1. Introduction

The rapid growth of the world population has caused an increase in food demand, resulting in substantial environmental pressures [

1]. The aquaculture industry plays a vital role in food security. According to the FAO, aquaculture production in China reached 214 million tons in 2020, including 178 million tons of aquatic animals and 36 million tons of algae [

2]. However, rapid expansion has also placed enormous pressures on local ecosystems through pollution and greenhouse gas emissions. Therefore, it is essential to investigate aquaculture for achieving pollution reduction and China’s sustainable development goals.

Aquaculture can be broadly divided into coastal/inshore (including inland tanks, ponds, and aquaponics) and pelagic systems [

3]. Coastal and inshore aquaculture operates under controlled conditions (e.g., water quality, feed, temperature) [

4], while pelagic systems employ diverse fishing methods [

5]. Previous studies have shown that aquaculture, particularly coastal and inshore models, may lead to environmental risks such as waste discharge, antibiotic resistance, and habitat degradation [

6]. Pelagic fisheries have been linked to high waste accumulation on the seafloor and ecosystem disruption [

7,

8]. Therefore, to mitigate these impacts many studies have increasingly turned to Life Cycle Assessment (LCA) as a tool to identify environmental hotspots and guide sustainable practices in aquaculture [

9].

Understanding the system and identifying critical problems is necessary for finding solutions to reduce aquaculture pollution discharge. LCA is a systematic methodology for evaluating the environmental impacts associated with all the stages of a product’s life from cradle to grave [

10]. The LCA method covers all life cycle stages including the raw material, the process and the final product. It has been widely applied to aquaculture [

11]. Early studies mainly examined infrastructure and fuel inputs, often excluding capital goods due to their minor contribution [

12,

13,

14]. Other research incorporated policy scenarios to forecast potential impacts [

15].

Traditionally, land-based intensive aquaculture farms or inshore waters have been more technically feasible than exposed marine environments due to lower operational challenges and costs [

16,

17]. These farms, often using reservoirs for finfish and crustaceans, typically adopt high automation and large-scale operations to achieve economies of scale [

18,

19]. Feed production has been identified as the major environmental hotspot, driving energy demand and nutrient use regardless of system yield [

20,

21,

22]. Commercial aquafeeds generally include fishmeal, fish oil, and plant-derived proteins, each associated with specific impacts [

23]. While intensification can exacerbate acidification, eutrophication, and ecotoxicity, it may also improve freshwater efficiency [

24].

Rather than detailing multiple aquaculture subtypes and offshore logistics, recent LCA studies can be summarized as follows: some studies have focused on optimizing the environmental performance of intensive aquaculture. For example, Poore and Nemecek highlighted three main pathways for sustainability: (1) offshore marine fish farming, (2) shellfish farming, and (3) recirculating aquaculture systems (RAS) [

25]. Offshore systems require substantial off-farm resources and are costly to operate [

26]. Shellfish production is limited by low edible yields, consumer demand, and logistics [

27]. RASs are still emerging [

28]. Belton noted traditional aquaculture systems exhibit significant “performance gaps” that can be narrowed to improve sustainability [

16]. Comparative studies show that different aquaculture systems have distinct environmental impacts [

3]. In 2021, Bohnes and Laurent further compared eight aquaculture systems in Singapore and tested feed alternatives such as insect meal and algal oil, finding that RASs and marine cages were the most attractive options [

3].

Aquaponic systems are considered a more sustainable aquaculture production option due to their reduced water input and nutrient discharge in localized areas [

29,

30,

31,

32,

33]. However, most previous studies only examined laboratory-scale aquaponics, with results varying across regions [

34,

35,

36,

37,

38]. It was found that combining aquaponics facilities with industrial practices that generate waste heat could reduce energy burdens [

39].

Despite promising results, industrial facilities differ significantly from laboratory systems in scale and resource intensity. For instance, large-scale facilities require significantly more electricity and materials, extending their environmental footprint across broader regions. In China, aquaponics started relatively late compared to Europe and North America, and comprehensive sustainability assessments remain scarce.

This paper aims to develop China’s first aquaponics life cycle database, and establish an LCA model to explore the environmental impacts of industrial aquaponics. In detail, first-hand observational data are obtained from a complete production cycle (2021–2022) of an IAS in Chongqing, and a set of material and energy inputs and outputs is compiled. During the environmental impact assessments, a comparison is made between the environmental impacts of aquaponics products and traditional agricultural products using the same nutrient unit to ensure a comprehensive evaluation. After that, some scenario assumptions and in-depth explorations are carried out through the sensitive factors, energy and fish food. A detailed case study of an IAS in Chongqing is carried out to illustrate the potential benefits of aquaponics for reducing traditional aquaculture emissions and possible future improvements.

The article is structured as follows:

Section 2 provides an overview of the research objectives, system boundaries, system details, functional units, and introduces the aquaponic system in Chongqing. It also introduces the feature factor evaluation method and the experimental platform utilized. In

Section 3, a life cycle inventory (LCI) analysis is conducted using data from various sources. The section focuses on the environmental impact assessment and sensitivity analysis of industrial aquaponic systems, identifying significant areas of impact. It includes a comparison between the environmental performance of Chongqing’s Industrial Aquaponic system’s aquatic products and the global average agricultural products. Furthermore, the primary impact areas related to fish food and potential alternative energy sources are analyzed and assessed. Lastly,

Section 4 summarizes the contributions of the paper, discusses limitations, and provides an outlook for future research.

2. Materials and Methods

LCA is a standard method developed by International Standard Organization (ISO, 2006) [

40] to assess the impact of environmental impact and identify the environmental hotspot. The LCA method consists of four phases: Goal and scope, establishment of inventory, analysis of impact assessment, and interpretation of the result. In the first phase, the goals, scope, unit of functions, and boundaries of the system are defined. In the inventory phase, the resources consumed and environmental emissions are quantified. The third phase is to identify and evaluate the environment hotspot. The final phase explains the sources and reasons for the major environmental impacts and presents the improvement focus and suggestions.

