Abstract

The plastics manufacturing sector has experienced remarkable growth, requiring more optimized operations through reduced repair times and product defects. In this context, the theoretical aim of this research is to prove that the integration of classic continuous improvement tools (TPM and SMED) with advanced data science techniques (machine learning) forms a synergistic approach capable of significantly increasing operational efficiency in manufacturing environments. The study was conducted at a Peruvian plastic container manufacturing company with a first overall equipment efficiency (OEE) of 61.87%, affected by low availability of injection and blow molding machines and a high rework rate. Total Productive Maintenance (TPM) strategies were implemented to improve equipment maintenance, the SMED method to reduce setup times, and a machine learning model to predict defects and burs in products. The effectiveness of the approach was confirmed through simulations in Arena and analysis of historical data. As a result, OEE increased to 80.86%, reducing downtime and rework. In conclusion, this study shows that the combination of TPM, SMED, and machine learning not only improves operational performance but also offers a replicable and robust methodological framework for process optimization in the manufacturing industry.

1. Introduction

The plastic sector plays a critical role in the global economy, supplying lightweight, durable, and versatile materials used in a broad range of products, from packaging to industrial components. As demand for these products continues to grow, companies in this industry face significant challenges related to operational efficiency, sustainability, and competitiveness, particularly in an increasingly demanding market environment. In the Peruvian context, where small and medium enterprises (SMEs) prevail, the plastic industry contributes approximately 0.5% to the Gross Domestic Product (GDP) and generates thousands of jobs [1].

Plastic sector firms meet operational obstacles, such as outdated technology and inadequate maintenance, leading to inefficiencies that undermine competitiveness and market responsiveness. To address these issues, companies have adopted Total Productive Maintenance (TPM) strategies, including planned maintenance and operator-driven activities, to reduce equipment failures, enhance machine availability, and minimize downtime [2]. Additionally, SMED has proven effective in cutting setup times, enabling faster batch transitions and reducing production delays [3]. Furthermore, Industry 4.0 advancements, such as AI-driven predictive maintenance and the Internet of Things (IoT), facilitate real-time equipment monitoring, enabling proactive actions to prevent failures and boost machine performance and efficiency [4].

Low operational efficiency, a common issue in manufacturing, particularly affects the plastic industry, where a low OEE is tied to poor maintenance, extended setup times, and lack of production control [5]. This inefficiency not only impacts production capacity but also incurs additional costs from failure management, poor product quality, and order fulfillment penalties [6].

The key contribution of this paper is the integration of TPM, SMED, and machine learning to improve operational efficiency in plastic packaging production, which distinguishes it from earlier approaches that applied these tools independently. TPM was specifically implemented through the third pillar, planned maintenance, with the aim of improving the mechanical availability of injection molding and blow molding machines. The machines with the greatest impact on operational efficiency were found to prioritize their maintenance. Preventive maintenance tasks (cleaning, inspection of critical parts, calibration of sensors, etc.) were set up with specific frequencies. Standardized maintenance manuals were developed, along with a maintenance planning and control dashboard. On the other hand, SMED (Single Minute Exchange of Die) was applied with the aim of significantly reducing machine setup times, especially during mold changes, configurations, and cleaning, on injection and blow molding machines. A study of current mold change and machine setup procedures was conducted, and tasks were classified as internal and external. Tasks that were previously performed with the machine stopped (such as tool preparation or mold verification) were moved to be performed while the equipment was still running, minimizing downtime. Critical activities were simplified, redundant steps were eliminated, and standardized procedures were set up for setup, cleaning, and adjustment.

Unlike TPM and SMED, which focus on structural and organizational improvements in maintenance and readiness, Machine Learning was implemented as a predictive and real-time control tool. A database was compiled with multiple production variables from injections and blow molding machines. The information was cleaned and normalized to feed the model. XGBoost, a decision tree-based regression algorithm, was used and trained to predict two key variables: percentage of wasted material and percentage of defective products.

This article is structured by a literature review, followed by an outline of the methodology used to analyze the production plant’s current state, identifying key efficiency issues impacting productivity. After that, it details the implemented tools for process optimization and the validation approach, including Arena simulations and Machine Learning model validation with historical data. Next, the article presents the validation process, demonstrating tool application and evaluation, followed by results from simulations and validation, and a discussion analyzing the impact of implemented improvements on operational efficiency.

2. Literature Review

2.1. The Third Pillar of TPM: Planned Maintenance

The third pillar of TPM, known as Planned Maintenance, focuses on ensuring equipment runs without failure from the preliminary stages of its life cycle. This approach is crucial for minimizing future issues, reducing downtime, and maximizing equipment durability and efficiency [7]. By integrating operational ability during the design, installation, and commissioning phases, planned maintenance perfects equipment performance from the outset, preventing premature failures and ensuring operational continuity in production plants [8]. In one plastics production plant, a 13% increase in OEE, a 48% reduction in mold changeover time from 4.82 h to 2.49 h, and a 0.77% decrease in the rate of defective products, from 2.7% to 1.93%, were achieved thanks to the application of preventive and autonomous maintenance, and improved organization and availability of tools [9]

2.2. SMED for Reducing Setup Times of Blow and Injection Molding Machines

In the realm of operational efficiency improvement, SMED has emerged as a key methodology for reducing tool changeover times and enhancing production flexibility. This technique focuses on converting internal activities (those requiring machine stoppage) into external ones (performable while the machine operates) and optimizing internal tasks to shorten their duration [10]. Through the standardization of procedures and simplification of tasks, SMED enables a significant reduction in setup times, directly contributing to greater machine availability. The use of SMED not only boosts operational efficiency but also reduces costs by minimizing non-productive time [11]. SMED has demonstrated its effectiveness in a bus assembly company, achieving a 56.2% reduction in model changeover time in the body assembly line, optimizing tasks, and eliminating unnecessary ones [12].

2.3. Machine Learning for Reducing Defective Products

Machine Learning, a branch of artificial intelligence, enables systems to automatically learn from data and improve their performance without explicit programming, allowing machines to identify patterns in large datasets to make predictions or decisions without direct human intervention [13]. In the context of plastic packaging production, Machine Learning is used to model and predict critical mechanical properties of polymers during the rotomolding process, optimizing parameters such as oven residence time to achieve superior quality products [14]. In one study, a real-time monitoring system with temperature and flow sensors was implemented using Artificial Neural Networks and Multiple Linear Regression to predict critical dimensions in molded parts, achieving an accuracy of 99.79% in the prediction of part diameter and improving quality control [15]. In another study, an automated online quality control system based on Artificial Intelligence was developed using Convolutional Neural Networks (CNN) for surface quality analysis and real-time adjustments, achieving an 85% improvement in the quality of molded surfaces and a 20% reduction in production scrap [16].

2.4. Sustainability in Plastic Container Production

Industrial sustainability is not limited solely to the choice of materials or the final disposal of waste but extends to the design and efficient operation of production processes. In the specific case of plastic container manufacturing, there is a direct relationship between operational efficiency and environmental performance: the greater the efficiency of the process, the lower the energy consumption, waste generation, and need for reprocessing [17]. Studies have shown that technologies such as injection molding, when run efficiently, can offer a significantly lower environmental footprint than alternative methods such as additive manufacturing (FFF), due to shorter cycle times and more controlled energy consumption [18]. This shows that improvements in efficiency not only impact productivity but also reduce the environmental impact associated with the intensive use of energy and raw materials [19]. Likewise, it has been documented that preventive maintenance practices (TPM) and setup time optimization (SMED) contribute to sustainability by minimizing downtime, unexpected failures, and variability in product quality [20]. When these inefficiencies are not corrected, they generate material and energy waste that increases the ecological footprint of the process, which is particularly relevant in sectors such as plastics, where waste has a high environmental cost [21].

