1. Introduction

Lack of adequate knowledge and training in occupational health and safety (OHS) is one of the leading causes of fatal accidents in enterprises. This introduction provides the foundation for the statistical analysis presented later in this article, which examines the relationship between the level of OHS education, the implementation of modern technologies, and enterprise innovation.

Employees’ perception of safety is primarily the identification of hazards and related risks. The main cause of accidents at work in Poland for many years has been employee misconduct; in 2023 it was responsible for 41.1% of all accidents at work [

1]. Studies have shown that many accidents occur because employees do not feel the presence of a threat, which is often due to a lack of adequate knowledge, routine and habits in performing tasks, as well as insufficient understanding of the potential consequences of their actions or omissions [

2]. Hence, occupational health and safety training is one of the ways to eliminate employee misconduct, which supports the process of building safety awareness among employees. Training provides employees with the necessary knowledge and skills to safely perform work tasks and promotes a culture of proactive approach to identifying and managing hazards occurring in the work environment.

This article addresses a research gap resulting from the lack of comprehensive empirical analyses assessing the impact of modern technologies on the effectiveness of occupational health and safety training across various industrial sectors. A literature review indicates the limited effectiveness of traditional forms of occupational health and safety education in light of dynamic changes in the work environment [

3,

4,

5,

6]. Our study addresses this gap by integrating data from 597 companies and verifying the relationship between technological support for training, the level of company innovation, and the quality of employee education.

Modern occupational health and safety training should prepare employees to respond effectively to a wide range of workplace risks and emergency scenarios, including accidents, equipment failures, and hazardous exposures. Artificial intelligence (AI) and immersive technologies such as virtual and augmented reality (VR/AR) are increasingly integrated into OHS training programs [

7,

8,

9]. These tools enhance employee engagement, simulate high-risk environments, and provide personalized feedback based on individual performance. As a result, employees are better equipped to identify threats, react appropriately in critical situations, and apply learned procedures in practice. The application of such innovative solutions significantly contributes to increasing the effectiveness of safety training and aligns with the goals of Industry 5.0, where human well-being and cooperation with technology are prioritized.

In addition, studies indicate [

10,

11,

12,

13] that the adequacy and quality, as well as the involvement of participants in occupational health and safety training, have a direct impact on effectiveness. Traditional training methods based on theoretical lectures, PowerPoint presentations, and case studies [

14] may not be adapted to the recipients and the developing industry, in which new threats are identified, e.g., impacts or collisions with a robot or self-driving machines. Technological progress and changing human needs, as well as increasing legal requirements, have led to changes in the way training is conducted in the last decade [

15]. These changes closely correlate with the development of the industrial revolution and the theory of the learning process. The technologies of Industry 4.0, such as autonomous robots, horizontal and vertical system integration, industrial internet of things (IIoT), cyber security, big data, augmented reality, and cloud technology, have significant impacts on the position and responsibilities of humans in the working environment.

This article also distinguishes between Industry 4.0, which focuses on automation, systems and data integration, and Industry 5.0, which emphasizes the role of humans, their well-being, and the resilience of work systems. As a result, a new concept and typology called “Operator 4.0” was introduced to describe new human roles and interactions with various technologies [

16].

Taking into account the new roles of humans in industrial processes, there is a need to introduce new forms of safety and health training, taking into account the innovative tools used as well as their topics. Now, the various mental health and culture of wellbeing activities are becoming an integrated part of the best training course. Companies are introducing VR and AI into mental health and wellbeing programs as a part of an HS training management system to analyse employee needs. Individualization (personalization) of employee benefits is becoming a mandatory standard, covering different areas such as mental health, which is a priority, physical activity, or health prevention. Safety, health, and wellbeing are a natural part of an innovative and sustainable education system. Training could be increasingly adapted to the actual needs and expectations of trainees, both in terms of content and the educational methods and techniques used [

17].

