Integrated Optimization Method of External Wall Insulation for Granaries in Different Climate Regions in China

Abstract

1. Introduction

2. Methodology

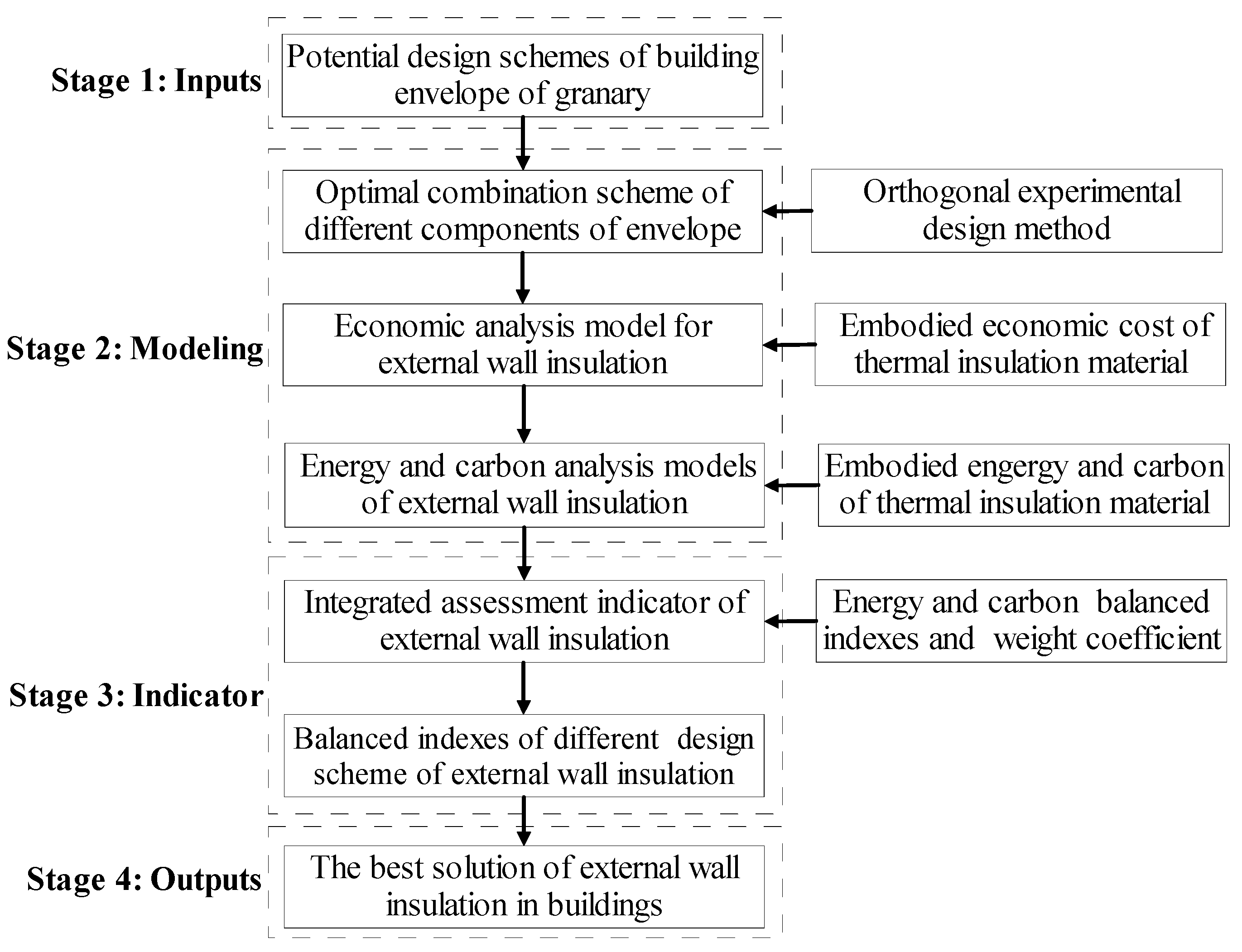

2.1. Overview of the Integrated Optimization Approach for External Wall Insulation

2.2. Determination of Optimal Combination Scheme of Different Construction Forms of Components

