How Industry 4.0 Technologies Enhance Supply Chain Resilience: The Interplay of Agility, Adaptability, and Customer Integration in Manufacturing Firms

Abstract

1. Introduction

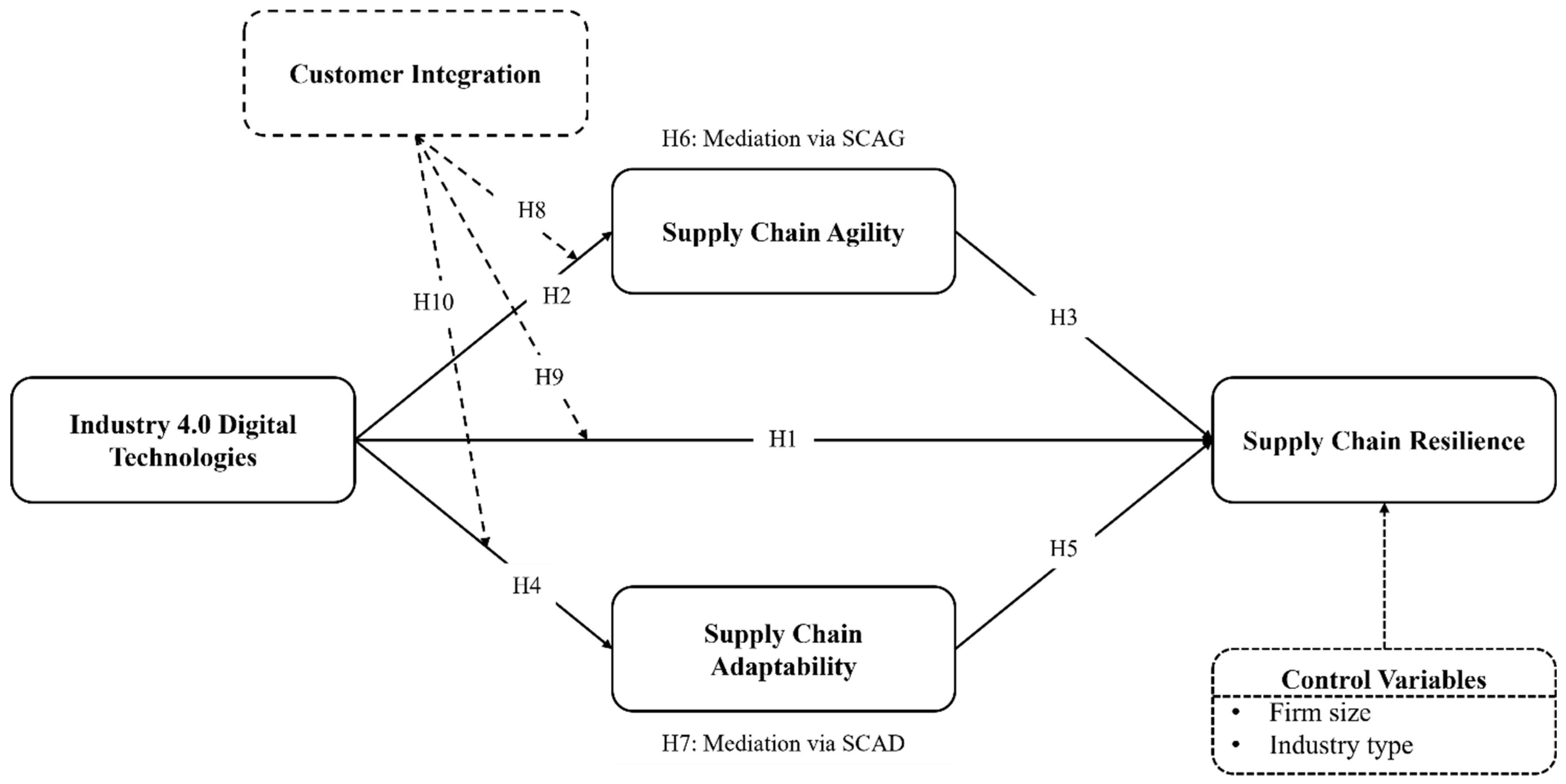

- How do Industry 4.0 digital technologies influence supply chain resilience in manufacturing firms?

- To what extent do supply chain agility and adaptability mediate the relationship between Industry 4.0 digital technologies and supply chain resilience?

- How does customer integration moderate the effects of Industry 4.0 digital technologies on agility, adaptability, and, ultimately, supply chain resilience?