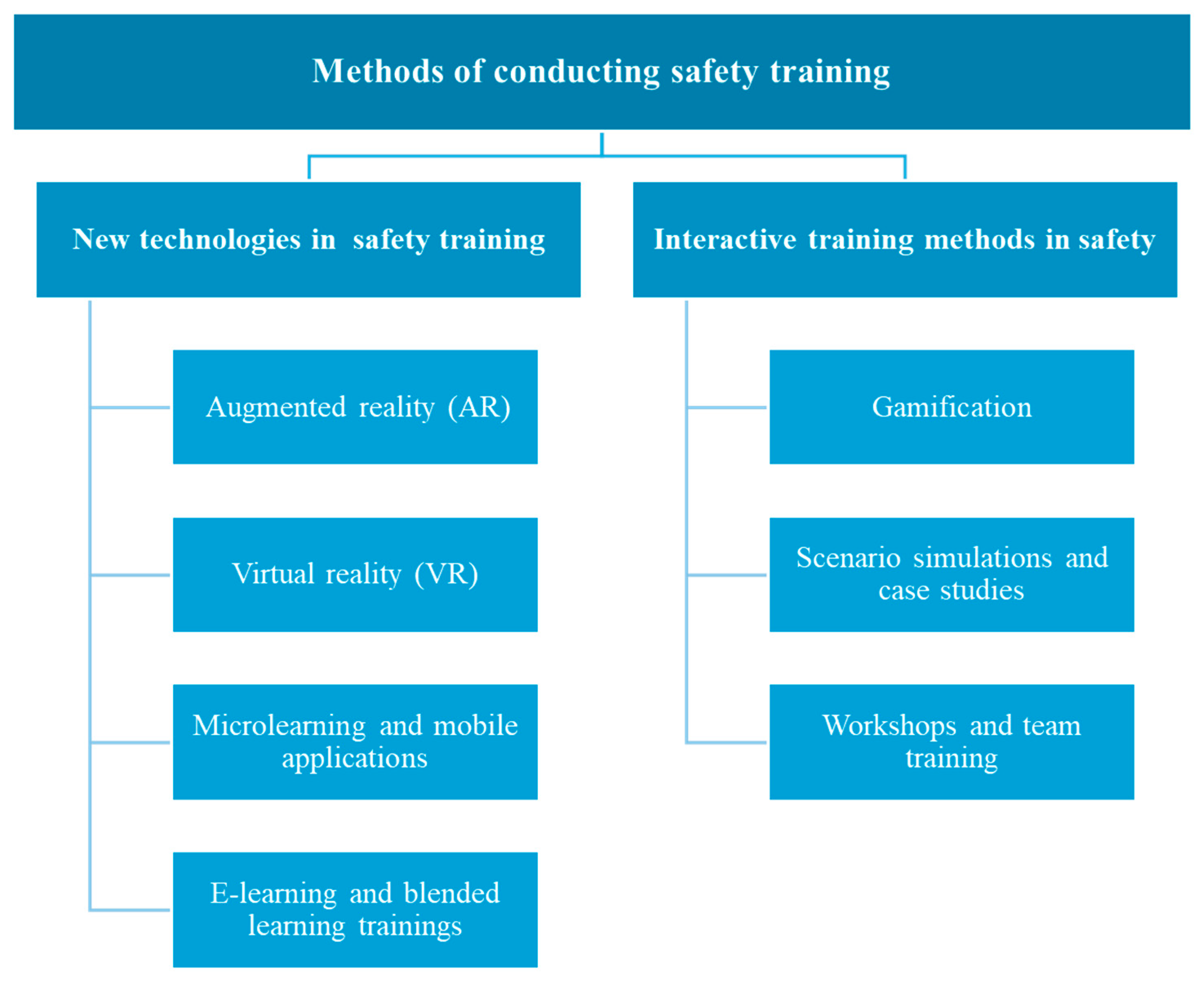

Figure 1 presents new technologies and interactive methods for conducting modern occupational safety training.

One of the solutions is augmented reality (AR), which is the application of virtual elements to the real environment. It is used, among others, to display instructions for machines and devices or visualize threats in a real place [

18]. With the significant progress in computer technology, simulation using augmented reality (AR) has transformed into an effective tool for learning through experience and promotes a better understanding of production technology process procedures and the identification of threat risks [

19]. The second method used during safety training is virtual reality (VR), which allows for simulations of real dangerous situations in an artificial 3D computer environment [

20,

21]. VR allows for the recreation of training scenarios that would be difficult to implement in real life or would require too many resources. VR is particularly used for training in emergency response [

22]. Another method used to consolidate knowledge in the field of safety is microlearning and mobile applications, which consists of providing short, content-rich educational materials that employees can learn at any time and place [

23,

24]. In addition, mobile applications such as quizzes, video materials, tests, and checklists are used, which are mainly used during field training, e.g., in the construction industry [

25]. The last method from the digital technologies group is e-learning training and blended learning. E-learning is understood as distance learning, which allows for the transfer of knowledge via an Internet platform using teaching materials in the form of multimedia presentations, videos, or graphics [

26]. E-learning, combined with blended learning elements, where traditional teaching methods are supplemented by online modules, promotes effective acquisition of knowledge in the field of security.

Interactive training methods are the second group of teaching methods that are characterized by engaging training participants. Each of these variables was directly related to the others for producers of wearable apparel, concluding that increases in one correspond to increases in the others. Training games involve introducing game elements into the teaching process. Gaining points and competing between training participants has a positive effect on their engagement, which improves the effectiveness of learning [

27]. The second way of engaging training participants is through scenario simulations and case studies, during which training participants are required to make decisions in situations similar to real ones [

28,

29]. One of the applications is the simulation of a chemical leak, equipment failures, and accidents at work, which allow theoretical knowledge to be used in practice. Additionally, simulations develop analytical skills and reinforce the correct pattern of behaviour during crisis situations. The last group of teaching methods are team workshops and trainings, during which training participants jointly solve exercises in the field of safety procedures. This method of teaching improves communication in the group and cooperation in crisis situations.

Today, companies are striving to implement Industry 5.0, which combines modern technologies together with the humanisation of processes and takes care of sustainability [

30]. With regard to modern safety training, which is based on advanced technologies such as VR and AR, training scenarios are immersive and realistic, so that trainees practise under controlled conditions without the risk of real threats. This approach supports the ideas of Industry 5.0, as not only are the practical skills of employees developed, but above all man and technology work together to improve safety and efficiency.