2.3. Integrated Economical, Energy, and Carbon Analysis Models of External Wall Insulation

2.3.1. Energy Analysis Model of External Wall Insulation in Granary

2.3.2. Economic Analysis Model of External Wall Insulation in Granary

2.3.3. Carbon Analysis Model of External Wall Insulation in Granary

2.4. Integrated Assessment Indicator of External Wall Insulation in Granary

3. Case Study Building and Typical Climate Regions of Granary in China

3.1. Case Study of Granary Building

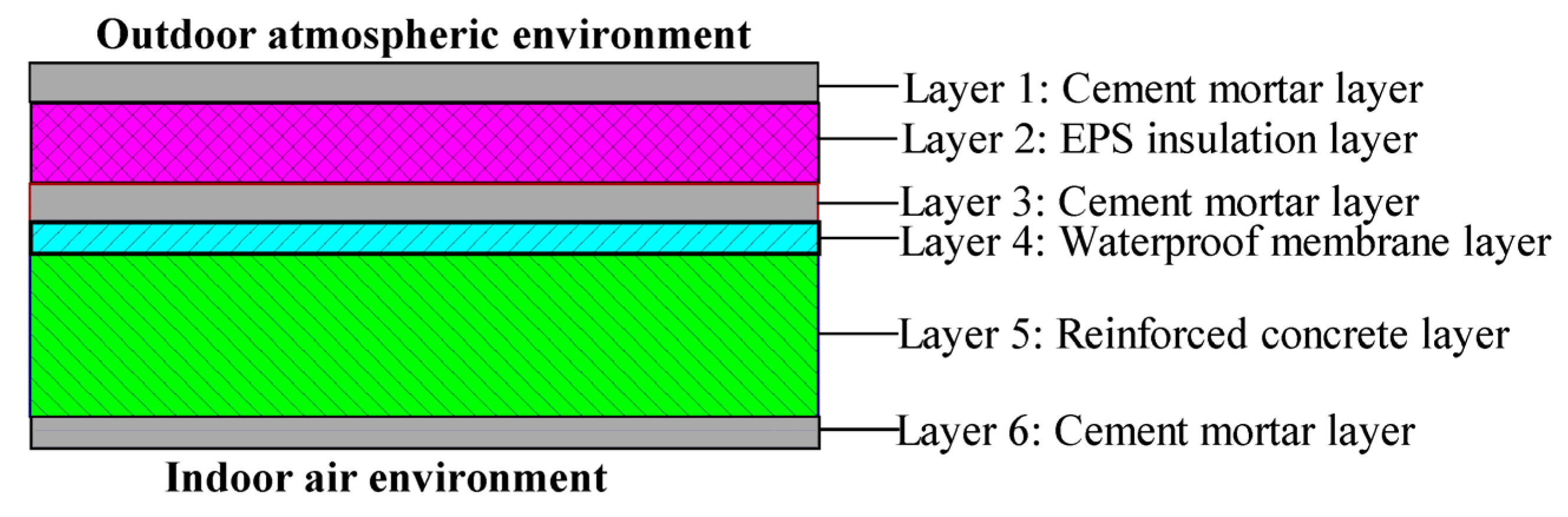

3.2. Potential Construction Form of Building Envelope Structure

3.3. Typical Climate Regions of Granary in China

4. Results and Discussions

4.1. Optimal Combination Scheme of Different Construction Forms of Building Components

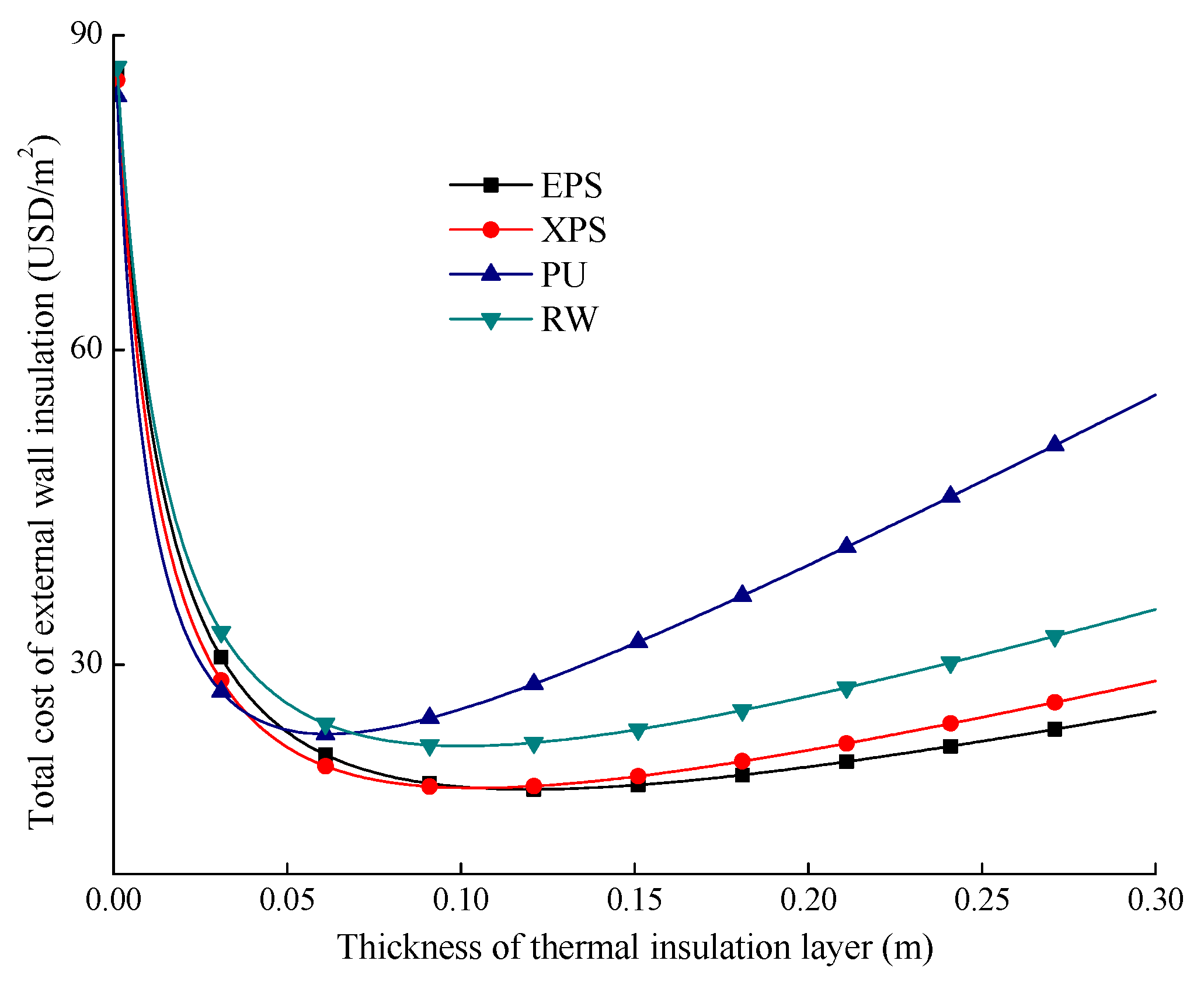

4.2. Economic Performance Assessment of Different Insulation Materials in Changsha City

