The Spatiotemporal Patterns and Driving Mechanism of the Synergistic Effects in Industrial Green Production

Abstract

1. Introduction

2. Indicator System and Research Methodologies

2.1. Industrial Green Production Indicator System

- (1)

- The core components in SGPMS were green production support and industrial development capacity. Green production support was characterised mainly by the amount of green policy and the total investment in urban environmental infrastructure, which were derived from the Peking University Legal Information Database and the China Urban Construction Statistical Yearbook, respectively. SGPMS was influenced by green production support through the dual path of ‘institutional incentives and infrastructural safeguards’ [45,46]. The key indicators of industrial development capacity were expenditures on new product development and expenditures on technology introduction, which were obtained from the China Industrial Statistical Yearbook. The mechanism of industrial development capacity in SGPMS was mainly reflected in the reduction in resource consumption intensity and pollution emissions through the application of green technologies [19,47].

- (2)

- The core components in PGPOS were the utilisation of energy and waste, as well as innovation capacity. The data on the utilisation of energy and waste were obtained from the China Energy Statistical Yearbook, the China Electricity Statistical Yearbook, provincial statistical yearbooks, and the China Industrial Statistical Yearbook. Indicators of energy utilisation determined the pollution emissions from the industrial production process through the intensity of energy consumption, the optimisation of the energy structure, and the conservation and recycling of energy [48,49]. The data for innovation capacity were from the China Science and Technology Statistical Yearbook and the China Statistical Yearbook. Studies have shown that technician reserves and investment in R&D have a significant positive impact on the green growth of PGPOS [7,47].

- (3)

- The core components in EGPCS were industrial growth quality, industrial pollution control and investment, and carbon sink capacity. In this study, industrial growth quality was represented by the growth rate of industrial added value and the sales revenue of new products per unit of industrial added value, with data from the China Industrial Statistical Yearbook. The improvement in output efficiency presented by the indicators of industrial growth quality reflected the enhancement of capacity in EGPCS [50]. Industrial pollution control and investment were described by six indicators related to pollutant emissions and environmental investment, with data from the China Environmental Statistics Yearbook. Research has shown that industrial pollution control and investment have a decisive effect on pollution reduction in EGPCS [5,51]. The core evaluation indicators of carbon sinks were the forest coverage rate and the greening coverage rate of built-up areas, with data from the China Urban Construction Statistical Yearbook, the China Statistical Yearbook, and provincial statistical yearbooks. The forest coverage rate was the core carrier of natural carbon sinks, while the greening coverage rate of built-up areas reflected the construction level of artificial carbon sinks. Their ecological regulation function significantly reduced pollution emissions in EGPCS [22,46].

