1. Introduction

The building sector is among the highest contributors to global energy consumption and greenhouse gas (GHG) emissions, accounting for approximately 40% of total energy use and 36% of GHG emissions in the European Union (EU), with an estimated 75% of buildings being energy inefficient [

1,

2]. In Ireland, the situation is equally pressing; the residential sector alone consumes 21.1% of national energy, totalling 29.6 TWh in 2023, posing a significant challenge to achieving the 2030 target of a 51% reduction in energy-related emissions [

3,

4]. While energy standards such as the Nearly Zero Energy Building (NZEB) have led to 99% of newly built homes since 2019 achieving an A-rated Building Energy Rating (BER), these account for only a small portion of Ireland′s housing stock [

5,

6], leaving a vast backlog of inefficient existing homes [

2,

7]. This significant gap between the energy efficiency of newly built and existing residential dwellings emphasizes the necessity for the expansion of retrofitting Irish homes.

Retrofitting, upgrading buildings through interventions like fabric improvements, renewable energy systems, and HVAC enhancements, is therefore an essential strategy for decarbonizing the sector and enhancing sustainability [

7,

8]. Retrofitting actions range from shallow to deep interventions.

Shallow retrofits involve low-cost, limited-scope improvements such as lighting upgrades, basic insulation, or boiler replacement. In contrast, deep retrofits encompass more extensive interventions, including comprehensive thermal envelope upgrades, high-efficiency HVAC systems, and on-site renewable energy integration, aiming to significantly reduce energy demand and emissions.

A growing body of literature has evaluated the effectiveness of various retrofit strategies across different building types and climates. The selection of measures typically depends on the unique characteristics of each project. In another study, it is reported that about 70% of global retrofit strategies focus on building envelope insulation, lighting, and renewable integration, tailored to building type and climate [

9]. Kadrić et al. developed a linear model using TABULA data to predict energy and CO

2 emissions, highlighting the role of scalable tools in retrofit planning [

10]. Similarly, Jafari et al. evaluated the whole-life economic benefits of replacing lighting, HVAC, and equipment systems with efficient alternatives [

11]. Another study analysed the impact of energy-efficient retrofit measures, such as improving airtightness, enhancing envelope insulation, upgrading heating systems, and incorporating mechanical ventilation, on both indoor environmental quality and overall energy performance in dwellings [

2].

Beyond single-criterion approaches that emphasise energy savings or emissions reductions, several studies have employed multi-criteria decision-making (MCDM) frameworks to capture a broader set of performance indicators and stakeholder perspectives. For example, in a study, D′Agostino et al. (2025) proposed a hybrid MCDM methodology for the retrofit of a shopping mall in Southern Italy, ranking alternative interventions based on electricity savings, net present value, and discounted payback period, while explicitly incorporating the differing priorities of policymakers and tenants [

12]. In a similar study, D′Agostino et al. (2025) applied multi-objective optimization and robust MCDM methods to the retrofit of a university lecture room, balancing public and private interests across indoor air quality, infection risk reduction, energy consumption, and cost [

13]. These contributions demonstrate that retrofit decision-making benefits from considering not only technical efficiency but also economic feasibility, health, and stakeholder priorities, thereby enriching the evidence base for more holistic retrofit strategies.

In particular, many studies have examined the effectiveness of upgrading HVAC systems and implementing renewable technologies in residential buildings, focusing on their potential to reduce both final and primary energy consumption and to support decarbonisation goals [

2,

8]. Carutasiu and Necula (2024) simulated a 57% reduction in heat energy through the application of insulation and air-source heat pumps (ASHPs), while demonstrating that photovoltaic (PV) integration could reduce reliance on fossil fuels by up to 75% [

14]. In a comparative assessment, Kumar and Murugesan (2023) found that ground-source heat pumps (GSHPs) outperformed ASHPs, delivering up to 48% more energy savings [

15]. Shen et al. (2024) proposed an automated retrofit strategy for educational buildings, identifying cooling setpoints as key energy conservation measures through sensitivity analysis [

16]. Marino (2024) evaluated Life Carbon impacts across diverse retrofit scenarios and uncertainty ranges, concluding that organic insulation combined with heat pump systems yielded the most resilient results [

17].

A comprehensive review of the literature shows that most renovation research to date has concentrated on reducing operational energy use, which refers to the energy consumed and carbon emitted during the in-use stage of buildings. Operational energy is only one part of the puzzle of the whole life cycle energy assessment. The embodied environmental impacts, such as carbon emissions associated with materials, construction, maintenance, and end-of-life processes, remain comparatively underexplored [

18]. Operational and embodied impacts are closely interconnected, and improvements in one can often lead to trade-offs or reductions in the other [

19,

20]. This imbalance risks undermining the broader decarbonisation objectives outlined in major policy frameworks such as the European Green Deal, which targets net-zero emissions by 2050 and a 55% reduction by 2030 [

21]. Therefore, Life Cycle Assessment (LCA) offers a vital methodology for capturing both operational and embodied emissions across a building′s entire lifespan [

22,

23,

24,

25]. However, its effectiveness is limited by inconsistencies in embodied carbon databases and the fragmented integration of LCA tools in retrofit planning.

