Analysing the Usefulness of Circular Strategies to Improve Supply Chain Resilience Against Demand Changes

Abstract

1. Introduction

2. Literature Review

2.1. Demand Changes and Resilience in Supply Chains

2.2. Circular Concepts in Supply Chains

2.2.1. Quantitative Studies on Circular Supply Chains

2.2.2. Case Studies on Circular Supply Chains

2.2.3. Empirical Studies on Circular Supply Chains

2.3. Circular Supply Chains and Resilience

| Reference | Contributions | Findings | Methods Used | Industry Sectors | Regions | Key Strategies | Performance Indicators |

|---|---|---|---|---|---|---|---|

| [46] |

|

| Case study, analytical hierarchy process | Sugar cane, paper industry, cement industry | Not specific | Energy optimisation, decarbonisation of operations, secondary material sourcing, material synergy, utility synergy, collaboration with partners, information sharing, real-time monitoring | Cost reduction Recovery lead-time Minimisation of waste generation |

| [12] |

|

| Case study, qualitative data analysis | Healthcare | Brazil | Public–private volunteer partnership, knowledge transfer, reusing parts, redistributing the demand, volunteer repair services, volunteer training, sharing expertise, collaboration to develop alternatives, consolidating information, online collaboration with partners | Not mentioned |

| [47] |

|

| Case study | European process industry | Europe | Structured design, suitable logistics, urban symbiosis practices, sustainable consumption, electric vehicles, leadership support, cultural mindset, user-centred design, dematerialisation, sharing of reused/recycled materials, alternative processing techniques, increased product lifetime, and collaboration with suppliers | Environmental footprint Cost efficiency |

| [49] |

|

| Opinions | Fashion industry | Not specific | Reuse, recycle, recover, redesign, invest in innovation, use sustainable fibre, use biobased materials, increase product lifecycle | Reduce CO2 emissions Reduce pollution Improve product safety Eliminate harmful chemicals Reduce toxicity |

| [48] |

|

| Qualitative case study | Seafood sector | Not specific | Diversification, knowledge exchange, dematerialisation, and reducing waste generation | Not mentioned |

| [13] |

|

| Structural equation modelling | Automotive, heavy engineering, and mining equipment | South Africa | Skilled workforce, reverse logistics, using advanced technology, recycling, changeover systems, alternative component design | Optimise cost Optimal pricing Customer demand fulfilment |

2.4. Research Gaps

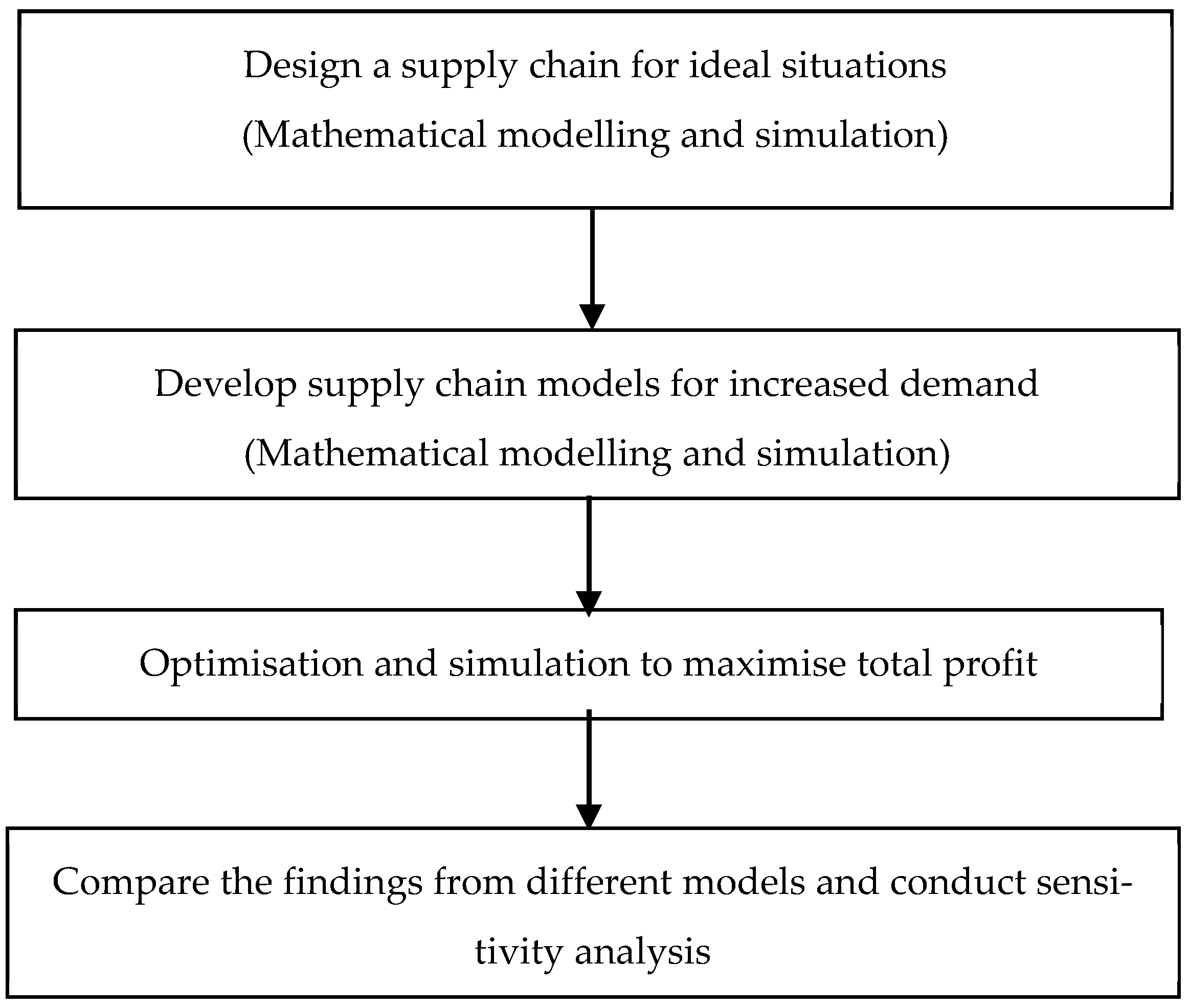

3. Model Development and Research Methodology

3.1. Model 1: Model to Design a Supply Chain Under Ideal Situations

3.2. Model 2: Model for Supply Chain Plans Under Increased Demand with No Strategies

3.3. Model 3: Model for Supply Chain Plans Under Increased Demand with Strategies

- Use of repair centres: In this study, repair centres are established along with DCs and used mobile phones are collected to repair them. After repair, mobile phones are sold as refurbished at a discounted price.

- Use of reuse centres: Some used mobile phones can be sold directly without being repaired. They are collected at the reuse centres and are sold at a lower price than the new phones.

