1. Introduction

Bioeconomy presents a promising solution to global challenges such as pollution, climate change, and the depletion of natural resources—issues intensified by population growth and uncontrolled economic activities [

1]. It integrates the principles of circular and ecological (biological) economics. While the first focuses on maximizing resource efficiency by transforming waste into raw materials, the latter aims to replace fossil-based resources with renewable, biologically sourced alternatives for energy, fuels, and products [

2,

3]. This approach involves shifting away from a traditional linear economy to a sustainable model that uses bioprocesses to convert biological waste into valuable products, contributing to a greener, low-carbon economy. Countries with abundant natural resources, such as Colombia, can particularly benefit from this transition, as it enhances material management, boosts economic performance, and supports vulnerable rural populations [

4].

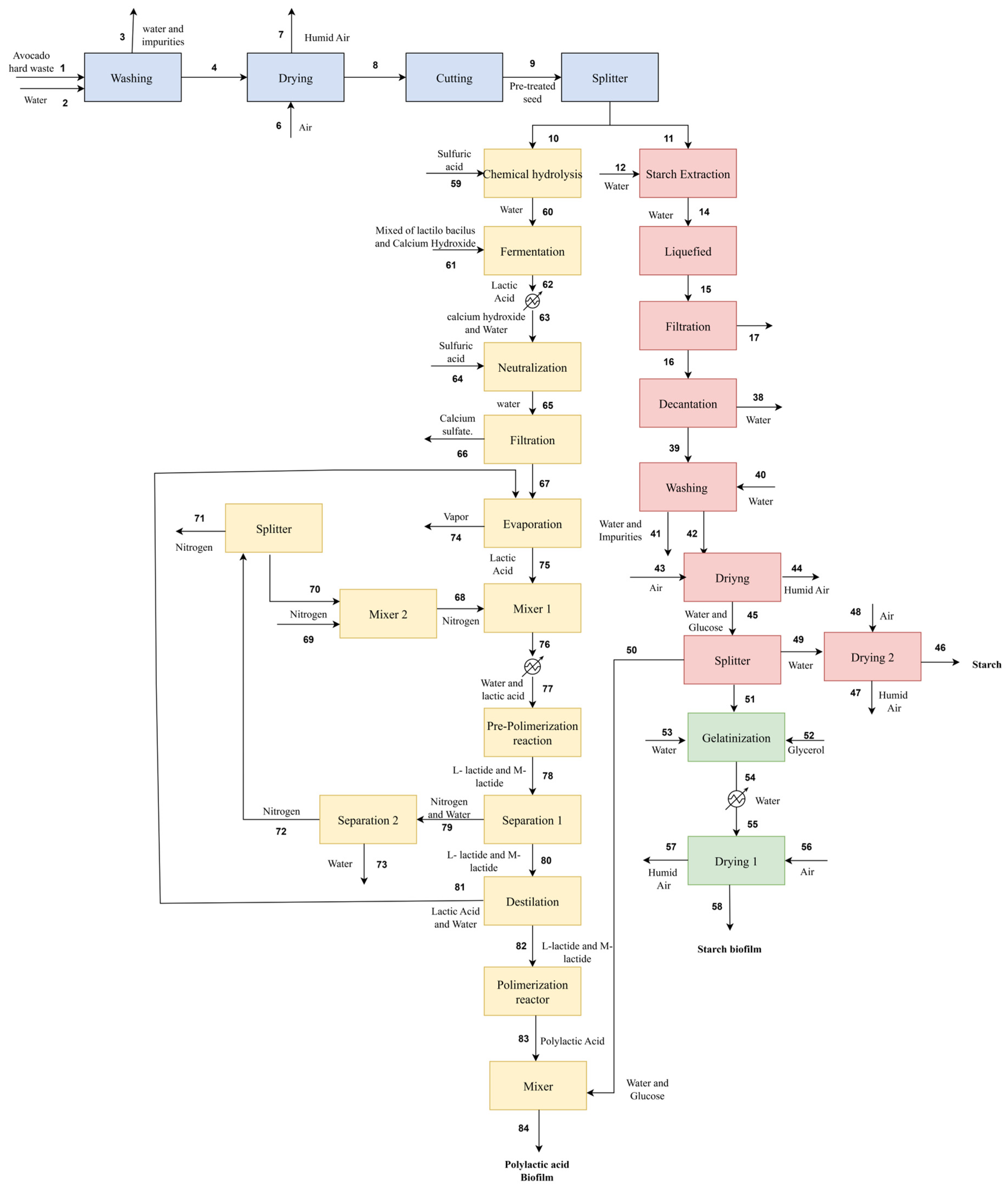

Biorefineries are envisioned to be a fundamental pillar of the bioeconomy. These are dynamic facilities that through the integration of conversion technologies (thermochemical, biochemical, etc.) and transform various forms of biomass into high-value-added products such as biofuels, bioplastics, biochemicals, and biomaterials, among others [