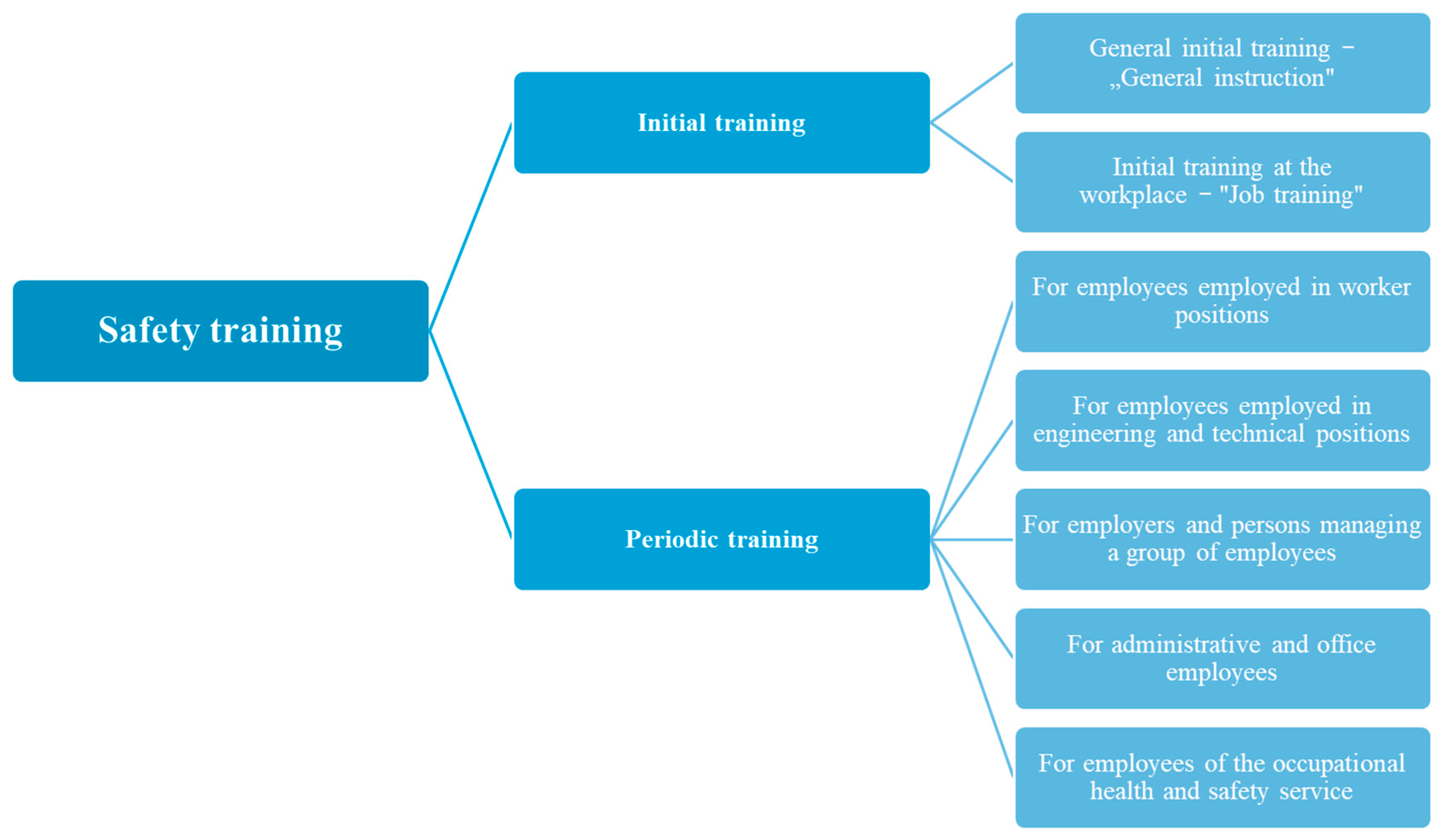

In Polish law, the Regulation of the Minister of Economy and Labour on occupational health and safety training includes a provision on the obligation of the employer to conduct occupational health and safety training before the employee starts work and periodic training during the employee’s employment [

31]. The types of training in Poland are presented in

Figure 2. The main objective of this regulation is to update employees’ knowledge of safety, promote best practices, and identify and prevent hazards in the workplace. Despite the restrictions that exist in Polish law, many companies encounter problems with the effective implementation and integration of occupational health and safety training into the safety management system in the company.

This article aimed to assess the implementation of modern technologies in Polish occupational health and safety training (OHS training) across various industrial sectors. Additionally, this research considered variations in training program development based on company size and financial capacity, highlighting the importance of integrating training, education, and innovative technologies into the company’s overall development strategy.

The impact of modern forms of teaching on the effectiveness of OHS training and the improvement of working conditions and the identification of threats in various sectors of the economy are also discussed.