3.4. Solution Methodology

4. Result Analysis

4.1. Results of Supply Chain Plans Under Ideal Situations

4.2. Results for Supply Chain Plans Under Increased Demand with No Strategies

4.3. Results for Supply Chain Plans Under Increased Demand with Circular Strategies

4.4. Comparison of Results

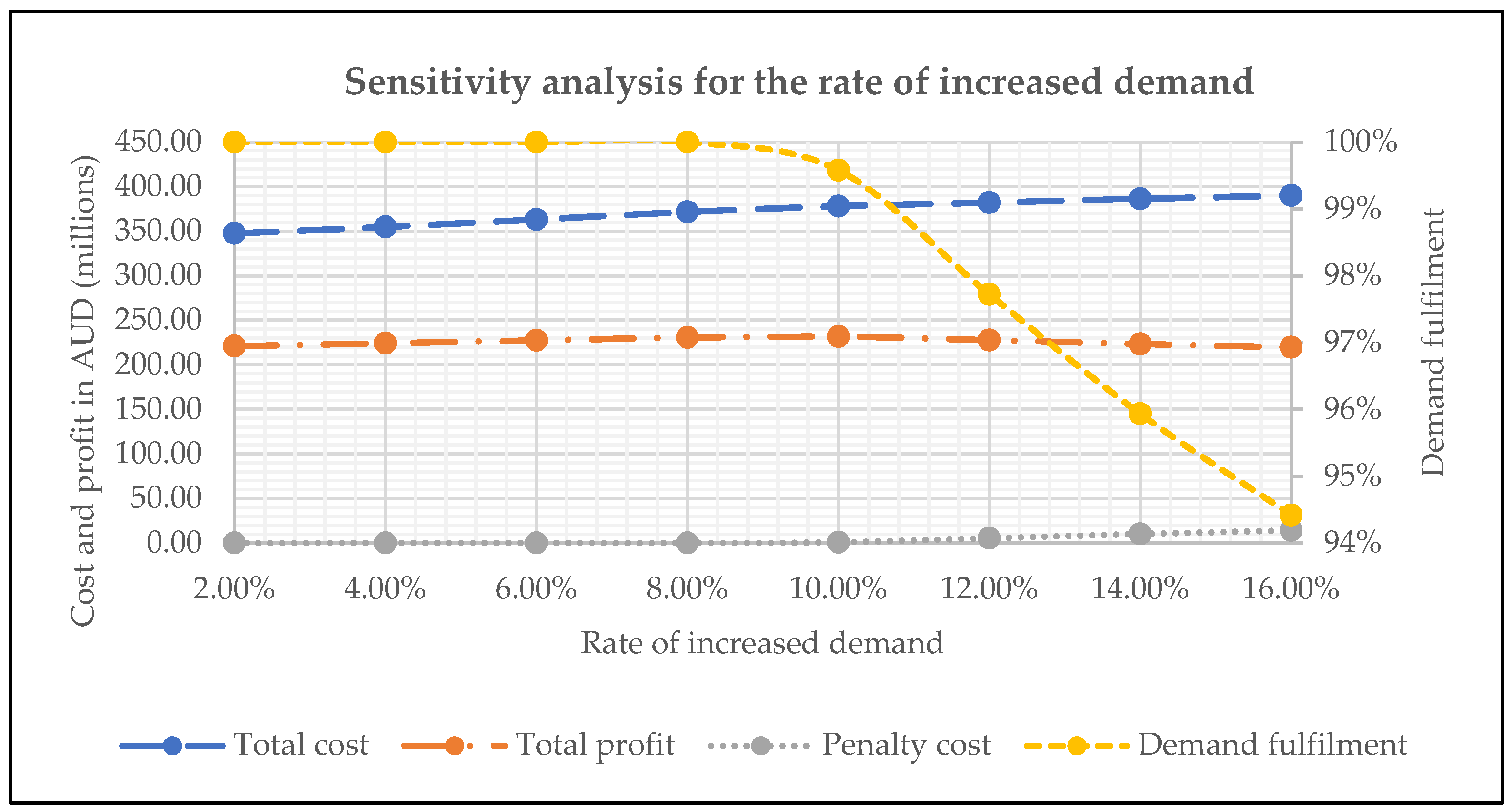

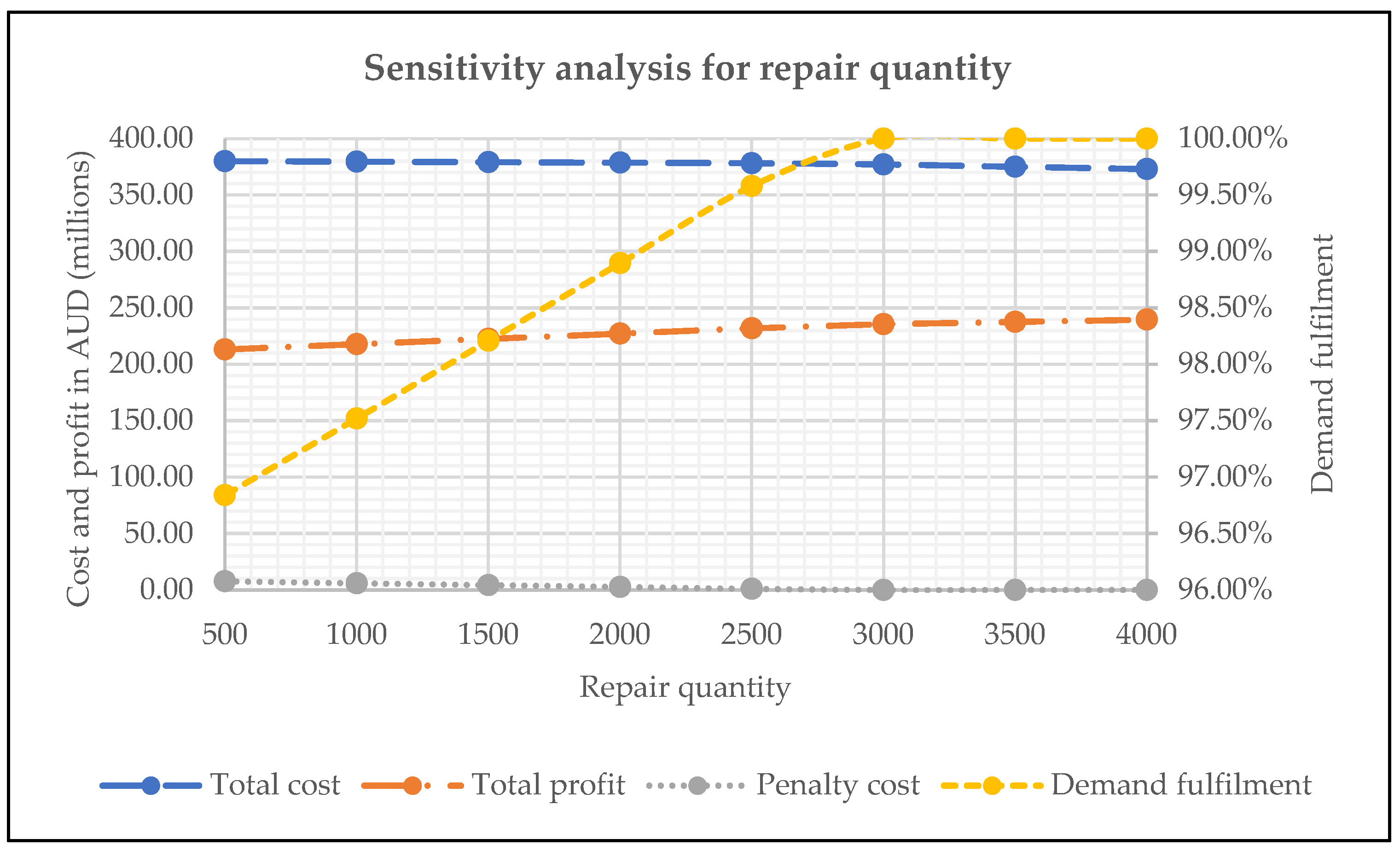

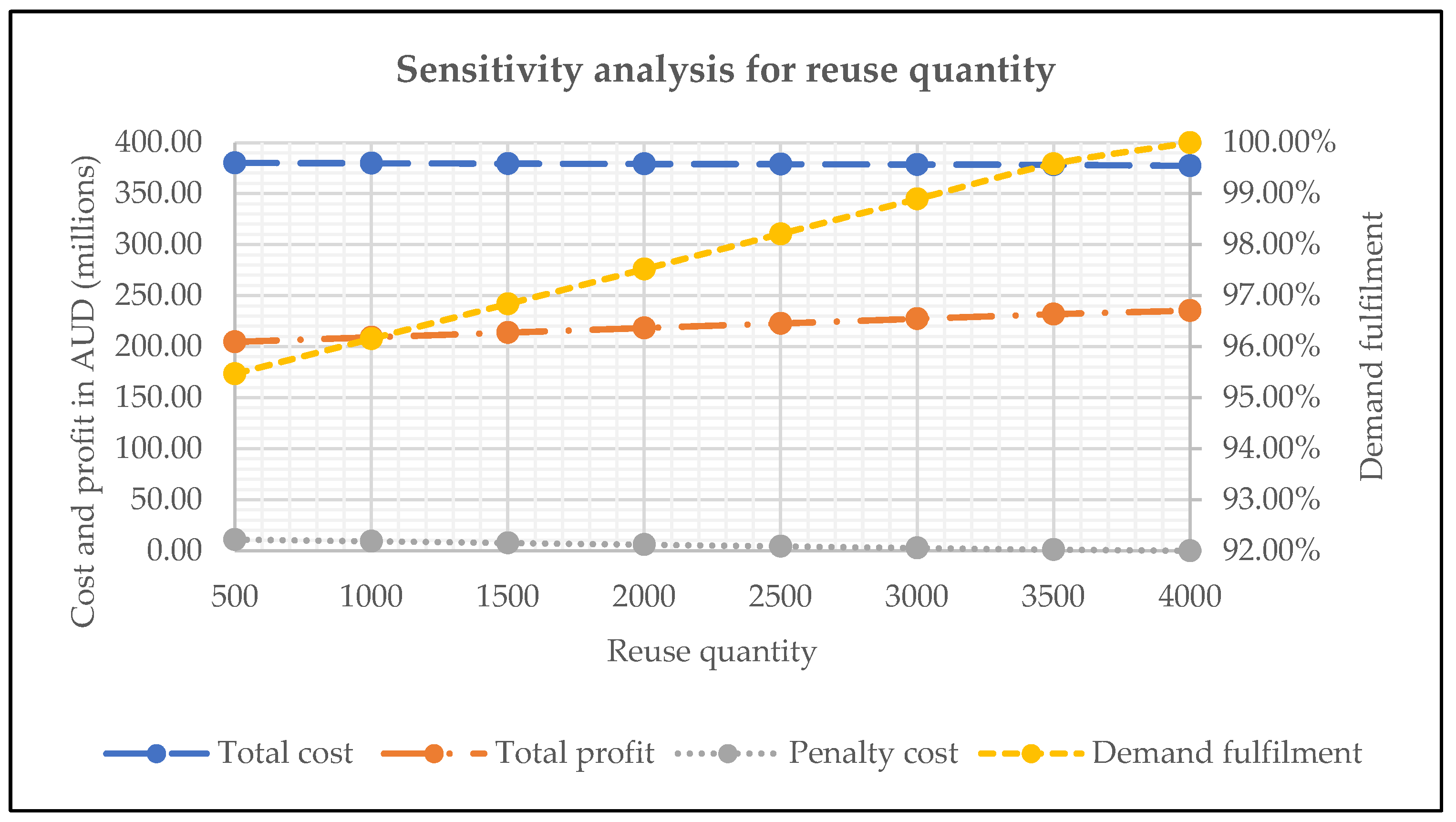

