Advancements in Energy-Storage Technologies: A Review of Current Developments and Applications

Abstract

1. Introduction

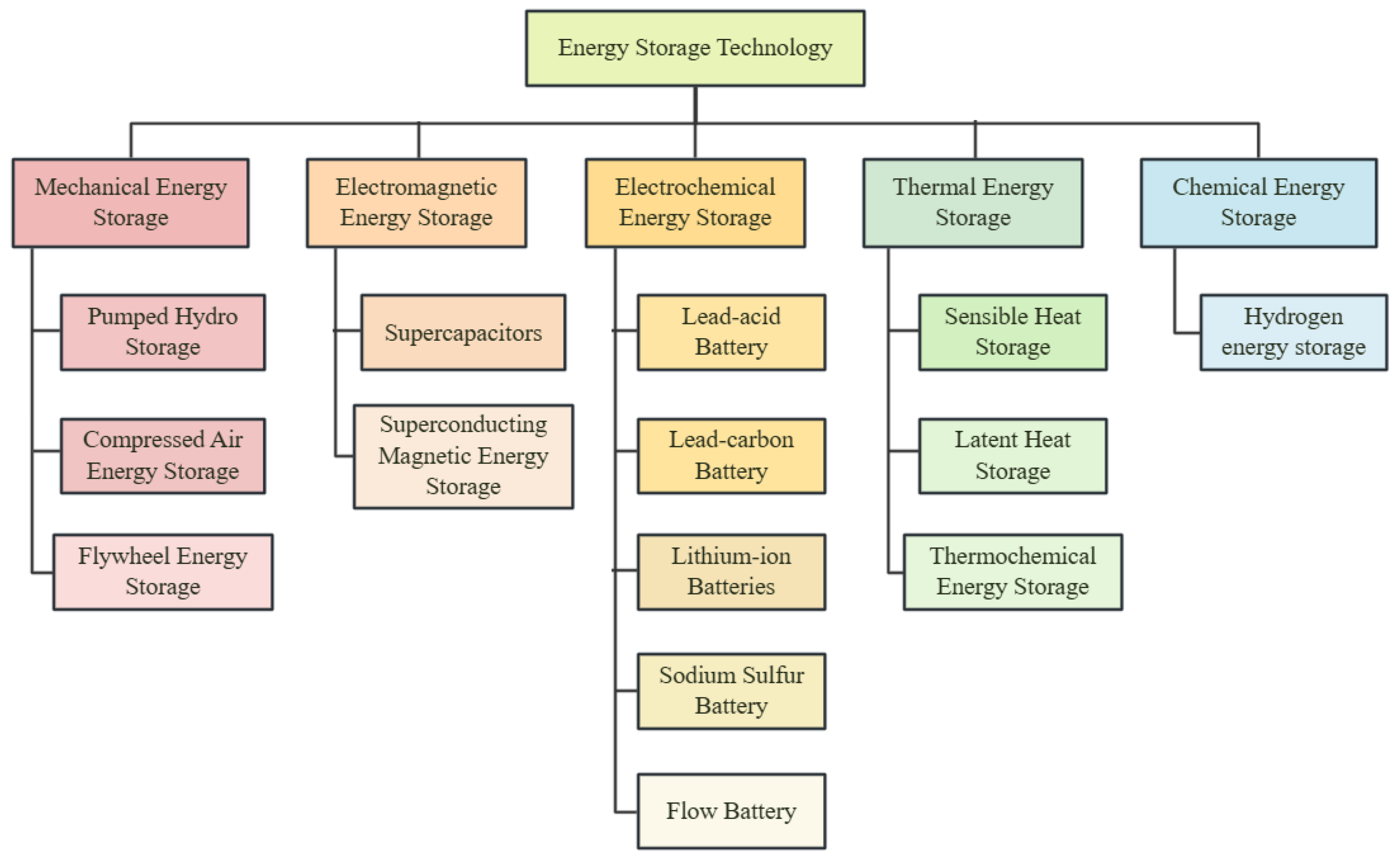

2. Types of Energy-Storage Technologies

2.1. Mechanical Energy Storage

2.1.1. Pumped Hydro Storage

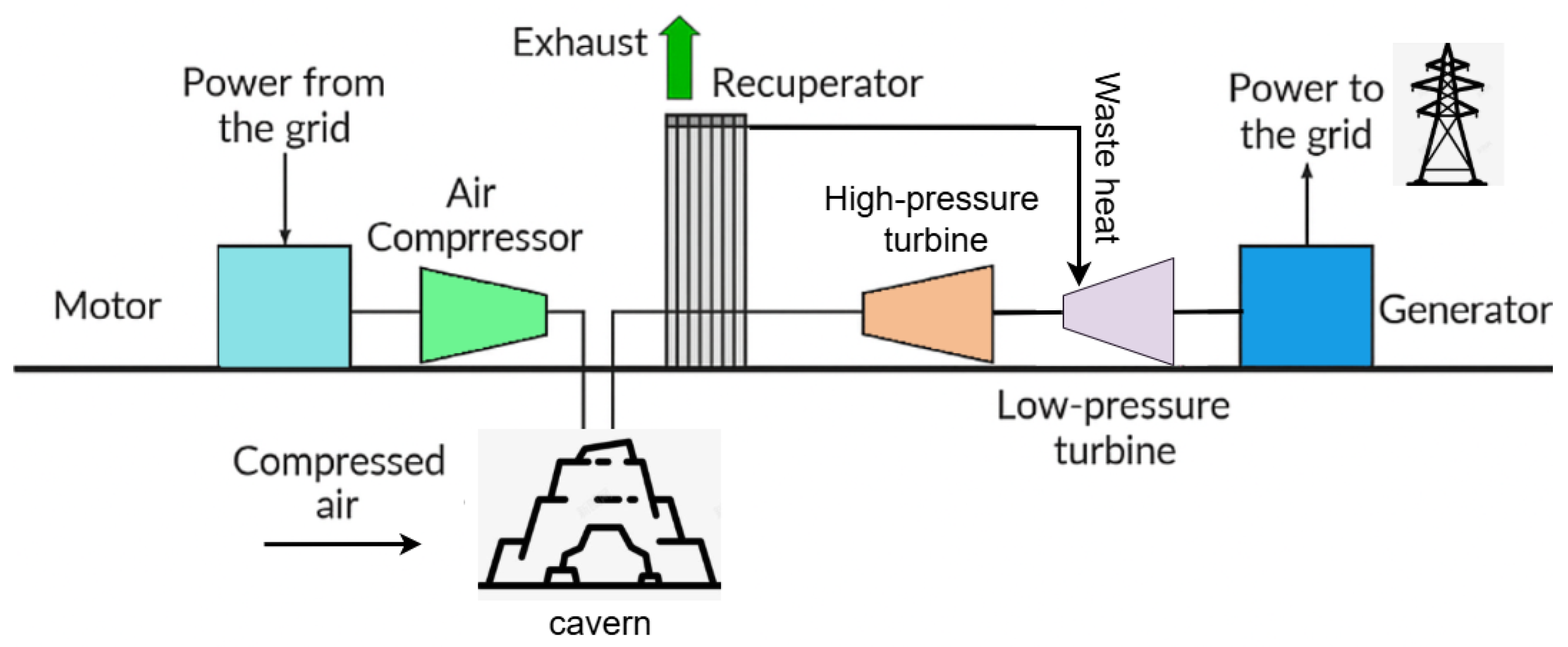

2.1.2. Compressed Air Energy Storage

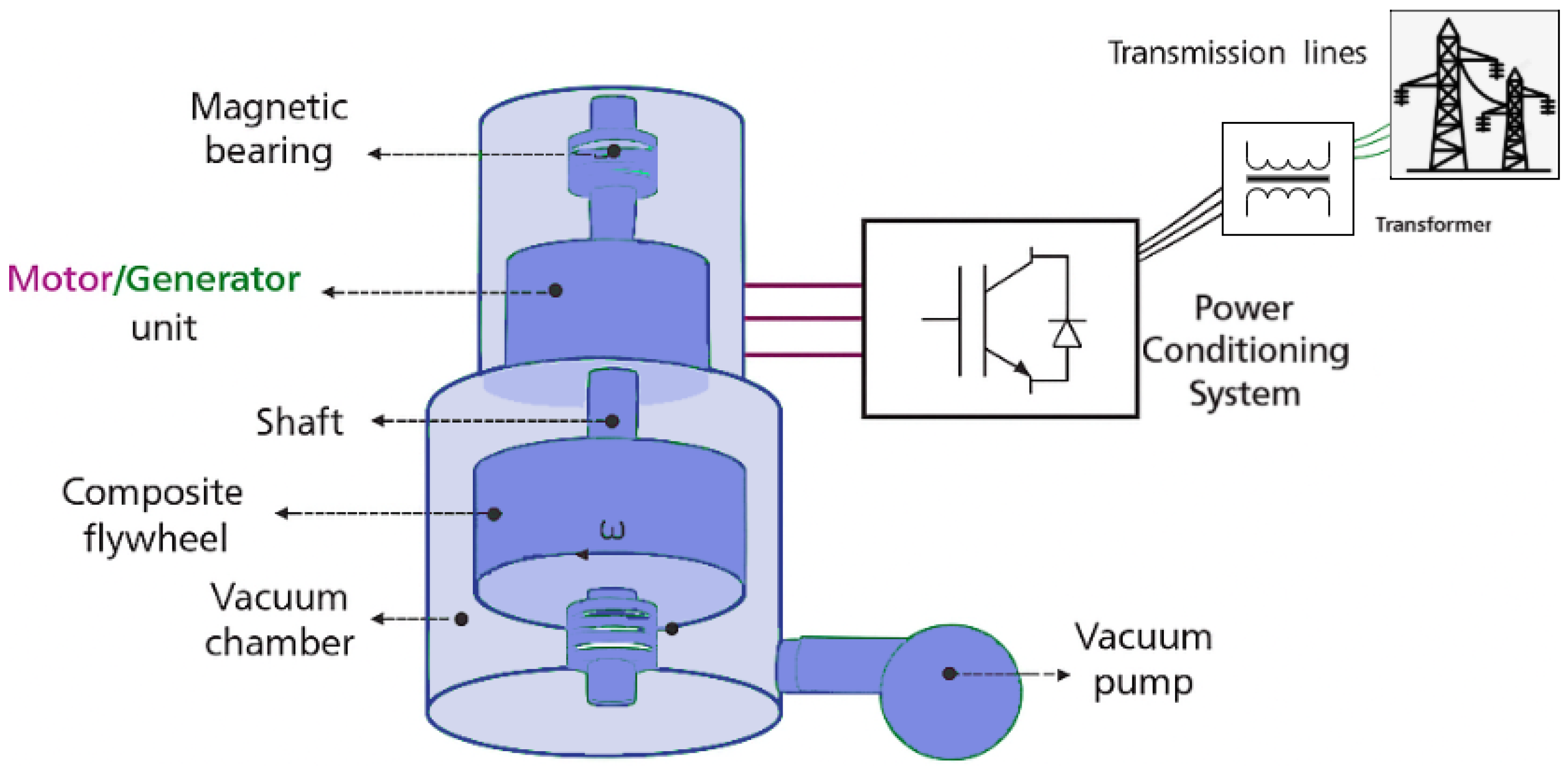

2.1.3. Flywheel Energy Storage

2.2. Electrochemical Energy Storage

2.2.1. Lithium-Ion Batteries

2.2.2. Flow Batteries

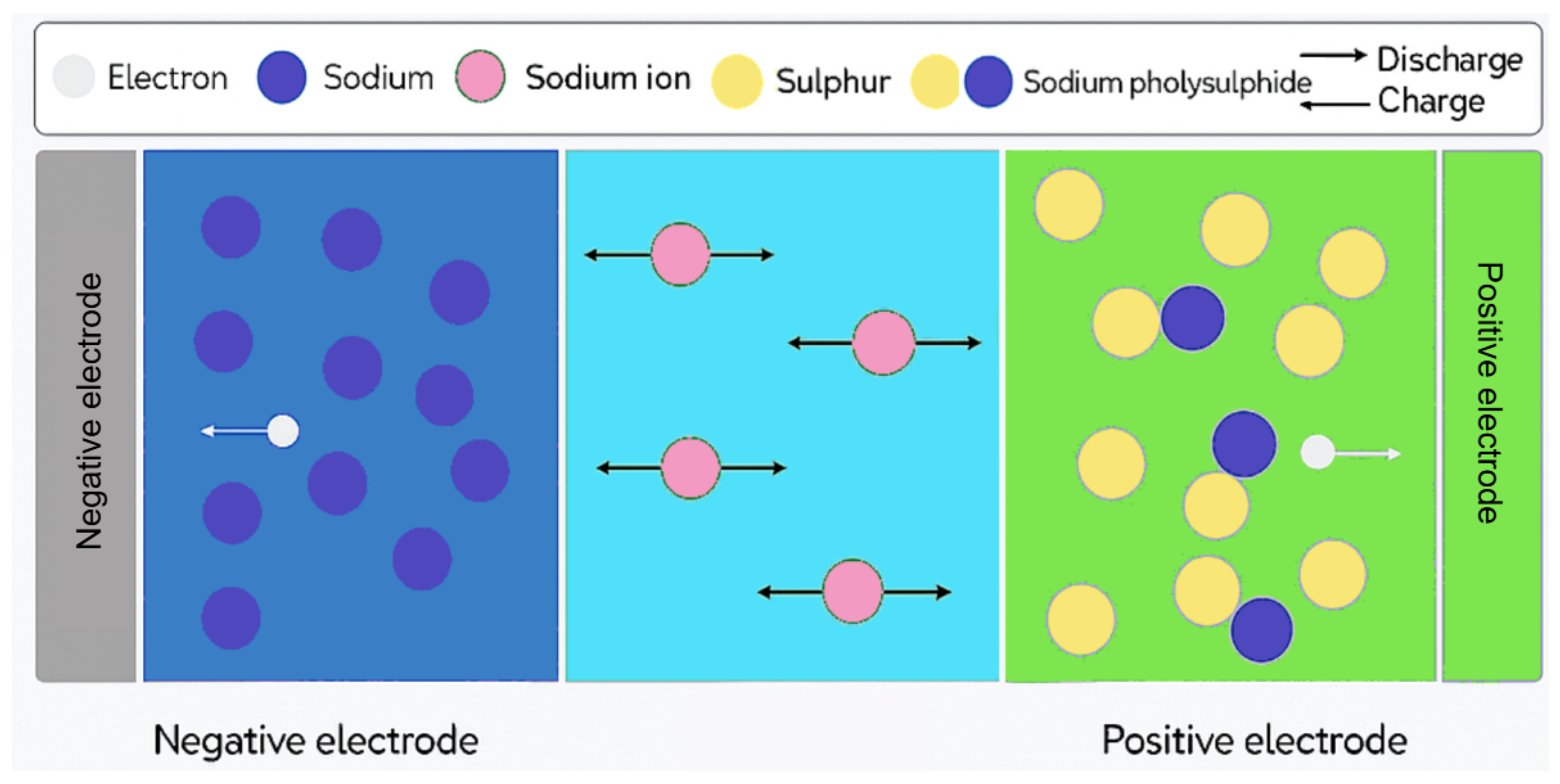

2.2.3. Sodium-Sulfur Batteries

