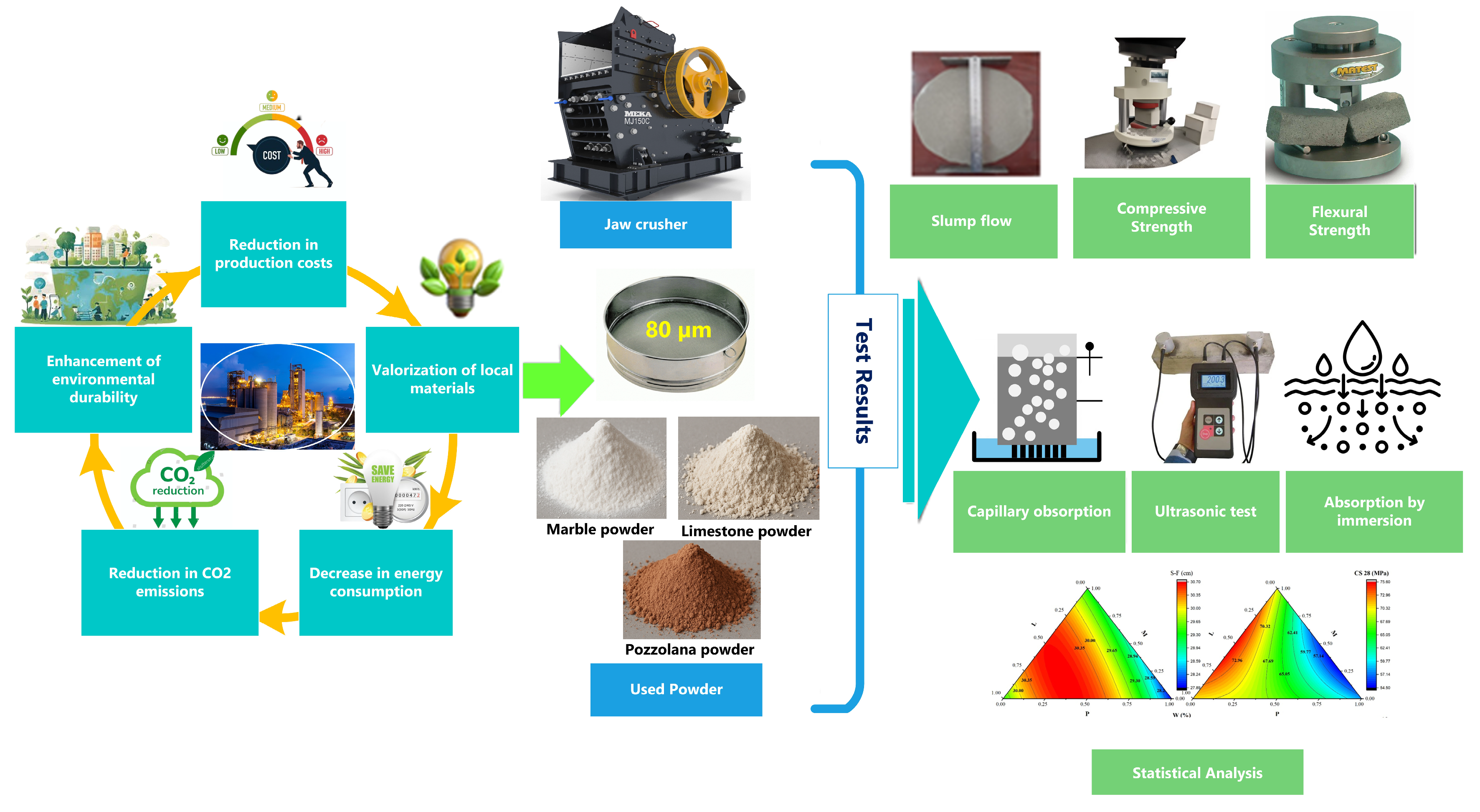

Synergistic Optimization of Mortar Performance and Carbon Footprint Reduction Using Quarry Wastes and Natural Pozzolana: A Statistical and Experimental Study

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Mortars and Specimens’ Preparation