5. Sensitivity Analysis

5.1. Sensitivity Analysis for the Rate of Increased Demand

5.2. Sensitivity Analysis for Repair Quantity

5.3. Sensitivity Analysis for Reuse Quantity

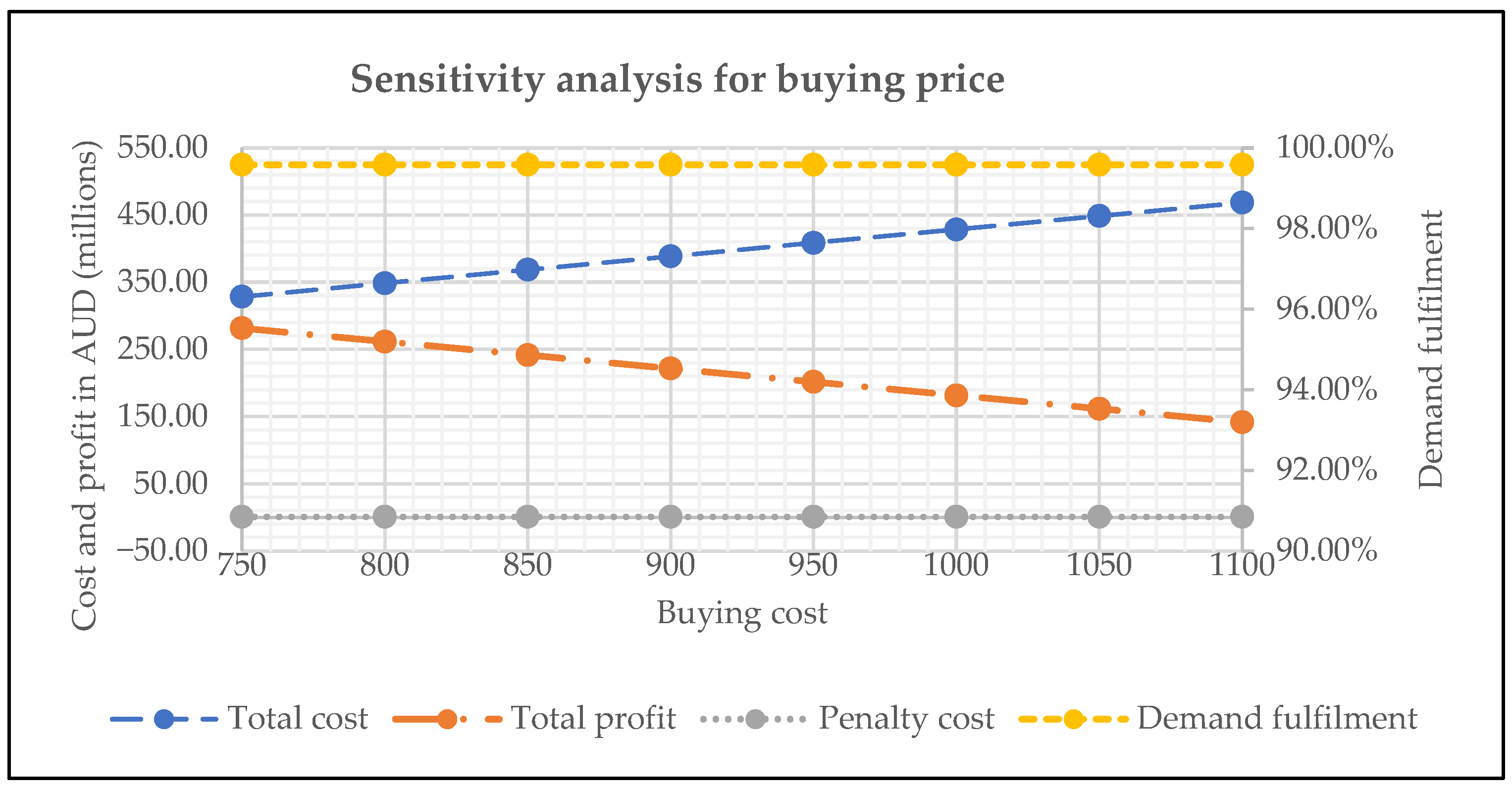

5.4. Sensitivity Analysis for the Buying Price

6. Practical Implications

7. Conclusions and Future Research Directions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A. Product Flow Under Different Situations