2. Literature Review

2.1. Underpinning Theories

2.2. I4.0 Digital Technologies

2.3. Dynamic Supply Chain Capabilities

2.4. Supply Chain Resilience in Manufacturing

3. Conceptual Model and Hypotheses Development

3.1. I4.0 Digital Technologies and Supply Chain Resilience

3.2. I4.0 Digital Technologies, Supply Chain Agility, and Resilience

3.3. I4.0 Digital Technologies, Supply Chain Adaptability, and Resilience

3.4. The Mediating Mechanism of Supply Chain Agility and Adaptability

3.5. The Moderating Role of Customer Integration

3.6. Conceptual Framework

4. Methodology

4.1. Sample and Data Collection

4.2. Instrumentation

4.2.1. Operationalization of I4.0 Digital Technologies

4.2.2. Supply Chain Agility and Adaptability

4.2.3. Customer Integration

4.2.4. Supply Chain Resilience

4.2.5. Control Variables

4.3. Common Method Bias Check

5. Analysis and Results

5.1. Confirmatory Factor Analysis

5.2. Hypotheses Testing

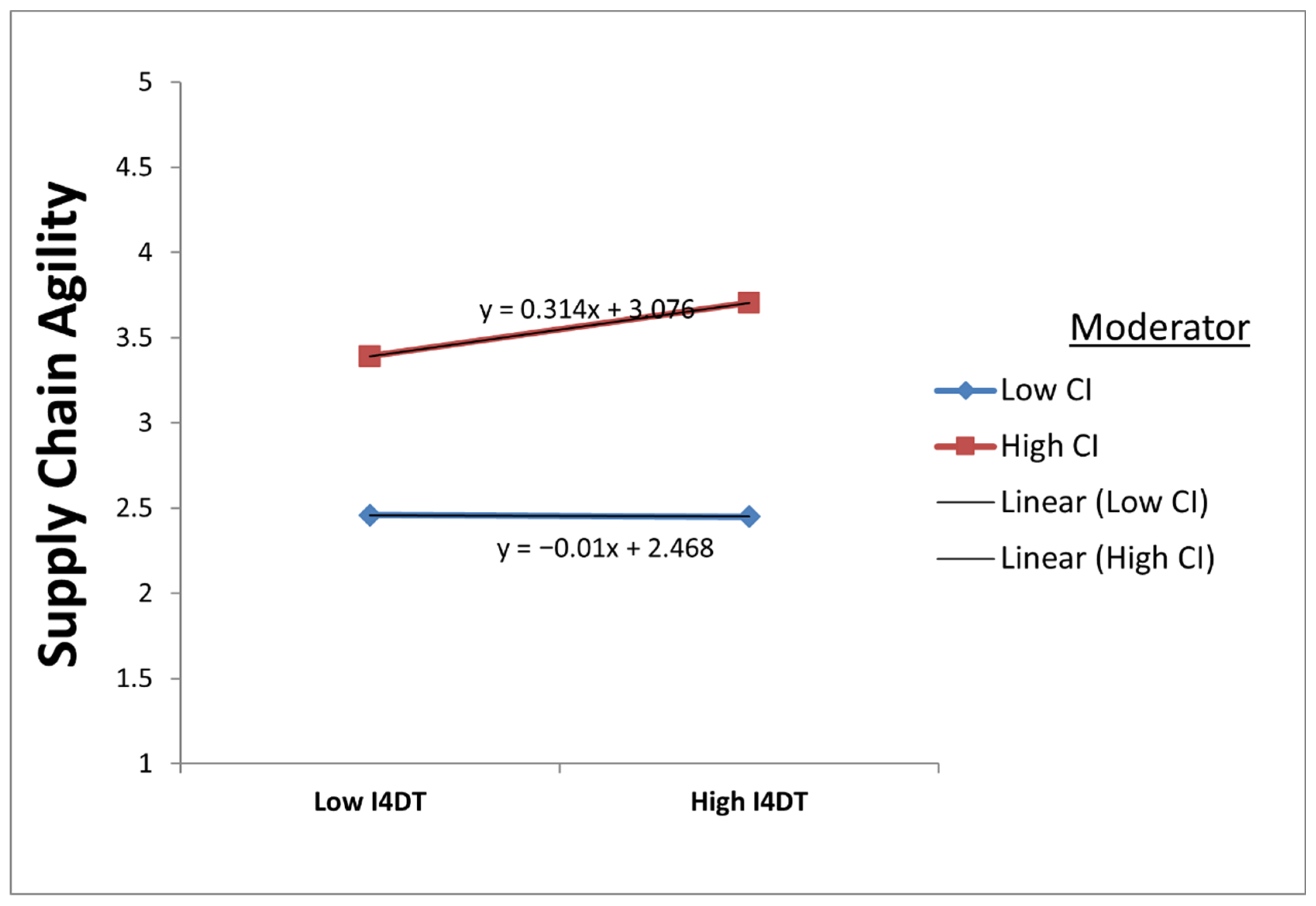

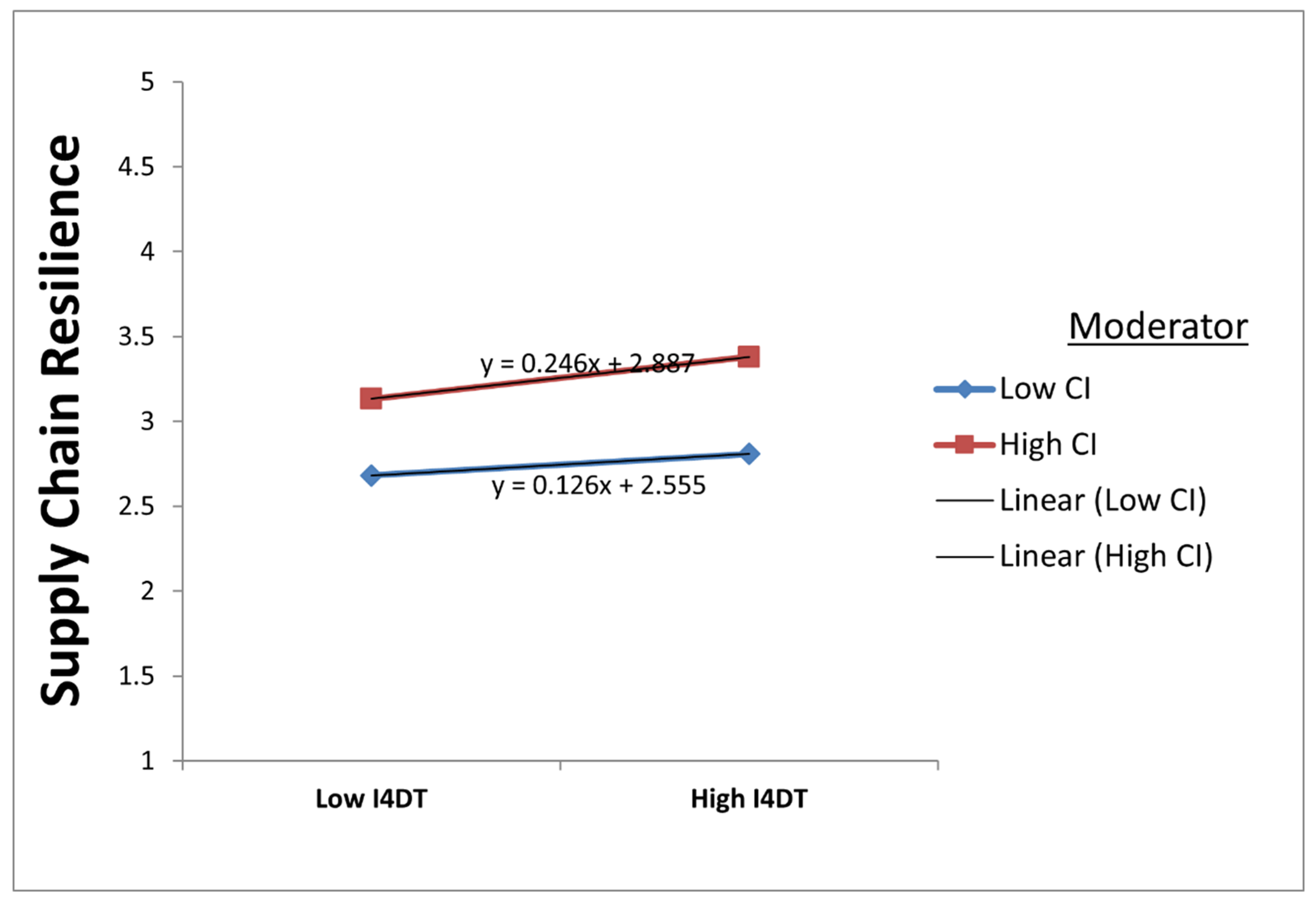

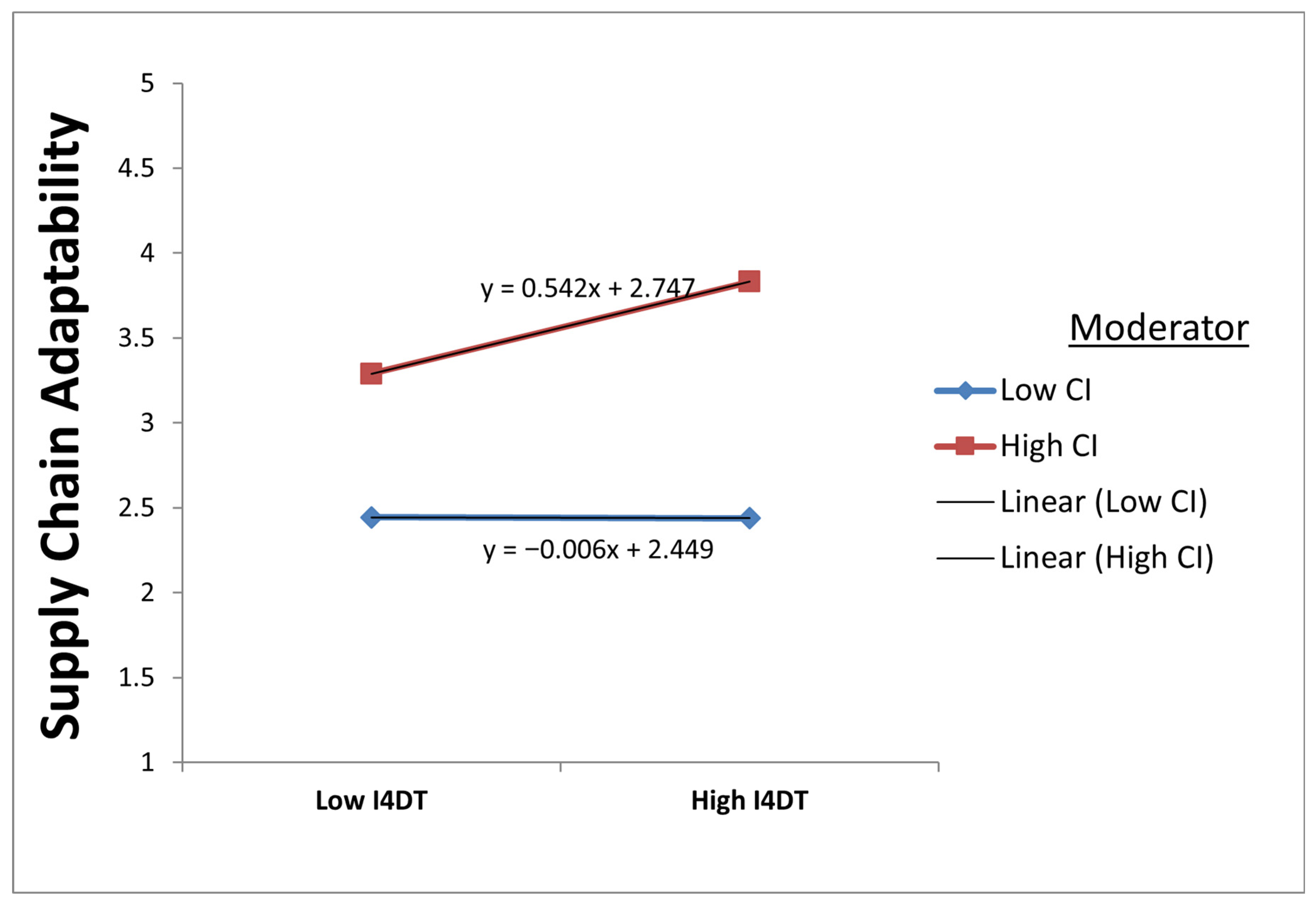

5.3. Moderating Effect Analysis

6. Discussion and Implications

6.1. Discussion of Major Findings

6.2. Theoretical Implications

6.3. Managerial Implications

6.4. Limitations and Future Studies

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Industry 4.0 Digital Technologies (I4DT) |

| Using the five-point scale of never (1) to always (5), please indicate the frequency your company uses the Industry 4.0 digital technologies listed below. |

| I4DT1: Big data analytics. |

| I4DT2: Cloud-based e-procurement. |

| I4DT3: Internet of Things. |

| I4DT4: Artificial Intelligence. |

| Supply Chain Agility (SCAG) |

| Our organization: |

| SCAG1: Works hard to promote the flow of information with its suppliers and customers. |

| SCAG2: Works hard to develop collaborative relationships with suppliers. |

| SCAG3: Builds inventory buffers by maintaining a stockpile of inexpensive but key components. |

| SCAG4: Has a dependable logistics system or partner. |

| SCAG5: Draws up contingency plans and develops crisis management teams. |

| Supply Chain Adaptability (SCAD) |

| Our organization: |

| SCAD1: Monitors economies all over the world to spot new supply bases and markets. |

| SCAD2: Use of intermediaries to develop fresh suppliers and logistics infrastructure. |

| SCAD3: Evaluates needs of ultimate consumers—not just immediate customers. |

| SCAD4: Creates flexible product designs. |

| SCAD5: Determines where companies’ products stand in terms of technology cycles and product life cycles. |

| Customer Integration (CI) |