Moreover, the performance and impact of retrofit strategies are highly sensitive to local conditions. Embodied emissions can vary significantly depending on the availability of low-carbon materials, regional construction practices, and supply chain characteristics, factors that are often overlooked in generalised models. These location-specific dynamics are particularly important in Ireland, where the building stock, material supply chains, and renovation practices differ substantially from those in other European contexts. Despite this, there is a lack of Ireland-specific studies that comprehensively evaluate retrofit scenarios using holistic, location-aware LCA approaches.

Ireland′s retrofit sector has advanced significantly in recent years, supported by the National Retrofit Plan and grant schemes administered by the Sustainable Energy Authority of Ireland (SEAI). These frameworks adopt a “fabric-first” approach, prioritizing envelope upgrades, such as insulation, windows, and airtightness improvements, before transitioning to system enhancements like heat pump installations [

26]. Despite this progress, when benchmarked against international best practices, Ireland′s retrofit pace and ambition remain comparatively modest. The SEAI reported approximately 30,000 retrofits completed in 2023, well below the government′s target of 500,000 homes by 2030 [

27].

In contrast, Germany has institutionalized large-scale, standardized retrofit models such as the

EnerPHit standard for deep retrofits [

28], often employing prefabricated elements to accelerate delivery at scale [

29]. Moreover, while Irish strategies are primarily oriented toward operational energy savings, several European countries are embedding life cycle thinking directly into regulation. Denmark, for example, has mandated the inclusion of Life Cycle Assessment (LCA) in building regulations, ensuring that retrofit pathways are assessed for both operational and embodied impacts [

30]. These contrasts highlight a key gap in Ireland′s retrofit trajectory regarding the underdeveloped integration of LCA in retrofit planning. Given Ireland′s distinct housing stock, construction practices, and material supply chains, a critical evaluation of the applicability of international LCA databases is necessary to ensure context-sensitive environmental assessments.

To address these gaps, an environmental study is considered. This study develops and applies an integrated assessment framework that combines dynamic energy simulation with LCA to evaluate the full carbon footprint of residential retrofit strategies. The methodology accounts for both operational and embodied carbon impacts, enabling a comprehensive comparison of retrofit scenarios across varying levels of intervention, from improved systems within the original building fabric to shallow and deep retrofits involving envelope and HVAC upgrades. By applying this framework to a representative case study of a typical residential dwelling, the study quantifies trade-offs between energy savings and material-related emissions, while also conducting comparative analysis on key parameters such as system efficiency and temperature setpoints. The objective is to provide a robust, location-sensitive evidence base that supports data-driven decision-making for low-carbon renovation strategies, with insights that are broadly applicable but tailored to regional construction practices and performance baselines. This study focuses exclusively on the environmental dimension of retrofit evaluation, quantifying operational and embodied carbon impacts without incorporating financial metrics such as capital expenditure, payback time, or cost of abatement.

The structure of the paper is as follows:

Section 1 outlines the objectives and research motivation.

Section 2 introduces the methodological framework, detailing the integration of dynamic energy simulation and LCA.

Section 3 presents the results of the retrofit scenario analyses.

Section 4 provides a critical discussion of the findings, including implications for policy and practice. Finally,

Section 5 concludes the paper by summarising key insights and identifying directions for future research.

