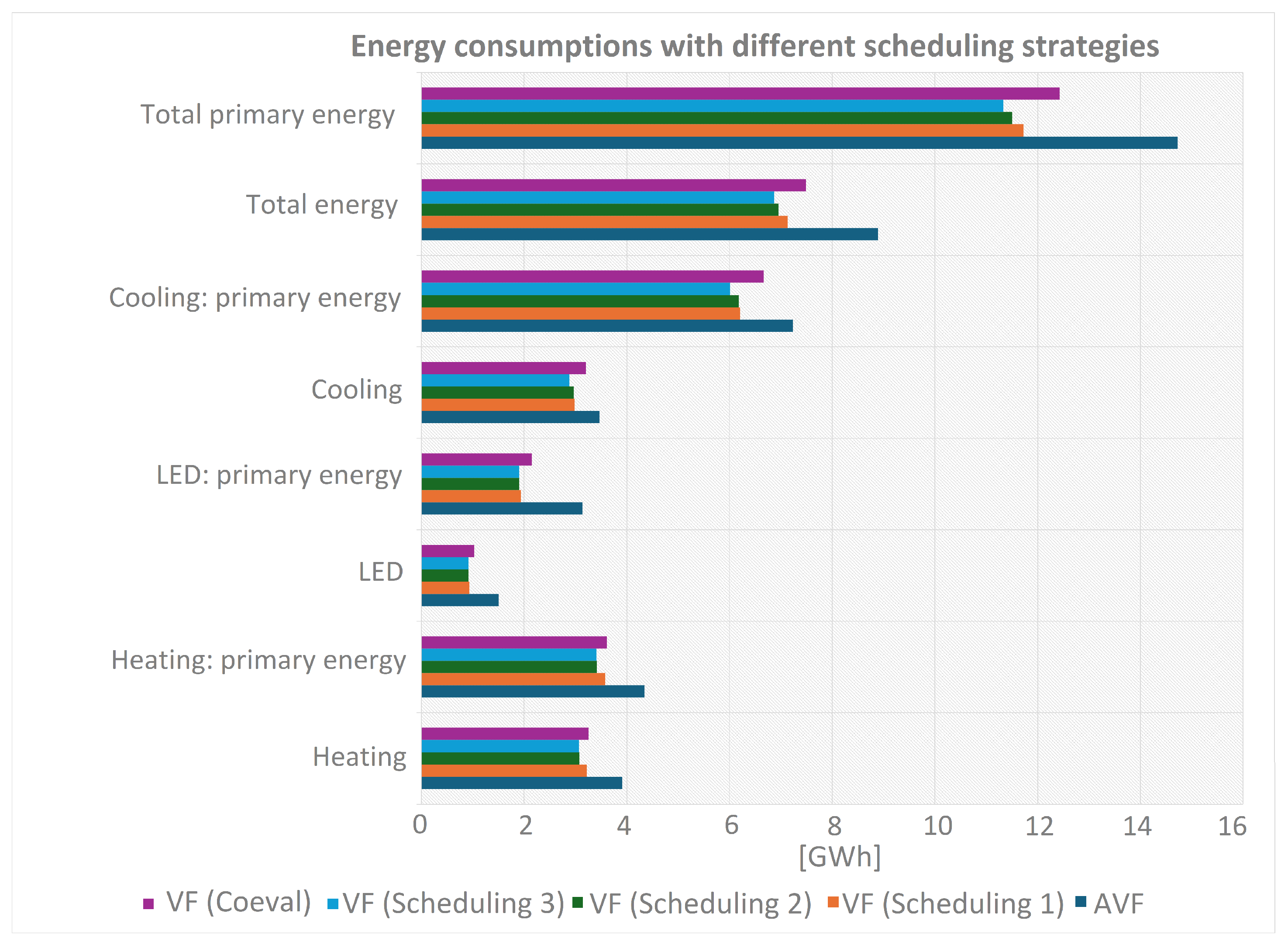

5.2. Energy Consumption for Air Conditioning

- Scheduling 1: AVF energy saving is 24%.