| For the past three years … |

| IC1: We have a high level of information sharing with major customers about market information. |

| IC2: We share information to major customers through information technologies. |

| IC3: We have a high degree of joint planning and forecasting with major customers to anticipate demand visibility. |

| IC4: Our customers provide information to us in the procurement and production processes. |

| IC5: Our customers are involved in our product development processes. |

| Supply Chain Resilience (SCR) |

| Please evaluate to what degree the following statements is valid for your company (1 = to a very low degree and 5 = to a very high degree) |

| SCR1: Our firm’s supply chain is able to adequately respond to unexpected disruptions by quickly restoring its product flow. |

| SCR2: Our firm’s supply chain can quickly return to its original state after being disrupted. |

| SCR3: Our firm’s supply chain can move to a new, more desirable state after being disrupted. |

| SCR4: Our firm’s supply chain is well prepared to deal with financial outcomes of supply chain disruptions. |

| SCR5: Our firm’s supply chain has the ability to maintain a desired level of control over structure and function at the time of disruption. |

| SCR6: Our firm’s supply chain has the ability to extract meaning and useful knowledge from disruptions and unexpected events. |

References

- Frank, A.G.; Dalenogare, L.S.; Ayala, N.F. Industry 4.0 Technologies: Implementation Patterns in Manufacturing Companies. Int. J. Prod. Econ. 2019, 210, 15–26. [Google Scholar] [CrossRef]

- Ivanov, D. Supply Chain Viability and the COVID-19 Pandemic: A Conceptual and Formal Generalisation of Four Major Adaptation Strategies. Int. J. Prod. Res. 2021, 59, 3535–3552. [Google Scholar] [CrossRef]

- Brusset, X.; Teller, C. Supply Chain Capabilities, Risks, and Resilience. Int. J. Prod. Econ. 2017, 184, 59–68. [Google Scholar] [CrossRef]

- Pettit, T.J.; Croxton, K.L.; Fiksel, J. The Evolution of Resilience in Supply Chain Management: A Retrospective on Ensuring Supply Chain Resilience. J. Bus. Logist. 2019, 40, 56–65. [Google Scholar] [CrossRef]

- Jum’a, L.; Zighan, S.; Alkalha, Z. Influence of Supply Chain Digitalization on Supply Chain Agility, Resilience and Performance: Environmental Dynamism as a Moderator. J. Manuf. Technol. Manag. 2025, 36, 798–819. [Google Scholar] [CrossRef]

- Li, L.; Ye, F.; Zhan, Y.; Kumar, A.; Schiavone, F.; Li, Y. Unraveling the Performance Puzzle of Digitalization: Evidence from Manufacturing Firms. J. Bus. Res. 2022, 149, 54–64. [Google Scholar] [CrossRef]