| From (DCs) | To (Retailers) | Quantity |

| Melbourne 2 | Retailer Traralgon | 5473 |

| Melbourne 2 | Retailer Albury | 5473 |

| Melbourne 2 | Retailer Balwyn North | 5473 |

| Melbourne 2 | Retailer Wangaratta | 5473 |

| Melbourne 2 | Retailer Shepparton | 5473 |

| Melbourne 2 | Retailer Canberra | 2972 |

| Melbourne 2 | Retailer Glen Iris | 5473 |

| Melbourne 2 | Retailer Melbourne | 3244 |

| Melbourne 2 | Retailer Wodonga | 5473 |

| Melbourne 2 | Retailer Frankston East | 5473 |

| Sydney 2 | Retailer Katoomba | 1758 |

| Sydney 2 | Retailer Orange | 5473 |

| Sydney 2 | Retailer Bathurst | 5473 |

| Sydney 2 | Retailer Epping | 5473 |

| Sydney 2 | Retailer Hornsby | 5473 |

| Sydney 2 | Retailer Port Stephens | 5473 |

| Sydney 2 | Retailer Forster | 4458 |

| Sydney 2 | Retailer Newcastle | 5473 |

| Sydney 2 | Retailer Maitland | 5473 |

| Sydney 2 | Retailer City of Parramatta | 5473 |

| Sydney 1 | Retailer Wollongong | 5473 |

| Sydney 1 | Retailer Liverpool | 5473 |

| Sydney 1 | Retailer Nowra | 5473 |

| Sydney 1 | Retailer Sydney | 5473 |

| Sydney 1 | Retailer Katoomba | 3715 |

| Sydney 1 | Retailer Queanbeyan | 5473 |

| Sydney 1 | Retailer Canberra | 2501 |

| Sydney 1 | Retailer Strathfield | 5473 |

| Sydney 1 | Retailer Parramatta | 5473 |

| Sydney 1 | Retailer Goulburn | 5473 |

| Melbourne 1 | Retailer Devonport | 5473 |

| Melbourne 1 | Retailer Launceston | 5473 |

| Melbourne 1 | Retailer Burnie | 5473 |

| Melbourne 1 | Retailer Ballarat | 5473 |

| Melbourne 1 | Retailer Warrnambool | 3987 |

| Melbourne 1 | Retailer Echuca | 5473 |

| Melbourne 1 | Retailer Melbourne | 2229 |

| Melbourne 1 | Retailer Bendigo | 5473 |

| Melbourne 1 | Retailer Geelong | 5473 |

| Melbourne 1 | Retailer St Albans | 5473 |

| Adelaide | Retailer Prospect | 5473 |

| Adelaide | Retailer Gawler | 5473 |

| Adelaide | Retailer Murray Bridge | 5473 |

| Adelaide | Retailer Adelaide Hills | 5473 |

| Adelaide | Retailer Whyalla | 4730 |

| Adelaide | Retailer Warrnambool | 1486 |

| Adelaide | Retailer Mildura | 5473 |

| Adelaide | Retailer Adelaide | 5473 |

| Adelaide | Retailer Broken Hill | 5473 |

| Adelaide | Retailer Mount Gambier | 5473 |

| Perth | Retailer Kwinana | 5473 |

| Perth | Retailer Rockingham | 5473 |

| Perth | Retailer Albany | 5473 |

| Perth | Retailer Whyalla | 743 |

| Perth | Retailer Busselton | 5473 |

| Perth | Retailer Geraldton | 5473 |

| Perth | Retailer Bunbury | 5473 |

| Perth | Retailer Perth | 5473 |

| Perth | Retailer Kalgoorlie | 5473 |

| Perth | Retailer Mandurah | 5473 |

| Darwin | Retailer Cairns | 5473 |

| Darwin | Retailer Gladstone | 5473 |

| Darwin | Retailer Palmerston | 5473 |

| Darwin | Retailer Alice Springs | 5473 |

| Darwin | Retailer Mackay | 5473 |

| Darwin | Retailer Bundaberg | 743 |

| Darwin | Retailer Mount Isa | 5473 |

| Darwin | Retailer Townsville | 5473 |

| Darwin | Retailer Darwin | 5473 |

| Darwin | Retailer Rockhampton | 5473 |

| Brisbane | Retailer Coffs Harbour | 1486 |

| Brisbane | Retailer Maryborough | 5473 |

| Brisbane | Retailer Lismore | 5473 |

| Brisbane | Retailer Woodridge | 5473 |

| Brisbane | Retailer Gold Coast | 5473 |

| Brisbane | Retailer Brisbane | 5473 |

| Brisbane | Retailer Caloundra | 5473 |

| Brisbane | Retailer Toowoomba | 5473 |

| Brisbane | Retailer Bundaberg | 4730 |

| Brisbane | Retailer Logan City | 5473 |

| From (DCs) | To (Retailers) | Quantity |

| Sydney 2 | Retailer Tamworth | 5473 |

| Sydney 2 | Retailer Orange | 5473 |

| Sydney 2 | Retailer Hornsby | 5473 |

| Sydney 2 | Retailer Taree | 5473 |

| Sydney 2 | Retailer Newcastle | 5473 |

| Sydney 2 | Retailer Port Stephens | 5473 |

| Sydney 2 | Retailer Maitland | 5473 |

| Sydney 2 | Retailer Forster | 5473 |

| Sydney 2 | Retailer Port Macquarie | 743 |

| Sydney 2 | Retailer Bathurst | 5473 |

| Adelaide | Retailer Adelaide | 5473 |

| Adelaide | Retailer Prospect | 5473 |

| Adelaide | Retailer Adelaide Hills | 5473 |

| Adelaide | Retailer Dubbo | 5473 |

| Adelaide | Retailer Murray Bridge | 5473 |

| Adelaide | Retailer Mildura | 5473 |

| Adelaide | Retailer Echuca | 2540 |

| Adelaide | Retailer Gawler | 5473 |

| Adelaide | Retailer Broken Hill | 4203 |

| Adelaide | Retailer Warrnambool | 5473 |

| Adelaide | Retailer Mount Gambier | 5473 |

| Perth | Retailer Geraldton | 5473 |