- Scheduling 2: AVF energy saving is 22%.

- Scheduling 3: AVF energy saving is 21%.

- Coeval: AVF energy saving is 28%.

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Symbol | Description | Unit |

| Ground surface | m2 | |

| Surface covered by the canopy | m2 | |

| Cultivated area | m2 | |

| COP | Coefficient of performance | - |

| Specific heat capacity | J kg−1 K−1 | |

| Cultivation day | - | |

| h | Specific enthalpy | J kg−1 |

| i | Relative humidity | % |

| K | Thermal transmittance | W m−2 K−1 |

| l | Average leaf size | |

| Leaf area index | - | |

| Light hours | ||

| Dry air flow rate | kg s−1 | |

| Transpiration flow rate | kg s−1 | |

| N | Number of air changes | h−1 |

| Photosynthetically active radiation | W m−2 | |

| Photosynthetic photon flux density | μmol m−2 s−1 | |

| Dispersed heat flux | ||

| Required heat flow | ||

| Latent heat flux | ||

| Latent specific heat flux | W m−2 | |

| LED dissipated heat flux | ||

| Sensible heat flux | ||

| Sensible specific heat flux | W m−2 | |

| Ventilation heat flow | ||

| Radiation absorbed by leaves | W m−2 | |

| LED reflected radiation | ||

| LED radiation on the ground | ||

| Aerodynamic resistance to heat transfer | s m−1 | |

| Resistance of the stoma to vapor diffusion | s m−1 | |

| T | Temperature | °C |

| u∞ | Air velocity near the leaf | m s−1 |

| Conditioned volume | ||

| v | Specific volume | m3 kg−1 |

| y | Absolute humidity | kg kg−1 |

| Difference in h | J kg−1 | |

| Leaf reflection coefficient | - | |

| Density | kg m−3 | |

| LED efficiency | - | |

| Latent heat of vaporization of water | J kg−1 | |

| Vapor concentration in humid air | kg m−3 |

References

- Erekath, S.; Seidlitz, H.; Schreiner, M.; Dreyer, C. Food for future: Exploring cutting-edge technology and practices in vertical farm. Sustain. Cities Soc. 2024, 106, 105357. [Google Scholar] [CrossRef]

- Kabir, M.S.N.; Reza, M.N.; Chowdhury, M.; Ali, M.; Samsuzzaman; Ali, M.R.; Lee, K.Y.; Chung, S.O. Technological Trends and Engineering Issues on Vertical Farms: A Review. Horticulturae 2023, 9, 1229. [Google Scholar] [CrossRef]

- Buscher, J.; Bakunowitsch, J.; Specht, K. Transformative Potential of Vertical Farming—An Urban Planning Investigation Using Multi-Level Perspective. Sustainability 2023, 15, 15861. [Google Scholar] [CrossRef]

- Elsevier. ScienceDirect. 2025. Available online: https://www.sciencedirect.com/ (accessed on 4 March 2025).

- Celestre, A.; Mina, G.; Bollani, L.; Peira, G.; Bonadonna, A. Vertical Farming as a Sustainable Alternative for Agriculture: The Italian Consumer Point of View. Biol. Life Sci. Forum 2023, 26, 35. [Google Scholar] [CrossRef]

- Al-Chalabi, M. Vertical farming: Skyscraper sustainability? Sustain. Cities Soc. 2015, 18, 74–77. [Google Scholar] [CrossRef]

- Elsoragaby, S.; Yahya, A.; Mahadi, M.R.; Nawi, N.M.; Mairghany, M. Energy utilization in major crop cultivation. Energy 2019, 173, 1285–1303. [Google Scholar] [CrossRef]

- Arabzadeh, V.; Miettinen, P.; Kotilainen, T.; Herranen, P.; Karakoc, A.; Kummu, M.; Rautkari, L. Urban vertical farming with a large wind power share and optimised electricity costs. Appl. Energy 2023, 331, 120416. [Google Scholar] [CrossRef]