2. Methodology

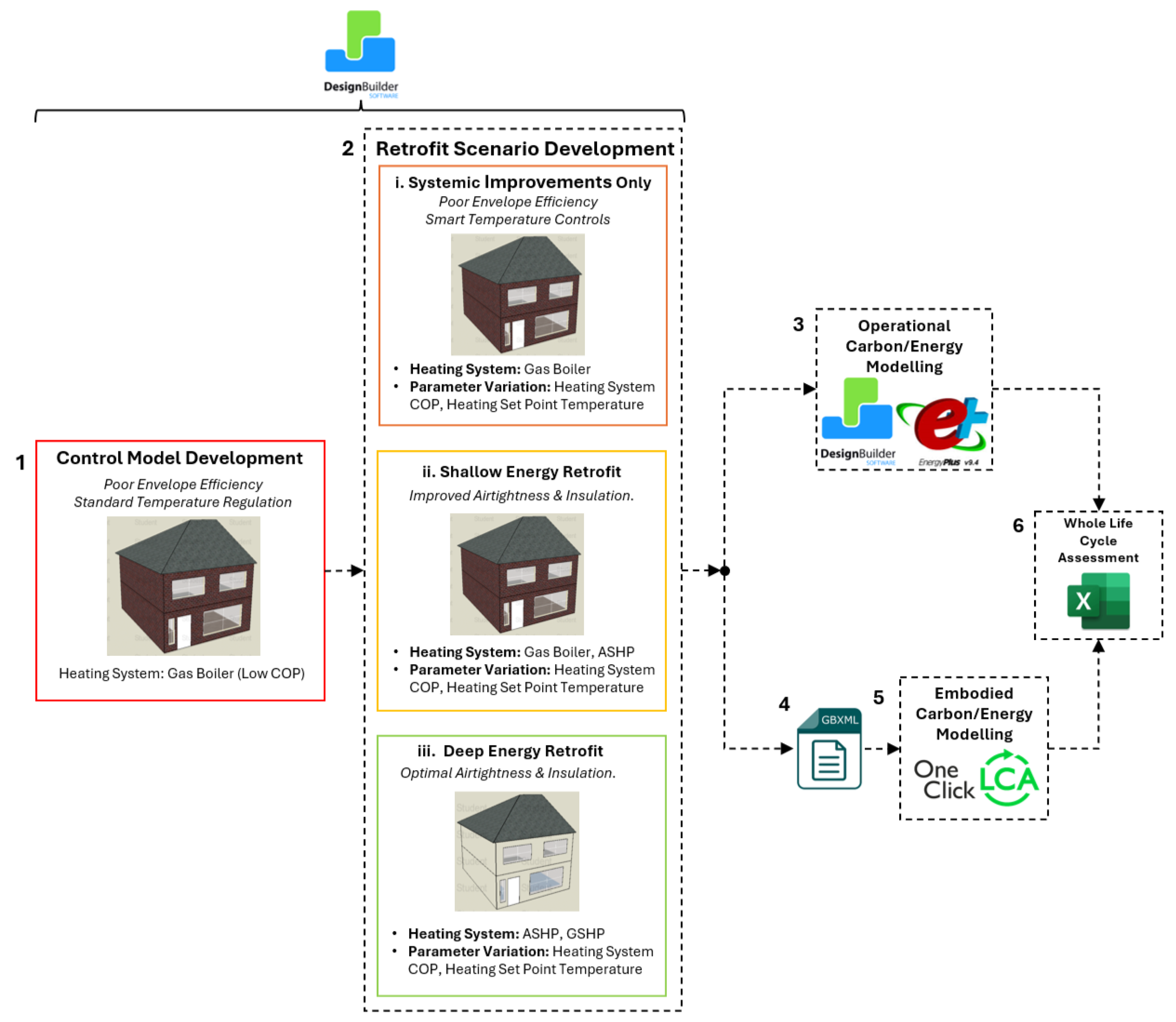

This integrated approach forms a decision-making toolchain designed to assess and compare retrofit strategies from both an energy and carbon perspective. The proposed methodology to develop the toolchain is structured around four core phases, designed to assess the whole life carbon impacts of residential retrofit strategies: (1) A baseline control model representing typical Irish dwellings is developed, followed by the formulation of retrofit scenarios that incorporate building envelope upgrades and HVAC system improvements. (2) Dynamic energy simulations are conducted to evaluate operational energy demand and associated carbon emissions using an energy modelling platform. (3) Model interoperability is established by exporting building geometry and material data to facilitate embodied carbon analysis through a LCA tool. (4) Operational and embodied carbon outputs are integrated to calculate whole life cycle emissions for each scenario. The framework concludes with a comparative and trade-off analysis to identify retrofit configurations that optimise carbon performance and cost-effectiveness (

Figure 1). Detailed steps involved are as follows:

- (1)

Baseline and Retrofit Model Development:

A representative control model of a typical Irish dwelling was developed in DesignBuilder (version 7.0.2.006), reflecting pre-retrofit conditions including a poor thermal envelope and low-efficiency heating systems. Based on this control model, three retrofit archetypes generated original fabric (no envelope improvements), shallow retrofit (moderate upgrades), and deep retrofit (comprehensive enhancements), each characterized by varying levels of insulation, airtightness, and glazing performance. In total, 30 models were developed: six representing the original archetype, 12 for shallow retrofit scenarios, and 12 for deep retrofit scenarios. These models provide a foundation for assessing different HVAC systems, setpoint strategies, and envelope upgrades.

- (2)

Operational Energy Carbon Simulation:

Operational energy use and associated carbon emissions were evaluated using dynamic simulation in DesignBuilder, driven by the EnergyPlus engine. Each archetype was tested under multiple system configurations, varying parameters such as heating technology, coefficient of performance (COP), and room-specific temperature setpoints. The simulations quantified space heating demand and associated operational carbon for each scenario.

- (3)

Embodied Carbon Assessment:

To assess embodied carbon, model geometries and material specifications were exported in GBXML format from DesignBuilder and processed in One Click LCA, version 7. This stage quantified emissions related to construction materials, installation processes, and end-of-life treatments. Embodied carbon values were calculated over defined time horizons, using environmental product declarations (EPDs) and region-specific datasets.

In line with ISO 14040 [

31], the LCA methodology followed four main phases: goal and scope definition, where the objective was to assess the life cycle carbon footprint of systemic retrofit actions for Irish residential dwellings, with the functional unit defined as one semi-detached two-storey dwelling in Dublin and system boundaries set cradle-to-grave; life cycle inventory (LCI) analysis, which combined DesignBuilder simulations for operational energy/carbon with One Click LCA (EN 15804 EPDs) for embodied impacts using both primary and secondary data; life cycle impact assessment (LCIA), where Global Warming Potential (GWP, kgCO

2e) was selected as the impact category; and interpretation, where results were checked for completeness, consistency, and sensitivity, with uncertainties and performance trade-offs explicitly discussed. The detailed inventory of processes, data sources, assumptions, and validation/uncertainty handling are provided in

Table 1. This study, however, primarily excluded B1 and B6 due to complications in the modelling of maintenance and repair works [

32].

