Optimizing Carbon Footprint and Strength in High-Performance Concrete Through Data-Driven Modeling

Abstract

1. Introduction

2. Data Collection

3. ML Training and Testing

3.1. ML Algorithms

3.1.1. Gaussian Process Regression

3.1.2. Ensemble Techniques

3.1.3. Artificial Neural Networks

3.2. Model Performance Evaluation Criteria

4. HPC Mix Optimization

5. Results and Discussion

5.1. ML Prediction Models

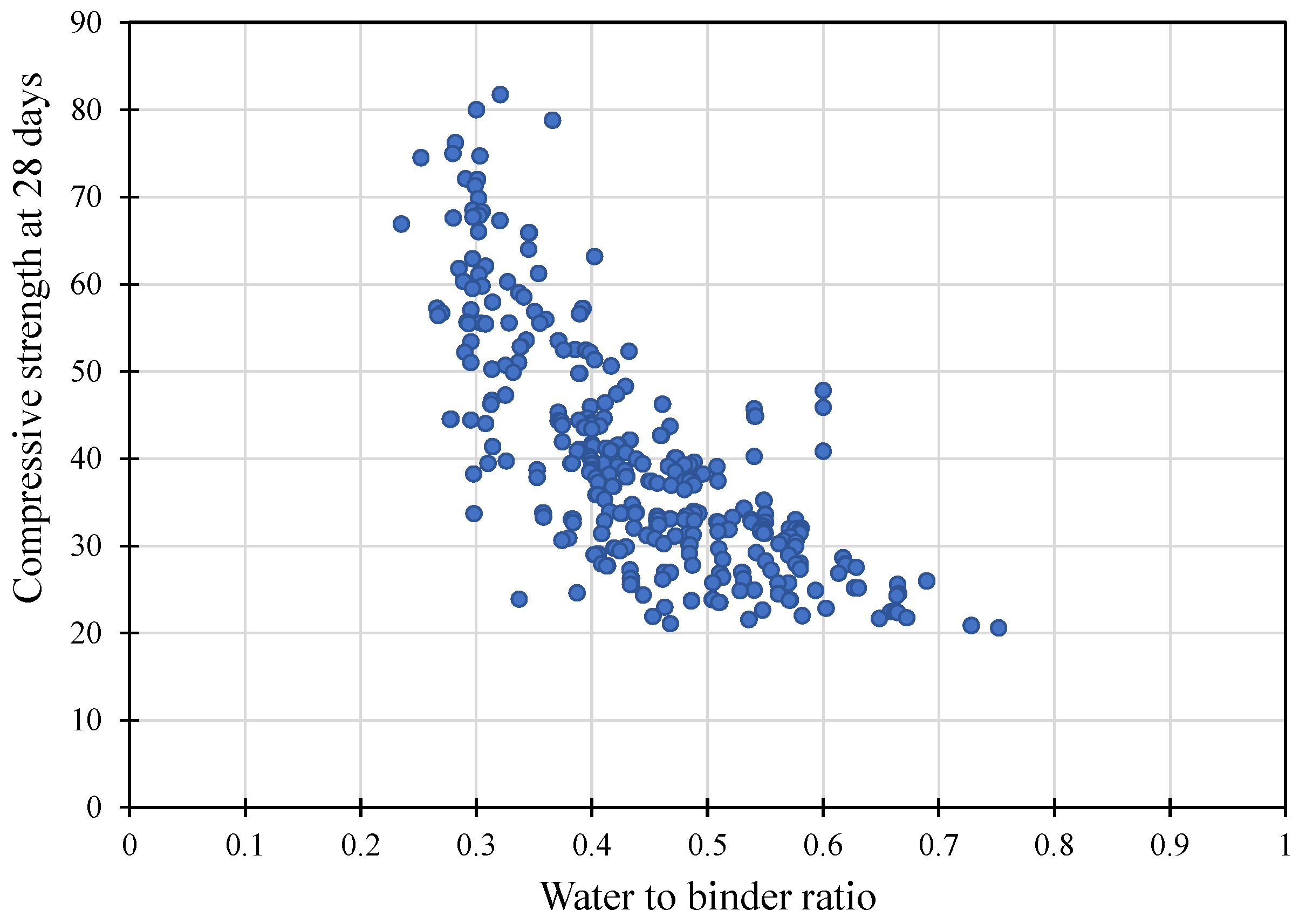

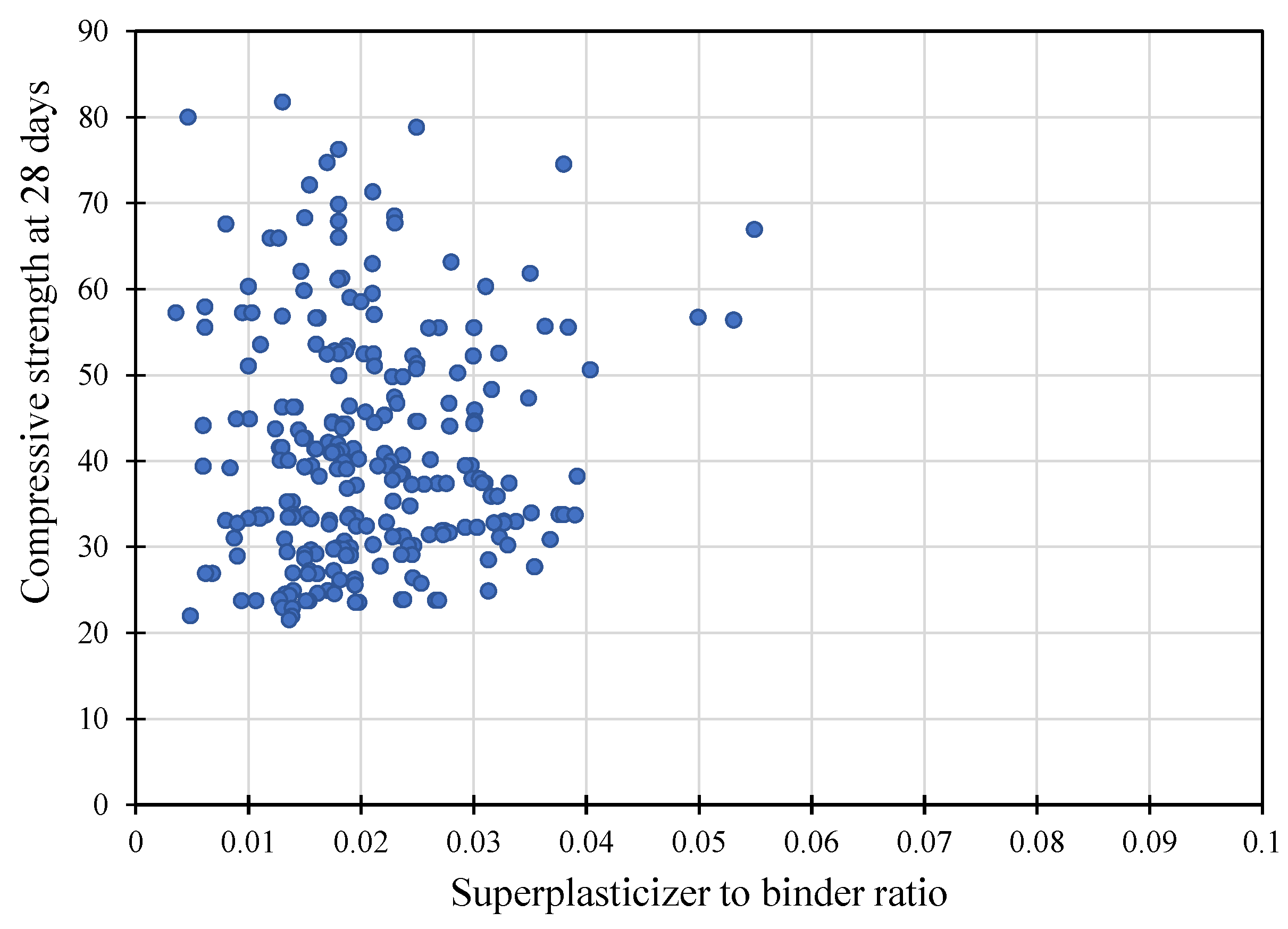

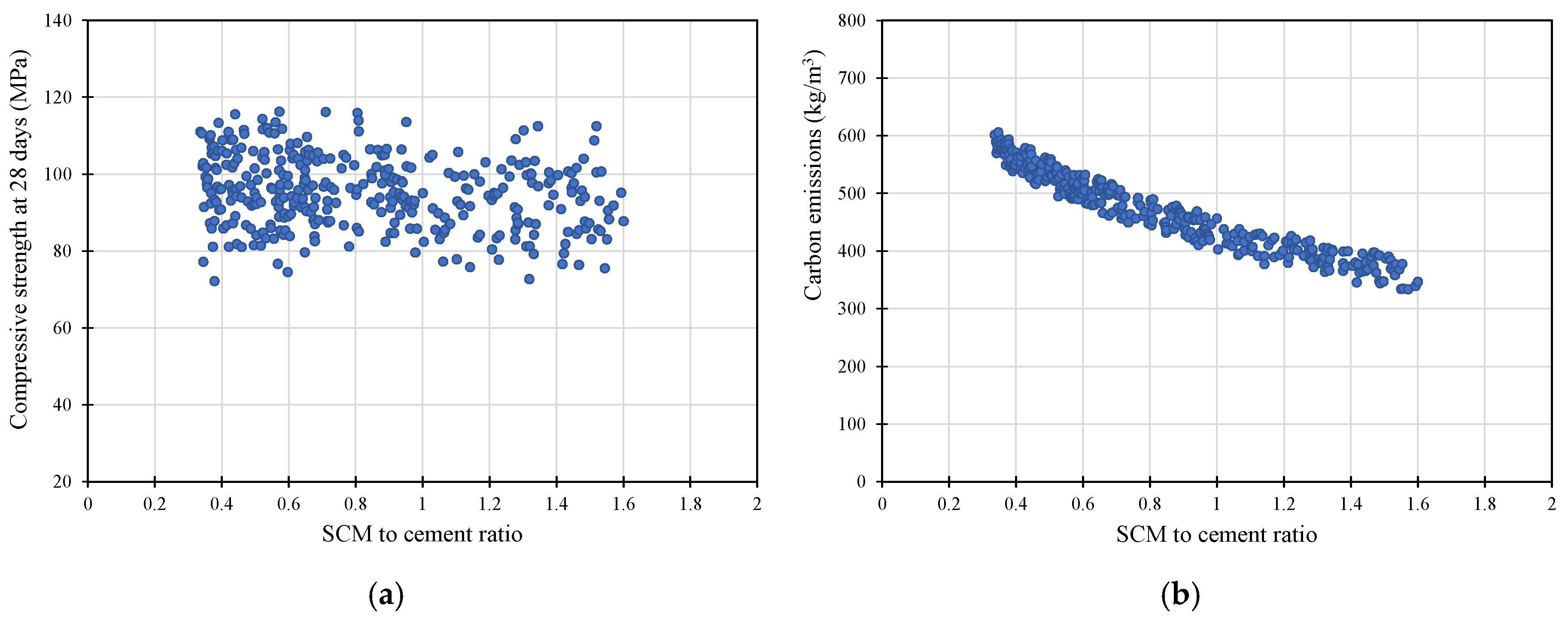

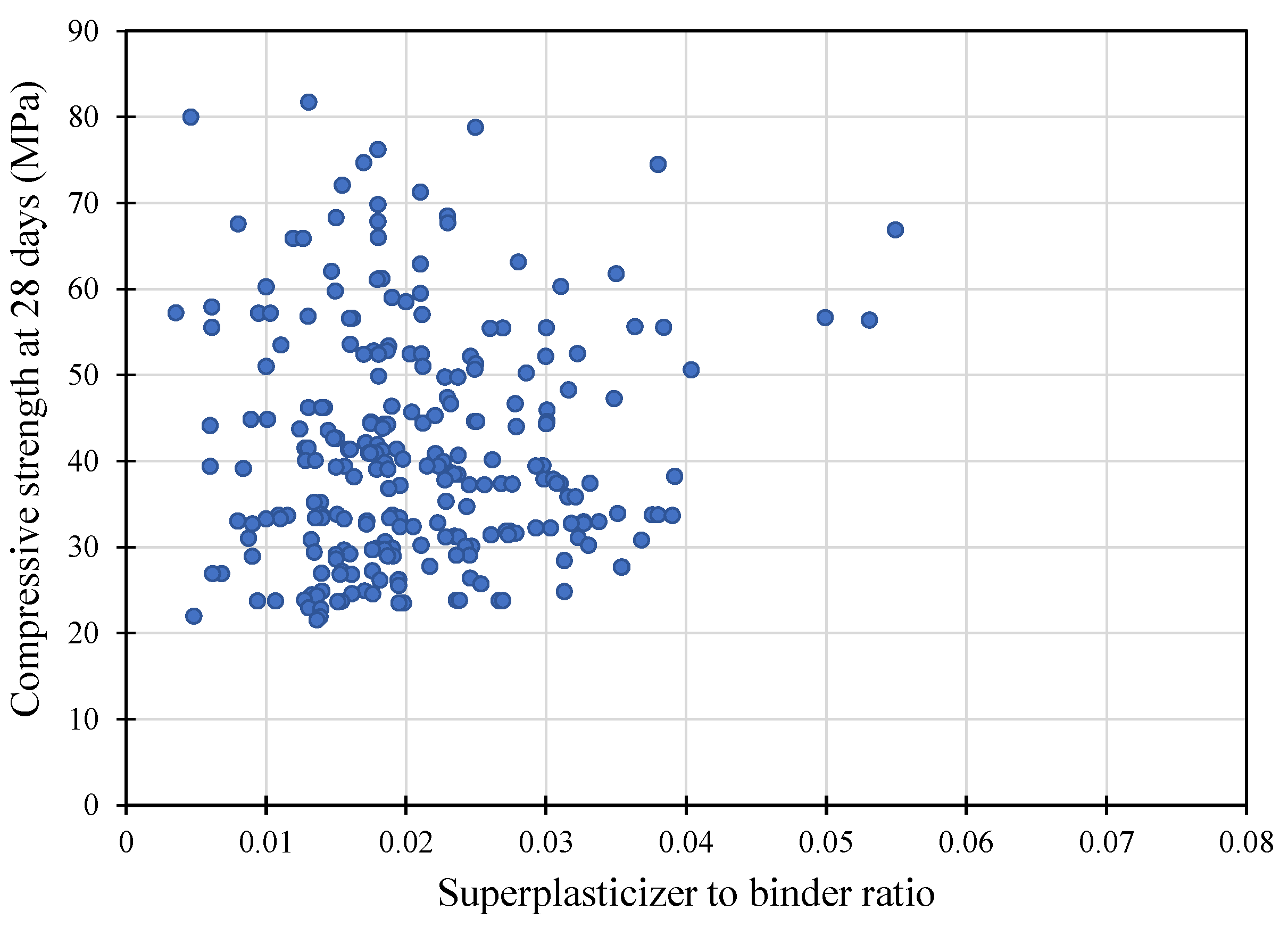

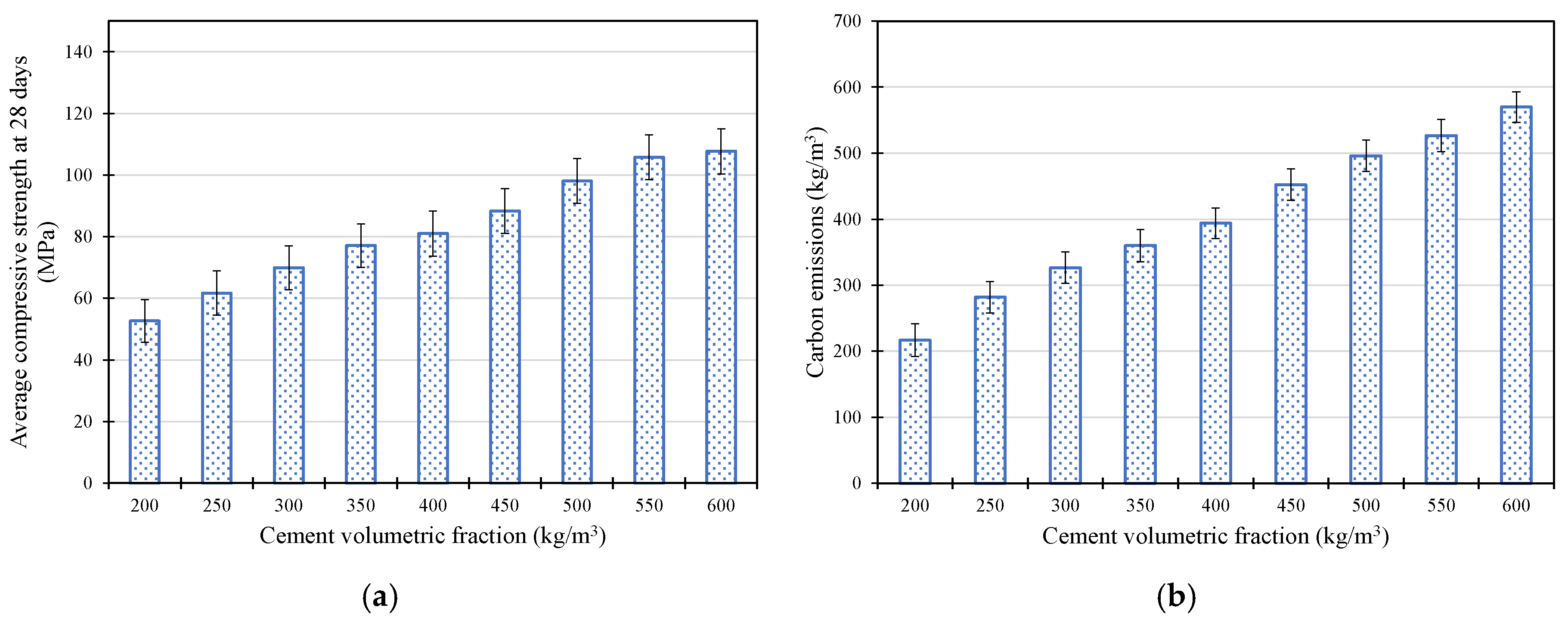

5.2. Parametric Study

5.3. Mix Optimization Results

6. Conclusions

- -

- The ML algorithms tested all showed comparable performance, with the determination coefficient ranging between 0.88 and 0.93. For the reduced dataset, the determination coefficients were slightly lower but still showing a good correlation (R2 ranging from 0.8 to 0.89).

- -

- The best predictive performance was obtained using the GPR algorithm. The model trained using 356 records has a determination coefficient of 0.93, which is comparable with the findings of many published research works using similar datasets. The compressive strength at 28 days is typically considered the design strength, which justifies the investigation of a data-driven model to predict the compressive strength specifically after 28 days from concrete casting.