2.2. Methodologies

2.2.1. Indicator Weighting Methods

2.2.2. Synergetic Model

2.2.3. Spatial Autocorrelation and Standard Deviation Ellipse

2.2.4. GWR

2.3. Data Sources

3. Empirical Analysis

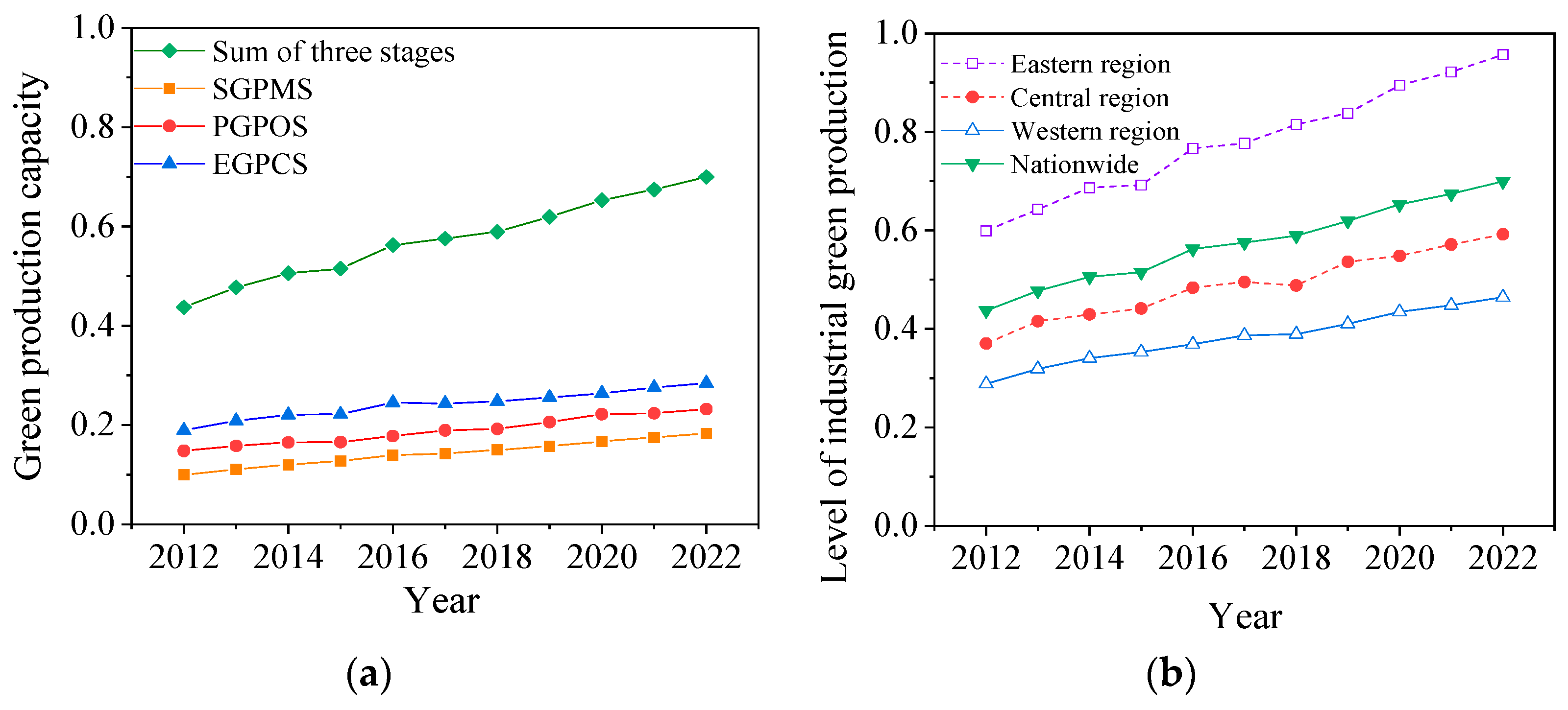

3.1. Evolutionary Characteristics of Industrial Green Production Capacity

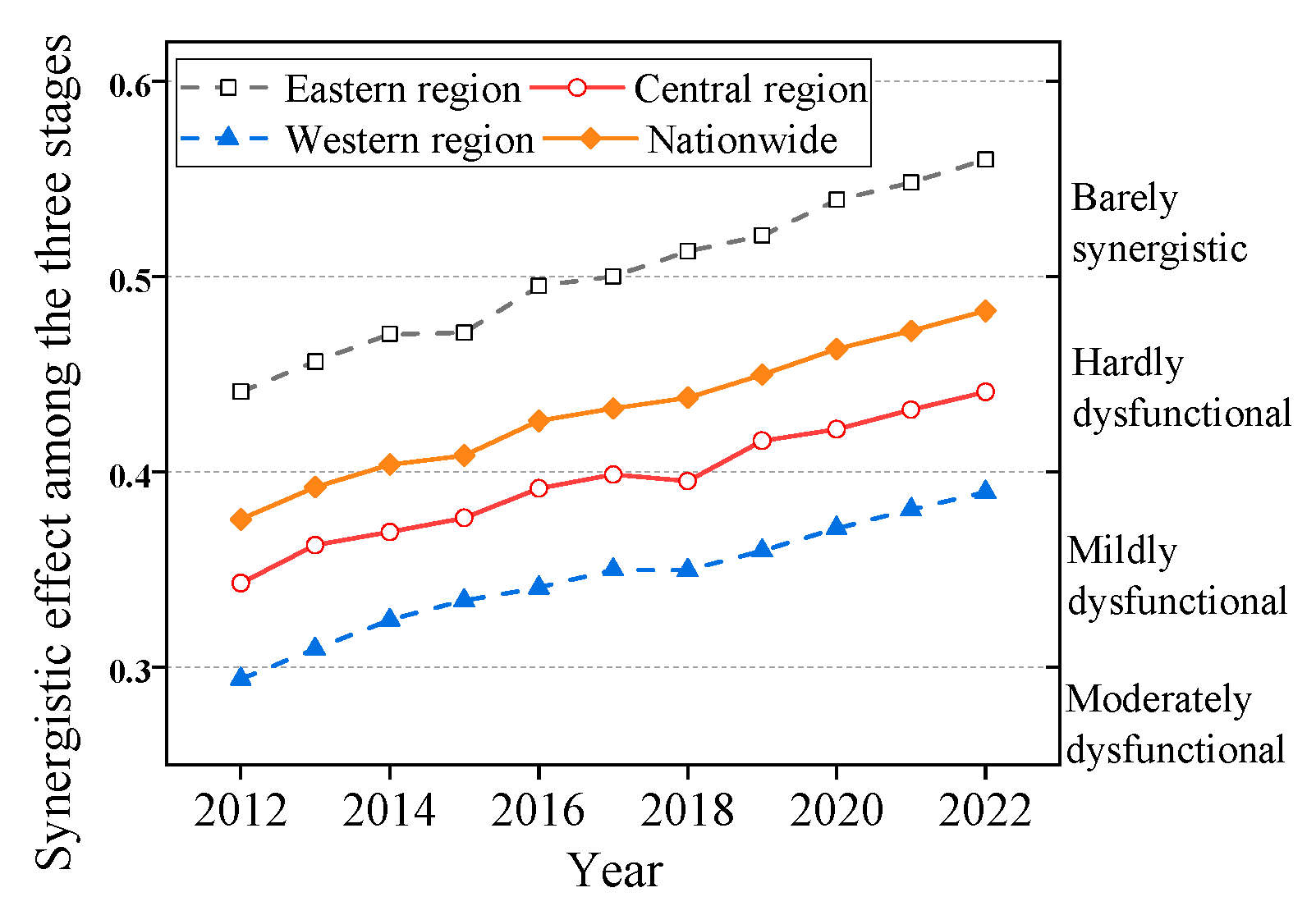

3.2. Evolutionary Characteristics of Synergistic Effects in Industrial Green Production

3.3. Spatial Patterns of Synergistic Effects in Industrial Green Production

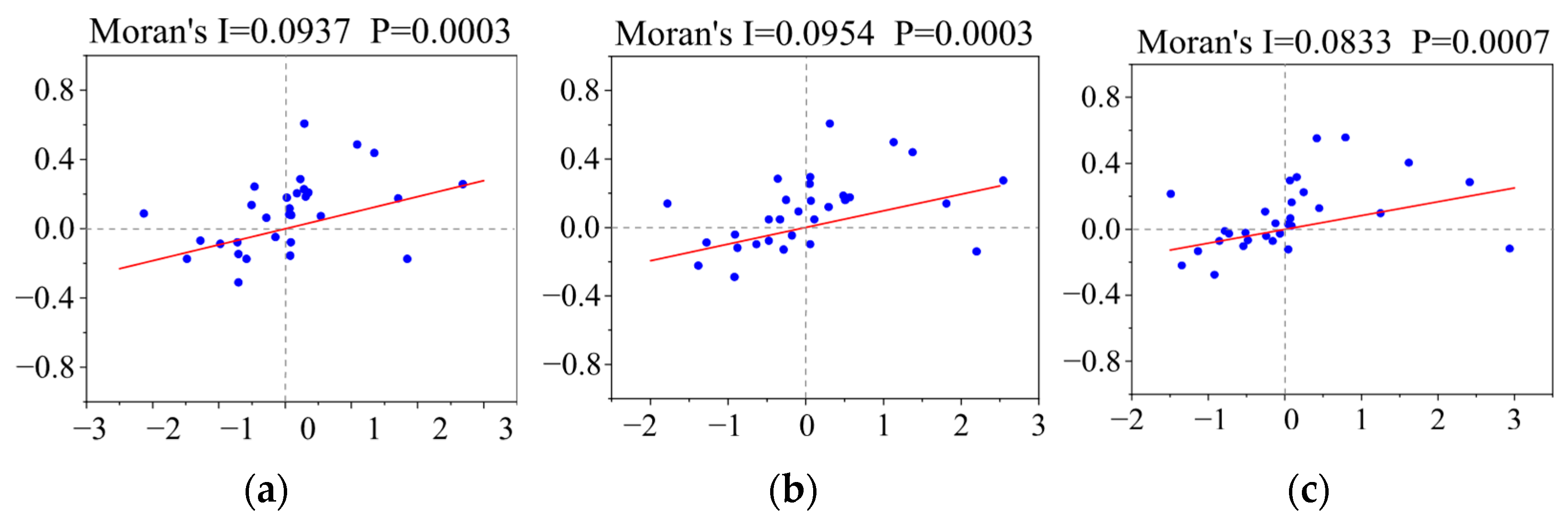

3.3.1. Global Autocorrelation Analysis

3.3.2. Local Autocorrelation Analysis

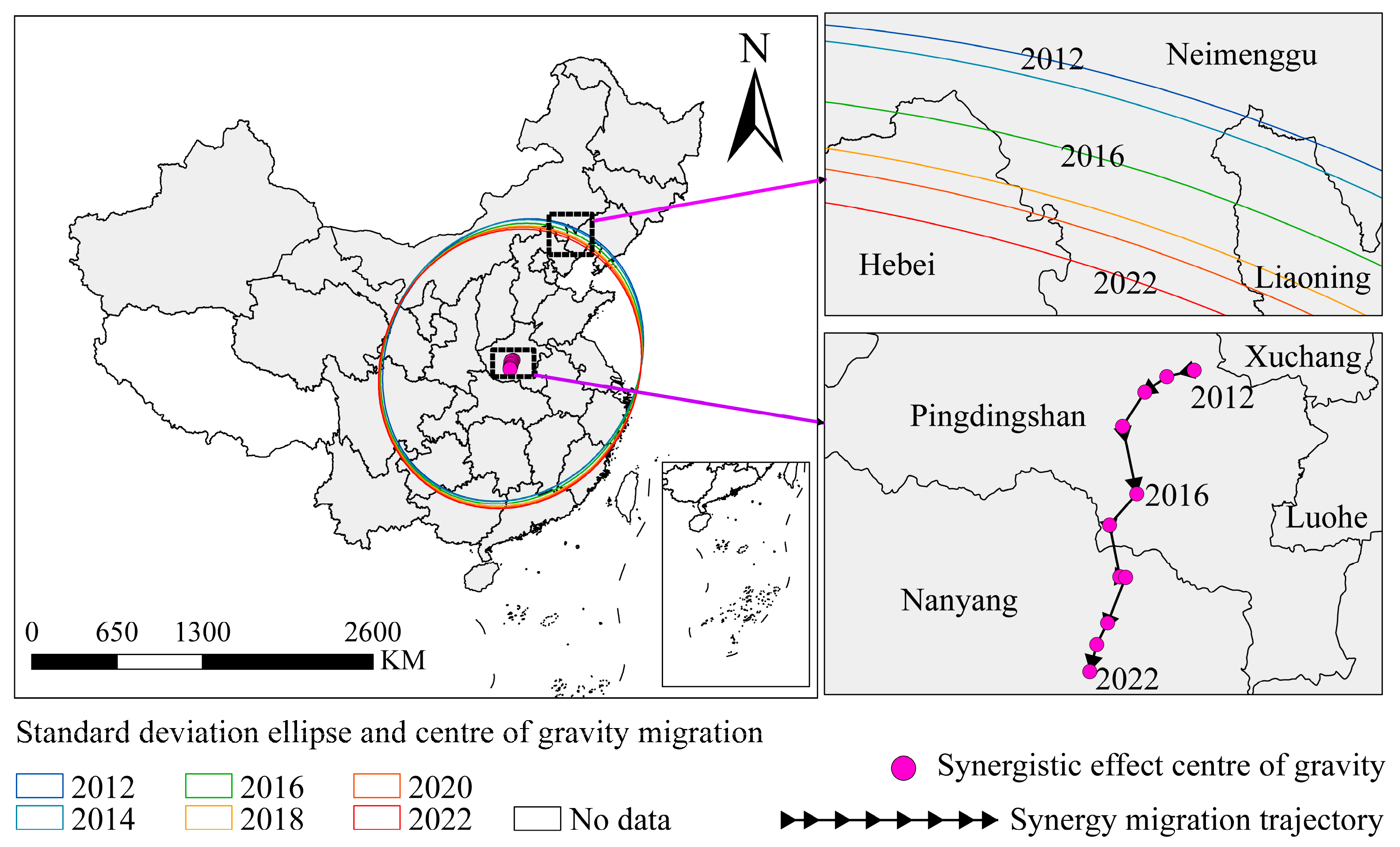

3.3.3. Directional Distribution and Centre of Gravity Migration Characteristics

3.4. Spatially Heterogeneous Driving Factors for Synergistic Effects in Industrial Green Production

3.4.1. Influential Factor Selection and Testing

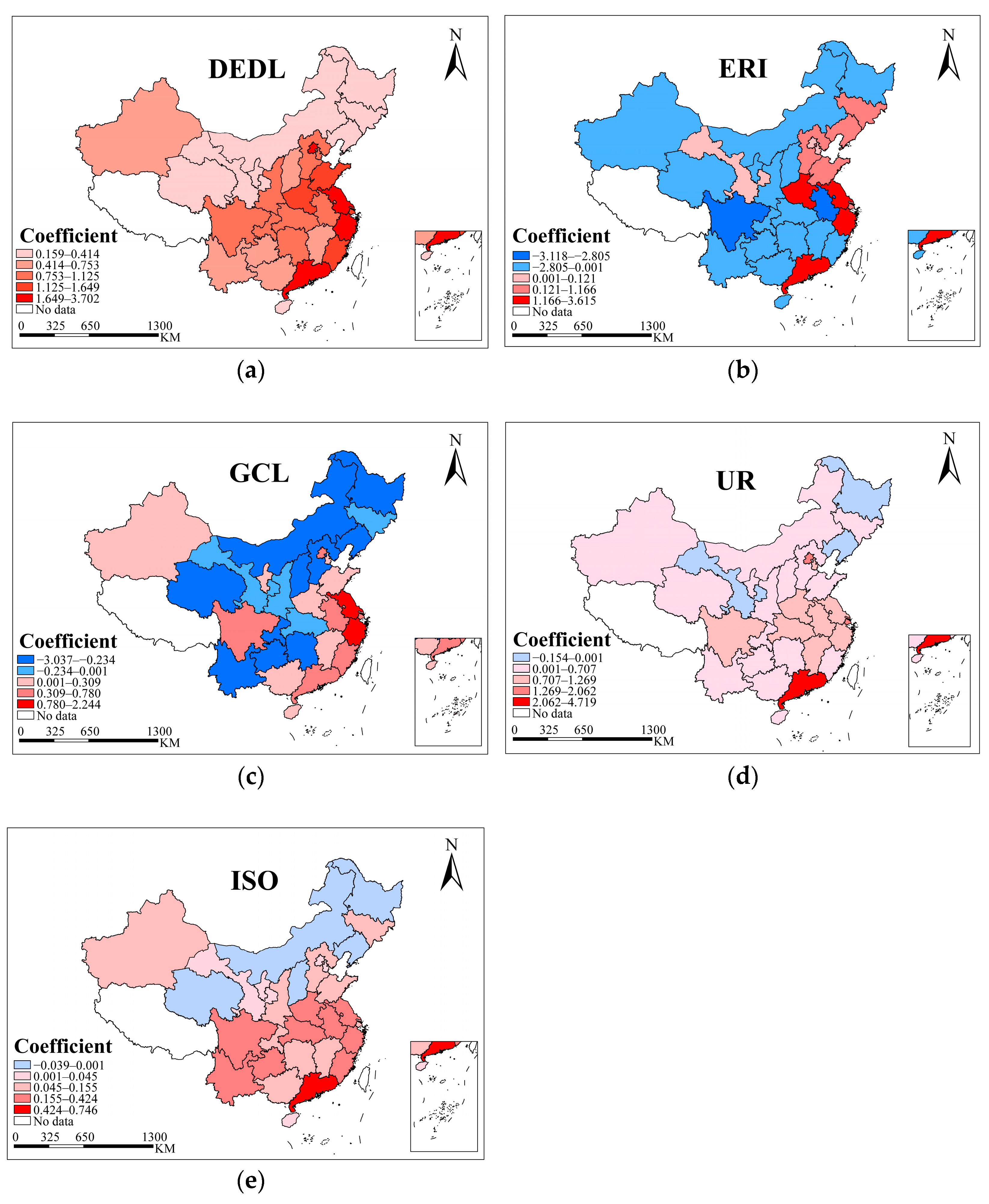

3.4.2. Spatial Heterogeneity Analysis of Impacts of Driving Factors

- (1)

- DEDL was positively correlated with the synergistic effects in industrial green production. The extreme values of positive correlation occurred in coastal areas of southeast China, such as Guangdong province, Jiangsu province, Zhejiang province, Fujian province, and Shanghai municipality. However, northeast China, such as the Inner Mongolia autonomous region, Liaoning province, Jilin province, and Heilongjiang province, showed weak positive correlations. This phenomenon was primarily attributed to the more advanced digital economy infrastructure in China’s southeastern coastal regions, where digital technologies were deeply embedded throughout the entire industrial chain [67]. This integration facilitated more effective coordination and control of industrial green production processes. However, in northeast China, the poor digitalization infrastructure increased the cost of digital transformation for industrial firms and inhibited the spread of digital technology adoption [68]. Moreover, the region’s industrial structure, dominated by energy-intensive industries, had low adaptability to digital green technologies, further weakening the role of the digital economy in promoting the green transformation of industrial production [61].