- Huang, K.; Wang, K.; Lee, P.K.C.; Yeung, A.C.L. The Impact of Industry 4.0 on Supply Chain Capability and Supply Chain Resilience: A Dynamic Resource-Based View. Int. J. Prod. Econ. 2023, 262, 108913. [Google Scholar] [CrossRef]

- Spieske, A.; Birkel, H. Improving Supply Chain Resilience through Industry 4.0: A Systematic Literature Review under the Impressions of the COVID-19 Pandemic. Comput. Ind. Eng. 2021, 158, 107452. [Google Scholar] [CrossRef] [PubMed]

- Ning, Y.; Li, L.; Xu, S.X.; Yang, S. How Do Digital Technologies Improve Supply Chain Resilience in the COVID-19 Pandemic? Evidence from Chinese Manufacturing Firms. Front. Eng. Manag. 2023, 10, 39–50. [Google Scholar] [CrossRef]

- Piprani, A.Z.; Khan, S.A.R.; Yu, Z. Driving Success through Digital Transformation: Influence of Industry 4.0 on Lean, Agile, Resilient, Green Supply Chain Practices. J. Manuf. Technol. Manag. 2024, 35, 1175–1198. [Google Scholar] [CrossRef]

- Kong, T.; Feng, T. Enhancing Supply Chain Resilience: The Role of Big Data Analytics Capability and Organizational Ambidexterity. Ind. Manag. Data Syst. 2025, 125, 2348–2370. [Google Scholar] [CrossRef]

- Aslam, H.; Blome, C.; Roscoe, S.; Azhar, T.M. Dynamic Supply Chain Capabilities: How Market Sensing, Supply Chain Agility and Adaptability Affect Supply Chain Ambidexterity. Int. J. Oper. Prod. Manag. 2018, 38, 2266–2285. [Google Scholar] [CrossRef]

- Mamun, A.A.; Reza, M.N.H.; Yang, Q.; Aziz, N.A. Dynamic Capabilities in Action: The Synergy of Big Data Analytics, Supply Chain Ambidexterity, Green Supply Chain and Firm Performance. J. Enterp. Inf. Manag. 2025, 38, 636–659. [Google Scholar] [CrossRef]

- Wamba, S.F.; Dubey, R.; Gunasekaran, A.; Akter, S. The Performance Effects of Big Data Analytics and Supply Chain Ambidexterity: The Moderating Effect of Environmental Dynamism. Int. J. Prod. Econ. 2020, 222, 107498. [Google Scholar] [CrossRef]

- Eckstein, D.; Goellner, M.; Blome, C.; Henke, M. The Performance Impact of Supply Chain Agility and Supply Chain Adaptability: The Moderating Effect of Product Complexity. Int. J. Prod. Res. 2015, 53, 3028–3046. [Google Scholar] [CrossRef]

- Eslami, M.H.; Jafari, H.; Achtenhagen, L.; Carlbäck, J.; Wong, A. Financial Performance and Supply Chain Dynamic Capabilities: The Moderating Role of Industry 4.0 Technologies. Int. J. Prod. Res. 2021, 62, 8092–8109. [Google Scholar] [CrossRef]

- Sharma, M.; Antony, R.; Sharma, A.; Daim, T. Can Smart Supply Chain Bring Agility and Resilience for Enhanced Sustainable Business Performance? Int. J. Logist. Manag. 2024, 36, 501–555. [Google Scholar] [CrossRef]

- Lee, S.M.; Rha, J.S. Ambidextrous Supply Chain as a Dynamic Capability: Building a Resilient Supply Chain. Manag. Decis. 2016, 54, 2–23. [Google Scholar] [CrossRef]

- Lee, H.L. Harvard Business Review; Harvard Business Publishing: Brighton, MA, USA, 2004; pp. 102–113. [Google Scholar]

- Munir, M.A.; Hussain, A.; Farooq, M.; Habib, M.S.; Shahzad, M.F. Data-Driven Transformation: The Role of Ambidexterity and Analytics Capability in Building Dynamic and Sustainable Supply Chains. Sustainability 2023, 15, 10896. [Google Scholar] [CrossRef]

- Fianko, A.O.; Essuman, D.; Boso, N.; Muntaka, A.S. Customer Integration and Customer Value: Contingency Roles of Innovation Capabilities and Supply Chain Network Complexity. Supply Chain Manag. Int. J. 2022, 28, 385–404. [Google Scholar] [CrossRef]

- Martinelli, E.M.; Tunisini, A. Customer Integration into Supply Chains: Literature Review and Research Propositions. JBIM 2019, 34, 24–38. [Google Scholar] [CrossRef]

- Flynn, B.B.; Huo, B.; Zhao, X. The Impact of Supply Chain Integration on Performance: A Contingency and Configuration Approach. J. Oper. Manag. 2010, 28, 58–71. [Google Scholar] [CrossRef]

- Huo, B. The Impact of Supply Chain Integration on Company Performance: An Organizational Capability Perspective. Supply Chain Manag. Int. J. 2012, 17, 596–610. [Google Scholar] [CrossRef]

- Salah, A.; Çağlar, D.; Zoubi, K. The Impact of Production and Operations Management Practices in Improving Organizational Performance: The Mediating Role of Supply Chain Integration. Sustainability 2023, 15, 15140. [Google Scholar] [CrossRef]

- AlAjlouni, A.O.; Aljuhmani, H.Y. Leveraging Business Intelligence for Enhanced Financial Performance: The Mediating Effect of Supply Chain Integration. In Achieving Sustainable Business Through AI, Technology Education and Computer Science: Volume 3: Business Sustainability and Artificial Intelligence Applications; Hamdan, A., Ed.; Springer Nature Switzerland: Cham, Switzerland, 2024; pp. 79–89. ISBN 978-3-031-73632-2. [Google Scholar]

- Cui, L.; Wu, H.; Wu, L.; Kumar, A.; Tan, K.H. Investigating the Relationship between Digital Technologies, Supply Chain Integration and Firm Resilience in the Context of COVID-19. Ann. Oper. Res. 2023, 327, 825–853. [Google Scholar] [CrossRef] [PubMed]

- Ma, L.; Wang, J.; Feng, M. Promoting Food Industry Supply Chain Agility and Performance through the Development of Big Data Analytics: Based on PLS-SEM and fsQCA Approaches. J. Enterp. Inf. Manag. 2025. [Google Scholar] [CrossRef]

- Ruzo-Sanmartín, E.; Abousamra, A.A.; Otero-Neira, C.; Svensson, G. The Impact of the Relationship Commitment and Customer Integration on Supply Chain Performance. J. Bus. Ind. Mark. 2022, 38, 943–957. [Google Scholar] [CrossRef]

- Alsafadi, Y.; Aljuhmani, H.Y. The Influence of Entrepreneurial Innovations in Building Competitive Advantage: The Mediating Role of Entrepreneurial Thinking. Kybernetes 2023, 53, 4051–4073. [Google Scholar] [CrossRef]

- Chen, M.-J.; Michel, J.G.; Lin, W. Worlds Apart? Connecting Competitive Dynamics and the Resource-Based View of the Firm. J. Manag. 2021, 47, 1820–1840. [Google Scholar] [CrossRef]

