1. Introduction

The agricultural industry is characterized by significant energy and resource inefficiency [

1] and is a main contributor to environmental degradation [

2]. It is estimated that food system emissions represent 34% of the total greenhouse gas (GHG) emissions—71% of which results from agriculture and land use activities [

3]. Moreover, traditional agricultural systems lead to excessive operational costs [

1] and socio-ecological impacts [

4,

5], including excessive water consumption and Global Warming Potentials (GWPs) [

6], which in turn harm crop productivity [

7].

Nevertheless, the agriculture sector is essential for food production [

8], and in the context of an increasing world population [

8,

9,

10], the environmental impact caused by agriculture is expected to be further increased [

8]. The food sector must adopt an efficient and sustainable use of resources to ensure food availability for current and future generations [

11], while supporting most of the United Nations Sustainable Development Goals [

12]. In this light, various government support mechanisms have been introduced to implement sustainable practices and reduce the environmental impacts caused by the agricultural sector [

13].

Wheat production, like many agricultural activities, generates a significant amount of waste [

14]. Fruits, vegetables, and cereal crops are among the leading contributors to food loss and waste [

15]. Despite wheat cultivation requiring only 120–140 kg of seed, farmers sow between 180 and 300 kg of seed to ensure a sufficient yield [

15]. Hence, managing agricultural waste, including wheat straw, is becoming an increasing concern [

16]. By the valorization of agricultural waste, valuable materials and energy could be retrieved, enhancing the circular economy model and biofuel production [

17]. To do so, various methods are available, such as pyrolysis, gasification, anaerobic digestion, and fermentation [

18,

19]. Nevertheless, the practical application of the circular economy model in the context of agriculture remains minimal or limited [

20]. Despite the production of biofuels raising important concerns due to food versus fuel for feedstocks, the utilization of crop residues can avoid such conflicts [

21].

The Life Cycle Assessment (LCA) is one of the most widely used methodologies for assessing the environmental impacts of products and services of all sectors in their whole supply chain, including agriculture [

22,

23]. It enables the identification of environmental hotspots and provides opportunities to reduce environmental burdens, thereby supporting more informed decision-making [

24]. In the agricultural sector, LCAs can guide improvements in resource efficiency and sustainability and can serve as a decision support tool and a foundation for external environmental communication through certifications and declarations [

25]. Environmental certification, such as Environmental Product Declarations (EPDs), can encourage more sustainable resource use [

26], contribute to GHG emission reductions [

27], and promote transparency and accountability within the agrifood industry. Such certification schemes not only support climate change mitigation efforts [

28] but also signal a commitment to sustainability, potentially influencing consumer choices and policy development [

29,

30,

31]. To carry out an LCA study, and therefore obtain an environmental certification, software is typically required due to the large volume of data, characterization factors, and calculations involved. However, most LCA tools currently available on the market rely on static life cycle inventory (LCI) databases, which can lead to significant uncertainties in the results [

32]. Due to the dynamic nature of product systems and services, the use of real-time data is crucial to the accuracy and reliability of the LCA results [

33]. Real-time LCA engines provide advantages over the typical LCA software, as reported in [

34], such as the dynamic integration of data from several sensors to the LCI. As reported by Vyrkou et al. (2025), only a few published papers referred to “real-time” LCAs, despite several studies agreeing that a real-time assessment leads to improved accuracy, better insight into the process, and time savings in the analysis [

35]. The LCA studies that were performed in real-time incorporate some type of real-time monitoring/data collection and a digital representation of the system [

35]. Domínguez-Patiño et al. (2014) utilized a real-time data monitoring and processing software to build the inventory of coffee cup systems and then integrated it in LCA software to assess the impacts [

36]. They concluded that a real-time LCA allows for a better understanding of the processes and to take immediate actions in favor of the environment [

36]. Hagen et al. (2020) introduced a real-time product LCA in a learning factory [

37]. Their methodology consists, among others, of a code that receives, processes, and stores the data. The data are eventually extracted into LCA software, which sources background data from the Ecoinvent database, and calculates the environmental impacts [

37]. Boje et al. (2021) applied the combination of Building Information Modeling and LCAs, with the use of a digital twin to provide real-time data about the inhabited environment of the building [

38]. By using real-time data from sensors, their study implemented a constant re-evaluation of the impacts with time, and improvement in the accuracy of the calculations as the volume of data gathered increases [

38]. Ferrari et al. (2021) present a pattern that offers dynamic data collection through factory sensors, which can then be exported in an LCA tool to perform the assessment [

39]. They concluded that time and cost savings and improved data reliability can occur because of the real-time data collection [

39]. Piron et al. (2025) integrate digital twins and LCAs to perform a dynamic environmental analysis of plastics [

40]. The digital twin acquires the data and uses them for the formation of the inventory [

40].

Moreover, traditional LCA software often contains a large number of features, processes, and data, which increases the complexity for users, especially non-experts. Additionally, uncertainties and variations occur in the LCA results when using different software [

41,

42]. Therefore, developing user-friendly and dynamic LCA tools and inventories that are product- and location-specific can substantially improve the accuracy and reliability of the assessment [

33,

43], while also expanding sustainability assessments across the industry, particularly among Small–Medium Enterprises (SMEs).

In this light, a user-friendly, real-time, and web-based LCA tool, FARMBENV [

44], was developed, focusing exclusively on the agrifood sector, where the demand for environmental certification is increasing. The FARMBENV tool can be utilized to assess the environmental impacts of any agricultural product and integrates a dynamic LCA engine with real-time sensor data, enabling personalized, context-specific environmental assessments. This approach contrasts with typical LCA software, which typically relies on static, generic LCI databases. In a previous study [

45], the requirements of potential end-users were identified and incorporated into the tool’s design, enhancing its user-friendliness and applicability for producers, certifiers, and policymakers.