5]. The production of these bioresources not only addresses concerns related to energy and environmental security but also enables better waste flow management. Furthermore, cascading processing is an innovative approach that increases the overall processing of these biomasses, as a greater proportion of residual streams are transformed through sequential processes [

6]. The heterogeneous composition (starch, cellulose, hemicellulose, lignin, oil, starch, and proteins, etc.) of feedstock can be overcome, as it is harnessed into various functionalized bioproducts by using a combination of multiple processes [

7].

Depending on the composition, biorefineries can perform physical pretreatment to reduce particle size, increase surface area, and improve the accessible surface for heat and mass transfer [

8]. The extraction of valuable bioactive compounds (if present) uses different extraction methods, ranging from conventional solvent extraction to novel methods like microwave or ultrasonic, among others [

9]. After this extraction, the depleted solid fraction can enter hydrothermal, thermochemical, physical, physicochemical, or biological pretreatment to fraction long structures into more easily processing compounds (short monomers) [

10]. Then, these compounds are transformed through biochemical (microbial fermentation) and thermochemical technologies such as transesterification, liquefaction, torrefaction, pyrolysis, or gasification) that transform the treated compounds into commodities for further processing or valuable products where material products are prioritized. Subsequently, the waste of these subprocesses are transformed into energy, like biofuels or biochar, among others [

11]. However, due to wide variability in biomass composition based on their source, type, and recalcitrance level, there is no standard method for the bioconversion of lignocellulosic biomass; sequencing and hierarchization are crucial for ensuring techno-economic feasibility [

12]. Additionally, these processing systems follow the principles of green chemistry, as they must be technically and economically viable while posing no additional risk to human health and the environment [

13].

The main raw materials include various types of waste materials, such as food waste, industrial residues (e.g., from the paper and pulp industry, among others), agro-industrial byproducts, forestry and agricultural waste, and lignocellulosic materials, as well as wastewater or sludge. Among all biomass resources, avocado has emerged as a particularly valuable raw material due to its chemical composition [

14]. This fruit not only contains significant lignocellulosic material, but also has a high content of nutritionally valuable compounds, such as fatty acids and bioactive substances [

15]. For Colombia, avocado represents a major economic opportunity, as the country is one of the leading producers in Latin America, ranking third in production. In 2021, Colombia produced approximately 61,853.6 tons of native avocado [

16]. Moreover, the Colombian avocado oil market reached USD 484.6 million in 2020 [

17].

Furthermore, the growing demand for avocado consumption has led to a significant increase in waste along the supply chain, including rejected avocado or its peel and seeds fractions, due to multiple reasons, ranging from not conforming to quality standards to sickness and transportation issues. The improper management of these residues represents a significant challenge, contributing to air and wastewater pollution, as well as having a negative impact on public health [

18]. Considering this abundant raw material, integrating the utilization and valorization of avocado waste into the avocado value chain is justified through biorefinery schemes. This strategy fosters sustainability and supports the bioeconomic growth of the producing regions [

19]. However, this alternative requires rigorous holistic analysis to maximize socioeconomic benefits while minimizing environmental impacts. This calls for a comprehensive evaluation of sustainability dimensions, including safety, to improve feasibility for industrial applications.

Since biorefineries are based on green chemistry principles, the safety of these processes must be addressed through the concept of inherently safe design. This approach focuses on eliminating, avoiding, or minimizing process risks prior to the implementation of control measures [

20]. It aims to identify the potential hazards in equipment and processes at the early design stages and make modifications to eliminate them, leading to substantial reductions in cost and efforts [

21]. There are various methods for analyzing the inherent safety of processes, such as index-based approaches, graphical methodologies, and computer-assisted techniques [

22]. Index-based methods simplify the evaluation process by consolidating multiple hazard parameters into a quantitative factor that aids decision-making. These methods assess different process route alternatives by assigning scores and categorizing process routes from the safest to the most hazardous [

23].