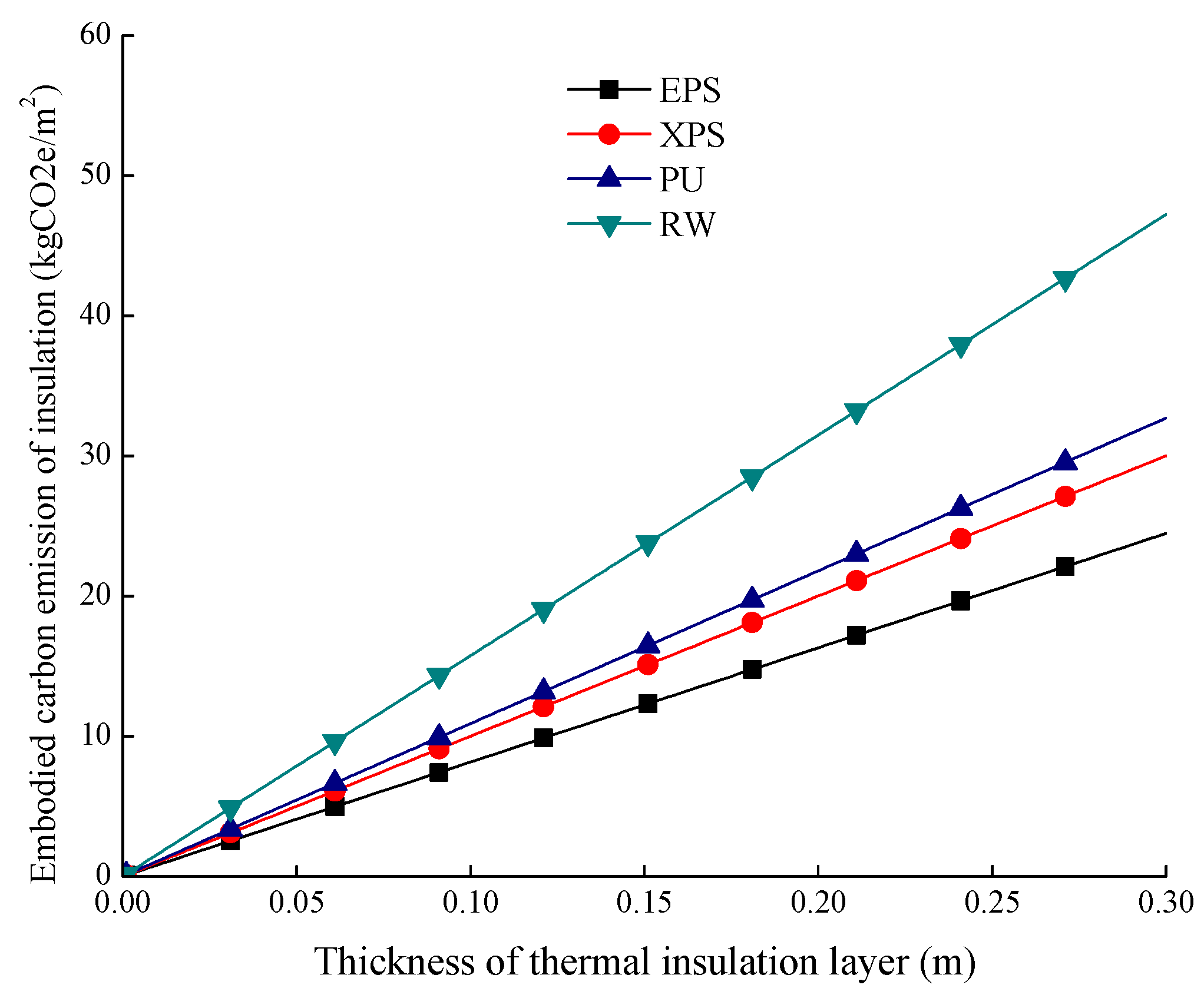

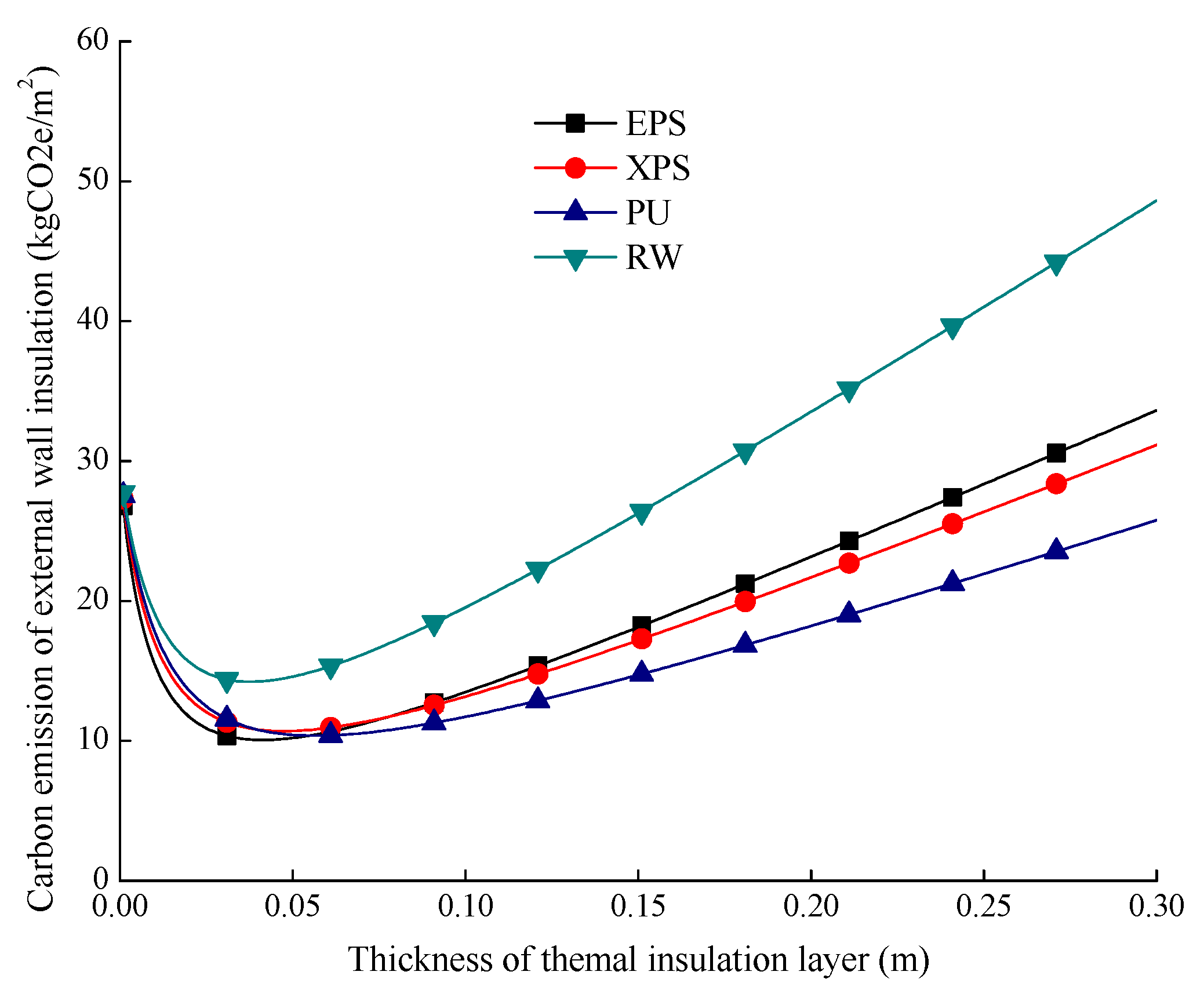

4.3. Carbon Assessment of Different Insulation Materials in Changsha City

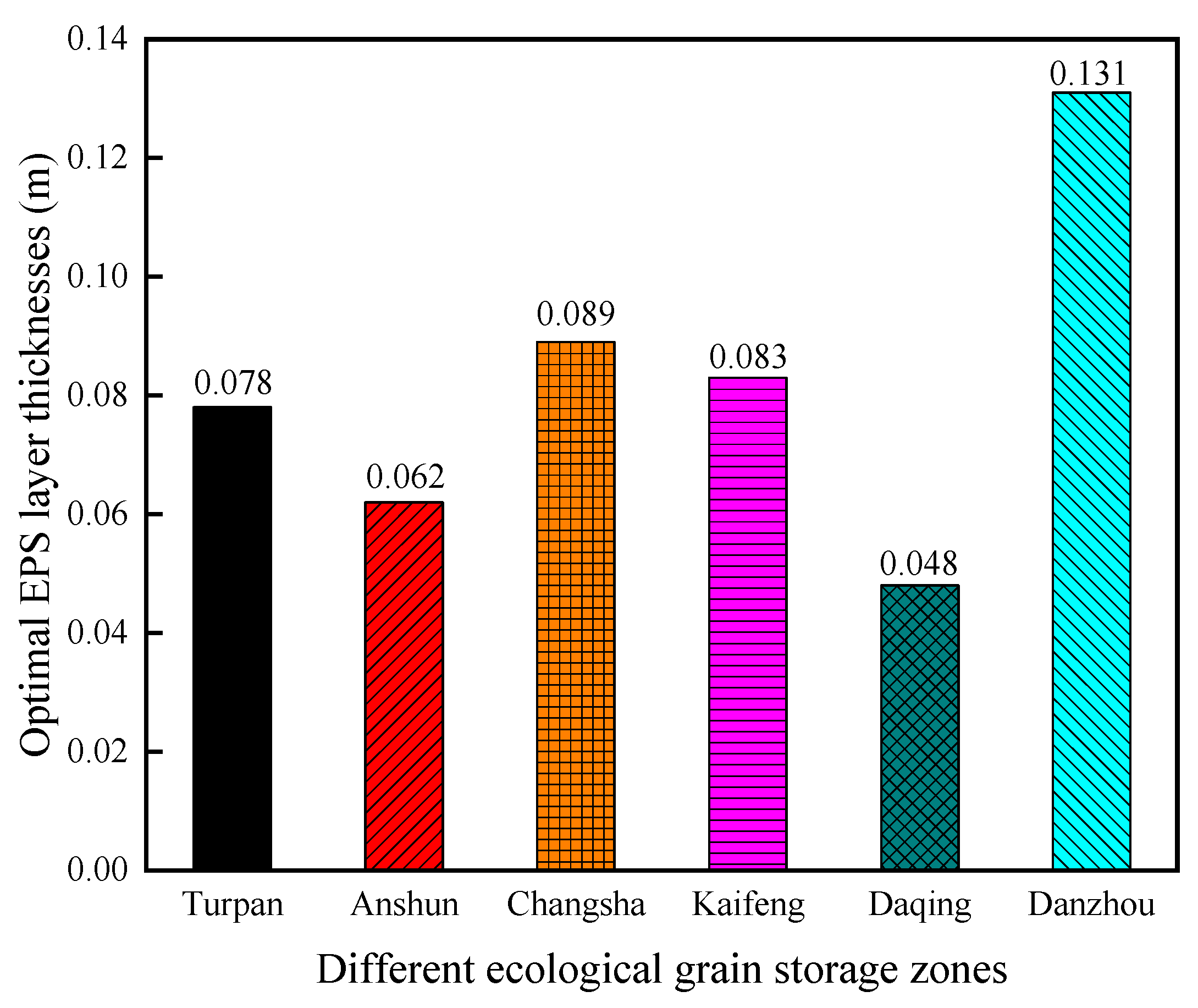

4.4. Impacts of Different Climate Region on the Design of External Wall Insulation

4.5. Calculated Integrated Assessment Indicators for Different Climate Regions

5. Conclusions

- (1)