- Barney, J. Firm Resources and Sustained Competitive Advantage. J. Manag. 1991, 17, 99–120. [Google Scholar] [CrossRef]

- Riaz, A.; Rehman, H.M.; Sohail, A.; Rehman, M. Industry 4.0 Supply Chain Nexus: Sequential Mediating Effects of Traceability, Visibility and Resilience on Performance. Asia Pac. J. Mark. Logist. 2024, 37, 842–860. [Google Scholar] [CrossRef]

- Teece, D.J.; Pisano, G.; Shuen, A. Dynamic Capabilities and Strategic Management. Strateg. Manag. J. 1997, 18, 509–533. [Google Scholar] [CrossRef]

- Aslam, H.; ur Rehman, A.; Iftikhar, A.; ul Haq, M.Z.; Akbar, U.; Kamal, M.M. Digital Transformation: Unlocking Supply Chain Resilience through Adaptability and Innovation. Technol. Forecast. Soc. Change 2025, 219, 124234. [Google Scholar] [CrossRef]

- Ghobakhloo, M.; Iranmanesh, M.; Foroughi, B.; Tseng, M.-L.; Nikbin, D.; Khanfar, A.A.A. Industry 4.0 Digital Transformation and Opportunities for Supply Chain Resilience: A Comprehensive Review and a Strategic Roadmap. Prod. Plan. Control 2025, 36, 61–91. [Google Scholar] [CrossRef]

- Shi, Y.; Zheng, X.; Venkatesh, V.G.; Humdan, E.A.; Paul, S.K. The Impact of Digitalization on Supply Chain Resilience: An Empirical Study of the Chinese Manufacturing Industry. J. Bus. Ind. Mark. 2022, 38, 1–11. [Google Scholar] [CrossRef]

- Aslam, H.; Waseem, M.; Muneeb, D.; Ali, Z.; Roubaud, D.; Grebinevych, O. Customer Integration in the Supply Chain: The Role of Market Orientation and Supply Chain Strategy in the Age of Digital Revolution. Ann. Oper. Res. 2025, 348, 2145–2169. [Google Scholar] [CrossRef]

- Salamah, E.; Alzubi, A.; Yinal, A. Unveiling the Impact of Digitalization on Supply Chain Performance in the Post-COVID-19 Era: The Mediating Role of Supply Chain Integration and Efficiency. Sustainability 2024, 16, 304. [Google Scholar] [CrossRef]

- Neiroukh, S.; Emeagwali, O.L.; Aljuhmani, H.Y. Artificial Intelligence Capability and Organizational Performance: Unraveling the Mediating Mechanisms of Decision-Making Processes. Manag. Decis. 2024. [Google Scholar] [CrossRef]

- Ayoub, H.S.; Aljuhmani, H.Y. Artificial Intelligence Capabilities as a Catalyst for Enhanced Organizational Performance: The Importance of Cultivating a Data-Driven Culture. In Achieving Sustainable Business Through AI, Technology Education and Computer Science: Volume 2: Teaching Technology and Business Sustainability; Hamdan, A., Ed.; Springer Nature Switzerland: Cham, Switzerland, 2024; pp. 345–356. ISBN 978-3-031-71213-5. [Google Scholar]

- Emeagwali, O.L.; Aljuhamni, H.Y. Introductory Chapter: Strategic Management—A Dynamic Approach. In Strategic Management—A Dynamic View; IntechOpen: London, UK, 2019; ISBN 978-1-83962-505-3. [Google Scholar]

- Nayak, B.; Bhattacharyya, S.S.; Krishnamoorthy, B. Integrating the Dialectic Perspectives of Resource-Based View and Industrial Organization Theory for Competitive Advantage—A Review and Research Agenda. J. Bus. Ind. Mark. 2022, 38, 656–679. [Google Scholar] [CrossRef]

- de Oliveira-Dias, D.; Maqueira-Marin, J.M.; Moyano-Fuentes, J.; Carvalho, H. Implications of Using Industry 4.0 Base Technologies for Lean and Agile Supply Chains and Performance. Int. J. Prod. Econ. 2023, 262, 108916. [Google Scholar] [CrossRef]

- Abuseta, H.; Iyiola, K.; Aljuhmani, H.Y. Digital Technologies and Business Model Innovation in Turbulent Markets: Unlocking the Power of Agility and Absorptive Capacity. Sustainability 2025, 17, 5296. [Google Scholar] [CrossRef]

- Argyropoulou, M.; Garcia, E.; Nemati, S.; Spanaki, K. The Effect of IoT Capability on Supply Chain Integration and Firm Performance: An Empirical Study in the UK Retail Industry. J. Enterp. Inf. Manag. 2023, 37, 875–902. [Google Scholar] [CrossRef]

- Ivanov, D.; Dolgui, A. Viability of Intertwined Supply Networks: Extending the Supply Chain Resilience Angles towards Survivability. A Position Paper Motivated by COVID-19 Outbreak. Int. J. Prod. Res. 2020, 58, 2904–2915. [Google Scholar] [CrossRef]

- Aslam, H.; Khan, A.Q.; Rashid, K.; Rehman, S. Achieving Supply Chain Resilience: The Role of Supply Chain Ambidexterity and Supply Chain Agility. J. Manuf. Technol. Manag. 2020, 31, 1185–1204. [Google Scholar] [CrossRef]

- Karmaker, C.L.; Aziz, R.A.; Ahmed, T.; Misbauddin, S.M.; Moktadir, M.A. Impact of Industry 4.0 Technologies on Sustainable Supply Chain Performance: The Mediating Role of Green Supply Chain Management Practices and Circular Economy. J. Clean. Prod. 2023, 419, 138249. [Google Scholar] [CrossRef]

- Qader, G.; Junaid, M.; Abbas, Q.; Mubarik, M.S. Industry 4.0 Enables Supply Chain Resilience and Supply Chain Performance. Technol. Forecast. Soc. Change 2022, 185, 122026. [Google Scholar] [CrossRef]

- Yavuz, O.; Uner, M.M.; Okumus, F.; Karatepe, O.M. Industry 4.0 Technologies, Sustainable Operations Practices and Their Impacts on Sustainable Performance. J. Clean. Prod. 2023, 387, 135951. [Google Scholar] [CrossRef]

- Almuammari, K.; Iyiola, K.; Alzubi, A.; Aljuhmani, H.Y. AI-Powered Insights: How Digital Supply Networks and Public–Private Alliances Shape Socio-Economic Paths to Sustainability. Systems 2025, 13, 691. [Google Scholar] [CrossRef]

- Aslam, H.; Blome, C.; Roscoe, S.; Azhar, T.M. Determining the Antecedents of Dynamic Supply Chain Capabilities. Supply Chain Manag. Int. J. 2020, 25, 427–442. [Google Scholar] [CrossRef]

- Blome, C.; Schoenherr, T.; Rexhausen, D. Antecedents and Enablers of Supply Chain Agility and Its Effect on Performance: A Dynamic Capabilities Perspective. Int. J. Prod. Res. 2013, 51, 1295–1318. [Google Scholar] [CrossRef]