2. Materials and Methods

The survey was conducted to analyse the use of modern teaching methods during safety training in Polish enterprises. The survey was conducted in the enterprises from various economic sectors located in Poland. A large number of enterprises from different regions of Poland representing different sectors of the economy were reached. Then, the industrial factories were grouped into the following economic sectors, which are presented in

Table 1 based on the Polish Classification of Activities (PKD 2007) [

32].

The survey was conducted using three methods: by phone, online via an online questionnaire and e-mails, and in person. The answers were most often provided by employees who work in the safety department.

The survey questionnaire contained questions, for example: “Health and safety training is based on modern forms of education (e.g., training games, e-learning training)”. Respondents answered the questions with a “Strongly Agreed” to “Strongly Disagreed” 5 point Likert Scale. In addition, in order to obtain a broader perspective on the subject under study, several questions were asked that characterize the enterprise. These questions concerned, among others: the number of employees and the annual turnover of the enterprise.

The statistical analysis of survey data was carried out using the program Statistical Package for the Social Sciences SPSS version 21, which allowed for quantitative and qualitative analyses. Based on the collected data, total 612 responses were collected, out of which only 527 responses were considered as valid and reliable. The main goal of which was to determine the relationship between the use of modern teaching methods during safety training and other variables.

The first test that was performed was demographic data to analyse how many males and females are working in these industries, what their ages are, and what the annual income is.

Moreover, a correlation analysis was performed to find the relationship between training, innovation programs in different companies, and modern form of education. A statistical technique SPSS V21 was used in research to calculate the link between different manufacturing companies and safety training (including training, innovation, and modern education) and gauge the strength of their linear relationship through the correlation analysis. In a nutshell, correlation analysis determines how a change in one variable affects another.

Additionally, a regression analysis was conducted to show how the implementation of innovation and training changes with the number of employees in the company and annual balance of the companies. A statistical technique SPSS V21 was used in this research to look at the relationship between variables through the regression analysis. The relationship between variables can be described, estimated, predicted, and controlled with its help.

Furthermore, to check which type of industry has most developed training system and which has the least developed training system, the analysis of variance (ANOVA) was applied by using SPSS V21.

Thus, SPSS v21 was employed for correlation, regression, and ANOVA analyses because it offers a comprehensive, validated statistical toolkit within a user-friendly interface, enabling accurate computation, efficient data management, and clear output presentation, while maintaining wide acceptance and credibility in academic research. Based on the statistical analyses conducted, the conclusions were drawn on the development and level of implementation of modern teaching methods during safety training in Polish enterprises.

Quantification of Variables

The variable training referred to the quality and effectiveness of occupational health and safety (OHS) training received by respondents. It was measured using three items evaluating (i) the relevance of training content to workplace hazards, (ii) the practical applicability of training, and (iii) the frequency of training sessions. Each item was rated on a five-point Likert scale (1 = strongly disagree, 5 = strongly agree), and the average score was computed to form the Training Index, with higher scores indicating more comprehensive and effective training.

Innovation represented the extent to which modern and interactive forms of training were implemented. This variable was assessed using four items covering the use of training games, e-learning modules, virtual simulations, and other non-traditional learning tools. Each item was rated on the same five-point Likert scale, and the Innovation Index was calculated as the mean score of these four items, with higher scores reflecting greater integration of modern educational tools.

Education was defined as the respondents’ highest completed level of formal education. Educational attainment was coded on an ordinal scale: 1 = primary education, 2 = secondary education, 3 = vocational/technical qualification, 4 = bachelor’s degree, and 5 = master’s degree or higher.

For multi-item scales (training and innovation), internal consistency was assessed using Cronbach’s α prior to statistical analysis. All analyses were performed using SPSS version 21.

3. Results

The survey included 597 companies located in Poland. The demographic distribution shows that the majority of respondents (81.9%) are female, with males making up 18.1% of the sample. In terms of company size by employee count, 50.2% of respondents work in companies with an unspecified size (Other) followed by 37.1% in companies employing between 10 and 49 people, and 12.8% in companies with 50 to 250 employees. Regarding total annual balance sheets, most respondents (75.2%) work in companies with a balance sheet under EUR 2 million, 15.6% in companies with a balance sheet between EUR 2 million and EUR 10 million, 5.4% in companies with a balance sheet between EUR 10 million and EUR 43 million, and 3.9% in companies with a balance sheet over EUR 43 million. Characteristics of respondents and companies involved in the study are presented in

Table 2.

The relationship between training, innovation programs in companies, and modern forms of education was examined by applying a correlation analysis for companies according to the Polish Classification of Activities. For the manufacturers of wearing apparel, the results revealed a statistically significant and positive relationship between training, innovation programs, and education. As the

Table A1 (in

Appendix A) displays, R = 0.800 with a

p-value less than 0.01 indicated that education and training programs in the companies are positively and highly connected. Similarly, innovation and modern forms of education have R = 0.593 with a

p-value less than 0.05, which indicates a moderately positive relationship. Moreover, the relationship between training programs and innovation was also moderately positive, with R = 0.591 and a

p-value of 0.033. These relationships indicated that each of these variables was directly related to the others for manufacturers of wearing apparel, concluding that increases in training and education in these organizations lead to increases in innovation, and vice versa.