- An integrated optimization approach was proposed for external wall insulation in buildings based on orthogonal experimental design method, comprehensive analysis models, and integrated assessment indicator. The optimization approach is very helpful to searching for the best solution of external wall insulation in real buildings.

- (2)

- Orthogonal experimental design method was utilized to determine the optimal combination scheme of different construction forms of components in building envelopes.

- (3)

- Integrated economic, energy, and carbon analysis models were developed to assess the comprehensive performance of external wall insulation.

- (4)

- An integrated assessment indicator consisting of an energy balanced index, a carbon balanced index, and weight coefficients was presented to determine the best solution of external wall insulation.

- (5)

- Outdoor climate characteristics in different climate regions in China could affect the comprehensive performance of external wall insulation in buildings, significantly. The optimum thickness of EPS insulation layer of external wall in the concerned granary in Turpan city, Daqing city, Kaifeng city, Changsha city, Anshun city, and Danzhou city was EPS insulation with a layer thickness of 0.078 m, 0.048 m, 0.083 m, 0.089 m, 0.062 m, and 0.131 m, respectively.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Adam, Q.F.; Segui, P.; Côté, J.; Bilodeau, J.; Doré, G. Thermal insulation of flexible pavements utilizing foam glass aggregates to mitigate frost action in cold regions—Development of design tools. Constr. Build. Mater. 2024, 414, 134841. [Google Scholar] [CrossRef]

- Yuan, L.T.; Wang, Z.Y.; Zhu, X.D.; Wu, Y.X.; Cui, H.J. Analysis of factors influencing energy-saving advantages of outside and inside insulation of external walls in intermittent air-conditioned buildings. Case Stud. Therm. Eng. 2023, 50, 103495. [Google Scholar] [CrossRef]

- Lassandro, P.; Zaccaro, S.A.; Di Turi, S. Mitigation and adaptation strategies for different urban fabrics to face increasingly hot summer days due to climate change. Sustainability 2024, 16, 2210. [Google Scholar] [CrossRef]

- Lassandro, P.; Devitofrancesco, A.; Bellazzi, A.; Cascardi, A.; De Aloysio, G.; Laghi, L.; Malvezzi, R. Facing the constraints to the deep energy renovation process of residential built stock in European markets. Sustainability 2024, 16, 294. [Google Scholar] [CrossRef]

- Longo, F.; Lassandro, P.; Moshiri, A.; Phatak, T.; Aiello, M.A.; Krakowiak, K.J. Lightweight geopolymer-based mortars for the structural and energy retrofit of buildings. Energy Build. 2020, 225, 11035. [Google Scholar] [CrossRef]

- Li, M.; Zhao, S.Y.; Yao, S.; Huo, Q.; Yuan, J.Y.; Li, Y.N. A performance-responsive generative design framework integrating multi-objective optimization for the layout of residential buildings oriented towards low-carbon emission: A case study of Tianjin in China. J. Build. Eng. 2025, 108, 112805. [Google Scholar] [CrossRef]

- Torabi, M.; Simonen, K.; Evins, R. What matters the most in designing low-carbon buildings in Canada? Exploring the tradeoff between embodied and operational carbon in early stage design. Energy Build. 2025, 334, 115482. [Google Scholar] [CrossRef]

- Cheng, B.Y.; Mei, L.; Long, W.J.; Luo, Q.L.; Zhang, J.R.; Xiong, C.; Shu, Y.Q.; Li, Z.J.; Gao, S. Data driven multi-objective design for low-carbon self-compacting concrete considering durability. J. Clean. Prod. 2024, 450, 141947. [Google Scholar] [CrossRef]

- Kathiravel, R.; Feng, H.B. Structural and embodied carbon performance optimization for low carbon buildings through BIM-based integrated design. J. Build. Eng. 2024, 98, 111008. [Google Scholar] [CrossRef]

- Lu, K.; Deng, X.Y. OpenBIM driven marginal abatement cost of low-carbon measures in building design. Appl. Energy 2025, 377 Pt B, 124477. [Google Scholar] [CrossRef]

- Shi, Y.Z.; Yang, Z.Y.; Zheng, S.; Gao, D.; Yang, X.D. Multi-objective optimization of embodied carbon emission, energy consumption, and daylighting performance of educational building in the schematic design stage. J. Build. Eng. 2025, 106, 112594. [Google Scholar] [CrossRef]

- Li, S.; Bai, Y.B.; Liu, H.; Tang, N.; Shao, X.Y. Building envelopes for carbon storage: A design-driven approach to enhancing the performance of alkali-activated materials through a cavity. Constr. Build. Mater. 2025, 476, 141238. [Google Scholar] [CrossRef]

- Jimenez, M.S.; Cortesão, J.; Lenzholzer, S.; Walker, R. Early-stage design of a low-embodied carbon and cost-effective green facade system. J. Build. Eng. 2023, 72, 106588. [Google Scholar] [CrossRef]