2.3. Experimental Program

3. Results and Discussion

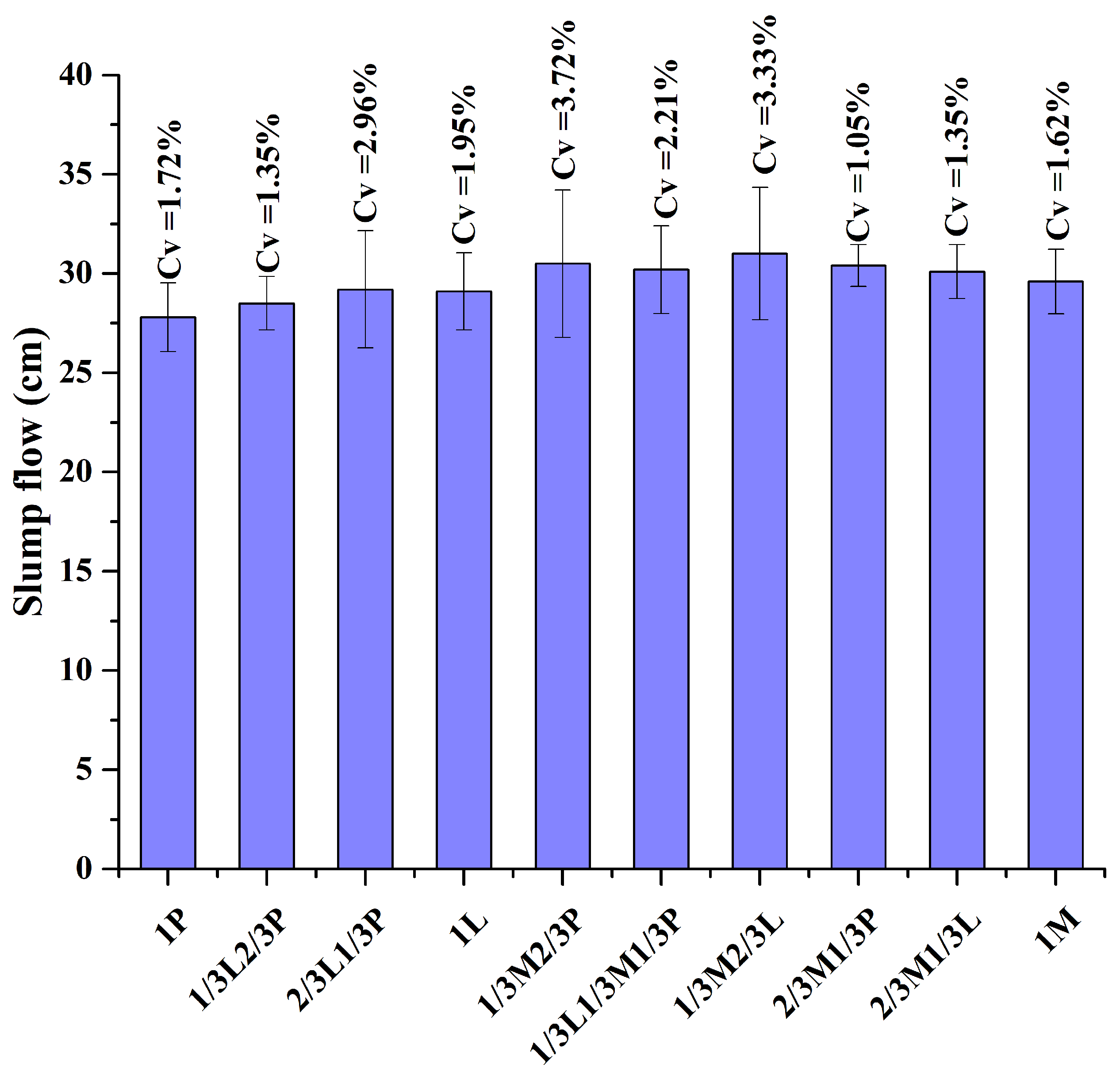

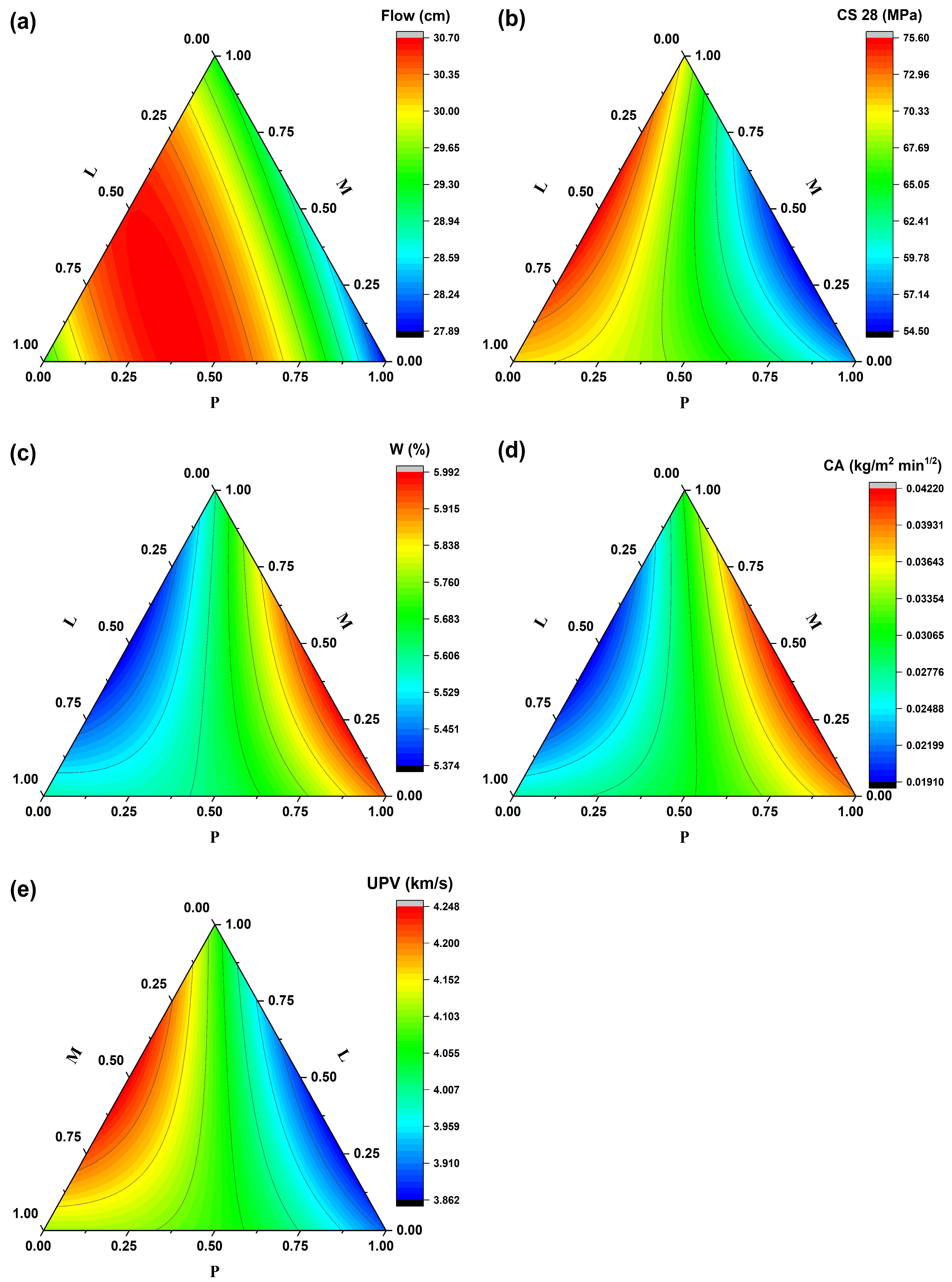

3.1. Flow of Self-Compacting Mortars

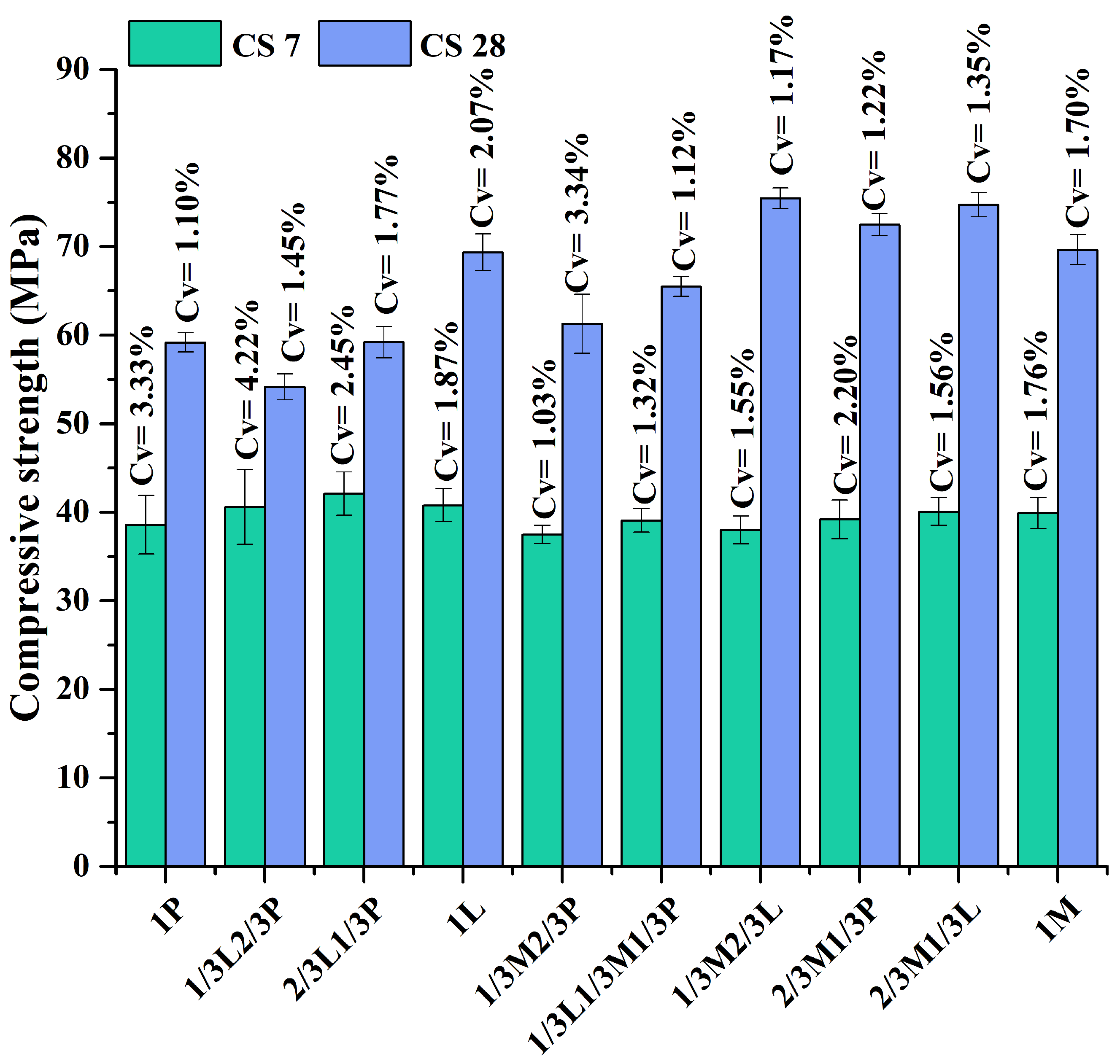

3.2. Compressive Strength

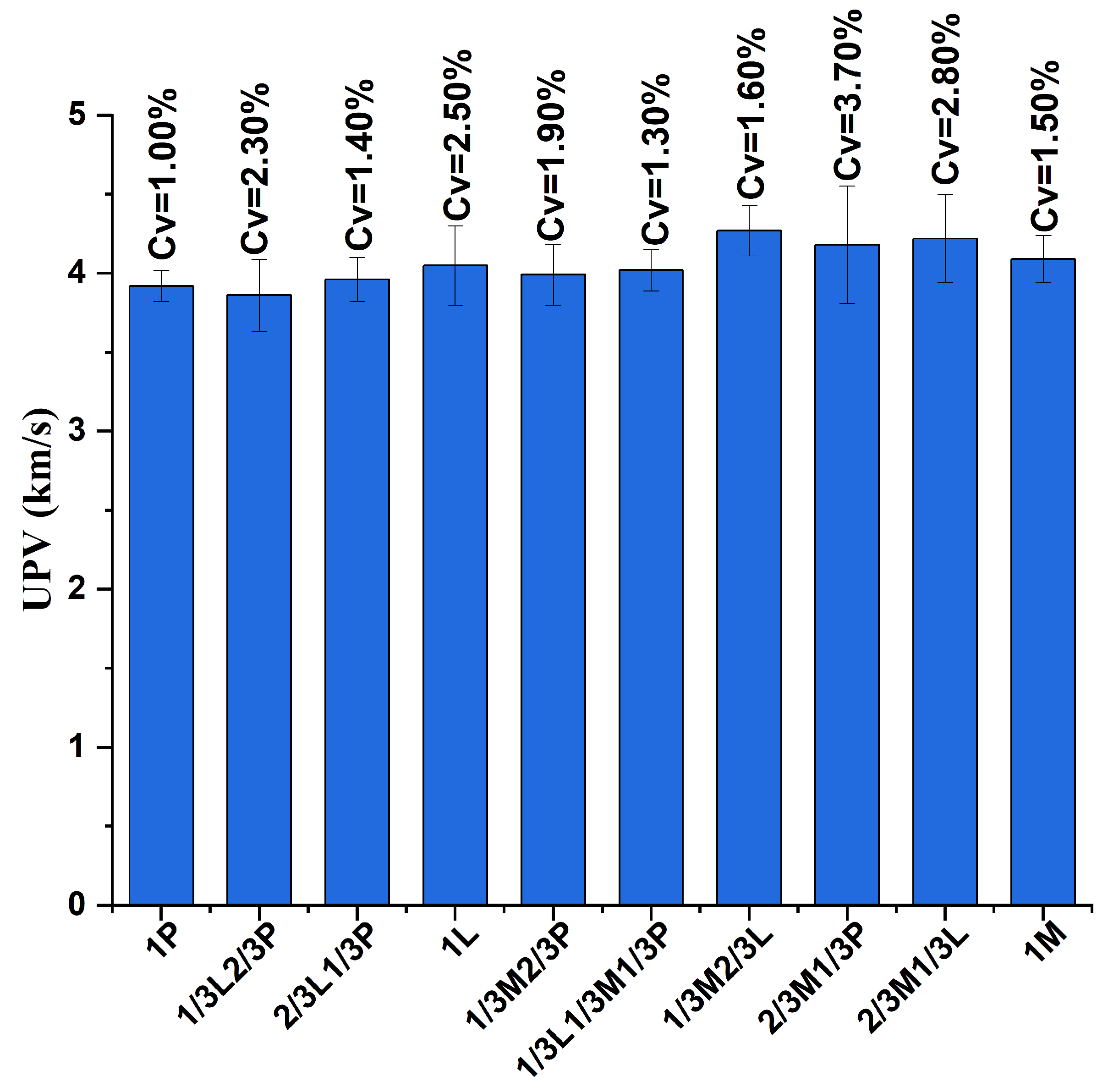

3.3. Ultrasonic Pulse Velocity

3.4. Water Absorption by Immersion

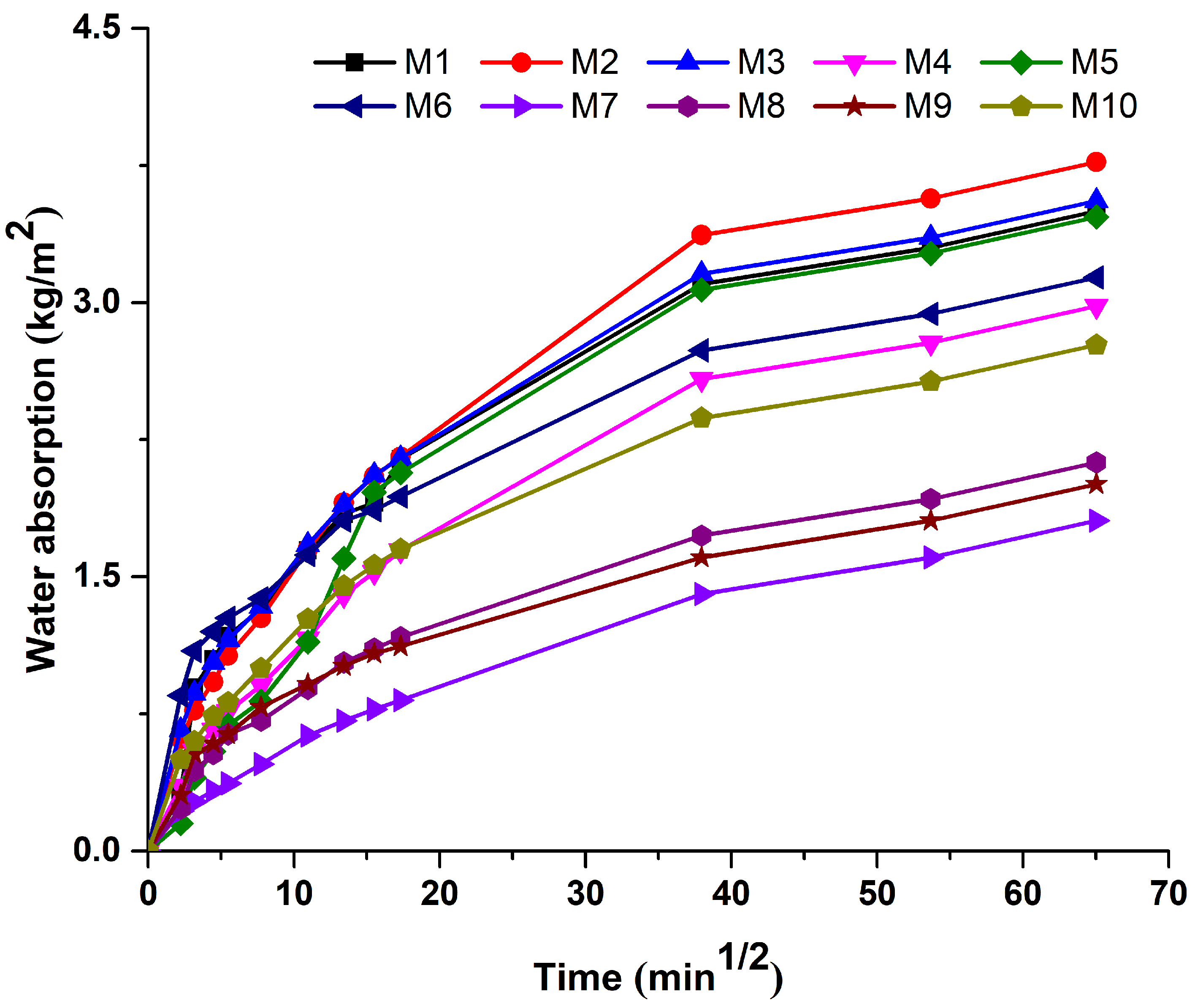

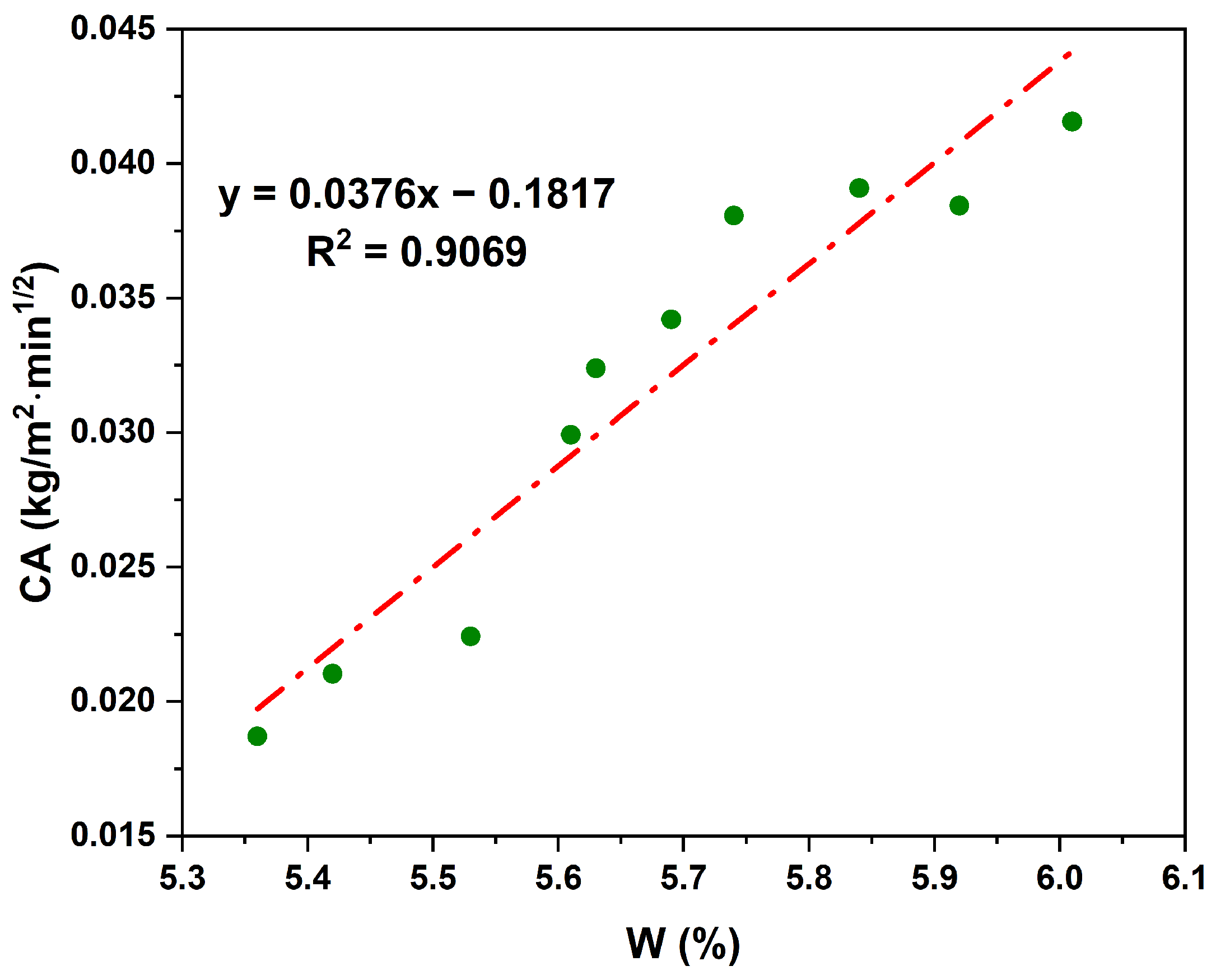

3.5. Capillary Absorption of Mortars

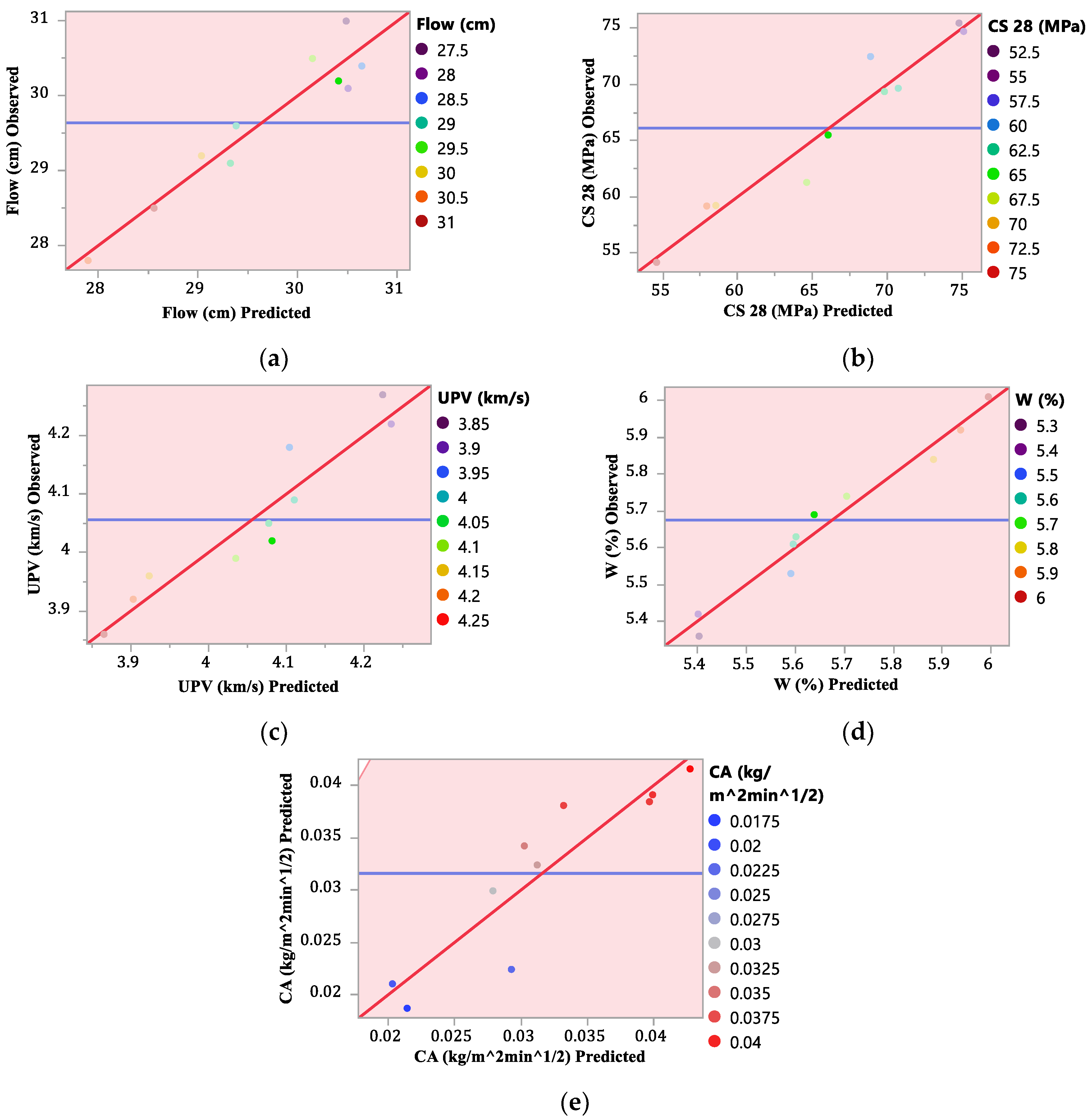

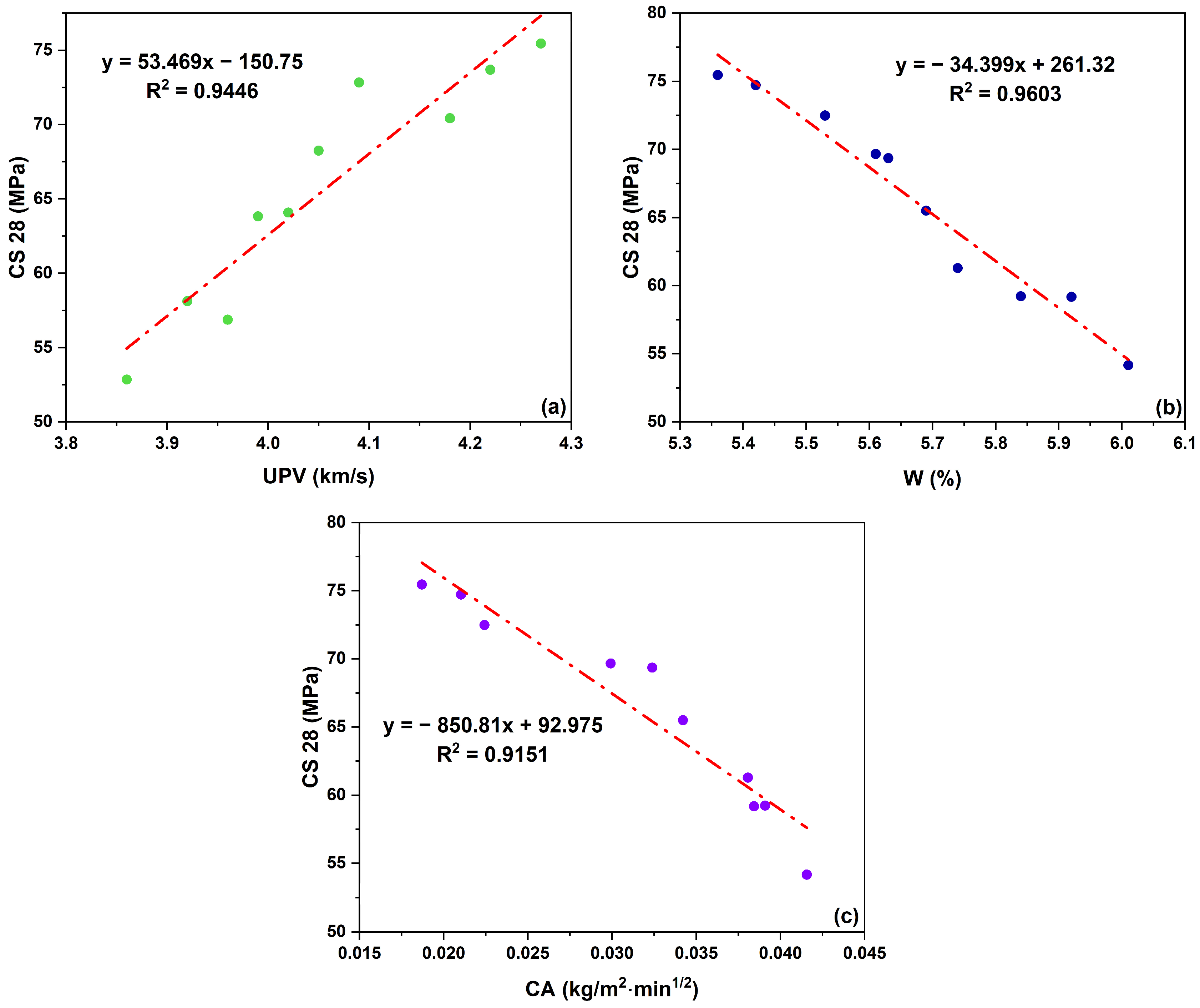

3.6. Statistical Analysis

4. Life Cycle Assessment of Studied Self-Compacting Mortars

4.1. Study Assumptions

- A uniform transport distance of 150 km was adopted in the modeling due to the lack of precise extraction site data. This assumption enables the integration of transportation impacts into the environmental balance while avoiding bias in favor of or against any specific material based on geographic proximity. It represents a plausible and regionally representative estimate, ensuring fair comparability among raw materials.

- Unlike pozzolana, which is considered a natural resource, limestone and marble were treated as recycled construction waste in the modeling. This distinction is critical, as recycled materials generally have a lower environmental impact due to the avoided extraction phase.

- Due to differences in hardness, marble requires more electrical energy for grinding than limestone (0.06 kWh vs. 0.04 kWh per unit weight, respectively). This factor significantly influences the overall energy balance of the different mortar formulations.

- Mortar mixing and preparation were assumed to be manual, requiring no additional electrical energy. This assumption aligns with small-scale production scenarios but may differ in large industrial applications.