For the manufacture of food products, the results showed R= 0.363 with a p-value greater than 0.05, meaning that education and training programs in the companies are insignificantly connected as there was no relationship between them, while the innovation and modern form of education had R = 0.421 with a p-value lesser than 0.05 indicates a moderate positive relationship. Moreover, the relationship between training programs and innovation is also moderately positive with R = 0.472 with a p-value 0.015. These relationships indicates that education and training programs for the manufacture of food products is not linked, but when the training and education increases in this organization, the innovation increases.

For the manufacture of wood and cork products (except furniture), the results show a significant positive relationship between training and education with R = 0.657 and a p-value of 0.006. Similarly, training and innovation are moderately positively related with R = 0.622 and a p-value of 0.010. However, education and innovation show no significant relationship, with R = 0.277 and a p-value of 0.299. These findings suggest that in this sector, increased training is linked to both higher education levels and innovation.

For the manufacture of paper and paper products, the results show a significant strong positive relationship between training and education with R = 0.870 and a p-value of 0.011. Training and innovation are also significantly positively correlated with R = 0.844 and a p-value of 0.017. Additionally, education and innovation have a very strong positive relationship with R = 0.931 and a p-value of 0.002. These findings indicate that training, education, and innovation are closely linked in this sector.

For the printing and reproduction of recorded media, the results indicate no significant relationship between training and education, with R = 0.206 and a p-value of 0.275. However, training and innovation show a significant strong positive relationship with R = 0.679 and a p-value of 0.000. Additionally, education and innovation have a moderately positive significant relationship with R = 0.436 and a p-value of 0.016. These results suggest that while training and education are not strongly linked, both training and education positively contribute to innovation in this sector.

For the manufacture of chemicals and chemical products, the results show no significant relationship between training and education, with R= 0.253 and a p-value of 0.512, or between education and innovation, with R = 0.346 and a p-value of 0.361. However, training and innovation have a significant strong positive relationship with R= 0.884 and a p-value of 0.002. This indicates that while training and education are not strongly linked, increased training is strongly associated with higher innovation in this sector.

For the manufacture of rubber and plastic products, the results showed significant strong positive relationships between training and education (R = 0.734, p = 0.001), training and innovation (R = 0.881, p = 0.000), and education and innovation (R = 0.668, p = 0.005). These findings suggest that in this sector, increased training and education were closely linked, and both training and education were positively associated with higher levels of innovation.

For the manufacture of metals, the results show significant strong positive relationships between training and education (R = 0.874, p = 0.010), training and innovation (R = 0.887, p = 0.008), and education and innovation (R = 0.802, p = 0.030). These findings indicate that in this sector, training is strongly linked to both education and innovation, and education also positively influences innovation.

For the manufacture of fabricated metal products (except machinery and equipment), the results show significant strong positive relationships between training and education (R = 0.623, p = 0.000), training and innovation (R = 0.696, p = 0.000), and education and innovation (R = 0.722, p = 0.000). These findings suggest that in this sector, higher levels of training and education are strongly associated with increased innovation.

For the manufacture of computer, electronic, and optical products, the results show no significant relationship between training and education (R = 0.322, p = 0.167). However, training and innovation have a significant positive relationship with R = 0.545 and a p-value of 0.013. Education and innovation show no significant correlation (R = 0.090, p = 0.707). These findings suggest that while training is positively associated with innovation, education does not strongly influence innovation in this sector.

For the manufacture of electrical equipment, the results show significant positive relationships between training and education (R = 0.517, p = 0.004), training and innovation (R = 0.387, p = 0.038), and education and innovation (R = 0.458, p = 0.012). These findings suggest that in this sector, training is positively associated with both education and innovation, and education also positively influences innovation.

For the manufacture of machinery and equipment not elsewhere classified (N.E.C.), the results show significant positive relationships between training and education (R = 0.494, p = 0.000), and training and innovation (R = 0.578, p = 0.000). However, the relationship between education and innovation is not significant (R = 0.263, p = 0.060). These findings suggest that in this sector, increased training is associated with both higher levels of education and innovation, but education itself does not have a strong influence on innovation.

For the manufacture of motor vehicles, trailers, and semi-trailers (except motorcycles), the results show no significant relationship between training and education (R = 0.029, p = 0.950). Additionally, the relationship between training and innovation is not significant (R = 0.621, p = 0.137), and there is no significant relationship between education and innovation (R = −0.044, p = 0.926). These findings suggest that in this sector, neither training, education, nor their combinations have significant associations with innovation.

For the manufacture of other transport equipment, there is a significant positive relationship between education and training (R = 0.879, p = 0.049), indicating that higher levels of education are associated with increased training. Furthermore, the relationship between education and innovation is also significant (R = 0.898, p = 0.039), suggesting that as education increases, innovation tends to increase as well. However, the relationship between training and innovation is not significant (R = 0.807, p = 0.099). These results suggest that in this sector, education plays a key role in both training and innovation, while training alone does not have a significant impact on innovation.