- -

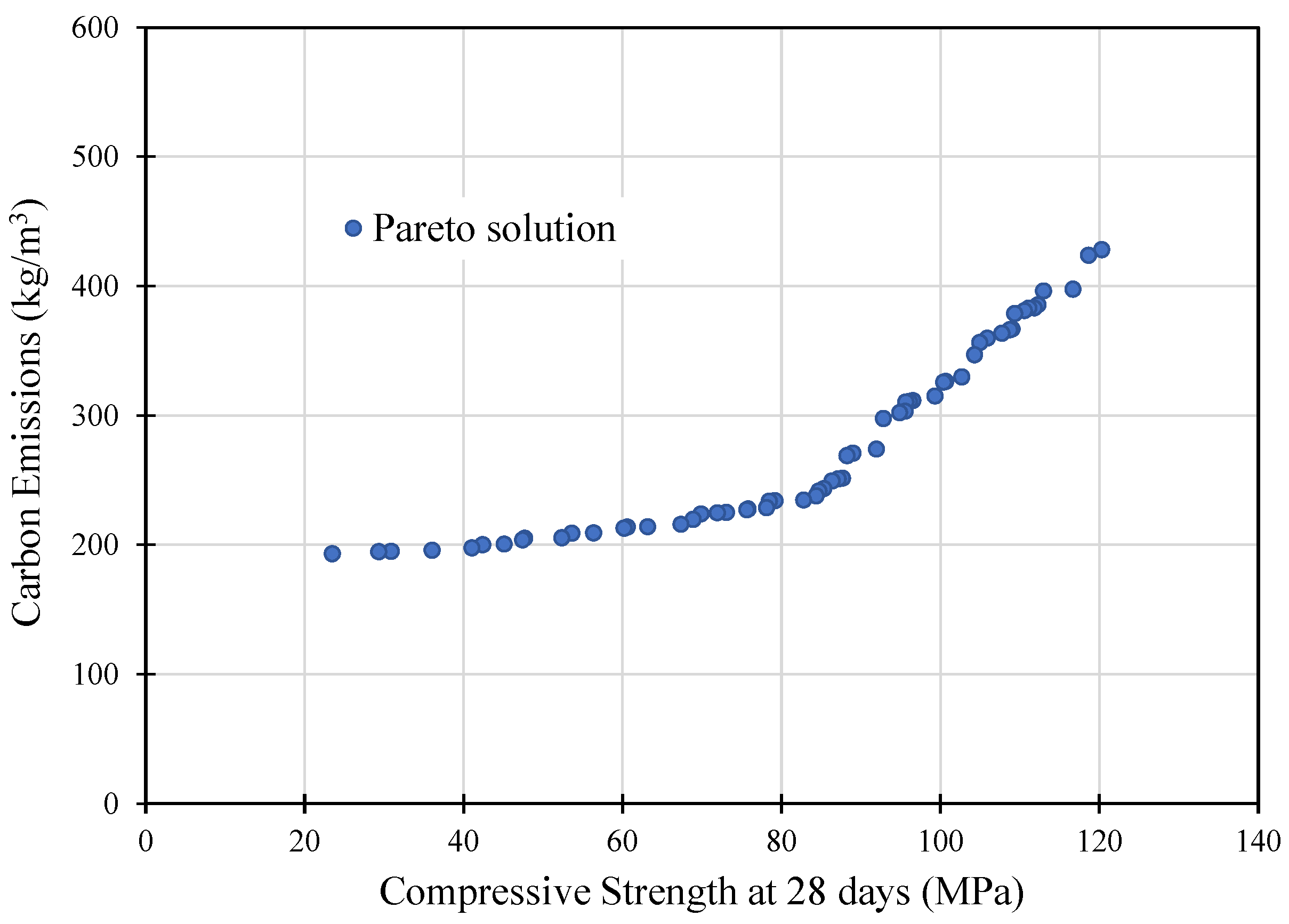

- The prediction model is used as the fitness function, and boundary constraints are defined based on the lower and the upper limits for the volumetric fraction of the concrete components. Optimization employing genetic algorithms allowed for the determination of the Pareto optimal mix configuration, leading to the best compromise between the concrete compressive strength and its carbon footprint. The proposed optimization framework can be improved through the consideration of financial and environmental aspects.

- -

- Performance differences in supplementary cementitious materials (SCMs) from different regions may affect the stability of the model. In addition, mix proportioning or workability could be optimized in a more comprehensive view of the HPC optimization task. These points could be part of future endeavors.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- O’Hegarty, R.; Kinnane, O.; Newell, J.; West, R. High performance, low carbon concrete for building cladding applications. J. Build. Eng. 2021, 43, 102566. [Google Scholar] [CrossRef]

- El-Abbasy, A.A. Production, behaviour and mechanical properties of ultra-high-performance fiber concrete—A comprehensive review. Case Stud. Constr. Mater. 2022, 17, e01637. [Google Scholar] [CrossRef]

- Wang, S.; Wang, B.; Zhu, H.; Chen, G.; Li, Z.; Yang, L.; Zhang, Y.; Zhou, X. Ultra-high performance concrete: Mix design, raw materials and curing regimes-A review. Mater. Today Commun. 2023, 35, 105468. [Google Scholar] [CrossRef]

- Han, Y.; Zhou, T. Performance Analysis of High-Performance Concrete Materials in Civil Construction. Materials 2023, 16, 5711. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Sun, W.; Liu, S. Study on the hydration heat of binder paste in high-performance concrete. Cem. Concr. Res. 2002, 32, 1483–1488. [Google Scholar] [CrossRef]

- Dushimimana, A.; Niyonsenga, A.A.; Nzamurambaho, F. A review on strength development of high performance concrete. Constr. Build. Mater. 2021, 307, 124865. [Google Scholar] [CrossRef]

- Jibril, M.M.; Zayyan, M.A.; Malami, S.I.; Usman, A.G.; Salami, B.A.; Rotimi, A.; Abba, S.I. Implementation of nonlinear computing models and classical regression for predicting compressive strength of high-performance concrete. Appl. Eng. Sci. 2023, 15, 100133. [Google Scholar] [CrossRef]

- Moula, S.; Ben Fraj, A.; Wattez, T.; Bouasker, M.; Hadj Ali, N.B. Mechanical properties, carbon footprint and cost of ultra-high performance concrete containing ground granulated blast furnace slag. J. Build. Eng. 2023, 79, 107796. [Google Scholar] [CrossRef]

- Naser, M.Z.; Kodur, V.; Thai, H.-T.; Hawileh, R.; Abdalla, J.; Degtyarev, V.V. StructuresNet and FireNet: Benchmarking databases and machine learning algorithms in structural and fire engineering domains. J. Build. Eng. 2021, 44, 102977. [Google Scholar] [CrossRef]

- Naser, M.Z. Machine learning for all! Benchmarking automated, explainable, and coding-free platforms on civil and environmental engineering problems. J. Infrastruct. Intell. Resil. 2023, 2, 100028. [Google Scholar] [CrossRef]