- (2)

- With respect to ERI, 60% of China’s regional ERI was negatively correlated with synergistic effects in industrial green production. The extreme values of negative correlations occurred in areas with ‘strong provincial capital’ development patterns, such as Sichuan province and Anhui province. The ‘resource siphoning’ phenomenon in these regions concentrated high-quality resources, such as population, capital, and technology, in the provincial capitals, weakening the technological upgrading capacity of industrial enterprises in non-provincial capitals to cope with environmental regulations. Furthermore, provincial capitals may transfer polluting industries to their neighbourhoods in pursuit of economic performance, ultimately leading to a weakening of the overall synergistic effects [69]. Positive correlations were found in economically strong provinces such as Jiangsu province, Zhejiang province, Guangdong province, and Henan province. To enhance economic competitiveness, industrial enterprises in these regions were quicker to respond to synergistic policies [62,70], especially in Zhejiang province and Guangdong province, where the private economy was well developed.

- (3)

- GCL was negatively correlated with the synergistic effects in industrial green production in northeast China and southwest China, but positively correlated with the synergistic effects in industrial green production in the coastal regions of the East China Sea and South China Sea. This phenomenon stemmed mainly from the fact that northeast China and southwest China relied heavily on traditional heavy industries. Such traditional industries were generally characterised by high asset specificity and high costs of technological transformation [71], resulting in constraints on the synergistic potential of the green credit to support industrial green production. With a high efficiency in the allocation of green credit resources to industrial enterprises, the regions of the East China Sea and South China Sea had a concentration of high technology industries and advanced manufacturing industries, resulting in strong synergistic effects of green production [65].

- (4)

- A higher UR indicated a stronger ability of the regional population, capital, and technology agglomeration. UR was positively correlated with the synergistic effects of industrial green production for 90% of China’s regions. First, UR effectively reduced the marginal environmental governance cost per unit of industrial output by promoting the centralised construction of environmental protection infrastructure and the large-scale treatment of pollutants in industrial enterprises [66]. Second, the resource agglomeration effect generated by UR made clean technology diffusion more economical, thus reducing the cost of industrial green production [21]. Finally, the increased innovation factor density brought about by urbanisation accelerated green technology spillovers [21], which reduced the cost of industrial green transformation to further drive the synergistic effects of industrial green production [66].

- (5)

- ISO determined the efficiency of resource allocation in industrial production [61,72]. The extreme values of the positive correlation between this driving factor and the synergistic effects in industrial green production were found in provinces with more marketization, such as Guangdong province, Jiangsu province, and Zhejiang province. The reason was mainly due to the high level of ISO in these regions, which facilitated the development of numerous high-value industrial chains, such as the electronics industry in Guangdong province, the high-value equipment industry in Jiangsu province, and the digital security industry in Zhejiang province. These high-value industrial chains promoted cross-sectoral technology diffusion and drove the optimisation of the industrial ecological circulation system, thereby enhancing the synergistic effectiveness of the industrial green production system [73]. Regions with weak negative correlations between ISO and the synergistic effects in industrial green production were provinces with deeply locked-in energy structures, such as Shanxi province, Liaoning province, Heilongjiang province, and the Inner Mongolia autonomous region. These regions had high degrees of coal dependence and high barriers to energy conversion costs, for which industrial green production was more inclined towards passive compliance than active synergy [74]. In addition, industrial enterprises in these regions had long remained in the high energy consumption segments of the industrial chain, which had a dampening effect on the synergistic effects of industrial green production.

4. Discussion

5. Conclusions and Implications

5.1. Conclusions

- (1)

- Industrial green production capacity increased rapidly over time from 2012 to 2022, and in terms of regional distribution, it was highest in the east and lowest in the west. Industrial green production capacity exhibited the characteristic of EGPCS > PGPOS > SGPMS. The synergistic effects among the stages of industrial green production clearly increased, shifting from mildly dysfunctional to hardly dysfunctional, with a regional distribution characterised by a decrease from east to west.

- (2)

- The synergistic effects in industrial green production had a significant positive spatial correlation. The number of provinces with H-H aggregation increased during the study period. The standard deviation ellipse of the synergistic effects in China’s industrial green production essentially showed a distribution pattern of ‘northeast–southwest’. The centre of gravity migrated to the southwest and was distributed mainly in Pingdingshan city and Nanyang city in Henan province.

- (3)

- Among the five driving factors, DEDL, ERI, GCL, UR, and ISO, DEDL had the greatest influence on the synergistic effects in industrial green production, and ERI had the least influence. The influence of each driving factor on the synergistic effects in industrial green production showed significant spatial differentiation characteristics. The spatial heterogeneity was most prominent for the impacts of ERI on synergistic effects in industrial green production, while the impacts of DEDL had the least differences across regions.

5.2. Implications

- (1)

- This study confirmed that green production capacity was strongest in EGPCS but weakest in SGPMS. Therefore, the Chinese government should focus on industrial products with outstanding green attributes and high consumption, and formulate green design evaluation standards to guide the Chinese industry in implementing green design and procurement. For industrial enterprises, the concept of green production should be institutionalised. Setting a red line to constrain energy consumption, pollution control, and emissions may affect economic benefits in the short term, but from a development perspective, the full implementation of green manufacturing not only creates new market opportunities for enterprises, but also helps to enhance the brand value of enterprises.

- (2)

- The number of regions with H-H aggregation for synergistic effects in industrial green production increased and the differences between regions decreased. However, the synergistic effects of industrial green production still remained in a hardly dysfunctional recession type. Therefore, at the industrial enterprise level, sectoral, industrial, and regional constraints should be broken down to synergistically promote innovation in green production technologies through information sharing, system sharing, and experience sharing. At the regional level, industrial chains and industrial parks should be leveraged to strengthen the synergistic effects of green production at the whole life cycle stages. For provinces with better synergistic development of industrial green production, on the one hand, they should continuously explore innovative measures for green production synergy, and on the other hand, they should link up with provinces with lower synergistic development to jointly improve the institutional system of synergistic development for industrial green production. For provinces with low synergistic development of green production in industry, they should actively learn from provinces with high synergistic development and improve synergistic measures to better achieve pollution reduction.

- (3)

- The driving factors DEDL, ERI, GCL, UR, and ISO revealed the enhancement mechanism of synergistic effects in industrial green production. Based on the spatially heterogeneous influences of the drivers, the Chinese government needs to adopt synergistic measures of green production tailored to local conditions. Eastern regions such as Guangdong, Jiangsu, and Zhejiang provinces should focus on promoting the integration of digital technologies into advanced manufacturing systems and optimising the differentiated pricing system for green credits based on environmental performance. Central regions, like Anhui, Shanxi, and Heilongjiang provinces, need to improve incentive and constraint mechanisms for environmental regulation while establishing restrictive industry catalogues to promote the transition of industrial enterprises. Western regions, especially Liaoning province, Inner Mongolia autonomous region, and Qinghai province, should focus on the matching degree of the urbanisation process with the ecological carrying capacity, strengthen the construction of digital economy infrastructure, to promote the green and intelligent transformation of traditional industries.

