Enhancing the Sustainability of Retail Supply Chains Through an Integrated Industry 4.0 Model

Abstract

1. Introduction

2. Literature Analysis

3. Methodology

3.1. Research Plan and Data Collection

3.2. Analysis of Multi-Criteria Decision-Making Methods

3.3. Determining the Consistency of Expert Group Opinions and the Importance of Challenges Affecting the Implementation of I4.0 in the Retail Sector Supply Chain

4. Research Findings/Results

- High investment and resource requirements—0.18;

- Incompatible technological infrastructure—0.16;

- Unclear value chain—0.15;

- Shortage of highly skilled personnel—0.14;

- Ineffective management of technological transitions—0.12;

- Complexity of database system management—0.08;

- Resistance to change—0.08;

- Lack of government support and regulation—0.06;

- Unclear return on digitalization—0.03.

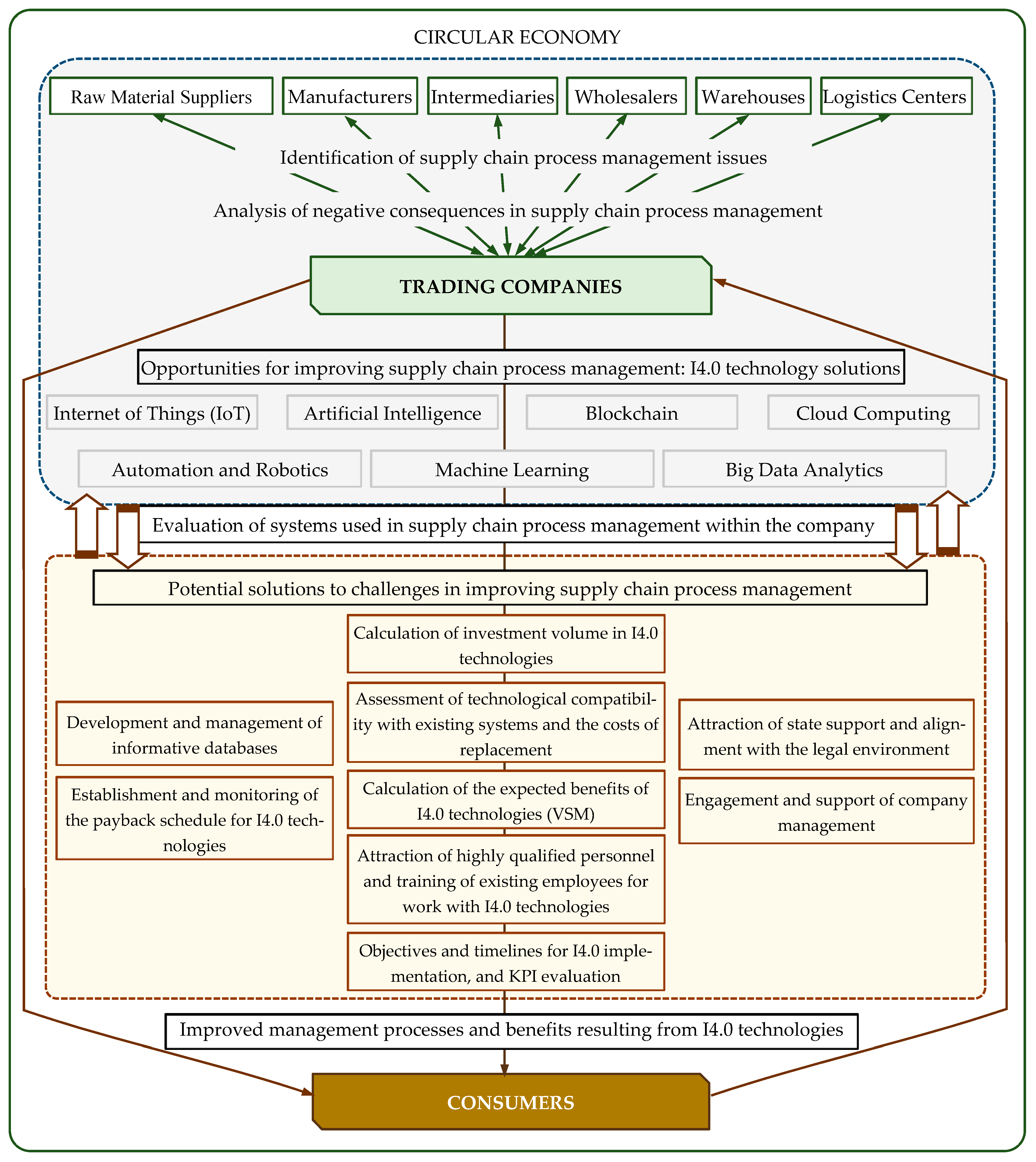

5. Model for Enhancing the Sustainability of Retail Supply Chains

6. Conclusions and Recommendations

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sharma, V.; Raut, R.D.; Mangla, S.K.; Narkhede, B.E.; Luthra, S.; Gokhale, R. A systematic literature review to integrate lean, agile, resilient, green and sustainable paradigms in the supply chain management. Bus. Strateg. Environ. 2021, 30, 1191–1212. [Google Scholar] [CrossRef]

- Richey, R.G.; Roath, A.S.; Adams, F.G.; Wieland, A. A Responsiveness View of logistics and supply chain management. J. Bus. Logist. 2022, 43, 62–91. [Google Scholar] [CrossRef]

- García-Reyes, H.; Avilés-González, J.; Avilés-Sacoto, S.V. A Model to Become a Supply Chain 4.0 Based on a Digital Maturity Perspective. Procedia Comput. Sci. 2022, 200, 1058–1067. [Google Scholar] [CrossRef]

- Naz, F.; Agrawal, R.; Kumar, A.; Gunasekaran, A.; Majumdar, A.; Luthra, S. Reviewing the applications of artificial intelligence in sustainable supply chains: Exploring research propositions for future directions. Bus. Strateg. Environ. 2022, 31, 2400–2423. [Google Scholar] [CrossRef]