- Cossu, M.; Tiloca, M.T.; Cossu, A.; Deligios, P.A.; Pala, T.; Ledda, L. Increasing the agricultural sustainability of closed agrivoltaic systems with the integration of vertical farming: A case study on baby-leaf lettuce. Appl. Energy 2023, 344, 121278. [Google Scholar] [CrossRef]

- Stanghellini, C.; Katzin, D. The dark side of lighting: A critical analysis of vertical farms’ environmental impact. J. Clean. Prod. 2024, 458, 142359. [Google Scholar] [CrossRef]

- Liu, J.; Oita, A.; Hayashi, K.; Matsubae, K. Sustainability of Vertical Farming in Comparison with Conventional Farming: A Case Study in Miyagi Prefecture, Japan, on Nitrogen and Phosphorus Footprint. Sustainability 2022, 14, 42. [Google Scholar] [CrossRef]

- Wang, C.; Han, Q.; Li, J.; Li, C.; Zou, X. YOLO-BLBE: A Novel Model for Identifying Blueberry Fruits with Different Maturities Using the I-MSRCR Method. Agronomy 2024, 14, 658. [Google Scholar] [CrossRef]

- Gong, L.; Gao, B.; Sun, Y.; Zhang, W.; Lin, G.; Zhang, Z.; Li, Y.; Liu, C. preciseSLAM: Robust, Real-Time, LiDAR–Inertial–Ultrasonic Tightly-Coupled SLAM With Ultraprecise Positioning for Plant Factories. IEEE Trans. Ind. Inform. 2024, 20, 8818–8827. [Google Scholar] [CrossRef]

- Blom, T.; Jenkins, A.; Pulselli, R.; Van den Dobbelsteen, A. The embodied carbon emissions of lettuce production in vertical farming, greenhouse horticulture, and open-field farming in the Netherlands. J. Clean. Prod. 2022, 377, 134443. [Google Scholar] [CrossRef]

- Naus, T. Is Vertical Farming Really Sustainable. EIT Food, 2018. Available online: https://www.eitfood.eu/blog/is-vertical-farming-really-sustainable (accessed on 18 July 2022).

- Bagnerini, P.; Gaggero, M.; Ghio, M.; Malerba, F.; Malerba, M. Adaptive Vertical Farm for Fresh Food Production in Orbital Stations and Future Lunar Settlements. In Proceedings of the 2022 IEEE 9th International Workshop on Metrology for AeroSpace (MetroAeroSpace), Pisa, Italy, 27–29 June 2022; pp. 402–407. [Google Scholar]

- Bagnerini, P.; Gaggero, M.; Ghio, M.; Malerba, F. The Adaptive Vertical Farm as an Efficient Tool for the Cultivation of Multiple Crops in Space. In Proceedings of the 2023 IEEE 10th International Workshop on Metrology for AeroSpace (MetroAeroSpace), Milan, Italy, 19–21 June 2023. [Google Scholar]

- Bagnerini, P.; Gaggero, M.; Ghio, M. Mixed-Integer Linear Programming for the Scheduling of Seedings in an Industrial Adaptive Vertical Farm. In Proceedings of the 2023 IEEE 19th International Conference on Automation Science and Engineering (CASE), Auckland, New Zealand, 26–30 August 2023. [Google Scholar]

- Germina S.r.l. Available online: https://www.germina.bio (accessed on 4 March 2025).

- Ghio, M. System for the Vegetable Garden and Nursery Cultivation of Plants. Italian Patent Number 12120995, 22 October 2024. [Google Scholar]

- Orsini, F. Sistemi per Vertical Farming: Valutazione Tecnico-Economica dell’Adozione del Sistema Adattivo Germina; Technical Report; Department of Agricultural Sciences, University of Bologna; Unpublished; 2022. [Google Scholar]

- Huang, Z.; Du, X.; Castillo, C.S.Z. How does urbanization affect farmland protection? Evidence from China. Resour. Conserv. Recycl. 2019, 145, 139–147. [Google Scholar] [CrossRef]