2.1. Description of Chongqing IAS

The Chongqing IAS is a factory-style circulating water fish farming system which was designed to operate at a maximum stocking density of 150 kg/m

3. In practice, actual densities vary during the production cycle, ranging from 70–80 kg/m

3 at early stages to 120–130 kg/m

3 at later stages, depending on fish growth and management needs. An average value of ~100 kg/m

3 is reported in this study to represent typical operation. The factory-style circulating water fish farming system consists of twelve fish ponds, one biochemical filter, one regulating pond, one aerobic pond and one anaerobic pond. During fish growth, six closed enclosure systems (each with 2 rearing ponds with a total culture volume of 700 m

3) operate in parallel. Each rearing pond has a volume of 23.0 m

3 (2.53 m depth, 4.29 m diameter). The regulation and microfilter ponds have similar volumes (23.0 m

3 each). For plant production, the system includes four floating ponds (13.7 m

3 each), 70 Nutrient Film Technique (NFT) grooves (7.7 m length, 0.125 m depth), and 180 stereoscopic grooves (2.7 m diameter, 0.12 m depth). Approximately 43,000 planting cups and 1600 planting trays are used to support vegetable cultivation. Further equipment detail of the Chongqing IAS is shown in

Table S4 of Supplemental Information based on one-year operational and functional units. Water quality parameters, including dissolved oxygen (DO), pH, and electrical conductivity (EC), were continuously monitored using professional in situ sensors. All measurements were uploaded in real time to the cloud platform for operational management. Optimal ranges of water quality parameters were maintained during operation, including dissolved oxygen (6–8 mg/L), pH (6.5–7.5), and EC (1.2–1.8 mS/cm). These were regulated by a combination of automated aerators, recirculating water pumps, and greenhouse climate controls. If any parameter exceeded its threshold, the real-time monitoring system triggered alarms and corrective measures were applied immediately, either through automated adjustments or manual intervention by operators.