| Perth | Retailer Busselton | 5473 |

| Perth | Retailer Albany | 5473 |

| Perth | Retailer Mandurah | 5473 |

| Perth | Retailer Whyalla | 5473 |

| Perth | Retailer Rockingham | 5473 |

| Perth | Retailer Kwinana | 5473 |

| Perth | Retailer Kalgoorlie | 5473 |

| Perth | Retailer Broken Hill | 1270 |

| Perth | Retailer Perth | 5473 |

| Perth | Retailer Bunbury | 5473 |

| Melbourne 1 | Retailer Burnie | 5473 |

| Melbourne 1 | Retailer Devonport | 5473 |

| Melbourne 1 | Retailer Bendigo | 5473 |

| Melbourne 1 | Retailer St Albans | 5473 |

| Melbourne 1 | Retailer Launceston | 5473 |

| Melbourne 1 | Retailer Echuca | 2933 |

| Melbourne 1 | Retailer Hobart | 5473 |

| Melbourne 1 | Retailer Melbourne | 5473 |

| Melbourne 1 | Retailer Shepparton | 3810 |

| Melbourne 1 | Retailer Geelong | 5473 |

| Melbourne 1 | Retailer Ballarat | 5473 |

| Brisbane | Retailer Brisbane | 5473 |

| Brisbane | Retailer Armidale | 5473 |

| Brisbane | Retailer Coffs Harbour | 5473 |

| Brisbane | Retailer Gold Coast | 5473 |

| Brisbane | Retailer Woodridge | 5473 |

| Brisbane | Retailer Caloundra | 5473 |

| Brisbane | Retailer Logan City | 5473 |

| Brisbane | Retailer Port Macquarie | 2540 |

| Brisbane | Retailer Maryborough | 4203 |

| Brisbane | Retailer Lismore | 5473 |

| Brisbane | Retailer Toowoomba | 5473 |

| Melbourne 2 | Retailer Wangaratta | 5473 |

| Melbourne 2 | Retailer Canberra | 5473 |

| Melbourne 2 | Retailer Glen Iris | 5473 |

| Melbourne 2 | Retailer Traralgon | 5473 |

| Melbourne 2 | Retailer Albury | 5473 |

| Melbourne 2 | Retailer Queanbeyan | 4553 |

| Melbourne 2 | Retailer Frankston East | 5473 |

| Melbourne 2 | Retailer Balwyn North | 5473 |

| Melbourne 2 | Retailer Shepparton | 1663 |

| Melbourne 2 | Retailer Wodonga | 5473 |

| Sydney 1 | Retailer Goulburn | 5473 |

| Sydney 1 | Retailer City of Parramatta | 5473 |

| Sydney 1 | Retailer Parramatta | 5473 |

| Sydney 1 | Retailer Liverpool | 5473 |

| Sydney 1 | Retailer Epping | 5473 |

| Sydney 1 | Retailer Wollongong | 5473 |

| Sydney 1 | Retailer Nowra | 5473 |

| Sydney 1 | Retailer Queanbeyan | 920 |

| Sydney 1 | Retailer Sydney | 5473 |

| Sydney 1 | Retailer Katoomba | 5473 |

| Sydney 1 | Retailer Port Macquarie | 350 |

| Sydney 1 | Retailer Strathfield | 5473 |

| Darwin | Retailer Alice Springs | 5473 |

| Darwin | Retailer Townsville | 5473 |

| Darwin | Retailer Bundaberg | 5473 |

| Darwin | Retailer Cairns | 5473 |

| Darwin | Retailer Gladstone | 5473 |

| Darwin | Retailer Palmerston | 5473 |

| Darwin | Retailer Darwin | 5473 |

| Darwin | Retailer Mount Isa | 5473 |

| Darwin | Retailer Rockhampton | 5473 |

| Darwin | Retailer Maryborough | 1270 |

| Darwin | Retailer Mackay | 5473 |

References

- Rahman, T.; Paul, S.K.; Shukla, N.; Agarwal, R.; Taghikhah, F. Supply Chain Resilience Initiatives and Strategies: A Systematic Review. Comput. Ind. Eng. 2022, 170, 108317. [Google Scholar] [CrossRef]

- Paul, S.K.; Sarker, R.; Essam, D. Managing Real-Time Demand Fluctuation under a Supplier–Retailer Coordinated System. Int. J. Prod. Econ. 2014, 158, 231–243. [Google Scholar] [CrossRef]

- Rahman, T.; Paul, S.K.; Agarwal, R.; Shukla, N.; Taghikhah, F. A Viable Supply Chain Model for Managing Panic-Buying Related Challenges: Lessons Learned from the COVID-19 Pandemic. Int. J. Prod. Res. 2024, 62, 3415–3434. [Google Scholar] [CrossRef]

- Lee, J.; Moon, I. An Integrated Model of Supply Chain Resilience Considering Supply and Demand Uncertainties. Int. Trans. Oper. Res. 2025, 32, 1834–1860. [Google Scholar] [CrossRef]

- Scholten, K.; Stevenson, M.; van Donk, D.P. Dealing with the Unpredictable: Supply Chain Resilience. Int. J. Oper. Prod. Manag. 2020, 40, 1–10. [Google Scholar] [CrossRef]

- Paul, S.K.; Sarker, R.; Essam, D. A Quantitative Model for Disruption Mitigation in a Supply Chain. Eur. J. Oper. Res. 2017, 257, 881–895. [Google Scholar] [CrossRef]

- Suryadi, A.; Rau, H. Considering Region Risks and Mitigation Strategies in the Supplier Selection Process for Improving Supply Chain Resilience. Comput. Ind. Eng. 2023, 181, 109288. [Google Scholar] [CrossRef]

- Hamidu, Z.; Issau, K.; Boachie-Mensah, F.O.; Asafo-Adjei, E. On the Interplay of Supply Chain Network Complexity on the Nexus between Supply Chain Resilience and Performance. Benchmarking 2024, 31, 1590–1610. [Google Scholar] [CrossRef]