For the manufacture of furniture, the results show no significant relationship between training and education (R = −0.021, p = 0.922). However, there is a significant positive relationship between training and innovation (R = 0.508, p = 0.011), while the relationship between education and innovation is not significant (R = 0.321, p = 0.126). These findings suggest that in this sector, training is positively associated with innovation, but education does not appear to have a significant influence on innovation.

For other manufacturing, the results show significant positive relationships between training and education (R = 0.603, p = 0.000), training and innovation (R = 0.672, p = 0.000), and education and innovation (R = 0.507, p = 0.000). These findings suggest that in this sector, higher levels of training and education are strongly associated with increased innovation.

In the sector of repair, maintenance, and installation of machinery and equipment, the correlation between training and education is moderately positive (Pearson correlation = 0.489), with a significance level of 0.000, indicating that higher education was associated with more training. The correlation between training and innovation is strongly positive (Pearson correlation = 0.659, p < 0.01), suggesting that as training increases, so does innovation. Additionally, education and innovation also show a strong positive correlation (Pearson correlation = 0.638, p < 0.01), indicating that higher education levels are linked to greater innovation in the sector. These results highlight the important role that both education and training play in fostering innovation.

In

Table A1,

Table A2,

Table A3,

Table A4,

Table A5,

Table A6,

Table A7,

Table A8,

Table A9,

Table A10,

Table A11,

Table A12,

Table A13,

Table A14,

Table A15,

Table A16 and

Table A17 (in

Appendix A), the details of the statistical analysis for the various sectors of industries are presented.

After conducting statistical analyses on the following manufacturing sectors: tobacco, beverages, textiles, leather and related products, basic pharmaceutical products, and other non-metallic mineral products, the results indicated no significant relationships between training, education, and innovation, as all p-values were greater than 0.05.

A regression analysis was performed to examine how the level of innovation varied with the number of employees and the annual balance sheet of companies. While the original research design included both innovation and safety training as relevant aspects of digital transformation, only innovation was retained as the dependent variable in the regression model due to the low variance and insufficient reporting on training activities in several sectors. All industries were analysed according to the Polish Classification of Activities. The correlations were observed only for three industries (manufacture of wearing apparel, printing and reproduction of recorded media, manufacture of other transport equipment). The remaining regression models were insignificant for the other industry sectors, indicating that the number of employees and the annual balance of these companies did not affect the innovativeness of these companies. Since all p-values exceed 0.05, the F-statistic did not provide sufficient evidence to show that the independent variables (number of employees and annual balance) significantly affect the dependent variable (innovation) for any of the listed companies. A low F-value combined with a high p-value suggests that the model does not explain the variability of the dependent variable better than chance. Future research may explore potential interaction effects between organizational size and financial capacity on innovation and training outcomes.

For the manufacture of food products, the regression model shows that annual balance does affects the innovation positively with a coefficient value of 0.609, which indicates moderate impact, while the number of employee in the company has insignificant impact with −0.224 coefficient on the implementation of innovation and training in the company (

Appendix A,

Table A18). This concludes that innovation positively changes when annual balance increases for the manufacturers of food products.

For the manufacture of fabricated metal products, except machinery and equipment, the regression model showed that annual balance did not affect the innovation positively, while the number of employees in the company has significant impact with 0.255 coefficient on the implementation of innovation and training in the company (

Table 3). This concludes that innovation positively changes when the number of employees increases in the manufacturers of fabricated metal products, except machinery and equipment.

For the repair companies, and maintenance and installation of machinery and equipment, the regression model showed that annual balance did not affect the innovation positively, while the number of employees in the company has significant impact with 0.253 coefficient on the implementation of innovation and training in the company (

Table 4). This concludes that innovation positively changes when the number of employees increases in the companies of repair, maintenance, and installation of machinery and equipment.