- Wu, T.; Jin, L.B.; Zhang, Y.S. A data-driven method for the design and calculation of recycled concrete mix proportions based on carbon footprint. Mater. Today Commun. 2025, 42, 111528. [Google Scholar] [CrossRef]

- Wang, J.; Li, X.; Chen, C.; Zhu, W.T. Proof of carbon reduction: A novel incentive mechanism in blockchain for carbon emissions reduction in construction. Build. Environ. 2025, 272, 112684. [Google Scholar] [CrossRef]

- Li, Y.; Li, S.; Xia, S.; Li, B.; Zhang, X.; Wang, B.; Ye, T.; Zheng, W. A Review on the Policy, Technology and Evaluation Method of Low-Carbon Buildings and Communities. Energies 2023, 16, 1773. [Google Scholar] [CrossRef]

- Xi, C.; Cao, S.-J. Challenges and future development paths of low carbon building design: A review. Buildings 2022, 12, 163. [Google Scholar] [CrossRef]

- Qian, F.; Shi, Z.; Yang, L. A review of green, low-carbon, and energy-efficient research in sports buildings. Energies 2024, 17, 4020. [Google Scholar] [CrossRef]

- He, L.H.; Wang, W. Design optimization of public building envelope based on multi-objective quantum genetic algorithm. J. Build. Eng. 2024, 91, 109714. [Google Scholar] [CrossRef]

- Es-sakali, N.; Pfafferott, J.; Mghazli, M.O.; Cherkaoui, M. Towards climate-responsive net zero energy rural schools: A multi-objective passive design optimization with bio-based insulations, shading, and roof vegetation. Sustain. Cities Soc. 2025, 120, 106142. [Google Scholar] [CrossRef]

- Shi, L.; Xu, D.; Li, X.; Huang, L.; Li, Y.; Huang, T.; Yang, Y. The impact characteristics of common low-carbon design methods on reducing carbon emissions in industrial plant buildings in architectural design. Buildings 2025, 15, 974. [Google Scholar] [CrossRef]

- Xu, L.; Yu, D.; Zhou, J.; Jin, C. A review of key technologies for green and low-carbon future buildings in China. Processes 2025, 13, 574. [Google Scholar] [CrossRef]

- Zhang, L.; Wu, H.; Wang, X.; Wu, F.; Ding, Z.; Song, L.; Rong, X.; Liu, J.; Wen, X.; Zhong, P. Quantification of carbon emissions of building decoration processes. Buildings 2024, 14, 3570. [Google Scholar] [CrossRef]

- Buyak, N.; Deshko, V.; Borodinecs, A.; Bilous, I.; Naumchuk, O.; Sukhodub, I. Assessment of strategies for low-carbon regeneration of buildings in Eastern Europe. Energy 2025, 325, 136069. [Google Scholar] [CrossRef]

- D’Agostino, D.; Falco, F.D.; Minelli, F.; Minichiello, F. New robust multi-criteria decision-making framework for thermal insulation of buildings under conflicting stakeholder interests. Appl. Energy 2024, 376, 124262. [Google Scholar] [CrossRef]

- Chang, D.; Tang, S. Research on low-carbon building development and carbon emission control based on mathematical models: A case study of Jiangsu Province. Energies 2024, 17, 4545. [Google Scholar] [CrossRef]

- Chen, X.; Cimillo, M.; Chow, D.; Chen, B. Assessing the energy performance and retrofit potential of the 1980–1990s’ residential building stock in China’s Jiangsu Province: A simulation-based study. Energies 2024, 17, 1260. [Google Scholar] [CrossRef]

- Zheng, F.; Wang, Y.; Shen, Z.; Wang, Y. Research on the correlations between spatial morphological indices and carbon emission during the operational stage of built environments for old communities in cold regions. Buildings 2023, 13, 2222. [Google Scholar] [CrossRef]

- Zhao, S.; Zhu, Y.; Lou, P.; Hu, Y.; Xu, C.; Chen, Y. Optimization model of substation building envelope–renewable energy utilization based on life-cycle minimum carbon emissions. Buildings 2023, 13, 1602. [Google Scholar] [CrossRef]

- Tian, Z.J.; Liu, Y.F.; Chen, Y.W.; Song, C.; Liang, Y.X. Thermal analysis and optimization of data center building envelope insulation in different climate zones. Appl. Therm. Eng. 2024, 257, 124366. [Google Scholar] [CrossRef]

- Liu, C.; Sharples, S.; Mohammadpourkarbasi, H. A review of building energy retrofit measures, passive design strategies and building regulation for the low carbon development of existing dwellings in the hot summer–cold winter region of China. Energies 2023, 16, 4115. [Google Scholar] [CrossRef]

- Wang, H.T.; Huang, Y.G.; Guo, C.Z.; Yang, L.; Huang, L. A low-carbon optimization design method for building roof insulation using comprehensive economic analysis model and evaluation index. Sustain. Energy Technol. Assess. 2023, 55, 102937. [Google Scholar] [CrossRef]

- Yang, L.; Yao, H.D.; Zhang, Q.Q.; Chen, X.; Liu, Y. Enhancing thermal insulation and energy efficiency in low-temperature granaries using pipe-embedded envelopes. Case Stud. Therm. Eng. 2025, 73, 106481. [Google Scholar] [CrossRef]

- Zeng, C.; Hu, C.; Li, W. Thermal regulation performance of shape-stabilized-phase-change-material-based prefabricated wall for green grain storage. Materials 2023, 16, 964. [Google Scholar] [CrossRef]