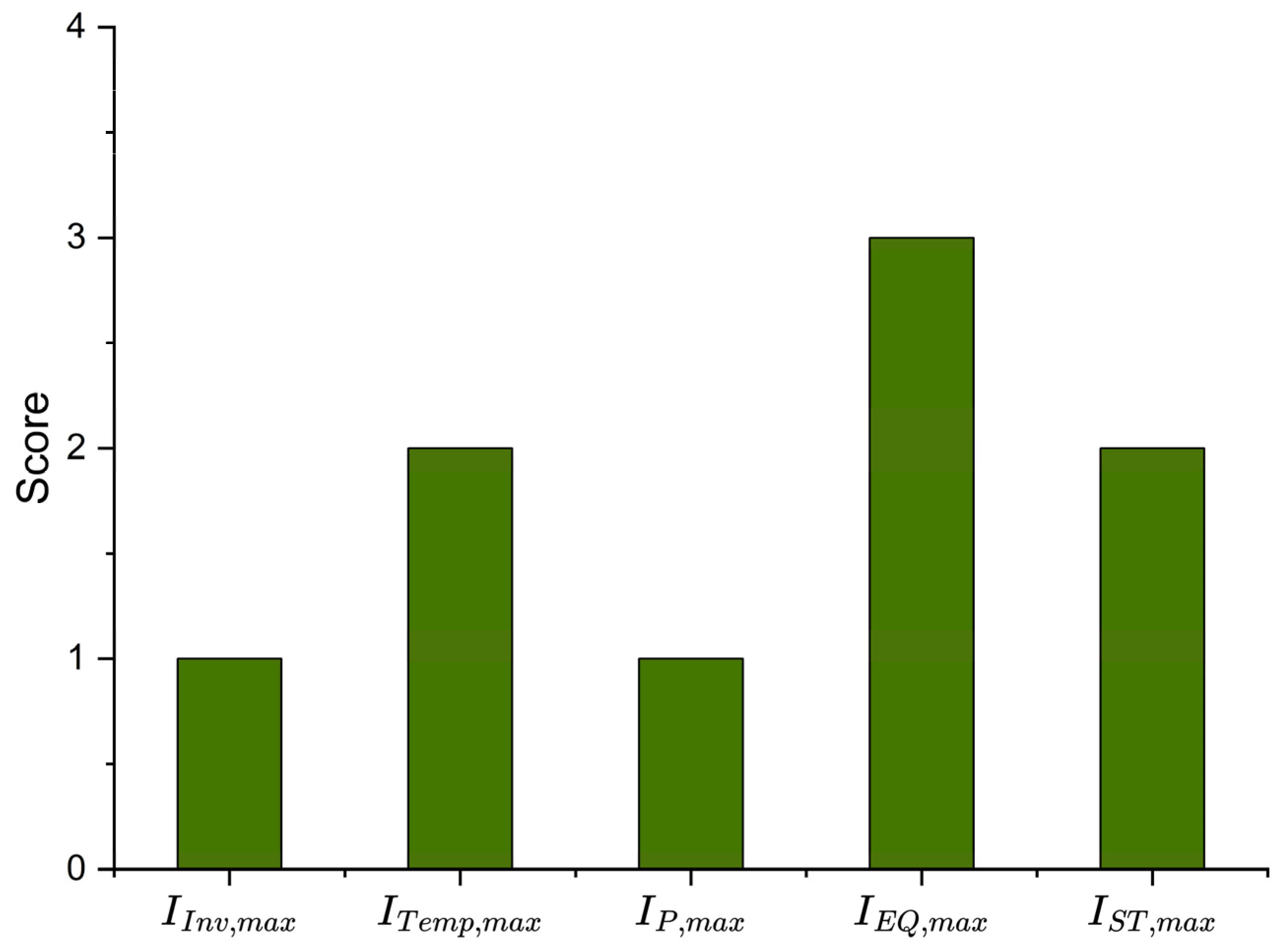

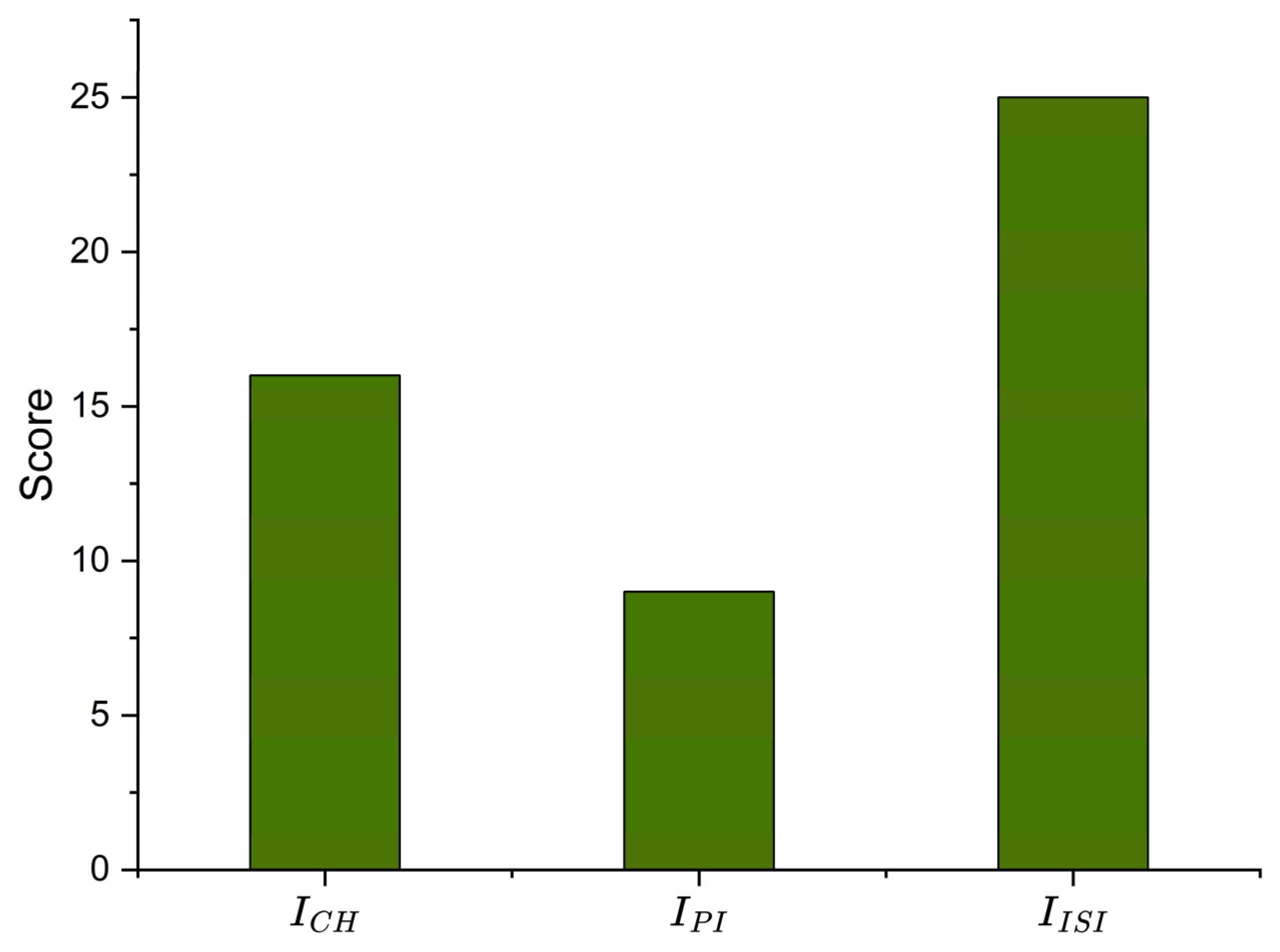

Among these methods, the Inherent Safety Index (ISI) is the ideal tool for comprehensive safety analysis during the conceptual stage. This method, proposed by Heikkilä, is capable of analyzing processes and systems with limited information [

24]. Its holistic approach evaluates both chemical and process hazards by considering multiple risk factors (e.g., flammability, toxicity, temperature, etc.), based on the intrinsic properties of the process and its components (substances, equipment, operating conditions, etc.) [

25]. Additionally, ISI consolidates these indicators into a single value, allowing for the comprehensive comparison and analysis of different process routes.