- Shakur, M.S.; Lubaba, M.; Debnath, B.; Bari, A.B.M.M.; Rahman, M.A. Exploring the Challenges of Industry 4.0 Adoption in the FMCG Sector: Implications for Resilient Supply Chain in Emerging Economy. Logistics 2024, 8, 27. [Google Scholar] [CrossRef]

- Končar, J.; Grubor, A.; Marić, R.; Vučenović, S.; Vukmirović, G. Setbacks to IoT Implementation in the Function of FMCG Supply Chain Sustainability during COVID-19 Pandemic. Sustainability 2020, 12, 7391. [Google Scholar] [CrossRef]

- Butollo, F.; Gereffi, G.; Yang, C.; Krzywdzinski, M. Digital transformation and value chains: Introduction. Glob. Netw. 2022, 22, 585–594. [Google Scholar] [CrossRef]

- Raja Santhi, A.; Muthuswamy, P. Pandemic, War, Natural Calamities, and Sustainability: Industry 4.0 Technologies to Overcome Traditional and Contemporary Supply Chain Challenges. Logistics 2022, 6, 81. [Google Scholar] [CrossRef]

- Cotta, D.; Klink, L.; Alten, T.; Al Madhoon, B. How do supply chain managers perceive the relationship between resilience and sustainability practices? An exploratory study. Bus. Strateg. Environ. 2023, 32, 3737–3751. [Google Scholar] [CrossRef]

- Echegaray, N.; Hassoun, A.; Jagtap, S.; Tetteh-Caesar, M.; Kumar, M.; Tomasevic, I.; Goksen, G.; Lorenzo, J.M. Meat 4.0: Principles and Applications of Industry 4.0 Technologies in the Meat Industry. Appl. Sci. 2022, 12, 6986. [Google Scholar] [CrossRef]

- Tang, Y.M.; Chau, K.Y.; Lau, Y.-y.; Zheng, Z. Data-Intensive Inventory Forecasting with Artificial Intelligence Models for Cross-Border E-Commerce Service Automation. Appl. Sci. 2023, 13, 3051. [Google Scholar] [CrossRef]

- Butollo, F.; Schneidemesser, L. Who runs the show in digitalized manufacturing? Data, digital platforms and the restructuring of global value chains. Glob. Netw. 2022, 22, 595–614. [Google Scholar] [CrossRef]

- Rusch, M.; Schöggl, J.-P.; Baumgartner, R.J. Application of digital technologies for sustainable product management in a circular economy: A review. Bus. Strateg. Environ. 2023, 32, 1159–1174. [Google Scholar] [CrossRef]

- Swink, M.; Sant’Ana Gallo, I.; Defee, C.; da Silva, A.L. Supply chain visibility types and contextual characteristics: A literature-based synthesis. J. Bus. Logist. 2024, 45, e12366. [Google Scholar] [CrossRef]