- Wall, D.H.; Nielsen, U.N.; Six, J. Soil biodiversity and human health. Nature 2015, 528, 69–76. [Google Scholar] [CrossRef] [PubMed]

- Arcasi, A.; Mauro, A.; Napoli, G.; Tariello, F.; Vanoli, G. Energy and cost analysis for a crop production in a vertical farm. Appl. Therm. Eng. 2024, 239, 122129. [Google Scholar] [CrossRef]

- Graamans, L.; van den Dobbelsteen, A.; Meinen, E.; Stanghellini, C. Plant factories; crop transpiration and energy balance. Agric. Syst. 2017, 153, 138–147. [Google Scholar] [CrossRef]

- Stanghellini, C. Transpiration of Greenhouse Crops: An Aid to Climate Management; Wageningen University and Research: Wageningen, The Netherlands, 1987. [Google Scholar]

- Brouwer, C.; Heibloem, M. Irrigation water management: Irrigation water needs. Train. Man. 1986, 3, 1–5. [Google Scholar]

- Monteith, J.L. Evaporation and environment. In Symposia of the Society for Experimental Biology; Cambridge University Press: Cambridge, UK, 1965; Volume 19, pp. 205–234. [Google Scholar]

- Weidner, T.; Yang, A.; Hamm, M.W. Energy optimisation of plant factories and greenhouses for different climatic conditions. Energy Convers. Manag. 2021, 243, 114336. [Google Scholar] [CrossRef]

- Arcasi, A.; Mastrullo, R.; Mauro, A.; Pantaleo, A. State of the Art of Evapotranspiration Models for Plant Cultivation in Open Fields, Greenhouse Systems and Plant Factories. J. Phys. Conf. Ser. 2022, 2385, 012002. [Google Scholar] [CrossRef]

- Gates, D.M. Energy, plants, and ecology. Ecology 1965, 46, 1–13. [Google Scholar] [CrossRef]

- Frantz, J.M.; Ritchie, G.; Cometti, N.N.; Robinson, J.; Bugbee, B. Exploring the limits of crop productivity: Beyond the limits of tipburn in lettuce. J. Am. Soc. Hortic. Sci. 2004, 129, 331–338. [Google Scholar] [CrossRef]

- Alados, I.; Foyo-Moreno, I.; Alados-Arboledas, L. Photosynthetically active radiation: Measurements and modelling. Agric. For. Meteorol. 1996, 78, 121–131. [Google Scholar] [CrossRef]

- Fuchs, M. Transpiration and foliage temperature in a greenhouse. In Proceedings of the International Workshop on Cooling Systems for Greenhouses, Tel Aviv, Israel, 2–5 May 1993; pp. 89–98. [Google Scholar]

- Perrier, A. Étude physique de l’évapotranspiration dans les conditions naturelles. III. Évapotranspiration réelle et potentielle des couverts végétaux. Ann. Agron. 1975, 26, 529–556. [Google Scholar]

- Allen, R.G.; Pereira, L.S.; Raes, D.; Smith, M. Crop evapotranspiration-Guidelines for computing crop water requirements-FAO Irrigation and drainage paper 56. Fao Rome 1998, 300, D05109. [Google Scholar]

- Tei, F.; Scaife, A.; Aikman, D. Growth of lettuce, onion, and red beet. 1. Growth analysis, light interception, and radiation use efficiency. Ann. Bot. 1996, 78, 633–643. [Google Scholar] [CrossRef]

- Tuzet, A.; Perrier, A.; Leuning, R. A coupled model of stomatal conductance, photosynthesis and transpiration. Plant Cell Environ. 2003, 26, 1097–1116. [Google Scholar] [CrossRef]

- Ohashi-Kaneko, K.; Takase, M.; Kon, N.; Fujiwara, K.; Kurata, K. Effect of light quality on growth and vegetable quality in leaf lettuce, spinach and komatsuna. Environ. Control Biol. 2007, 45, 189–198. [Google Scholar] [CrossRef]

