Performance Enhancement of Asphalt Mixtures Using Recycled Wind Turbine Blade Fiber

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Bitumen

2.1.2. Asphalt Mixture

2.1.3. RWTB Fibers

2.1.4. Comparison of Multiple Fibers

2.2. Experiments

2.2.1. Marshall Stability Test

2.2.2. Rutting Test

2.2.3. Low-Temperature Bending Beam Test

2.2.4. Immersion Marshall Test

2.2.5. Freeze–Thaw Splitting Test

2.2.6. Scanning Electron Microscopy (SEM) Test

2.2.7. Fourier Transform Infrared Spectroscopy (FTIR) Test

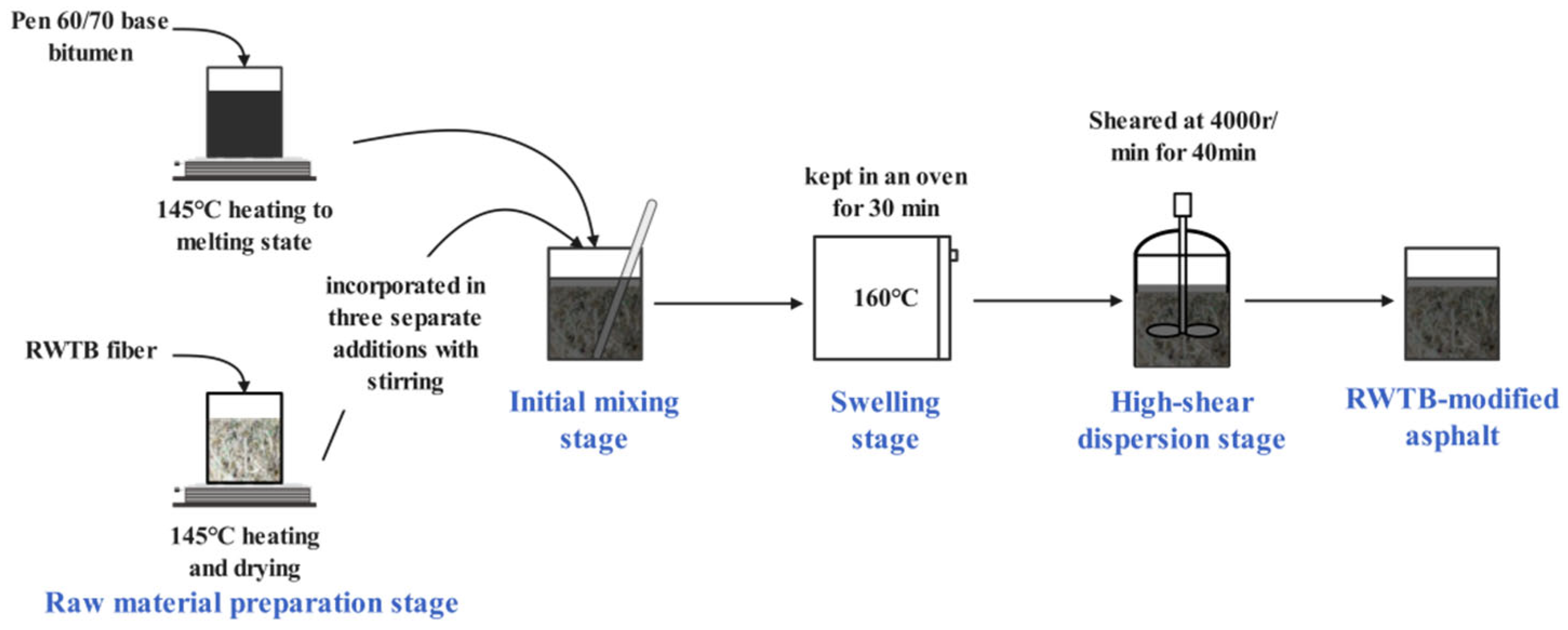

2.3. Preparation Process of RWTB Fiber-Modified Asphalt

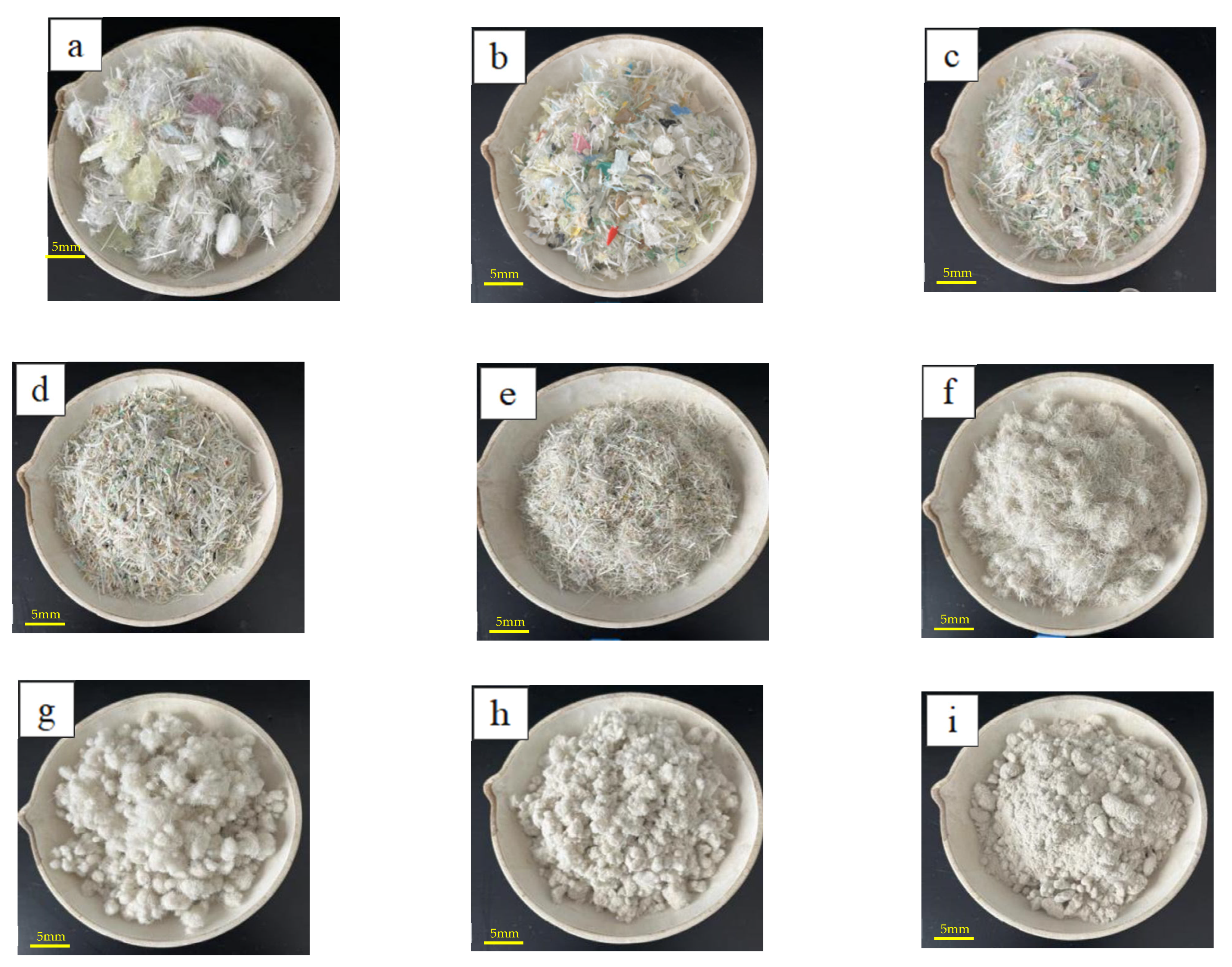

2.4. Optimal Particle Size Range

2.5. Methods

3. Results and Discussion

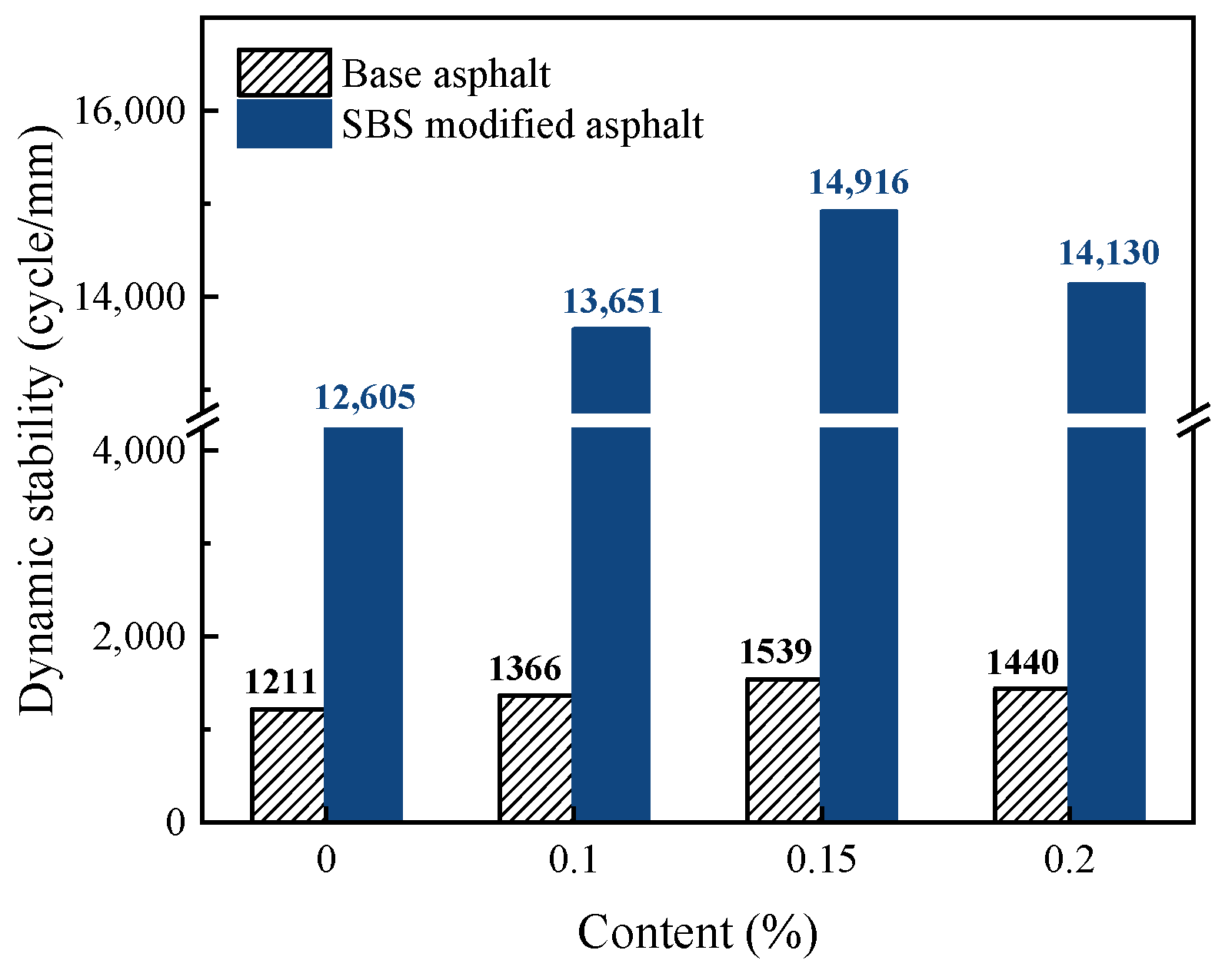

3.1. High-Temperature Stability

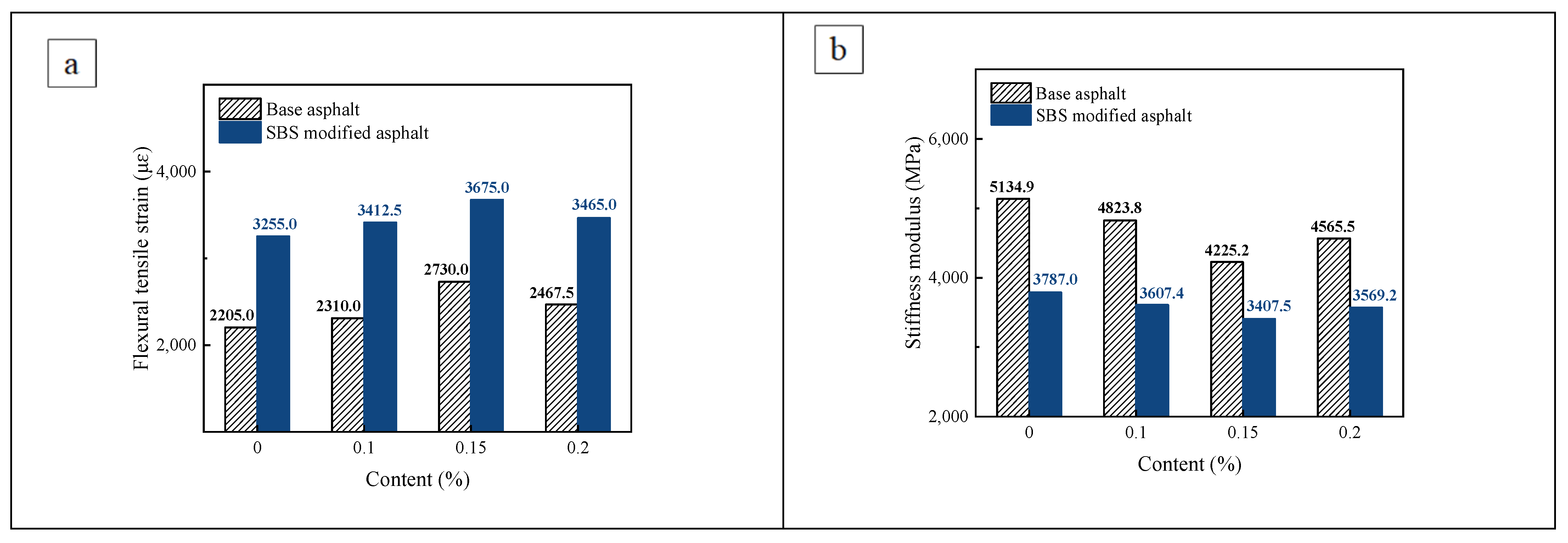

3.2. Low-Temperature Cracking Resistance

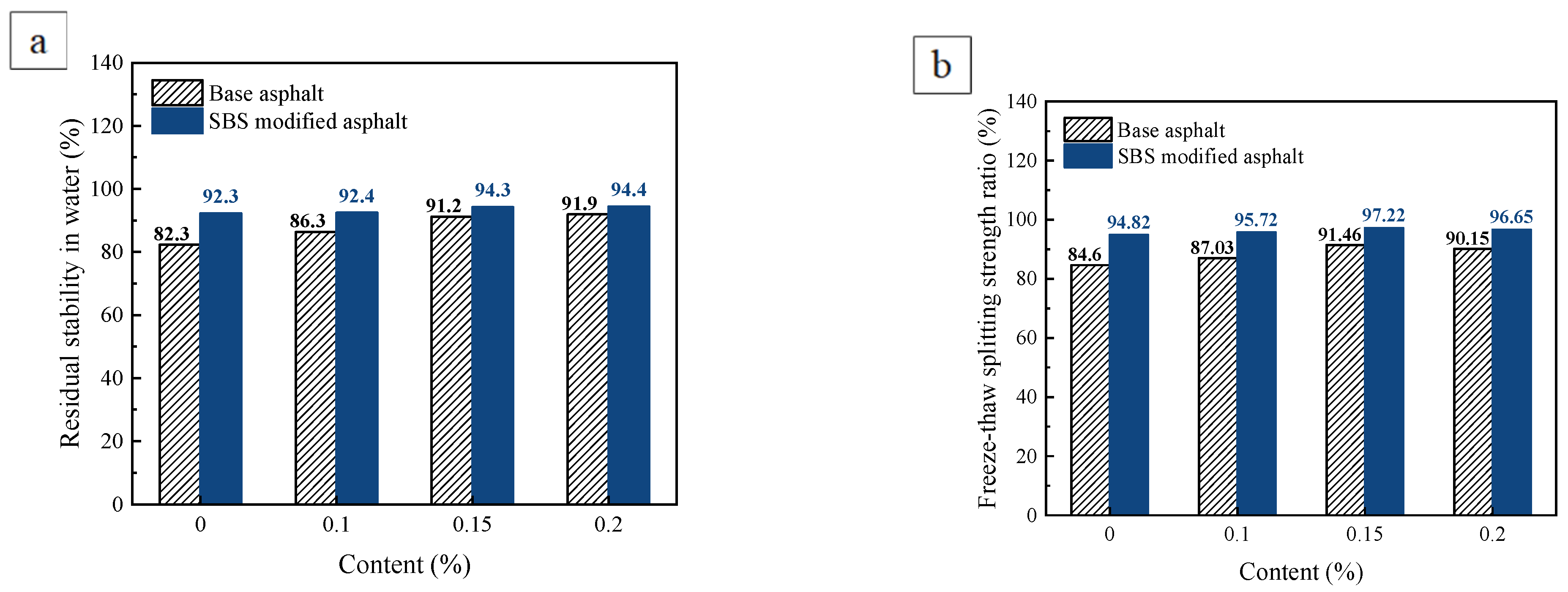

3.3. Water Stability Performance

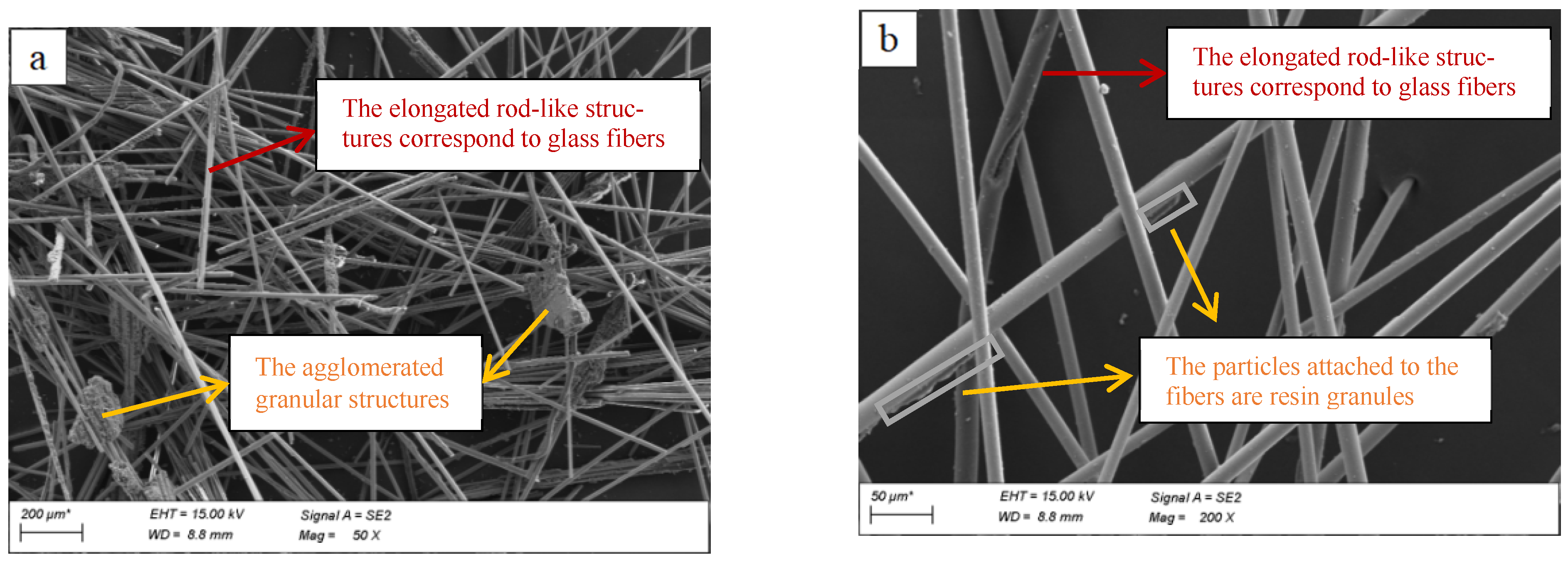