In the context of plastic packaging production, improving operational efficiency is not only a competitive strategy but also a key approach to achieving more sustainable production by reducing resource intensity per unit of product and perfecting the environmental performance of the production process.

3. Methodology

3.1. Analysis

The methodology used to diagnose the problem of low efficiency in the production of plastic packaging includes several tools and techniques used to identify the root causes. Initially, information was gathered on the production process by measuring data on machine performance, quality, and availability. Subsequently, overall equipment efficiency (OEE) Analysis was used for each area of the company, which allowed the identification of the areas with the highest inefficiency and the underlying causes.

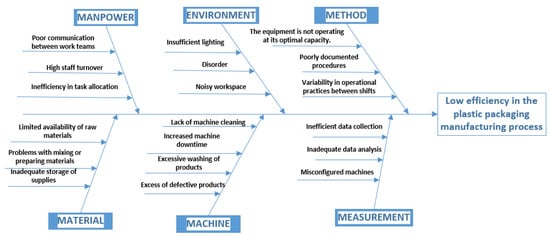

To further analyze the causes, tools such as the Ishikawa Diagram, the 5 Whys Analysis, and the creation of a Problem Tree were applied. The Ishikawa Diagram shown in Figure 1 helped visualize the main causes of low efficiency, such as lack of proper machine maintenance, excessive casting, and production defects. The 5 Whys Analysis identified root causes such as wear and tear on critical components, lack of standardization in setup times, injection speed adjustments without visual control of the screw status (a component that influences speed), and inadequate cooling cycle time settings. Finally, the Problem Tree was a key tool for structuring the relationships between the different factors affecting operational efficiency and enabled the design of specific corrective actions.

Figure 1.

Ishikawa diagram.

This diagnosis was complemented by a detailed analysis of the OEE for each area, as shown in Table 1, to identify the main bottleneck, which reflected the low availability and performance of the blow molding machines and injection molding machines in the transformation area, with an average OEE of 61.9%, contributing to the high cost of rework and production failures.

Table 1.

OEE evaluation results by work area.

3.2. Validation Foundations

Initially, TPM and SMED were selected for validation using Arena Simulation software version 16. This tool enabled modeling and simulation of production processes, replicating pre-improvement and post-improvement conditions. The Input Analyzer, included with Arena, was used to determine the distribution of each dataset. Through these simulations, the impact of improvements on equipment availability and setup time reduction was assessed, theoretically enhancing operational efficiency.

For Machine Learning, validation relied on historical production data. The model was trained with this data to predict failures and adjust operational parameters in real time. This validation process evaluated the model’s predictive accuracy, its effectiveness in detecting failures, and its ability to optimize production parameters. Cross-validation techniques and test sets were applied to ensure the model performed reliably under real production conditions.

To develop the validation models, a detailed collection of historical production data was conducted, encompassing operating times, failure incidents, downtime, and other relevant operational parameters. This information was processed and analyzed to build accurate models simulating the plant’s behavior before and after the implementation of improvements.

4. Contribution

4.1. Rationale

The proposed model integrates the third pillar of TPM (Planned Maintenance), SMED, and Machine Learning to optimize processes in the plastic industry. The application of planned maintenance in this sector significantly reduces downtime due to failures and increases injection machine efficiency by 15%, enhancing productivity and reducing waste [19,20]. The implementation of SMED allows for a reduction of up to 40% in machine setup times, including critical activities such as mold changes, configuration, and cleaning [21,22]. Additionally, the model incorporates Machine Learning to predict the quality of molded products with 90% accuracy, minimizing defects and reducing process variability [23,24].

4.2. Model Implemented

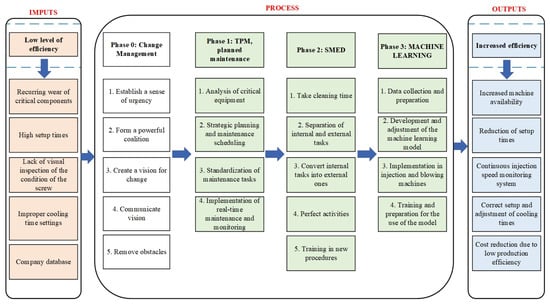

The proposed general model, detailed in the following sections, aims to improve operational efficiency in plastic packaging production through a structured three-phase approach integrating TPM, SMED, and Machine Learning. This framework targets key inefficiencies, including prolonged downtime, extended setup times, and elevated defect rates such as flash and defective products, by enhancing equipment reliability, optimizing setup processes, and employing data-driven predictive maintenance. The initial phase establishes a foundation via planned maintenance and process standardization, followed by a second phase that reduces setup durations through task reallocation and optimization [25]. The final phase leverages Machine Learning for real-time data analysis and parameter adjustments. Implemented within a Peruvian SME in the plastic sector, this model seeks to boost machine availability, streamline production, and reduce costs associated with inefficiencies, presenting an innovative solution for under-explored industrial settings [26,27]. The model’s structure and implementation are illustrated in Figure 2.

Figure 2.

General model implemented.

4.3. Detail in the Relation to Model

The model, outlined in Figure 2, is a four-phase framework designed to enhance operational efficiency in plastic packaging production within a Peruvian SME. It integrates Change Management, TPM, SMED, and Machine Learning to address inefficiencies such as unplanned downtime, extended setup times, and defect-related challenges (e.g., flash). Each phase is structured to systematically develop and implement strategies that build upon one another, targeting a comprehensive improvement in production processes.

Component 1: Planned Maintenance

Step 1: Critical Equipment Analysis

A preliminary critical analysis was carried out for the injection and blow molding machines as a first step to propose a planned maintenance plan. A multidisciplinary team, made up of operators, technicians, supervisors, and engineers, applied the FMEA method (Analysis of Failure Modes and Effects) to identify potential failures. This analysis evaluated severity (S), occurrence (O), and detection (D), calculating a risk priority number (RPN) to prioritize interventions. In the injectors, leaks in hydraulic systems and wear of key components were observed, while in the blowers, thermal deviations and mechanical misalignments were detected, affecting operational continuity (Table 2).

Table 2.

Results of the FMEA analysis of critical equipment.

Step 2: Strategic planning and maintenance scheduling

A maintenance plan was developed for the injection and blow molding machines, based on the findings of Step 1, where critical failure modes such as hydraulic leakage, component wear, thermal deviations, and mechanical misalignments were identified. The aim is to prevent these failures, ensure the operational continuity of the production line and optimize the performance of the equipment.

Maintenance activities focus on the main components of each piece of equipment, with frequencies defined by both calendar times (daily, weekly, monthly, quarterly, yearly) and hours of use, to ensure flexible and effective scheduling. Below are the maintenance tables for each type of machine (Table 3).

Table 3.

Maintenance scheduling for injectors.

Table 4 shows the maintenance schedule for blow molding machines.

Table 4.

Maintenance scheduling for blow molding machines.