- (4)

Whole Life Carbon Analysis and Comparative Testing:

Results from operational and embodied carbon assessments were consolidated to calculate the whole LCA for each of the 30 retrofit scenarios. A structured data-driven platform enabled comparative analysis, while comparative analysis was carried out on key parameters, such as retrofit depth, COP, and heating setpoints, to evaluate their influence on total carbon outcomes. Trade-off analyses were used to identify retrofit strategies that optimise both operational and embodied performance (

Figure 2).

2.1. Base Case Model

The control model was defined within the DesignBuilder tool to represent a typical Irish residential dwelling in Dublin, specifically a semi-detached house, which is one of the five official national archetypes and represents a substantial share of the Irish housing stock. This model was validated against measured data to ensure it accurately represents the actual performance of the building [

7]. Development of the control model whereby the house is designed using the most likely materials, possessing poor thermal characteristics, and has a low-performance gas boiler. The dwelling is segmented into two distinct heating zones. Zone 1 encompasses the ground floor, including the living room, dining room, and kitchen, and is maintained at 21 °C. Zone 2 comprises the first-floor bedrooms, where a lower temperature of 18 °C is applied, aligning with recommendations that cooler conditions are more conducive to sleep [

33] (

Figure 3). In addition,

Table 2 outlines the thermal characteristics of the original Fabric of the dwelling. The building utilizes a gas boiler for heating with a thermal efficiency of 0.75 and an instant water heater for DHW with a COP of 1 (

Table 3).

Based on this control model, three archetype models were developed, each representing the same house after differing levels of fabric upgrades (original, shallow, and Deep retrofit). These three models possessed thermal performance characteristics and airtightness properties as listed in

Table 2, corresponding to poor efficiency, moderate efficiency, and highly efficient building envelopes. The purpose of developing three control models with varying efficiencies is not only to ensure the adaptability of the toolchain but also to offer conclusive insights that apply to a large portion of Irish homes. By analysing the performance of these models under different starting conditions, the study could establish a comprehensive framework that can guide stakeholders in making informed decisions regarding retrofit strategies for all types of houses.

Furthermore, in the retrofit models, room-specific heating setpoints are applied to align energy use with occupants′ activities and enhance comfort [

34]. This strategy targets areas with higher heating demand while reducing energy consumption in less demanding zones.

Table 4 presents the investigated setpoint temperatures, with a modelled 2 °C variation in each room to determine the range of operational energy consumption in each retrofit solution.

2.2. Retrofit Scenario Development

As mentioned, three retrofit levels were defined: original fabric, shallow retrofit, and deep retrofit:

The first retrofit scenarios will be developed by investigating the impact of solely upgrading the heating system within the building, where the original fabric of the control model will remain, as outlined above in

Table 2. The objective of this systemic retrofit is to reduce the operational energy of the building, without any significant retrofitting that would contribute to a large increase in the building′s embodied carbon.