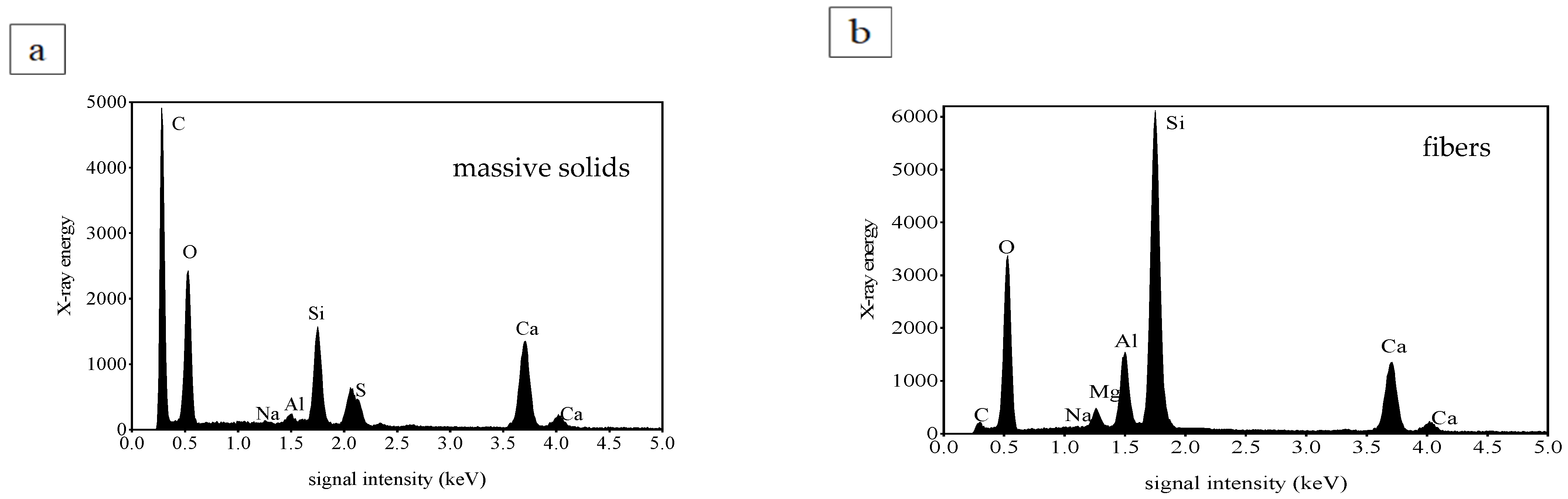

3.4. SEM Analysis

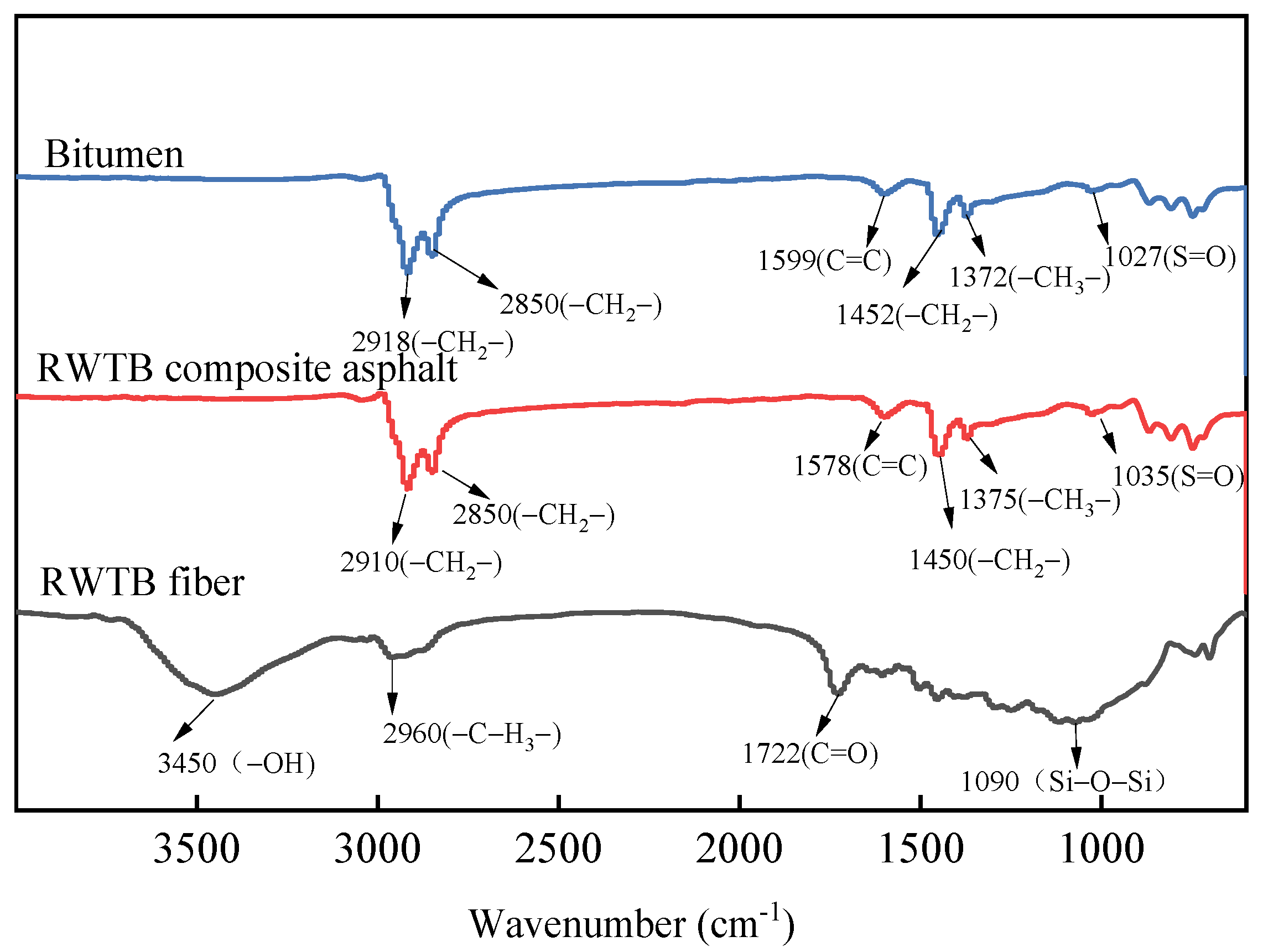

3.5. FTIR Analysis

3.6. Determining the Optimal Dosage

4. Evaluation of the Comprehensive Performance of Four Types of Fibers Based on the AHP Method

4.1. Comparative Analysis of Pavement Performance and Cost of Four Types of Fibers

4.2. Analytic Hierarchy Process (AHP)

4.3. Analysis of Results

5. Conclusions

- (1)

- RWTB fibers are cylindrical glass fiber bundles with diameters of approximately 10–15 μm and lengths exceeding 200 μm. These fibers exhibit uniform thickness and an interwoven structure, with residual resin microparticles adhered to their surfaces. No new chemical reactions or functional groups were identified between the fibers and the asphalt matrix. The reinforcing and bridging effects of the fibers promote internal network formation, thereby enhancing the toughness, elasticity, and overall mechanical performance of asphalt mixtures.