- Tubis, A.A.; Rohman, J. Intelligent Warehouse in Industry 4.0—Systematic Literature Review. Sensors 2023, 23, 4105. [Google Scholar] [CrossRef]

- Deepu, T.S.; Ravi, V. A review of literature on implementation and operational dimensions of supply chain digitalization: Framework development and future research directions. Int. J. Inf. Manag. Data Insights 2023, 3, 100156. [Google Scholar] [CrossRef]

- Pessot, E.; Zangiacomi, A.; Marchiori, I.; Fornasiero, R. Empowering supply chains with Industry 4.0 technologies to face megatrends. J. Bus. Logist. 2023, 44, 609–640. [Google Scholar] [CrossRef]

- Zhang, D.; Frei, R.; Wills, G.; Gerding, E.; Bayer, S.; Senyo, P.K. Strategies and practices to reduce the ecological impact of product returns: An environmental sustainability framework for multichannel retail. Bus. Strateg. Environ. 2023, 32, 4636–4661. [Google Scholar] [CrossRef]

- Bai, S.; Wang, Y. Green Investment Decision and Coordination in a Retailer-Dominated Supply Chain Considering Risk Aversion. Sustainability 2022, 14, 13606. [Google Scholar] [CrossRef]

- Olaghere, J.A.; Inegbedion, H.E.; Osiobe, F.O. The Implications of Digitalization in Retail Service Delivery on Circular Economy in Nigeria: An Exploratory Case Study. Sustainability 2023, 15, 13192. [Google Scholar] [CrossRef]

- Calandra, D.; Secinaro, S.; Massaro, M.; Dal Mas, F.; Bagnoli, C. The link between sustainable business models and Blockchain: A multiple case study approach. Bus. Strateg. Environ. 2022, 32, 1403–1417. [Google Scholar] [CrossRef]

- Govindan, K.; Aditi; Kaul, A.; Darbari, J.D.; Jha, P.C. Analysis of supplier evaluation and selection strategies for sustainable collaboration: A combined approach of best–worst method and TOmada de Decisao Interativa Multicriterio. Bus. Strateg. Environ. 2023, 32, 4426–4447. [Google Scholar] [CrossRef]

- Qiao, J.; Li, S.; Capaldo, A. Green supply chain management, supplier environmental commitment, and the roles of supplier perceived relationship attractiveness and justice. A moderated moderation analysis. Bus. Strateg. Environ. 2022, 31, 3523–3541. [Google Scholar] [CrossRef]

- Mandičák, T.; Mésároš, P.; Kanáliková, A.; Špak, M. Supply Chain Management and Big Data Concept Effects on Economic Sustainability of Building Design and Project Planning. Appl. Sci. 2021, 11, 11512. [Google Scholar] [CrossRef]

- Aman, S.; Seuring, S.; Khalid, R.U. Sustainability performance measurement in risk and uncertainty management: An analysis of base of the pyramid supply chain literature. Bus. Strateg. Environ. 2022, 32, 2373–2398. [Google Scholar] [CrossRef]

- López, T.; Riedler, T.; Köhnen, H.; Fütterer, M. Digital value chain restructuring and labour process transformations in the fast-fashion sector: Evidence from the value chains of Zara & H&M. Glob. Netw. 2022, 22, 684–700. [Google Scholar] [CrossRef]

- Zorić, N.; Marić, R.; Đurković-Marić, T.; Vukmirović, G. The Importance of Digitalization for the Sustainability of the Food Supply Chain. Sustainability 2023, 15, 3462. [Google Scholar] [CrossRef]

- Liu, Y.; Quan, B.-t.; Li, J.; Forrest, J.Y.-L. A Supply Chain Coordination Mechanism with Cost Sharing of Corporate Social Responsibility. Sustainability 2018, 10, 1227. [Google Scholar] [CrossRef]

- Oliveira-Dias, D.; Maqueira-Marín, J.M.; Moyano-Fuentes, J. The link between information and digital technologies of industry 4.0 and agile supply chain: Mapping current research and establishing new research avenues. Comput. Ind. Eng. 2022, 167, 108000. [Google Scholar] [CrossRef]

- Holmström, J.; Holweg, M.; Lawson, B.; Pil, F.K.; Wagner, S.M. The digitalization of operations and supply chain management: Theoretical and methodological implications. J. Oper. Manag. 2019, 65, 728–734. [Google Scholar] [CrossRef]

- Qi, M.; Mak, H.-Y.; Shen, Z.-J.M. Data-driven research in retail operations—A review. Nav. Res. Logist. 2020, 67, 595–616. [Google Scholar] [CrossRef]