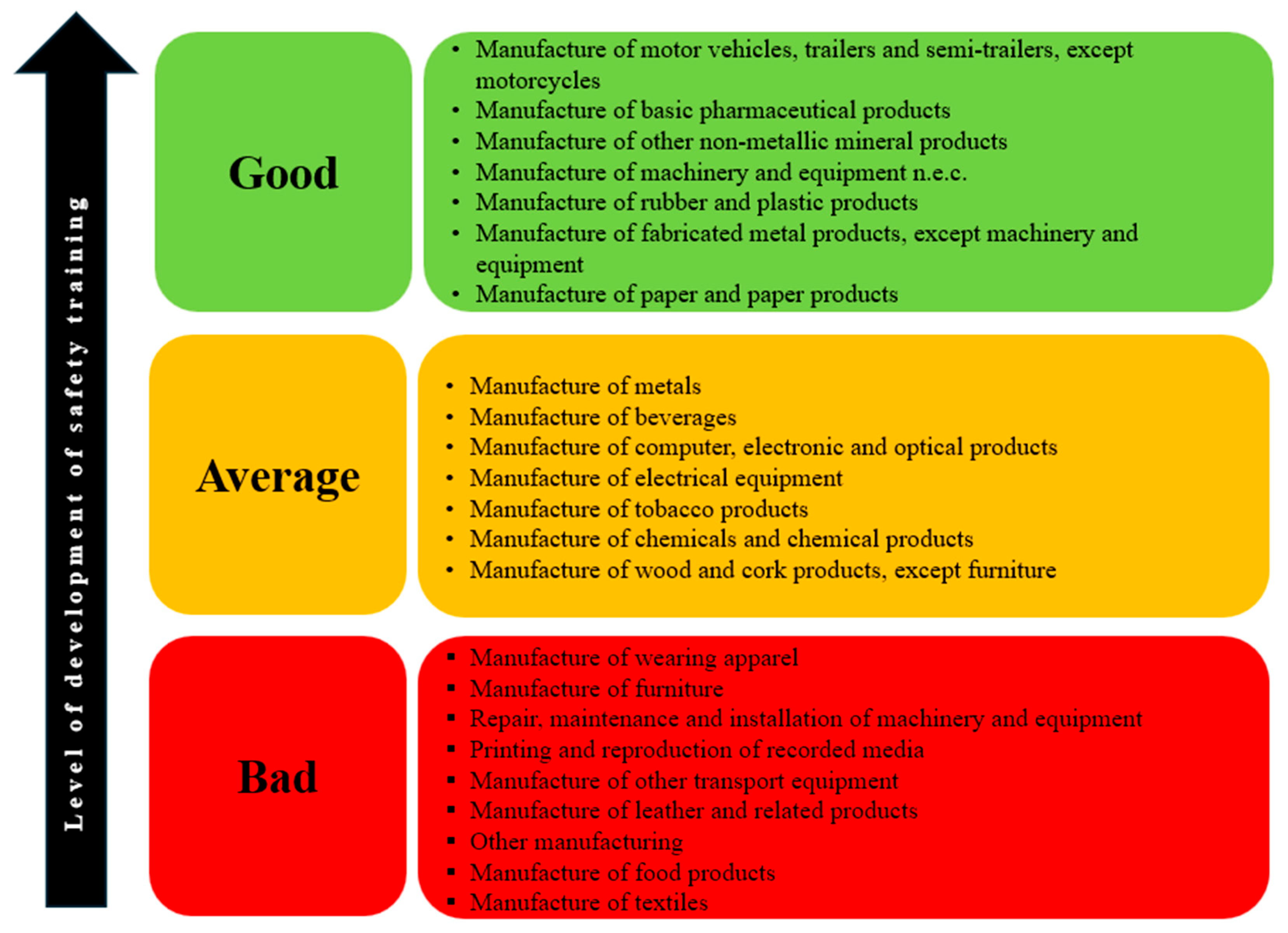

Table 5 presents a summary of the data used in the statistical analyses, while

Figure 3 shows the graphical form of the results to facilitate their interpretation.

To check which type of industry has most the developed training system and which type of industry has least the developed training systems, the one-way ANOVA was applied and the results show that there are significant differences between the organizations’ training systems (F = 1.702, p-value = 0.024). The results came out with the manufacturers of motor vehicles, trailers, and semi-trailers, except motorcycles, having the highest mean of training systems (Mean = 3.0495); this shows that this organization has the most developed health and safety training systems, followed by manufacture of beverages (Mean = 2.846), manufacture of paper and paper products (Mean = 2.868), manufacture of basic pharmaceutical products (Mean = 2.942), manufacture of rubber and plastic products (Mean = 2.901), manufacture of other non-metallic mineral products (Mean = 2.927), and manufacture of machinery and equipment n.e.c. (Mean = 2.923). The least developed health and safety training is for manufacturers of textiles, with the lowest mean value (Mean = 2.176).

4. Discussion

The results of the conducted research draw particular attention to the role of education, training, and innovation in the context of digital transformation. These findings suggest associations between these variables in various industrial sectors, particularly within the frameworks of Industry 4.0 and Industry 5.0. These two industrial revolutions are introducing significant changes in the technology industry and indicate the need to adapt the company’s strategy and in particular in the area of employee training and innovation management. Industry 4.0 technologies have revolutionized the way health and safety training is conducted. Traditional training methods often rely on classroom-based instruction and static materials, which may not effectively simulate real-life workplace hazards. The integration of VR and AR enables immersive interactive training experiences where employees can practice handling hazardous situations in a controlled, risk-free environment. This hands-on approach improves knowledge retention and prepares workers for real-world scenarios.

The conducted research indicates a statistically significant relationship between training and innovation in the Polish companies analysed, rather than establishing a direct causal link. Based on the research conducted for the computer, electronics, and optical products production sector, the results showed a lack of significant relationship between education and training, while a strong relationship between training and innovation (R = 0.545,

p = 0.013) was observed. These results are consistent with previous studies presented in the literature, which also reported correlations between training and innovation [

33,

34,

35,

36], without asserting direct causation. In the era of digital transformation, enterprises must quickly adapt to the changing technological environment and invest in human capital, especially in relation to the introduction of new technologies related to Industry 4.0/5.0, including artificial intelligence (AI), robotics, the Internet of Things (IoT), big data analysis (Big Data), cloud computing, 3D printing, virtual reality (VR). augmented reality (AR), or process automation.