5.3. Limitations and Research Prospects

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tong, Y.; Wang, K.; Liu, J.; Zhang, Y.; Gao, J.; Dan, M.; Zhao, Z. Refined assessment and decomposition analysis of carbon emissions in high-energy intensive industrial sectors in China. Sci. Total Environ. 2023, 872, 162161. [Google Scholar] [CrossRef]

- Zhu, T.; Liu, X.; Wang, X.; He, H. Technical development and prospect for collaborative reduction of pollution and carbon emissions from iron and steel industry in China. Engineering 2023, 31, 37–49. [Google Scholar] [CrossRef]

- Zhang, Z.; Gao, Q.; Shao, S.; Zhang, Y.; Bao, Y.; Zhao, L. Carbon emission scenarios of China’s construction industry using a system dynamics methodology—Based on life cycle thinking. J. Clean. Prod. 2024, 435, 140457. [Google Scholar] [CrossRef]

- Alkandi, I.; Alhajri, N.; Alnajim, A. Green supply chain management, business performance, and future challenges: Evidence from emerging industrial sector. Sustainabilty 2025, 17, 29. [Google Scholar] [CrossRef]

- Guo, M.; Cui, Y. Research on the impact path of China’s environmental protection investment on green development—Based on the perspective of industrial structure upgrading. Front. Environ. Sci. 2024, 11, 1328231. [Google Scholar] [CrossRef]

- Lin, J.; Zhang, L.; Dong, Z. Exploring the effect of green finance on green development of China’s energy-intensive industry—A spatial econometric analysis. Resour. Environ. Sustain. 2024, 16, 100159. [Google Scholar] [CrossRef]

- Li, M.; Zhao, Y.; Yan, J.; Huang, Y. Enterprise digital transformation and green technology innovation: Evidence from innovation sub-dimension and time lag effect. Pol. J. Environ. Stud. 2025, 34, 177–186. [Google Scholar] [CrossRef]

- Yang, X.; Hunjra, A.; Grebinevych, O.; Roubaud, D.; Zhao, S. Roads to sustainable development: Pioneering industrial green transformation through digital economy policy. J. Environ. Manag. 2025, 387, 125721. [Google Scholar] [CrossRef]

- Zhao, R.; Hu, C.; Du, C.; Wang, C.; Sun, L. Synergistic effect assessment of pollution and carbon reduction and pathway of green transformation at regional level in China. J. Clean. Prod. 2025, 495, 145013. [Google Scholar] [CrossRef]

- Feng, T.; Liu, B.; Wei, Y.; Xu, Y.; Zheng, H.; Ni, Z.; Zhu, Y.; Fan, X.; Zhou, Z. Research on the low-carbon path of regional industrial structure optimization. Energy. Strateg. Rev. 2024, 54, 101485. [Google Scholar] [CrossRef]

- Yan, X.; Sun, H.; Xin, L. “Harmonization” or “Fragmentation”: The impact of low-carbon policy synergy on inclusive low-carbon development. Sustainabilty 2023, 15, 7009. [Google Scholar] [CrossRef]

- Liu, Y.Q.; Feng, C. Synergies between global low-carbon development processes and financial fluctuations from 1991–2019: A functional data analysis. J. Environ. Plann. Manag. 2023, 67, 1–22. [Google Scholar] [CrossRef]

- Ijaz, T.; Qazalbash, A.H.R.; Razzaq, A.A.; Rafique, M.Z.; Khan, M.A.; Jamshaid, S.H. Development of green manufacturing implementation framework based on life-cycle assessment. Sustain. Environ. Res. 2024, 34, 23. [Google Scholar] [CrossRef]

- Shirinkina, E.V.; Romansky, R. Assessment of the synergetic efficiency of industrial companies reengineering processes. J. Phys. Conf. Ser. 2020, 1679, 032014. [Google Scholar] [CrossRef]

- Siwiec, D.; Gajdzik, B.; Gawlik, R.; Wolniak, R.; Pacana, A. Open eco-innovations in sustainable product development: Model framework of design thinking in quality life cycle assessment (DT-QLCA). J. Open. Innov. Technol. Mark. Complex. 2025, 11, 100480. [Google Scholar] [CrossRef]

- Qiu, W.; Zhang, Y.; Kong, L. Promoting industrial symbiosis: Does the synergistic drive of innovation and domestic demand work? Evidence from listed enterprises in China. Sustainability 2025, 17, 165. [Google Scholar] [CrossRef]

- Feng, M.; Liu, G.; Yue, Q.; Wang, H. Energy saving and carbon reduction in steel production: Synergy and optimization based on long and short processes. Steel Res. Int. 2025, 2400924. [Google Scholar] [CrossRef]

- Hao, X.; Li, Y.; Wang, K.; Sun, Q.; Wu, H. Eco-intelligent production: Intelligent manufacturing and industrial green transition. Environ. Dev. Sustain. 2025. [CrossRef]

- Yu, S.; Liu, J.; Zhou, S. Synergy evaluation of China’s economy–energy low-carbon transition and its improvement strategy for structure optimization. Environ. Sci. Pollut. Res. 2022, 29, 65061–65076. [Google Scholar] [CrossRef]

- Pang, G.; Li, L.; Guo, D. Does the integration of the digital economy and the real economy enhance urban green emission reduction efficiency? Evidence from China. Sustain. Cities Soc. 2025, 122, 106269. [Google Scholar] [CrossRef]

- He, Y.; Liu, G. Coupling coordination analysis of low-carbon development, technology innovation, and new urbanization: Data from 30 provinces and cities in China. Front. Public Health 2022, 10, 1047691. [Google Scholar] [CrossRef] [PubMed]

- Xiong, X.; He, W.; Chen, S.; Wu, Y. Green finance, green technology innovation, and carbon emission reduction. Environ. Res. Commun. 2025, 7, 045018. [Google Scholar] [CrossRef]

- Zhang, J.; Sun, Z. Does the synergy between fintech and green finance lead to the enhancement of urban green total factor energy efficiency? Empirical evidence from China. J. Environ. Manag. 2025, 382, 125366. [Google Scholar] [CrossRef]

- Wen, S.; Jia, Z. Call for multi-policy approach: Synergistic effects of emissions trading scheme and energy efficiency policies. J. Environ. Manag. 2024, 360, 121186. [Google Scholar] [CrossRef]

- Yu, Y.; Jin, Z.; Li, J.; Jia, L. Low-carbon development path research on China’s power industry based on synergistic emission reduction between CO2 and air pollutants. J. Clean. Prod. 2020, 275, 123097. [Google Scholar] [CrossRef]

- Sun, S.; Zhang, M.; Liu, L.; Zhou, D. Synergistic governance efficiency of industrial pollution and CO2 emissions under the digital economy. J. Environ. Manag. 2025, 374, 124148. [Google Scholar] [CrossRef]

- Ruhrmann, H.; Fritsch, M.; Leydesdorff, L. Synergy and policy-making in German innovation systems: Smart specialisation strategies at national, regional, local levels? Reg. Stud. 2022, 56, 1468–1479. [Google Scholar] [CrossRef]

- Wu, H.; Wen, X. Research on the efficiency and synergistic effect of industrial green innovation development in the Beijing-Tianjin-Hebei urban agglomeration. Sustainability 2025, 17, 1244. [Google Scholar] [CrossRef]