- Martín-Gómez, A.M.; Agote-Garrido, A.; Lama-Ruiz, J.R. A Framework for Sustainable Manufacturing: Integrating Industry 4.0 Technologies with Industry 5.0 Values. Sustainability 2024, 16, 1364. [Google Scholar] [CrossRef]

- Selicati, V.; Cardinale, N. Benchmarking sustainability on an industrial case within industry 4.0 Paradigm: Advantages of involving exergetic analysis in life cycle thinking. J. Eng. Sci. 2020, 64, 244–250. [Google Scholar] [CrossRef]

- Zaid, M.; Farooqi, R.; Azmi, S.N. Driving sustainable supply chain performance through digital transformation: The role of information exchange and responsiveness. Cogent Bus. Manag. 2024, 12, 2443047. [Google Scholar] [CrossRef]

- Schilling, L.; Seuring, S. Linking the digital and sustainable transformation with supply chain practices. Int. J. Prod. Res. 2023, 62, 949–973. [Google Scholar] [CrossRef]

- Elgarahy, A.M.; Eloffy, M.G.; Priya, A.K.; Hammad, A.; Zahran, M.; Maged, A.; Elwakeel, K.Z. Revitalizing the circular economy: An exploration of e-waste recycling approaches in a technological epoch. Sustain. Chem. Environ. 2024, 7, 100124. [Google Scholar] [CrossRef]

- Zavadskas, E.K. Kompleksinis Vertinimas ir Resursų Taupymo Sprendimų Pasirinkimas Statybose [Кoмплексная oценка и выбoр ресурсoсберегающих решений в стрoительстве]; Mokslas [Мoкслас]: Vilnius, Lithuania, 1987; Available online: http://economy-lib.com/kompleksnaya-otsenka-i-vybor-resursosberegayuschih-proektnyh-resheniy#ixzz6KRavrnGn (accessed on 2 April 2025). (In Russian)

- Sivilevičius, H. Application of expert evaluation method to determine the importance of operating asphalt neixing plant quality criteria and rank correlation. Balt. J. Road Bridge Eng. 2011, 6, 48–58. [Google Scholar] [CrossRef]

- Evlanov, L. Theory and Practice Decision Making [Теoрия и практика принятия решений]; Экoнoмика: Мoсква, Russia, 1984. (In Russian) [Google Scholar]

- Simanavičienė, R. Sensitivity Analysis of Quantitative Multi-Objective Decision-Making Methods [Kiekybinių daugiatikslių sprendimo priėmimo metodų jautrumo analizė]. Ph.D. Thesis, VGTU leidykla “Technika”, Vilnius, Lithuania, 2011. Available online: http://dspace.vgtu.lt/bitstream/1/926/3/1973_Simanaviciene_Disertacija_WEB.pdf (accessed on 12 February 2025). (In Lithuanian).

- Kendall, M.G. Rank Correlation Methods; Griffin and Co.: London, UK, 1975; Available online: https://www.worldcat.org/title/Rank-correlation-methods/oclc/3827024 (accessed on 12 February 2025).

- Maskeliūnaitė, L.; Sivilevičius, H. Identifying the importance of criteria for passenger choice of sustainable travel by train using ARTIW and IHAMCI methods. Appl. Sci. 2021, 11, 11503. [Google Scholar] [CrossRef]

- Podvezko, V. Agreement of expert estimates. Technol. Econ. Dev. Econ. 2005, 11, 101–107. [Google Scholar] [CrossRef]

- Kendall, M.; Gibbons, J.D. Rank Correlation Methods, 5th ed.; Oxford University Press: New York, NY, USA, 1990. [Google Scholar]

- Montgomery, D.C. Decision and Analysis of Experiments. International Student Version, 8th ed.; John Wiley & Sons, Inc.: Singapore, 2013. [Google Scholar]

| Model | Orientation | Methodology | Uniqueness | Comparison with the Research Model |

|---|---|---|---|---|

| A Framework for Sustainable Manufacturing: Integrating Industry 4.0 Technologies with Industry 5.0 Values [32] | Sustainable manufacturing, Industry 4.0 and 5.0 integration | Analytical framework, synthesis of technological and ethical aspects | Combining technological solutions with social values | Different orientation–focus on manufacturing, not retail |