- Wang, J.; Lu, W.; Tong, Y.; Yang, Q. Leaf morphology, photosynthetic performance, chlorophyll fluorescence, stomatal development of lettuce (Lactuca sativa L.) exposed to different ratios of red light to blue light. Front. Plant Sci. 2016, 7, 250. [Google Scholar] [CrossRef] [PubMed]

- Wheeler, R.; Mackowiak, C.; Sager, J.; Yorio, N.; Knott, W.; Berry, W. Growth and gas exchange by lettuce stands in a closed, controlled environment. J. Am. Soc. Hortic. Sci. 1994, 119, 610–615. [Google Scholar] [CrossRef]

- Shasteen, K.; Kacira, M. Predictive Modeling and Computer Vision-Based Decision Support to Optimize Resource Use in Vertical Farms. Sustainability 2023, 15, 7812. [Google Scholar] [CrossRef]

- Esmaili, M.; Aliniaeifard, S.; Mashal, M.; Ghorbanzadeh, P.; Mehdi, S.; Gavilan, M.U.; Carrillo, F.F.; Lastochkina, O.; Tao, L. CO2 enrichment and increasing light intensity till a threshold level, enhance growth and water use efficiency of lettuce plants in controlled environment. Not. Bot. Horti Agrobot. Cluj-Napoca 2020, 48, 2244–2262. [Google Scholar] [CrossRef]

- Royal Philips, N. Philips Horticulture LED Solutions—GreenPower LED Toplighting—High Output. Available online: https://www.lighting.philips.com/application-areas/specialist-applications/horticulture/greenpower-specialist-applications/led-toplighting (accessed on 15 September 2024).

- Chang, C.L.; Huang, Y.M.; Hong, G.F. Using a Novel Wireless-Networked Decentralized Control Scheme under Unpredictable Environmental Conditions. Sensors 2015, 15, 28690–28716. [Google Scholar] [CrossRef] [PubMed]

- Gao, H.; Tan, Z.C.; Yang, M.; Ma, C.P.; Tang, Y.F.; Zhao, F.Y. Microclimate Air Motion and Uniformity of Indoor Plant Factory System: Effects of Crop Planting Density and Air Change Rate. Appl. Sci. 2025, 15, 4329. [Google Scholar] [CrossRef]

- Okochi, G.S.; Yao, Y. A review of recent developments and technological advancements of variable-air-volume (VAV) air-conditioning systems. Renew. Sustain. Energy Rev. 2016, 59, 784–817. [Google Scholar] [CrossRef]

- Goudriaan, J.; Van Laar, H. Modelling Potential Crop Growth Processes: Textbook with Exercises; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012; Volume 2. [Google Scholar]

- Wu, T.; Liu, K.; Cheng, M.; Gu, Z.; Guo, W.; Jiao, X. Paddy Field Scale Evapotranspiration Estimation Based on Two-Source Energy Balance Model with Energy Flux Constraints and UAV Multimodal Data. Remote Sens. 2025, 17, 1662. [Google Scholar] [CrossRef]

- Balaras, C.A.; Dascalaki, E.G.; Psarra, I.; Cholewa, T. Primary energy factors for electricity production in Europe. Energies 2022, 16, 93. [Google Scholar] [CrossRef]

- Luo, J.; Zhao, C.; Chen, Q.; Li, G. Using deep belief network to construct the agricultural information system based on Internet of Things. J. Supercomput. 2022, 78, 379–405. [Google Scholar] [CrossRef]

| Feature | VF | AVF |

|---|---|---|

| Shelves per rack | 8 | 15 |

| Shelf surface | 2.04 m2 | 1.79 m2 |

| Total shelves | 2176 | 4080 |

| Cultivable area | 4439 m2 | 7303 m2 |

| Floor area | 1358 m2 | 1358 m2 |

| Increase for the same amount of land | +226% | +437% |

| Set Point | Temperature (Ta) [°C] | Relative Humidity (ia) | PAR [W/m2] | PPFD [mol/m2s] | Hours |