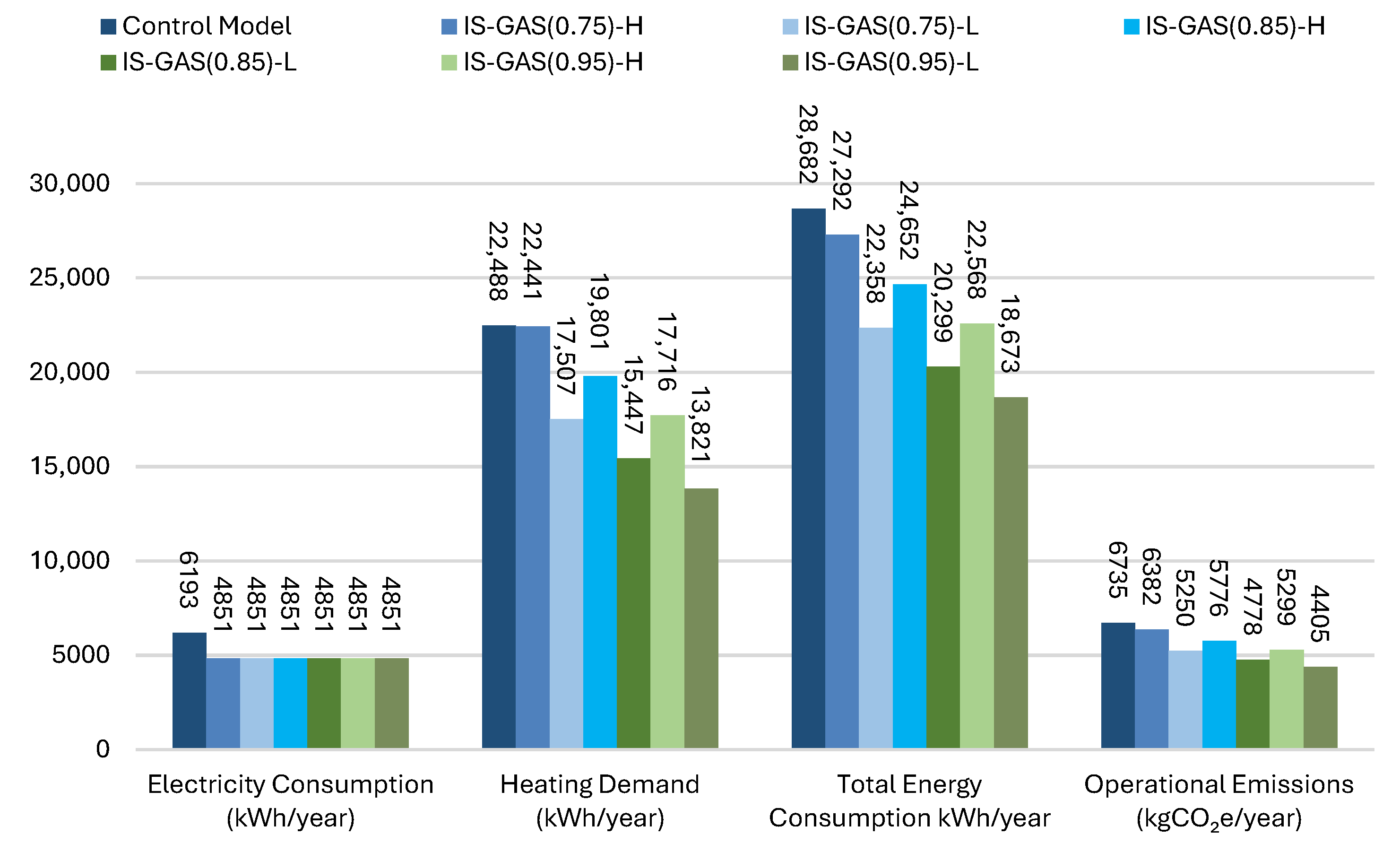

Table 5 outlines the scenarios that will be developed by investigating the energy performance of three gas boilers with different thermal efficiency while varying the heating set point temperatures throughout the house. This table lists the six scenarios developed within this model, pairing each boiler thermal efficiency with the upper and lower heating set point temperature limit.

In the shallow retrofit scenarios, moderate envelope improvements were introduced, such as internal wall insulation and improved airtightness, while maintaining the original windows, as mentioned in

Table 2. This enabled the integration of both gas boilers and ASHPs with thermal efficiency and COPs ranging from 0.75 to 4.0, along with consistent setpoint variations. Domestic hot water (DHW) was supplied by heat pumps, eliminating the need for instant water heaters (

Table 6).

The deep retrofit scenarios applied comprehensive fabric upgrades, including external insulation, triple-glazed windows, and enhanced roof insulation, as mentioned in