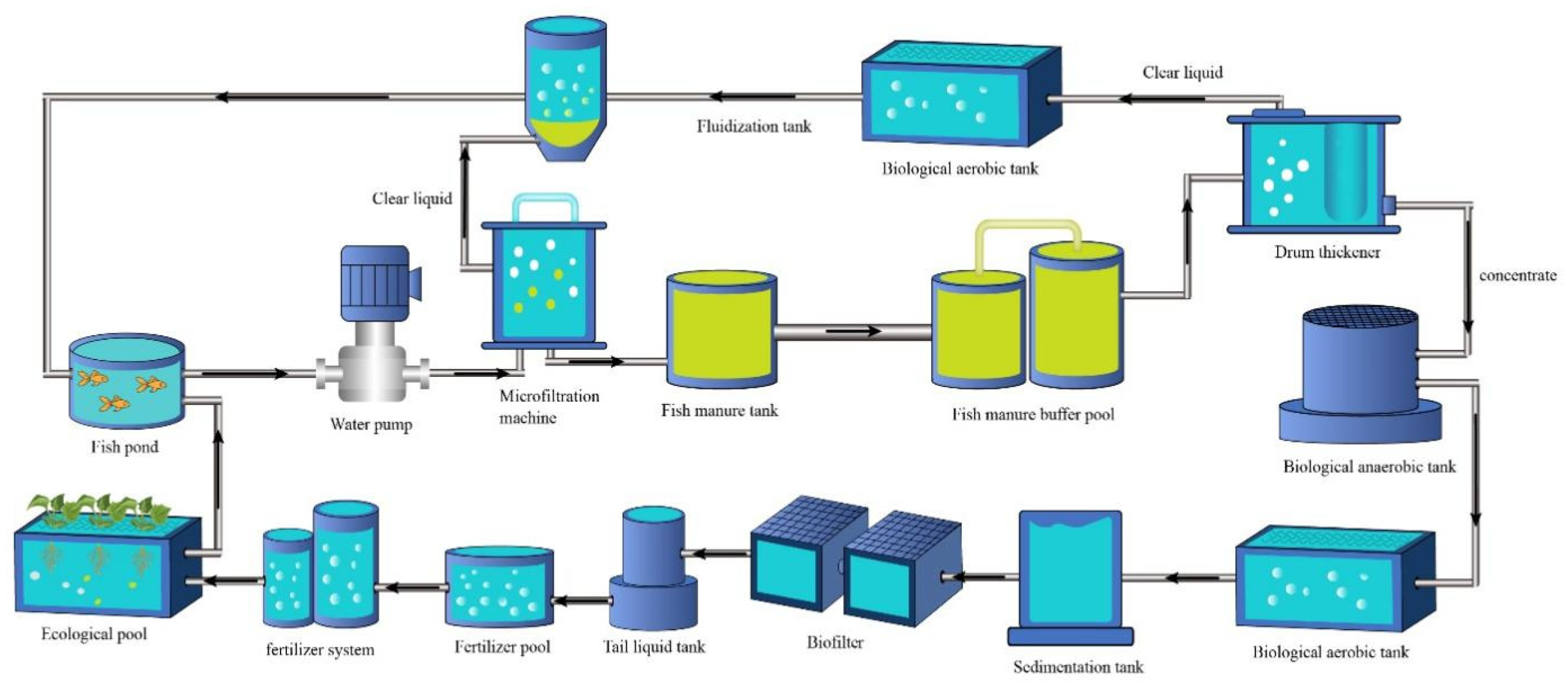

Figure 1 shows the simplified Chongqing Industrial aquaponic system. The wastewater generated by the fish pond is transported by the water pump to the microfilter for filtration. The microfiltration machine transports the clear liquid filtered out of the wastewater to the fluidized tank for nitrification to reduce the biological oxygen demand (BOD) and ammonia nitrogen concentration. After the clear liquid is re-transport to the fish pond, the turbid liquid will be transported to the fish manure tank for temporary buffering. The buffered turbid liquid passes through the rotary drum thickener, and the fish manure is further filtered into a clear and turbid liquid through secondary concentration treatment. After secondary concentration treatment, the clear liquid will be transported to the biochemical aerobic tank for an aerobic reaction. The rotary drum thickener separates the wastewater into a clarified supernatant and a concentrated sludge fraction. The clarified liquid, after passing through multi-stage concentration and biological treatment, has already removed harmful substances and can therefore be safely recirculated to the fish ponds. In contrast, the concentrated sludge fraction undergoes further treatment in anaerobic and aerobic units before being converted into nutrient solution for hydroponic plant cultivation. This dual pathway ensures both water quality for aquaculture and efficient nutrient recycling for crops. The activated sludge can undergo aerobic respiration, converting organic matter into inorganic matter and then removing ammonia nitrogen in the water. The treated supernatant will be transported to the fluidized bed for nitrification and then back to the fish pond. The turbid liquid produced after the secondary concentration treatment will be transported to the anaerobic pool and the biological aerobic pool successively, and the organic matter in the wastewater will be removed by the action of anaerobic bacteria and aerobic bacteria. Then the turbid liquid will be sent to the sedimentation tank to remove the suspended particles in the water and then sent to the biological filter for secondary filtration to form a nutrient solution. This nutrient solution is buffered in the tail liquid tank and fertilizer pool (collectively referred to as the ‘fertilization pool’) before being supplied to the hydroponic vegetables through the fertigation/irrigation system (here termed the ‘fertilization system’). The ecological pond provides final polishing of the water before it is returned to the fish pond.

2.2. Functional Unit, Goal and Scope Definition

The functional unit (FU) of this study is defined as the production of 1 kg of marketable largemouth bass (Micropterus salmoides) from the Chongqing IAS. To reflect the coupled nature of aquaponics production, the associated vegetable output is proportionally allocated based on the system’s actual fish-to-vegetable production ratio, which is approximately 1.33:1 by mass. All life cycle inputs and outputs, including feed, water, energy consumption, equipment usage, and waste treatment, are evaluated relative to this functional unit, representing the system’s primary commercial product.

Accordingly, a cradle-to-gate system boundary is applied, covering all material and energy flows associated with the production of 1 kg of marketable fish. This boundary includes all upstream and on-site processes related to feed production, aquaponics system operation, and waste management, based on measured data from one full year of commercial operation. Specifically, the system boundary considers the production and transportation of fish feed ingredients, such as fishmeal, soybean meal, fish oil, maize, wheat, and other agricultural or marine-based materials. Energy inputs are based on the 2021 Chongqing electricity mix, which consists of 70.9% coal-based power and 29.1% hydropower. Electricity is consumed across various subsystems, including fishpond aeration, water circulation, greenhouse lighting and climate control, auxiliary workshops, automated harvesting, and supplemental lighting.

Water use is accounted for based on the total volume required for recirculating aquaculture and hydroponic plant production, with a water reuse efficiency exceeding 97% and daily replenishment limited to less than 3%. The infrastructure of the IAS includes fish tanks, NFT grooves, stereoscopic cultivation modules, planting trays, and planting cups, primarily made of high-density polyethylene (HDPE) and polystyrene (EPS). The environmental impacts of these components are distributed annually based on their expected service lifespans.

Outputs considered include marketable fish (functional unit), co-produced leafy vegetables (Lactuca sativa, Cichorium intybus, and Glebionis coronaria), and plant biomass residues. Waste management processes involve the biological conversion of fish waste into plant nutrients and the handling of residual plant materials.

The Chongqing IAS was originally designed for an annual output of approximately 100,000 kg of largemouth bass and 40,000 kg of vegetables, corresponding to a nominal plant-to-fish ratio of 0.4:1 by mass. In practice, however, part of the production capacity was allocated to research trials with alternative species and cultivation technologies. As a result, the actual output during the study year (2021–2022) was 114,700 kg of fish and 97,117 kg of vegetables, yielding a plant-to-fish ratio closer to 0.85:1.

The life cycle flow of the IAS is illustrated in

Figure 2, detailing the key material and energy exchanges within the system.

Table S4 provides a detailed inventory of the materials required for the construction of the IAS, including polystyrene planting cups and HDPE grow beds. Post-farm processes such as packaging, shipping, distribution, consumption, and end-of-life disposal are excluded from this study.

2.3. Life Cycle Inventory

The life cycle inventory (LCI) was developed based on empirical data collected from the first year of full-scale operation of the Chongqing IAS. Primary data on feed consumption, water use, electricity consumption, and production outputs were provided by the facility’s operator, while background data on feed ingredients, energy production, and material manufacturing were sourced from the Ecoinvent 3 and Agri-Footprint databases, as well as published literature.

The total fish feed input was 232,267.5 kg per year, sourced from a commercial supplier (Fujian Tianma Technology Co., Ltd., Fuqing, Fujian, China). The feed formulation includes fishmeal, soybean meal, fish oil, wheat starch, and capelin oil. The detailed composition per kilogram of feed was modeled based on Agri-Footprint data and relevant literature sources, accounting for upstream resource extraction and processing.

Water consumption totaled 24,900 m3 per year, primarily used for maintaining the recirculating aquaculture and hydroponic systems, with a water reuse efficiency of over 97%. This volume was modeled as municipal tap water sourced from Ecoinvent 3.

Electricity consumption was measured for all operational subsystems, totaling 400,309 kWh per year. Electricity consumption was monitored using digital energy meters (multi-channel power analyzers installed on each subsystem), with all data logged to the facility’s supervisory control and the cloud platform. This includes 16,420 kWh for fish pond operation, 151,728 kWh for greenhouse climate control, 126,943 kWh for water circulation, 35,913 kWh for auxiliary workshops, 46,417 kWh for fan operation, and 26,888 kWh for supplemental lighting. The electricity mix is modeled based on 2021 Chongqing grid data, which consists of 70.9% coal, 29.1% hydropower, and negligible contributions from other sources.