- (2)

- The optimal preparation parameters for RWTB fiber-reinforced asphalt mixtures were identified as follows: fiber preheating at 120 °C, aggregate heating at 170 °C, mixing temperature at 180 °C, and a total mixing duration of 180 s (60 s for each stage: dry mixing with aggregate, wet mixing after asphalt addition, and final mixing after mineral filler incorporation). The optimal fiber particle size range was determined to be 0.3–1.18 mm.

- (3)

- Based on gray relational analysis and the entropy weighting method, the optimal RWTB fiber content was determined to be 0.15 wt%. Under this dosage, the base asphalt mixtures showed performance improvements of 27.1% in dynamic stability, 23.8% in low-temperature flexural tensile strain, 9.9% in Marshall stability after immersion, and 8.1% in freeze–thaw splitting strength. Corresponding enhancements in SBS-modified mixtures were 18.3%, 12.9%, 2.3%, and 2.5%, respectively.

- (4)

- A comprehensive performance evaluation using the Analytic Hierarchy Process (AHP) revealed the following ranking of fiber-reinforced asphalt mixtures: BF > RWTB > GF > PF. RWTB fibers outperformed both GF and PF, ranking second only to BF, indicating their high potential for enhancing asphalt pavement performance.

- (5)

- This study presents a systematic and practical approach to the high-value utilization of recycled wind turbine blade (RWTB) materials in road engineering. It offers a feasible technical solution for the resource recovery of wind power composites, contributing to the reduction, harmless disposal, and reuse of retired turbine blades. These findings carry significant environmental and engineering implications and support the development of green, low-carbon, and sustainable transportation infrastructure aligned with global sustainability goals.

- (1)

- investigate the mechanisms by which RWTB fibers enhance low-temperature cracking resistance, including potential surface treatments to improve adhesion;

- (2)

- conduct long-term durability tests—such as aging, fatigue, and moisture resistance tests—to evaluate performance throughout the pavement lifecycle;

- (3)

- implement pilot-scale or field applications to validate the laboratory results under real-world operating conditions.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, H.X.; Li, N.L.; Hu, C.S.; Zhang, Z. Mechanical performance of fibers-reinforced asphalt mixture. J. Chan. Univ. (Nat. Sci. Ed.) 2004, 24, 1–5. [Google Scholar]

- Putman, B.J.; Amirkhanian, S.N. Utilization of waste fibers in stone matrix asphalt mixtures. Resour. Conserv. Recycl. 2004, 42, 265–274. [Google Scholar] [CrossRef]

- Peltonen, P. Wear and deformation characteristics of fibre reinforced asphalt pavements. Constr. Build. Mater. 1991, 5, 18–22. [Google Scholar] [CrossRef]

- Zhang, M.; Zhang, J.; Lyu, L.; Li, Y.; Tan, X.; Li, Z.; Pei, J. Durable and Environmental Asphalt Pavement with Plant Fiber: A State-of-the-Art Review. J. Mater. Civ. Eng. 2024, 36, 03123003. [Google Scholar] [CrossRef]

- Donchenko, M.; Grynyshyn, O.; Prysiazhnyi, Y.; Pyshyev, S.; Kohut, A. The Problem of Road Bitumen Technological Aging and Ways to Solve It: A Review. Chem. Chem. Technol. 2024, 18, 284–294. [Google Scholar] [CrossRef]

- Onyshchenko, A.; Lisnevskyi, R.; Viesich, I.; Poliak, O.; Rybchynskyi, S.; Shyshkin, E. Study on the Effect of Butonal NX4190 Polymer Latex on the Properties of Bitumen Binder and Asphalt Concrete. Chem. Chem. Technol. 2023, 17, 688–700. [Google Scholar] [CrossRef]

- Xiao, P.; Chen, J.; Kang, A.; Kong, H.; Deng, Y. Properties of epoxy asphalt mixtures toughened with different fibers. Exp. Technol. Manag. 2024, 41, 1–6. [Google Scholar] [CrossRef]

- Zhen, T.; Zhao, P.; Zhang, X.; Si, W.; Ling, T. The Effect of GFRP Powder on the High and Low-Temperature Properties of Asphalt Mastic. Materials. 2023, 16, 2662. [Google Scholar] [CrossRef]

- Zhang, J.; Huang, W.; Zhang, Y.; Lv, Q.; Yan, C. Evaluating four typical fibers used for OGFC mixture modification regarding drainage, raveling, rutting and fatigue resistance. Constr. Build. Mater. 2020, 253, 119131. [Google Scholar] [CrossRef]

- Xie, T.; Wang, L. Optimize the design by evaluating the performance of asphalt mastic reinforced with different basalt fiber lengths and contents. Constr. Build. Mater. 2022, 363, 129698. [Google Scholar] [CrossRef]

- Jiu, X.; Xiao, P.; Li, B.; Wang, Y.; Kang, A. Pavement Performance Investigation of Asphalt Mixtures with Plastic and Basalt Fiber Composite (PB) Modifier and Their Applications in Urban Bus Lanes Using Statics Analysis. Materials 2023, 16, 770. [Google Scholar] [CrossRef]

- Fazli, A.; Rodrigue, D. Sustainable Reuse of Waste Tire Textile Fibers (WTTF) as Reinforcements. Polymers 2022, 14, 3933. [Google Scholar] [CrossRef] [PubMed]

- Al-Mammori, Z.A.; Al-Janabi, I.M.K.; Abbas, G.H.; Aziz, D.H.; Alaaraji, F.H.; Abbas, E.S.; Al-Shimmery, B.M.; Hashim, T.M.; Al-Jameel, G.Q.; Shubbar, A.; et al. Mechanical and Performance Characteristics of Warm Mix Asphalt Modified with Phase Change Materials and Recycled Cigarette Filters. CivilEng 2025, 6, 41. [Google Scholar] [CrossRef]

- Zeng, B.; Wan, N.; Zhang, S.; Yu, X.; Zhang, Z.; Chen, J.; Lei, B. Feasibility Study of Waste Rock Wool Fiber as Asphalt Mixture Additive: Performance Test and Environmental Effect Analysis. Buildings 2025, 15, 2022. [Google Scholar] [CrossRef]

- Alonso-Troyano, C.; Llopis-Castelló, D.; Olaso-Cerveró, B. Incorporating Recycled Textile Fibers into Stone Mastic Asphalt. Buildings 2025, 15, 1310. [Google Scholar] [CrossRef]

- Hasheminezhad, A.; Nazari, Z.; Yang, B.; Ceylan, H.; Kim, S. A comprehensive review of sustainable solutions for reusing wind turbine blade waste materials. J. Environ. Manag. 2024, 366, 121735. [Google Scholar] [CrossRef]

- Cai, X.; Duan, H.; Ma, Y.; Li, X.; Xie, M. Environmental impact assessment of wind turbine blades based on life cycle analysis. J. Shenzhen Univ. Sci. Eng. 2023, 40, 40–47. [Google Scholar]