It should be noted that FARMBENV does not replace conventional LCI databases but rather complements them. Background processes, such as fertilizer production or electricity generation, are modeled using established static datasets (e.g., Ecoinvent), which provide consistency and comparability with the standard LCA practice. At the same time, FARMBENV introduces the dynamic integration of real-time foreground data through sensors monitoring the on-farm energy use, irrigation, or fertilizer application. For example, while the background impacts of fertilizer production and transport are modeled using Ecoinvent, the actual quantity of the fertilizer applied can be updated dynamically in FARMBENV based on live sensor data. In practice, this means that while Ecoinvent provides the static background system, FARMBENV continuously updates the model with live, context-specific inputs from the production site. By merging static background data with real-time, site-specific inputs, FARMBENV enables more accurate and context-sensitive results than conventional tools, which rely solely on static data. This hybrid approach ensures both methodological robustness and enhanced relevance for certification and decision-making.

By leveraging real-time data, FARMBENV provides immediate feedback on environmental impacts, allowing users to implement timely adjustments to reduce emissions, energy consumption, or resource inefficiencies. The tool supports the real-time assessment of carbon footprints and other environmental indicators, making it particularly valuable for EPDs and sustainability certification processes. Compared to existing studies on real-time LCAs, FARMBENV offers an easy-to-use, web-based application designed for non-experts, integrating both real-time data collection and an impact assessment within a single platform. The FARMBENV tool ensures the direct and continuous transformation of real-time data into LCA results, while aggregating data to enable EPD certification. This methodological innovation reduces delays and inconsistencies while enhancing transparency and accuracy. Furthermore, FARMBENV is tailored to the agricultural sector, accounting for its inherent variability, and it uniquely applies real-time LCAs in this context. As a web-based tool, it is openly accessible to stakeholders and policymakers for monitoring sustainability performances. In addition, it can contribute to reduced production costs by optimizing resource use and minimizing environmental burdens. Ultimately, FARMBENV enables tailored sustainability assessments for farmers and agrifood businesses, while promoting the circular economy and bioeconomy practices within the agricultural sector.

Th wheat cultivation stage is recognized as the biggest environmental hotspot in the life cycle of wheat [

46], with the efficiency and GHG emissions significantly affected by farming technologies [

47]. Numerous studies have assessed the environmental impacts of wheat production, utilizing primary [

48,

49,

50,

51,

52] and secondary data [

53,

54,

55,

56,

57]. Among sustainable practices, the use of green manure, particularly through the addition of vetch [

58], has been shown to increase soil fertility and reduce the demand for fertilizers [

59] while preserving the wheat yield [

60]. Moreover, it could reduce the amount of NOx (nitrous oxide) emissions from wheat production [

61]. However, while LCA studies have assessed the impacts of wheat–vetch systems using primary data, these are limited to Spain [

62] and Italy [

63]. To date, no LCA study using primary data has been identified for wheat production systems in Greece nor for the integration of vetch in this context. This highlights a clear research gap regarding region-specific environmental performance and the potential benefits of green manure in Greek wheat cultivation systems.

In this light, this work offers a novel contribution by achieving the following:

- (i)

Presenting and demonstrating the functionality of FARMBENV, a user-friendly, real-time, and web-based LCA tool specifically developed for the agricultural sector, and validating its accuracy through a comparison with OpenLCA v2.4.1 using the Ecoinvent v3.9.1 database;

- (ii)

Assessing the environmental impacts of three wheat production routes, differentiated by the inclusion of vetch and the number of harvests, using primary data collected through an interview with a farmer in the region of Central Macedonia in Greece;

- (iii)

Presenting laboratory-scale experimental results on biofuel production from wheat residues, utilizing three waste-to-energy (WtE) technologies (pellet mill, oil press, and ethanol still) to support a circular economy approach in agriculture;

- (iv)

Evaluating the potential reduction in environmental impacts achievable through each WtE pathway and integrating these reductions into the wheat production pathways to highlight the benefits of incorporating circular economy practices into conventional agricultural systems.

Section 2 presents the methodology, including the laboratory-scale experimental processes, a description of wheat production scenarios, the LCI data, and the LCA framework applied in this study.

Section 3 provides a brief overview of the FARMBENV tool, presents the results from the lab-scale experiments and the LCA results of wheat production scenarios, WtE pathways, and their integration.

Section 3 also includes the sensitivity analysis conducted and discusses the key findings of this study. Finally,

Section 4 summarizes the conclusions and outlines this study’s limitations.

2. Materials and Methods

2.1. Laboratory-Scale Biofuel Production Experiments

The equipment employed consisted of an oil press (Ölwerk GmbH, Cottbus, Germany) with a rated power of 1.5 kW, a pellet mill (TECHTONGDA, Jinan, China) with 2.2 kW of rated power, a dryer (Karamco, Seoul, South Korea) with 2 kW of rated power, and the ethanol still (Inoxform, Athens, Greece). The ethanol still uses a 38 W pump (SICCE, Pozzoleone, Italy) and an LPG cylinder (TOPGAS, Athens, Greece) with a 0.25 kg/h flow rate. Moreover, to process the mixture into a suitable form to produce ethanol, alpha amylase, glucoamylase, yeast, and an electric heater (Nahita Blue, Navarra, Spain), with a rated power of 120 W, are required. Finally, methanol and sodium hydroxide are required to process the produced biodiesel.