The infrastructure inventory includes HDPE fish tanks, NFT grooves, stereoscopic plant cultivation modules, planting trays, and planting cups. Material quantities and lifespans are detailed in

Table S4, with environmental impacts annualized based on their expected service life. The annual output includes 114,700 kg of marketable largemouth bass and 86,546 kg of vegetables, consisting of

Lactuca sativa (45,314 kg),

Cichorium intybus (25,890 kg), and

Glebionis coronaria (15,342 kg). Additionally, 10,571.8 kg of plant waste is generated and modeled using data from Ecoinvent 3.

A summary of the LCI data used for this study is provided in

Table S1, which lists all inputs and outputs per year and normalized to the functional unit of 1 kg of marketable fish.

2.4. Life Cycle Impact Assessment Methodology

The life cycle assessment of the Chongqing IAS was conducted using SimaPro 9.0.0, integrating primary data from field measurements with background data obtained from the Agri-footprint and Ecoinvent-3 databases. Environmental impact characterization was performed using the CML-IA baseline method, which offers a well-established and widely accepted framework for quantifying midpoint environmental indicators relevant to food production systems. This method was selected due to its comprehensive coverage of critical impact categories such as climate change, acidification, and eutrophication, which are particularly important in evaluating the sustainability of integrated aquaculture and horticulture systems.

The impact categories considered in this study include global warming potential (GW, kg CO2-eq), representing greenhouse gas emissions contributing to climate change; ozone depletion potential (ODP, kg CFC-11-eq), capturing emissions that harm the stratospheric ozone layer; human toxicity (HT, kg 1,4-dichlorobenzene-eq), assessing potential impacts on human health; terrestrial acidification potential (AP, kg SO2-eq), measuring emissions that contribute to acid rain and soil degradation; freshwater eutrophication potential (FE, kg P-eq) and marine eutrophication potential (ME, kg N-eq), both indicating nutrient emissions that disrupt aquatic ecosystems; and photochemical ozone formation potential (POFP, kg NMVOC-eq), which reflects the formation of ground-level ozone from volatile organic compounds.

All environmental impacts were calculated relative to the production of 1 kg of marketable largemouth bass, with proportional allocation of the associated vegetable production based on the system’s observed fish-to-vegetable production ratio. To contextualize the environmental performance of the aquaponics system, the results were compared with reported environmental impact data from conventional aquaculture and open-field vegetable production systems. This comparison aims to provide a detailed understanding of the resource efficiency and potential sustainability advantages of industrial aquaponics in the context of integrated food production.

2.5. Sensitivity Analysis

A life cycle assessment relies on numerous input parameters that are often subject to uncertainty, making sensitivity analysis an essential component of result interpretation. In this study, a uniform variation of ±20% was applied to each key input parameter to evaluate its influence on the overall environmental impact. This ±20% range was selected to reflect the operational variability observed in the aquaponics facility, which operates not only as a commercial production system but also as a research and demonstration platform. This dual function introduces occasional shifts in energy use, resource inputs, and production intensity due to experimental trials, system testing, or fluctuating market demands, as documented during one year of operation.

The sensitivity analysis specifically examined the energy consumption of various system components, including the auxiliary workshop, circulating water system, and greenhouse climate control systems. By systematically varying these parameters, the analysis helps to identify the most critical contributors to the system’s environmental performance, providing valuable insights for future operational optimization and decision-making under uncertainty.