- Chen, W.; Ye, M.; Li, M.; Xi, B.; Hou, J.; Qi, X.; Zhang, J.; Wei, Y.; Meng, F. Characteristics, kinetics and product distribution on pyrolysis process for waste wind turbine blades. J. Anal. Appl. Pyrolysis 2023, 169, 105859. [Google Scholar] [CrossRef]

- Alshannaq, A.A.; Bank, L.C.; Scott, D.W.; Gentry, R. A Decommissioned Wind Blade as a Second-Life Construction Material for a Transmission Pole. Constr. Mater. 2021, 1, 95–104. [Google Scholar] [CrossRef]

- Sorte, S.; Figueiredo, A.; Vela, G.; Oliveira, M.; Vicente, R.; Relvas, C.; Martins, N. Evaluating the feasibility of shredded wind turbine blades for sustainable building components. J. Clean. Prod. 2023, 434, 139867. [Google Scholar] [CrossRef]

- Baturkin, D.; Hisseine, O.A.; Masmoudi, R.; Tagnit-Hamou, A.; Metiche, S.; Massicotte, L. Compressive behavior of FRP-tube-confined concrete short columns using recycled FRP materials from wind turbine blades: Experimental investigation and analytical modelling. Clean Technol. Recycl. 2022, 2, 136–164. [Google Scholar] [CrossRef]

- Yu, X.; Zhang, C.; Li, J.; Bai, X.; Yang, L.; Han, J.; Zhou, G. Reuse of Retired Wind Turbine Blades in Civil Engineering. Buildings 2025, 15, 2414. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, Z.; Bai, S.; Zhao, Y.; Ji, Y. Road Performance and Multi-Objective Optimization Study of rWTB—Salt-Retaining Asphalt Mixture. Polymers 2025, 17, 1304. [Google Scholar] [CrossRef]

- Li, P.; Wang, X.; Chen, W.; Yang, T.; Bian, X.; Xu, X. Recycling of Retired Wind Turbine Blades into Modifiers for Composite-Modified Asphalt Pavements: Performance Evaluation. Sustainability 2024, 16, 2343. [Google Scholar] [CrossRef]

- Lan, T.; Wang, B.; Zhang, J.; Wei, H.; Liu, X. Utilization of waste wind turbine blades in performance improvement of asphalt mixture. Front. Mater. 2023, 10, 1164693. [Google Scholar] [CrossRef]

- Nie, Y.; Liu, Q.; Xiang, Z.; Zhong, S.; Huang, X. Performance and Modification Mechanism of Recycled Glass Fiber of Wind Turbine Blades and SBS Composite-Modified Asphalt. Appl. Sci. 2023, 13, 6335. [Google Scholar] [CrossRef]

- Ministry of Transport of the People’s Republic of China. JTG E20-2011; Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering. China Communications Press: Beijing, China, 2011.

- Ministry of Communications of the People’s Republic of China. JTG F40-2004; Technical Specifications for Construction of Highway Asphalt Pavements. China Communications Press: Beijing, China, 2004.

- Gao, W. Research on the Preparation Process and Technical Performance of Composite Fiber Modified Asphalt from Waste wind Turbine Blades. Master’s Thesis, Hunan University of Science and Technology, Xiangtan, China, 2022. [Google Scholar] [CrossRef]

- Al-Kahtani, M.S.M.; Zhu, H.; Haruna, S.I.; Shao, J. Evaluation of Mechanical Properties of Polyurethane-Based Polymer Rubber Concrete Modified Ground Glass Fiber Using Response Surface Methodology. Arab. J. Sci. Eng. 2022, 48, 4695–4710. [Google Scholar] [CrossRef]

- Zhu, H.; Tan, Q.; Yang, X.; Fan, S.; Zhao, H. Research status and prospect of fiber-modified asphalt mixture performance. Sci. Technol. Engineering 2022, 22, 2573–2584. [Google Scholar] [CrossRef]

- Ministry of Transport of the People’s Republic of China. JTG E42-2005; Test Methods of Aggregate for Highway Engineering. China Communications Press: Beijing, China, 2005.

- Zou, G.; Xu, J.; Wu, C. Evaluation of factors that affect rutting resistance of asphalt mixes by orthogonal experiment design. Int. J. Pavement Res. Technol. 2017, 10, 282–288. [Google Scholar] [CrossRef]

- Pan, R.; Chang, J.; Chen, Y. Study on Composition Design and Performance Characteristics of Warm-Mixed Rubber–Asphalt Mixture for Cold-Region Stress Absorption Layers. Buildings 2025, 15, 1164. [Google Scholar] [CrossRef]

- Liu, F.; Pan, B.; Bian, J.; Zhou, C. Experimental investigation on the performance of the asphalt mixture with ceramic fiber. J. Clean. Prod. 2023, 384, 135585. [Google Scholar] [CrossRef]

- Xie, M.; Wen, Y.; Xu, L.; Wu, K.; Jiang, Z. Research on the effect of lignin/glass fiber composite-modified asphalt concrete road performance enhancement. J. Build. Materials. 2023, 26, 1200–1206. [Google Scholar]

- Cai, D.; Yue, X.; Hao, B.; Ma, P. A sustainable poly (vinyl chloride) plasticizer derivated from waste cooking oil. J. Clean. Prod. 2020, 274, 122781. [Google Scholar] [CrossRef]

- Marsac, P.; Piérard, N.; Porot, L.; Van den Bergh, W.; Grenfell, J.; Mouillet, V.; Pouget, S.; Besamusca, J.; Farcas, F.; Gabet, T.; et al. Potential and limits of FTIR methods for reclaimed asphalt characterisation. Mater. Struct. 2014, 47, 1273–1286. [Google Scholar] [CrossRef]

- Gao, J.; Wang, H.; You, Z.; Yang, X. Gray relational entropy analysis of high temperature performance of bio-asphalt binder and its mixture. Int. J. Pavement Res. Technol. 2018, 11, 698–708. [Google Scholar] [CrossRef]

- Fan, X.; Xu, Z. Recycling and reuse of retired wind turbine blades. Energy Conserv. Environ. Prot. 2024, 2, 46–52. [Google Scholar]

- Ma, J.; Cui, Y.; Xing, Y.; Chen, X.; Wu, J. Optimization and pavement performance of buton-rock-asphalt modified asphalt mixture with basalt-fibre. Case Stud. Constr. Mater. 2024, 21, e03429. [Google Scholar] [CrossRef]