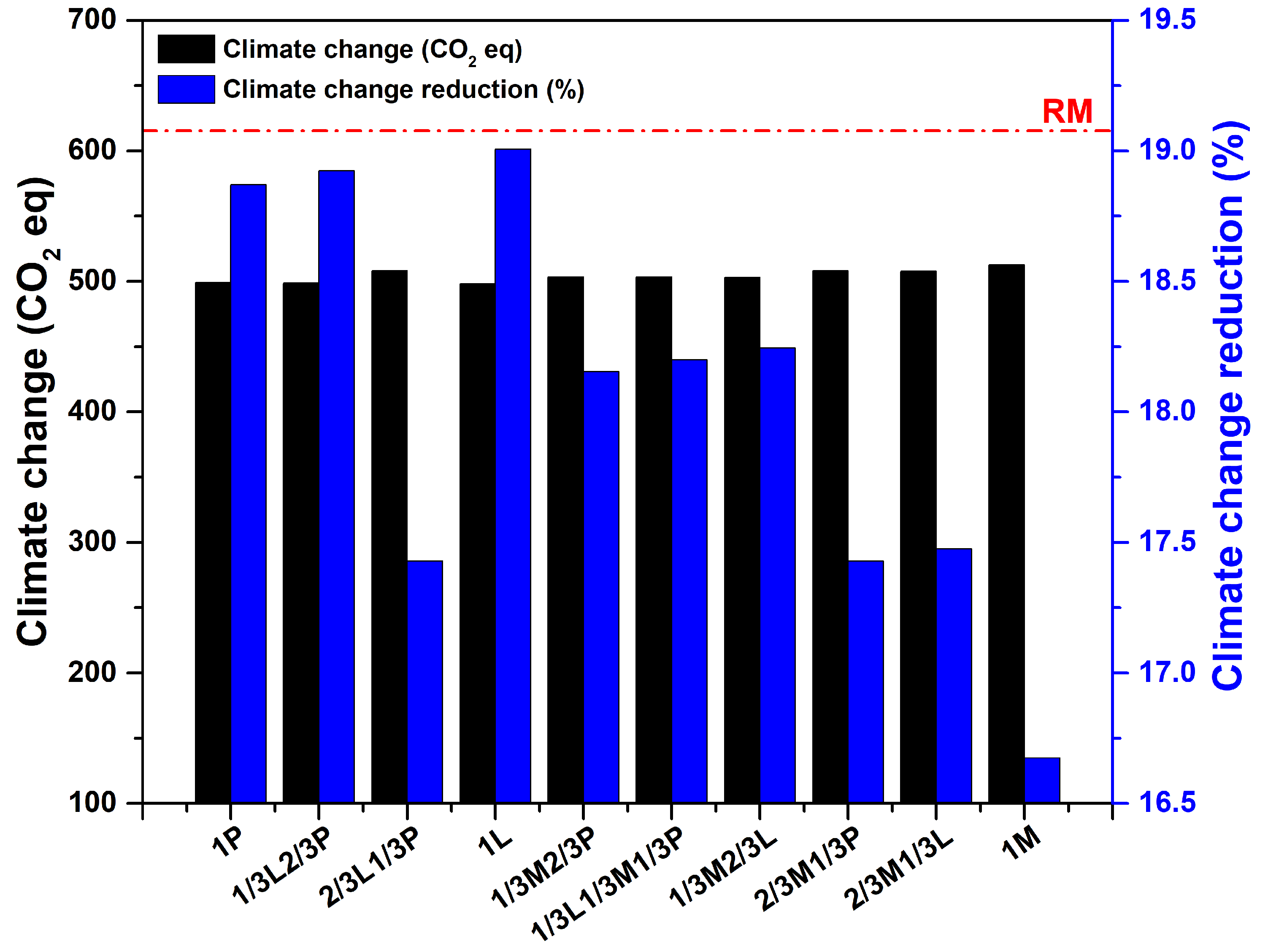

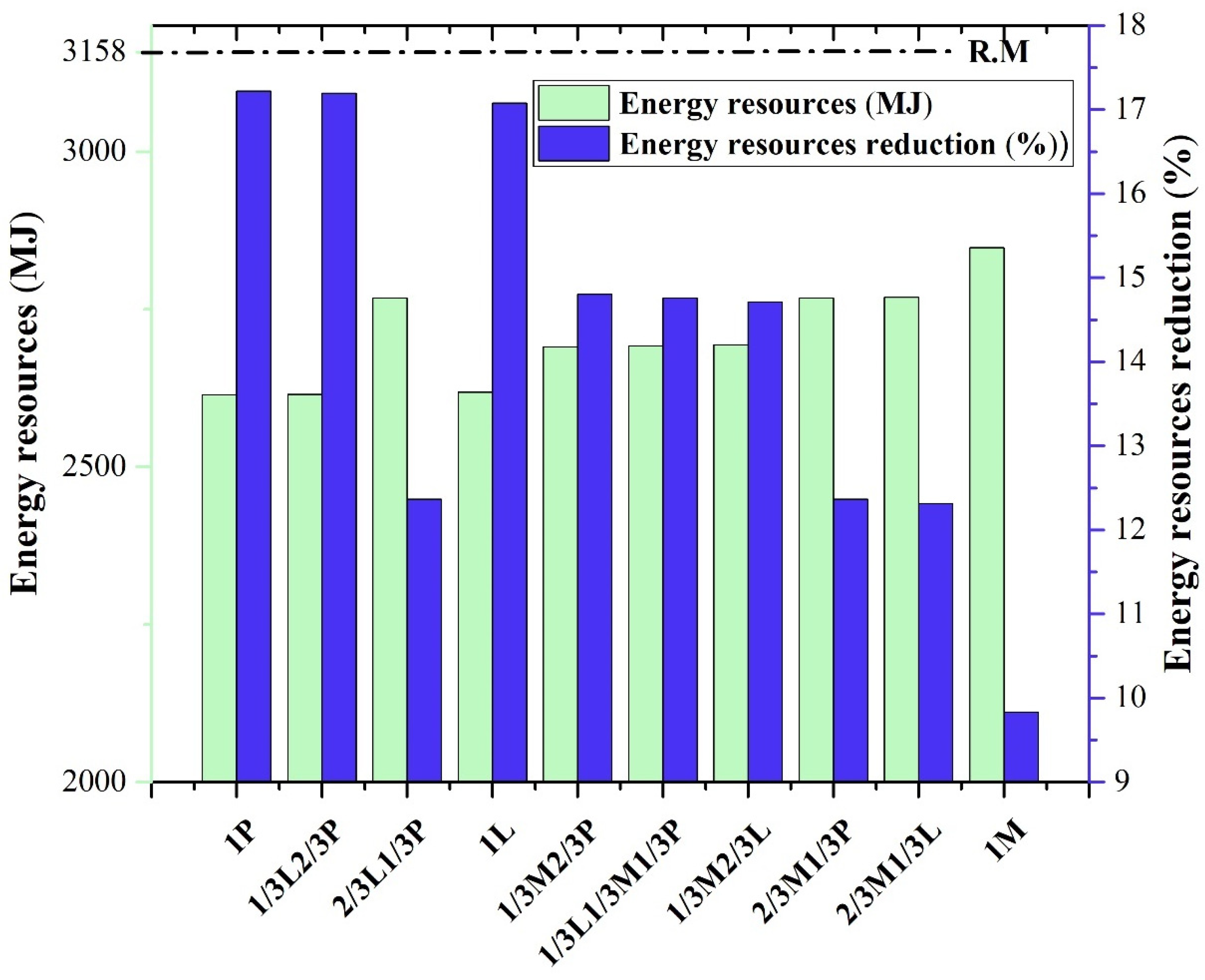

4.2. Impact of Greenhouse Gas Emissions and Non-Renewable Energy Resources on the Studied Mortars

5. Discussion

6. Conclusions

- Mortars containing marble powder exhibited superior flowability, with a spread value reaching up to 32 cm, outperforming other mixtures by up to 9%.

- The results highlight that Blaine specific surface alone does not govern compressive strength. Despite its high fineness (480 m2/kg), marble led to 12% lower strength at 28 days compared to limestone (422 m2/kg). In contrast, ternary blends combining high BSS and pozzolanic reactivity (e.g., M7, M9) achieved the highest strengths (up to 75 MPa), confirming that optimized synergy between surface area and reactivity is key to mechanical performance.

- The UPV values ranged from 3.86 to 4.27 km/s, with the highest values observed in mortars containing limestone or marble due to their filler effect, which improves the microstructure. In contrast, pozzolana substitution led to lower UPV due to its delayed pozzolanic reaction and increased porosity. A strong correlation (R2 = 0.94) was found between compressive strength and UPV, confirming UPV as a reliable indicator of the mechanical performance of self-compacting mortars.

- Water absorption tests indicated that mortars containing powders of marble (M5) or natural pozzolana (M1) had slightly higher water absorption by immersion than those with only limestone powder (M10), with increases of 2% and 3%, respectively.

- The capillary analysis revealed that marble powder contributed to the lowest capillary coefficient, likely due to its high specific surface area.

- Statistical analysis, including R2 and ANOVA, validated the effectiveness of the models in predicting flowability, 28-day compressive strength, water absorption, and capillarity.

- The optimization process successfully identified the most effective mortar formulations, balancing these properties to meet specific performance criteria.

- The partial replacement of cement in mortar formulations led to a reduction in GHG emissions by up to 19.01% (M4) and a decrease in non-renewable energy consumption by up to 17.22% (M1). Pozzolana-based mixtures demonstrated the most significant environmental benefits, with emission reductions of 18.87% (M1) and 18.92% (M2), while marble-based mixtures exhibited the lowest reductions, reaching only 9.83% (M10).

- Limestone substitution proved to be an effective alternative, achieving emission reductions of up to 18.24% (M7) and energy savings of 14.76% (M6). However, the environmental benefits of cement reduction must be assessed alongside mechanical and durability performance to ensure that these optimized formulations maintain or enhance structural integrity.

- This study provided a comprehensive evaluation of the mechanical, environmental, and durability performance of various blended mortar formulations incorporating pozzolana, limestone, and marble powders. The results highlight a performance trade-off between compressive strength and environmental impact, largely governed by the nature and proportion of the supplementary materials. Marble-based mortars (M8–M10) exhibited the highest strength improvements but delivered modest reductions in GHG emissions, due to their higher energy footprint. In contrast, pozzolana-based mixes (M1, M2) achieved the greatest environmental gains, albeit at the cost of lower mechanical performance. Limestone-based mixtures, particularly M4, demonstrated the most balanced profile, combining a notable GHG reduction (19.01%) with a modest strength gain (+2%), confirming its suitability for sustainable and high-performance applications. Overall, the findings underscore the importance of holistic mix design strategies that integrate technical properties, durability criteria, and life cycle impacts to guide the development of environmentally optimized mortars for the construction sector.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Shah, I.H.; Miller, S.A.; Jiang, D.; Myers, R.J. Cement substitution with secondary materials can reduce annual global CO2 emissions by up to 1.3 gigatons. Nat. Commun. 2022, 13, 5758. [Google Scholar] [CrossRef] [PubMed]

- Chaudhury, R.; Sharma, U.; Thapliyal, P.; Singh, L. Low-CO2 emission strategies to achieve net zero target in cement sector. J. Clean. Prod. 2023, 417, 137466. [Google Scholar] [CrossRef]

- Mora, P.; Sanjuán, M.; Moraño, A.; Fernández-Hernández, M. Cement Sector and Promising Technologies to Reduce CO2 Footprint Through Circular Economy: Novel Raw Materials and Products. In Circular Economy on Energy and Natural Resources Industries: New Processes and Applications to Reduce, Reuse and Recycle Materials and Decrease Greenhouse Gases Emissions; Springer: Cham, Switzerland, 2024; pp. 53–71. [Google Scholar]

- Teker Ercan, E.E.; Andreas, L.; Cwirzen, A.; Habermehl-Cwirzen, K. Wood Ash as Sustainable Alternative Raw Material for the Production of Concrete—A Review. Materials 2023, 16, 2557. [Google Scholar] [CrossRef]

- Jittin, V.; Bahurudeen, A. Production of cleaner binders by reusing agricultural by-products: An approach towards zero cement concrete for sustainable future infrastructure. J. Clean. Prod. 2024, 451, 141990. [Google Scholar] [CrossRef]

- Akram, R.; Ibrahim, R.L.; Wang, Z.; Adebayo, T.S.; Irfan, M. Neutralizing the surging emissions amidst natural resource dependence, eco-innovation, and green energy in G7 countries: Insights for global environmental sustainability. J. Environ. Manag. 2023, 344, 118560. [Google Scholar] [CrossRef]

- Ghulam, S.T.; Abushammala, H. Challenges and opportunities in the management of electronic waste and its impact on human health and environment. Sustainability 2023, 15, 1837. [Google Scholar] [CrossRef]