- Wang, N.; Qu, Z.; Li, J.; Zhang, Y.; Wang, H.; Xi, H.; Gu, Z. Spatial-temporal patterns and influencing factors of carbon emissions in different regions of China. Environ. Res. 2025, 276, 121447. [Google Scholar] [CrossRef]

- Zhai, Y.; Zhai, G.; Yu, Z.; Lu, Z.; Chen, Y.; Liu, J. Coupling coordination between urbanization and ecosystem services value in the Beijing-Tianjin-Hebei urban agglomeration. Sustain. Cities Soc. 2024, 113, 105715. [Google Scholar] [CrossRef]

- Zhang, Q.; Shen, J.; Sun, F. Spatiotemporal differentiation of coupling coordination degree between economic development and water environment and its influencing factors using GWR in China’s province. Ecol. Model. 2021, 462, 109794. [Google Scholar] [CrossRef]

- Meng, Q.; Chen, X.; Wang, H.; Shen, W.; Duan, P.; Liu, X. Spatiotemporal evolution and driving factors of the synergistic effects of pollution control and carbon reduction in China. Ecol. Indic. 2025, 170, 113103. [Google Scholar] [CrossRef]

- Li, Y.; Hao, S.; Liu, Y.; Chen, B.; Zou, T. Research on the spatial correlation network and its driving factors for synergistic development of pollution reduction, carbon reduction, greening, and growth in China’s tourism industry. J. Environ. Manag. 2025, 377, 124579. [Google Scholar] [CrossRef]

- Liao, B.; Tian, C.; Zhou, T.; Han, L. Synergistic regional emission reductions in China: Network evolution, spatial and temporal characteristics, and driving factor. Ecol. Indic. 2024, 162, 112026. [Google Scholar] [CrossRef]

- Qin, P.; Ren, C.; Li, L.; Lei, Y.; Wu, S. Evaluation of PM2.5 and CO2 synergistic emission reduction and its driving factors in China. J. Clean. Prod. 2023, 428, 139296. [Google Scholar] [CrossRef]

- Kang, S.; Shang, Y. How artificial intelligence drives industrial digitalization and greening synergies? Evidence from China’s AI innovation and development pilot zones. Technol. Soc. 2025, 83, 103011. [Google Scholar] [CrossRef]

- Xu, A.; Dai, Y.; Hu, Z.; Qiu, K. Can green finance policy promote inclusive green growth?—Based on the quasi-natural experiment of China’s green finance reform and innovation pilot zone. Int. Rev. Econ. Financ. 2025, 100, 104090. [Google Scholar] [CrossRef]

- Mehmood, K.; Kautish, P.; Mehrotra, A.; Alofaysan, H.; Papa, A. Forging sustainable synergies: Unleashing fintech-driven supply chain collaboration for enhanced green supply chain performance. Technol. Forecast. Soc. Change 2025, 219, 124244. [Google Scholar] [CrossRef]

- Vadurin, K.; Perekrest, A.; Bakharev, V.; Shendryk, V.; Parfenenko, Y.; Shendryk, S. Towards digitalization for air pollution detection: Forecasting information system of the environmental monitoring. Sustainability 2025, 17, 3760. [Google Scholar] [CrossRef]

- Anser, M.K.; Sajjad, F.; Nassani, A.A.; Al-Aiban, K.M.; Zaman, K.; Haffar, M. Urban energy efficiency in China: Examining the role of renewable energy, smart Grids, and sustainable design through spatial and policy perspectives (1990–2022). Energy. Build. 2025, 339, 115791. [Google Scholar] [CrossRef]

- Fabrizi, A.; Gentile, M.; Guarini, G.; Meliciani, V. The impact of environmental regulation on innovation and international competitiveness. J. Evol. Econ. 2024, 34, 169–204. [Google Scholar] [CrossRef]

- Liu, L.; Cui, K. How does market-incentive environmental regulation affect enterprises green growth? The mediating role of R&D investment and innovation output. Heliyon 2024, 10, e30847. [Google Scholar] [CrossRef]

- Han, X.; Cai, Q. Environmental regulation, green credit, and corporate environmental investment. Innov. Green Dev. 2024, 3, 100135. [Google Scholar] [CrossRef]

- Zhao, Y.; Wang, S.; Gao, G.; Wu, Y.; Zhang, R. Integrated optimization model to explore the green transformation of energy-intensive industrial parks from environmental-economic perspectives. Energy 2025, 325, 136200. [Google Scholar] [CrossRef]

- Yang, Z.; Fan, M.; Shao, S.; Yang, L. Does carbon intensity constraint policy improve industrial green production performance in China? A quasi-DID analysis. Energy Econ. 2017, 68, 271–282. [Google Scholar] [CrossRef]

- Tian, C.; Liang, Y.; Lin, Q.; You, D.; Liu, Z. Environmental pressure exerted by the petrochemical industry and urban environmental resilience: Evidence from Chinese petrochemical port cities. J. Clean. Prod. 2024, 471, 143430. [Google Scholar] [CrossRef]

- Gao, Q.; Cheng, C.; Sun, G. Big data application, factor allocation, and green innovation in Chinese manufacturing enterprises. Technol. Forecast. Soc. Change 2023, 192, 122567. [Google Scholar] [CrossRef]

- Ran, Q.; Yang, X.; Yan, H.; Xu, Y.; Cao, Z. Natural resource consumption and industrial green transformation: Does the digital economy matter? Resour. Policy 2023, 81, 103396. [Google Scholar] [CrossRef]

- Tian, X.; Chen, P. The interplay among energy utilisation efficiency and industrial agglomeration through spatial heterogeneity insights. Sci. Rep. 2025, 15, 5020. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; He, Z. Synergistic industrial agglomeration, new quality productive forces and high-quality development of the manufacturing industry. Int. Rev. Econ. Financ. 2024, 94, 103373. [Google Scholar] [CrossRef]

- Ren, S.; Hao, Y.; Wu, H. How does green investment affect environmental pollution? Evidence from China. Environ. Resour. Econ. 2022, 81, 25–51. [Google Scholar] [CrossRef]

- Ganguly, K.; Kumar, G. Supply chain risk assessment: A fuzzy AHP approach. Oper. Supply Chain Manag. 2019, 12, 1–13. [Google Scholar] [CrossRef]

- Yu, X.; Qi, Y.; Yu, L.; He, Y. Temporal and spatial evolution of coupling coordination degree of industrial innovation ecosystem—From the perspective of green transformation. Sustainability 2022, 14, 4111. [Google Scholar] [CrossRef]

- Deng, Z.; Zong, S.; Su, C.; Chen, Z. Research on coupling coordination development between ecological civilization construction and new urbanization and its driving forces in the Yangtze River economic zone. Econ. Geogr. 2019, 39, 78–86. [Google Scholar] [CrossRef]

- Elhorst, J.P. Spatial Econometrics: From Cross-Sectional Data to Spatial Panels; Springer: Berlin/Heidelberg, Germany, 2015. [Google Scholar] [CrossRef]

- Anselin, L. Local indicator of spatial association-LISA. Geogr. Anal. 1995, 27, 91–115. [Google Scholar] [CrossRef]

- Duman, Z.; Mao, X.; Cai, B.; Zhang, Q.; Chen, Y.; Gao, Y.; Guo, Z. Exploring the spatiotemporal pattern evolution of carbon emissions and air pollution in Chinese cities. J. Environ. Manag. 2023, 345, 118870. [Google Scholar] [CrossRef] [PubMed]