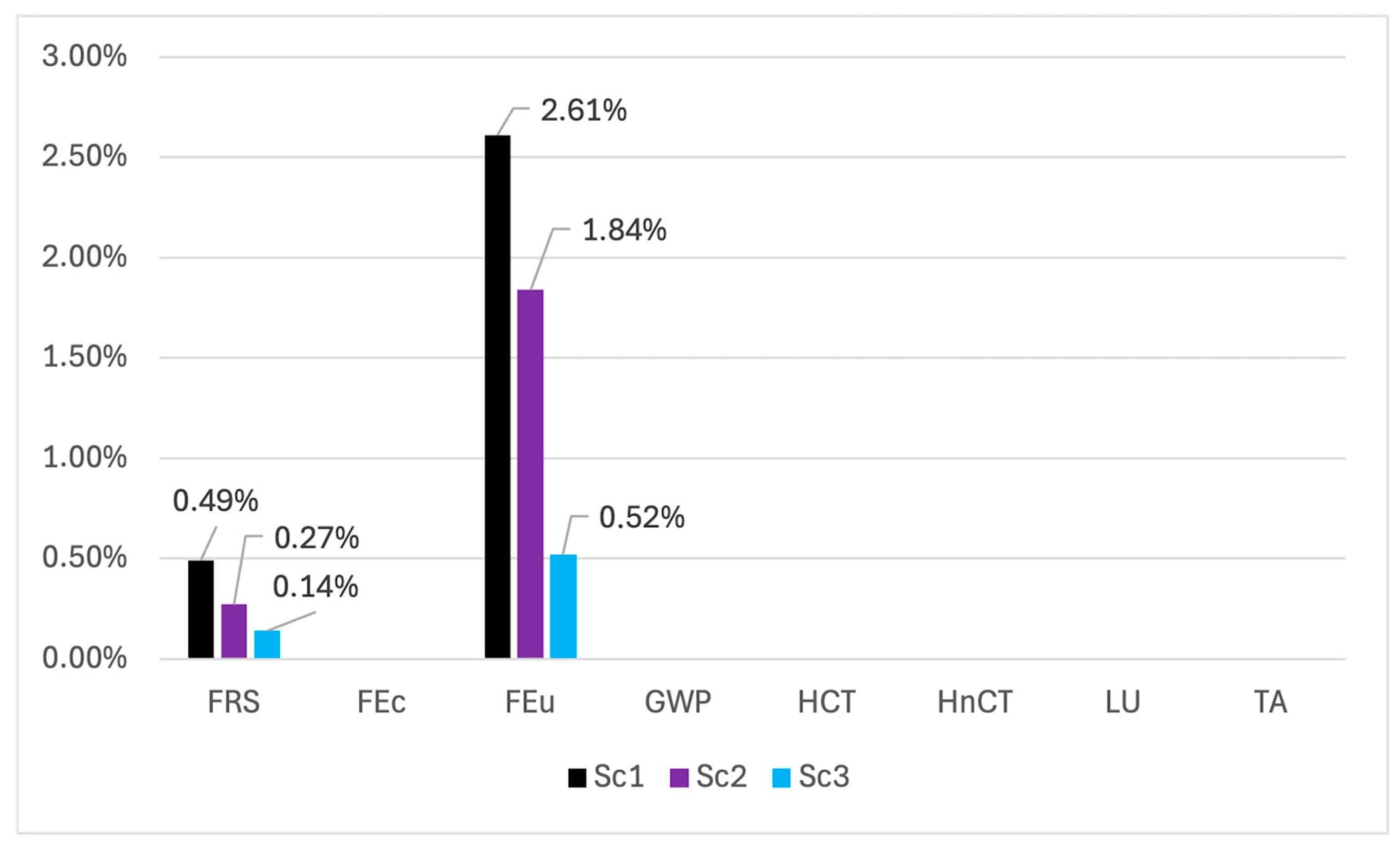

Figure 1 presents the schematic representation of each WtE pathway. The wheat residues processed were provided by the local farmer, who provided the inventory regarding wheat production scenarios.

In the WtE-1 pathway, 300 g of wheat was added to the oil press, which operated for 10 min, producing 204 g of solid residue and zero liquid. Then, the mixture was entered into the pellet mill, which operated for 5 min, and 110 g of pellets was produced.

In the WtE-2 pathway, 600 g of wheat was germinated using water for five days, before entering the dryer for 4 h. The final mixture added to the oil press weighed 888 g. The oil press worked for 20 min and produced 673 g of solid residue and 110 mL of liquid. Eventually, 355 g of pellets was produced from the pellet mill, which operated for 15 min. For the transesterification process, 0.9 g of sodium hydroxide and 20 mL of methanol were added to the liquid produced by the oil press. The mixture was kept together for 1 week so the glycerin could settle to be removed, and after biodiesel was washed to remove various residues, 80 mL of biodiesel was produced.

In the WtE-3 pathway, 2 kg of wheat was milled and mixed with 5 L of water. The mixture was heated for 2 h by the electric heater. Then, 0.4 g of alpha amylase was added, and then the mixture was cooled to 60 °C before 0.7 g of glucoamylase and 4.5 g of yeast were added to the mix, which was left to ferment for 1 week. LPG cylinder was used to provide the required heat for the distillation of ethanol, while a pump for the circulation of water was also used to cool the steam to condense into a liquid form. The distillation process lasted 1 h, and 1.2 L of ethanol at 30% concentration was produced.

2.2. Wheat Production Scenarios and Inventory Data Collection

Three scenarios regarding wheat production were evaluated. Scenario 1 (Sc1) includes one harvest period without the addition of vetch, while Scenario 2 (Sc2) includes two harvesting periods with the addition of vetch. Finally, Scenario 3 (Sc3) includes three harvesting periods with the addition of vetch. Among the scenarios, some common group processes took place. Therefore, those groups’ processes were modeled as modules. Modules 1 and 2 refer to the operations required for the initial wheat and vetch sowing, respectively. Module 3 refers to the processes required for wheat cultivation after vetch, while Module 4 refers to the processes required for wheat sowing after wheat.

The LCI was built based on interviews conducted with a local farmer in Central Macedonia, Greece.

Table 1 presents the processes included in each module, referring to the initial wheat and vetch sowing, and the wheat sowing after vetch or wheat sowing. Moreover,

Table 2 presents how many times each module takes place in each scenario, the number of harvest periods, and the amount of produced wheat. No irrigation is used because the cultivation is rainfed. It should be noted that the information that the farmer provided included the required process (e.g., application of plant protection) that takes place and the amount of diesel that is consumed for each process. Based on the description provided by the Ecoinvent v3.9.1 database for its processes, the amount of diesel that is consumed for each process differs from what is reported by the farmer. The required amount of each process, based on the Ecoinvent v3.9.1 database, was adjusted to match the actual diesel consumption, as measured and reported by the farmer. Therefore, this approach prioritizes site-specific data, increasing the accuracy, transparency, and reliability of the LCI and hence the results of LCA.

2.3. Life Cycle Assessment Framework

LCA was carried out according to ISO standards [

64,

65]. The goals of the study are as follows:

- (i)

Evaluate the environmental impacts of 3 WtE pathways by utilizing wheat residues;

- (ii)

Assess the environmental impacts of 3 wheat production scenarios, with or without the addition of vetch and with different harvest crops;

- (iii)

Demonstrate the role of circular economy towards sustainable agriculture by integrating WtE pathways and wheat production scenarios;

- (iv)

Demonstrate the functionality and accuracy of the FARMBENV tool by comparing its results with the results of the OpenLCA software v2.4.1 and the Ecoinvent v3.9.1 database.