2.3. Thermal Energy Storage

2.3.1. Sensible Heat Storage

2.3.2. Latent Heat Storage

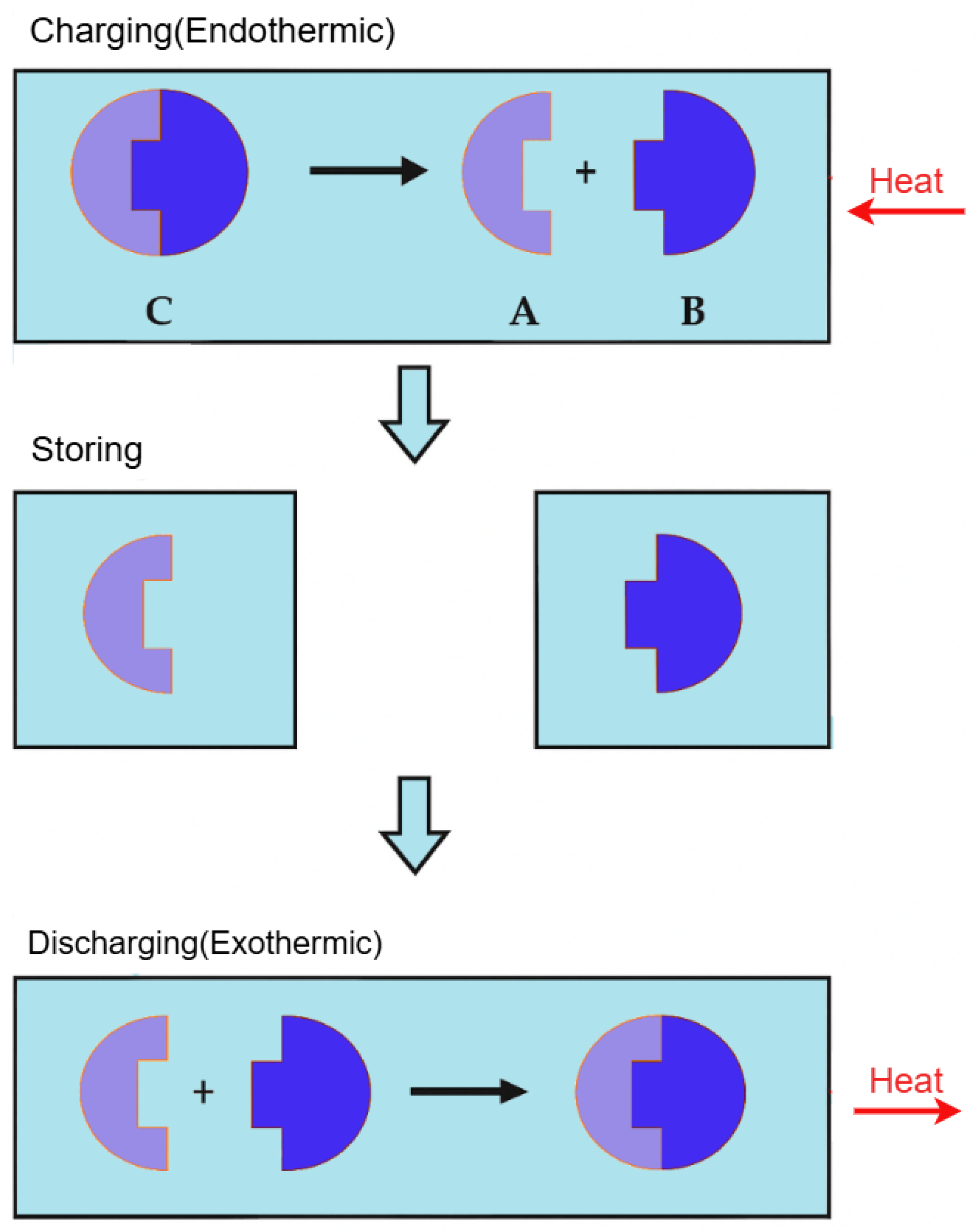

2.3.3. Thermochemical Energy Storage

2.4. Electromagnetic Energy Storage

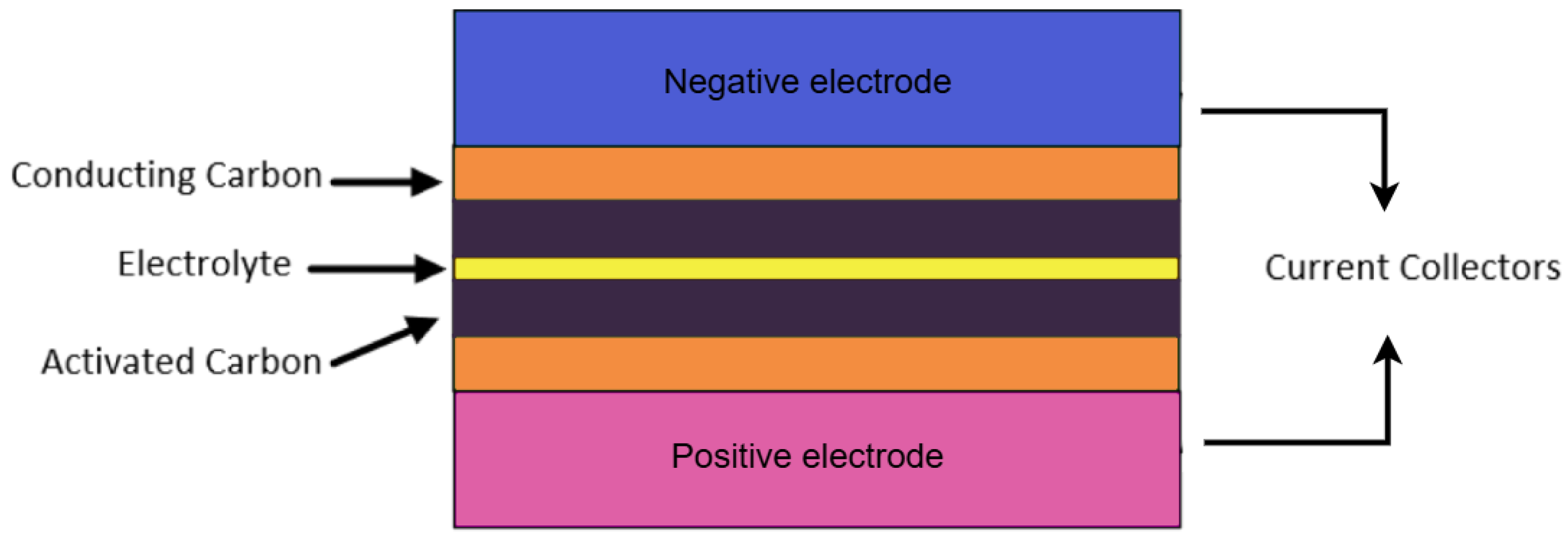

2.4.1. Supercapacitors

2.4.2. Superconducting Magnetic Energy Storage

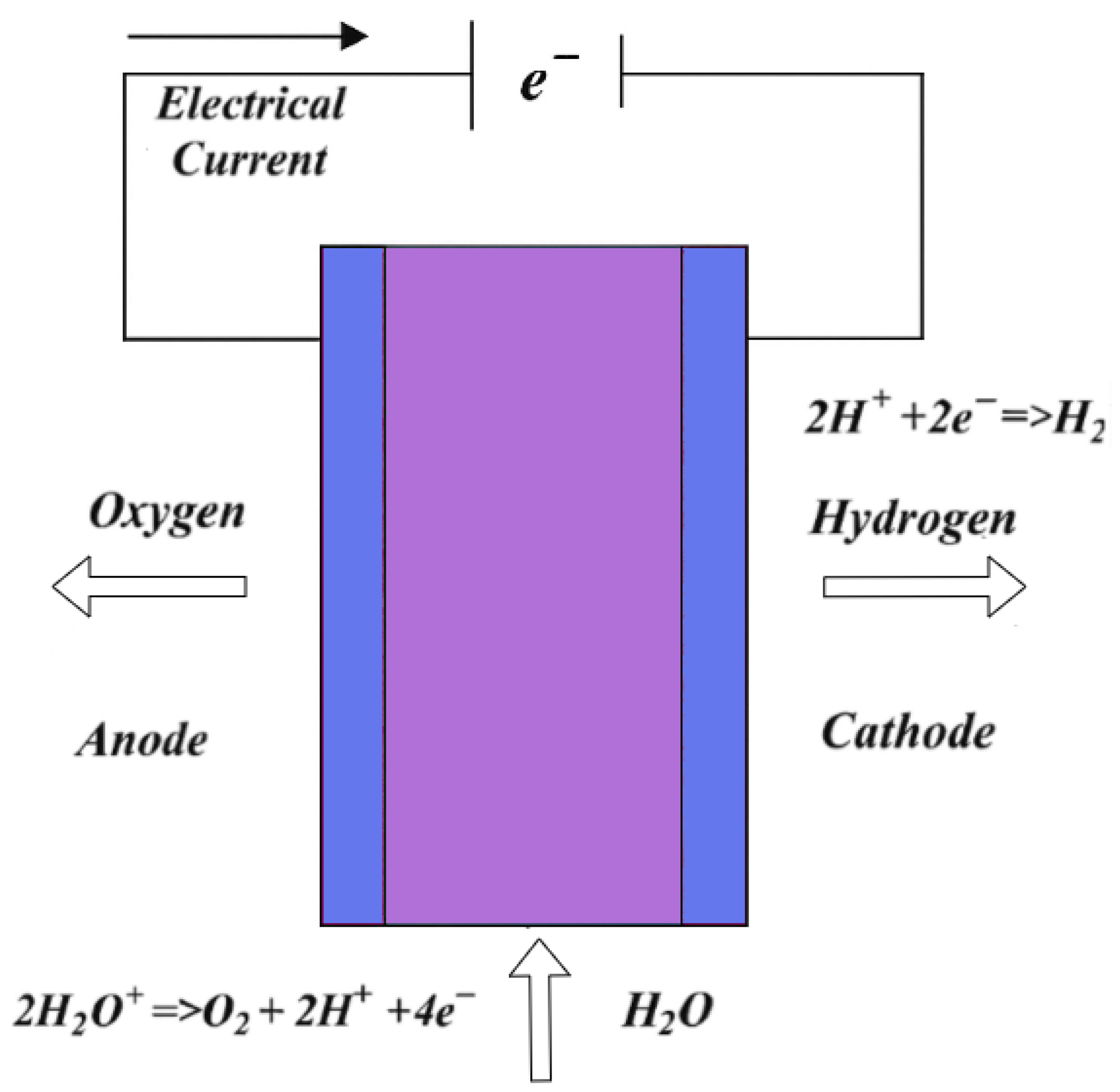

2.5. Chemical Energy Storage

3. Current Development Status of Technical Characteristics of Energy-Storage Technology

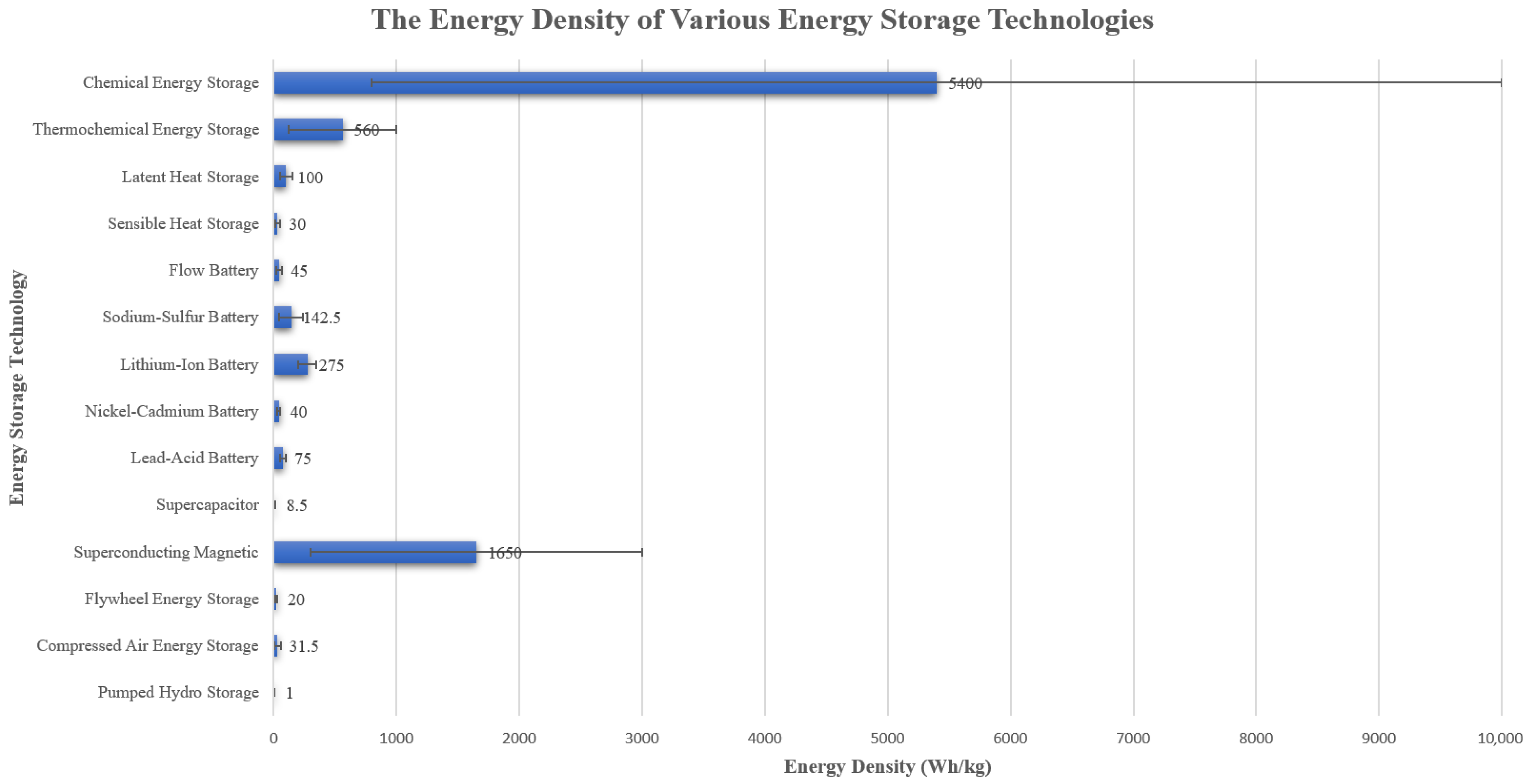

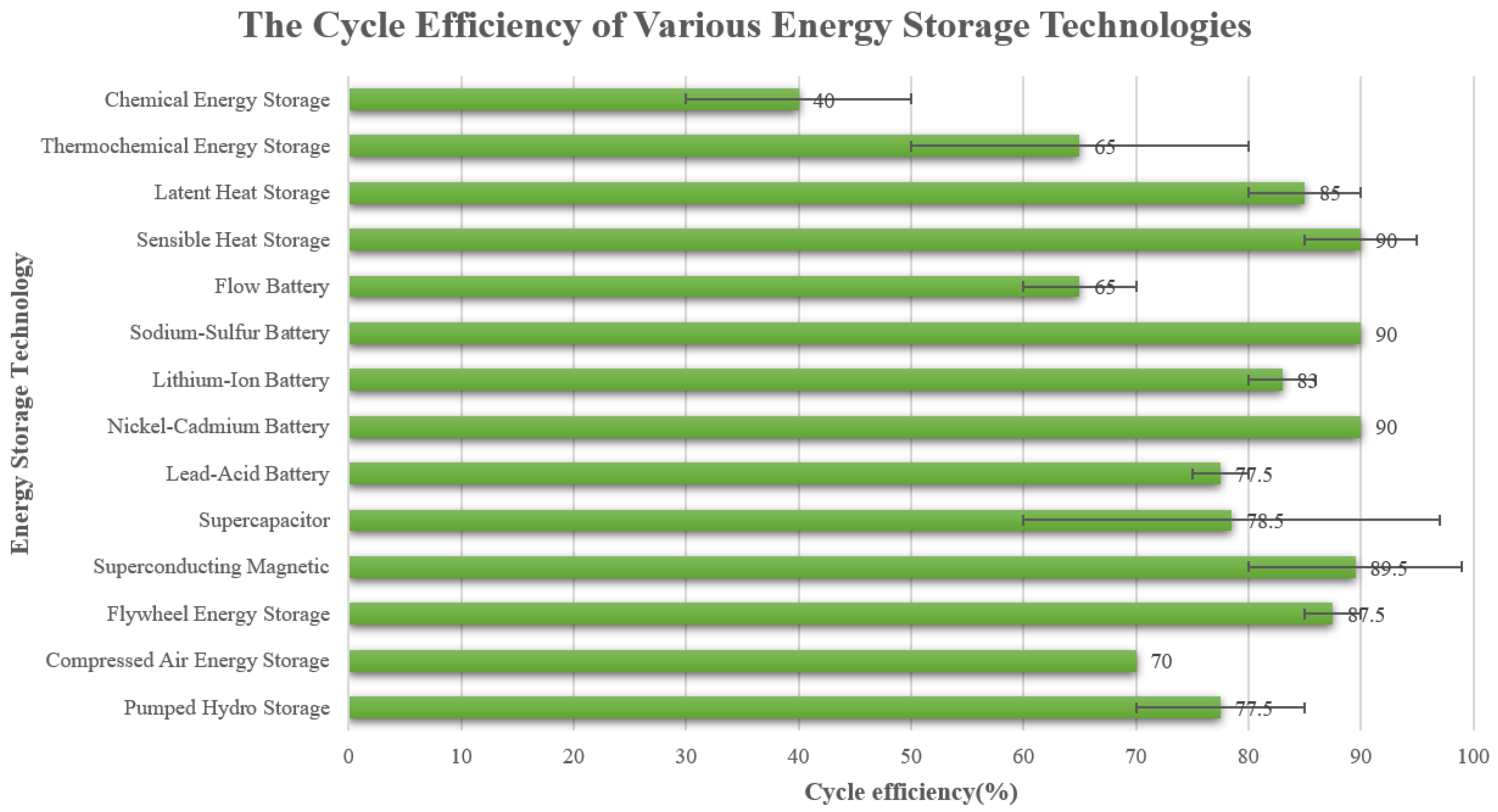