- Brunsdon, C.; Fotheringham, A.S.; Charlton, M.E. Geographically weighted regression: A method for exploring spatial nonstationarity. Geogr. Anal. 1996, 28, 281–298. [Google Scholar] [CrossRef]

- Pang, J.; Liang, Y.; Sun, K.; Shi, Y. An analysis of the decoupling effect and influencing factors of economic growth and coal consumption in China’s provinces. China Environ. Sci. 2023, 10, 1–14. [Google Scholar] [CrossRef]

- Chen, F.; Shao, M.; Chen, W.; Wang, F. Environmental regulation, energy consumption structure, and industrial pollution emissions. Environ. Res. Commun. 2024, 6, 015011. [Google Scholar] [CrossRef]

- Wang, H. Industrial structure upgrading and technological capability in China-based on the perspective of industrial structure depth. Asian J. Technol. Innov. 2024, 32, 416–436. [Google Scholar] [CrossRef]

- Xu, L.; Peng, S.; Wang, L. The synergy of pollution and carbon reduction by green fiscal policy: A quasi-natural experiment utilizing a pilot program from China’s comprehensive demonstration cities of energy conservation and emission reduction fiscal policy. Sustainabilty 2025, 17, 667. [Google Scholar] [CrossRef]

- Dou, J.; Han, X. How does the industry mobility affect pollution industry transfer in China: Empirical test on pollution haven hypothesis and porter hypothesis. J. Clean. Prod. 2019, 217, 105–115. [Google Scholar] [CrossRef]

- Zhou, J.; Li, Y. Research on the threshold effect of green technology innovation on fog–haze pollution in the transfer of air pollution-intensive industries: A Perspective of Thermal Power. Atmosphere 2025, 16, 471. [Google Scholar] [CrossRef]

- Lv, C.; Fan, J.; Lee, C. Can green credit policies improve corporate green production efficiency? J. Clean. Prod. 2023, 397, 136573. [Google Scholar] [CrossRef]

- Aleksy, K.; Lyulyov, O.; Pimonenko, T. The effects of urbanisation on green growth within sustainable development goals. Land 2023, 12, 511. [Google Scholar] [CrossRef]

- Tang, L.; Lu, B.; Tian, T. Spatial correlation network and regional differences for the development of digital economy in China. Entropy 2021, 23, 1575. [Google Scholar] [CrossRef] [PubMed]

- Ma, W.; Yang, T. Can new infrastructure become a new driving force for high-quality industrial development in the Yellow River basin? Sustainability 2024, 16, 6831. [Google Scholar] [CrossRef]

- Cheng, Y.; Du, K.; Yao, X. Restructuring and relocation of polluting industries under air pollution control: Evidence from industrial investment flows between Chinese cities. China Econ. Rev. 2024, 83, 102099. [Google Scholar] [CrossRef]

- Xu, P. The impact of heterogeneous environmental regulations on regional spatial differences in net carbon emissions. Environ. Sci. Pollut. Res. 2023, 30, 1413–1427. [Google Scholar] [CrossRef]

- Li, J.; Zhang, Y.; Tian, Y.; Cheng, W.; Yang, J.; Xu, D.; Wang, Y.; Xie, K.; Ku, A.Y. Reduction of carbon emissions from China’s coal-fired power industry: Insights from the province-level data. J. Clean. Prod. 2020, 242, 118518. [Google Scholar] [CrossRef]

- Dong, G.; Huang, Y.; Liao, C.; Zhao, D.; Wang, P.; Sun, C. Analysis of the environmental and economic impacts of industrial restructuring and identification of key sectors based on an industrial correlation perspective. Sustainability 2025, 17, 817. [Google Scholar] [CrossRef]

- Dong, Z.; Tan, Y.; Wang, L.; Zheng, J.; Hu, S. Green supply chain management and clean technology innovation: An empirical analysis of multinational enterprises in China. J. Clean. Prod. 2021, 310, 127377. [Google Scholar] [CrossRef]

- Guo, B.; Hu, J.; Guo, X. Can the industrial transformation and upgrading demonstration zones policy improve urban green technology innovation? An empirical test based on old industrial cities and resource-based cities in China. Front. Environ. Sci. 2025, 12, 1505177. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, Z.; Li, Y.; Zhang, D.; Balezentis, T. Can green credit policy with dual-carbon targets make highly polluting enterprises “green”: A micro-analysis of total factor productivity growth. J. Environ. Manag. 2024, 367, 121981. [Google Scholar] [CrossRef] [PubMed]

| Level 1 Indicators | Level 2 Indicators | Interpretation of Indicators | Property | Entropy Weights | AHP Weights | Comprehensive Weights |

|---|---|---|---|---|---|---|

| SGPMS | Green production support | Number of industrial green policies (units) | + | 0.169 | 0.517 | 0.343 |

| Total investment in urban environmental infrastructure construction (billion yuan) | + | 0.103 | 0.306 | 0.205 | ||

| Industrial development capacity | Expenditure on new product development in industrial enterprises (10 thousand yuan) | + | 0.298 | 0.101 | 0.199 | |

| Expenditure on technology introduction in industrial enterprises (10 thousand yuan) | + | 0.429 | 0.077 | 0.253 | ||

| PGPOS | Utilisation of energy and waste | Comprehensive energy consumption per unit of industrial GDP (10 thousand tons of standard coal/billion yuan) | − | 0.118 | 0.171 | 0.144 |

| Coal consumption per unit of industrial GDP (10 thousand tons/billion yuan) | − | 0.074 | 0.168 | 0.121 | ||

| Clean new energy generation per unit of industrial GDP (100 million kilowatt hours/billion yuan) | + | 0.007 | 0.184 | 0.096 | ||

| Industrial water volume conserved (10 thousand cubic metres) | + | 0.188 | 0.064 | 0.126 | ||

| Industrial water volume reused (10 thousand cubic metres) | + | 0.153 | 0.063 | 0.108 | ||

| Integrated utilisation of general industrial solid waste (10 thousand tons) | + | 0.065 | 0.057 | 0.061 | ||

| Innovation capacity | Full-time equivalent of R&D personnel in industrial enterprises (person-years) | + | 0.155 | 0.105 | 0.130 | |

| Technological transformation expenditure of industrial enterprises (10 thousand yuan) | + | 0.094 | 0.086 | 0.090 | ||

| Industrial enterprises’ R&D expenditures (10 thousand yuan) | + | 0.146 | 0.102 | 0.124 | ||

| EGPCS | Industrial growth quality | Growth rate of industrial added value (%) | + | 0.151 | 0.173 | 0.162 |

| Sales revenue of new products per unit of industrial added value (10 thousand yuan) | + | 0.236 | 0.210 | 0.223 | ||

| Industrial pollution control and investment | Wastewater emissions from industry (10 thousand tons) | − | 0.017 | 0.052 | 0.034 | |

| SO2 emissions from industry (10 thousand tons) | − | 0.016 | 0.052 | 0.034 | ||

| Fumes emissions from industry (10 thousand tons) | − | 0.010 | 0.047 | 0.028 | ||

| General solid waste emissions from industry (10 thousand tons) | − | 0.014 | 0.042 | 0.028 | ||

| Industrial pollution control investment (10 thousand yuan) | + | 0.125 | 0.076 | 0.100 | ||

| Completed annual investment in industrial waste gas treatment (10 thousand yuan) | + | 0.157 | 0.088 | 0.123 | ||