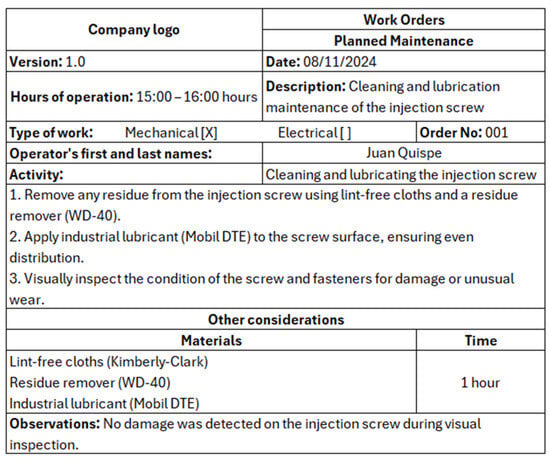

Step 3: Standardization of maintenance tasks

Maintenance tasks for injection and blow molding machines were standardized, with the aim of ensuring that all activities are carried out consistently, safely, and efficiently Figure 3. Standardization is crucial in the manufacturing industry, as it reduces human error, improves operational safety, and facilitates staff training.

Figure 3.

Work order format.

Step 4: Implementation of maintenance and real-time monitoring

To ensure continuous control over equipment performance and maintenance activities, a real-time monitoring KPI dashboard was developed. This tool provides immediate visibility of key performance indicators, allowing quick decision-making and prompt corrective actions when deviations occur Figure 4.

Figure 4.

Real-time monitoring KPI dashboard. Adapted from [28].

To measure the efficiency of the proposed maintenance plan, a real-time monitoring system is proposed to supervise it.

The implementation of TPM required an investment of $65,912. This amount includes staff training in maintenance routines, the purchase of machinery components, maintenance labor, the design and printing of manuals and operating guides, as well as the implementation of the planned maintenance control panel, which includes system development and the acquisition of support materials. These activities are essential to improving the availability of critical equipment in injection and blow molding machines, one of the main sources of efficiency loss identified.

Component 2: SMED

Step 1: Take time

In this initial phase, detailed measurement of the times associated with the setup activities, including cleaning, mold change, and configuration, was carried out for the injection and blow molding machines. This step is essential to establish a baseline that allows identifying opportunities for improvement in rapid change processes. A time study summary sheet format was designed, based on the best practices of the SMED methodology, to record each activity, its duration, and its preliminary classification as internal (performed with the machine stopped) or external (executable before or after the stop). The summary of the time quantification is presented in the following table (Table 5).

Table 5.

Time-taking of setup activities by machine.

Step 2: Separation of internal and external tasks

In this second stage, the classification of the setup activities recorded in Phase 1 was carried out, dividing them into internal tasks, performed while the machine remains stopped, and external tasks, executable outside the idle period. This process is key to minimizing downtime, fostering more agile and efficient operations on the production line. A detailed analytical approach, based on previously measured times, was used to evaluate each activity and define its nature, considering the availability of resources and the operational sequence.

Step 3: Turn internal activities into external ones

Internal tasks, performed during machine shutdown, were transferred to external activities executable before or after shutdown, with the aim of reducing setup times. To this end, the recorded operations were analyzed in detail, evaluating whether each task could be executed outside the idle period, considering the availability of tools and the coordination of the team. Practical solutions, such as quick-connect systems and pre-assembled kits, were implemented based on the previous analysis.

The activities selected for this conversion were chosen for their feasibility to be prepared in advance or to be carried out at non-productive times. For example, hose handling and tool collection became external using quick-coupling equipment and pre-configured assemblies, eliminating interventions during shutdown. Similarly, the preparation of the new mold and the verification of the refrigeration systems were relocated as external by being organized before the stoppage, minimizing the dependence on the idle machine. In addition, the discharge of excess material and the cleaning of ventilation areas were delegated to periods of low activity, optimizing the workflow.

Step 4: Refine Activities

Work was done to perfect the setup tasks that remained after the previous stages, focusing on eliminating redundant actions and adjusting processes to achieve greater efficiency. Specific improvements were implemented, such as the use of quick-anchor systems to disassemble molds, soft-bristled brushes to clean cavities, and specialized cleaning agents for the nozzles, reducing setup times by 35%. Table 6 presents a comparison of times before and after these improvements.

Table 6.

Setup time after converting activities.

For the implementation of the SMED methodology, an investment of $534 was presented. This amount mainly covers the training of operational and maintenance personnel in techniques to reduce setup times, the standardization and redesign of mold change procedures, and the adaptation of the layout of tools and materials to facilitate quick changes. This investment aims to reduce downtime during machine setup, especially in injection molding and blow molding processes.

Component 3: Machine Learning

Step 1: Data collection and preparation

The data utilized for the machine learning model were extracted from the historical production records of the company under study, stored in a CSV file. These records were loaded into a Python 3.11.16 notebook using the pandas library for preprocessing. The dataset for injection molding machines comprises 4502 records, while the dataset for blow molding machines includes 1855 records. Preprocessing steps included cleaning null values by replacing them with zeros and removing duplicate records to ensure data quality. The variables collected for injection molding machines are presented in Table 7, while those for blow molding machines are detailed in Table 8.

Table 7.

Comparison of times before and after the SMED.

Table 8.

Variables of injection molding machines.

Below are the variables of blow molding machines (Table 9).

Table 9.

Variables of blow molding machines.

Step 2: Model Selection and Evaluation

To identify the most effective machine learning model for predicting Percentage Flash and Percentage Defective in injection molding and blow molding processes, a rigorous evaluation of regression algorithms was conducted. These target variables were selected due to their critical role in assessing quality, as they quantify excess material (flash) and defective products, both of which significantly influence production efficiency and cost in plastic manufacturing.

For injection molding, five regression models were evaluated: Linear Regression, Random Forest Regressor, XGBoost Regressor, Support Vector Regressor (SVR) with a radial basis function (RBF) kernel, and a Multi-Layer Perceptron (MLP) Neural Network with two hidden layers (100 and 50 neurons). The evaluation was performed using Python with scikit-learn and XGBoost libraries. For each machine, the dataset was partitioned into training (80%) and testing (20%) sets, employing a random seed of 42 for reproducibility. Features were standardized using StandardScaler to ensure model consistency. Performance was assessed using Mean Absolute Error (MAE), Root Mean Square Error (RMSE), and R2 score, with MAE as the primary selection criterion due to its direct relevance to prediction accuracy. Machines with fewer than 15 records were excluded to ensure robust model training (Table 10).

Table 10.

Best model performance per machine and target variable for injection molding.

For blow molding machines, the same five regression models (Linear Regression, Random Forest, XGBoost, SVR, and MLP Neural Network) were evaluated using Python with scikit-learn and XGBoost libraries. The dataset for each machine was split into training (80%) and testing (20%) set with a random seed of 42, and features were standardized using StandardScaler. Performance was assessed using MAE, RMSE, and R2, with MAE as the primary metric. Machines with fewer than 10 records were excluded to ensure reliable modeling (Table 11).

Table 11.

Best model performance per machine and target variable for blow molding.