3.1. Characterization of Energy-Storage Technologies

3.2. Comparison of Application Characteristics of Energy-Storage Technologies

4. Economic Feasibility of Energy-Storage Technologies

4.1. Lifecycle Cost

4.1.1. Capital Expenditure

4.1.2. Operation and Maintenance Cost

4.1.3. Replacement Cost

4.1.4. Charging Cost

4.1.5. Recycling Cost

4.1.6. Net Present Value of Total Lifecycle Cost

4.1.7. Net Present Value of Total Discharged Energy

4.1.8. Levelized Cost of Electricity (LCOE)

4.2. Benefit Analysis of Energy-Storage Technologies

4.2.1. User-Side Time-of-Use Peak-Valley Arbitrage

4.2.2. Auxiliary Services Market Revenues

4.2.3. Energy-Storage Capacity Revenue

5. Application of Energy-Storage Technologies

5.1. Enhancing Power System Stability

5.1.1. Generation Side

5.1.2. Generation Side

5.1.3. Grid Side

5.1.4. User Side

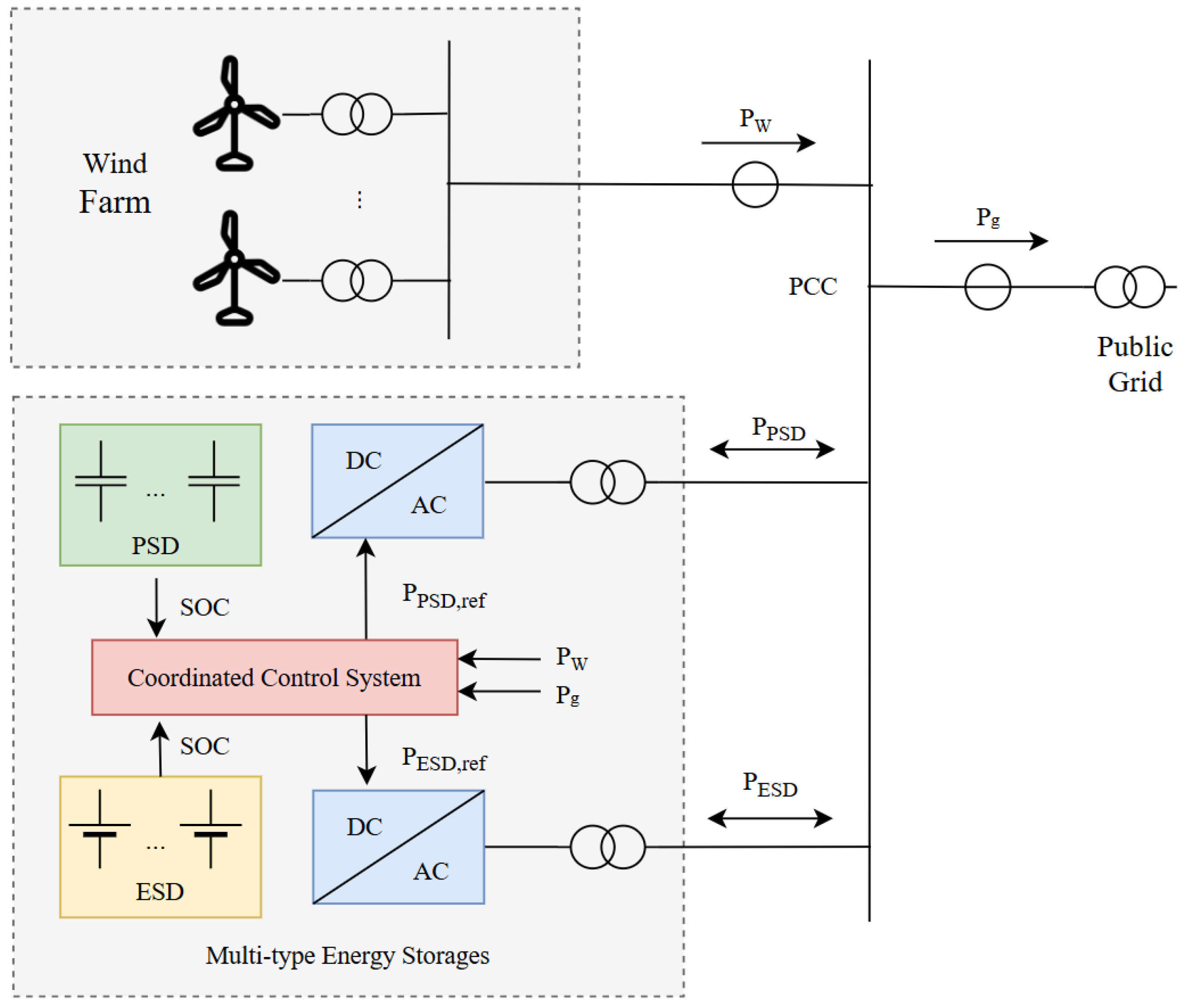

5.2. Improving the Reliability of Renewable Energy Integration

5.3. Transportation

5.3.1. Electric Vehicles

5.3.2. Urban Rail Transit

5.3.3. Ships

5.4. Domestic Energy-Storage Projects in China

5.5. Domestic Energy-Storage Projects in China

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- United Nations Framework Convention on Climate Change (UNFCCC). Paris Agreement. Adopted at COP 21, Paris, 12 December 2015; Entered into Force 4 November 2016. 2015. Available online: https://unfccc.int/sites/default/files/english_paris_agreement.pdf (accessed on 18 July 2025).

- International Renewable Energy Agency. Innovation Outlook: Smart Charging for Electric Vehicles. 2023. Available online: https://www.irena.org/publications/2023/Mar/Smart-Charging-Innovation-Outlook (accessed on 18 July 2025).