- Tan, W.J.; Cai, W.; Zhang, A.N. Structural-Aware Simulation Analysis of Supply Chain Resilience. Int. J. Prod. Res. 2020, 58, 5175–5195. [Google Scholar] [CrossRef]

- Macdonald, J.R.; Zobel, C.W.; Melnyk, S.A.; Griffis, S.E. Supply Chain Risk and Resilience: Theory Building through Structured Experiments and Simulation. Int. J. Prod. Res. 2018, 56, 4337–4355. [Google Scholar] [CrossRef]

- Trabucco, M.; De Giovanni, P. Achieving Resilience and Business Sustainability during COVID-19: The Role of Lean Supply Chain Practices and Digitalization. Sustainability 2021, 13, 12369. [Google Scholar] [CrossRef]

- Cobra, R.; Moroni, I.T.; Rodrigues, V.P.; Fradinho, J.M.S.; Mascarenhas, J. Repair as a Circular Strategy for Increasing Resource Availability and Health System Resilience during a Crisis. Health Policy Technol. 2023, 12, 100778. [Google Scholar] [CrossRef]

- Bag, S.; Gupta, S.; Foropon, C. Examining the Role of Dynamic Remanufacturing Capability on Supply Chain Resilience in Circular Economy. Manag. Decis. 2019, 57, 863–885. [Google Scholar] [CrossRef]

- Zhou, X.; Jiang, J.; Zhou, C.; Li, X.; Yin, M. Circular Supply Chain Management: Antecedent Effect of Social Capital and Big Data Analysis Capability and Their Impact on Sustainable Performance. Sustain. Dev. 2024, 32, 5311–5330. [Google Scholar] [CrossRef]

- Lahane, S.; Kant, R.; Shankar, R. Circular Supply Chain Management: A State-of-Art Review and Future Opportunities. J. Clean. Prod. 2020, 258, 120859. [Google Scholar] [CrossRef]

- Farooque, M.; Zhang, A.; Thürer, M.; Qu, T.; Huisingh, D. Circular Supply Chain Management: A Definition and Structured Literature Review. J. Clean. Prod. 2019, 228, 882–900. [Google Scholar] [CrossRef]

- Triguero, Á.; Moreno-Mondéjar, L.; Sáez-Martínez, F.J. Circular Economy and Firm Performance: The Influence of Product Life Cycle Analysis, Upcycling, and Redesign. Sustain. Dev. 2023, 31, 2318–2331. [Google Scholar] [CrossRef]

- Paul, A.; Saha, S.C. A Systematic Literature Review on Flexible Strategies and Performance Indicators for Supply Chain Resilience. Glob. J. Flex. Syst. Manag. 2025, 26, 207–231. [Google Scholar] [CrossRef]

- Paul, S.K.; Chowdhury, P. A Production Recovery Plan in Manufacturing Supply Chains for a High-Demand Item during COVID-19. Int. J. Phys. Distrib. Logist. Manag. 2021, 51, 104–125. [Google Scholar] [CrossRef]

- Wang, P.; Yang, Y.-Y.; Heidrich, O.; Chen, L.-Y.; Chen, L.-H.; Fishman, T.; Chen, W.-Q. Regional Rare-Earth Element Supply and Demand Balanced with Circular Economy Strategies. Nat. Geosci. 2024, 17, 94–102. [Google Scholar] [CrossRef]

- Takimoto, H.; Kosai, S.; Watari, T.; Yamasue, E. Circular Economy Can Mitigate Rising Mining Demand from Global Vehicle Electrification. Resour. Conserv. Recycl. 2024, 209, 107748. [Google Scholar] [CrossRef]

- Gaustad, G.; Krystofik, M.; Bustamante, M.; Badami, K. Circular Economy Strategies for Mitigating Critical Material Supply Issues. Resour. Conserv. Recycl. 2018, 135, 24–33. [Google Scholar] [CrossRef]

- Taddei, E.; Sassanelli, C.; Rosa, P.; Terzi, S. Circular Supply Chains in the Era of Industry 4.0: A Systematic Literature Review. Comput. Ind. Eng. 2022, 170, 108268. [Google Scholar] [CrossRef]

- de Lima, F.A.; Seuring, S.; Sauer, P.C. A Systematic Literature Review Exploring Uncertainty Management and Sustainability Outcomes in Circular Supply Chains. Int. J. Prod. Res. 2022, 60, 6013–6046. [Google Scholar] [CrossRef]

- Sudusinghe, J.I.; Seuring, S. Supply Chain Collaboration and Sustainability Performance in Circular Economy: A Systematic Literature Review. Int. J. Prod. Econ. 2022, 245, 108402. [Google Scholar] [CrossRef]

- Vegter, D.; van Hillegersberg, J.; Olthaar, M. Supply Chains in Circular Business Models: Processes and Performance Objectives. Resour. Conserv. Recycl. 2020, 162, 105046. [Google Scholar] [CrossRef]

- Bui, T.D.; Tseng, J.W.; Aminah, H.; Sulistiawan, J.; Ali, M.H.; Tseng, M.L. Causality of Total Resource Management in Circular Supply Chain Implementation under Uncertainty: A Context of Textile Industry in Indonesia. Ann. Oper. Res. 2023, 1–41. [Google Scholar] [CrossRef]

- Cao, Y.; Qu, Y.; Guo, L. Identifying Critical Eco-Innovation Practices in Circular Supply Chain Management: Evidence from the Textile and Clothing Industry. Int. J. Logist. Res. Appl. 2023, 26, 1462–1483. [Google Scholar] [CrossRef]

- Stumpf, L.; Schöggl, J.P.; Baumgartner, R.J. Circular Plastics Packaging—Prioritizing Resources and Capabilities along the Supply Chain. Technol. Forecast. Soc. Change 2023, 188, 122261. [Google Scholar] [CrossRef]

- Dwivedi, A.; Paul, S.K. A Framework for Digital Supply Chains in the Era of Circular Economy: Implications on Environmental Sustainability. Bus. Strateg. Environ. 2022, 31, 1249–1274. [Google Scholar] [CrossRef]

- Orji, I.J.; U-Dominic, C.M.; Okwara, U.K. Exploring the Determinants in Circular Supply Chain Implementation in the Nigerian Manufacturing Industry. Sustain. Prod. Consum. 2022, 29, 761–776. [Google Scholar] [CrossRef]

- Sawe, F.B.; Kumar, A.; Garza-Reyes, J.A.; Agrawal, R. Assessing People-Driven Factors for Circular Economy Practices in Small and Medium-Sized Enterprise Supply Chains: Business Strategies and Environmental Perspectives. Bus. Strateg. Environ. 2021, 30, 2951–2965. [Google Scholar] [CrossRef]

- Lahcen, B.; Eyckmans, J.; Rousseau, S.; Dams, Y.; Brusselaers, J. Modelling the Circular Economy: Introducing a Supply Chain Equilibrium Approach. Ecol. Econ. 2022, 197, 107451. [Google Scholar] [CrossRef]