The target variables, Percentage Flash and Percentage Defective, were prioritized as they directly address critical quality issues in plastic manufacturing, impacting production costs and product quality. XGBoost was selected as the sole model for both injection and blow molding due to its exceptional predictive performance, as evidenced by low MAE values (0.0000–0.0082 for injection molding, 0.0000–0.0027 for blow molding) and high R2 scores (0.9992–1.0 for injection molding, 0.9256–1.0 for blow molding). Its gradient boosting framework excels at capturing complex, non-linear relationships between process parameters and quality outcomes, making it ideal for modeling the intricate dynamics of both manufacturing processes. For injection molding, XGBoost’s consistent performance across all machines ensured reliable predictions. For blow molding, Bayesian hyperparameter optimization further enhanced XGBoost’s ability to model diverse machine behaviors, providing a robust and unified approach. This selection supports subsequent optimization efforts to meet quality targets of less than 5% for Percentage Flash and less than 3% for Percentage Defective.

Step 3: Model training optimization

Following the selection of the XGBoost Regressor in Step 2 for predicting Flash Percentage and Defective Percentage, this step details the mathematical formulation, training, and optimization of machine-specific XGBoost models for injection molding and blow molding processes. These target variables, representing excess material (flash) and defective products, are critical quality metrics that impact production efficiency and cost in plastic manufacturing. The process involved training models, optimizing hyperparameters using Bayesian optimization, and simulating optimal operating conditions within physically realistic parameter ranges to minimize quality defects.

The XGBoost Regressor constructs an ensemble of decision trees to predict continuous outcomes, such as Flash Percentage and Defective Percentage. For a dataset with n observations , where is the feature vector is the target variable, the prediction is given by:

where is the output of the decision tree, and K is the number of trees. The model minimizes a regularized objective function:

where the loss function for regression is the squared error, , and the regularization term is:

with as the number of leaves in tree , as leaf weights, controlling tree complexity, as the L2 regularization parameter, and α as the L1 regularization parameter. The optimization proceeds iteratively via gradient boosting, where each tree fits the negative gradient of the loss:

For injection molding machines, XGBoost models were trained separately for each machine to predict Flash Percentage and Defective Percentage. The dataset was filtered to include only machines with at least 15 records to ensure robust training. The feature set included process parameters (e.g., injection pressure, holding pressure, melt temperature, mold temperature, cycle time, cooling time, ejection time, holding time, injection speed, mold cavities) and production variables (e.g., product weight, required production, total production, average gross weight, polypropylene consumption, pigment consumption, reprocessed material percentage). The target variable were . The dataset was split into training (80%) and testing (20%) sets:

Features were standardized to zero mean and unit variance:

where and are the mean and standard deviation of feature j. Non-numeric features were converted to numeric, and rows with missing values were removed.

Hyperparameter optimization was conducted using BayesSearchCV from the scikit-optimize library, maximizing negative Mean Absolute Error (MAE):

over a search space Θ:

- Number of estimators: nestimators ∈ [100, 500],

- Learning rate: η ∈ [0.01, 0.2] (log-uniform),

- Maximum depth: dmax ∈ [3, 10],

- Subsample ratio: s ∈ [0.6, 1.0],

- Column sample by tree: ctree ∈ [0.6, 1.0],

- L1 regularization: α ∈ [0, 1.0],

- L2 regularization: λ ∈ [0, 1.0].

The optimization performed 40 iterations with 5-fold cross-validation to select

Optimal operating conditions were identified using a Monte Carlo simulation with 5000 iterations. For each iteration t = 1, ….. 5000, adjustable parameters were sampled from uniform distributions within physical ranges:

for parameters: injection pressure (800–2000 bar), holding pressure (300–1200 bar), melt temperature (180–300 °C), mold temperature (20–90 °C), cycle time (5–60 s), cooling time (2–40 s), ejection time (0.5–5 s), holding time (1–15 s), injection speed (50–150 mm/s), and mold cavities (1–16). Non-adjustable features were fixed at their mean values:

The simulated feature matrix was standardized, and predictions were computed:

Viable conditions satisfied:

Feature importance was computed as the gain in loss reduction per feature.

For blow molding machines, XGBoost models were trained similarly, with datasets filtered for at least 10 records. The feature set included process parameters (e.g., parison extrusion time, mold closing time, blowing time, cooling time, ejection time, blowing pressure, airflow rate, mold cavities) and production variables (e.g., product weight, required production, total production, average gross weight, polypropylene consumption, pigment consumption, reprocessed material percentage). Data preprocessing, splitting, and standardization followed the same methodology. Hyperparameter optimization used BayesSearchCV with the same search space and settings.

Monte Carlo simulation sampled parameters within physical ranges: melt temperature (170–250 °C), mold temperature (15–70 °C), cycle time (8–60 s), parison extrusion time (1–12 s), mold closing time (0.5–6 s), blowing time (0.5–12 s), cooling time (2–25 s), ejection time (0.5–6 s), blowing pressure (30–150 psi), airflow rate (100–200 L/min), and mold cavities (1–8, fixed to the mode). Predictions identified viable conditions meeting quality targets, and feature importance was analyzed.

The training process produced robust XGBoost models, with Bayesian optimization ensuring optimal hyperparameters by maximizing negative MAE. Monte Carlo simulations identified viable parameter settings, enabling practical adjustments to minimize Flash Percentage and Defective Percentage. Feature importance analysis highlighted critical parameters, such as injection pressure for injection molding and blowing pressure for blow molding, guiding process optimization.

Step 4: Evaluation Metrics

To evaluate the XGBoost models for predicting the proportion of flash and percentage of defective products in injection and blow molding machines, mean absolute error (MAE), coefficient of determination (R2), and mean squared error (MSE) from 5-fold cross-validation were calculated on the 20% test set, with performance metrics for injection molding machines summarized separately from those for blow molding machines (Table 12).

Table 12.

Metrics of the XGBOOST regressor model for injectors.

The XGBoost model for injection molding machines demonstrates excellent performance, with a mean absolute error (MAE) of 0.1272 for the proportion of flash and 0.0596 for the percentage of defective products, indicating highly accurate predictions, while the coefficient of determination (R2) values of 0.9813 for flash and 0.9936 for defective products reflect a near-perfect fit to the data, further supported by mean squared error (MSE) values from 5-fold cross-validation of 0.4647 for flash and 0.0379 for defective products, confirming strong generalizability and robustness for both metrics (Table 13).

Table 13.

Metrics of the XGBOOST regressor model for blowers.

For blow molding machines, the XGBoost model shows acceptable to good performance, with an MAE of 0.3068 for the proportion of flash indicating moderate error and an R2 of 0.8657 suggesting a reasonable fit with some variability, while the MAE of 0.0953 and R2 of 0.9719 for the percentage of defective products demonstrate high accuracy and a superior fit, reinforced by a low MSE from cross-validation of 0.0195, highlighting the model’s particular effectiveness for predicting defective products.

The implementation of the machine learning model had a budget of $3 436, distributed across three main components: training technical staff in data science and the use of predictive models, contracting the development of the machine learning model based on XGBoost, and implementing the system to predict and monitor critical variables in the plant. This tool allows for the optimization of operating parameters in real time to minimize defects and waste, complementing the physical actions developed with TPM and SMED.