- Wang, Y.; Yi, Y.; Zhang, N.; Du, J. A study of the forms and technology of traditional granary buildings in the middle and lower reaches of the Fu river. J. Asian Archit. Build. 2018, 17, 175–182. [Google Scholar] [CrossRef]

- Pasqualone, A. Addressing shortages with storage: From old grain pits to new solutions for underground storage systems. Agriculture 2025, 15, 289. [Google Scholar] [CrossRef]

- Xu, W.; Wang, Q.; Deng, H.; Zhu, Z. Research on the sustainable design strategies of vernacular architecture in Southwest Hubei—A case study of the first granary of Xuan’en County. PLoS ONE 2024, 19, e0316518. [Google Scholar] [CrossRef] [PubMed]

- Zheng, Z.H.; Xiao, J.; Yang, Y.; Xu, F.; Zhou, J.; Liu, H.C. Optimization of external wall insulation in office buildings based on wall orientation: Economic, energy and carbon saving potential in China. Energy 2024, 290, 130300. [Google Scholar] [CrossRef]

- Laasri, I.A.; Outzourhit, A.; Mghazli, M.O. Multi-parameter analysis of different building forms in a semi-arid climate: Effect of building construction and phase change materials. Sol. Energy 2023, 250, 220–240. [Google Scholar] [CrossRef]

- Ning, B.S.; Fu, X.H.; Zhang, M.D.; Chen, Y.M. Verification of the radiant time factor (RTF) and convective time factor (CTF) for radiant systems in the buildings. J. Build. Eng. 2024, 98, 111378. [Google Scholar] [CrossRef]

- Liu, Y.; Qi, H.; Chen, J.Y.; Li, X.L.; Chen, Y.M.; Lu, L. Investigation on the influence of solar spectrum on the energy performance of aerogel glazing system. Energy 2024, 313, 133869. [Google Scholar] [CrossRef]

- Zhang, L.L.; Liu, Z.A.; Hou, C.P.; Hou, J.W.; Wei, D.; Hou, Y.Y. Optimization analysis of thermal insulation layer attributes of building envelope external wall based on DeST and life cycle economic evaluation. Case Stud. Therm. Eng. 2019, 14, 100410. [Google Scholar] [CrossRef]

- Kobeyev, S.; Tokbolat, S.; Durdyev, S. Design and energy performance analysis of a hotel building in a hot and dry climate: A case study. Energies 2021, 14, 5502. [Google Scholar] [CrossRef]

- Monteiro, H.; Freire, F.; Fernández, J.E. Life-cycle assessment of alternative envelope construction for a new house in south-western Europe: Embodied and operational magnitude. Energies 2020, 13, 4145. [Google Scholar] [CrossRef]

- Annibaldi, V.; Cucchiella, F.; Rotilio, M. Economic and environmental assessment of thermal insulation. a case study in the Italian context. Constr. Build. Mater. 2021, 15, e00682. [Google Scholar] [CrossRef]

- Liu, X.W.; Chen, Y.M.; Ge, H.; Fazio, P.; Chen, G.J.; Guo, X.G. Determination of optimum insulation thickness for building walls with moisture transfer in hot summer and cold winter zone of China. Energy Build. 2015, 109, 361–368. [Google Scholar] [CrossRef]

- Zhu, Q.Q.; Ran, L.L.; Zhang, Y.C.; Guan, Q.F. Integrating geographic knowledge into deep learning for spatiotemporal local climate zone mapping derived thermal environment exploration across Chinese climate zones. ISPRS J. Photogramm. Remote Sens. 2024, 217, 53–75. [Google Scholar] [CrossRef]

- Yang, Y.R.; Liu, Y.; Zhang, Y.H.; Shu, S.L.; Zheng, J.S. DEST-GNN: A double-explored spatio-temporal graph neural network for multi-site intra-hour PV power forecasting. Appl. Energy 2025, 378, 124744. [Google Scholar] [CrossRef]

- Liu, S.; Ye, W.; Wu, Y.; Ye, Z. An improved tiered electricity pricing scheme considering energy saving and carbon reduction, cross-subsidy handling, and user demands. Energies 2025, 18, 2610. [Google Scholar] [CrossRef]

- Yu, J.H.; Yang, C.Z.; Tian, L.W.; Liao, D. A study on optimum insulation thicknesses of external walls in hot summer and cold winter zone of China. Appl. Energy 2009, 86, 2520–2529. [Google Scholar] [CrossRef]

- Huang, H.K.; Zhou, Y.J.; Huang, R.D.; Wu, H.J.; Sun, Y.J.; Huang, G.S.; Xu, T. Optimum insulation thicknesses and energy conservation of building thermal insulation materials in Chinese zone of humid subtropical climate. Sustain. Cities Soc. 2020, 52, 101840. [Google Scholar] [CrossRef]

- Zhou, H.; Pervaiz, A.; Bukhari, W.A.; Bukhari, A.A.; Sadiq, S.Z. Green technology and stringent environmental policy interactions in a spatial context: Assessing domestic and cross-border CO2 emission reductions in border sharing OECD economies. J. Environ. Manag. 2025, 391, 126435. [Google Scholar] [CrossRef]

- Bi, Y.; Sun, M.; Jing, S.; Hou, D.; Zhuang, W.; Chen, S.; Jiao, X.; Zhao, Q. Interlaminar shear characteristics, energy consumption, and carbon emissions of polyurethane mixtures. Coatings 2022, 12, 400. [Google Scholar] [CrossRef]

- Yang, L.; Wang, S.; Zhang, Z.; Lin, K.; Zheng, M. Current development status, policy support and promotion path of China’s green hydrogen industries under the target of carbon emission peaking and carbon neutrality. Sustainability 2023, 15, 10118. [Google Scholar] [CrossRef]