3. Results & Discussion

3.1. Environment Impact & Sensitivity Analysis

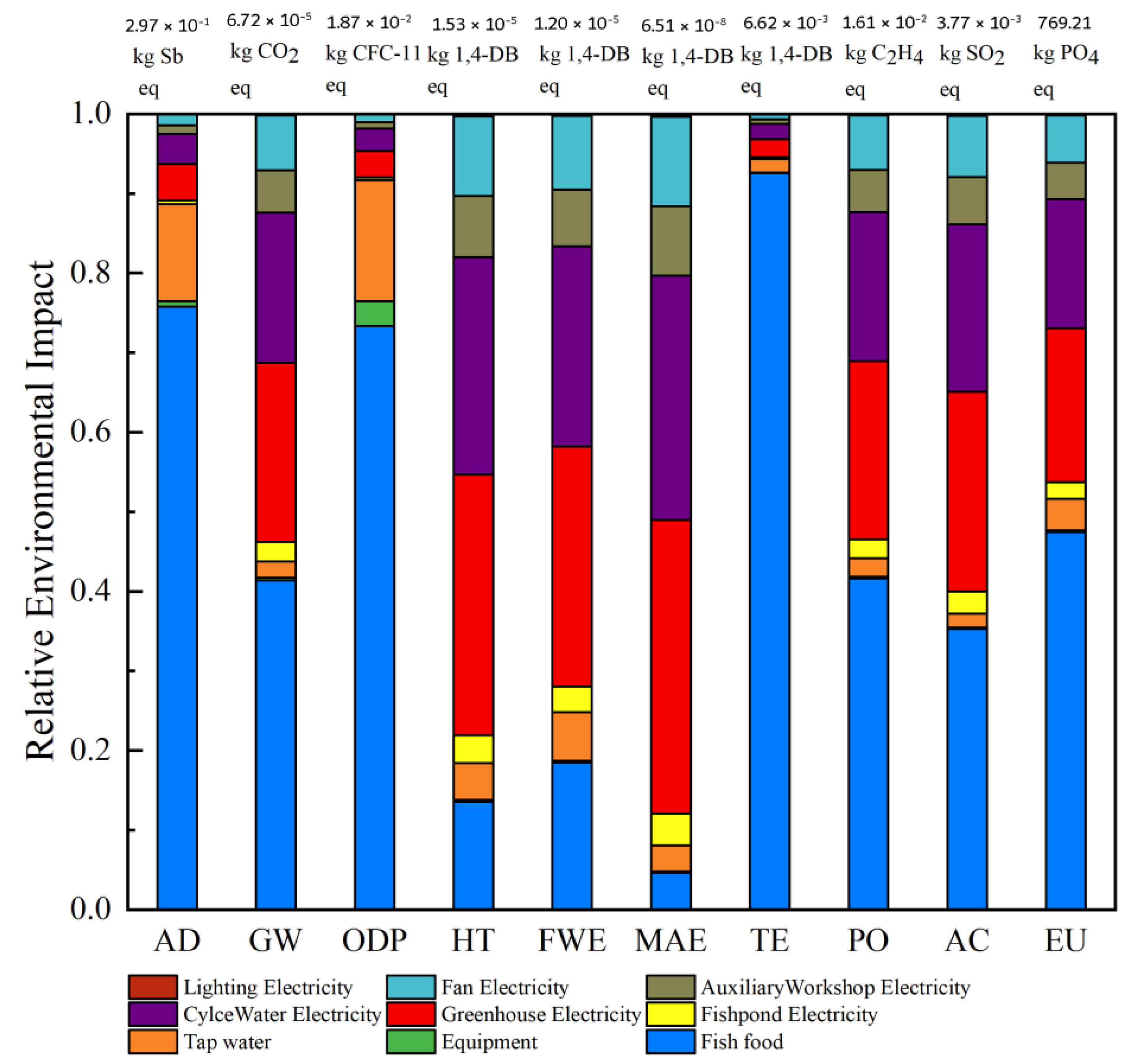

Figure 3 presents the total environmental impacts of the Chongqing IAS over one year of full-scale operation, corresponding to the production of approximately 114,700 kg of marketable largemouth bass and 86,546 kg of leafy vegetables. The relative contributions of major input sources—such as fish feed, water, electricity across various subsystems, and equipment—are shown across ten environmental impact categories using the CML-IA baseline method. While these values are not normalized to the functional unit, they provide valuable insight into the absolute magnitude and structure of environmental burdens across the integrated system.

Among all categories, global warming (GW) was the most significant, with a total emission of 6.72 × 105 kg CO2-eq, indicating that climate change is a primary concern for the aquaponics system under the current energy supply structure. Marine ecotoxicity (MAE) and human toxicity (HT) also showed high impact values, largely driven by the upstream production of fish feed and energy consumption during operation. In contrast, categories such as ozone depletion and photochemical oxidant formation presented relatively lower total impacts.

In terms of input contributions, fish feed was the dominant source of impact in most categories—particularly GW, AC, and EU—accounting for over half of the total impact in each. This reflects the high environmental burden associated with marine-based ingredients such as fishmeal and fish oil used in the feed formulation. Electricity consumption was the second-largest contributor, with notable influence in categories such as HT and ODP. This is attributed to the coal-intensive electricity mix of Chongqing, which accounted for over 70% of the power supply in 2021. Subsystems including water circulation, greenhouse climate control, and auxiliary workshop activities were the primary energy consumers. Equipment and water inputs contributed marginally across all impact categories, primarily due to the long service lifespan of infrastructure and the system’s high water reuse efficiency (>97%).

To evaluate the robustness of the LCA results and identify critical inputs influencing environmental performance, a sensitivity analysis was performed using the one-at-a-time (OAT) method. Key input parameters—including fish feed, water, equipment, and electricity consumption from major subsystems—were independently varied by ±20%. This range was chosen to reflect the observed operational variability during the first year of the IAS’s operation, which involved both commercial production and research trials, occasionally leading to fluctuations in energy and material use.