- Ai, Q.; Huang, J.; Du, S.; Yang, K.; Wang, H. Comprehensive Evaluation of Very Thin Asphalt Overlays with Different Aggregate Gradations and Asphalt Materials Based on AHP and TOPSIS. Buildings 2022, 12, 1149. [Google Scholar] [CrossRef]

| Index | Pen 60/70 Base Bitumen | SBS Modified Bitumen | Test Method | ||

|---|---|---|---|---|---|

| Test Value | Specification | Test Value | Specification | ||

| Penetration (25 °C)/0.1 mm | 68.3 | 60~80 | 52.8 | 40~55 | T0604 |

| Softening point/°C | 48.0 | ≥45 | 85.0 | ≥75 | T0606 |

| Ductility (15 °C)/cm | >100 | ≥100 | — | — | T0605 |

| Ductility (5 °C)/cm | — | — | 32.2 | ≥25 | |

| Flash point/°C | 297 | ≥260 | 285 | ≥230 | T0611 |

| Density (15 °C)/g·cm−3 | 1.033 | ― | 1.039 | — | T0603 |

| Coarse Aggregate | |||||

|---|---|---|---|---|---|

| Index | Unit | Technical requirement | Test result | Test method | |

| Crushed stone value (9.5~13.2 mm) | % | ≤28 | 12.2 | T0316-2005 | |

| Apparent relative density | 9.5~13.2 mm | t/m3 | ≥2.5 | 2.725 | T0304-2005 |

| 4.75~9.5 mm | t/m3 | 2.726 | |||

| 2.36~4.75 mm | t/m3 | 2.716 | |||

| Water absorption | 9.5~13.2 mm | % | ≤3.0 | 0.35 | T0304-2005 |

| 4.75~9.5 mm | % | 0.53 | |||

| 2.36~4.75 mm | % | 1.02 | |||

| Bulk relative density | 9.5~13.2 mm | t/m3 | — | 2.699 | T0304-2005 |

| 4.75~9.5 mm | t/m3 | 2.688 | |||

| 2.36~4.75 mm | t/m3 | 2.643 | |||

| Flakiness index | 9.5~13.2 mm | % | ≤15 | 9.6 | T0312-2005 |

| 4.75~9.5 mm | % | 10.7 | |||

| 2.36~4.75 mm | % | 8.2 | |||

| Passing 0.075 mm sieve by washing method | 9.5~13.2 mm | % | ≤1 | 0.2 | T0302-2005 |

| 4.75~9.5 mm | % | 0.2 | |||

| 2.36~4.75 mm | % | 0.4 | |||

| Fine aggregate | |||||

| Apparent relative density | t/m3 | ≥2.50 | 2.700 | T0328-2005 | |

| Bulk relative density | t/m3 | — | 2.698 | ||

| Passing 0.075 mm sieve by washing method | % | ≤3 | 2.6 | T0327-2005 | |

| Sand equivalent | % | ≥60 | 70 | T0334-2005 | |

| Index | Unit | Technical Requirement | Test Result | Test Method | |

|---|---|---|---|---|---|

| Apparent density | t/m3 | ≥2.50 | 2.691 | T0352-2000 | |

| Particle size range | <0.6 mm | % | 100 | 100 | T0351-2000 |

| <0.15 mm | % | 90~100 | 99.8 | ||

| <0.075 mm | % | 75~100 | 95.5 | ||

| Water affinity coefficient | — | <1 (preferably <0.8) | 0.6 | T0353-2000 | |

| Plasticity index | — | ≤4 | 2.4 | T0354-2000 | |

| Sieve Size/mm | 16 | 13.2 | 9.5 | 4.75 | 2.36 | 1.18 | 0.6 | 0.3 | 0.15 | 0.075 |

| Synthetic grade/% | 100.0 | 92.8 | 72.3 | 39.0 | 24.9 | 17.9 | 12.0 | 8.7 | 7.0 | 5.0 |

| Upper limit of grading/% | 100 | 100 | 85 | 68 | 50 | 38 | 28 | 20 | 15 | 8 |

| Lower Grading Limit/% | 100 | 90 | 68 | 38 | 24 | 15 | 10 | 7 | 5 | 4 |

| Gross Volume Relative Density | Theoretical Maximum Relative Density | Void Ratio/% | VMA/% | VFA/% | Degree of Stability/kN | Stream Value/mm | |

|---|---|---|---|---|---|---|---|

| Result | 2.428 | 2.512 | 4.8 | 13.7 | 68.3 | 12.80 | 2.4 |

| Specification | — | — | 3–6 | >13 | 65–75 | >8 | 2–4 |

| Particle Size | Percentage/% | Appearance Description |

|---|---|---|

| >9.5 mm | 4.7 | Predominantly flake resin and impurities |

| 9.5–4.75 mm | 14.9 | More flaky resin and balsa with attached fibers |

| 4.75–2.36 mm | 17.4 | Strips of resin, fibers, increased particles |

| 2.36–1.18 mm | 12.5 | Strips of resin with more small particles |

| 1.18–0.6 mm | 18.1 | Striped fibers agglomerated with resin, small particle size |

| 0.6–0.3 mm | 10.9 | Fibers agglomerated and attached around striated fibers, fewer particles |

| 0.3–0.15 mm | 6.1 | White appearance, fluffy volume, fiber agglomeration and mixed with resin |

| 0.15–0.075 mm | 7.3 | Short fibers agglomerated with resin, soft to the touch, dusty |

| <0.075 mm | 8.1 | More fine dust, fiber and dust adsorption |

| Fiber Types | Fiber Length/ mm | Fiber Diameter/ μm | Density/(g/cm3) | Safety |

|---|---|---|---|---|

| RWTB fiber | 5~8 | 15 | 1.58 | non-toxic |

| GF | 6 | 13 | 2.51 | non-toxic |

| PF | 6 | 13.4 | 1.36 | non-toxic |

| BF | 6 | 17 | 2.65 | non-toxic |

| WFB Particle Size on Screen/mm | Oil-Rock Ratio/% | Gross Volume Relative Density | Theoretical Maximum Relative Density | Void Ratio/% | VMA/% | VFA/% | Degree of Stability/KN | Stream Value/mm |

|---|---|---|---|---|---|---|---|---|

| Fiber-free | 4.80 | 2.428 | 2.512 | 3.4 | 13.7 | 68.3 | 12.8 | 2.4 |

| Bottle | 4.90 | 2.421 | 2.471 | 1.9 | 13.2 | 82.7 | 13.00 | 3.0 |

| 0.075 | 4.85 | 2.412 | 2.508 | 3.6 | 13.5 | 69.6 | 13.74 | 2.5 |

| 0.15 | 4.85 | 2.409 | 2.502 | 3.5 | 13.6 | 70.5 | 12.84 | 3.0 |

| 0.3 | 4.85 | 2.414 | 2.499 | 3.2 | 13.5 | 72.5 | 14.37 | 2.9 |

| 0.6 | 4.85 | 2.424 | 2.495 | 2.7 | 13.1 | 76.4 | 13.99 | 2.6 |

| 1.18 | 4.85 | 2.426 | 2.498 | 2.3 | 12.6 | 78.8 | 14.49 | 2.7 |

| 2.36 | 4.80 | 2.428 | 2.506 | 2.9 | 12.9 | 74.3 | 13.64 | 2.9 |

| 4.75 | 4.80 | 2.415 | 2.508 | 3.5 | 13.4 | 70.2 | 13.69 | 3.3 |

| 9.5 | 4.80 | 2.408 | 2.499 | 3.4 | 13.7 | 71.2 | 13.13 | 2.4 |

| Specification | — | — | — | 3–6 | >13 | 65–75 | >8 | 2–4 |

| WFB Particle Size on Screen/mm | Oil-Rock Ratio/% | Gross Volume Relative Density | Theoretical Maximum Relative Density | Void Ratio/% | VMA/% | VFA/% | Degree of Stability/KN | Stream Value/mm |