- Aravecchia, N.; Bañuls-Ciscar, J.; Caverzan, A.; Ceccone, G.; Cuenca, E.; Ferrara, L.; Grigoriadis, K.; Negro, P.; Rodriquens, M. On the feasibility of using Polyester (PE) waste particles from metal coating industry as a secondary raw materials in concrete. Clean. Mater. 2023, 9, 100193. [Google Scholar] [CrossRef]

- Anandaraj, S.; Karthik, S.; Elango, K.; Nishiketan, S.; Pandiyarajan, G.; Kumar, P.N.; Palanikumar, R.; Harihanandh, M. An experimental study on Fly Ash (FA) and marble powder in the properties of Self-Compacting Concrete (SCC). Mater. Today Proc. 2022, 52, 1771–1774. [Google Scholar] [CrossRef]

- Nasr, M.S.; Salman, A.J.; Ghayyib, R.J.; Shubbar, A.; Al-Mamoori, S.; Al-khafaji, Z.; Hashim, T.M.; Hasan, Z.A.; Sadique, M. Effect of clay brick waste powder on the fresh and hardened properties of self-compacting concrete: State-of-the-art and life cycle assessment. Energies 2023, 16, 4587. [Google Scholar] [CrossRef]

- Gautam, L.; Jain, J.K.; Jain, A.; Kalla, P.J.C.; Materials, B. Valorization of bone-china ceramic powder waste along with granite waste in self-compacting concrete. Constr. Build. Mater. 2022, 315, 125730. [Google Scholar] [CrossRef]

- Danish, P.; Ganesh, G.M. Study on influence of Metakaolin and waste marble powder on self-compacting concrete–a state of the art review. Mater. Today Proc. 2021, 44, 1428–1436. [Google Scholar] [CrossRef]

- Aidjouli, Y.; Belebchouche, C.; Hammoudi, A.; Kadri, E.-H.; Zaouai, S.; Czarnecki, S. Modeling the Properties of Sustainable Self-Compacting Concrete Containing Marble and Glass Powder Wastes Using Response Surface Methodology. Sustainability 2024, 16, 1972. [Google Scholar] [CrossRef]

- Rojo-López, G.; González-Fonteboa, B.; Martínez-Abella, F.; González-Taboada, I. Rheology, durability, and mechanical performance of sustainable self-compacting concrete with metakaolin and limestone filler. Case Stud. Constr. Mater. 2022, 17, e01143. [Google Scholar] [CrossRef]

- Zaouai, S.; Tafraoui, A.; Makani, A.; Benmerioul, F. Hardened and transfer properties of self-compacting concretes containing pre-coated rubber aggregates with crushed dune sand. J. Rubber Res. 2020, 23, 5–12. [Google Scholar] [CrossRef]

- Goual, I.; Benabed, B. Mix-design and properties of self-compacting concrete made with calcareous tuff. J. Build. Eng. 2020, 27, 100997. [Google Scholar]

- Najeeb, Z.; Mosaberpanah, M.A. Mechanical and durability properties of modified High-Performance mortar by using cenospheres and Nano-Silica. Constr. Build. Mater. 2023, 362, 129782. [Google Scholar] [CrossRef]

- Environment, U.; Scrivener, K.L.; John, V.M.; Gartner, E.M. Eco-efficient cements: Potential economically viable solutions for a low-CO2 cement-based materials industry. Cem. Concr. Res. 2018, 114, 2–26. [Google Scholar]

- Habert, G.; De Lacaillerie, J.D.E.; Roussel, N. An environmental evaluation of geopolymer based concrete production: Reviewing current research trends. J. Clean. Prod. 2011, 19, 1229–1238. [Google Scholar] [CrossRef]

- Anderson, D.J.; Smith, S.T.; Au, F.T. Mechanical properties of concrete utilising waste ceramic as coarse aggregate. Constr. Build. Mater. 2016, 117, 20–28. [Google Scholar] [CrossRef]

- Khitas, N.E.H.; Hebbache, K.; Douadi, A.; Boutlikht, M.; Belebchouche, C.; Messai, A.; Mahar, N.E.-H.; Del Serrone, G.; Moretti, L.; Czarnecki, S.J.C.; et al. Modeling and optimizing the properties of mortars based on natural pozzolan, silica sand, and recycled brick waste mixture design: A technical and environmental study. Constr. Build. Mater. 2025, 459, 139706. [Google Scholar] [CrossRef]

- El-Dieb, A.S.; Kanaan, D.M. Ceramic waste powder an alternative cement replacement–Characterization and evaluation. Sustain. Mater. Technol. 2018, 17, e00063. [Google Scholar] [CrossRef]

- Douadi, A.; Hebbache, K.; Boutlikht, M.; Tabchouche, S.; Belebchouche, C.; Hammouche, R.; Del Serrone, G.; Moretti, L. Physical and mechanical effects of silica sand in cement mortars: Experimental and statistical modeling. Materials 2023, 16, 6861. [Google Scholar] [CrossRef]

- Barbhuiya, S.; Nepal, J.; Das, B.B. Properties, compatibility, environmental benefits and future directions of limestone calcined clay cement (LC3) concrete: A review. J. Build. Eng. 2023, 79, 107794. [Google Scholar] [CrossRef]

- Prakash, B.; Saravanan, T.J.; Kabeer, K.S.A.; Bisht, K. Exploring the potential of waste marble powder as a sustainable substitute to cement in cement-based composites: A review. Constr. Build. Mater. 2023, 401, 132887. [Google Scholar] [CrossRef]

- Özkılıç, Y.O.; Zeybek, Ö.; Bahrami, A.; Çelik, A.İ.; Mydin, M.A.O.; Karalar, M.; Hakeem, I.Y.; Roy, K.; Jagadesh, P. Optimum usage of waste marble powder to reduce use of cement toward eco-friendly concrete. J. Mater. Res. Technol. 2023, 25, 4799–4819. [Google Scholar] [CrossRef]

- Soni, A.; Das, P.K.; Hashmi, A.W.; Yusuf, M.; Kamyab, H.; Chelliapan, S. Challenges and opportunities of utilizing municipal solid waste as alternative building materials for sustainable development goals: A review. Sustain. Chem. Pharm. 2022, 27, 100706. [Google Scholar] [CrossRef]

- Wang, D.; Shi, C.; Farzadnia, N.; Shi, Z.; Jia, H.; Ou, Z.J.C.; Materials, B. A review on use of limestone powder in cement-based materials: Mechanism, hydration and microstructures. Constr. Build. Mater. 2018, 181, 659–672. [Google Scholar] [CrossRef]

- Ghezal, A.; Khayat, K.H. Optimizing self-consolidating concrete with limestone filler by using statistical factorial design methods. Mater. J. 2002, 99, 264–272. [Google Scholar]

- Sonebi, M.; Svermova, L.; Bartos, P.J.M. Factorial design of cement slurries containing limestone powder for self-consolidating slurry-infiltrated fiber concrete. Mater. J. 2004, 101, 136–145. [Google Scholar]

- Rizwan, S.A.; Bier, T.A. Blends of limestone powder and fly-ash enhance the response of self-compacting mortars. Constr. Build. Mater. 2012, 27, 398–403. [Google Scholar] [CrossRef]

- Khalid, A.R.; Rizwan, S.A.; Hanif, U.; Hameed, M.H. Effect of mixing time on flowability and slump retention of self-compacting paste system incorporating various secondary raw materials. Arab. J. Sci. Eng. 2016, 41, 1283–1290. [Google Scholar] [CrossRef]

- Felekoğlu, B.; Tosun, K.; Baradan, B.; Altun, A.; Uyulgan, B.J. The effect of fly ash and limestone fillers on the viscosity and compressive strength of self-compacting repair mortars. Cem. Concr. Res. 2006, 36, 1719–1726. [Google Scholar] [CrossRef]

- Rizwan, S.A.; Bier, T.A. Self-consolidating mortars using various secondary raw materials. ACI Mater. J. 2009, 106, 25. [Google Scholar] [CrossRef]

- Belaidi, A.; Azzouz, L.; Kadri, E.; Kenai, S. Effect of natural pozzolana and marble powder on the properties of self-compacting concrete. Constr. Build. Mater. 2012, 31, 251–257. [Google Scholar] [CrossRef]

- Cerquitelli, T.; Pagliari, D.J.; Calimera, A.; Bottaccioli, L.; Patti, E.; Acquaviva, A.; Poncino, M. Manufacturing as a data-driven practice: Methodologies, technologies, and tools. Proc. IEEE 2021, 109, 399–422. [Google Scholar] [CrossRef]

- Hammoudi, A.; Moussaceb, K.; Belebchouche, C.; Dahmoune, F. Comparison of artificial neural network (ANN) and response surface methodology (RSM) prediction in compressive strength of recycled concrete aggregates. Constr. Build. Mater. 2019, 209, 425–436. [Google Scholar] [CrossRef]

- Ali, M.; Macioszek, E. Effect of Pumice Stone as a Coarse Aggregate Replacement on Lightweight Concrete Properties Using Response Surface Methodology. In Proceedings of the International Conference on Computer Methods in Mechanics and 5th Polish Congress of Mechanics, Gliwice, Poland, 4–7 September 2023; pp. 12–26. [Google Scholar]

- de Matos, P.R.; Pilar, R.; Bromerchenkel, L.H.; Schankoski, R.A.; Gleize, P.J.; de Brito, J. Self-compacting mortars produced with fine fraction of calcined waste foundry sand (WFS) as alternative filler: Fresh-state, hydration and hardened-state properties. J. Clean. Prod. 2020, 252, 119871. [Google Scholar] [CrossRef]

- Adamu, M.; Trabanpruek, P.; Jongvivatsakul, P.; Likitlersuang, S.; Iwanami, M. Mechanical performance and optimization of high-volume fly ash concrete containing plastic wastes and graphene nanoplatelets using response surface methodology. Constr. Build. Mater. 2021, 308, 125085. [Google Scholar] [CrossRef]