- Braunscheidel, M.J.; Suresh, N.C. The Organizational Antecedents of a Firm’s Supply Chain Agility for Risk Mitigation and Response. J. Oper. Manag. 2009, 27, 119–140. [Google Scholar] [CrossRef]

- Swafford, P.M.; Ghosh, S.; Murthy, N. The Antecedents of Supply Chain Agility of a Firm: Scale Development and Model Testing. J. Oper. Manag. 2006, 24, 170–188. [Google Scholar] [CrossRef]

- Dubey, R.; Altay, N.; Gunasekaran, A.; Blome, C.; Papadopoulos, T.; Childe, S.J. Supply Chain Agility, Adaptability and Alignment. Int. J. Oper. Prod. Manag. 2018, 38, 129–148. [Google Scholar] [CrossRef]

- Phadnis, S. A Review of Research on Supply Chain Adaptability: Opening the Black Box. J. Bus. Logist. 2024, 45, e12370. [Google Scholar] [CrossRef]

- Wong, C.Y.; Boon-itt, S.; Wong, C.W.Y. The Contingency Effects of Environmental Uncertainty on the Relationship between Supply Chain Integration and Operational Performance. J. Oper. Manag. 2011, 29, 604–615. [Google Scholar] [CrossRef]

- Kochan, C.G.; Nowicki, D.R. Supply Chain Resilience: A Systematic Literature Review and Typological Framework. Int. J. Phys. Distrib. Logist. Manag. 2018, 48, 842–865. [Google Scholar] [CrossRef]

- Mubarik, M.S.; Naghavi, N.; Mubarik, M.; Kusi-Sarpong, S.; Khan, S.A.; Zaman, S.I.; Kazmi, S.H.A. Resilience and Cleaner Production in Industry 4.0: Role of Supply Chain Mapping and Visibility. J. Clean. Prod. 2021, 292, 126058. [Google Scholar] [CrossRef]

- Ponomarov, S.Y.; Holcomb, M.C. Understanding the Concept of Supply Chain Resilience. Int. J. Logist. Manag. 2009, 20, 124–143. [Google Scholar] [CrossRef]

- Modgil, S.; Gupta, S.; Stekelorum, R.; Laguir, I. AI Technologies and Their Impact on Supply Chain Resilience during COVID-19. Int. J. Phys. Distrib. Logist. Manag. 2021, 52, 130–149. [Google Scholar] [CrossRef]

- Madrid-Guijarro, A.; Maldonado-Guzmán, G.; Rodríguez-González, R. Unlocking Resilience: The Impact of Industry 4.0 Technologies on Manufacturing Firms’ Response to the COVID-19 Pandemic. Manag. Decis. 2024, 63, 126–154. [Google Scholar] [CrossRef]

- Ismail, K.; Nikookar, E.; Pepper, M.; Stevenson, M. The Implications of Industry 4.0 for Managing Supply Chain Disruption and Enhancing Supply Chain Resilience: A Systematic Literature Review. Int. J. Prod. Res. 2025, 1–27. [Google Scholar] [CrossRef]

- Zouari, D.; Ruel, S.; Viale, L. Does Digitalising the Supply Chain Contribute to Its Resilience? Int. J. Phys. Distrib. Logist. Manag. 2020, 51, 149–180. [Google Scholar] [CrossRef]

- Aljuhmani, H.Y.; Neiroukh, S. From AI Capability to Enhanced Organizational Performance: The Path Through Organizational Creativity. In Achieving Sustainable Business Through AI, Technology Education and Computer Science: Volume 2: Teaching Technology and Business Sustainability; Hamdan, A., Ed.; Springer Nature Switzerland: Cham, Switzerland, 2024; pp. 667–676. ISBN 978-3-031-71213-5. [Google Scholar]

- Raji, I.O.; Shevtshenko, E.; Rossi, T.; Strozzi, F. Industry 4.0 Technologies as Enablers of Lean and Agile Supply Chain Strategies: An Exploratory Investigation. Int. J. Logist. Manag. 2021, 32, 1150–1189. [Google Scholar] [CrossRef]

- Neiroukh, S.; Aljuhmani, H.Y.; Alnajdawi, S. In the Era of Emerging Technologies: Discovering the Impact of Artificial Intelligence Capabilities on Timely Decision-Making and Business Performance. In Proceedings of the 2024 ASU International Conference in Emerging Technologies for Sustainability and Intelligent Systems (ICETSIS), Manama, Bahrain, 28–29 January 2024; pp. 1–6. [Google Scholar]

- Dubey, R.; Bryde, D.J.; Dwivedi, Y.K.; Graham, G.; Foropon, C.; Papadopoulos, T. Dynamic Digital Capabilities and Supply Chain Resilience: The Role of Government Effectiveness. Int. J. Prod. Econ. 2023, 258, 108790. [Google Scholar] [CrossRef]

- Tortorella, G.; Fogliatto, F.S.; Gao, S.; Chan, T.-K. Contributions of Industry 4.0 to Supply Chain Resilience. Int. J. Logist. Manag. 2021, 33, 547–566. [Google Scholar] [CrossRef]

- Qrunfleh, S.; Tarafdar, M. Supply Chain Information Systems Strategy: Impacts on Supply Chain Performance and Firm Performance. Int. J. Prod. Econ. 2014, 147, 340–350. [Google Scholar] [CrossRef]

- Pozzi, R.; Rossi, T.; Secchi, R. Industry 4.0 Technologies: Critical Success Factors for Implementation and Improvements in Manufacturing Companies. Prod. Plan. Control 2023, 34, 139–158. [Google Scholar] [CrossRef]

- Abdirad, M.; Krishnan, K. Industry 4.0 in Logistics and Supply Chain Management: A Systematic Literature Review. Eng. Manag. J. 2021, 33, 187–201. [Google Scholar] [CrossRef]

- Hahn, G.J. Industry 4.0: A Supply Chain Innovation Perspective. Int. J. Prod. Res. 2020, 58, 1425–1441. [Google Scholar] [CrossRef]

- Reaidy, P.; Alaeddini, M.; Gunasekaran, A.; Lavastre, O.; Shahzad, M. Unveiling the Impact of Industry 4.0 on Supply Chain Performance: The Mediating Role of Integration and Visibility. Prod. Plan. Control 2024. [Google Scholar] [CrossRef]

- Tera, A.A.; Alzubi, A.; Iyiola, K. Supply Chain Digitalization and Performance: A Moderated Mediation of Supply Chain Visibility and Supply Chain Survivability. Heliyon 2024, 10, e25584. [Google Scholar] [CrossRef] [PubMed]

- Yang, L.; Huo, B.; Gu, M. The Impact of Information Sharing on Supply Chain Adaptability and Operational Performance. IJLM 2022, 33, 590–619. [Google Scholar] [CrossRef]

- Altay, N.; Gunasekaran, A.; Dubey, R.; Childe, S.J. Agility and Resilience as Antecedents of Supply Chain Performance under Moderating Effects of Organizational Culture within the Humanitarian Setting: A Dynamic Capability View. Prod. Plan. Control 2018, 29, 1158–1174. [Google Scholar] [CrossRef]