- Wan, S.; Li, S.; Chen, Z.; Tang, Y. An ultrasonic-AI hybrid approach for predicting void defects in concrete-filled steel tubes via enhanced XGBoost with Bayesian optimization. Case Stud. Constr. Mater. 2025, 22, e04359. [Google Scholar] [CrossRef]

- Yeh, I.C. Modeling of strength of high-performance concrete using artificial neural networks. Cem. Concr. Res. 1998, 28, 1797–1808. [Google Scholar] [CrossRef]

- Yu, Y.; Li, W.; Li, J.; Nguyen, T.N. A novel optimised self-learning method for compressive strength prediction of high performance concrete. Constr. Build. Mater. 2018, 184, 229–247. [Google Scholar] [CrossRef]

- Bui, D.-K.; Nguyen, T.; Chou, J.-S.; Nguyen-Xuan, H.; Ngo, T.D. A modified firefly algorithm-artificial neural network expert system for predicting compressive and tensile strength of high-performance concrete. Constr. Build. Mater. 2018, 180, 320–333. [Google Scholar] [CrossRef]

- Moayedi, H.; Foong, L.K.; Le, B.N. Three intelligent computational models to predict the high-performance concrete mixture. Neural Comput. Appl. 2023, 36, 3479–3498. [Google Scholar] [CrossRef]

- Han, Q.; Gui, C.; Xu, J.; Lacidogna, G. A generalized method to predict the compressive strength of high-performance concrete by improved random forest algorithm. Constr. Build. Mater. 2019, 226, 734–742. [Google Scholar] [CrossRef]

- Hameed, M.M.; AlOmar, M.K.; Baniya, W.J.; AlSaadi, M.A. Incorporation of artificial neural network with principal component analysis and cross-validation technique to predict high-performance concrete compressive strength. Asian J. Civ. Eng. 2021, 22, 1019–1031. [Google Scholar] [CrossRef]

- Anyaoha, U.; Zaji, A.; Liu, Z. Soft computing in estimating the compressive strength for high-performance concrete via concrete composition appraisal. Constr. Build. Mater. 2020, 257, 119472. [Google Scholar] [CrossRef]

- Farooq, F.; Ahmed, W.; Akbar, A.; Aslam, F.; Alyousef, R. Predictive modeling for sustainable high-performance concrete from industrial wastes: A comparison and optimization of models using ensemble learners. J. Clean. Prod. 2021, 292, 126032. [Google Scholar] [CrossRef]

- Li, Q.-F.; Song, Z.-M. High-performance concrete strength prediction based on ensemble learning. Constr. Build. Mater. 2022, 324, 126694. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, Y.; Lei, S.; Yang, S. Estimating the mechanical properties of high-performance concrete via automated and ensembled machine learning methods. Mater. Today Commun. 2023, 37, 107386. [Google Scholar] [CrossRef]

- Imran, M.; Khushnood, R.A.; Fawad, M. A hybrid data-driven and metaheuristic optimization approach for the compressive strength prediction of high-performance concrete. Case Stud. Constr. Mater. 2023, 18, e01890. [Google Scholar] [CrossRef]

- Fantilli, A.P.; Mancinelli, O.; Chiaia, B. The carbon footprint of normal and high-strength concrete used in low-rise and high-rise buildings. Case Stud. Constr. Mater. 2019, 11, e00296. [Google Scholar] [CrossRef]

- United Nations Environment Programme. Building Materials and the Climate: Constructing a New Future; United Nations Environment Programme: Paris, France, 2023. [Google Scholar]

- Adhikari, S.; Chougale, J.B.; Radke, A. A Review on the Investigation of Durability Performance of High-Performance Concrete with Cementitious Materials. Int. Res. J. Adv. Eng. Hub (IRJAEH) 2024, 2, 622–628. [Google Scholar] [CrossRef]

- Wałach, D.; Mach, A. Effect of Concrete Mix Composition on Greenhouse Gas Emissions over the Full Life Cycle of a Structure. Energies 2023, 16, 3229. [Google Scholar] [CrossRef]

- Rajagopal, M.R.; Pamu, Y.; Anusha, I. Comparative analysis of environmental footprints: Conventional versus high-strength concrete in construction. IOP Conf. Ser. Earth Environ. Sci. 2024, 1409, 012007. [Google Scholar] [CrossRef]

- Golafshani, E.M.; Behnood, A.; Kim, T.; Ngo, T.; Kashani, A. A framework for low-carbon mix design of recycled aggregate concrete with supplementary cementitious materials using machine learning and optimization algorithms. Structures 2024, 61, 106143. [Google Scholar] [CrossRef]

- Wang, M.; Du, M.; Jia, Y.; Chang, C.; Zhou, S. Carbon Emission Optimization of Ultra-High-Performance Concrete Using Machine Learning Methods. Materials 2024, 17, 1670. [Google Scholar] [CrossRef]

- Sun, C.; Wang, K.; Liu, Q.; Wang, P.; Pan, F. Machine-Learning-Based Comprehensive Properties Prediction and Mixture Design Optimization of Ultra-High-Performance Concrete. Sustainability 2023, 15, 15338. [Google Scholar] [CrossRef]