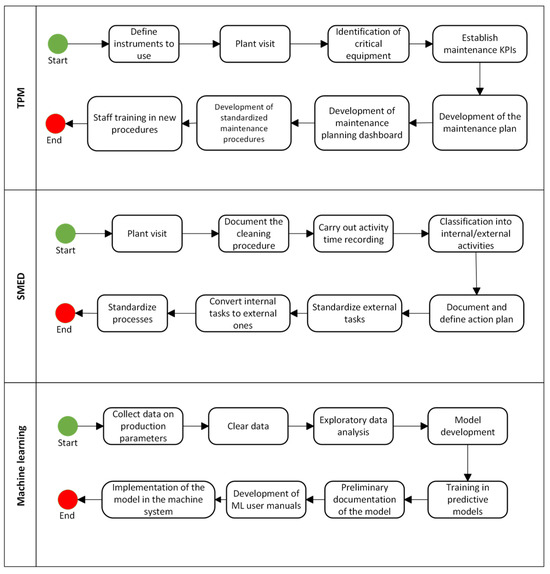

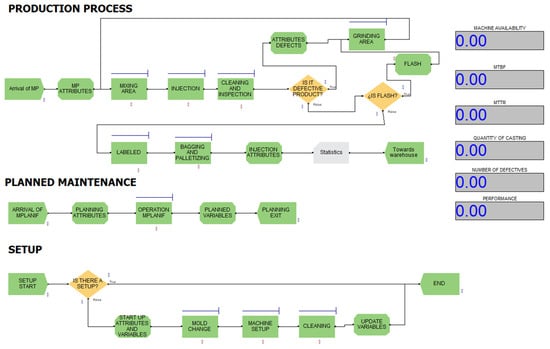

4.4. Process Implemented

As outlined in the previous section, the flowchart presented in Figure 5 illustrates the key phases and procedures associated with each tool to be implemented. This diagram provides an overview of the steps designed for TPM, SMED, and Machine Learning, tailored to the operational context of the manufacturing system under study.

Figure 5.

Process implemented.

4.5. Main Indicators

The Overall Equipment Effectiveness (OEE) indicator was selected as the main metric because it provides a comprehensive and quantifiable view of equipment operational performance, allowing for the structured identification of the main causes of inefficiency in manufacturing systems. OEE evaluates three critical dimensions: availability (time that the equipment is effective in production), performance (actual operating speed versus ideal speed), and quality (proportion of good products relative to total production). This structure directly coincides with the root causes identified in the initial diagnosis: recurrent wear of critical components, long setup times, injection speed adjustments made without visual control of the screw status, and inadequate configuration of cooling cycle times. To complement this comprehensive measurement, the mean time to repair (MTTR) and mean time between failures (MTBF) indicators were incorporated, which are essential for evaluating the reliability and maintainability of the equipment. MTTR reflects how quickly equipment can be recovered after a failure, while MTBF indicates the average time between two consecutive failures. These two indicators are essential within the TPM approach, as they allow the impact of planned maintenance on operational continuity to be measured. Their inclusion allows the availability component of OEE to be broken down, providing a more accurate view of the root causes of downtime and facilitating the prioritization of improvement actions. Other key indicators include the defective product rate and the casting rate to assess the number of reprocesses generated in production. These indicators allow for a comprehensive assessment, aligned with the central objective of improving operational efficiency in the production of plastic containers.

This research used the following indicators to measure the performance of the implemented proposal, as presented in Table 14.

Table 14.

Indicators Used to Measure Proposal Performance.

5. Validation

5.1. Description of the Validation

The validation approach in this study employs a pilot simulation that integrates the third pillar of TPM-planned maintenance-alongside SMED and a Machine Learning model based on gradient boosting regression. This Machine Learning model calculates the optimal proposed values for the production parameters of plastic containers and predicts the percentage of runners and defective products that could result from this configuration [29]. These forecasted outcomes were incorporated into the Arena simulator, combining the three methodologies to assess the potential increase in the production of plastic container batches achievable. The selection of this pilot simulation is grounded in its ability to evaluate the proposed strategies under controlled conditions, supported by the effectiveness demonstrated in similar industrial studies [9]. This approach validates the technical feasibility, promotes operational adaptability, and maximizes efficiency in the production process.

5.2. Initial Diagnosis and Previous Studies

The company under investigation specializes in the production of plastic containers, including pesticide bottles, gallons, and buckets. The initial assessment revealed that the OEE for its injection and blow molding machines averages 61.87%, which is notably lower than the benchmark of 81.67% observed in a peer company within the same sector [30]. This performance discrepancy has led to a significant economic impact, accounting for 5.94% of the company’s revenue in 2023. To address this inefficiency, the implementation of TPM, SMED, and Machine Learning techniques is proposed to achieve favorable outcomes. Previous studies underscore the efficacy of TPM in enhancing machine reliability and reducing downtime, often validated through simulation-based approaches. Likewise, literature supports SMED’s effectiveness in reducing setup times, frequently assessed using simulation tools like Arena due to their efficiency in limited timeframes.

Additionally, Machine Learning applications, particularly predictive models, have been recognized for improving production quality by forecasting defect rates, with research advocating their use in process optimization within the sector.

5.3. Validation Design

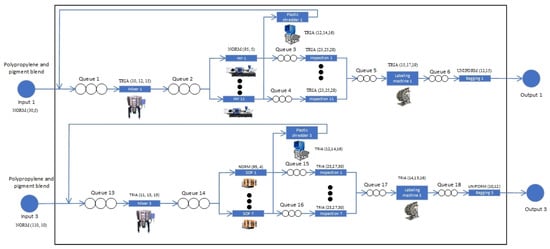

The validation design for the simulation pilot relies on operational data gathered from a plastic packaging plant operating 18 machines, encompassing both injection molding and blow molding units. These machines are categorized into two primary groups based on their production capacity. Injection molding machines bear the code “INY” and carry identifiers beginning with the letter “I,” whereas blow molding machines utilize the code “SOP” and feature labels starting with the letter “S.” This classification appears in Table 15. Additionally, each machine type is further divided by size into large and small categories. Specifically, “INY1” and “SOP1” denote large-capacity machines for injection and blow molding, respectively, while “INY2” and “SOP2” represent smaller-capacity units. This distribution is depicted in Figure 6.

Table 15.

Classification of Machines by Type and Code.

Figure 6.

Representation of the Production Process System.

The SMED process commenced with a detailed analysis of current setup activities, identifying internal tasks (performed during machine downtime) and external tasks (conductable during operation). The next step involved converting internal tasks to external ones where feasible, followed by optimizing the remaining internal tasks through streamlined procedures and standardized workflows. This approach included eliminating redundant steps and refining tool preparation, aiming to minimize downtime and enhance production flexibility. The effectiveness of these steps is evaluated using simulation data, with results summarized in Table 16, which compares setup times before and after optimization.

Table 16.

Post-Implementation Setup Times After SMED Application (min).

To support the simulation model and improve machine reliability, a planned maintenance schedule was established for both injection and blow molding machines, as shown in Table 17. The schedule includes preventive maintenance tasks such as fillet wear inspections, internal cleaning, seal checks, and resistance measurements, performed at defined intervals (e.g., every 3000 h or 1500 h). Since the plant operates continuously in three shifts of eight hours each, all maintenance activities are conducted during productive hours. The schedule provides key parameters for simulation input: maintenance arrival times, based on the specified frequency intervals, and operation durations, determined by task-specific estimates (e.g., 45 min for spindle inspection, 30 min for cylinder cleaning). These values are incorporated into the simulation model to evaluate their effect on machine downtime and overall equipment availability for both machine types.