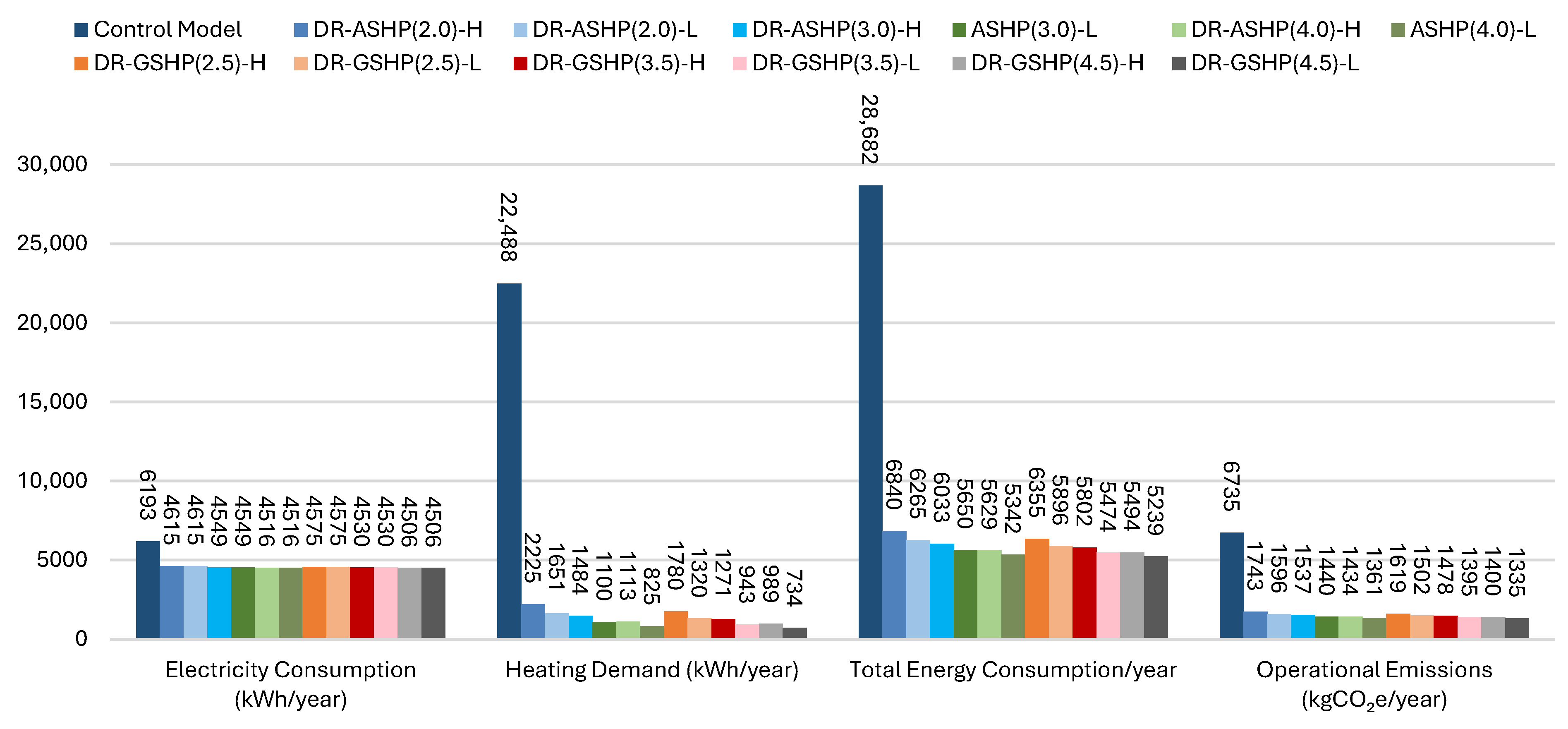

Table 2. Two heat pump systems, ASHPs and GSHPs, were modelled in this category, with higher system COPs (up to 4.5) and the use of underfloor heating on the ground floor and radiators upstairs. Across all scenarios, the aim was to quantify both operational energy use and embodied carbon, facilitating a comparative evaluation of retrofit efficiency based on building performance levels.

Table 7 lists the configurations of systems that will be analysed in this study.

The summary of developments across all these scenarios is presented in

Table 8.