In the case of avocado waste biorefineries, the implementation and commercialization of the proposed processes remain limited. This is primarily due to challenges such as an irregular biomass supply chain, market uncertainties, and difficulties associated with scale-up—particularly the low technology readiness level and the lack of information regarding their viability and performance at an industrial scale [

26]. Therefore, most of the literature addresses the analysis of rural applications, centered on technical feasibility at mostly the small or medium scales, technoeconomic potential, and environmental assessments using life-cycle-based analysis. Cardona et al. assessed the benefits of several food waste biorefinery processes, including avocado agricultural waste (300, 150, and 75 kg/h) proposed for rural populations. This analysis showcased the potential economic benefit of small-scale and low-technology applications in rural communities. The production of avocado oil, fertilizer, and biogas presented with positive maximum VPN values at 6 years for 75 kg/h (lowest at 3 years for 300 kg/h) [

27]. The extraction of bioactive (from peel and seed) compounds using supercritical fluids increases the technological requirements and cost expenditure (more equipment required and cost to acquire and operate) of the biorefinery, but benefits the economic performance of the process; however, it is conditional on the composition of the feedstock, as peel presented more yield than the seed. Furthermore, the production of ethanol, syngas, and another energy vectors (steam) improved economic processes, as they reduced material and energy intake (from 21% to 47%) [

28]. Moreover, Herrara et al. economically analyzed a biorefinery using oil extraction and biochar production from rejected avocado, with a higher scale of 10,500 t/y, and showed positive performance with a return on 6.67 years of investment. The process would be benefited if a cascade system were to be implemented, as several waste and byproducts are not considered in the economic analysis [

29]. In contrast, Solarte-Toro et al. showcased the critical influence of the product cost and scale of biorefineries. Rural small-scale (2 t/h) biorefineries presented better economic performance (return on investment between 2 and 6 years) compared to high-scale (between 27 and 42 t/day) biorefineries (between 14 and 19 years); however, rural biorefineries offer low-cost high-volume products, whereas high-scale biorefineries offer specialty chemicals that are much more valuable [

30].

In the case of environmental analyses, Solarte-Toro showcased that creole avocado biorefineries have low environmental impact, with a carbon footprint of 0.59 kg CO

2-eq/kg and a water footprint of 2.13 m

3/kg. Among the two proposed biorefineries, Small-B1 (focused on avocado oil and animal feed) had significantly higher environmental impacts—8.99 kg CO

2-eq/kg and 6.63 m

3/kg—while Small-B2 (guacamole production) showed much lower values at 0.72 kg CO

2-eq/kg and 1.38 m

3/kg. The inclusion of further processing units for valorization generate a greater impact and need more water to operate, increasing environmental impact [

31]. Furthermore, Piedrahita-Rodríguez showcased the importance of biorefinery location using an environmental analysis. Optimally, the facility should be close to both residue generation and product commercialization areas, as the latter have the highest emissions, around 60%–72% of the total CO

2 of the whole value chain. In rural areas, location strongly influences both fuel costs and environmental impact [

32]. These studies highlight the limited attention given to the safety performance of these processes.