- Adamu, M.; Marouf, M.L.; Ibrahim, Y.E.; Ahmed, O.S.; Alanazi, H.; Marouf, A.L. Modeling and optimization of the mechanical properties of date fiber reinforced concrete containing silica fume using response surface methodology. Case Stud. Constr. Mater. 2022, 17, e01633. [Google Scholar] [CrossRef]

- Li, B.; Chi, Y.; Xu, L.; Shi, Y.; Li, C. Experimental investigation on the flexural behavior of steel-polypropylene hybrid fiber reinforced concrete. Constr. Build. Mater. 2018, 191, 80–94. [Google Scholar] [CrossRef]

- Lalitha, G.; Kumar, S.; Ravali, G.; Santhosh, M.; Dileep, M.J.M. An experimental study on strength parameters of OPC, PPC and geopolymer mortars. Management 2022, 9, 21–28. [Google Scholar]

- Faraj, R.H.; Ahmed, H.U.; Rafiq, S.; Sor, N.H.; Ibrahim, D.F.; Qaidi, S.M. Performance of Self-Compacting mortars modified with Nanoparticles: A systematic review and modeling. Clean. Mater. 2022, 4, 100086. [Google Scholar] [CrossRef]

- Rocha, S.; Ascensão, G.; Maia, L. Exploring Design Optimization of Self-Compacting Mortars with Response Surface Methodology. Appl. Sci. 2023, 13, 10428. [Google Scholar] [CrossRef]

- Goupy, J. Introduction aux Plans D’expériences, 1st ed.; Bordas: Paris, France, 2013. [Google Scholar]

- Li, L.; Wan, Y.; Chen, S.; Tian, W.; Long, W.; Song, J. Prediction of optimal ranges of mix ratio of self-compacting mortars (SCMs) based on response surface method (RSM). Constr. Build. Mater. 2022, 319, 126043. [Google Scholar] [CrossRef]

- Ghrici, M.; Kenai, S.; Said-Mansour, M. Mechanical properties and durability of mortar and concrete containing natural pozzolana and limestone blended cements. Cem. Concr. Compos. 2007, 29, 542–549. [Google Scholar] [CrossRef]

- Shah, V.; Parashar, A.; Mishra, G.; Medepalli, S.; Krishnan, S.; Bishnoi, S. Influence of cement replacement by limestone calcined clay pozzolan on the engineering properties of mortar and concrete. Adv. Cem. Res. 2020, 32, 101–111. [Google Scholar] [CrossRef]

- Benkaddour, M.; Kenai, S.; Yahiaoui, W.; Bensaci, H.; Khatib, J. Rheological, mechanical and durability performance of some North African commercial binary and ternary cements. Case Stud. Constr. Mater. 2023, 19, e02689. [Google Scholar] [CrossRef]

- EN 197-1:2011; Cement—Part 1: Composition, Specifications and Conformity Criteria for Common Cements. iTeh Standards: Etobicoke, ON, Canada, 2011.

- Moulay-Ali, A.; Abdeldjalil, M.; Khelafi, H. An experimental study on the optimal compositions of ordinary concrete based on corrected dune sand—Case of granular range of 25 mm. Case Stud. Constr. Mater. 2021, 14, e00521. [Google Scholar] [CrossRef]

- Okamura, H.; Ozawa, K.; Ouchi, M. Self-compacting concrete. Struct. Concr. 2000, 1, 3–17. [Google Scholar] [CrossRef]

- ASTM C1585; Standard Test Method for Measurement of Rate of Absorption of Water by Hydraulic-Cement Concretes. ASTM International: West Conshohocken, PA, USA, 2013; Volume 41, pp. 1–6.

- EN 1015-11; Methods of Test for Mortar for Masonry—Part 11: Determination of Flexural and Compressive Strength of Hardened Mortar. iTeh Standards: Etobicoke, ON, Canada, 2019.

- C1403–13; Standard Test Method for Rate of Water Absorption of Masonry Mortars1. ASTM International: West Conshohocken, PA, USA, 2015.

- Raju, M.R.; Ahmad, S.I.; Hasan, M.M.; Hasan, N.M.S.; Islam, M.M.; Basit, M.A.; Hossain, I.T.; Santo, S.A.; Alam, M.S.; Rahman, M. Machine learning for predicting strength properties of waste iron slag concrete. Heliyon 2025, 11, e42133. [Google Scholar] [CrossRef]

- Pelánek, R. Metrics for Evaluation of Student Models. J. Educ. Data Min. 2015, 7, 1–19. [Google Scholar]

- Hammouche, R.; Belebchouche, C.; Hammoudi, A.; Douadi, A.; Czarnecki, S.J.J.o.C.P. Modeling and Optimizing the Durability of Self-Compacting Mortars Incorporating Cement Kiln Dust and Glass Powder: A Box-Behnken Design Study. J. Clean. Prod. 2025, 502, 145282. [Google Scholar] [CrossRef]

- Liu, C.; Li, Z.; Bezuijen, A.; Chen, L.; Cachim, P. Optimizing the shield tunnel backfilling grouts with supplementary cementitious materials by response surface methodology. Constr. Build. Mater. 2024, 421, 135575. [Google Scholar] [CrossRef]

- Badaoui, M.; Hebbache, K.; Douadi, A.; Mansouri, L.; Merdas, A.; Gherbi, S.; Kada, K.; Boutlikht, M.; Belebchouche, C.; Szymanowski, J. Utilization of Algerian calcined clay in sustainable mortars considering thermal treatment and granulometry effects on mechanical properties. Sci. Rep. 2025, 15, 21704. [Google Scholar] [CrossRef]

- Belkadi, A.A.; Kessal, O.; Berkouche, A.; Noui, A.; Daguiani, S.E.; Dridi, M.; Benaniba, S.; Tayebi, T. Experimental investigation into the potential of recycled concrete and waste glass powders for improving the sustainability and performance of cement mortars properties. Sustain. Energy Technol. Assess. 2024, 64, 103710. [Google Scholar]

- Yahia, A.; Tanimura, M.; Shimoyama, Y. Rheological properties of highly flowable mortar containing limestone filler-effect of powder content and W/C ratio. Cem. Concr. Res. 2005, 35, 532–539. [Google Scholar] [CrossRef]

- Belouadah, M.; Rahmouni, Z.E.; Tebbal, N.; Hicham, M.E.H. Evaluation of Concretes Made with Marble Waste Using Destructive and Non-Destructive Testing. Ann. Chim. Sci. Matériaux 2021, 45, 361–368. [Google Scholar] [CrossRef]

- Chen, H.; Feng, P.; Du, Y.; Jiang, J.; Sun, W. The effect of superhydrophobic nano-silica particles on the transport and mechanical properties of hardened cement pastes. Constr. Build. Mater. 2018, 182, 620–628. [Google Scholar] [CrossRef]

- Oltulu, M.; Şahin, R. Pore structure analysis of hardened cement mortars containing silica fume and different nano-powders. Constr. Build. Mater. 2014, 53, 658–664. [Google Scholar] [CrossRef]

- Lanzón, M.; García-Ruiz, P. Evaluation of capillary water absorption in rendering mortars made with powdered waterproofing additives. Constr. Build. Mater. 2009, 23, 3287–3291. [Google Scholar] [CrossRef]

- Benli, A. Mechanical and durability properties of self-compacting mortars containing binary and ternary mixes of fly ash and silica fume. Struct. Concr. 2019, 20, 1096–1108. [Google Scholar] [CrossRef]

- Olivier, J.G.; Schure, K.; Peters, J.A.H.W. Trends in Global CO2 and Total Greenhouse Gas Emissions; PBL Netherlands Environmental Assessment Agency: The Hague, The Netherlands, 2017; Volume 5, pp. 1–11.

- Makhlouf, A.; Kardache, R.; Chaabia, R.; Drouiche, A.; Brahmi, B. Environmental Impact Assessment of the Algerian Cement Industry: A Case Study with Life Cycle Assessment Methodology. In Selected Studies in Environmental Geosciences and Hydrogeosciences; Springer: Cham, Switzerland, 2020; pp. 83–85. [Google Scholar]

- Singh, A.; Thakare, A.A.; Chaudhary, S. A case study on examining the fresh-state behavior of self-compacting mortar containing waste powders from various sources. Case Stud. Constr. Mater. 2023, 19, e02684. [Google Scholar] [CrossRef]

- Souza, A.T.; Barbosa, T.F.; Riccio, L.A.; dos Santos, W.J. Effect of limestone powder substitution on mechanical properties and durability of slender precast components of structural mortar. J. Mater. Res. Technol. 2020, 9, 847–856. [Google Scholar] [CrossRef]

- Faheem, A.; Rizwan, S.A.; Bier, T.A. Properties of self-compacting mortars using blends of limestone powder, fly ash, and zeolite powder. Constr. Build. Mater. 2021, 286, 122788. [Google Scholar] [CrossRef]

- Ezziane, K.; Kadri, E.; Hallal, A.; Duval, R. Effect of mineral additives on the setting of blended cement by the maturity method. Mater. Struct. 2010, 43, 393–401. [Google Scholar] [CrossRef]

- Türkel, S.; Altuntaş, Y. The effect of limestone powder, fly ash and silica fume on the properties of self-compacting repair mortars. Sadhana 2009, 34, 331–343. [Google Scholar] [CrossRef]

- Gürol, G. Components for Economic Concrete, cement/water/fine and coarse aggregate/chemical and mineral admixtures. J. Des. Constr. 1999, 164, 66–74. [Google Scholar]