|---|---|---|---|---|---|

| Light | 25 | 65% | 60 | 300 | 16 h |

| Dark | 23 | 75% | 0 | 0 | 8 h |

| Coefficient | 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|---|

| a | 16.7 | 0.3033 | 0.1701 | 0.0647 | 0.02787 |

| b | 0.008718 | 0.2072 | 0.3492 | 0.5711 | 0.7886 |

| c | 0.01462 | −1.633 | 3.71 | 2.436 | 2.23 |

| Cultivation Cycles | ||||||

|---|---|---|---|---|---|---|

| Shelves | 1 | 2 | 3 | 4 | 5 | 6 |

| 1 | 4 | 25 | 47 | 69 | 91 | 117 |

| 2 | 13 | 35 | 56 | 77 | 98 | 119 |

| 3 | 9 | 30 | 51 | 72 | 98 | 119 |

| 4 | 6 | 27 | 49 | 72 | 95 | 116 |

| 5 | 9 | 30 | 54 | 75 | 98 | 119 |

| 6 | 2 | 23 | 44 | 65 | 89 | 110 |

| 7 | 10 | 34 | 55 | 76 | 97 | 119 |

| 8 | 14 | 35 | 56 | 77 | 98 | 119 |

| 9 | 4 | 27 | 49 | 70 | 92 | 113 |

| 10 | 10 | 32 | 53 | 77 | 98 | 119 |

| 11 | 5 | 26 | 47 | 70 | 91 | 114 |

| 12 | 11 | 32 | 53 | 74 | 97 | 119 |

| 13 | 8 | 32 | 53 | 74 | 96 | 117 |

| 14 | 1 | 30 | 54 | 76 | 97 | 118 |

| 15 | 3 | 24 | 45 | 67 | 88 | 112 |

| Technology | AVF | VF (Scheduling 1) | VF (Scheduling 2) | VF (Scheduling 3) | VF (Coeval) |

|---|---|---|---|---|---|

| Heating [MWh] | 3911 | 3220 | 3075 | 3070 | 3252 |

| Heating: primary energy [MWh] | 4346 | 3578 | 3417 | 3411 | 3613 |

| LED [MWh] | 1507 | 931 | 915 | 916 | 1032 |

| LED: primary energy [MWh] | 3140 | 1940 | 1906 | 1908 | 2150 |

| Cooling [MWh] | 3474 | 2980 | 2968 | 2885 | 3200 |

| Cooling: primary energy [MWh] | 7238 | 6208 | 6183 | 6010 | 6667 |

| Total energy [MWh] | 8892 | 7131 | 6958 | 6871 | 7484 |

| Total primary energy [MWh] | 14,723 | 11,726 | 11,506 | 11,330 | 12,430 |

| Total specific primary energy [MWh/m2] | 2.02 | 2.64 | 2.59 | 2.55 | 2.80 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

De Donno, A.; Tagliafico, L.A.; Bagnerini, P. Innovation in Vertical Farming: A Model-Based Energy Assessment and Performance Comparison of Adaptive Versus Standard Systems. Sustainability 2025, 17, 8319. https://doi.org/10.3390/su17188319

De Donno A, Tagliafico LA, Bagnerini P. Innovation in Vertical Farming: A Model-Based Energy Assessment and Performance Comparison of Adaptive Versus Standard Systems. Sustainability. 2025; 17(18):8319. https://doi.org/10.3390/su17188319

Chicago/Turabian StyleDe Donno, Antonio, Luca Antonio Tagliafico, and Patrizia Bagnerini. 2025. "Innovation in Vertical Farming: A Model-Based Energy Assessment and Performance Comparison of Adaptive Versus Standard Systems" Sustainability 17, no. 18: 8319. https://doi.org/10.3390/su17188319

APA StyleDe Donno, A., Tagliafico, L. A., & Bagnerini, P. (2025). Innovation in Vertical Farming: A Model-Based Energy Assessment and Performance Comparison of Adaptive Versus Standard Systems. Sustainability, 17(18), 8319. https://doi.org/10.3390/su17188319