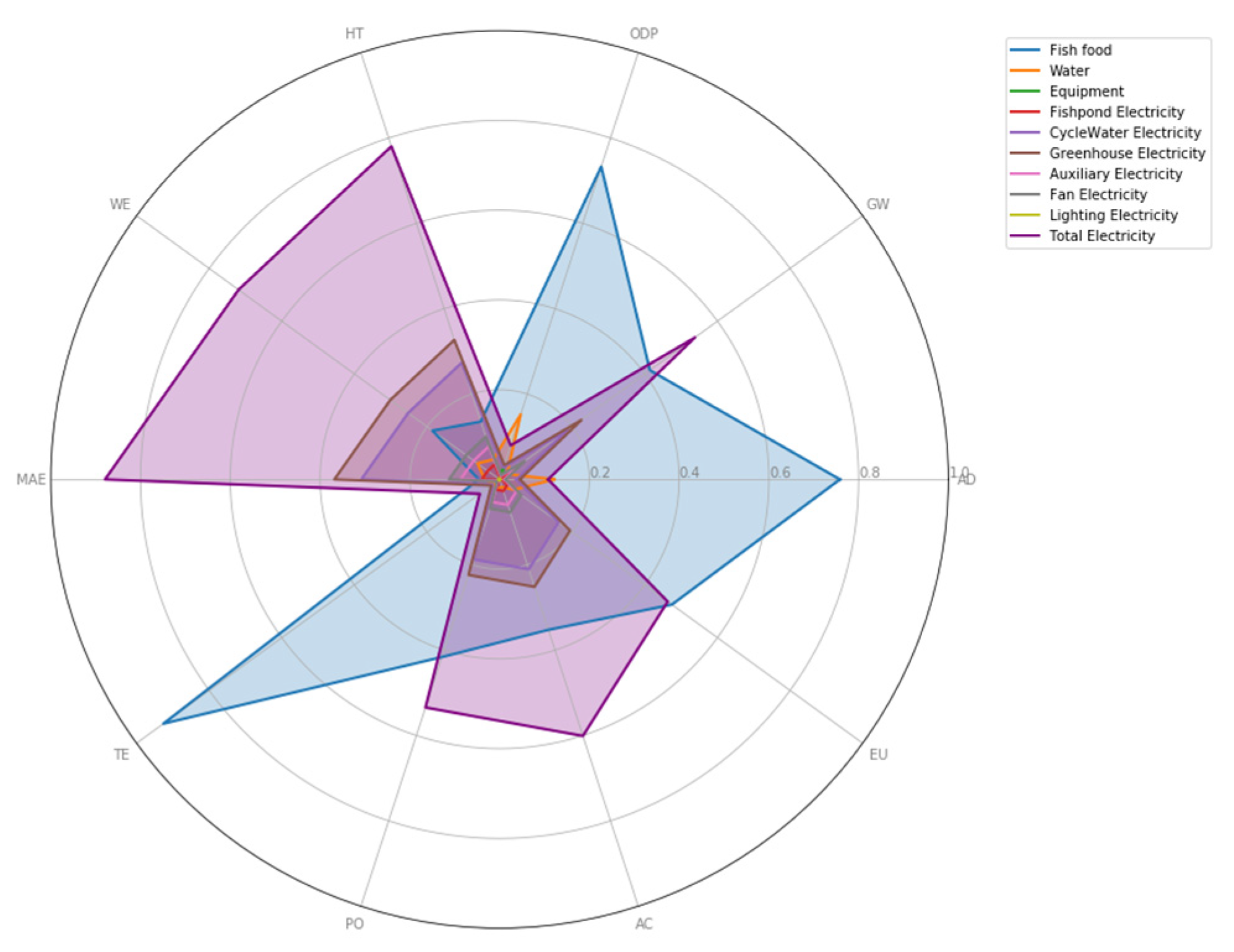

As shown in

Figure 4, the radar chart illustrates the sensitivity index of each input across the ten environmental impact categories. Fish feed exhibited the highest sensitivity in global warming (GW), acidification (AC), and eutrophication (EU) categories, reaffirming its dominant role in driving environmental burdens through upstream feed ingredient production, especially fishmeal and fish oil. Electricity consumption also showed significant sensitivity, particularly in human toxicity (HT), marine ecotoxicity (MAE), and freshwater ecotoxicity (FWE), with recirculating water and greenhouse electricity being the most influential subsystems.

Other inputs, such as water and equipment, showed limited sensitivity across most categories, suggesting that infrastructure and water use efficiency are relatively stable aspects of the system’s environmental performance. Notably, the sensitivity of electricity-related inputs is tightly coupled with the coal-dominated regional grid mix, emphasizing the potential for environmental improvements through energy structure optimization or on-site renewable integration.

These results highlight that feed formulation and energy efficiency are the two most impactful levers for reducing the environmental footprint of industrial aquaponics. Previous LCA studies of aquaponic systems have primarily focused on small-scale or pilot systems, including vertical layouts using rainwater [

41] and commercial-scale urban systems adjacent to retail stores [

42]. Boxman et al. [

43] examined a freshwater aquaponic system and similarly highlighted feed and electricity as key hotspots. However, our study advances this body of work by evaluating an industrial-scale facility using full-year operational data. We further explore specific scenario optimizations, offering scalable and context-specific insights for improving environmental performance in Chinese aquaponics. Future efforts targeting low-impact, plant-based feed alternatives and low-carbon power sourcing could deliver substantial environmental benefits.

3.2. Sustainability Analysis

To further evaluate the sustainability performance of the Chongqing IAS, a comparative analysis was conducted using the globally harmonized agricultural dataset developed by Poore and Nemecek [

25]. This dataset compiles life cycle environmental impacts from over 38,700 farms across 119 countries, covering 40 agricultural products and representing approximately 90% of global protein and caloric intake. By aligning functional units with nutritional metrics, this analysis enables a fair comparison between aquaponics products and other major protein sources.