- Khanduzi, R. Developing a Stackelberg Security Game for Circular Supply Chain Network. Environ. Dev. Sustain. 2022, 1–32. [Google Scholar] [CrossRef]

- Li, G.; Wu, H.; Sethi, S.P.; Zhang, X. Contracting Green Product Supply Chains Considering Marketing Efforts in the Circular Economy Era. Int. J. Prod. Econ. 2021, 234, 108041. [Google Scholar] [CrossRef]

- Kumar, P.; Singh, R.K.; Kumar, V. Managing Supply Chains for Sustainable Operations in the Era of Industry 4.0 and Circular Economy: Analysis of Barriers. Resour. Conserv. Recycl. 2021, 164, 105215. [Google Scholar] [CrossRef]

- Bimpizas-Pinis, M.; Santagata, R.; Kaiser, S.; Liu, Y.; Lyu, Y. Additives in the Food Supply Chain: Environmental Assessment and Circular Economy Implications. Environ. Sustain. Indic. 2022, 14, 100172. [Google Scholar] [CrossRef]

- Sehnem, S.; Chiappetta Jabbour, C.J.; Farias Pereira, S.C.; de Sousa Jabbour, A.B.L. Improving Sustainable Supply Chains Performance through Operational Excellence: Circular Economy Approach. Resour. Conserv. Recycl. 2019, 149, 236–248. [Google Scholar] [CrossRef]

- Betts, K.; Gutierrez-Franco, E.; Ponce-Cueto, E. Key Metrics to Measure the Performance and Impact of Reusable Packaging in Circular Supply Chains. Front. Sustain. 2022, 3, 910215. [Google Scholar] [CrossRef]

- Bracquené, E.; Dewulf, W.; Duflou, J.R. Measuring the Performance of More Circular Complex Product Supply Chains. Resour. Conserv. Recycl. 2020, 154, 104608. [Google Scholar] [CrossRef]

- Stillitano, T.; Falcone, G.; Iofrida, N.; Spada, E.; Gulisano, G.; De Luca, A.I. A Customized Multi-Cycle Model for Measuring the Sustainability of Circular Pathways in Agri-Food Supply Chains. Sci. Total Environ. 2022, 844, 157229. [Google Scholar] [CrossRef]

- Farooque, M.; Zhang, A.; Liu, Y.; Hartley, J.L. Circular Supply Chain Management: Performance Outcomes and the Role of Eco-Industrial Parks in China. Transp. Res. Part E Logist. Transp. Rev. 2022, 157, 102596. [Google Scholar] [CrossRef]

- Nayal, K.; Kumar, S.; Raut, R.D.; Queiroz, M.M.; Priyadarshinee, P.; Narkhede, B.E. Supply Chain Firm Performance in Circular Economy and Digital Era to Achieve Sustainable Development Goals. Bus. Strateg. Environ. 2022, 31, 1058–1073. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, M. Improving Circular Supply Chain Performance through Green Innovations: The Moderating Role of Economic Policy Uncertainty. Sustainability 2022, 14, 16888. [Google Scholar] [CrossRef]

- Saroha, M.; Garg, D.; Luthra, S. Analyzing the Circular Supply Chain Management Performance Measurement Framework: The Modified Balanced Scorecard Technique. Int. J. Syst. Assur. Eng. Manag. 2022, 13, 951–960. [Google Scholar] [CrossRef]

- Vimal, K.E.K.; Shaikh, M.F.; Chouhan, A.P.; Kandasamy, J. Developing a Framework for Achieving Optimal Sustainability and Resilience in Circular Sharing Network. Environ. Dev. Sustain. 2024, 26, 18267–18295. [Google Scholar] [CrossRef]

- Chari, A.; Niedenzu, D.; Despeisse, M.; Machado, C.G.; Azevedo, J.D.; Boavida-Dias, R.; Johansson, B. Dynamic Capabilities for Circular Manufacturing Supply Chains—Exploring the Role of Industry 4.0 and Resilience. Bus. Strateg. Environ. 2022, 31, 2500–2517. [Google Scholar] [CrossRef]

- Fletcher, C.A.; St Clair, R.; Sharmina, M. Seafood Businesses’ Resilience Can Benefit from Circular Economy Principles. Nat. Food 2021, 2, 228–232. [Google Scholar] [CrossRef]

- D’Adamo, I.; Lupi, G. Sustainability and Resilience after COVID-19: A Circular Premium in the Fashion Industry. Sustainability 2021, 13, 1861. [Google Scholar] [CrossRef]

- Australia’s Smartphone Sales Bounce Back. Emerging Technology Insights. 2024. Available online: https://www.telsyte.com.au/announcements/2024/10/8/australias-smartphone-sales-bounce-back (accessed on 8 February 2025).

- Man, H. The Most Expensive Countries to Buy a Samsung Galaxy. The Burrow. 2025. Available online: https://www.comparethemarket.com.au/home-contents-insurance/features/samsung-price-index-2025/ (accessed on 11 February 2025).

- Statista Smartphone Market in Australia—Statistics & Facts. Technology & Telecommunications. 2025. Available online: https://www.statista.com/topics/4605/smartphone-market-in-australia/ (accessed on 18 March 2025).

| Reference | Contributions | Findings | Methods Used | Industry Context | Country/Regional Context |

|---|---|---|---|---|---|

| [27] |

|

| Fuzzy Delphi method, Fuzzy DEMATEL | Textile industry | Indonesia |

| [28] |

|

| Fuzzy set theory, DEMATEL | Textile and clothing industry | China |

| [29] |

|

| Delphi method, analytic hierarchy process | Plastic packaging industry | European Union, mostly Austria and Germany |

| [30] |

|

| Fuzzy best–worst method | Not specific | Not specific |

| [33] |

|

| Equilibrium model, product–service system | Plastic industry | Belgium |

| [34] |

|

| Mathematical programming | Paper industry | India |

| [31] |

|

| Best–worst method, evaluation based on distance from the average solution | Not specific | Nigeria |

| [35] |

|

| Game theory | Retail | China |

| [32] |

|

| DEMATEL | Not specific | Not specific |

| [36] |

|

| Analytic hierarchy process | Automobile and electronics industries | India |

| Reference | Contributions | Findings | Methods Used | Industry Context | Country/Regional Context |

|---|---|---|---|---|---|

| [37] |

|

| Case study | Food industry | Greece |

| [39] |

|

| Case study | Physical retail outlets | Not specific |

| [40] |

|

| Case study, life-cycle assessment | Washing machine industry | Belgium |

| [38] |

|

| Case study | Agri-business, packaging, and catering industries | Brazil and Scotland |

| Reference | Contributions | Findings | Methods Used | Industry Context | Country/Regional Context |

|---|---|---|---|---|---|

| [44] |

|

| Structural equation modelling | Multiple industries, such as electronics, machinery, and communications | China |

| [41] |

|

| Multi-cycle model | Agri-food supply chain | Not specific |

| [42] |

|

| Structural equation modelling | Multiple industries, such as metal products, chemicals, automotive, electrical appliances, pharmaceuticals, food, electronics, textiles, and wood | China |