| Carbon sink capacity | Forest coverage rate (%) | + | 0.131 | 0.137 | 0.134 | |

| Greening coverage rate of built-up areas (%) | + | 0.144 | 0.123 | 0.134 |

| Interval | Synergistic Effects Type | Interval | Synergistic Effects Type |

|---|---|---|---|

| (0.0, 0.1] | Extremely dysfunctional recession type | (0.5, 0.6] | Barely synergistic development type |

| (0.1, 0.2] | Severe dysregulation recession type | (0.6, 0.7] | Primary synergistic development type |

| (0.2, 0.3] | Moderately dysfunctional recession type | (0.7, 0.8] | Intermediate synergistic development type |

| (0.3, 0.4] | Mildly dysfunctional recession type | (0.8, 0.9] | Good synergy development type |

| (0.4, 0.5] | Hardly dysfunctional recession type | (0.9, 1.0] | Excellent synergistic development type |

| Category | Variable | Mean | P50 | SD | Min | Max |

|---|---|---|---|---|---|---|

| industrial green production capacity | Green production capacity in EGPCS | 0.143 | 0.103 | 0.155 | 0.001 | 0.906 |

| Green production capacity in PGPOS | 0.189 | 0.158 | 0.110 | 0.046 | 0.632 | |

| Green production capacity in SGPMS | 0.241 | 0.193 | 0.144 | 0.105 | 0.810 | |

| Synergistic effects | synergistic effects in industrial green production | 0.402 | 0.381 | 0.131 | 0.133 | 0.910 |

| Driving factors | Green Innovation (Ginnov) | 8.488 | 8.496 | 1.339 | 4.466 | 11.207 |

| Level of transport infrastructure (Tinfra) | 11.714 | 11.986 | 0.852 | 9.437 | 12.913 | |

| Level of digital economy development (DEDL) | 0.112 | 0.070 | 0.111 | 0.017 | 0.711 | |

| Labour level (Labour) | 7.601 | 7.658 | 0.768 | 5.545 | 8.864 | |

| Per capita GDP (PGDP) | 10.908 | 10.859 | 0.445 | 9.849 | 12.155 | |

| Environmental regulation intensity (ERI) | 0.260 | 0.232 | 0.111 | 0.105 | 0.758 | |

| Level of green credit (GCL) | 0.521 | 0.507 | 0.154 | 0.192 | 0.906 | |

| Level of social consumption (Sconsum) | 0.389 | 0.394 | 0.059 | 0.180 | 0.504 | |

| Intensity of foreign direct investment (FDI) | 0.265 | 0.145 | 0.268 | 0.008 | 1.354 | |

| Urbanisation level (UR) | 0.607 | 0.593 | 0.117 | 0.363 | 0.896 | |

| Optimisation of industrial structure (ISO) | 1.384 | 1.221 | 0.751 | 0.611 | 5.283 |

| Year | Moran’I | Z (I) | p |

|---|---|---|---|

| 2012 | 0.094 | 3.622 | 0.000 |

| 2013 | 0.095 | 3.651 | 0.000 |

| 2014 | 0.096 | 3.666 | 0.000 |

| 2015 | 0.090 | 3.530 | 0.000 |

| 2016 | 0.096 | 3.653 | 0.000 |

| 2017 | 0.089 | 3.452 | 0.001 |

| 2018 | 0.090 | 3.514 | 0.000 |

| 2019 | 0.091 | 3.557 | 0.000 |

| 2020 | 0.084 | 3.389 | 0.001 |

| 2021 | 0.088 | 3.509 | 0.000 |

| 2022 | 0.087 | 3.501 | 0.000 |

| Category | Variable | Description | Data Source | Coefficient & Significance | VIF |

|---|---|---|---|---|---|

| dependent variable | − | Synergistic effects of the three phases of industrial green productive capacity | Calculated from Equation (5) | − | − |

| Constant | − | − | − | −0.607 (−5.60) | − |

| Basic support conditions | Green Innovation (Ginnov) | Logarithmic number of green patent applications | Chinese Research Data Services (CNRDS) | 0.008 (1.33) | 31.71 |

| Level of transport infrastructure (Tinfra) | Logarithm of road mileage | China Statistical Yearbook | 0.003 (0.42) | 8.72 | |

| Level of digital economy development (DEDL) | Logarithm of the count of terms related to the digital economy | Government working report | 0.551 *** (15.20) | 3.15 | |

| Labour level (Labour) | Logarithm of total employed persons | China Statistical Yearbook | 0.092 *** (7.31) | 18.17 | |

| Per capita GDP (PGDP) | Per capita GDP | China Statistical Yearbook | −0.006 (−1.32) | 17.02 | |

| Institutional environment | Environmental regulation intensity (ERI) | Logarithm of the count of terms related to the environment | Government working report | 0.093 ** (2.10) | 4.85 |

| Level of green credit (GCL) | Green credit ratio | The People’s Bank of China | 0.058 ** (2.49) | 2.52 | |

| Market environment | Level of social consumption (Sconsum) | Total consumption of consumer goods/GDP | China Statistical Yearbook | −0.071 (−1.58) | 1.57 |

| Intensity of foreign direct investment (FDI) | Total trade in goods and services/GDP | China Statistical Yearbook | 0.006 (0.29) | 6.38 | |

| Urbanisation level (UR) | Urban population/total population | China Statistical Yearbook | 0.388 *** (7.29) | 7.64 | |

| Optimisation of industrial structure (ISO) | Tertiary industry value added/GDP | China Statistical Yearbook | −0.045 *** (−10.52) | 1.97 |

| Model | R2 | Adj.R2 | AICc |

|---|---|---|---|

| OLS | 0.834 | 0.806 | −87.498 |

| GWR | 0.932 | 0.896 | −105.100 |

| Variable | Mean | SD | Min | Max | P50 | CV |

|---|---|---|---|---|---|---|

| DEDL | 1.093 | 0.901 | 0.159 | 3.702 | 0.956 | 0.825 |

| ERI | −0.037 | 1.474 | −3.118 | 3.615 | −0.181 | −40.295 |

| GCL | 0.046 | 0.897 | −3.037 | 2.244 | 0.008 | 19.533 |

| UR | 0.799 | 0.877 | −0.154 | 4.719 | 0.607 | 1.098 |

| ISO | 0.140 | 0.155 | −0.039 | 0.746 | 0.136 | 1.104 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, C.; Deng, H.; Wang, L. The Spatiotemporal Patterns and Driving Mechanism of the Synergistic Effects in Industrial Green Production. Sustainability 2025, 17, 7439. https://doi.org/10.3390/su17167439

Li C, Deng H, Wang L. The Spatiotemporal Patterns and Driving Mechanism of the Synergistic Effects in Industrial Green Production. Sustainability. 2025; 17(16):7439. https://doi.org/10.3390/su17167439

Chicago/Turabian StyleLi, Chuang, Hui Deng, and Liping Wang. 2025. "The Spatiotemporal Patterns and Driving Mechanism of the Synergistic Effects in Industrial Green Production" Sustainability 17, no. 16: 7439. https://doi.org/10.3390/su17167439

APA StyleLi, C., Deng, H., & Wang, L. (2025). The Spatiotemporal Patterns and Driving Mechanism of the Synergistic Effects in Industrial Green Production. Sustainability, 17(16), 7439. https://doi.org/10.3390/su17167439