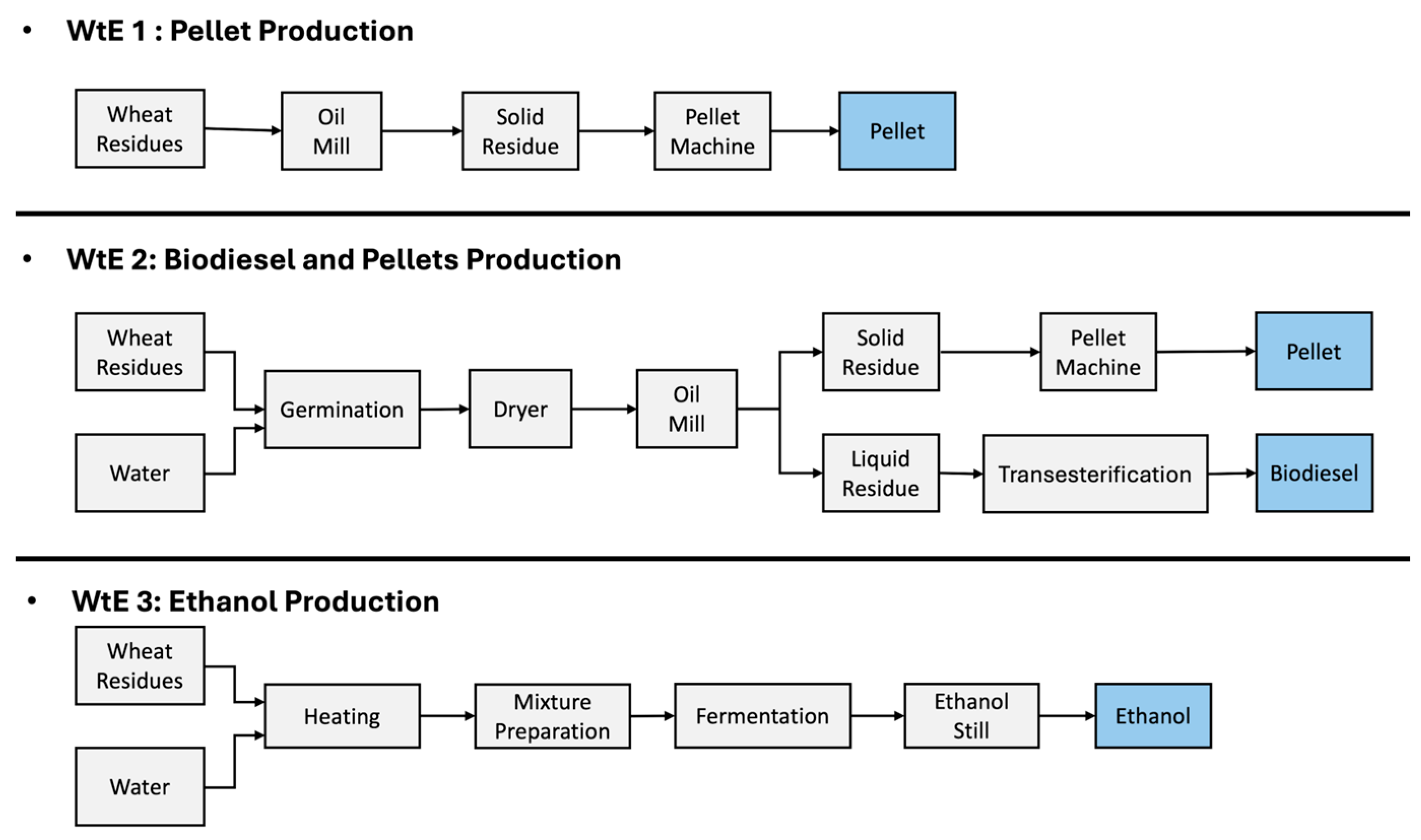

Figure 2 presents the methodology that was applied to fulfill the goals of this study.

Regarding wheat production scenarios, the functional unit is defined as “the production of 1000 kg of wheat”, and the system boundaries are set as “Cradle-to-Gate”. To facilitate a clear and transparent comparison of the scenarios, the packaging and transportation of wheat to the final user were excluded, since they are the same for all scenarios. The LCI was built based on the interview conducted with the farmer, and the background data were based on the Ecoinvent v3.9.1 database. It should be noted that the production and use phases of the necessary agricultural machinery and diesel are included in this study by the use of Ecoinvent v3.9.1, although they are not presented in

Table 1. As mentioned, the processes of Ecoinvent v3.9.1 were customized to reflect the actual diesel consumption, as reported by the farmer. The required electricity is provided by the Greek electricity mix.

Regarding the WtE pathways, the functional unit is defined as the “valorization of 1 kg of wheat residues for energy production”, and the system boundaries are set as “Cradle-to-Grave”. Once the biofuels were produced, they were assumed to be combusted to produce heat. Regarding pellets, they was assumed to have a lower heating value equal to 18 MJ/kg, and the emission factors were based on the literature, while it was assumed to provide heat with an 80% efficiency [

66]. Biodiesel and ethanol were assumed to provide heat with a 44% efficiency [

67] and to have an energy density equal to 32.9 MJ/L [

67] and 19.6 MJ/L [

68], respectively, while their emission factors were retrieved from the literature [

69,

70]. CO

2 emissions were treated as biogenic, since the evaluated fuels are biofuels. By applying System Expansion–Substitution method [

71], the produced heat was assumed to substitute for heat provided by light fuel oil. The LCI was built based on the lab-scale experiments that are presented in this study. Finally, the required electricity in the WtE pathways is also provided by the Greek electricity mix.