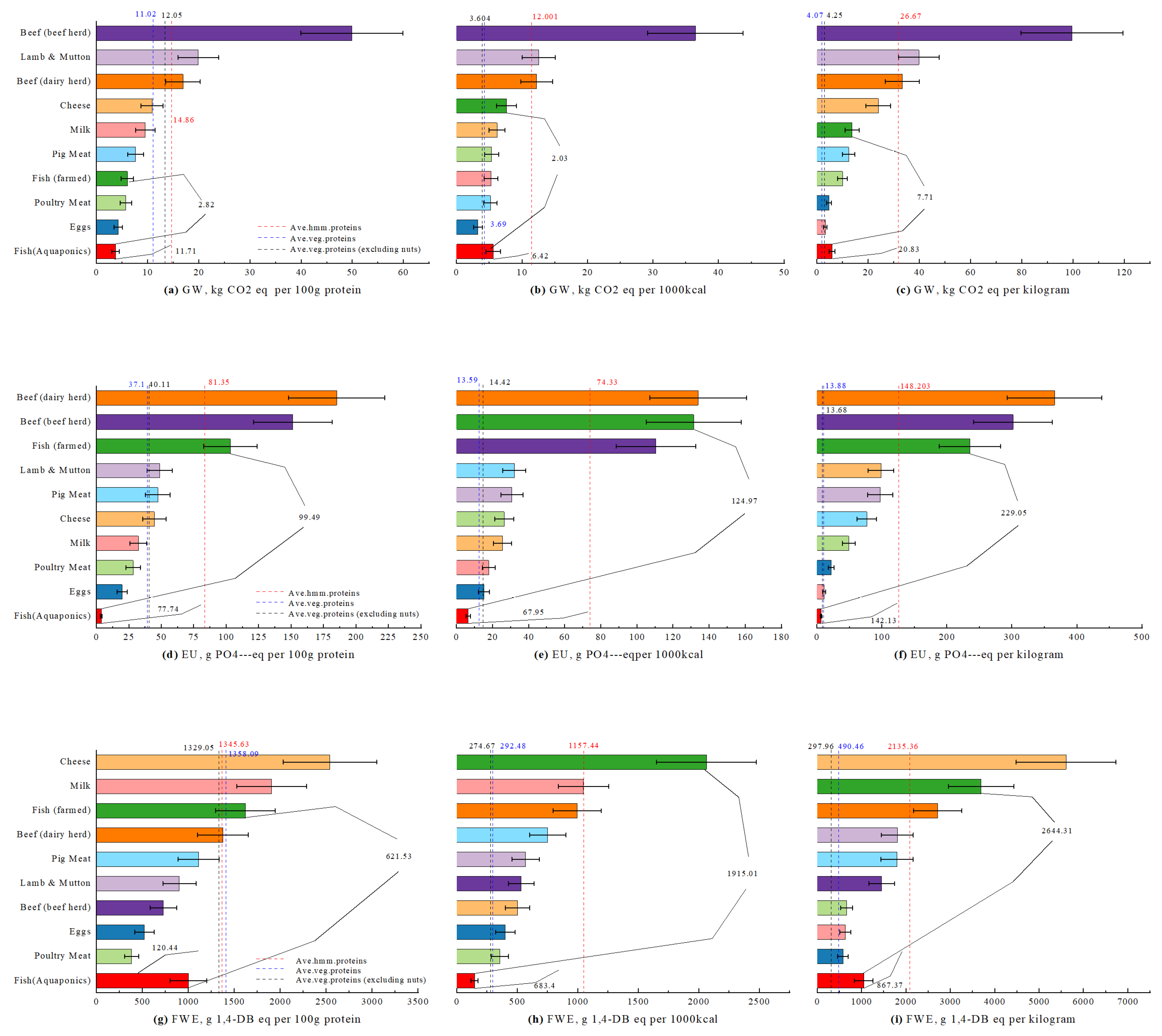

In this study, the nutritional content of fish products from the IAS was estimated at 18.6 g of protein and 105 kcal per 100 g edible portion, based on national food composition standards. These values were used to convert the total annual output of the IAS into nutritional equivalents, which were then compared to other animal and plant-based protein sources using three normalization bases: per 100 g protein, per 1000 kcal, and per kilogram edible product.

As shown in

Figure 5, the aquaponics system demonstrated consistently lower environmental impacts across all indicators and normalization schemes compared to conventional animal protein sources such as beef, lamb, and dairy. Specifically, aquaponics fish exhibited significantly lower global warming potential (GW), eutrophication potential (EU), and freshwater ecotoxicity (FWE). For example, the GW impact per 100 g protein from aquaponics fish was 11.71 kg CO

2-eq, compared to 60–100 kg CO

2-eq for ruminant meat. Similarly, EU and FWE values remained well below the global average of animal-based proteins.

Furthermore,

Figure 5 shows that aquaponics fish performs favorably even against plant-based proteins and vegetables, particularly when evaluated per kilocalorie, suggesting strong potential for contributing to sustainable and nutrient-dense food systems.

The inclusion of vegetable co-products in the IAS further enhances its sustainability profile, although their environmental burdens were allocated proportionally based on mass and excluded from the nutritional normalization for clarity.

This comparative analysis confirms that industrial aquaponics—when optimized for feed efficiency and energy use—offers a viable low-impact alternative for protein production, aligning with global sustainability targets in food systems.

3.3. Energy Mix Scenario Analysis

To further explore the environmental performance of the Chongqing IAS, a scenario-based analysis was conducted to assess the sensitivity of life cycle impacts to changes in the electricity supply structure. Given the energy-intensive nature of aquaponics operations—particularly in water circulation, greenhouse climate control, and supplemental lighting—electricity composition plays a pivotal role in determining the overall environmental footprint.

Table 1 presents nine different energy mix scenarios. The first four are based on historical data from China (2008, 2015, and 2020) and the European Union (2016), reflecting regional variations in fossil and renewable energy sources. The remaining five are hypothetical 100% single-source scenarios, designed to isolate the environmental consequences of electricity derived exclusively from coal, natural gas, wind, solar, or hydropower.

Among the real-world scenarios, the 2020 Chinese electricity mix (CN2020) offers the most favorable balance, with 33% renewable energy and 61% coal, reflecting national progress in low-carbon energy deployment. In contrast, the CN2008 scenario, dominated by coal (79%), represents a high-impact energy structure with substantially greater greenhouse gas emissions and air pollution-related categories such as acidification and human toxicity.

The 100% renewable scenarios demonstrate the theoretical minimum impact of aquaponics under ideal decarbonization conditions. Notably, scenarios based on wind and solar sources nearly eliminate contributions to global warming (GW) and acidification (AC), while the hydropower scenario shows relatively higher values in freshwater ecotoxicity (FWE) due to dam-related infrastructure impacts captured in the Ecoinvent database [

44].

This analysis highlights that transitioning the electricity supply from coal-dominated to renewable-dominated mixes can lead to significant environmental impact reductions—particularly in climate-related categories. Since energy is the second-largest contributor to most impact categories after feed, decarbonizing the energy input presents a high-leverage strategy for improving the sustainability of aquaponics systems.

For further breakdowns of renewable electricity compositions (e.g., hydro, wind, solar proportions), refer to

Supplementary Table S3.

Figure 6 presents the comparative environmental impacts of the Chongqing IAS under the nine electricity scenarios described in

Table 1, across all impact categories defined by the CML-IA baseline method. The analysis clearly demonstrates that the energy composition has a substantial influence on overall environmental performance, particularly in categories associated with emissions and resource extraction.

The coal-based scenario results in the highest impact values in nearly all categories, including global warming (GW), human toxicity (HT), marine ecotoxicity (MAE), and acidification (AC), due to high emissions of CO2, SO2, and heavy metals from coal combustion. This scenario represents the upper bound of environmental burden under fossil-fuel-dependent energy systems.

In contrast, the 100% renewable scenarios—especially wind and solar—exhibit the lowest environmental impacts in most categories, nearly eliminating contributions to global warming and acidification. Wind energy, in particular, consistently yields the lowest impacts across GW, ODP, and TE. However, the hydropower scenario, while low in emissions, shows a relatively higher abiotic depletion (AD), due to the material and land use intensity of dam construction captured in the background datasets.

The CN2020 scenario demonstrates a moderate improvement over earlier Chinese mixes (e.g., CN2008 and CN2015), indicating a positive shift toward decarbonization. Nevertheless, its coal share (61%) still results in higher impacts compared to the EU2016 scenario, which benefits from a more balanced energy portfolio including greater contributions from gas and nuclear energy.

These results suggest that decarbonizing the electricity supply—especially by replacing coal with wind or solar—can substantially mitigate the environmental footprint of aquaponics production. Since electricity is the second-largest contributor to the system’s impacts after fish feed, energy transition strategies have the potential to significantly enhance the system’s overall sustainability.