- National Energy Administration of China. Notice on Promoting the Grid Connection and Dispatch of New Energy Storage. Issued April 2024. 2024. Available online: https://zfxxgk.nea.gov.cn/2024-04/02/c_1310771072.htm (accessed on 18 July 2025). (In Chinese)

- Calero, F.; Cañizares, C.A.; Bhattacharya, K.; Anierobi, C.; Calero, I.; de Souza, M.F.Z.; Farrokhabadi, M.; Guzman, N.S.; Mendieta, W.; Peralta, D.; et al. A Review of Modeling and Applications of Energy Storage Systems in Power Grids. Proc. IEEE 2023, 111, 806–831. [Google Scholar] [CrossRef]

- Li, X.; Wang, S. Energy management and operational control methods for grid battery energy storage systems. CSEE J. Power Energy Syst. 2019, 7, 1026–1040. [Google Scholar]

- Wang, W.; Yuan, B.; Sun, Q.; Wennersten, R. Application of energy storage in integrated energy systems—A solution to fluctuation and uncertainty of renewable energy. J. Energy Storage 2022, 52, 104812. [Google Scholar] [CrossRef]

- Liu, Y.; He, Q.; Shi, X.; Zhang, Q.; An, X. Energy storage in China: Development progress and business model. J. Energy Storage 2023, 72, 108240. [Google Scholar] [CrossRef]

- Erdemir, D.; Dincer, I. Historical dimensions and directions on energy storage: Unique perspectives. J. Energy Storage 2025, 128, 117199. [Google Scholar] [CrossRef]

- Aghmadi, A.; Mohammed, O.A. Energy storage systems: Technologies and high-power applications. Batteries 2024, 10, 141. [Google Scholar] [CrossRef]

- Xing, K.; Gui, L.; Zhang, Q.; Wang, K.; Chen, L. Single-phase ground fault area localization on the rotor side of variablespeed pumped storage units based on frequency characteristics. Autom. Electr. Power Syst. 2025, 49, 187–194. [Google Scholar]

- Feng, Q.; Wu, X.; Cheng, C.; Huang, S.; Wei, X. Peak-shaving optimization method for pumped storage station group considering the cumulative error of wind and PV output prediction. Proc. CSEE 2025, 1–13. [Google Scholar]

- Zhu, Y.; Yao, S.; Zhang, Y.; Cao, M. Environmental and economic scheduling for wind-pumped storage-thermal integrated energy system based on priority ranking. Electr. Power Syst. Res. 2024, 231, 110353. [Google Scholar] [CrossRef]

- Elalfy, D.A.; Gouda, E.; Kotb, M.F.; Bureš, V.; Sedhom, B.E. Comprehensive review of energy storage systems technologies, objectives, challenges, and future trends. Energy Strategy Rev. 2024, 54, 101482. [Google Scholar] [CrossRef]

- Li, J.; Yang, Z.; Wang, Y.; Zhang, L.; Xu, Y.; Wang, Y. Parameter optimization of building compressed air energy storage cavities in aquifers based on high-speed non Darcy flow pattern. Nat. Gas Ind. 2025, 45, 180–188. [Google Scholar]

- Shi, G.; Tao, H.; Zuo, Z.; Li, J.; Chen, J.; Chen, J.; Chen, H. Research on blade stress optimization method of axial flow compressor in compressed air energy storage system. Energy Storage Sci. Technol. 2025, 14, 1522–1532. [Google Scholar] [CrossRef]

- Wang, J.; Miao, S.; Wang, T.; Yao, F.; Tan, H.; Wang, B. Multi-stage Optimization Planning of Large-scale A-CAES with Consideration of Mul-ti-application Values Including Peak Regulation, Backup, Ramping and Inertia. High Volt. Eng. 2025, 51, 1339–1350. [Google Scholar] [CrossRef]

- Qiao, T.; Liang, S.; Guo, P.; Liang, J.; Liu, Y. Simulation Study on Primary Frequency Regulation of Pumped Storage Unit Assisted by Flywheel Energy Storage. Acta Energiae Solaris Sin. 2024, 45, 619–626. [Google Scholar] [CrossRef]

- Li, J.; Wei, L.; Fang, F.; Wang, B.; Li, Z. Two-Layer Distributed Cooperative Control of Flywheel Energy Storage Groups Based on Consensus Algorithm. Acta Energiae Solaris Sin. 2025, 46, 34–42. [Google Scholar] [CrossRef]

- Detka, K.; Górecki, K. Selected technologies of electrochemical energy storage—A review. Energies 2023, 16, 5034. [Google Scholar] [CrossRef]

- Liu, H.; Wang, J.; Zhao, J.; Li, C.; Lv, Y. Research on heat generation behavior and capacity attenuation of large capacity energy storage battery. CIESC J. 2025, 1–11. [Google Scholar]

- Zhang, C.; Wei, Y.L.; Cao, P.F.; Lin, M.C. Energy storage system: Current studies on batteries and power condition system. Renew. Sustain. Energy Rev. 2018, 82, 3091–3106. [Google Scholar] [CrossRef]

- Zhao, C.; Cheng, C.; Wu, X.; Huang, Y.; Liu, R.; Zhang, H.; Gao, D. Performance Analysis and Flexibility Improvement Research on the Molten Salt Energy Storage System of Coal-fired Power Plant. Proc. CSEE 2025, 1–10. [Google Scholar]

- Sikiru, S.; Oladosu, T.L.; Amosa, T.I.; Kolawole, S.Y.; Soleimani, H. Recent advances and impact of phase change materials on solar energy: A comprehensive review. J. Energy Storage 2022, 53, 105200. [Google Scholar] [CrossRef]

- Yan, T.; Zhang, H. A critical review of salt hydrates as thermochemical sorption heat storage materials: Thermophysical properties and reaction kinetics. Sol. Energy 2022, 242, 157–183. [Google Scholar] [CrossRef]

- Zhang, G.; Zhang, K.; An, Y.; Li, C.; Liu, G.; Sun, X.; Yuan, C.; Wang, K.; Zhang, X.; Ma, Y. Application of dry electrodes in supercapacitors and lithium-ion batteries. Chin. J. Eng. 2025, 47, 897–909. [Google Scholar] [CrossRef]

- Liang, Y.; Chen, D. Research Progress on Properties of Bio-Carbon Electrode Materials for Supercapacitors. Adv. New Renew. Energy 2025, 13, 51–68. [Google Scholar]

- Li, C.; Li, G.; Xin, Y.; Li, W.; Yang, T.; Li, B. A high-temperature superconducting energy conversion and storage system with large capacity. J. Energy Storage 2022, 53, 104957. [Google Scholar] [CrossRef]

- Li, W.; Yang, T.; Xin, Y. New configuration to improve the power input/output quality of a superconducting energy storage/convertor. J. Energy Storage 2023, 68, 107654. [Google Scholar] [CrossRef]

- De Carne, G.; Maroufi, S.M.; Beiranvand, H.; De Angelis, V.; D’Arco, S.; Gevorgian, V.; Waczowicz, S.; Mather, B.; Liserre, M.; Hagenmeyer, V. The role of energy storage systems for a secure energy supply: A comprehensive review of system needs and technology solutions. Electr. Power Syst. Res. 2024, 236, 110963. [Google Scholar] [CrossRef]

- Wu, D.; Cui, J.; Zhao, Y.; Wang, S.; Wu, X.; Qin, B. Research on adaptive optimal energy dispatch for hydrogen-based integrated energy systems. Adv. Technol. Electr. Eng. 2025, 44, 9–16. [Google Scholar]

- Jamil, H.; Naqvi, S.S.A.; Kim, D.H. Hydrogen storage capability optimization based on multi-objective function for decision of hydrogen production and utilization. Int. J. Hydrogen Energy 2024, 95, 1095–1110. [Google Scholar] [CrossRef]

- Xiong, X.; Yang, M.; Chen, L. Development and Application of Electric Energy Storage System. Electr. Technol. Intell. Build. 2024, 18, 111–116. [Google Scholar] [CrossRef]

- Malik, F.H.; Hussain, G.A.; Alsmadi, Y.; Haider, Z.M.; Mansoor, W.; Lehtonen, M. Integrating Energy Storage Technologies with Renewable Energy Sources: A Pathway Toward Sustainable Power Grids. Sustainability 2025, 17, 4097. [Google Scholar] [CrossRef]

- Dan, S.; Di, W. Review and Research Outlook on the Construction of a New Energy System. J. Lanzhou Univ. (Soc. Sci.) 2025, 53, 5–14. [Google Scholar] [CrossRef]