Table 17.

Annual Maintenance Plan for Injection Machines.

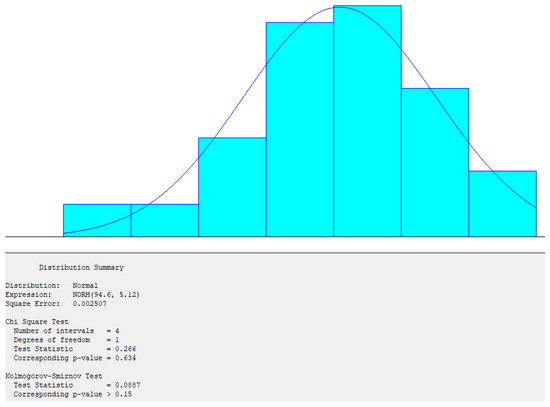

The current production system, illustrated in Figure 6, outlines the operational flow of the plastic packaging plant. To accurately simulate this process in the Arena software 16.20.09, time samples were collected from each area of the system to represent the behavior of different entities. Prior to their implementation in the model, these data were statistically validated using Arena’s Input Analyzer tool, employing both the Chi-square and Kolmogorov-Smirnov goodness-of-fit tests. This procedure ensured the selection of the most appropriate probability distribution for each entity. An example of the fitted distribution is presented in Figure 7, while the complete set of distribution expressions used in the simulation model is summarized in Table 18. The same methodology was consistently applied across all remaining entities in the system.

Figure 7.

Input analyzer results for injection area samples.

Table 18.

Attributes and Distribution Expressions for Production Processes.

The statistical distributions modeling process variability, including operation times, material arrivals, planned maintenance arrivals, and their operations, are detailed in Table 18. This data supports the Arena simulation, enabling accurate recreation of operational conditions to validate the proposed improvements.

Prior to simulating the improved model, a base model was built in Arena to represent the current situation of the production system. This model was calibrated using actual operational data recorded at the plant to validate its accuracy against observed behavior. Subsequently, the results obtained in the simulation were compared with the actual indicators measured, as shown in Table 19, finding a high similarity in key values such as OEE, mechanical availability, performance, and quality, as well as MTBF and MTTR. This agreement validates the representativeness of the simulation model of the current situation, providing confidence to evaluate, under controlled conditions, the impact of the improvements proposed in the optimized model.

Table 19.

Validation of the results of the current situation.

After the results of the current situation were simulated to represent the real situation almost perfectly, the improved model was created, with the proposed improvement integrating the solution tools.

The operational dynamics of the selected plant are modeled in Figure 8, which presents the Arena model of the improved production system. This model visualizes the production flow, integrating the time distributions specified in Table 18, including operating times, material arrivals, planned maintenance arrivals, and maintenance operations. These parameters enable a complete simulation to evaluate process efficiency and validate the proposed improvements.

Figure 8.

Arena model of the current production system.

The model developed in this study is a multiple regression approach based on the XGBoost algorithm, designed to predict and optimize quality and waste indicators (Runners and Defects products) for injection and blow molding machines. It was constructed using detailed operational data presented in Table 20, which encompasses specific variables such as weights, pressures, temperatures, and cycle times, collected from the historical processes of both machine categories.

Table 20.

Variables and Units for Machine Learning Model Data in Injection Machines.

To validate the predictive performance of the XGBoost regression model, three widely accepted metrics were employed: Mean Absolute Error (MAE), coefficient of determination (R2), and Cross-Validated Mean Squared Error (MSECV). These metrics were evaluated separately for the Percentage of Runner Waste (Colada) and the Percentage of Defective Products, across both injection and blow molding machines.

As shown in Table 21, for injection machines, the model achieved an MAE of 0.1272 and an R2 of 0.9813 for Runner Waste, while the MSECV of 0.4647 suggests variability potentially related to changing operational conditions. For Defective Products, the model yielded a MAE of 0.0596, an R2 of 0.9936, and an MSECV of 0.0379, indicating excellent predictive performance with low variability.

Table 21.

Performance metrics of the XGBoost regression model.

In contrast, for blow molding machines, the model’s accuracy in predicting Runner Waste was lower (MAE = 0.3068, R2 = 0.8657), with a higher MSECV of 0.2528, possibly due to the greater complexity of the blow molding process. However, for Defective Products, the model maintained strong performance, with an MAE of 0.0953, an R2 of 0.9719, and an MSECV of 0.0195.

These results demonstrate the model’s strong generalization capabilities across different machine types. Nonetheless, further improvements are recommended for predicting Runner Waste in blow molding machines, where techniques such as feature engineering could enhance model accuracy.

5.4. Comparison with Initial Diagnosis

Following the pilot simulation model, a comparison in Table 22 highlights notable improvements over the initial conditions, reflecting enhanced performance metrics.

Table 22.

As is—To be after simulation.

6. Discussion

The results obtained after implementing the improvements show considerable progress in key performance indicators. OEE (Overall Equipment Effectiveness) reached 80.86%, remarkably close to the proposed target of 81.06%, reflecting a notable optimization in OEE. This increase is based on specific improvements: mechanical availability rose to 90.66% (compared to the first 84.64%), operational performance reached 91.55% (well above the earlier 78.69%), and quality even exceeded the established goal, reaching 97.42%. In terms of reliability, the MTBF improved from 133.22 to 190.875 h, approaching the target of 200 h, while the MTTR was reduced to 1.25 h, proving greater efficiency in maintenance interventions. In addition, machine cleaning times decreased from 265.98 to 191.33 min, and production quality indicators showed remarkable progress, with substantial reductions in the proportion of castings (from 9.59% to 4.82%) and defective products (from 6.02% to 2.62%), exceeding the targets set in both cases. These results confirm the effectiveness of the strategies implemented and reflect a positive impact on both productivity and process quality. These advancements, boosting competitiveness and lowering costs, are supported by the findings presented in Table 23.

Table 23.

Comparison of Key Findings in Plastic Production Studies.

The results obtained after implementing improvements with SMED and TPM in operational processes show significant improvements compared to the initial values, aligning with and exceeding the findings of earlier researchers. Our 18.99% improvement in OEE (from 61.87% to 80.86%) exceeds the 12% increase reported in [33] and the 13% increase in [9], driven by a notable increase in machine availability (from 84.64% to 90.66%) and a reduction of 74.65 min in setup times (from 265.98 to 191.33 min), surpassing the 16.68% reduction (from 236.96 to 197.44 min) in [32]. Quality improved, with a 4.77% reduction in castings and a 3.40% reduction in defects, while a 2.15% reduction was achieved in [34]. This data proves a significant improvement in process efficiency and quality, reflecting the success of the strategies implemented in this article. In addition, the MTBF increased from 133.22 to 190.88 h and the MTTR decreased from 1.56 to 1.25 h, reflecting greater reliability and efficiency than the improvements seen in [9,32].

7. Limitations

The study was conducted in a single Peruvian SME, focusing on injection and blow molding machines. Factors such as local operational practices, machine types, and production scale may limit the generalizability of results to other manufacturing sectors, larger enterprises, or different geographic regions.

The proposed improvements required significant investments ($65,912 for TPM, $534 for SMED, and $3436 for ML), covering training, system development, and equipment upgrades. These costs may be prohibitive for smaller SMEs with limited budgets, potentially hindering the model’s scalability.