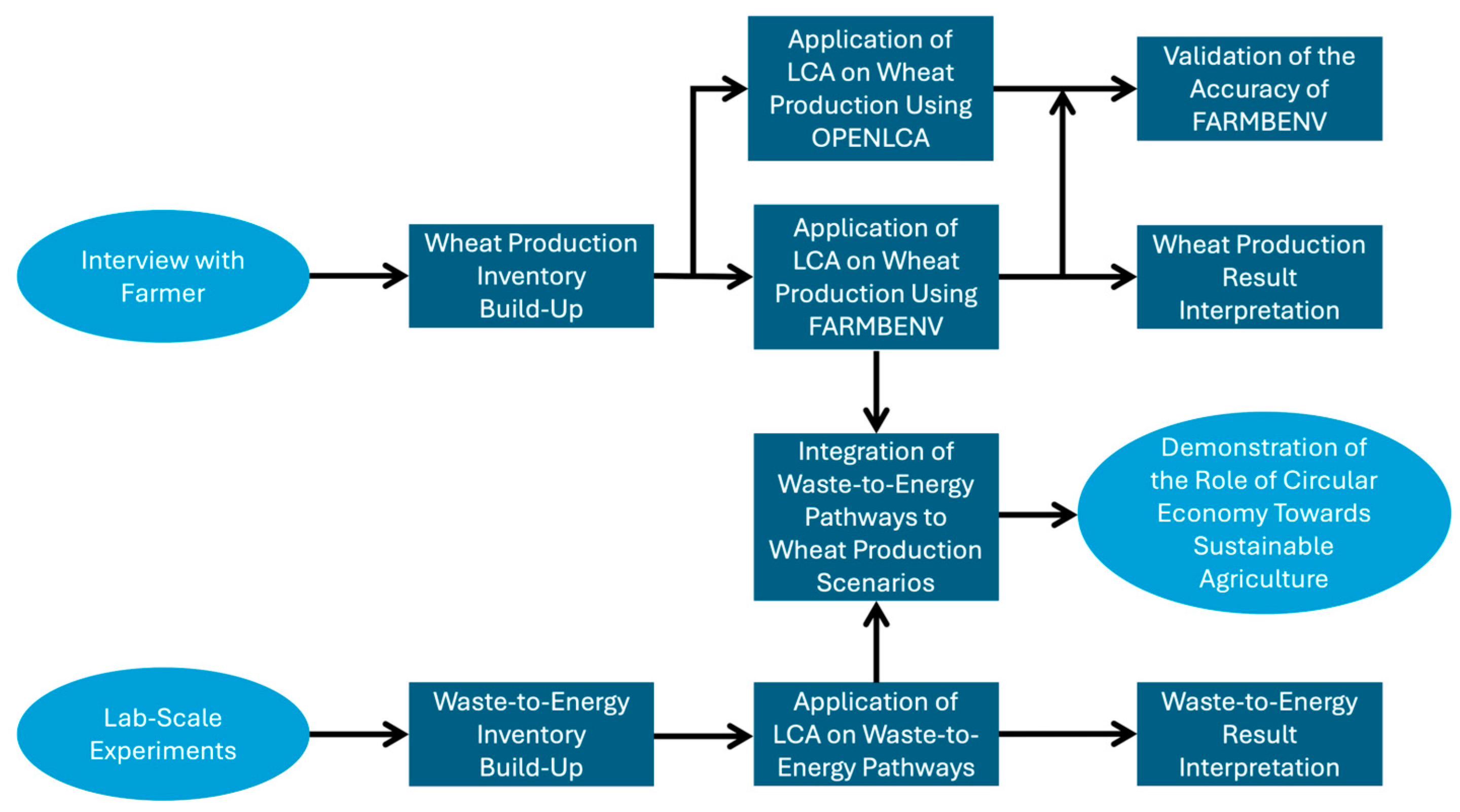

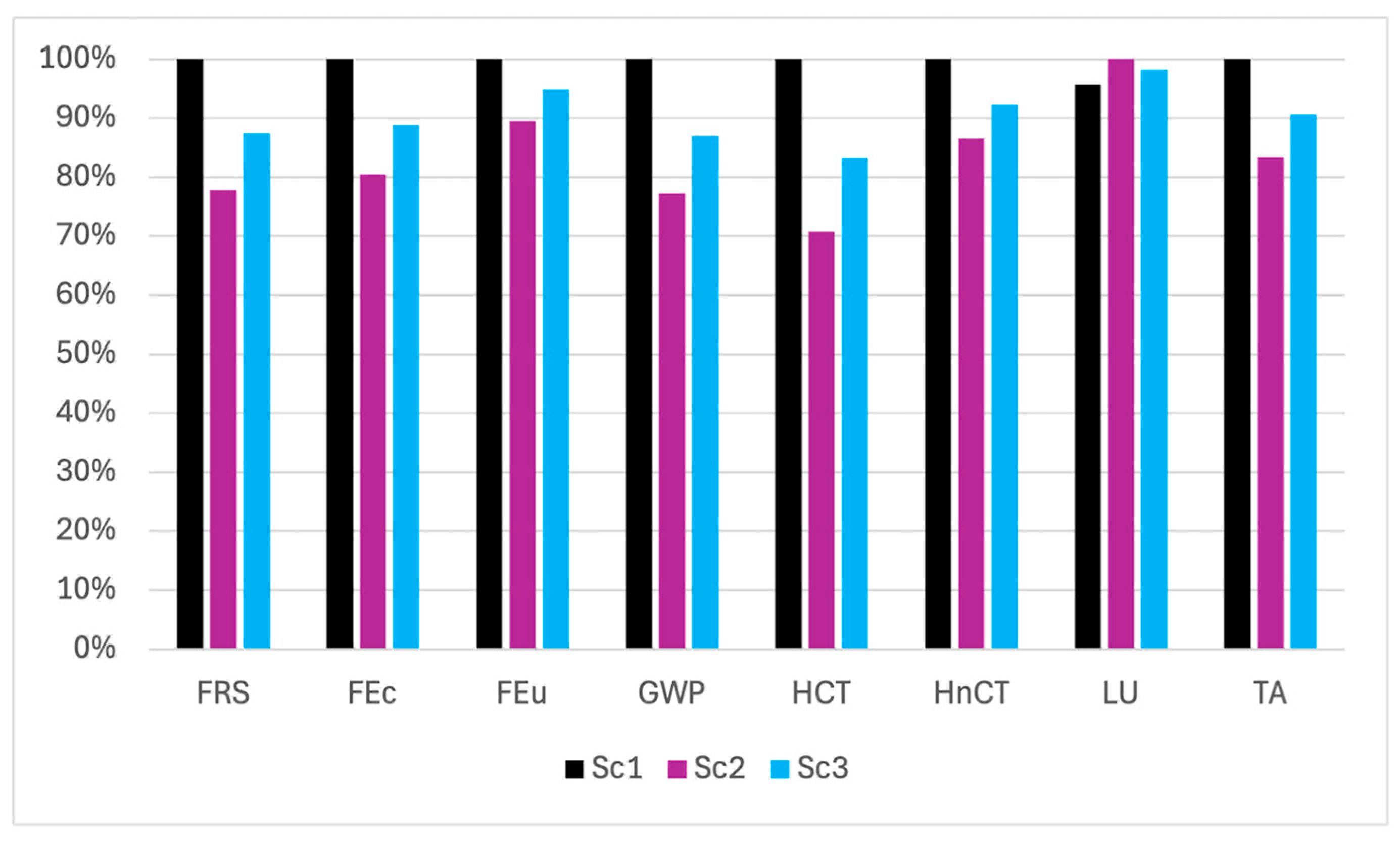

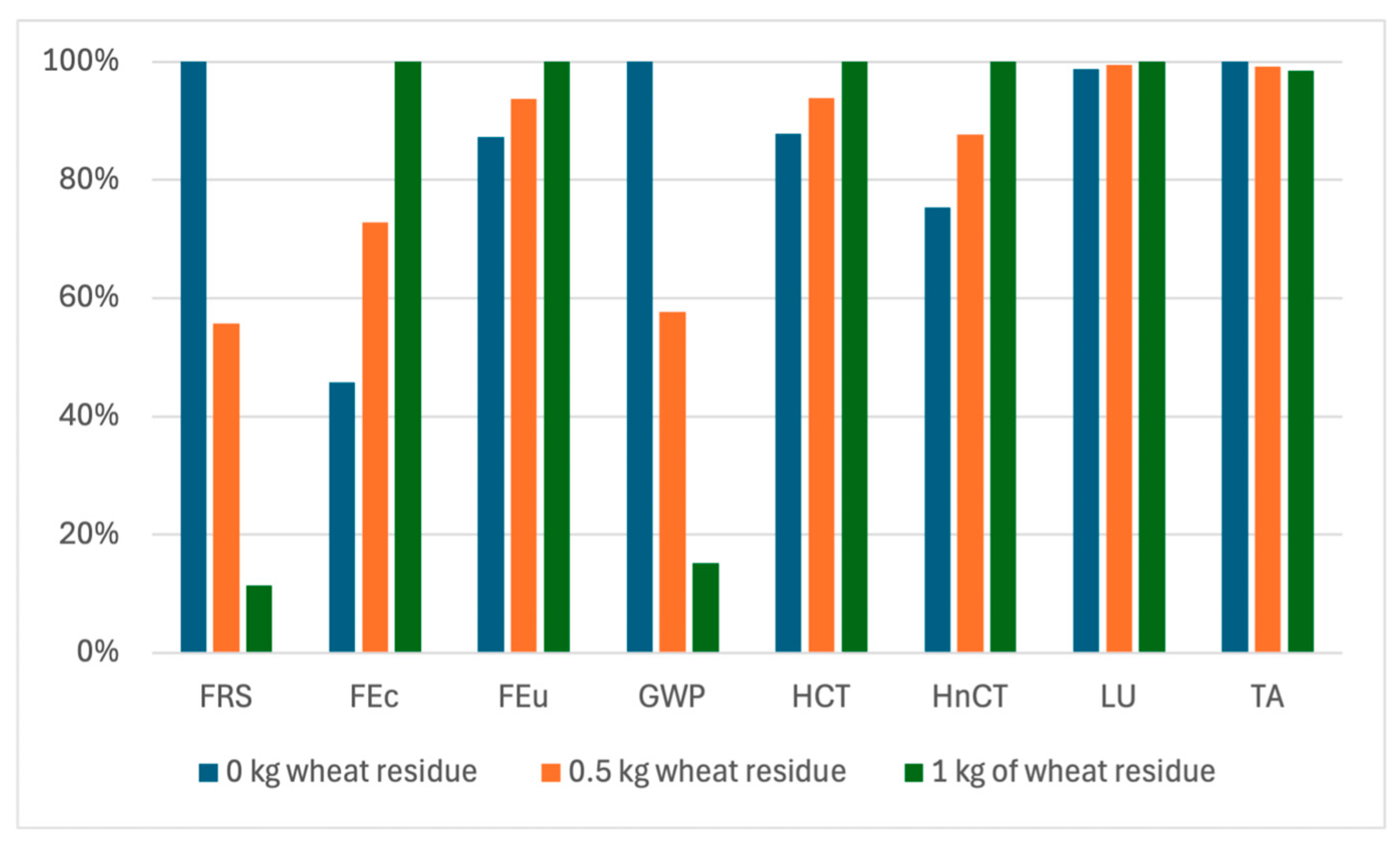

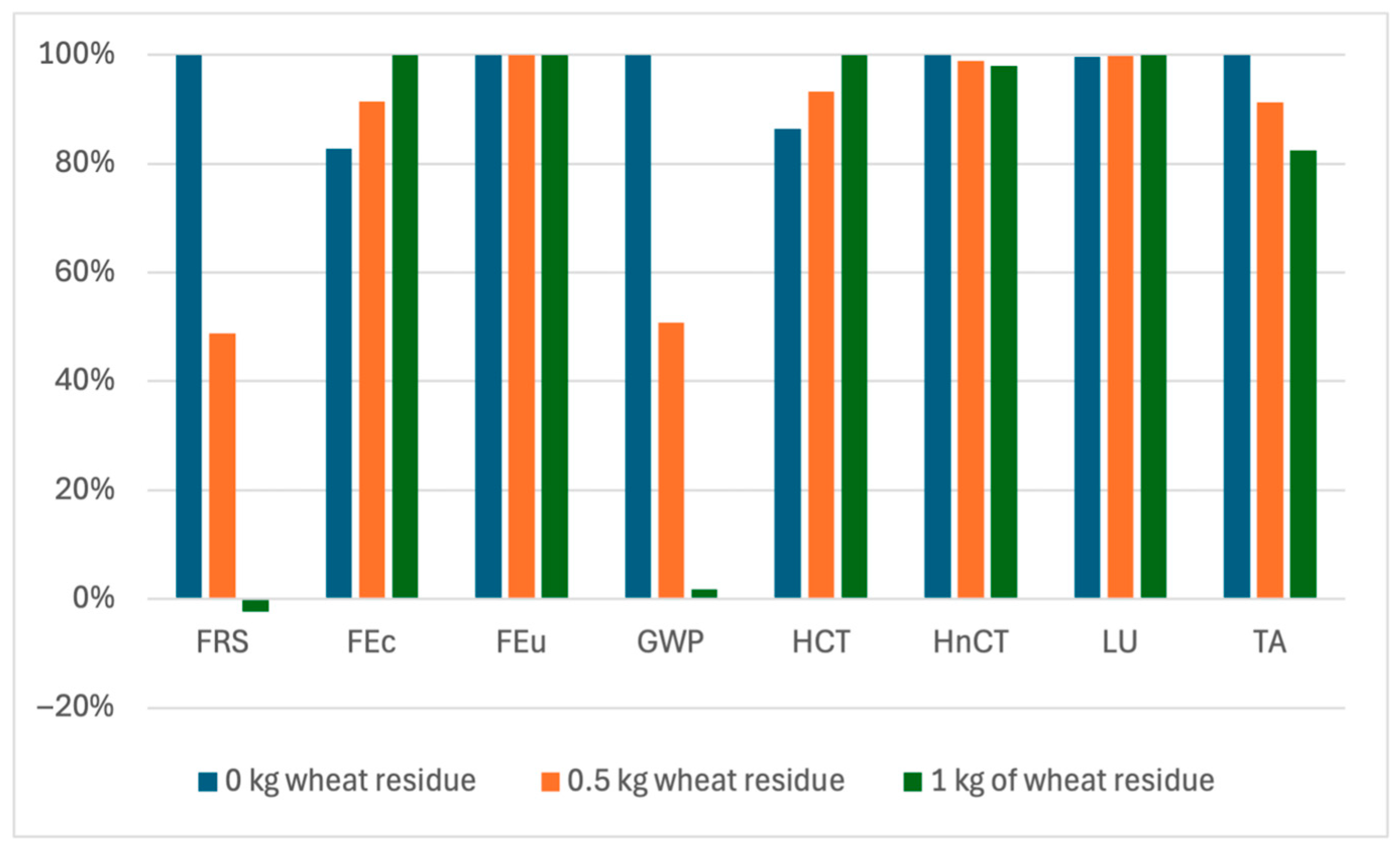

Eventually, the results of the WtE pathways were integrated into the results of wheat production. In this case, the functional unit is defined as “the production of 1000 kg of wheat”, and the system boundaries are set as “Cradle-to-Gate”. Nevertheless, by assuming that 0.5 kg of recoverable wheat residues is produced per 1 kg of produced wheat, the production of energy by the wheat residues was included in the system boundaries. By doing so, the benefits of enhancing a circular economy approach in the agricultural sector are demonstrated.