- Wakjira, T.G.; Kutty, A.A.; Alam, M.S. A novel framework for developing environmentally sustainable and cost-effective ultra-high-performance concrete (UHPC) using advanced machine learning and multi-objective optimization techniques. Constr. Build. Mater. 2024, 416, 135114. [Google Scholar] [CrossRef]

- Jin, L.; Zhang, Y.; Liu, P.; Fan, T.; Wu, T.; Wu, Q. Carbon-footprint based concrete proportion design using LSTM and MOPSO algorithms. Mater. Today Commun. 2024, 38, 107837. [Google Scholar] [CrossRef]

- Rahman, M.A.; Lu, Y. EcoBlendNet: A physics-informed neural network for optimizing supplementary material replacement to reduce the carbon footprint during cement hydration. J. Clean. Prod. 2024, 464, 142777. [Google Scholar] [CrossRef]

- Li, Y.; Shen, J.; Lin, H.; Li, Y. Optimization design for alkali-activated slag-fly ash geopolymer concrete based on artificial intelligence considering compressive strength, cost, and carbon emission. J. Build. Eng. 2023, 75, 106929. [Google Scholar] [CrossRef]

- Katoch, S.; Chauhan, S.S.; Kumar, V. A review on genetic algorithm: Past, present, and future. Multimed. Tools Appl. 2021, 80, 8091–8126. [Google Scholar] [CrossRef] [PubMed]

- UCI. UC Irvine Machine Learning Repository. Available online: https://archive.ics.uci.edu/ (accessed on 22 July 2025).

- Wang, L.; Ma, Y.; Li, L. Uncovering the role of superplasticizer in developing nano-engineered ultra-high-performance concrete. Front. Mater. 2023, 10, 1177189. [Google Scholar] [CrossRef]

- Wang, X.-Y. Simulation for optimal mixture design of low-CO2 high-volume fly ash concrete considering climate change and CO2 uptake. Cem. Concr. Compos. 2019, 104, 103408. [Google Scholar] [CrossRef]

- Jones, C.; Hammond, G. Embodied Carbon—The ICE Database. Available online: https://circularecology.com/embodied-carbon-footprint-database.html (accessed on 22 July 2025).

- Ciaburro, G. MATLAB for Machine Learning: Practical Examples of Regression, Clustering and Neural Networks; Packt Publishing: Birmingham, UK, 2017. [Google Scholar]

- James, G.; Witten, D.; Hastie, T.; Tibshirani, R. An Introduction to Statistical Learning: With Applications in R; Springer: New York, NY, USA, 2014. [Google Scholar]

- Wong, T.T.; Yang, N.Y. Dependency Analysis of Accuracy Estimates in k-Fold Cross Validation. IEEE Trans. Knowl. Data Eng. 2017, 29, 2417–2427. [Google Scholar] [CrossRef]

- Williams, C.K.I.; Rasmussen, C.E. Gaussian processes for regression. In Proceedings of the Advances in Neural Information Processing Systems 8, San Francisco, CA, USA, 13–17 August 2016; pp. 290–297. [Google Scholar]

- Schulz, E.; Speekenbrink, M.; Krause, A. A tutorial on Gaussian process regression: Modelling, exploring, and exploiting functions. J. Math. Psychol. 2018, 85, 1–16. [Google Scholar] [CrossRef]

- González, S.; García, S.; Del Ser, J.; Rokach, L.; Herrera, F. A practical tutorial on bagging and boosting based ensembles for machine learning: Algorithms, software tools, performance study, practical perspectives and opportunities. Inf. Fusion 2020, 64, 205–237. [Google Scholar] [CrossRef]

- Chen, T.; Guestrin, C. XGBoost: A Scalable Tree Boosting System. In Proceedings of the 22nd ACM SIGKDD International Conference on Knowledge Discovery and Data Mining, San Francisco, CA, USA, 13–17 August 2016; pp. 785–794. [Google Scholar]

- Bishop, C.M. Pattern Recognition and Machine Learning (Information Science and Statistics); Springer: Berlin/Heidelberg, Germany, 2006. [Google Scholar]

- Goldberg, D.E. Genetic Algorithms in Search, Optimization, and Machine Learning; Addison-Wesley: Boston, MA, USA, 1989. [Google Scholar]

- Yang, X.-S. Chapter 5—Genetic Algorithms. In Nature-Inspired Optimization Algorithms; Yang, X.-S., Ed.; Elsevier: Oxford, UK, 2014; pp. 77–87. [Google Scholar]

- Zhang, Y.; Ren, W.; Chen, Y.; Mi, Y.; Lei, J.; Sun, L. Predicting the compressive strength of high-performance concrete using an interpretable machine learning model. Sci. Rep. 2024, 14, 28346. [Google Scholar] [CrossRef] [PubMed]

- Vu-Bac, N.; Le-Anh, T.; Rabczuk, T. A Machine Learning based uncertainty quantification for compressive strength of high-performance concrete. Front. Struct. Civ. Eng. 2025, 19, 824–836. [Google Scholar] [CrossRef]

- Kang, J.; Gao, J.; Liu, X. Machine learning for predicting the compressive strength of high-performance concrete materials. Multiscale Multidiscip. Model. Exp. Des. 2025, 8, 403. [Google Scholar] [CrossRef]