| Benchmarking Sustainability on an Industrial Case Within Industry 4.0 Paradigm: Advantages of Involving Exergetic Analysis in Life Cycle Thinking [33] | Industrial case analysis, energy efficiency | Life cycle assessment, exergetic analysis | Technical approach to energy and resource efficiency | Different methodology–technical assessment instead of practical solution presentation |

| Driving sustainable supply chain performance through digital transformation the role of information exchange and responsiveness [34] | Sustainable supply chain, digital transformation | Analysis of data exchange and responsiveness capabilities | Focus on the impact of digital technologies on sustainability | Digital transformation is examined more broadly, lacks specific sector application |

| Linking the digital and sustainable transformation with supply chain practices [35] | Supply chain practices, digital and sustainable transformation | Literature review, analysis of best practices | Conceptualization of the link between digitization and sustainability | Theoretical model, lacking specific sector application |

| Revitalizing the circular economy: An exploration of e-waste recycling approaches in a technological epoch [36] | Circular economy, e-waste recycling | Analysis of technological recycling methods | Focus on waste management technologies | Different thematic area–focused on waste recycling, not supply chain sustainability |

| Expert Number, i = (1, 2, …, n) | Challenges Affecting the Implementation of I4.0 in the Retail Supply Chain, j = (1, 2, …, m) | Sum | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| K1 | K2 | K3 | K4 | K5 | K6 | K7 | K8 | K9 | ||

| E1 | 2 | 7 | 4 | 3 | 1 | 9 | 6 | 8 | 5 | 45 |

| E2 | 1 | 6 | 2 | 5 | 3 | 9 | 4 | 8 | 7 | 45 |

| E3 | 3 | 6 | 1 | 5 | 2 | 8 | 7 | 9 | 4 | 45 |

| E4 | 2 | 8 | 3 | 5 | 1 | 9 | 4 | 7 | 6 | 45 |

| E5 | 5 | 4 | 6 | 1 | 2 | 8 | 3 | 7 | 9 | 45 |

| E6 | 3 | 6 | 1 | 5 | 4 | 7 | 8 | 9 | 2 | 45 |

| E7 | 4 | 8 | 3 | 5 | 1 | 9 | 2 | 6 | 7 | 45 |

| E8 | 5 | 7 | 4 | 2 | 1 | 8 | 3 | 6 | 9 | 45 |

| E9 | 2 | 6 | 3 | 5 | 1 | 8 | 4 | 9 | 7 | 45 |

| E10 | 4 | 6 | 3 | 1 | 2 | 9 | 5 | 8 | 7 | 45 |

| E11 | 1 | 8 | 4 | 2 | 3 | 9 | 6 | 6 | 6 | 45 |

| 32 | 72 | 34 | 39 | 21 | 93 | 52 | 83 | 69 | 495 | |

| 2.9 | 6.5 | 3.1 | 3.5 | 1.9 | 8.5 | 4.7 | 7.5 | 6.3 | 45 | |

| −23 | 17 | −21 | −16 | −34 | 38 | −3 | 28 | 14 | 0 | |

| 529 | 289 | 441 | 256 | 1156 | 1444 | 9 | 784 | 196 | 5104 | |

| Indicator | Challenges Affecting the Implementation of I4.0 in the Retail Supply Chain, j = (1, 2, …, m) | Sum | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| K1 | K2 | K3 | K4 | K5 | K6 | K7 | K8 | K9 | ||

| Importance indicators, Qj | 0.16 | 0.08 | 0.15 | 0.14 | 0.18 | 0.03 | 0.12 | 0.06 | 0.08 | 1.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jarašūnienė, A.; Paulauskas, D. Enhancing the Sustainability of Retail Supply Chains Through an Integrated Industry 4.0 Model. Sustainability 2025, 17, 8191. https://doi.org/10.3390/su17188191

Jarašūnienė A, Paulauskas D. Enhancing the Sustainability of Retail Supply Chains Through an Integrated Industry 4.0 Model. Sustainability. 2025; 17(18):8191. https://doi.org/10.3390/su17188191

Chicago/Turabian StyleJarašūnienė, Aldona, and Donaldas Paulauskas. 2025. "Enhancing the Sustainability of Retail Supply Chains Through an Integrated Industry 4.0 Model" Sustainability 17, no. 18: 8191. https://doi.org/10.3390/su17188191

APA StyleJarašūnienė, A., & Paulauskas, D. (2025). Enhancing the Sustainability of Retail Supply Chains Through an Integrated Industry 4.0 Model. Sustainability, 17(18), 8191. https://doi.org/10.3390/su17188191