The ML model focused on predicting flash and defective product percentages using XGBoost. Other potential applications, such as predictive maintenance for specific machine components or optimization of additional process parameters, were not explored, potentially limiting the model’s overall impact.

The study’s results were based on pilot simulation and short-term implementation. The long-term sustainability of improvements, particularly regarding maintenance adherence and consistent setup time reductions, requires further monitoring to ensure enduring benefits.

8. Conclusions

The implementation of TPM with planned maintenance, SMED, and machine learning has proven to be a robust strategy for enhancing operational efficiency in industrial settings. TPM effectively tackled low mechanical availability due to mechanical and electrical failures, resulting in a significant OEE increase from 61.87% to 80.86%, alongside a rise in mechanical availability from 84.64% to 90.66%, with MTBF improving from 133.22 to 190.88 h and MTTR decreasing from 1.56 to 1.25 h. SMED perfected setup times, reducing them from 265.98 to 191.33 min, improving production flow and continuity. The integration of an XGBoost-based ML model successfully mitigated reprocessing by predicting defective products and excess material (coladas), reducing defective product weight from 6.02% to 2.62% and runner weight from 9.59% to 4.82%. For injection machines, the model showed exceptional predictive accuracy with an MAE of 0.0596 and R2 of 0.9936 for defective products, and an MAE of 0.1272 with R2 of 0.9813 for coladas, despite a moderate MSE CV of 0.4647 showing some variability. For blow molding machines, colada prediction showed moderate accuracy (MAE 0.3068, R2 0.8657) with higher dispersion (MSE CV 0.2528), while defective product prediction remained exceptionally reliable (MAE 0.0953, R2 0.9719, MSE CV 0.0195). These outcomes underscore the synergistic potential of TPM, SMED, and ML in driving process optimization, with future research recommended to enhance colada prediction accuracy in blow molding through advanced feature engineering and data augmentation techniques.

The case study demonstrates solid profitability, with an investment of $69,882 achieving a Net Present Value (NPV) of $202,380. 55 and an Economic Internal Rate of Return (EIRR) of 37.32 percent, significantly higher than the Opportunity Cost of Capital (OCC) of 8.69 percent. The Economic Benefit-Cost Ratio (EBCR) reaches 3.90, indicating that for every dollar invested, 3.90 in profits are generated. In addition, the Economic Payback Period (EPP) is estimated at 2 years and 6 months, allowing for a competitive return on investment. These indicators confirm that the project is financially viable and represents an efficient investment under expected operating conditions.

The main innovation of this study lies in the combination of classic continuous improvement tools with advanced data science techniques, which allowed us to move from reactive interventions to a predictive and proactive model. Unlike previous studies that apply these tools in isolation, this research offers an integrated and validated methodological proposal that is adaptable to manufacturing environments with limited resources, as is the case with many SMEs in the plastics sector in developing countries.

9. Future Works

As future work, pilot implementations of the proposed innovative model are planned, contingent upon the company’s approval and availability. These implementations aim to assess the model’s predictive capabilities under real production conditions and to verify improvements in process control, quality outcomes, and efficiency rates.

In addition, they will enable an assessment of waste reduction, energy consumption, and rework rates. These metrics will serve as validation of the broader operational and sustainability benefits.

Author Contributions

Conceptualization, S.E.L.M. and B.L.N.A.; Methodology, S.E.L.M., B.L.N.A. and R.S.; Validation, S.E.L.M., B.L.N.A. and S.N.; Formal analysis, R.S. and S.N.; Investigation, S.E.L.M. and B.L.N.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Universidad Peruana de Ciencias Aplicadas grant number UPC-EXPOST-2025-1.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Acknowledgments

The authors would like to acknowledge Dirección de Investigación de la Universidad Peruana de Ciencias Aplicadas, which provided financial and research facilities support through UPC-EXPOST-2025-1 and Jadavpur University.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

| OEE | Overall Equipment Effectiveness |

| SMED | Single Minute Exchange of Die |

| TPM | Total Productive Maintenance |

| ML | Machine Learning |

| MP | Raw Material |

| MTTR | Mean Time to Repair |

| MTBF | Mean Time Between Failures |

References

- PRODUCE. Análisis Sectorial Desempeño e importancia de la Industria de Plásticos. Available online: https://www.producempresarial.pe/wp-content/uploads/2025/02/250-PPT_Industria-Plasticos_2019_2024_25.02.25.pdf (accessed on 29 July 2025).

- Hardt, F.; Kotyrba, M.; Volna, E.; Jarusek, R. Innovative Approach to Preventive Maintenance of Production Equipment Based on a Modified TPM Methodology for Industry 4.0. Appl. Sci. 2021, 11, 6953. [Google Scholar] [CrossRef]

- Singh, S.; Agrawal, A.; Sharma, D.; Saini, V.; Kumar, A.; Praveenkumar, S. Implementation of Total Productive Maintenance Approach: Improving Overall Equipment Efficiency of a Metal Industry. Inventions 2022, 7, 119. [Google Scholar] [CrossRef]

- El Kihel, Y.; El Kihel, A.; Bouyahrouzi, E.M. Contribution of Maintenance 4.0 in Sustainable Development with an Industrial Case Study. Sustainability 2022, 14, 11090. [Google Scholar] [CrossRef]

- Sunadi, S.; Purba, H.H.; Paulina, E. Overall Equipment Effectiveness to Increase Productivity of Injection Molding Machine: A Case Study in Plastic Manufacturing Industry. ComTech 2021, 12, 53–64. [Google Scholar] [CrossRef]

- Mohan, R.; Roselyn, J.P.; Uthra, R.A. LSTM Based Artificial Intelligence Predictive Maintenance Technique for Availability Rate and OEE Improvement in a TPM Implementing Plant through Industry 4.0 Transformation. J. Qual. Maint. Eng. 2023, 29, 763–798. [Google Scholar] [CrossRef]

- Wolska, M.; Gorewoda, T.; Roszak, M.; Gajda, L. Implementation and Improvement of the Total Productive Maintenance Concept in an Organization. Encyclopedia 2023, 3, 1537–1564. [Google Scholar] [CrossRef]

- Xiang, Z.T.; Feng, C.J. Implementing Total Productive Maintenance in a Manufacturing Small or Medium-Sized Enterprise. J. Ind. Eng. Manag. 2021, 14, 152–175. [Google Scholar] [CrossRef]

- Quiroz-Flores, J.C.; Vega-Alvites, M.L. Review Lean Manufacturing Model of Production Management under the Preventive Maintenance Approach to Improve Efficiency in Plastics Industry SMEs: A Case Study. South Afr. J. Ind. Eng. 2022, 33, 143–156. [Google Scholar] [CrossRef]

- Oliveira, C.; Lima, T.M. Setup Time Reduction of an Automotive Parts Assembly Line Using Lean Tools and Quality Tools. Eng 2023, 4, 2352–2362. [Google Scholar] [CrossRef]

- Parwani, V.; Hu, G. Improving Manufacturing Supply Chain by Integrating SMED and Production Scheduling. Logistics 2021, 5, 4. [Google Scholar] [CrossRef]