- Selmi, M.; Kormi, T.; Ali, N.B.H. Comparison of multi-criteria decision methods through a ranking stability index. Int. J. Oper. Res. 2016, 27, 165–183. [Google Scholar] [CrossRef]

- Coello, C.A.C.; Lamont, G.B.; Veldhuizen, D.A.V. Evolutionary Algorithms for Solving Multi-Objective Problems; Springer: Berlin/Heidelberg, Germany, 2007. [Google Scholar]

- Selmi, M.; Kormi, T.; Ali, N.B.H. Comparing Multi-Criteria Decision aid methods through a ranking stability index. In Proceedings of the 2013 5th International Conference on Modeling, Simulation and Applied Optimization (ICMSAO), Hammamet, Tunisia, 28–30 April 2013; pp. 1–5. [Google Scholar]

- Leung, C.K.Y. Concrete as a Building Material. In Encyclopedia of Materials: Science and Technology; Buschow, K.H.J., Cahn, R.W., Flemings, M.C., Ilschner, B., Kramer, E.J., Mahajan, S., Veyssière, P., Eds.; Elsevier: Oxford, UK, 2001; pp. 1471–1479. [Google Scholar]

| Variable | Min | Max | Median | Mean | Std. Dev. |

|---|---|---|---|---|---|

| Cement (kg/m3) | 108.3 | 540 | 282.5 | 279.3 | 103.1 |

| Blast Furnace Slag (kg/m3) | 0 | 359.4 | 100.5 | 92.7 | 88.4 |

| Fly Ash (kg/m3) | 0 | 195 | 12.2 | 58.3 | 62.4 |

| Water (kg/m3) | 126.6 | 247 | 185 | 182.8 | 19.6 |

| Superplasticizer (kg/m3) | 0 | 32.2 | 7.05 | 6.9 | 5.3 |

| Coarse Aggregate (kg/m3) | 801 | 1134.3 | 950.4 | 951.5 | 82.3 |

| Fine Aggregate (kg/m3) | 594 | 992.6 | 764.2 | 760.1 | 71.9 |

| 28-day Compressive Strength (MPa) | 20.6 | 81.7 | 37.4 | 39.7 | 13.0 |

| Materials | Carbon Emission (kg/ton) | References |

|---|---|---|

| Cement | 880 | [8,38] |

| Blast Furnace Slag | 100 | [8] |

| Fly Ash | 19.6 | [29,38] |

| Superplasticizer | 1880 | [39] |

| Coarse Aggregate | 7.5 | [39] |

| Fine Aggregate | 7.5 | [39] |

| Water | 0.2 | [29,38] |

| Variable | Min | Max |

|---|---|---|

| Cement (kg/m3) | 100 | 550 |

| Blast Furnace Slag (kg/m3) | 0 | 400 |

| Fly Ash (kg/m3) | 0 | 200 |

| Water (kg/m3) | 120 | 250 |

| Superplasticizer (kg/m3) | 0 | 40 |

| Coarse Aggregate (kg/m3) | 800 | 1200 |

| Fine Aggregate (kg/m3) | 500 | 1000 |

| Output | ML Algorithm | Metrics | ||

|---|---|---|---|---|

| RMSE | R2 | MAE | ||

| Compressive Strength (28 days) | Gaussian Process Regression | 4.5645 | 0.93 | 3.0930 |

| Ensemble Technique | 5.0002 | 0.91 | 3.5314 | |

| Artificial Neural Network | 5.7647 | 0.88 | 4.1764 | |

| Concrete Component | Volumetric Fraction (kg/m3) |

|---|---|

| Cement (kg/m3) | 500 |

| Blast Furnace Slag (kg/m3) | 364.2 |

| Fly Ash (kg/m3) | 17.9 |

| Water (kg/m3) | 156.55 |

| Superplasticizer (kg/m3) | 18.161 |

| Coarse Aggregate (kg/m3) | 1113.9 |

| Fine Aggregate (kg/m3) | 917.88 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Helali, S.; Albalawi, S.; Alanazi, M.; Alanazi, B.; Bel Hadj Ali, N. Optimizing Carbon Footprint and Strength in High-Performance Concrete Through Data-Driven Modeling. Sustainability 2025, 17, 7808. https://doi.org/10.3390/su17177808

Helali S, Albalawi S, Alanazi M, Alanazi B, Bel Hadj Ali N. Optimizing Carbon Footprint and Strength in High-Performance Concrete Through Data-Driven Modeling. Sustainability. 2025; 17(17):7808. https://doi.org/10.3390/su17177808

Chicago/Turabian StyleHelali, Saloua, Shadiah Albalawi, Maer Alanazi, Bashayr Alanazi, and Nizar Bel Hadj Ali. 2025. "Optimizing Carbon Footprint and Strength in High-Performance Concrete Through Data-Driven Modeling" Sustainability 17, no. 17: 7808. https://doi.org/10.3390/su17177808

APA StyleHelali, S., Albalawi, S., Alanazi, M., Alanazi, B., & Bel Hadj Ali, N. (2025). Optimizing Carbon Footprint and Strength in High-Performance Concrete Through Data-Driven Modeling. Sustainability, 17(17), 7808. https://doi.org/10.3390/su17177808