| [45] |

|

| Modified balanced scorecard | Not specific | India |

| [43] |

|

| Structural equation modelling | Multiple industries, such as automobile, electronics, plastics and rubber, and metal | India |

| From (DCs) | To (Retailers) | Quantity |

| Melbourne 2 | Retailer Shepparton | 4979 |

| Melbourne 2 | Retailer Wangaratta | 4979 |

| Melbourne 2 | Retailer Wodonga | 4979 |

| Melbourne 2 | Retailer Balwyn North | 4979 |

| Melbourne 2 | Retailer Traralgon | 4979 |

| Melbourne 2 | Retailer Glen Iris | 4979 |

| Melbourne 2 | Retailer Frankston East | 4979 |

| Melbourne 2 | Retailer Canberra | 4979 |

| Melbourne 2 | Retailer Queanbeyan | 4979 |

| Melbourne 2 | Retailer Melbourne | 210 |

| Melbourne 2 | Retailer Albury | 4979 |

| Sydney 2 | Retailer Port Macquarie | 4979 |

| Sydney 2 | Retailer Maitland | 4979 |

| Sydney 2 | Retailer Tamworth | 4979 |

| Sydney 2 | Retailer Taree | 4979 |

| Sydney 2 | Retailer Newcastle | 4979 |

| Sydney 2 | Retailer Port Stephens | 4979 |

| Sydney 2 | Retailer Bathurst | 4979 |

| Sydney 2 | Retailer Hornsby | 4979 |

| Sydney 2 | Retailer Orange | 4979 |

| Sydney 2 | Retailer Forster | 4979 |

| Sydney 2 | Retailer Armidale | 210 |

| Sydney 1 | Retailer Liverpool | 4979 |

| Sydney 1 | Retailer Katoomba | 4979 |

| Sydney 1 | Retailer Epping | 4979 |

| Sydney 1 | Retailer Parramatta | 4979 |

| Sydney 1 | Retailer Wollongong | 4979 |

| Sydney 1 | Retailer Goulburn | 4979 |

| Sydney 1 | Retailer City of Parramatta | 4979 |

| Sydney 1 | Retailer Sydney | 4979 |

| Sydney 1 | Retailer Nowra | 4979 |

| Sydney 1 | Retailer Strathfield | 4979 |

| Sydney 1 | Retailer Armidale | 210 |

| Melbourne 1 | Retailer Hobart | 4979 |

| Melbourne 1 | Retailer Warrnambool | 420 |

| Melbourne 1 | Retailer Burnie | 4979 |

| Melbourne 1 | Retailer Devonport | 4979 |

| Melbourne 1 | Retailer Ballarat | 4979 |

| Melbourne 1 | Retailer Geelong | 4979 |

| Melbourne 1 | Retailer Launceston | 4979 |

| Melbourne 1 | Retailer St Albans | 4979 |

| Melbourne 1 | Retailer Bendigo | 4979 |

| Melbourne 1 | Retailer Echuca | 4979 |

| Melbourne 1 | Retailer Melbourne | 4769 |

| Adelaide | Retailer Dubbo | 4979 |

| Adelaide | Retailer Prospect | 4979 |

| Adelaide | Retailer Mount Gambier | 4979 |

| Adelaide | Retailer Warrnambool | 4559 |

| Adelaide | Retailer Murray Bridge | 4979 |

| Adelaide | Retailer Gawler | 4979 |

| Adelaide | Retailer Adelaide Hills | 4979 |

| Adelaide | Retailer Whyalla | 630 |

| Adelaide | Retailer Broken Hill | 4979 |

| Adelaide | Retailer Adelaide | 4979 |

| Adelaide | Retailer Mildura | 4979 |

| Perth | Retailer Geraldton | 4979 |

| Perth | Retailer Rockingham | 4979 |

| Perth | Retailer Mandurah | 4979 |

| Perth | Retailer Kalgoorlie | 4979 |

| Perth | Retailer Albany | 4979 |

| Perth | Retailer Perth | 4979 |

| Perth | Retailer Whyalla | 4349 |

| Perth | Retailer Busselton | 4979 |

| Perth | Retailer Bunbury | 4979 |

| Perth | Retailer Kwinana | 4979 |

| Darwin | Retailer Rockhampton | 4979 |

| Darwin | Retailer Gladstone | 4979 |

| Darwin | Retailer Darwin | 4979 |

| Darwin | Retailer Alice Springs | 4979 |

| Darwin | Retailer Townsville | 4979 |

| Darwin | Retailer Mackay | 4979 |

| Darwin | Retailer Bundaberg | 4349 |

| Darwin | Retailer Palmerston | 4979 |

| Darwin | Retailer Mount Isa | 4979 |

| Darwin | Retailer Cairns | 4979 |

| Brisbane | Retailer Gold Coast | 4979 |

| Brisbane | Retailer Coffs Harbour | 4979 |

| Brisbane | Retailer Brisbane | 4979 |

| Brisbane | Retailer Lismore | 4979 |

| Brisbane | Retailer Maryborough | 4979 |

| Brisbane | Retailer Woodridge | 4979 |

| Brisbane | Retailer Logan City | 4979 |

| Brisbane | Retailer Bundaberg | 630 |

| Brisbane | Retailer Toowoomba | 4979 |

| Brisbane | Retailer Caloundra | 4979 |

| Brisbane | Retailer Armidale | 4559 |

| Model | Total Revenue | Total Cost | Total Profit | Demand Fulfilment | Penalty Cost |

| Model under ideal situations | AUD 557,249,680 | AUD 362,133,541.98 | AUD 195,116,138.02 | 100% | 0 |

| Model for increased demand with no strategies | AUD 559,600,000 | AUD 382,796,130.02 | AUD 176,803,869.98 | 91.36% | AUD 20,812,000 |

| Model for increased demand with circular strategies | AUD 609,964,000 | AUD 378,175,122.98 | AUD 231,788,877.02 | 99.58% | AUD 1,012,000 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Paul, A.; Saha, S.C. Analysing the Usefulness of Circular Strategies to Improve Supply Chain Resilience Against Demand Changes. Sustainability 2025, 17, 8248. https://doi.org/10.3390/su17188248

Paul A, Saha SC. Analysing the Usefulness of Circular Strategies to Improve Supply Chain Resilience Against Demand Changes. Sustainability. 2025; 17(18):8248. https://doi.org/10.3390/su17188248

Chicago/Turabian StylePaul, Ananna, and Suvash C. Saha. 2025. "Analysing the Usefulness of Circular Strategies to Improve Supply Chain Resilience Against Demand Changes" Sustainability 17, no. 18: 8248. https://doi.org/10.3390/su17188248

APA StylePaul, A., & Saha, S. C. (2025). Analysing the Usefulness of Circular Strategies to Improve Supply Chain Resilience Against Demand Changes. Sustainability, 17(18), 8248. https://doi.org/10.3390/su17188248

_Li.png)