4. Discussion

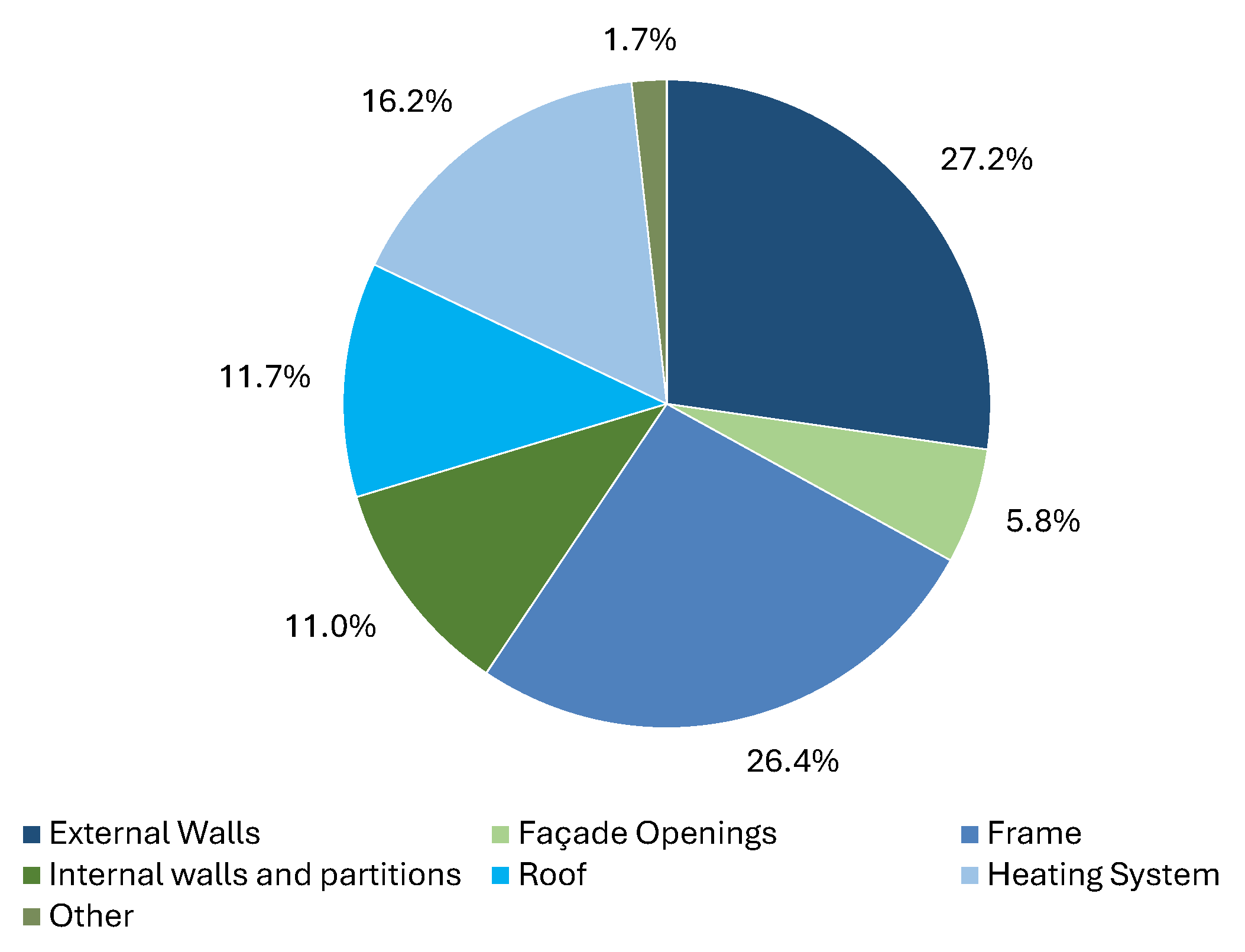

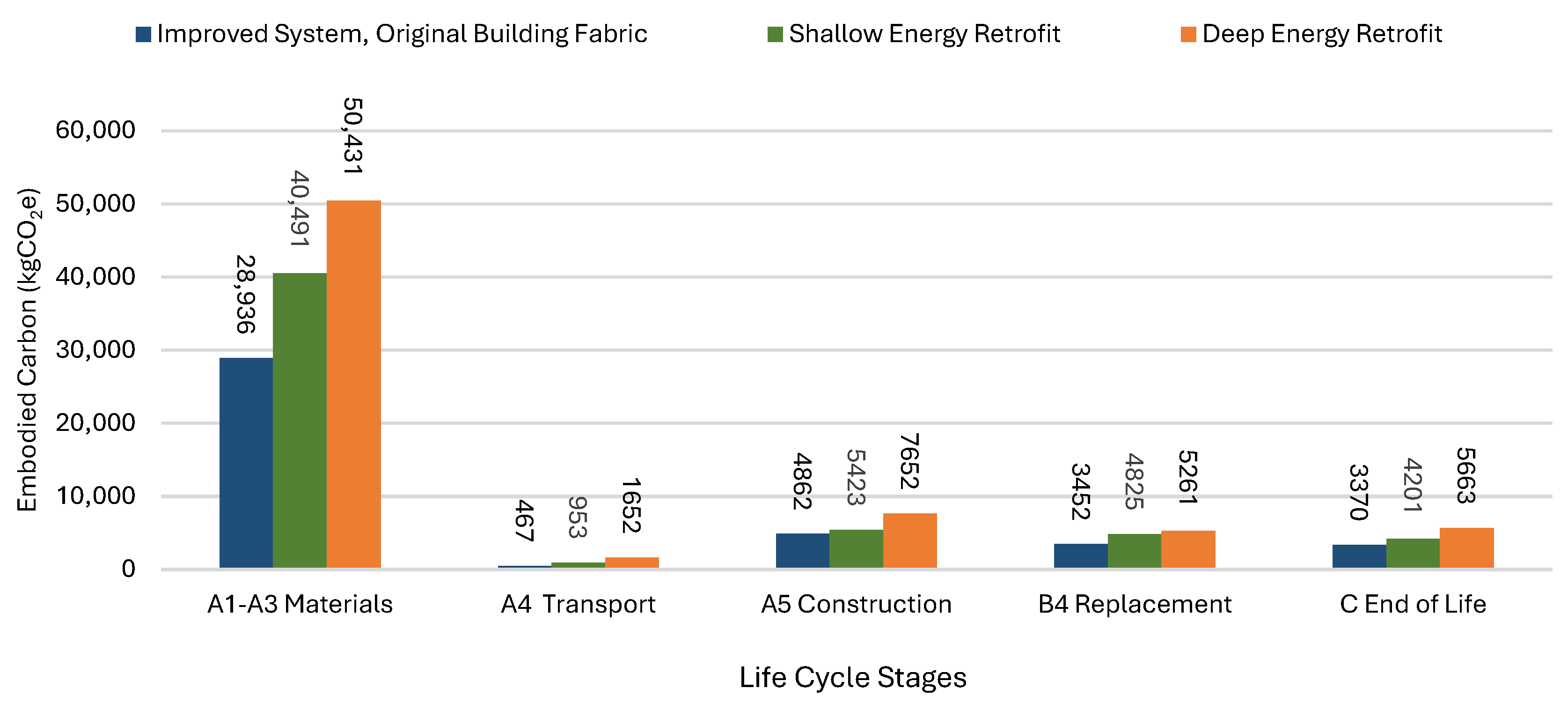

This study evaluated the whole life carbon impact of thirty retrofit scenarios applied to a representative Irish residential building, combining dynamic energy simulation with embodied carbon assessment using One Click LCA. Results highlight that both system-level upgrades and fabric improvements significantly affect operational emissions, with variations across retrofit depths and technology types. The baseline model, representing a poorly insulated dwelling with a low-efficiency gas boiler (thermal efficiency 0.75), resulted in annual operational emissions of 6735 kgCO2e and a total embodied carbon of 41,088 kgCO2e. Through system-only upgrades such as increasing COP or lowering heating setpoints, operational emissions could be reduced by up to 34.6% without incurring any additional embodied carbon. However, shallow and deep retrofit scenarios involving fabric upgrades introduced new embodied emissions, 14,806 kgCO2e and 29,572 kgCO2e, respectively, but also delivered greater operational savings of up to 75.9% and 80.2% annually.