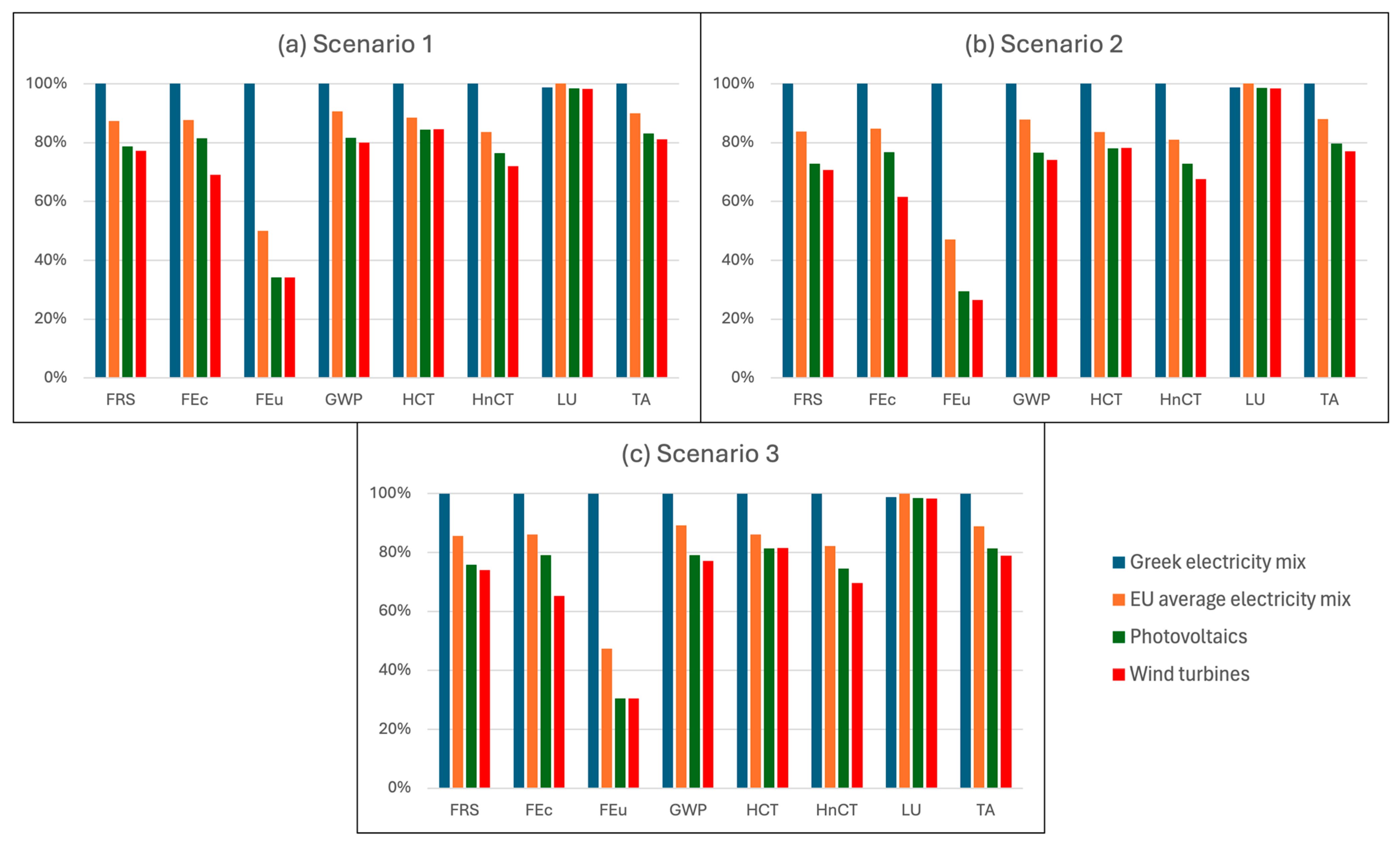

The FARMBENV tool was utilized to assess the impacts, sourcing background data from the Ecoinvent v3.9.1 database. Impact assessment was performed on a midpoint level, using the Recipe 2016 Midpoint (H) method, including the following impact categories: fossil resource scarcity (FRS), freshwater ecotoxicity (FEc), freshwater eutrophication (FEu), Global Warming Potential (GWP), human carcinogenic toxicity (HCT), human non-carcinogenic toxicity (HnCT), land use (LU), and terrestrial acidification (TA). It is worth mentioning that the FARMBENV tool supports all the available Life Cycle Impact Assessment methods, including the EN15084 method, which is a method compatible with an EPD. Regarding wheat production scenarios, LCA was also conducted using the OpenLCA software v2.4.1 and the Ecoinvent v.3.9.1 database with Recipe 2016 Midpoint (H) selected as the impact assessment method to validate the accuracy of the FARMBENV tool.

Sensitivity analysis was conducted to evaluate the influence of the electricity source in the results. Specifically, the electricity scenarios that were evaluated are the average European electricity mix, electricity by photovoltaic, and, finally, electricity by wind turbines. The electricity source was selected for sensitivity analysis because it is expected to be an environmental hotspot, influencing both wheat production and WtE pathways. As such, variations in the electricity grid mix are expected to have a significant impact on the overall environmental results, making it a key parameter to test for uncertainty in the assessment. For the WtE-3 pathway, where heat is required, it was assumed that heat would be provided by an electric heater with a 90% efficiency. Finally, the influence of the amount of recoverable wheat residues per 1 kg of wheat on the results was evaluated as well.

4. Conclusions

This study introduced FARMBENV, a user-friendly, real-time, and web-based LCA tool designed for the agriculture sector, and validated its accuracy through a comparison with OpenLCA v2.4.1. Overall, the results from the tools were consistent, validating the accuracy of the FARMBENV tool. Moreover, the end-users who used the tool characterized it as user-friendly and its function as easy to understand.

The tool was applied to assess three wheat production systems in Greece using primary data. Among the scenarios, Scenario 2 (two harvests, with vetch) showed the best environmental performance across most impact categories, which led to a 22.8% lower impact on the GWP compared to Scenario 1 (no vetch). These results highlight the importance of a more circular approach in agriculture through the application of green manure and suggest that, in terms of environmental impact, two harvesting periods should be preferred instead of three harvesting periods.

Moreover, three WtE pathways were evaluated through lab-scale experiments and LCAs. The WtE-1 pathway (pellet production) showed the best environmental performance in the GWP impact category for all cases, except the one where electricity is produced by wind turbines. Moreover, in WtE-1, the GWP can be reduced when the electricity is not provided by the Greek electricity mix, while in WtE-3 (ethanol production), the GWP can be reduced when the electricity is produced by photovoltaics or wind turbines. The WtE-2 (pellet and biodiesel production) pathway led to a reduction in the GWP only when electricity was produced by wind turbines. In that case, WtE-2 led to the greatest reduction in the GWP. Finally, the integration of wheat production Scenario 2 and WtE-1 demonstrated a 49% GWP reduction when the electricity used for the latter was produced by wind turbines.

The findings of the sensitivity analysis outline the strong influence of the electricity source on the overall environmental performance of agriculture and WtE pathways, especially in the categories of GWP, FRS, and FEu. Nevertheless, the integration of WtE pathways using renewable energy sources into the current wheat production scenarios demonstrates an increase in the overall impact caused on FEc and human toxicity, suggesting trade-offs that must be considered in system designs.

This study has several limitations. This study focused on a single case study to demonstrate the functionality of FARMBENV. Moreover, the agricultural data were obtained from a single farm under Mediterranean conditions, which may limit the generalizability of the results to other regions, management practices, or climates. Moreover, seasonal and inter-annual variations in crop performance were not considered, which could influence the LCA outcomes. In addition, this study examined only wheat–vetch systems, limiting insights into the tool’s applicability to other crops, while it does not integrate the live sensors data. Finally, regarding the WtE technologies, the amount of feedstock available was limited, restricting the experiments to lab-scale conditions.

Future research should expand to include the economic and social pillars of sustainability and investigate the integration of additional WtE technologies, such as anaerobic digestion, gasification, and pyrolysis, within the agricultural sector. Moreover, additional experiments with the equipment used should be performed with larger amounts of feedstock to optimize the procedures, lower the energy demand per kg of treated residues, and obtain a higher biofuel yield. Within this study, the main focus was to apply FARMBENV to a single case study to demonstrate its functionality and capabilities. The generalizability of the results could also be enhanced by incorporating data from multiple farms and regions, as well as by accounting for seasonal and inter-annual variations in crop performance. A further demonstration of FARMBENV through additional case studies and agricultural products could be carried out, particularly by utilizing the tool’s ability to source data from live sensors to support EPDs. Finally, while this study focused on wheat–vetch systems under Mediterranean conditions, the tool applies to other agricultural products. In this regard, assessing the environmental performance of wheat–vetch systems in humid and tropical regions, using region-specific data, would be especially valuable to better understand how the benefits of green manure vary across climates.