- Zhang, Z.; Huo, C.; Guo, Z.; Yang, Y.; Rong, X.; Wen, H.; Zhou, M.; Chen, Y. Overview and Research Prospects of Key Issues in Pumped Storage Cluster Planning and Operation under the New Type Power Systems. Proc. CSEE 2025, 45, 5810–5832. [Google Scholar]

- Khan, M.K.; Raza, M.; Shahbaz, M.; Farooq, U.; Akram, M.U. Recent advancement in energy storage technologies and their applications. J. Energy Storage 2024, 92, 112112. [Google Scholar] [CrossRef]

- Wen, J.; Liu, N.; Pei, J.; Xu, R.; Liu, D. Life cycle cost analysis for energy storage technology. Therm. Power Gener. 2021, 50, 24–29. [Google Scholar] [CrossRef]

- Li, M.; Dege, J. Economic Benefits of Energy Storage System Under the Electricity Spot Market. Distrib. Energy 2023, 8, 11–18. [Google Scholar] [CrossRef]

- Wang, Q.; Zhao, H. Discussion on Cost Compensation Mechanism of Flexible and Adjustable Resources Participating in Power Ancillary Services. Price Theory Pract. 2023, 87–90+209. [Google Scholar] [CrossRef]

- Wang, Q.; Zhao, H.; Chen, J. Research on the Cost Accounting Method of Considering the Participation of Energy Storage in Power Ancillary Services-Based on the comparative analysis of power-based energy storage and energy-based energy storage. Price Theory Pract. 2024, 129–134. [Google Scholar] [CrossRef]

- Zhang, L.; Liao, J.; Dai, D.; Liu, Y.; He, Y.; Xie, Y.; Meng, L. Research on the New Energy Storage Capacity Electricity Pricing Mechanism. Price Theory Pract. 2023, 122–127+210. [Google Scholar] [CrossRef]

- Tang, X.; Sun, Y.; Zhou, G.; Miao, F. Coordinated Control of Multi-Type Energy Storage for Wind Power Fluctuation Suppression. Energies 2017, 10, 1212. [Google Scholar] [CrossRef]

- Liu, X.; Li, C.; Liu, J.; Wu, Y.; Shi, M. Joint Scheduling Method for Peak Regulation and Frequency Regulation in Unit Commitment Using Battery Energy Storage Systems. J. Shanghai Jiaotong Univ. 2025, 1–26. [Google Scholar] [CrossRef]

- Feng, L.K.; Feng, Y.F.; Lu, K.; Wang, P.; Zhao, K.; Gu, Z.D.; Ren, Y.N.; Xie, S.L. The analysis of molten salt energy storage mode with multi-steam sources heating in thermal power unit peak shaving operation. Sci. Rep. 2025, 15, 11305. [Google Scholar] [CrossRef]

- Lin, L.; Cao, Y.; Kong, X.; Lin, Y.; Jia, Y.; Zhang, Z. Hybrid energy storage system control and capacity allocation considering battery state of charge self-recovery and capacity attenuation in wind farm. J. Energy Storage 2024, 75, 109693. [Google Scholar] [CrossRef]

- Li, C.; Wang, X.; Li, J.; Zhu, X.; Yan, G.; Jia, C. Multi-constrained optimal control of energy storage combined thermal power participating in frequency regulation based on life model of energy storage. J. Energy Storage 2023, 73, 109050. [Google Scholar] [CrossRef]

- Yan, J.; Sha, Y.; Zhang, Y.; He, Q.; Wang, Y. Review of key energy storage technologies for new energy consumption. China Energy Environ. Prot. 2024, 46, 202–209. [Google Scholar] [CrossRef]

- Li, Q.; Xu, J.; Zhang, S.; Zhang, J.; Zhang, Y.; Li, A. Decision for Day-Ahead and Real-Time Operation of Energy Storage Plants Considering Smoothing of New Energy Fluctuations. Acta Energiae Solaris Sin. 2025, 46, 43–53. [Google Scholar] [CrossRef]

- Liu, X.; Xie, L.; Ma, L.; Ye, J.; Bian, Y.; Cui, C. Hybrid Energy Storage Two-Layer Smoothing Control Model Considering Maximum Benefit of Wind Power. Acta Energiae Solaris Sin. 2024, 45, 596–605. [Google Scholar] [CrossRef]

- Habib, A.; Hasan, M.; Issa, G.; Singh, D.; Islam, S.; Ghazal, T. Lithium-Ion Battery Management System for Electric Vehicles: Constraints, Challenges, and Recommendations. Batteries 2023, 9, 152. [Google Scholar] [CrossRef]

- Ye, Y.; Wang, H.; Xu, B.; Zhang, J. An imitation learning-based energy management strategy for electric vehicles considering battery aging. Energy 2023, 283, 128537. [Google Scholar] [CrossRef]

- Zheng, W.; Rong, L.; Cheng, K. Current status of research and application of energy storage technology in urban rail transportation. Mod. Transp. Metall. 2025, 5, 84–90+104. [Google Scholar]

- Zhang, J.; Qi, G.; Fu, P.; Wen, S.; Tian, G.; Liu, G. Improved Active Disturbance Rejection Control Strategy of Flywheel Energy Storage System in Rail Transit. Power Syst. Technol. 2024, 1–11. [Google Scholar] [CrossRef]

- Wang, F.; Xue, Y. A Review of the Development of the Energy Storage Industry in China: Challenges and Opportunities. Energies 2025, 18, 1512. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhong, Z.; Lin, F.; Yang, Z. Multi time scale management and coordination strategy for stationary super capacitor energy storage in urban rail transit power supply system. Electr. Power Syst. Res. 2024, 228, 110046. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, X.; Li, X.; Zhou, Z.; Duan, Q.; Tang, T. Collaborative Optimization Method of Capacity Configuration and Operation Strategy of Hybrid Energy Storage System for All-electric Ships. Shipbuild. China 2024, 65, 106–121. [Google Scholar]

- Ding, T.; Xie, L.; Huang, Y.; Bie, Z.; He, Y.; Huang, S.; Sun, X.; Zhang, K.; Yu, L. Key Issues and Suggestions for Development of New Energy Storage in Northwestern China. Autom. Electr. Power Syst. 2025, 1–18. [Google Scholar]

- Zhang, X.; Zhang, X.; Wang, K.; Sun, X.; Ma, Y. Review of Power-type Energy Storage Technology and Application. J. Electr. Eng. 2024, 19, 385–398. [Google Scholar]

- Ju, W.; Wang, Y.; Zhao, Y.; Xie, X. Overview of long-term energy storage technologies in new power systems. Therm. Power Gener. 2024, 53, 1–9. [Google Scholar] [CrossRef]

- Chen, H.; Li, H.; Xu, Y.; Xu, D.; Wang, L.; Zhou, X.; Chen, M.; Hu, D.; Yan, J.; Li, X.; et al. Research progress on energy storage technologies of China in 2023. Energy Storage Sci. Technol. 2024, 13, 1359–1397. [Google Scholar] [CrossRef]