3.4. Fish Food Scenario Analysis

In aquaponics systems, feed formulation and consumption represent a major environmental hotspot, especially under high-density and high-frequency feeding regimes as observed in indoor industrial models. In the Chongqing IAS, fish are fed up to five times daily at optimal water temperatures to maximize growth, resulting in substantial feed consumption over the full production cycle. While fish reared under traditional conditions may require different feed compositions at various growth stages, the controlled environment of an aquaponics factory allows the use of a single feed formulation throughout the growth period, thereby simplifying inventory management and improving operational efficiency.

To evaluate the impact of alternative feed formulations on the system’s environmental performance, this study modeled several hypothetical fish feed scenarios based on established commercial feed types, as detailed in

Table 2. These scenarios include feeds originally developed for trout, tilapia, and black pacu, with varying protein levels (ranging from 24% to 42.5%) and ingredient compositions, including fishmeal, meat meal, plant-based proteins, and various oils and grains.

Based on label information from the actual feed used in the Chongqing IAS—Yuanpai largemouth bass feed, which contains ≥50% crude protein and ≥8% crude fat—the Trout C formulation (42.5% protein, 49% fishmeal, 17% fish oil) was selected as the baseline scenario due to its closest similarity in nutrient profile and ingredient composition. While not an exact match, it offers the most suitable proxy among the available formulations for modeling the environmental impacts of the current feeding practice.

Preliminary results suggest that replacing fishmeal- and fish oil-heavy feeds with plant-based alternatives can reduce impacts in most categories by up to 30–50%, particularly in GW, AC, and EU. However, some trade-offs were observed in abiotic depletion (AD) and land use, due to the increased reliance on agricultural crops such as maize and soy.

Overall, this analysis highlights the importance of feed formulation optimization as a key strategy for improving the sustainability of aquaponics systems. Among the scenarios evaluated, Tilapia B feed, which minimizes fishmeal use and relies on maize and soybean meal, emerged as one of the most environmentally favorable options, balancing nutritional adequacy with lower environmental impacts.

The environmental performance of different fish feed formulations used in the scenario analysis is further illustrated in

Figure 7, which presents the relative contribution of each feed type to ten environmental impact categories, based on both unit mass and equivalent protein content of the produced feed. Each colored bar represents one of the seven feed types, while the red dashed line indicates the average global warming (GW) impact across all feed scenarios.

Results show that feed formulations with higher proportions of fishmeal and fish oil, such as Trout C (42.5% protein), generally exhibit above-average environmental impacts, particularly in marine ecotoxicity (MAE), terrestrial ecotoxicity (TE), and abiotic depletion (AD). These effects are largely attributable to the upstream sourcing of marine ingredients and their associated emissions, land use, and biodiversity disruption.

In contrast, feeds such as Tilapia B (24–28% protein) and Black pacu A (24.5% protein), which rely more heavily on plant-based ingredients like maize, soybean meal, and rice, demonstrate consistently lower environmental burdens, particularly in categories such as GW, acidification (AC), and eutrophication (EU). Notably, Tilapia B shows the lowest relative impact in most categories, making it the most environmentally favorable among the tested scenarios, despite its lower protein content.

Interestingly, some plant-based feeds such as Tilapia A and Pacu B still show slightly elevated impacts in categories like water ecotoxicity (WAE) or ozone depletion (ODP), likely due to indirect emissions or intensive fertilizer use in crop production. However, these impacts remain well below the baseline feed represented by Trout C. It should be noted that only the baseline diet (Trout C proxy, closest to the Chongqing commercial bass feed) is nutritionally adequate for largemouth bass. The other formulations (e.g., tilapia and pacu diets) are included solely for comparative environmental assessment, as they represent common feed formulations in global aquaculture. These scenarios are not intended to imply practical substitution for largemouth bass, but rather to illustrate the environmental trade-offs between marine-based and plant-based feed strategies.

Overall, the results confirm that replacing marine-derived feed components with plant-based alternatives can significantly reduce environmental burdens in aquaponics systems. This supports a growing body of evidence suggesting that feed reformulation is one of the most effective levers for improving the environmental sustainability of aquaculture and aquaponics. The detailed composition of each feed formulation is provided in

Supplementary Information Table S2.

4. Conclusions

This study presents a comprehensive LCA of the Chongqing IAS, the first large-scale intelligent aquaponics facility in China, using the CML-IA baseline method and a functional unit of 1 kg of marketable largemouth bass. The system’s environmental performance was assessed across ten impact categories based on empirical inventory data, and multiple scenario analyses were conducted to explore optimization opportunities through feed composition and energy supply restructuring.

The results show that the main environmental burdens arise from fish feed production and electricity consumption, together contributing to the majority of impacts in categories such as global warming (GW), eutrophication (EU), and human toxicity (HT). Sensitivity analysis revealed that even modest changes (±20%) in these inputs lead to considerable variation in overall impacts, confirming their critical role in system sustainability. Comparative analysis with global protein sources further demonstrated that aquaponics-based fish production performs significantly better than most conventional animal proteins, especially when normalized by nutritional value (e.g., per 100 g protein), offering a compelling case for aquaponics in low-impact, high-efficiency protein systems.

The energy mix scenario analysis indicated that transitioning to low-carbon electricity sources, particularly wind and solar, could substantially reduce environmental impacts, particularly GW, AC, and ODP. However, hydropower, while renewable, presents trade-offs in freshwater-related categories. Meanwhile, fish feed reformulation presents another high-impact mitigation strategy. Among the alternative feed scenarios, Tilapia B (low in fishmeal and fish oil, high in soybean and maize) emerged as the most sustainable, reducing impacts across nearly all categories compared to the baseline feed (Trout C).

This research highlights the strong potential of IASs as climate-smart, resource-efficient agricultural solutions, particularly when combined with optimized feed strategies and decarbonized energy inputs. Future work should consider the inclusion of socio-economic and biodiversity dimensions, and further investigate localized feed ingredients and renewable integration pathways to fully realize the environmental and food security benefits of aquaponics in the Chinese context and beyond.