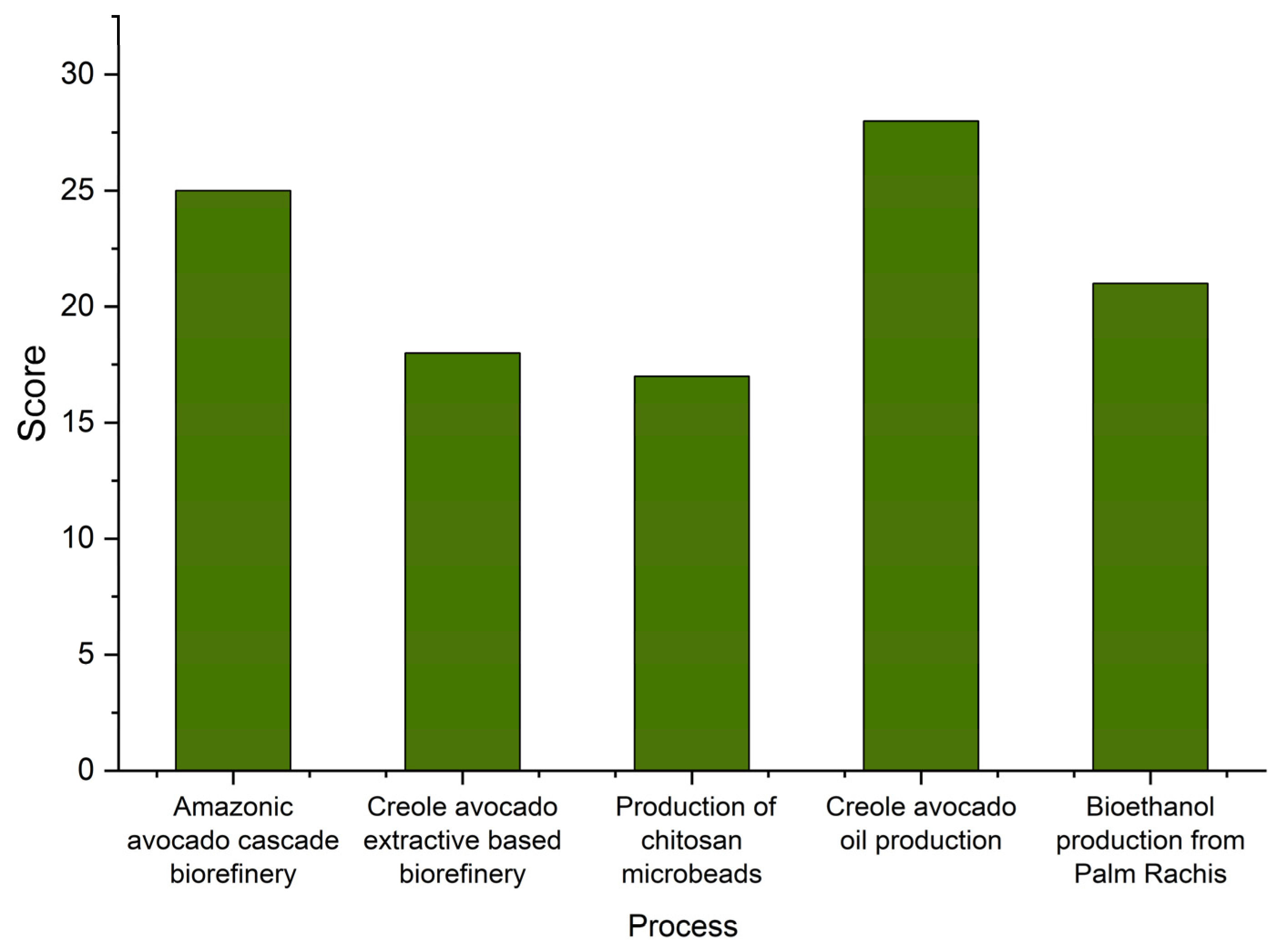

Table 1 shows that cascade processing is still an emerging alternative to valorize biomass residues. Cascading systems have been used to process residues from coffee grounds, grape, and wheat. However, the application of safety assessments has been used to study more conventional biorefineries. According to the authors, very few studies exist where avocado biorefineries were analyzed. Some relevant studies on the safety performance on biorefineries include the work of Herrera-Rodríguez et al., who applied the Inherent Safety Index (ISI) to assess the risks of a biorefinery that extracts bio-oil, biopesticide, and chlorophyll from creole avocado. Their findings indicate an inherently safe process, with a score of 18. The main strengths, in terms of safety, were the process scale and the use of low to moderate operating conditions. However, the complexity level was low, as no chemical reactions were involved, with the primary safety concern being the use of solvents for metabolite extraction (methanol, ethanol, and acetone) [

33].

The above discussion underscores the scarcity of information concerning safety issues in cascade biorefinery systems. While these configurations enhance the valorization of biomass by enabling the production of multiple valuable products (economic and technical), they also introduce heightened technological complexity due to the increased number of operations and substances involved. Therefore, for the first time, this study seeks to offer meaningful insights into the inherent risks associated with cascade biorefineries by identifying the key safety concerns and process vulnerabilities inherent to such systems. To this end, an inherent safety analysis is conducted. Data on the chemical properties of the compounds involved and the operational conditions are collected, and relevant chemical and process safety indicators are calculated to determine the overall inherent risk. The resulting scores are then analyzed and benchmarked against comparable processes to identify potential areas for improvement and critical bottlenecks.