The literature suggests that investing in employee training and education is often correlated with greater innovativeness, particularly in sectors intensively implementing Industry 4.0 technologies [

37,

38,

39]. Similar findings were presented by Sahoo et al. [

40], who observed that companies investing in the development of employees’ digital competences tend to be more innovative and implement technologies in safety training more effectively. Ghobakhloo and Iranmanesh [

41] also drew attention in their research to the development of innovation in enterprises through continuous improvement of employees’ professional qualifications. especially in the context of advanced technologies. Also, Müller et al. [

38] and Song [

42] proved that there are large disparities in the level of technological advancement between different sectors of the economy, which has a significant impact on the development of innovation strategies and the need to adapt educational and training programs depending on the characteristics of a given sector. Additionally, Baddeley et al. [

43] noted that in industries with higher automation, such as the automotive industry, electronics industry, energy industry, or chemical industry, the implementation of advanced technological tools requires specialized training and competences in programming, production engineering, and data management, while in enterprises with a different nature of production, these competences are not as important.

Our results show strong positive associations between training, education, and innovation for specific sectors; however, due to the cross-sectional nature of the data, these findings should not be interpreted as evidence of causation. In the electrical equipment production sector, the results align with the Industry 4.0 concept, which emphasizes comprehensive employee education and continuous competence development [

44]. Industry 4.0 drives not only the transformation of production processes but also organizational practices. In the production of other transport equipment, significant associations were noted between education and innovation (R = 0.898,

p = 0.039) and between education and training (R = 0.879,

p = 0.049). These findings suggest correlations consistent with the goals of Industry 5.0, which focus on sustainable development and human–technology cooperation [

40]. This necessitates proper training and education to prepare employees for work in complex and automated environments integral to Industry 5.0 [

45].

On the other hand, in industries such as textile production, food production, or leather goods production, among others, the results showed a lack of correlation between the analysed variables, i.e., education, training, and innovation. It can be assumed that in these sectors, innovation processes are not strongly linked to technological competencies, but are instead related to product or process improvements that may not require extensive investment in training. In relation to Industry 4.0 and Industry 5.0, this may mean that these industries are not undergoing intensive digital and technological transformation, as, for example, in the automotive industry or in the production of electronics, where innovations are driven by advanced technologies and the need for a highly qualified workforce [

46].

Studies conducted by scientists such as Liao et al. [

47], Eriksson and Lycke [

48], Nong et al. [

49], Kans and Campos [

50], and Erro-Garcés and Aramendia-Muneta [

51] show that in the future, changes related to digitalization as well as sustainable development will require new competencies from employees, including the ability to cooperate with robots, manage autonomous processes, or create sustainable, efficient production processes. This may translate into changing training and education requirements. Based on the regression analysis, in some industries, including the food production industry and the production of metal products, the number of employees and the annual financial balance sheet were statistically associated with higher levels of innovation. These findings indicate a relationship, but not necessarily a causal one. A higher number of employees might reflect greater capacity to implement innovative solutions in larger companies. This underscores the organizational importance of adaptability during digital transformation processes related to Industry 4.0 and 5.0 [

52].

However, the presented results regarding the level of development of training systems show that the automotive industry has the highest level of training, while the textile industry has the lowest. The results reflect the diversified approach to investment in human capital in various industries. The changes implemented in connection with Industry 4.0 and Industry 5.0 force enterprises to invest in the development of employee competences, which is visible in the automotive industry, which is characterized by a high level of development of training systems [

53].

To sum up, the presented research results confirm that education, training, and innovation are interrelated components in the digital and technological transformation of enterprises. While strong associations were observed, the findings should be interpreted with caution, and not as evidence of causal effects. In addition, many researchers point to the need to adapt educational and training programs to new challenges related to digital transformation and the growing role of digital competences, data management, and human–technology integration [

31,

54,

55,

56]. Future research should focus on understanding the specifics of various economic sectors and identifying key areas so that investments in education and training can contribute to improving innovation. Additionally, attention should be paid to the effectiveness of new teaching and training methods in the context of Industry 5.0, which focuses on human interaction with modern technologies. Some sectors in the sample (e.g., textiles, electronics) contain fewer than ten firms, which may limit the stability and reliability of correlation and regression estimates for these groups. Due to the predefined sector classifications used during data collection and the lack of additional background information required for re-coding, post-hoc aggregation of low-N sectors was not feasible at this stage. Consequently, sector-specific findings for small groups should be interpreted with caution, and future research should aim to ensure more balanced sectoral representation or apply broader grouping strategies during study design. Moreover, to strengthen causal inference and establish the directionality of the observed relationships, future research should employ longitudinal or experimental designs. A longitudinal design would allow for repeated measurements of the same firms over time, enabling the examination of temporal changes and the sequencing of variables, which can clarify cause–effect relationships. Alternatively, experimental or quasi-experimental approaches—such as field experiments, randomized controlled trials, or policy interventions—could provide controlled conditions to isolate the impact of specific factors (e.g., training programs, innovation initiatives) on outcomes of interest. Such designs would address the limitations of the current cross-sectional approach and offer stronger evidence regarding the causal pathways underlying the associations identified in this study.