|---|---|---|---|---|---|---|---|---|

| Fiber-free | 4.80 | 2.436 | 2.513 | 3.7 | 13.6 | 70.7 | 12.66 | 2.4 |

| Bottle~0.6 | 4.90 | 2.431 | 2.498 | 3.1 | 13.5 | 78.2 | 13.43 | 2.8 |

| 1.18~9.5 | 4.85 | 2.430 | 2.512 | 4.4 | 13.6 | 62.8 | 13.82 | 2.4 |

| 0~0.15 | 4.90 | 2.434 | 2.499 | 3.0 | 13.5 | 75.5 | 13.60 | 2.1 |

| 0.3~1.18 | 4.85 | 2.424 | 2.515 | 3.6 | 13.8 | 68.8 | 14.63 | 2.5 |

| 2.36~9.5 | 4.85 | 2.432 | 2.512 | 4.0 | 13.2 | 65.0 | 12.88 | 2.8 |

| Unscreened | 4.90 | 2.437 | 2.505 | 2.7 | 13.3 | 74.8 | 12.93 | 2.2 |

| Specification | — | — | — | 3–6 | >13 | 65–75 | >8 | 2–4 |

| Asphalt Types | Evaluation Items | Peak Dosage/% | Correlation Degree | Ranking |

|---|---|---|---|---|

| Base asphalt | Bending tensile strain | 0.15 | 0.673 | 1 |

| Dynamic stability | 0.15 | 0.661 | 2 | |

| Residual stability | 0.20 | 0.641 | 3 | |

| Freeze–thaw splitting tensile strength | 0.15 | 0.635 | 4 | |

| Elastic modulus | 0.15 | 0.583 | 5 | |

| SBS modified asphalt | Dynamic stability | 0.15 | 0.681 | 1 |

| Bending tensile strain | 0.15 | 0.673 | 2 | |

| Residual stability | 0.20 | 0.657 | 3 | |

| Freeze–thaw splitting tensile strength | 0.15 | 0.655 | 4 | |

| Elastic modulus | 0.15 | 0.633 | 5 |

| Asphalt Types | RWTB Fiber Content/ % | Overall Evaluation Score | Ranking |

|---|---|---|---|

| Base asphalt | 0.15 | 0.988 | 1 |

| 0.2 | 0.712 | 2 | |

| 0.1 | 0.347 | 3 | |

| 0.0 | 0.000 | 4 | |

| SBS modified asphalt | 0.15 | 0.981 | 1 |

| 0.2 | 0.732 | 2 | |

| 0.1 | 0.315 | 3 | |

| 0.0 | 0.000 | 4 |

| Fiber Types | Optimal Dosage/% | ||

|---|---|---|---|

| High-Temperature Stability | Low-Temperature Cracking Resistance | Water Stability | |

| RWTB fiber | 0.15 | 0.15 | 0.15 |

| GF | 0.3 | 0.2 | 0.4 |

| PF | 0.1 | 0.1 | 0.1 |

| BF | 0.5 | 0.5 | 0.3 |

| Pairwise Comparison Matrix | Cost | Bending Tensile Strain | Residual Stability | Dynamic Stability | Row Sum Product | Eigenvector | Normalization |

|---|---|---|---|---|---|---|---|

| Cost | 1.00 | 0.33 | 0.50 | 0.33 | 0.06 | 0.49 | 0.11 |

| Bending tensile strain | 3.00 | 1.00 | 2.00 | 1.00 | 6.00 | 1.57 | 0.35 |

| Residual stability | 2.00 | 0.50 | 1.00 | 0.50 | 0.50 | 0.84 | 0.19 |

| Dynamic stability | 3.00 | 1.00 | 2.00 | 1.00 | 6.00 | 1.57 | 0.35 |

| Criteria Layer | Normalization | AW | AW/W | Maximum Eigenvalue | CI | RI | CR |

|---|---|---|---|---|---|---|---|

| Cost | 0.11 | 0.44 | 4.02 | 4.01 | 0.00 | 0.90 | 0.004 |

| Bending tensile strain | 0.35 | 1.41 | 4.01 | ||||

| Residual stability | 0.19 | 0.76 | 4.02 | ||||

| Dynamic stability | 0.35 | 1.407 | 4.01 |

| Asphalt Mixture Types | Cost | Bending Tensile Strain | Residual Stability | Dynamic Stability | Overall Evaluation Score | Ranking |

|---|---|---|---|---|---|---|

| SBS/BF AC-13 | 1.71 | 1.19 | 0.99 | 1.12 | 1.19 | 1 |

| SBS/RWTB AC-13 | 0.66 | 1.03 | 0.31 | 0.95 | 0.82 | 2 |

| SBS/GF AC-13 | 0.79 | 0.86 | 0.19 | 0.91 | 0.75 | 3 |

| SBS/PF AC-13 | 0.60 | 0.20 | 0.82 | 1.10 | 0.68 | 4 |

| SBS AC-13 | 0.40 | 0.36 | −0.17 | 0.62 | 0.36 | 5 |

| BF AC-13 | 0.05 | 0.45 | 0.82 | −0.82 | 0.03 | 6 |

| RWTB AC-13 | −1.00 | −0.46 | −0.27 | −0.96 | −0.66 | 7 |

| GF AC-13 | −0.87 | −0.55 | −0.50 | −0.97 | −0.72 | 8 |

| PF AC-13 | −1.07 | −1.79 | 0.26 | −0.93 | −1.02 | 9 |

| AC-13 | −1.26 | −1.29 | −2.47 | −1.01 | −1.41 | 10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, R.; Nie, Y.; He, B.; He, L.; Long, L. Performance Enhancement of Asphalt Mixtures Using Recycled Wind Turbine Blade Fiber. Sustainability 2025, 17, 8112. https://doi.org/10.3390/su17188112

Zhang R, Nie Y, He B, He L, Long L. Performance Enhancement of Asphalt Mixtures Using Recycled Wind Turbine Blade Fiber. Sustainability. 2025; 17(18):8112. https://doi.org/10.3390/su17188112

Chicago/Turabian StyleZhang, Ruoxi, Yihua Nie, Bo He, Lingchao He, and Leixiang Long. 2025. "Performance Enhancement of Asphalt Mixtures Using Recycled Wind Turbine Blade Fiber" Sustainability 17, no. 18: 8112. https://doi.org/10.3390/su17188112

APA StyleZhang, R., Nie, Y., He, B., He, L., & Long, L. (2025). Performance Enhancement of Asphalt Mixtures Using Recycled Wind Turbine Blade Fiber. Sustainability, 17(18), 8112. https://doi.org/10.3390/su17188112