- Jajja, M.S.S.; Chatha, K.A.; Farooq, S. Impact of Supply Chain Risk on Agility Performance: Mediating Role of Supply Chain Integration. Int. J. Prod. Econ. 2018, 205, 118–138. [Google Scholar] [CrossRef]

- Tarigan, Z.J.H.; Siagian, H.; Jie, F. Impact of Internal Integration, Supply Chain Partnership, Supply Chain Agility, and Supply Chain Resilience on Sustainable Advantage. Sustainability 2021, 13, 5460. [Google Scholar] [CrossRef]

- Issa, A.; Khadem, A.; Alzubi, A.; Berberoğlu, A. The Path from Green Innovation to Supply Chain Resilience: Do Structural and Dynamic Supply Chain Complexity Matter? Sustainability 2024, 16, 3762. [Google Scholar] [CrossRef]

- Aljuhmani, H.Y.; Emeagwali, O.L.; Ababneh, B. The Relationships between CEOs’ Psychological Attributes, Top Management Team Behavioral Integration and Firm Performance. Int. J. Organ. Theory Behav. 2021, 24, 126–145. [Google Scholar] [CrossRef]

- Enbaia, E.; Alzubi, A.; Iyiola, K.; Aljuhmani, H.Y. The Interplay Between Environmental Ethics and Sustainable Performance: Does Organizational Green Culture and Green Innovation Really Matter? Sustainability 2024, 16, 10230. [Google Scholar] [CrossRef]

- Dillman, D.A.; Smyth, J.D.; Christian, L.M. Internet, Phone, Mail, and Mixed-Mode Surveys: The Tailored Design Method, 4th ed.; Wiley: Hoboken, NJ, USA, 2014; ISBN 978-1-118-45614-9. [Google Scholar]

- Armstrong, J.S.; Overton, T.S. Estimating Nonresponse Bias in Mail Surveys. J. Mark. Res. 1977, 14, 396–402. [Google Scholar] [CrossRef]

- Brislin, R.W. The Wording and Translation of Research Instruments. In Field Methods in Cross-Cultural Research; Cross-Cultural Research and Methodology Series; Sage Publications, Inc.: Thousand Oaks, CA, USA, 1986; Volume 8, pp. 137–164. ISBN 978-0-8039-2549-6. [Google Scholar]

- Stentoft, J.; Mikkelsen, O.S.; Wickstrøm, K.A. Supply Chain Resilience and Absorptive Capacity: Crisis Mitigation and Performance Effects during COVID-19. Supply Chain Manag. Int. J. 2023, 28, 975–992. [Google Scholar] [CrossRef]

- Podsakoff, P.M.; MacKenzie, S.B.; Lee, J.-Y.; Podsakoff, N.P. Common Method Biases in Behavioral Research: A Critical Review of the Literature and Recommended Remedies. J. Appl. Psychol. 2003, 88, 879–903. [Google Scholar] [CrossRef] [PubMed]

- Kock, F.; Berbekova, A.; Assaf, A.G. Understanding and Managing the Threat of Common Method Bias: Detection, Prevention and Control. Tour. Manag. 2021, 86, 104330. [Google Scholar] [CrossRef]

- Hazen, B.T.; Overstreet, R.E.; Boone, C.A. Suggested Reporting Guidelines for Structural Equation Modeling in Supply Chain Management Research. Int. J. Logist. Manag. 2015, 26, 627–641. [Google Scholar] [CrossRef]

- Byrne, B.M. Structural Equation Modeling with AMOS: Basic Concepts, Applications, and Programming, 2nd ed.; Routledge: New York, NY, USA, 2009; ISBN 978-0-8058-6373-4. [Google Scholar]

- Collier, J. Applied Structural Equation Modeling Using AMOS: Basic to Advanced Techniques, 1st ed.; Routledge: New York, NY, USA; London, UK, 2020; ISBN 978-0-367-43526-4. [Google Scholar]

- Hair, J.F.; Matthews, L.M.; Matthews, R.L.; Sarstedt, M. PLS-SEM or CB-SEM: Updated Guidelines on Which Method to Use. Int. J. Multivar. Data Anal. 2017, 1, 107–123. [Google Scholar] [CrossRef]

- Alkish, I.; Iyiola, K.; Alzubi, A.B.; Aljuhmani, H.Y. Does Digitization Lead to Sustainable Economic Behavior? Investigating the Roles of Employee Well-Being and Learning Orientation. Sustainability 2025, 17, 4365. [Google Scholar] [CrossRef]

- Hair, J.F.; Black, W.C.; Babin, B.J.; Anderson, R.E. Multivariate Data Analysis, 7th ed.; Pearson: Upper Saddle River, NJ, USA, 2009; ISBN 978-0-13-813263-7. [Google Scholar]

- Mamash, A.; Iyiola, K.; Aljuhmani, H.Y. The Role of Circular Economy Entrepreneurship, Cleaner Production, and Green Government Subsidy for Achieving Sustainability Goals in Business Performance. Sustainability 2025, 17, 3990. [Google Scholar] [CrossRef]

- Hu, L.; Bentler, P.M. Cutoff Criteria for Fit Indexes in Covariance Structure Analysis: Conventional Criteria versus New Alternatives. Struct. Equ. Model. A Multidiscip. J. 1999, 6, 1–55. [Google Scholar] [CrossRef]

- Alashiq, S.; Aljuhmani, H.Y. From Sustainable Tourism to Social Engagement: A Value-Belief-Norm Approach to the Roles of Environmental Knowledge, Eco-Destination Image, and Biospheric Value. Sustainability 2025, 17, 4353. [Google Scholar] [CrossRef]

- Bagozzi, R.P.; Yi, Y. On the Evaluation of Structural Equation Models. JAMS 1988, 16, 74–94. [Google Scholar] [CrossRef]

- Nunnally, J.C. Psychometric Theory, 1st ed.; McGraw-Hill: New York, NY, USA, 1967; ISBN 978-0-07-047562-5. [Google Scholar]

- Fornell, C.; Larcker, D.F. Evaluating Structural Equation Models with Unobservable Variables and Measurement Error. J. Mark. Res. 1981, 18, 39–50. [Google Scholar] [CrossRef]