- Xue, F.; Ma, X.; You, Y. Energy storage technologies and their applications and development. Integr. Intell. Energy 2023, 45, 48–58. [Google Scholar]

| Energy Storage Type | Energy Storage Type | Response Time | Cycle Life (Times) | Power Density (kW/m3) |

|---|---|---|---|---|

| Mechanical Energy Storage | Pumped Hydro Storage | Minute-level | ≥50 years | 0.5–1.5 |

| Compressed Air Energy Storage | Minute-level | 30–50 years | 0.5–2 | |

| Flywheel Energy Storage | 10 ms range | ≥20 years | 1000–2000 | |

| Electrical Storage | Superconducting Magnetic | Millisecond-level | 10,000–100,000 | 300–4000 |

| Supercapacitor | Millisecond-level | ≥50,000 | >100,000 | |

| Electrochemical Energy Storage | Lead-Acid Battery | 100 ms range | 500–2000 | 200–500 |

| Nickel-Cadmium Battery | 100 ms range | 1000–4500 | 250–1000 | |

| Lithium-Ion Battery | 100 ms range | 1000–5000 | 100–3500 | |

| Sodium-Sulfur Battery | 100 ms range | 2500–4500 | 150–230 | |

| Flow Battery | 100 ms range | >1000 | 0.5–2 | |

| Thermal Energy Storage | Sensible Heat Storage | Minutes to Hours | Thousands–Tens of Thousands | Hundreds–Thousands |

| Latent Heat Storage | Minutes to Hours | ≥Tens of Thousands | Hundreds | |

| Thermochemical Energy Storage | Hours to Days | Millions | 100–1000 | |

| Chemical Energy Storage | Hydrogen Energy Storage | Minute-level | 500–2000 | >500 |

| Energy Storage Type | Energy Storage Type | Application Phase | Market Development Stage | Advantages | Disadvantages |

|---|---|---|---|---|---|

| Mechanical Energy Storage | Pumped Hydro Storage | Integration of renewable energy, grid-scale energy storage, peaking, load balancing | maturity | High capacity, long service life, low maintenance | Requires specific terrain, geological, and water conditions, limited site selection |

| Compressed Air Energy Storage | Grid peaking, system backup power | Research phase | Long service life, fast response speed, environmentally friendly, high capacity and low cost | Efficiency fluctuations, potential safety hazards, and high requirements for geographical environment | |

| Flywheel Energy Storage | Peaking, frequency control, UPS, power quality regulation, transmission and distribution system stabilization | Demonstration phase | High power density, fast charging speed, long service life and high cycle efficiency | Low energy density, high self-discharge, high unit energy storage cost | |

| Electromagnetic Energy Storage | Superconducting Magnetic Energy Storage | UPS, power quality regulation, transmission and distribution system stability | Experimental research and early application phase | Fast response, high energy-storage capacity, high reliability | High cost, cooling issues, loss of super, large magnetic field requirement |

| Supercapacitors | Power quality regulation, transmission and distribution system stability | Demonstration application phase | High energy density | Interdependence of battery component characteristics, safety issues, environmental impacts | |

| Electrochemical Energy Storage | Lead-acid Battery | UPS, Renewable Energy Systems, Power Backups, Emergency Power Supplies | maturity | Fast reaction speed, low self-discharge rate, high cycle efficiency, low capital cost | Low energy density, high environmental impact |

| Lead-carbon Battery | Power quality, frequency control, plant standby, renewable energy storage | Early stage of industrialization | Cost-effective and low consistency | Low energy density, short cycle life, environmental issues | |

| Lithium-ion Batteries | Integrated renewable energy, grid-scale energy storage, electric vehicles | Commercial scale phase | High energy density, fast response, low self-discharge rate, long service life, high reliability | Lifecycle depends on discharge level, high cost, need for operating temperature and overcharge protection | |

| Sodium-Sulfur Battery | Power quality, backup power, peak-to-valley, energy management, renewable energy storage | Demonstration application phase | High energy density, low self-discharge rate, fast response time, non-toxic materials | High internal resistance, sodium corrosion, for additional systems requiring high-temperature heating | |

| Flow Battery | Backup power systems, grid-scale energy storage, renewable energy integration | Demonstration application phase | Fast response time and high energy-storage capacity | Complex structure, low energy and power density, environmental concerns | |

| Thermal Energy Storage | Sensible Heat Storage | Solar thermal systems, industrial waste heat recovery, centralized heat supply | maturity | No need to use toxic or expensive materials, wide range of available materials, low cost | Low energy density, high cycle efficiency, energy density is affected by the material selected |

| Latent Heat Storage | Solar thermal power, building thermoregulation, cold chain transportation | Demonstration application phase | High energy density, small temperature shift range | Differentiation of PCM volume per cycle, high demand for PCMs | |

| Thermochemical Energy Storage | High-temperature thermal energy storage, thermal energy management in industrial processes, energy conversion and storage | Research and development phase | High efficiency, high energy density, long-term stability during storage, low energy loss | High manufacturing cost, low efficiency, poor heat transfer performance | |

| Chemical Storage | Hydrogen Energy Storage | Balanced dispatch of renewable energy, enhanced power system stability, clean energy drive in transportation | demonstration application phase | High energy density, long discharge time, better environmental compatibility | Overall low energy conversion efficiency and high investment costs |

| Energy Storage Type | Project Location/Name | Installed Capacity | Function | Time |

|---|---|---|---|---|

| Pumped Hydro Storage | Fujian–Zhouning | 4 × 300 MW | Peak-shaving and valley-filling, emergency backup, and improvement of the operating conditions of regional nuclear power units | 2022 |

| Compressed Air Energy Storage | Hebei–Zhangjiakou | 100 MW | Peaking, frequency and phase control, rotating standby, black start | 2022 |

| Hubei Yingcheng compressed air energy storage power station | 300 MW | Peaking, frequency regulation, standby | 2024 | |

| Flywheel Energy Storage | Ningxia–Lingwu | 22 MW | Frequency regulation to promote new energy consumption | Construction to begin in 2021 |

| Flywheel Energy Storage | Shuozhou Cogeneration Flywheel Energy Storage Complex FM Project | 8 MW | frequency regulation | 2023 |

| Supercapacitors | Shanxi Intelligent Energy Internet Demonstration Project | — | Energy Time Shift, Power Smoothing, Voltage Support and System FM | 2023 |

| Huaneng Luoyuan Power Plant Hybrid Super Capacitor + Lithium Battery Energy Storage and FM System | 20 MW | Frequency regulation to improve grid frequency and voltage stability and promote renewable energy consumption | 2023 | |

| Lithium-ion Battery | CNNC Concentric Quanye 100 MW/200 MWh Energy Storage Power Station | 30 sets of 3.45 MW/ 6.7 MWh lithium iron phosphate battery energy storage systems | Shaving peaks and filling valleys, promoting new energy consumption and improving grid stability | 2022 |

| Lead-carbon Battery | Zhejiang Huzhou, Jidian’s first lead-carbon “100 MWh” customer-side energy storage project | Phase I; 10 MW/97.312 MWh | Peak-shaving and valley-filling, promotion of new energy consumption, backup power supply | Construction to begin in 2022 |

| Flow Battery | Liaoning-Dalian | 200 MW; Phase I: 100 MW/400 MW-h | Peaking to promote new energy consumption | Commissioning in 2022 |

| Hydrogen Energy Storage | Anhui-Liuan | 1 MW | valley-filling and peak-shaving | 2021 |

| Thermal Energy Storage | Jiangsu Jingjiang Power Plant Molten Salt Storage and Peaking Heat Supply Project | 75 MW·h | Peak-shaving and frequency regulation, Safe Steam Supply, New Energy Consumption | 2023 |

| Huayuan Jining Thermal Power Molten Salt Energy Storage FM Project | 50 MW (using “10 MW steam + 40 MW electricity” combined heating of molten salt) | Peak-shaving and frequency regulation, Safe Steam Supply, New Energy Consumption | 2024 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Li, W.; Guo, X.; Su, B.; Guo, S.; Jing, Y.; Zhang, X. Advancements in Energy-Storage Technologies: A Review of Current Developments and Applications. Sustainability 2025, 17, 8316. https://doi.org/10.3390/su17188316

Liu X, Li W, Guo X, Su B, Guo S, Jing Y, Zhang X. Advancements in Energy-Storage Technologies: A Review of Current Developments and Applications. Sustainability. 2025; 17(18):8316. https://doi.org/10.3390/su17188316

Chicago/Turabian StyleLiu, Xin, Wujing Li, Xiangyang Guo, Biao Su, Shuyu Guo, Yiran Jing, and Xi Zhang. 2025. "Advancements in Energy-Storage Technologies: A Review of Current Developments and Applications" Sustainability 17, no. 18: 8316. https://doi.org/10.3390/su17188316

APA StyleLiu, X., Li, W., Guo, X., Su, B., Guo, S., Jing, Y., & Zhang, X. (2025). Advancements in Energy-Storage Technologies: A Review of Current Developments and Applications. Sustainability, 17(18), 8316. https://doi.org/10.3390/su17188316