- Güneyisi, E.; Gesoğlu, M. Properties of self-compacting mortars with binary and ternary cementitious blends of fly ash and metakaolin. Mater. Struct. 2008, 41, 1519–1531. [Google Scholar] [CrossRef]

- Safiuddin, M.; West, J.; Soudki, K. Hardened properties of self-consolidating high performance concrete including rice husk ash. Cem. Concr. Compos. 2010, 32, 708–717. [Google Scholar] [CrossRef]

- Sua-Iam, G.; Makul, N. Utilization of limestone powder to improve the properties of self-compacting concrete incorporating high volumes of untreated rice husk ash as fine aggregate. Constr. Build. Mater. 2013, 38, 455–464. [Google Scholar] [CrossRef]

- Şahmaran, M.; Christianto, H.A.; Yaman, İ.Ö. The effect of chemical admixtures and mineral additives on the properties of self-compacting mortars. Cem. Concr. Compos. 2006, 28, 432–440. [Google Scholar] [CrossRef]

- Bonavetti, V.; Donza, H.; Menendez, G.; Cabrera, O.; Irassar, E. Limestone filler cement in low w/c concrete: A rational use of energy. Cem. Concr. Res. 2003, 33, 865–871. [Google Scholar] [CrossRef]

- Péra, J.; Husson, S.; Guilhot, B. Influence of finely ground limestone on cement hydration. Cem. Concr. Compos. 1999, 21, 99–105. [Google Scholar] [CrossRef]

- Toubal Seghir, N.; Mellas, M.; Sadowski, Ł.; Krolicka, A.; Żak, A. The Effect of Curing Conditions on the Properties of Cement-Based Composites Blended with Waste Marble Dust: Toubal Seghir, Mellas, Sadowski, Krolicka, and Żak. JOM 2019, 71, 1002–1015. [Google Scholar] [CrossRef]

- Çakır, Ö.; Aköz, F. Effect of curing conditions on the mortars with and without GGBFS. Constr. Build. Mater. 2008, 22, 308–314. [Google Scholar] [CrossRef]

| Compound (% wt.) | Cement | Pozzolana | Marble | Limestone |

|---|---|---|---|---|

| SiO2 | 22.7 | 47.8 | 7.44 | 1 |

| Al2O3 | 5.4 | 19.8 | 0.83 | 0.3 |

| Fe2O3 | 2.7 | 10.5 | 0.75 | 0.3 |

| CaO | 65.7 | 9.2 | 49.73 | 53.3 |

| MgO | 0.7 | 3.8 | 0.66 | 1.1 |

| SO3 | 0.6 | 0.2 | 0.01 | 0.07 |

| K2O | 0.4 | 0.5 | 0.02 | 0.04 |

| Na2O | 0.7 | 0.8 | 0.01 | 0.06 |

| Loss On Ignition L.O.I. | 0.3 | 6.5 | 39.8 | 43.6 |

| Specific gravity (g/cm3) | 3.15 | 3.13 | 3.24 | 3.18 |

| Blaine specific surface (kg/m2) | 326 | 370 | 480 | 422 |

| Mortars | Main Components (kg/m3) | Additives (kg/m3) | ||||

|---|---|---|---|---|---|---|

| Cement | Sand | Water | Pozzolana | Limestone Powder | Marble Powder | |

| M 1 (1P) | 564 | 1350 | 225 | 141 | 0 | 0 |

| M 2 (1/3L2/3P) | 93.07 | 46.53 | 0 | |||

| M 3 (2/3L1/3P) | 46.53 | 93.07 | 0 | |||

| M 4 (1L) | 0 | 141 | 0 | |||

| M 5 (1/3M2/3P) | 93.07 | 0 | 46.53 | |||

| M 6 (1/3L1/3M1/3P) | 46.53 | 46.53 | 46.53 | |||

| M 7 (1/3M2/3L) | 0 | 93.07 | 46.53 | |||

| M 8 (2/3M1/3P) | 46.53 | 0 | 93.07 | |||

| M 9 (2/3M1/3L) | 0 | 46.53 | 93.07 | |||

| M 10 (1M) | 0 | 0 | 141 | |||

| Flow | CS 28 | UPV | W | CA | |

|---|---|---|---|---|---|

| R2 | 0.911 | 0.942 | 0.896 | 0.967 | 0.832 |

| Adjusted R2 | 0.799 | 0.868 | 0.767 | 0.925 | 0.623 |

| Root-mean-square error (RMSE) | 0.445 | 2.669 | 0.065 | 0.057 | 0.005 |

| Mean response | 29.64 | 66.103 | 4.056 | 5.675 | 0.032 |

| Observations (or weighted sums) | 10.00 | 10.00 | 10.00 | 10.00 | 10.00 |

| Source | df | Sum of Squares | Mean Square | F Ratio | |

|---|---|---|---|---|---|

| Flow test | Model | 5 | 8.070 | 1.614 | 8.14 |

| Error | 4 | 0.794 | 0.198 | Prop. > F | |

| Uncorrected Total | 9 | 8.864 | 0.032 | ||

| CS 28 | Model | 5 | 458.80 | 91.760 | 12.88 |

| Error | 4 | 28.49 | 7.123 | Prop. > F | |

| Uncorrected Total | 9 | 487.29 | 0.014 | ||

| UPV | Model | 5 | 0.144 | 0.028 | 6.89 |

| Error | 4 | 0.016 | 0.004 | Prop. > F | |

| Uncorrected Total | 9 | 0.161 | 0.00424 | ||

| W | Model | 5 | 0.382 | 0.076 | 23.20 |

| Error | 4 | 0.013 | 0.003 | Prop. > F | |

| Uncorrected Total | 9 | 0.395 | 0.01047 | ||

| CA | Model | 5 | 0.001 | 0.0000103 | 3.97 |

| Error | 4 | 0.000 | 0.0000026 | ||

| Uncorrected Total | 9 | 0.001 |

| Flow | CS 28 | UPV | W | CA | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Model | F Ratio | p-Value | F Ratio | p-Value | F Ratio | p-Value | F Ratio | p-Value | F Ratio | p-Value |

| A-P | 4429.2 | <0.0001 * | 531.9 | <0.0001 * | 4111.15 | <0.0001 * | 12,077.4 | <0.0001 * | 68.7639 | 0.0012 * |

| B-L | 4894.44 | <0.0001 * | 772.47 | <0.0001 * | 4486.49 | <0.0001 * | 10,750.2 | <0.0001 * | 42.5829 | 0.0028 * |

| C-M | 4913.53 | <0.0001 * | 793.01 | <0.0001 * | 4559.09 | <0.0001 * | 10,728.2 | <0.0001 * | 33.9714 | 0.0043 * |

| (A) · (B) | 0.2028 | 0.6758 | 8.76 | 0.0415 * | 2.55 | 0.185 | 10.0607 | 0.0338 * | 1.5592 | 0.2799 |

| (A) · (C) | 18.15 | 0.013 * | 0.95 | 0.3838 | 1.1 | 0.353 | 4.9776 | 0.0895 | 0.2907 | 0.6184 |

| (B) · (C) | 7.68 | 0.0503 | 3.58 | 0.1312 | 5.13 | 0.086 | 13.5614 | 0.0212 * | 3.4038 | 0.1388 |

| OM1 | OM2 | OM3 | OM4 | |

|---|---|---|---|---|

| (A) P | 0.004 | 0.004 | 0.023 | 0.100 |

| (B) M | 0.535 | 0.385 | 0.264 | 0.254 |

| (C) L | 0.461 | 0.611 | 0.713 | 0.646 |

| F (min) | 30.631 | 30.586 | 30.436 | 30.596 |

| CS 28 (MPa) | 75.332 | 75.247 | 74.139 | 72.537 |

| UPV (km/s) | 4.242 | 4.240 | 4.214 | 4.189 |

| W (%) | 5.384 | 5.392 | 5.435 | 5.472 |

| AC (mm/s1/2) | 0.020 | 0.020 | 0.022 | 0.023 |

| Desirability | 0.894 | 0.888 | 0.833 | 0.793 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Douadi, A.; Makhlouf, A.; Belebchouche, C.; Hebbache, K.; Boutlikht, M.; Moretti, L.; Faria, P.; Abderazek, H.; Czarnecki, S.; Chajec, A. Synergistic Optimization of Mortar Performance and Carbon Footprint Reduction Using Quarry Wastes and Natural Pozzolana: A Statistical and Experimental Study. Sustainability 2025, 17, 7346. https://doi.org/10.3390/su17167346

Douadi A, Makhlouf A, Belebchouche C, Hebbache K, Boutlikht M, Moretti L, Faria P, Abderazek H, Czarnecki S, Chajec A. Synergistic Optimization of Mortar Performance and Carbon Footprint Reduction Using Quarry Wastes and Natural Pozzolana: A Statistical and Experimental Study. Sustainability. 2025; 17(16):7346. https://doi.org/10.3390/su17167346

Chicago/Turabian StyleDouadi, Abdellah, Ali Makhlouf, Cherif Belebchouche, Kamel Hebbache, Mourad Boutlikht, Laura Moretti, Paulina Faria, Hammoudi Abderazek, Sławomir Czarnecki, and Adrian Chajec. 2025. "Synergistic Optimization of Mortar Performance and Carbon Footprint Reduction Using Quarry Wastes and Natural Pozzolana: A Statistical and Experimental Study" Sustainability 17, no. 16: 7346. https://doi.org/10.3390/su17167346

APA StyleDouadi, A., Makhlouf, A., Belebchouche, C., Hebbache, K., Boutlikht, M., Moretti, L., Faria, P., Abderazek, H., Czarnecki, S., & Chajec, A. (2025). Synergistic Optimization of Mortar Performance and Carbon Footprint Reduction Using Quarry Wastes and Natural Pozzolana: A Statistical and Experimental Study. Sustainability, 17(16), 7346. https://doi.org/10.3390/su17167346