- Karmaker, C.L.; Ahmed, T. Modeling Performance Indicators of Resilient Pharmaceutical Supply Chain. Mod. Supply Chain Res. Appl. 2020, 2, 179–205. [Google Scholar] [CrossRef]

| Characteristics | Number | % | |

|---|---|---|---|

| Individual-level characteristics | |||

| Respondent’s position | Logistic manager | 36 | 13.2% |

| Plant manager | 31 | 11.4% | |

| Production manager | 22 | 8.1% | |

| Procurement manager | 18 | 6.6% | |

| Supply chain manager | 150 | 54.9% | |

| Others | 16 | 5.9% | |

| Functional experience | <5 years | 58 | 21.2% |

| 5–9 | 83 | 30.4% | |

| 10–19 | 52 | 19.0% | |

| 20–29 | 50 | 18.3% | |

| ≥30 years | 30 | 11.0% | |

| Firm-level characteristics | |||

| Nature of business | Machinery and hardware | 92 | 33.7% |

| Electrical and IT | 45 | 16.5% | |

| Plastic and rubber | 36 | 13.2% | |

| Leather and garment | 29 | 10.6% | |

| Food and beverages | 22 | 8.1% | |

| Chemical and cosmetic | 19 | 7.0% | |

| Pharmaceutical and medical | 17 | 6.2% | |

| Other manufacturing | 13 | 4.8% | |

| Firm size (number of employees) | Medium-size (<250) | 89 | 32.6% |

| Large-size (≥250) | 184 | 67.4% | |

| Firm age (years of operation) | <5 years | 7 | 2.6% |

| 5–14 | 102 | 37.4% | |

| 15–24 | 116 | 42.5% | |

| 25–34 | 30 | 11.0% | |

| ≥35 years | 18 | 6.5% | |

| Total | 273 | 100% | |

| Construct/Indicators | Mean | Std. Deviation | Factor Loadings | Cronbach’s α | CR | AVE |

|---|---|---|---|---|---|---|

| I4.0 Digital Technologies (I4DT) | 0.834 | 0.861 | 0.615 | |||

| I4DT1 | 3.08 | 1.177 | 0.845 | |||

| I4DT2 | 3.18 | 1.214 | 0.652 | |||

| I4DT3 | 2.80 | 1.145 | 0.771 | |||

| I4DT4 | 2.69 | 1.196 | 0.920 | |||

| Supply Chain Agility (SCAG) | 0.863 | 0.884 | 0.607 | |||

| SCAG1 | 3.01 | 1.080 | 0.685 | |||

| SCAG2 | 3.30 | 1.100 | 0.841 | |||

| SCAG3 | 3.41 | 1.084 | 0.792 | |||

| SCAG4 | 3.43 | 1.031 | 0.790 | |||

| SCAG5 | 3.40 | 1.130 | 0.857 | |||

| Supply Chain Adaptability (SCAD) | 0.893 | 0.910 | 0.670 | |||

| SCAD1 | 3.32 | 1.140 | 0.873 | |||

| SCAD2 | 3.26 | 1.068 | 0.832 | |||

| SCAD3 | 3.28 | 1.198 | 0.733 | |||

| SCAD4 | 3.30 | 1.086 | 0.787 | |||

| SCAD5 | 3.36 | 1.059 | 0.861 | |||

| Customer Integration (CI) | 0.791 | 0.810 | 0.564 | |||

| CI1 | 3.17 | 1.040 | 0.782 | |||

| CI2 | 2.95 | 1.197 | 0.655 | |||

| CI3 | 3.24 | 1.092 | 0.784 | |||

| CI4 | 3.38 | 1.092 | 0.721 | |||

| CI5 | 3.26 | 1.255 | 0.740 | |||

| Supply Chain Resilience (SCR) | 0.755 | 0.768 | 0.540 | |||

| SCR1 | 3.72 | 1.060 | 0.680 | |||

| SCR2 | 3.73 | 1.099 | 0.730 | |||

| SCR3 | 3.55 | 1.003 | 0.692 | |||

| SCR4 | 3.70 | 1.035 | 0.710 | |||

| SCR5 | 3.16 | 1.133 | 0.647 | |||

| SCR6 | 3.10 | 1.083 | 0.636 |

| Factors | I4DT | SCAG | SCAD | CI | SCR |

|---|---|---|---|---|---|

| I4.0 Digital Technologies (I4DT) | 0.784 | ||||

| Supply Chain Agility (SCAG) | 0.477 *** | 0.894 | |||

| Supply Chain Adaptability (SCAD) | 0.392 *** | 0.779 *** | 0.819 | ||

| Customer Integration (CI) | 0.498 *** | 0.596 *** | 0.416 *** | 0.682 | |

| Supply Chain Resilience (SCR) | 0.500 | 0.585 | 0.429 | 0.637 | 0.583 |

| Path | Hypothesis | β | Standard Error | t-Values | CI 95% | p-Values | Decision | |

|---|---|---|---|---|---|---|---|---|

| Lower | Upper | |||||||

| Direct effects | ||||||||

| I4DT → SCR | H1 | 0.191 *** | 0.019 | 4.401 | 0.119 | 0.263 | 0.001 | Supported |

| I4DT → SCAG | H2 | 0.176 ** | 0.033 | 3.262 | 0.077 | 0.282 | 0.006 | Supported |

| SCAG → SCR | H3 | 0.581 *** | 0.092 | 4.586 | 0.390 | 0.800 | 0.001 | Supported |

| I4DT → SCAD | H4 | 0.195 ** | 0.065 | 3.025 | 0.081 | 0.319 | 0.010 | Supported |

| SCAD → SCR | H5 | −0.319 ** | 0.074 | −3.009 | −0.524 | −0.165 | 0.003 | Not Supported |

| Indirect effects | ||||||||

| I4DT → (SCAG) → SCR | H6 | 0.102 ** | 0.018 | - | 0.021 | 0.182 | 0.004 | Supported |

| I4DT → (SCAD) → SCR | H7 | −0.062 ** | 0.014 | - | −0.059 | −0.011 | 0.006 | Not Supported |

| Moderating effects | ||||||||

| I4DT_X_CI → SCAG | H8 | 0.149 *** | 0.023 | 3.300 | 0.055 | 0.245 | 0.001 | Supported |

| I4DT_X_CI → SCR | H9 | 0.095 ** | 0.014 | 2.568 | 0.041 | 0.145 | 0.007 | Supported |

| I4DT_X_CI → SCAD | H10 | 0.139 ** | 0.045 | 2.577 | 0.018 | 0.253 | 0.010 | Supported |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alfaqiyah, E.; Alzubi, A.; Aljuhmani, H.Y.; Öz, T. How Industry 4.0 Technologies Enhance Supply Chain Resilience: The Interplay of Agility, Adaptability, and Customer Integration in Manufacturing Firms. Sustainability 2025, 17, 7922. https://doi.org/10.3390/su17177922

Alfaqiyah E, Alzubi A, Aljuhmani HY, Öz T. How Industry 4.0 Technologies Enhance Supply Chain Resilience: The Interplay of Agility, Adaptability, and Customer Integration in Manufacturing Firms. Sustainability. 2025; 17(17):7922. https://doi.org/10.3390/su17177922

Chicago/Turabian StyleAlfaqiyah, Emaduldin, Ahmad Alzubi, Hasan Yousef Aljuhmani, and Tolga Öz. 2025. "How Industry 4.0 Technologies Enhance Supply Chain Resilience: The Interplay of Agility, Adaptability, and Customer Integration in Manufacturing Firms" Sustainability 17, no. 17: 7922. https://doi.org/10.3390/su17177922

APA StyleAlfaqiyah, E., Alzubi, A., Aljuhmani, H. Y., & Öz, T. (2025). How Industry 4.0 Technologies Enhance Supply Chain Resilience: The Interplay of Agility, Adaptability, and Customer Integration in Manufacturing Firms. Sustainability, 17(17), 7922. https://doi.org/10.3390/su17177922