- Juárez, A.; Corona, J.R.; Rivera, H.; Montaño, O.; Medina, J. Application of the SMED Methodology through Folding References for a Bus Manufacturing Company. Int. J. Ind. Eng. Manag. 2023, 14, 232–243. [Google Scholar] [CrossRef]

- Selvaraj, S.K.; Raj, A.; Mahadevan, R.R.; Chadha, U.; Paramasivam, V. A Review on Machine Learning Models in Injection Molding Machines. Adv. Mater. Sci. Eng. 2022, 2022, 1. [Google Scholar] [CrossRef]

- Shirazian, S.; Huynh, T.; Sarkar, S.M.; Habibi Zare, M. Development and Optimization of Machine Learning Models for Estimation of Mechanical Properties of Linear Low-Density Polyethylene. Polym. Test. 2024, 137, 108525. [Google Scholar] [CrossRef]

- Chen, J.; Cui, Y.; Liu, Y.; Cui, J. Design and Parametric Optimization of the Injection Molding Process Using Statistical Analysis and Numerical Simulation. Processes 2023, 11, 414. [Google Scholar] [CrossRef]

- Aminabadi, S.S.; Tabatabai, P.; Steiner, A.; Gruber, D.P.; Friesenbichler, W.; Habersohn, C.; Berger-Weber, G. Industry 4.0 In-Line AI Quality Control of Plastic Injection Molded Parts. Polymers 2022, 14, 3551. [Google Scholar] [CrossRef]

- Mendoza-Sotomayor, R.; Sabogal-Arias, J.A.; Quiroz-Flores, J.C. Optimizing Beverage Manufacturing: Integrating Lean Manufacturing and Machine Learning to Enhance Efficiency and Reduce Waste. Int. J. Eng. Trends Technol. 2024, 72, 155–174. [Google Scholar] [CrossRef]

- Jung, H.; Jeon, J.; Choi, D.; Park, A.J.Y. Application of Machine Learning Techniques in Injection Molding Quality Prediction: Implications on Sustainable Manufacturing Industry. Sustainability 2021, 13, 4120. [Google Scholar] [CrossRef]

- Bezzina, C.M.; Refalo, P. Fused Filament Fabrication and Injection Moulding of Plastic Packaging: An Environmental and Financial Comparative Assessment. Machines 2023, 11, 634. [Google Scholar] [CrossRef]

- Junior, R.G.P.; Inácio, R.H.; da Silva, I.B.; Hassui, A.; Barbosa, G.F. A Novel Framework for Single-Minute Exchange of Die (SMED) Assisted by Lean Tools. Int. J. Adv. Manuf. Technol. 2022, 119, 6469–6487. [Google Scholar] [CrossRef]

- Calderon, J.; Cuellar, M.; Yildiz, O.; Aranda, D.; Alvarez, J.C. Business Process Model Re-Design with A Data-Based Green Lean Management Approach with OEEM: A Case of Plastic Product Manufacturing Firm. Int. J. Eng. Trends Technol. 2025, 73, 289–314. [Google Scholar] [CrossRef]

- Allca Chauca, V.S.; Yauri Mendoza, A.C.; Sáenz Morón, M.J. Improvement Model to Increase Efficiency through the Use of 5S, TPM and SMED Tools in a Plastic SME Company. In Proceedings of the LACCEI International Multi-Conference for Engineering, Education and Technology, Buenos Aires, Argentina, 19–21 July 2023; LACCEI: Boca Raton, FL, USA, 2023; pp. 1–9. [Google Scholar] [CrossRef]

- Osco, J.C.; Ricce, M.C.; Ipince, D.A.; Alvarez, J.C.; Yildiz, O. Operations Management Model Based on 5S, TPM, and SMED to Increase the Effectiveness of Equipment in a Plastics Company. In Proceedings of the 2023 9th International Conference on Innovation and Trends in Engineering, Bogota, Colombia, 4–6 October 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 1–6. [Google Scholar] [CrossRef]

- Mujica-Suarez, D.; Salvador-Ayala, J.; Castro-Rangel, P. Successful Implementation of the SMED and TPM Tools under the PDCA Methodology to Increase Order Fulfillment in a Company in the Plastic Sector. In Proceedings of the LACCEI International Multi-Conference for Engineering, Education and Technology, Buenos Aires, Argentina, 19–21 July 2023; LACCEI: Boca Raton, FL, USA, 2023; pp. 1–8. [Google Scholar] [CrossRef]

- Khakpour, R.; Ebrahimi, A.; Seyed-Hosseini, S.M. SMED 4.0: A Development of Single Minute Exchange of Die in the Era of Industry 4.0 Technologies to Improve Sustainability. J. Manuf. Technol. Manag. 2024, 35, 568–589. [Google Scholar] [CrossRef]

- Polenta, A.; Tomassini, S.; Falcionelli, N.; Contardo, P.; Dragoni, A.F.; Sernani, P. A Comparison of Machine Learning Techniques for the Quality Classification of Molded Products. Information 2022, 13, 272. [Google Scholar] [CrossRef]

- Tayalati, F.; Azmani, A.; Azmani, M. Application of Supervised Machine Learning Methods in Injection Molding Process for Initial Parameters Setting: Prediction of the Cooling Time Parameter. Prog. Artif. Intell. 2024, 2024, 1–15. [Google Scholar] [CrossRef]

- Luisi, G.; Di Pasquale, V.; Pietronudo, M.C.; Riemma, S.; Ferretti, M. A hybrid architectural model for monitoring production performance in the plastic injection molding process. Appl. Sci. 2023, 13, 12145. [Google Scholar] [CrossRef]

- Alhammad, M.; Avdelidis, N.P.; Ibarra-Castanedo, C.; Torbali, M.E.; Genest, M.; Zhang, H.; Maldgue, X.P. Automated Impact Damage Detection Technique for Composites Based on Thermographic Image Processing and Machine Learning Classification. Sensors 2022, 22, 9031. [Google Scholar] [CrossRef]

- Tucki, K.; Orynycz, O.; Wasiak, A.; Gola, A.; Mieszkalski, L. Potential Routes to the Sustainability of the Food Packaging Industry. Sustainability 2022, 14, 3924. [Google Scholar] [CrossRef]

- ALMashaqbeh, S.; Hernandez, E.M. Evaluation and Improvement of a Plastic Production System Using Integrated OEE Methodology: A Case Study. Manag. Syst. Prod. Eng. 2024, 32, 450–463. [Google Scholar] [CrossRef]

- Marcella, S.; Widjajati, E.P. Analysis of Lean Manufacturing Implementation through the Single Minute Exchange of Dies (SMED) Method to Reduce Setup Time in the Injection Molding Machine Process. J. Appl. Sci. Eng. Technol. Educ. (ASCI) 2024, 6, 17–26. [Google Scholar] [CrossRef]

- Silva, B.; Marques, R.; Faustino, D.; Ilheu, P.; Santos, T.; Sousa, J.; Rocha, A.D. Enhance the Injection Molding Quality Prediction with Artificial Intelligence to Reach Zero-Defect Manufacturing. Processes 2023, 11, 62. [Google Scholar] [CrossRef]

- Cruz, Y.J.; Villalonga, A.; Castaño, F.; Rivas, M.; Haber, R.E. Automated Machine Learning Methodology for Optimizing Production Processes in Small and Medium-Sized Enterprises. Oper. Res. Perspect. 2024, 12, 100308. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).