The analysis indicates that heating setpoint temperature had a greater impact on heating demand than improvements in system efficiency. For instance, reducing the setpoint by 2 °C in the baseline scenario decreased heating demand by 22.2%, compared to a 12% reduction achieved by improving boiler thermal efficiency from 0.75 to 0.85. This pattern persisted across retrofit levels, though it was attenuated in high-performance envelopes due to lower inherent demand. When assessing heating systems, ASHPs demonstrated significantly better performance than gas boilers. In the shallow retrofit archetype, installing an ASHP with COP 4.0 and maintaining a lower heating setpoint resulted in an operational emissions reduction of 75.9% per year, almost matching the deep retrofit′s maximum of 80.2%, but with half the embodied carbon cost. The impact of fabric upgrades was also notable. While the shallow retrofit increased embodied carbon by 14,806 kgCO

2e, it provided thermal performance improvements that significantly lowered demand and allowed for more efficient heat pump operation. Deep retrofit measures pushed emissions even lower, but offered diminishing operational returns relative to their high embodied carbon investment. The findings underscore the importance of a whole life cycle perspective in evaluating retrofit strategies. While operational carbon savings are often emphasized, this study shows that the embodied carbon cost of deep retrofit s may offset their benefits, especially over short to medium time horizons. As shown in

Table 12, shallow retrofits with high-efficiency ASHPs achieved 90.7% heating demand reduction with 14,806 kgCO

2e of additional embodied emissions. In contrast, deep retrofits achieved up to 96.7% reduction but required 29,572 kgCO

2e, twice the embodied carbon. Over a 25-year lifespan, the additional 4.5% operational savings from deep retrofit may not justify the doubled material impact, especially when shallow retrofits already provide substantial reductions with better carbon efficiency per investment.

5. Conclusions

This study developed and applied a structured, scenario-based toolchain integrating dynamic energy simulation and Life Cycle Assessment (LCA) to evaluate the whole life carbon impacts of retrofit interventions in residential buildings. Thirty retrofit scenarios were analysed across three levels of intervention: original fabric, shallow retrofit, and deep retrofit. The findings highlight that while deep retrofits achieved the highest operational carbon reductions, up to 80.2% compared to the baseline, they also introduced the largest increase in embodied emissions, adding 29,572 kgCO

2e, a 68% rise over the control model. In contrast, shallow retrofits with high-efficiency air-source heat pumps (ASHPs) delivered up to 75.9% annual operational emissions reduction with a more moderate 36% increase in embodied carbon. These findings are aligned with current SEAI-supported retrofit pathways, such as the Better Energy Homes program, Individual Energy Upgrade Grants, and the National Home Energy Upgrade Scheme, which incentivize shallow retrofit measures like insulation and heating control upgrades [

35,

37], thereby reinforcing the practical relevance of our results within the Irish policy landscape (SEAI, Scheer).

System-only upgrades (e.g., increased boiler thermal efficiency and lower heating setpoints) reduced operational emissions by up to 34.6% with no additional embodied impact. Comparative analysis revealed that adjusting heating setpoints had a greater influence on heating demand than increasing system COP or thermal efficiency, showing a 22% reduction versus 12% in the baseline scenario. Over a 25-year time horizon, shallow retrofit scenarios offered the best trade-off, achieving up to 76% total emissions reduction compared to 74% for deep retrofit scenarios, with only half the material-related carbon cost. The 25-year assessment horizon of this research reflects the typical planning and funding frameworks of Irish retrofit policy, as SEAI recognises that retrofit financing is commonly structured over repayment periods of up to 25 years [

37]. Nonetheless, deeper retrofits may confer greater advantage over extended lifespans in the context of long-term targets such as net-zero by 2050.

These results underscore the importance of adopting a whole life carbon perspective in retrofit decision-making. For policymakers and practitioners, the findings support prioritizing scalable, shallow-to-moderate retrofit strategies, particularly those combining modest envelope improvements with high-COP heat pumps and temperature zoning, as a cost-effective path to decarbonizing the residential sector without incurring excessive embodied emissions. In summary, the key conclusions include:

Whole life carbon emissions can be significantly reduced through targeted retrofit actions, but efficiency gains plateau as retrofit depth increases.

Heating setpoint temperature is the most influential operational parameter, though its impact diminishes in buildings with high-performance envelopes.

As buildings approach near-zero energy standards, the embodied carbon share increases, highlighting the importance of LCA in design decision-making.

Shallow retrofits with ASHPs present a strong balance between performance and embodied impacts and are preferable over gas boilers in nearly all cases

Deep retrofits, while effective in reducing operational emissions, may be environmentally inefficient unless justified by specific technical constraints.

While the study employed a robust LCA methodology, it was limited by the lack of detailed embodied carbon data for HVAC system components. This study primarily addresses the potential for carbon reduction; however, a detailed lifecycle cost analysis was not undertaken, as economic assessment falls outside the current scope. Moreover, the whole-life results are based on the present grid emission factor, without accounting for a future decarbonisation trajectory. In addition, the research does not explore low-carbon material alternatives or the effects of changing thermal performance of building elements over time. These factors should be addressed in future research to strengthen the robustness and relevance of the results.