- Wang, N.; Qu, Z.K.; Li, J.; Zhang, Y.; Wang, H.Y.; Xi, H.; Gu, Z.L. Spatial-temporal patterns and influencing factors of carbon emissions in different regions of China. Environ. Res. 2025, 276, 121447. [Google Scholar] [CrossRef] [PubMed]

- Ke, J.C.; Sheng, N.; Song, Q.B.; Yuan, W.Y.; Li, J.H. Empirical evidence on the characteristics and influencing factors of carbon emissions from household appliances operation in the Pearl River Delta region, China. Appl. Energy 2024, 376, 124191. [Google Scholar] [CrossRef]

- Zhai, Z.Y.; Zhang, L.; Wang, Y.D.; Hou, X.C.; Yang, Q. Optimization of power generation structure and electricity transmission pattern in China based on the electricity-carbon coordinated market. Renew. Energy 2025, 2025, 123359. [Google Scholar] [CrossRef]

- Akan, A.P.; Akan, A.E. Modeling of CO2 emissions via optimum insulation thickness of residential buildings. Clean Technol. Environ. 2022, 24, 949–967. [Google Scholar] [CrossRef]

| Level | Roof Insulation | Wall Insulation | Foundation Wall | External Window | Floor Type |

|---|---|---|---|---|---|

| 1 | A1 | B1 | C1 | D1 | E1 |

| 2 | A2 | B2 | C2 | D2 | E2 |

| 3 | A3 | B3 | C3 | D3 | E3 |

| 4 | A4 | B4 | C4 | D4 | E4 |

| Num. | Roof Insulation (A) | Wall Insulation (B) | Foundation Wall (C) | External Window (D) | Floor (E) | Cooling Load per Unit Area (W/m2) |

|---|---|---|---|---|---|---|

| 1 | 1 | 1 | 1 | 1 | 1 | 186.43 |

| 2 | 1 | 2 | 2 | 2 | 2 | 162.01 |

| 3 | 1 | 3 | 3 | 3 | 3 | 160.19 |

| 4 | 1 | 4 | 4 | 4 | 4 | 154.28 |

| 5 | 2 | 1 | 2 | 3 | 4 | 159.65 |

| 6 | 2 | 2 | 1 | 4 | 3 | 155.46 |

| 7 | 2 | 3 | 4 | 1 | 2 | 179.02 |

| 8 | 2 | 4 | 3 | 2 | 1 | 165.00 |

| 9 | 3 | 1 | 3 | 4 | 2 | 158.64 |

| 10 | 3 | 2 | 4 | 3 | 1 | 164.20 |

| 11 | 3 | 3 | 1 | 2 | 4 | 163.19 |

| 12 | 3 | 4 | 2 | 1 | 3 | 180.28 |

| 13 | 4 | 1 | 4 | 2 | 3 | 167.04 |

| 14 | 4 | 2 | 3 | 1 | 4 | 186.11 |

| 15 | 4 | 3 | 2 | 4 | 1 | 151.78 |

| 16 | 4 | 4 | 1 | 3 | 2 | 162.28 |

| k1 | 165.72 | 167.94 | 166.84 | 182.96 | 166.85 | - |

| k2 | 164.78 | 166.95 | 163.43 | 164.31 | 165.48 | - |

| k3 | 166.58 | 163.55 | 167.49 | 161.58 | 165.74 | - |

| k4 | 166.80 | 165.46 | 166.13 | 155.04 | 165.81 | - |

| R | 2.02 | 4.39 | 4.06 | 27.92 | 1.36 | - |

| Layers | Material Name | Thermal Conductivity (W/m·K) | Density (kg/m3) | Specific Heat Capacity (J/kg·K) | Thickness (mm) |

|---|---|---|---|---|---|

| 1 | Cement mortar | 0.93 | 1800 | 1050 | 15 |

| 2 | EPS insulation | 0.039 | 25 | 1380 | Optimum thickness |

| 3 | Cement mortar | 0.93 | 1800 | 1050 | 15 |

| 4 | Waterproof layer | 0.23 | 900 | 1620 | 5 |

| 5 | Reinforced concrete | 1.74 | 2500 | 920 | 240 |

| 6 | Cement mortar | 0.93 | 1800 | 1050 | 20 |

| Name of Power Grid | Carbon Emission Factor (kgCO2e/KWh) |

|---|---|

| Northeast China power grid | 0.7769 [55] |

| Northwest China power grid | 0.6671 [55] |

| North China power grid | 0.8843 [56] |

| Central China power grid | 0.5257 [56] |

| East China power grid | 0.7035 [57] |

| Southern China power grid | 0.5271 [57] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, R.; He, Z.; Guo, C.; Wang, H. Integrated Optimization Method of External Wall Insulation for Granaries in Different Climate Regions in China. Sustainability 2025, 17, 7489. https://doi.org/10.3390/su17167489

Liu R, He Z, Guo C, Wang H. Integrated Optimization Method of External Wall Insulation for Granaries in Different Climate Regions in China. Sustainability. 2025; 17(16):7489. https://doi.org/10.3390/su17167489

Chicago/Turabian StyleLiu, Ruili, Zhu He, Chengzhou Guo, and Haitao Wang. 2025. "Integrated Optimization Method of External Wall Insulation for Granaries in Different Climate Regions in China" Sustainability 17, no. 16: 7489. https://doi.org/10.3390/su17167489

APA StyleLiu, R., He, Z., Guo, C., & Wang, H. (2025). Integrated Optimization Method of External Wall Insulation for Granaries in Different Climate Regions in China. Sustainability, 17(16), 7489. https://doi.org/10.3390/su17167489